IWAKI MX-70, MX-100 Instruction Manual

IWAKI Magnetic Drive Pump

MX-70/-100 (Asia Edition)

Instruction Manual

Read this manual before use of product

Thank you for selecting an Iwaki MX-70/-100 type Magnetic Drive

Pump. This instruction manual deals with "Safety Instructions",

"Outline", "Installation", "Operation" and "Maintenance" sections.

Please read through this instruction manual to ensure the optimum performance, safety and service of your pump.

Contents

Safety Instructions ·········································································· 1

Outline 1. Unpacking & Inspection ······································· 3

2. Operating principle ··············································· 3

3. Identification code ················································4

4. Specification ·························································4

5. Outer dimensions ·················································· 5

6. Performance curves ·············································6

7. Overview & Label ·················································6

8. Part names & Structure ········································7

Installation 1. Before installation ·················································9

2. Installation/Piping/Electrical wiring ················· 11

Operation 1. Before operation ·················································· 14

Maintenance 1. Troubleshooting ·················································· 16

2. Maintenance & Inspection ································· 16

3. Drainage ······························································ 17

This instruction manual should be kept on hand by the end user

for quick reference.

Contact us or your nearest dealer if you have any questions.

Important Instruction

For the Safe and

Correct Handling of the Pump

● "Safety Instruction" section deals with important details about

handling of the product. Before use, read this section carefully for

the prevention of personal injury or property damage.

● Observe the instructions accompanied with "WARNING" or

"CAUTION" in this manual. These instructions are very important for protecting pump users from dangerous situations.

● The symbols on this instruction manual have the following meanings:

Nonobservance or misapplication of the

WARNING

CAUTION

Indicates a prohibited action or procedure. Inside or near this circle, a concrete and practical image of the activity to be avoided is

depicted.

Indicates an impor tant action or procedure which must be performed or car ried out without fail. Failure to follow the instructions herein can lead to malfunction or damage to the pump.

For expor tation

Technology related to the use of goods in this instruction manual falls

in the category of technology contained in the Foreign Exchange

Order Attachment, which includes complementary export control of

technology. Please be reminded that export license, which is issued

by the Ministry of Economy, Trade, and Industry could be required,

when this is exported or provided to someone even in Japan.

contents of “Warning” section could lead to

a serious accident which may result in death.

Nonobservance or misapplication of the

contents of “Caution” section could lead to

a personal injury or damage to the product.

Types of Symbols

Power of f

Safety Instructions

Prohibited

Prohibited

Prohibited

No modif icati on

No dismantlement

Caution

Caution

Wear prote ctors

Prohibited

Prohibited

● Turn off the power.

Risk of electrical shock. Dismantling/

assembling the pump unit without turning off the power may cause an electrical

shock. Before engaging in any maintenance

or inspection work, be sure to turn off the

pump and related devices.

● Terminate operation.

On sensing any abnormal sign, stop operation immediately and inspect/solve problems.

● For specified application only

The use of the pump in any application

other than those clearly specified may result

in injury or damage. Use the pump in a

specified condition.

● No dismantlement/modification

Do not dismantle/modify the pump. We are

not responsible for any accidents or damage

due to modification.

● Wear protective clothing.

Always wear protective clothing such as

safety goggles and protective gloves during

pipework or dismantlement.

WARNING

CAUTION

● Restriction on operator

The pump should be handled by a qualified

person with a full understanding.

● Specified power only

Do not apply any power other than the specified one on the nameplate. Otherwise damage, a fire or an electrical shock may result.

● Do not wet the pump.

If a liquid spills over electric parts or wires, a

fire or electrical shock may result. Install the

pump in a place free from liquid spillage.

● Ventilation

Poisoning may result when handling a toxic

or odorous liquid. Keep good ventilation in

your operating site.

● Countermeasure against efflux

Take a protective measure against the accidental efflux caused by pump or pipe breakage.

● Do not use a damaged pump.

Using a damaged pump may lead to an

electric leak or shock.

- 1 -

Prohibited

Safety Instructions

Caution

Prohibited

Prohibited

Electrical shock

Prohibited

Earthing

Electrical shock

CAUTION CAUTION

● Do not place the pump close to water.

The pump is not dust-/water-proof construction. The use of the pump in a humid place

or a place where the pump can get wet may

result in electrical shock or short-circuit.

● Do not run pump dry.

If the pump runs without a liquid, the pump

is damaged by friction heat.

● Do not damage the power cable.

Risk of fire or electrical shock. Do not

scratch, modify, or pull the power cable.

The cable can also be damaged when it is

heated or loaded with a heavy thing.

● Earthing

Risk of electrical shock. Always earth the pump.

● Do not pressurize the pump over the

maximum discharge pressure.

A leak may result from the sealing surface

of O ring or the pump fails at worst.

● Install an earth leakage breaker.

An electrical failure of the pump may adversely affect related devices. Purchase and

install an earth leakage breaker separately.

