IWAKI TC-X030V, TC-X050A, TC-X050S, TC-X050V, TC-X050D Operation Manual

...

SERVICE BOOK

PUMP OPERATION MANUAL

D082UIE-00

For safety purposes please be sure to read and follow the instructions

contained within this manual before pump installation and operation.

TC-X030V TC-X050A TC-X050S

TC-X050P TC-X050P-PP TC-X050V TC-X050D

Introduction

Thank you for Purchasing our company Air Operated Double Diaphragm Pump. Diaphragm Pumps fall under the positive-

displacement pump category. They are powered by compressed air and transfer liquids through the movement of 2

diaphragms connected by a center shaft. The pump runs through the use of an air switching mechanism which diverts

air to each diaphragm in turn on a continuous fashion. Depending on the liquid to be transferred, pumps are available

in a variety of body materials including; aluminum, stainless steel, cast iron, polypropylene, polyvinylidene uoride. The

diaphragms and valves within the pump are also available in various rubber, plastic and thermoplastic elastomers each

with its own chemical resistance properties.

Table of contents

Introduction .............................................................................................................................. 1

Important Items ...................................................................................................................... 2

For safe operation ................................................................................................................. 2

For safety .................................................................................................................................3~5

Product information .............................................................................................................. 6~9

1.Specications .................................................................................................................... 6

2.Accessories included with the pump ...................................................................... 6

3.Names of parts and materials .................................................................................... 7

4.Dimensions ......................................................................................................................... 8

5.Performance curves .......................................................................................................9

Installation ................................................................................................................................ 10 ~ 13

1.Installing and connecting the pump ......................................................................... 10

2.Recommended liquid piping connection diagram ................................................12

3.Recommended air piping connection diagram ..................................................... 13

Operation .................................................................................................................................. 14 ~ 15

1.Pump start up ................................................................................................................... 14

2.Liquid ow adjustments ................................................................................................ 14

3.Stopping the Pump ......................................................................................................... 14

4.Releasing pressure ......................................................................................................... 15

5.Method of cleaning the pump .....................................................................................15

Maintenance .............................................................................................................................16 ~ 20

Daily Maintenance checks ................................................................................................. 16

Troubleshooting ...................................................................................................................... 17

Limited Factory Warranty ..................................................................................................21

While pump is in operation do not cover the liquid inlet port with your hand or any another part of your body.

If the pump has remained unused for a long period or if you have any kind of misgivings about running the pump please

consult with your local our company distributor or contact our company directly.

- 1 -

Important Items

For safe operation

● Before using the pump, be sure to read this document carefully, particularly the "warnings and cautions," and

be fully familiar with the correct operating procedures.

● Within this document all the warnings and cautions will be indicated by the following symbols.

If you ignore the warning described and operate the product in an improper manner,

WARNING

CAUTION

there is danger of serious bodily injury or death.

If you ignore the caution described and operate the product in an improper manner,

there is danger of personal injury or property damage.

Furthermore, to indicate the type of danger and damage, the following symbols are also used along with those

mentioned above:

This symbol indicates a DON'T, and will be accompanied by an explanation on something you must

not do.

This symbol indicates a DO, and will be accompanied by instructions on something you must do in a

!

certain situation.

This symbol indicates important information is contained here.

- 2 -

For safety

WARNING

• When using compressed gas (hereinafter referred to as "compressed air") to drive this pump, be sure it is one of the following:

!

1)Compressed air supplied from an air compressor

(To drive this product, use supply air with a minimum moisture content.)

2)Nitrogen (N2) gas

The use of compressed air other than those mentioned above may cause air pollution, damage to the pump, or even an

explosion.

!

• Pressure Ratings are dependent on pump material and liquid temperature variations.

Please see the "Liquid Temperature Correlation Graph" in the [5. Performance curves] and check for the allowable working

pressure at the specic temperature of the liquid being pumped. Air pressure and discharge pressure must not exceed the

allowable working pressure. If air pressure and discharge pressure exceed the allowable working pressure, it may cause liquid

leaks, damage to the pump casings or diaphragms and could cause a fatal accident.

