IWAKI MDK Series, MDK-25, MDK-20, MDK-32, MDK-40 Instruction Manual

IWAKI Magnetic Drive Pump

MDK Series

Instruction Manual

Read this manual before use of product

(Europe Edition)

Thank you for selecting IWAKI Magnetic Drive Pump MDK Series. This instruction manual,

which is divided into five sections, namely "Safety", "Outline of Product", "Installation",

"Operation" and "Maintenance", deals with the correct handling and operation procedures for

the pump. To make maximum use of the pump and to ensure safe and long time operation of

the pump, please read this manual thoroughly and carefully prior to operating the pump.

Contents

Safety section

Outline of product

1. Unpacking and inspection

2. Operating principle

3. Model identification

4. Specification

5. Construction and material

6. Outline dimension

7. Performance curve

.............................................................................

......................................................................

.....................................................

................................................................

................................................................

..........................................................................

.....................................................

..................................................................

................................................................

8. Construction and parts names

Installation

................................................................................

1. Precautions before use of pump

2. Plumbing

3. Electrical wiring

Operation

.................................................................................

1. Precautions on operation

2. Preparation for operation

3. Operation

4. To stop pump

.............................................................................

...................................................................

....................................................

.....................................................

.............................................................................

.......................................................................

1~4

5~9

..............................................

10~16

.........................................

17~19

6

6

6

7

7

8

8

9

11

14

16

18

18

19

19

Maintenance

1. Troubleshooting

2. Maintenance and inspection

3. Consumable parts

............................................................................

...................................................................

................................................

...............................................................

4. Disassembling and assembling

20~27

...........................................

21

22

24

25

Safety section

For the Safe and

Correct Handling of the Pump

● "Safety Instruction" section deals with important details about handling of the product. Before

use, read this section carefully for the prevention of personal injury or property damage.

● Observe the instructions accompanied with "WARNING" or "CAUTION" in this manual. These

instructions are very important for protecting users from hazardous situations.

● The symbols on this instruction manual have the following meanings:

Nonobservance or misapplication of “Warning” sec-

WARNING

tions could lead to a serious accident which may

result in death.

Nonobservance or misapplication of “Caution” sec-

CAUTION

tions could lead to personal injury or property damage.

Types of Symbols

Indicates that “Warning” or “Caution” must be exercised. Inside this triangle, a con-

crete and practical image provided as a warning or caution message is depicted.

Indicates a prohibited action or procedure. Inside or near this circle, a concrete and

practical image of the activity to be avoided is depicted.

Indicates an important action or procedure which must be performed or carried out

without fail. Failure to follow the instructions herein can lead to malfunction or

damage to the pump.

Export Restrictions

Technical information contained in this instruction manual might be treated as controlled

technology in your countries, due to agreements in international regime for export control.

Please be reminded that export license/permission could be required when this manual is

provided, due to export control regulations of your country.

- 1 -

Safety section

Prohibited

Wear protective

gear

No Remodeling

Caution

Prohibited

WARNING

● Turn off power before service

Risk of electrical shock. Be sure to turn off power to stop the pump and

related devices before service is performed.

● Wear protective clothing

Always wear protective clothing such as an eye protection, chemical re-

sistant gloves, a mask and a face shield during disassembly, assembly or

maintenance work. The specic solution will dictate the degree of protec-

tion. Refer to MSDS precautions from the solution supplier.

● Use strong ropes (chains) for lifting up the pump

Serious injury may result if lifting ropes (chains) break. Check lifting ropes

(chains) are strong enough before use. Observe the maximum weight.

● Do not modify the pump

Alterations to the pump carries a high degree of risk. It is not the manufactur-

er’s responsibility for any failure or injury resulting from alterations to the pump.

● Access limitation

The magnet drive pump has a pair of strong magnets. The strong magnet

field could adversely affect the persons who are assisted by electronic

Turning off p ower

devices such as the pacemaker.

● Stop operation

If you notice any abnormal or dangerous conditions, suspend operation

immediately and inspect/solve problems.

● When handling hazardous liquid

For handling harmful liquids as mentioned below, be sure to conduct daily

inspection and maintenance for the prevention of liquid leakage. Otherwise

personal injury, explosion or fire may result.

1. Explosive or flammable liquid

2. Corrosive or stimulus toxic liquid

3. Health hazardous liquid

● Do not catch the finger

Magnetic force of the pump is powerful. Take care not to catch the finger in

the bracket.