● Power cable is not replaceable.

Do not use any damaged power cable

for the prevention of a fire or an electrical

shock. The cable is not replaceable, so that

the whole pump unit needs to be replaced

when the cable is damaged.

● Limited operating site and storage

Do not install or store the pump in the following places where...

1. Ambient is beyond the range of 0 - 40°C.

2. Under a flammable/corrosive atmosphere.

● Disposal of the used pump

Dispose of any used or damaged pump

in accordance with relevant regulations.

Consult a licensed industrial waste products

disposing company.

● Static electricity

When low electric conductivity liquids such

as ultra-pure water and fluor inactive liquid

(e.g. Fluorinert

TM

) are handled, static electricity may generate in the pump and may

cause static discharge. Take countermeasures to remove static electricity.

- 2 -

Outline

Before use, check the specification, limitation and hazardous

nature of the pump.

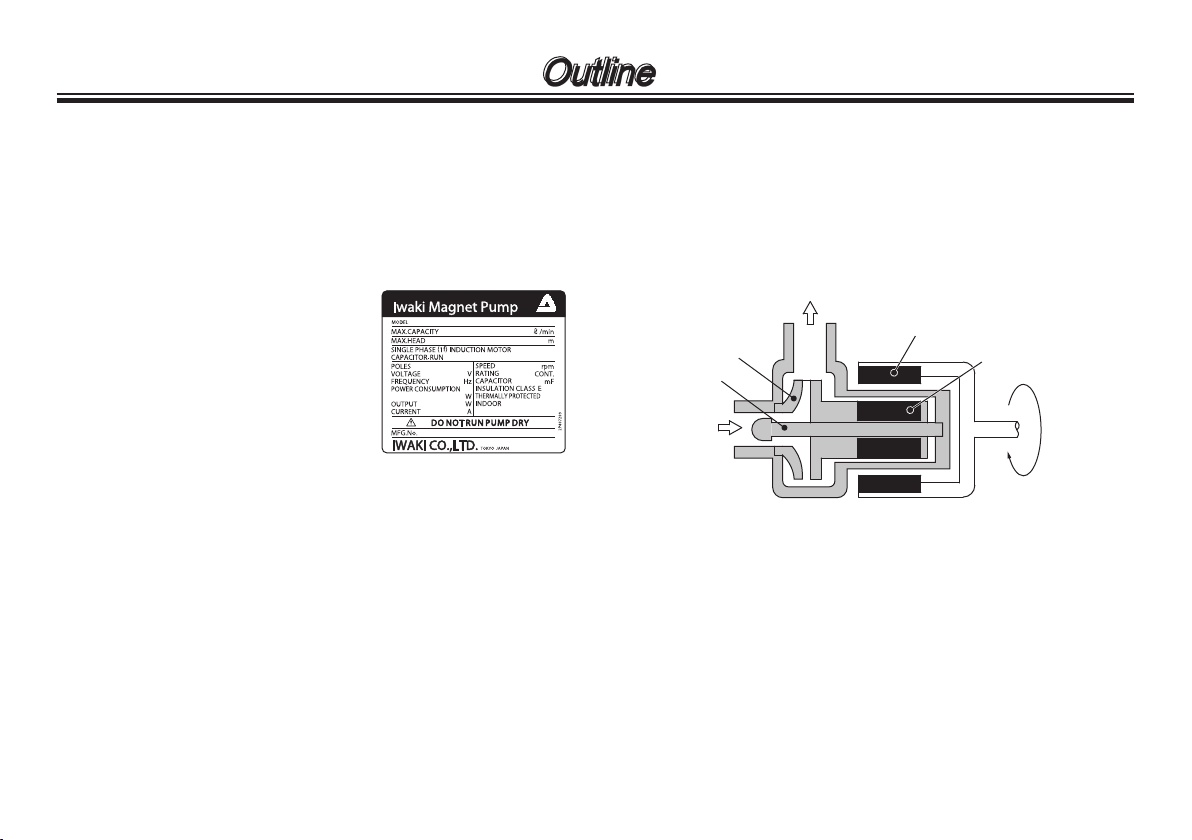

1. Unpacking & Inspection

On unpacking the product, check the following points. If

you find any problems, contact your nearest dealer.

1. Check the information on the nameplate such as model, discharge

capacity, discharge head and voltage to see that the product is delivered as per order.

2. Check for transit damage, deformation, and loose bolts.

2. Operating principle

The MX is a magnetic drive centrifugal pump.

The magnetic force between drive and driven magnets

rotates the impeller in the pump chamber, where a liquid

is transferred from the inlet to outlet.