• Before moving this product, make sure that the internal pressure is released. If the pump is moved while under pressure, any

!

shock imparted by knocking or dropping the pump etc. may damage the pump or even cause an explosion.

• Improper electrical grounding, poor ventilation, or unshielded re or spark can create a danger of re or explosion.

!

Therefore, the following precautions are strongly advised.

* All peripheral equipment and piping connected to this product should be properly grounded.

* To pump ammable liquids, use a model with a conductive aluminum or stainless-steel casing.

* Whenever you notice any spark while operating this product, immediately stop its operation, and do NOT start using it again

unless you are sure of the cause and corrective actions have been taken out.

* Depending upon the type of uid being pumped, bubbles of ammable gas may be generated. Make sure that ventilation is

satisfactory.

* This product itself, its piping and exhaust ports should be kept away from unshielded re, spark and other causes of ignition.

If a diaphragm is damaged, uid may gush out together with air from the exhaust port.

* Do NOT leave gasoline or solvent etc. that contains waste at the work site.

* Machinery and other equipment near the place of installation of this product should be properly insulated to prevent

electrical conduction with each other.

* Do NOT operate heating devices naked ames or have heating laments anywhere near the pump or its piping.

* If there are ammable gases in the immediate atmosphere while the pump is operating, do NOT switch electric appliance on

and off.

* Do NOT operate gasoline engines around the pump work site.

* Restrict smoking around the pump work site.

- 3 -

For safety

WARNING

• Before using this product, be sure you are familiar with the precautions regarding the fluid to be pumped, and verify the

!

corrosion resistance of the parts that will come into contact with the uid (wetted parts). NEVER use the product with any

uid against which it does not have sufcient corrosion resistance or with a uid that poses a risk of explosion. If you are

unsure of the corrosion resistance, contact your nearest distributor or our company directly. If you use this product with any

uid against which the parts that will come in contact with the uid do not have sufcient corrosion resistance, it may result in

damaging the product or leakage of uid or pump failure.

• When using this product, observe local relevant regulatory rules concerning transfer and storage of chemicals, re prevention,

!

labor safety standards, etc.

• Hazardous uids (such as strong acid or alkali, ammable or toxic liquids) or gas bubbles generated by such uids may cause

!

serious injury or even death if accidentally inhaled or consumed or if they come into contact with the eyes or adhere to the

skin. Therefore, the following precautions are strongly advised.

*Be fully familiar with the properties of the uid to be pumped and work in strict accordance with the operating instructions

provided by the suppliers of such uids (such as wearing goggles, gloves, mask or protective work clothes).

*When storing a hazardous uid, strictly comply with the regulatory procedures (such as using proper containers, storage

conditions, etc.).

*Always install the piping and exhaust port of this pump away from areas frequented by human and animal trafc.

- 4 -

For safety

CAUTION

・ If a diaphragm of this product is damaged, the supplied air may mix with the uid or the uid may ow into the main body (air-

switching portion). If the air supply is inadequate or the pump is contaminated, do NOT operate the pump.

・ After you shut down the pump and disconnect the piping, some uid may still be remaining inside the pump. Also, if the pump

!

is left unused for a prolonged period, some uid may remain inside the pump and within the connected piping. Therefore, be

sure to purge the system of uid and clean the pump before prolonged disuse or storage. If the product is left unused for a

prolonged period with uid remaining in the connected piping as well as the pump itself, the uid may expand, depending on the

ambient temperature (because of freezing or heat), which may cause damage to the pump and/or piping and possible leakage

of uid.

・ The Pumps Non wetted parts are made from various materials and are not designed to withstand corrosive chemicals.

!

Therefore there is a possibility of damage to the pumps non wetted parts through leaks or breakage of the diaphragm as

well as liquid or gas permeation through the actual diaphragm material. There is also a possibility of damage due to chemical

fumes in the local environment or fumes entering into the air line through the compressor. It is also possible to damage

these components when incorrect lubrication is used. To help prevent any unnecessary damage please follow the following

precautions. Ventilation of the local environment, remove liquids when the pump is not in use. (Long term). Open ventilation of

the switching area of pump. Clean and ush the pumps air switching section if a leak or diaphragm breakage occurs.