- 2 -

Safety section

Prohibited

Prohibited

Prohibited

Prohibited

Prohibited

Caution

CAUTION

● Qualified personnel only

The pump should be handled or operated by qualified personnel with a full

understanding of the pump. Any person not familiar with the product should

not take part in the operation or management of the pump.

● Do not use the pump in any condition other than its intended purpose

The use of the pump in any conditions other than those clearly specied

may result in failure or injury. Use this product in specied conditions only.

● Use specified power only

Do not apply power other than that specied on the nameplate. Otherwise,

failure or re may result. Ensure the pump is properly grounded.

● Ventilation

Fumes or vapours can be hazardous with certain solutions. Ensure proper

ventilation at the operation site.

● Spill precautions

Ensure protection and containment of solution in the event of plumbing or

pump damage (secondary containment).

● Do not run pump dry

Do not run pump dry (Operation without liquid). Friction heart builds up dur-

ing dry running operation and damages internal parts. If the pump is oper-

ated with a suction side valve closed or without priming, the pump runs dry.

● Do not operate the pump in a flammable atmosphere

Do not place explosive or ammable material near the pump.

● Do not stand on the pump

Do not use the pump as a platform. Injury or damage may result when the

pump turns over.

● Do not touch the pump or pipe with bare hands

Risk of burning. The surface temperature of the pump or pipe rises high

along with liquid temperature in or right after operation.

- 3 -

Safety section

Caution

Grounding

Electrical shock

Prohibited

Caution

Prohibited

CAUTION

● Grounding

Risk of electric shock! Always properly ground the pump. Conform to local

electric codes.

● Install a GFCI (earth leakage breaker)

An electrical failure of the pump may adversely affect other devices on the

same line. Purchase and install an earth leakage breaker separately.

● Do not install/store the pump:

• In a ammable/explosive/corrosive atmosphere.

• In a dusty/humid environment.

• Where ambient temperature can exceed 0-40°C.

• Under mechanical vibrations.

• In direct sunlight or wind & rain.

● Starting

The pump doesn’t have an ON-OFF switch. The pump starts as a power

cable is plugged in.

● Foreign matter

When foreign matters enter the pump, turn off power at once and remove

them. Using the pump with foreign matters may result in failure.

● Disposal of a used pump

Dispose of any used or damaged pump in accordance with local rules and reg-

ulations. If necessary, consult a licensed industrial waste disposal company.

● Static electricity

When low electric conductivity liquids such as ultra-pure water and fluor

inactive liquid (e.g. FluorinertTM) are handled, static electricity may generate

in the pump and may cause static discharge. Take countermeasures to

remove static electricity.

● Preventative maintenance

Follow instructions in this manual for replacement of wear parts. Do not

disassemble the pump beyond the extent of the instructions.

● Do not use a damaged pump

Use of a damaged pump could lead to an electric shock or death.

- 4 -

OUTLINE OF PRODUCT

1. Unpacking and inspection .................. 6

2. Operating principle ............................. 6

3. Model identification ............................. 6

4. Specification ....................................... 7

5. Construction and material ................... 7

6. Outline dimension ............................... 8

7. Performance curve ............................. 8

8. Construction and parts names ............ 9

- 5 -

1. Unpacking and inspection

After the product is unpacked, check followings.

1) Identify the product

Check nameplate if pump model, head, frequency,

discharge capacity, motor power, voltage etc. are correct.

2) Damage during transportation

Check if the product is not damaged and bolts and nuts

are not loosened during transportation.

3) Discharge and suction ports are plugged so that foreign

matters do not get into pump chamber. Remove the plug

when the product is installed.