Outlet

Drive magnet

Impeller

Spindle

Inlet

Driven magnet

- 3 -

Outline

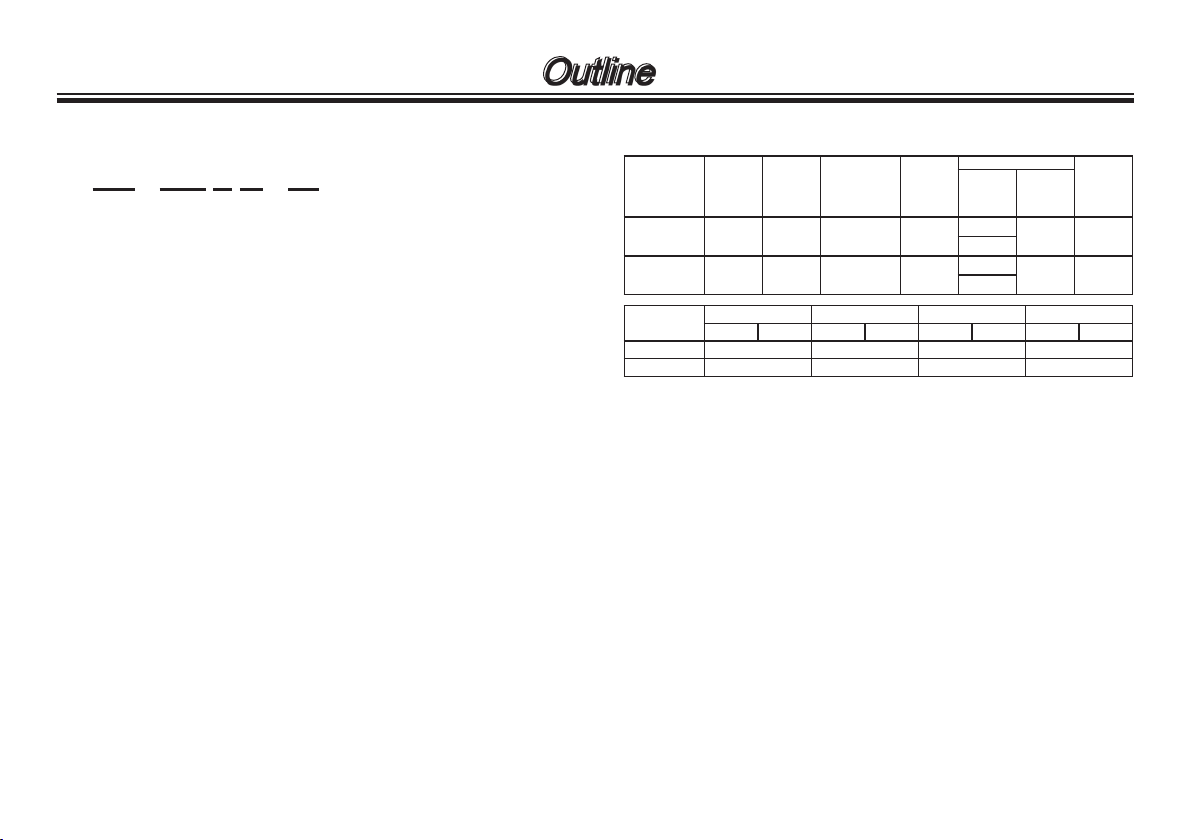

3. Identification code

MX - 100 V M - 32

a b c d e

a. Series model

GFRPP casing material

b. Pump size

70

100

c. O ring material

V: FKM

E: EPDM

d. Inlet/Outlet

No code: Tube connection

M : Thread type (G)

FL : Flange connection

e. Motor power voltage

No code: 1 phase 100V

32 : 3 phases 200/220V

4. Specification 50/60Hz

Model

MX-70 90/10 0 8/ 11 5.4-50/7.8-50 1.0

MX-1 00 110 /12 5 8.4/11.7 6-70/ 9-70 1. 2

Model

MX-70 26mm G1 20mm 25A

MX-1 00 26mm G1 20mm 25A

Max ow

(L/min)

Tube connec tion Thread connection Union connection Flange conne ction

Max

Norm ow

head

(m-L/min)

(m)

Inlet Outlet Inlet Outlet Inlet Outlet Inlet Outlet

Max SG

NOTE:

a. Performance data is based on pumping of clear water at

ambient temperature.

b. Allowable liquid temperature is 0-80°C (0-55°C for union

connection). Note that the temperature range may change

with liquid property. Avoid a precipitous fluctuation of temperature even in the liquid temperature range above.

c. The maximum head is a shutoff head. Note that shutoff oper-

ation is not allowed, or it may adversely affect a life period.

d. The maximum specific gravity is obtained at the normal flow

and changes with a duty point, room-/liquid-temperatures

and liquid viscosity.

e. A single-phase capacitor-start induction motor and a

3-phase motor are selectable.

f. See the specification label on the pump for detail info.

g. Performance and dimension are subject to change without

prior notice.

Power

(V)

100

200 or 2 20

100

200 or 2 20

Motor

Rated

output

(W)

150/180 6.5

260/260 8.2

Mass

(kg)

- 4 -

Loading...

Loading...