• For safe transport be sure to prevent liquid leaking from pump for safe transport.

!

It is the end-users responsibility to thoroughly wash and clean the pump(s) to prevent accidents caused by liquid leaks.

• Always use genuine parts when replacing component parts of this product. Do not attempt to modify the components parts or

!

replace them with anything other than genuine parts.

- 5 -

1.Specications

Product information

Model

Liquid port Rc 1/4 [NPT 1/4]

Material ・ Weight Table 1

Operating pressure ※ 1

Max discharge pressure

Discharge volume/Cycle

Max Discharge volume

Max air consumption

Max solid size

Limitation of viscosity 0.1 Pa ・ s or less

Ambient temperatur

Liquid temperatur

Dimensions

A-Weighted sound pressur level ※ 2

A-Weighted sound power level ※ 3

※ 1 The maximum applied air pressure of the plastic pump depends on the liquid temperature. (Table 3)

※ 2 Maasurement method of A-weighted sound pressure level is based on ISO 1996.

※ 3 Maasurement method of A-weighted sound power level is based on ISO 3744.

AT , ST PT , PT-PP , VT, DT VT

0 ~ 100℃ [32-212 ℉ ] 0 ~ 60 ℃ [32-140 ℉ ]

81dB 80dB

92dB 90dB

TC-X050 □ [NPT] TC-X030VT [NPT]

0.2 ~ 0.7 MPa [30-100 psi]

0.7 MPa [100 psi]

20 mL 15 mL

11.5 L/min [3.0 Gallon/min] 8 L/min [2.1 Gallon/min]

250 L/min(ANR) [8.83 SCFM]

-

0 ~ 70 ℃ [32-158 ℉ ]

Table 2

2.Accessories included with the pump

□ Pump Operation Manual .......................................... 1

□ Service Book ................................................................ 1

□ How to use the Service Book ............................... 1

□ Parts list ........................................................................1

□ Pump ................................................................................1

・ After delivery open the product packaging and check to make sure that all included accessories are present and in good order.

!

・ Remember that the pump is heavy, so extreme care must be taken when lifting it. When lifting the pump using a chain hoist or

!

crane, be sure to lift the pump by the specied lift point(s).

・ When installing the accessories, please use the pipe sealing tape as provided for each threaded position, Also take care that

!

broken or shredded pipe sealing tape does not contaminate the liquid or Air inlets. Note that a contaminated airline may cause

failure of the pumps air switching unit.

・ Please install the air inlet Airline ball valve by referring to [Outside view] of [3.Name of parts and materials].

!

□ Airline ball valve .......................................................... 1

□ Liquid Inlet/Outlet Plug ........................................... 2

□ Pipe Seal tape ............................................................. 1

CAUTION

(PT-PP only)

(PT-PP only)

・ Please install Liquid inlet/outlet plugs to discharge and suction ports as required and refer to [Outside view] of [3.Name of

!

parts and materials].