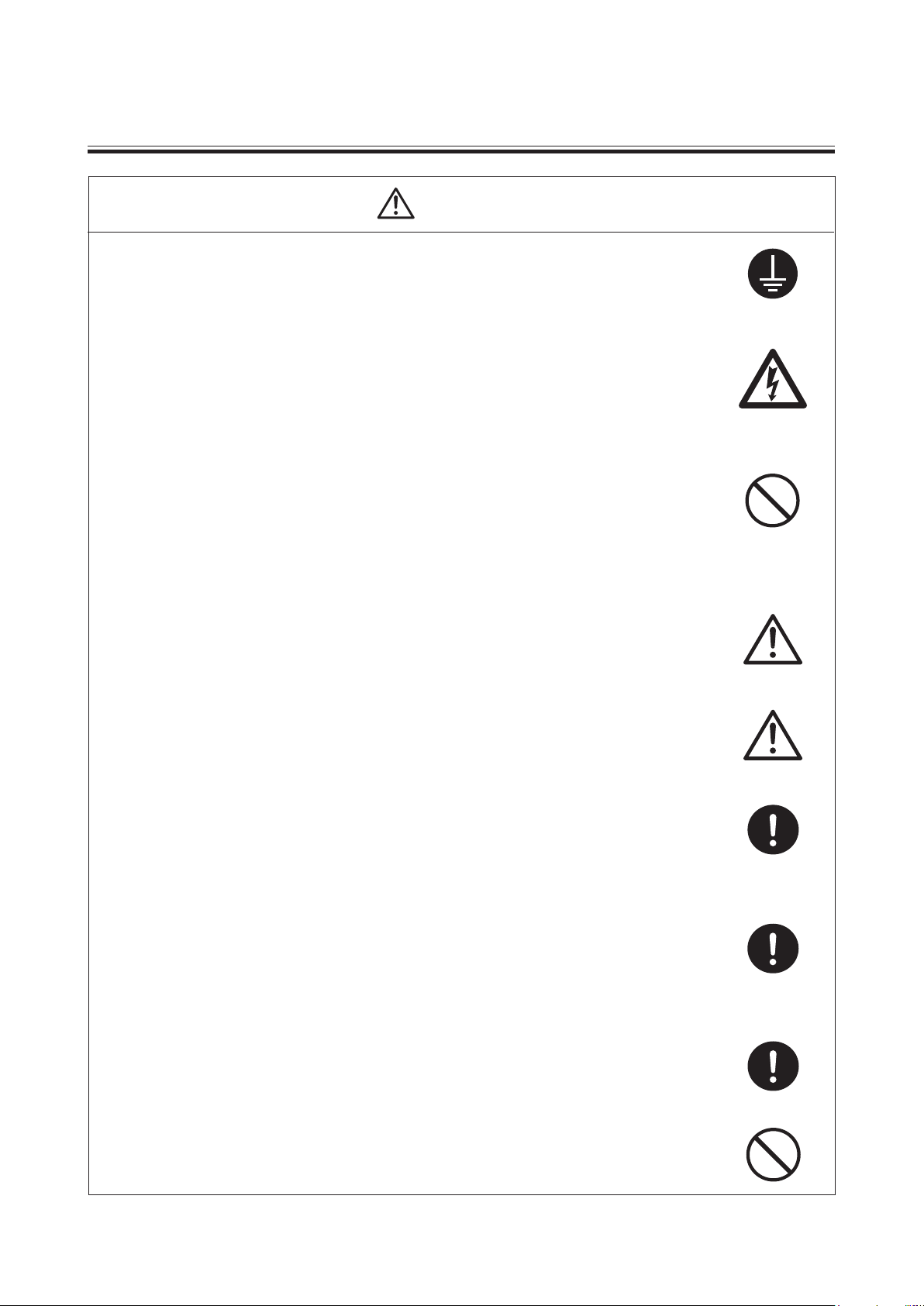

2. Operating principle

MDK Series pumps are magnetically driven turbine pump.

Impeller is rotated in pump chamber by the magnetic

coupling force to suck liquid from suction port and to

discharge to outlet.

3. Model identification

MDK ‒ 32 S6 TS EUR

(1) Pump bore : 20 ... 20mm, 25 ... 25mm, 32 ... 32mm, 40 ...40mm

(2) Pump material : S6 ... SCS14, SUS316, SUS329J1

(3) Check valve material : TS ... PTFE, SUS316

(4) Bearing material : EUR ... Carbon

EUR-R ... PTFE

(1) (2) (3) (4)

- 6 -

4. Specification

Model Bore

MDK-20

MDK-25

MDK-32

MDK-40

20mm

(Rp3/4)

25mm

(Rp1)

32mm

(Rp1-1/4)

40mm

(Rp1-1/2)

Standard flow rate (L/min.)