- 6 -

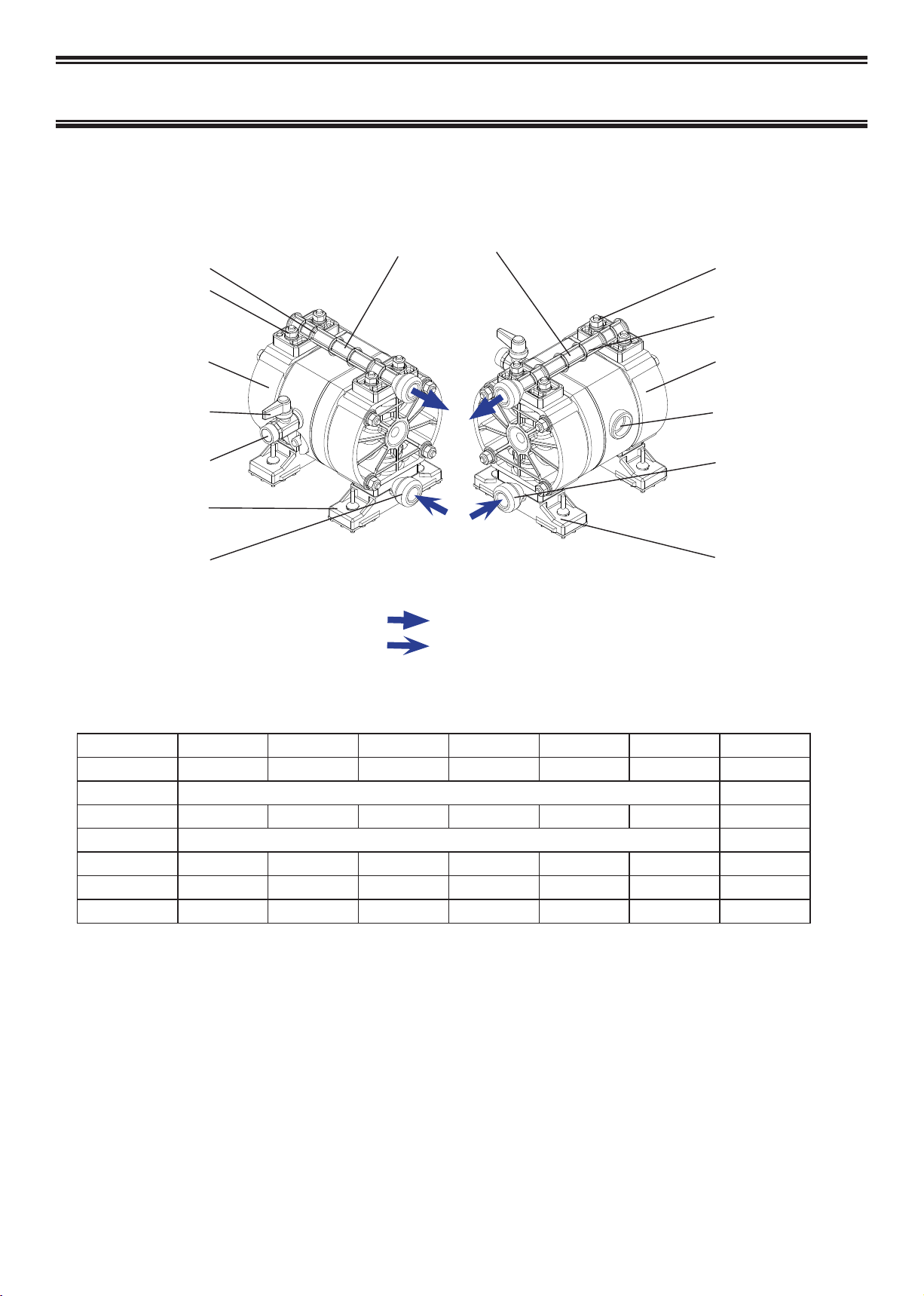

Product information

3.Names of parts and materials

Out Manifold

Ground Connection Point

Outside view

Lift Point

Ground Connection Point

Out Manifold

Out Chamber

Airline Ball Valve

Supply Air Port

In Manifold

MODEL

Pump Wetted Parts

Diaphragm

Valve Stopper

Flat Valve

Valve Seat

Center Disk

Weight

Out Chamber

Exhaust Port

In Manifold

Base

Base

: Discharge Port

: Suction Port

Material and weight

050AT 050ST 050PT 050PT-PP 050VT 050DT 030VT

ADC12 SCS14 PPG PP PVDF POM PVDF

PTFE PTFE

SUS316 SUS316 PPG PP PVDF POM PVDF

PTFE PTFE

SUS316 SUS316 PPG PP PVDF POM PVDF

A5056 SUS316 PPG PP PVDF POM PVDF

1.6 kg [3.51 lbs] 2.7 kg [6.0 lbs] 1.3 kg [2.91 lbs] 1.3 kg [2.91 lbs] 1.7 kg [3.7 lbs] 1.4 kg [3.1 lbs] 1.7 kg [3.7 lbs]

Table 1

- 7 -

Loading...

Loading...