50Hz 60Hz

9 - 10 12 - 12.5 1.3 0.2

12 - 15 16 - 18.5 1.3 0.37

25 - 29 30 - 36 1.3 1.5

30 - 45 40 - 60 1.3 4.0

■ Pump weight with no motor

MDK-20 MDK-25 MDK-32 MDK-40

15kg 20kg 25kg 50kg

Specific

gravity limit

Motor

power (kW)

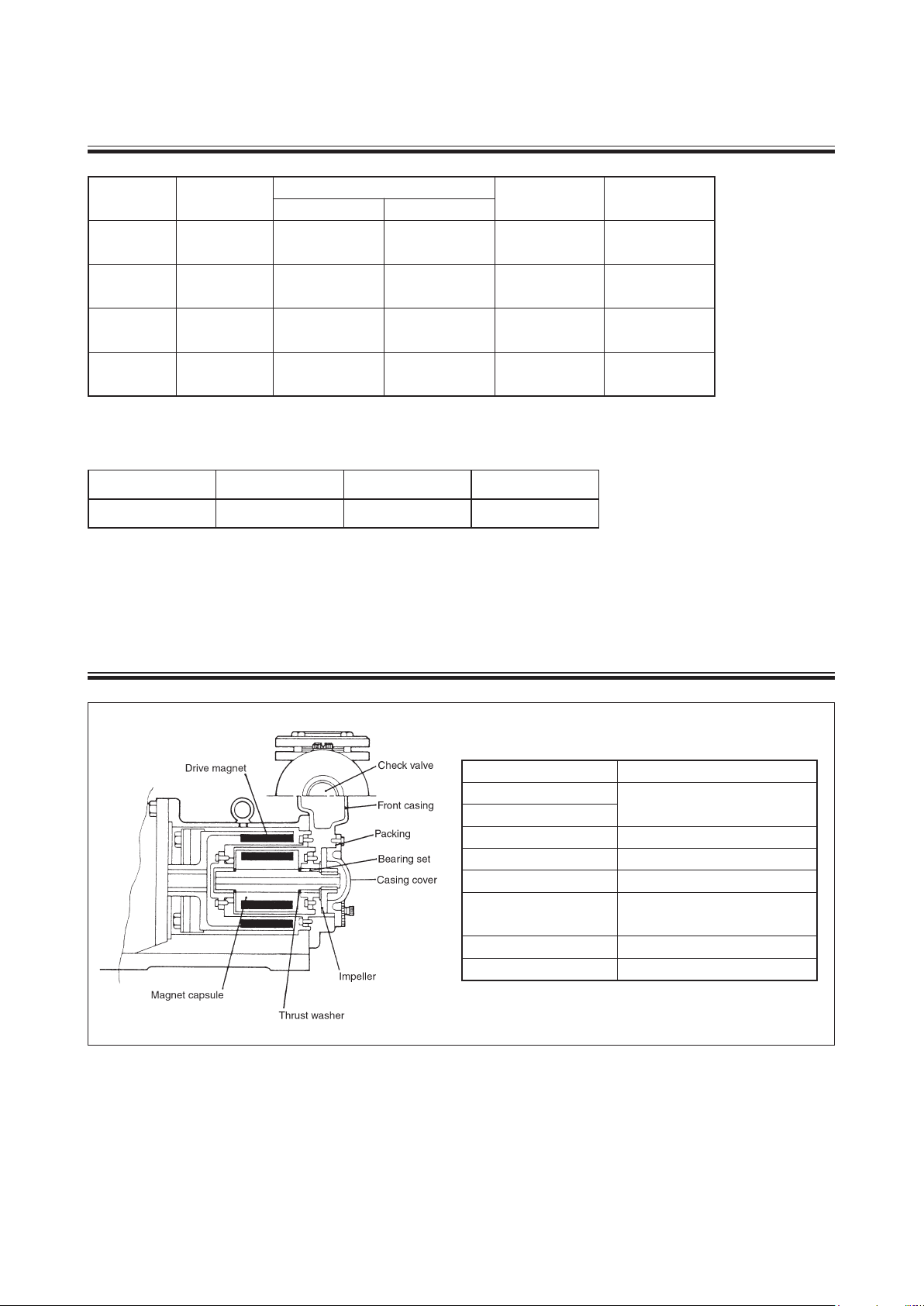

5. Construction and material

■ Wet end material

Casing

Casing cover

Impeller SUS316

Magnet capsule unit SUS329J1 + SUS316

Thrust washer PTFE

Bearing set

Cover packing PTFE

Check valve PTFE/SUS316

Parts Material

SCS14

Carbon/SCS14,SUS316 or

PTFE/SCS14,SUS316

- 7 -

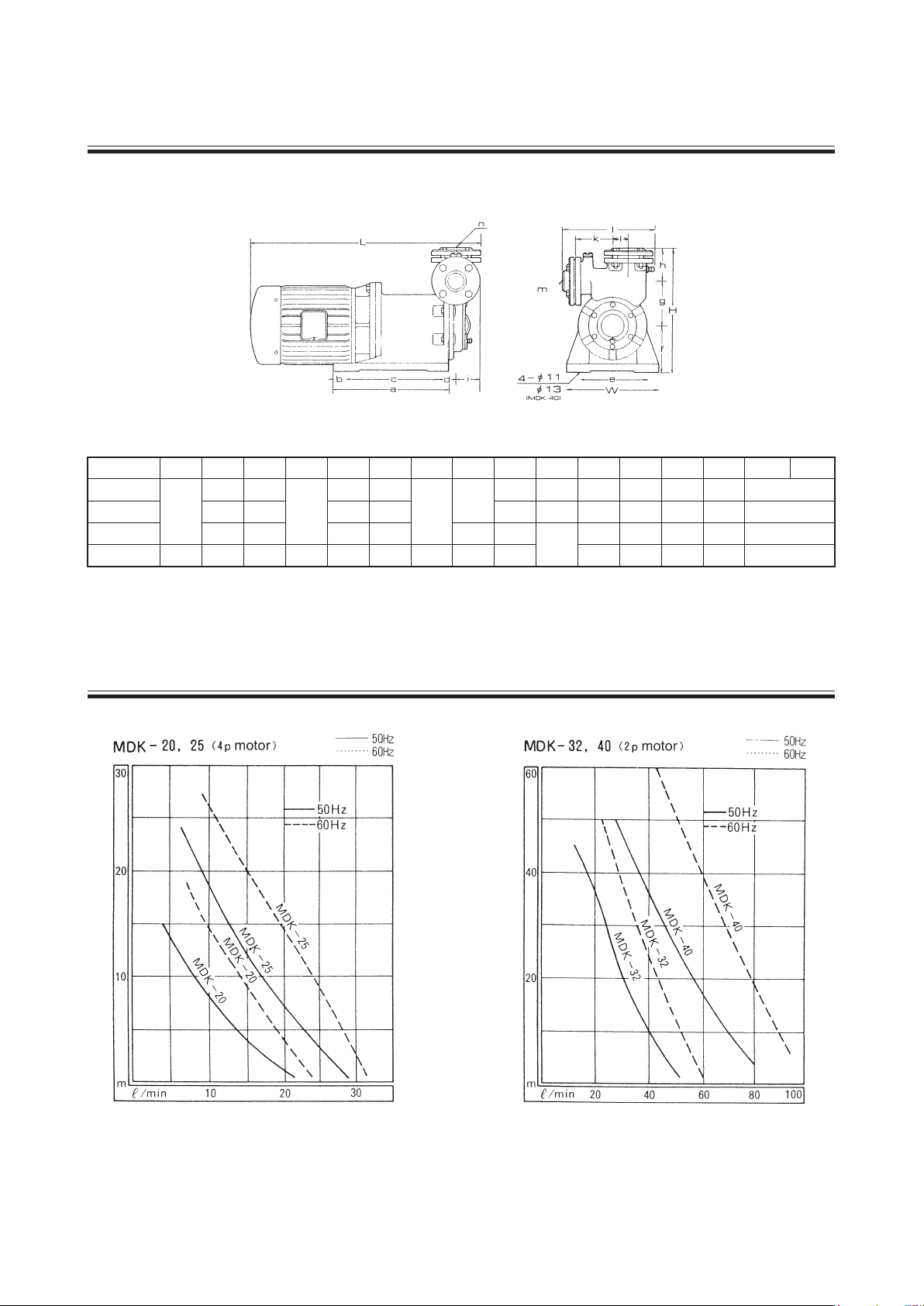

6. Outline dimension

Model W H a b c d e f g h i j k m n

MDK-20

MDK-25 267 200 140 50 100 77 63 228 96 (Rc1)

MDK-32 317 235 175 46 11 0 110

MDK-40 270 362 310 20 270 44 230 135 130 70 269 110 (Rc1-1/2)

180

260 140

30

80 44

150

95 75 50 209 90 (Rc3/4)

90

68 234 90 (Rc1-1/4)

97

l

20

27

40

45

7. Performance curves

- 8 -

Loading...

Loading...