IWAKI IX-C060 S6, IX-C060 TC/TE, IX-C150 S6, IX-C150 TC/TE Instruction Manual

IX-C series (North America)

Safety instructions

Overview Installation Operation Maintenance Specication

Instruction manual

Thank you for choosing our product.

Please read through this instruction manual before use.

This instruction manual describes important precautions and instructions for the product. Always keep it on hand for quick reference.

©2015 IWAKI CO., LTD.

Order conrmation

Open the package and check that the product conforms to your order. If any problem or

inconsistency is found, immediately contact your distributor.

a. Check if the delivery is correct.

Check the nameplate to see if the information such as model codes, discharge capacity and discharge

pressure are as ordered.

b. Check if the delivery is damaged or deformed.

Check for transit damage and loose bolts.

Order conrmation

2

Contents

Order conrmation ..........................................................................................................................................2

Safety instructions .................................................................... 6

Warning ..........................................................................................................................................................7

Caution ...........................................................................................................................................................8

Precautions for use ....................................................................................................................................10

Overview ...................................................................................12

Introduction .................................................................................................................................................12

Pump structure & Operating principle ......................................................................................................12

Features ...................................................................................................................................................13

Operational function ...................................................................................................................................13

Manual mode ...........................................................................................................................................13

EXT mode ................................................................................................................................................14

Analogue proportional control .............................................................................................................14

Pulse control .......................................................................................................................................16

Batch control .......................................................................................................................................16

Interval batch control ...........................................................................................................................18

AUX function ............................................................................................................................................18

Priming function .......................................................................................................................................18

STOP functions ........................................................................................................................................19

STOP function .....................................................................................................................................19

Pre-STOP function ..............................................................................................................................19

Analogue output function .........................................................................................................................19

Protective functions ..................................................................................................................................20

Interlock function .................................................................................................................................20

Diaphragm rupture detection ..............................................................................................................20

Pressure overload/Failed rotation control detection ...........................................................................20

Alarm output function ..........................................................................................................................21

Other functions .........................................................................................................................................21

Suction speed setting ..........................................................................................................................21

Maximum ow rate setting ..................................................................................................................21

Diaphragm position adjustment ..........................................................................................................21

Anti chattering programming ...............................................................................................................21

Output logic setting .............................................................................................................................21

Flow unit setting ..................................................................................................................................21

Language setting ................................................................................................................................21

Keypad lock .........................................................................................................................................21

Default setting .....................................................................................................................................21

Part names ...................................................................................................................................................22

Pump ........................................................................................................................................................22

Contents

3

Operational panel .....................................................................................................................................23

Basic displays & Pump states .............................................................................................................24

Identication codes ....................................................................................................................................25

Pump ........................................................................................................................................................25

Installation .............................................................................. 26

Pump mounting ...........................................................................................................................................26

Pipework ......................................................................................................................................................27

Piping layout ........................................................................................................................................27

Drain port (Vent hole) .................................................................................................................................28

Wiring ...........................................................................................................................................................29

End terminals ...........................................................................................................................................29

Power voltage/Earthing ............................................................................................................................30

Signal wire connection .............................................................................................................................31

EXT IN ................................................................................................................................................32

STOP IN ..............................................................................................................................................32

AUX IN/Analog OUT ...........................................................................................................................33

Alarm OUT (DIN connector) ................................................................................................................33

Operation ................................................................................. 34

Before operation .........................................................................................................................................34

Points to be checked ................................................................................................................................34

Retightening of pump head xing bolts ....................................................................................................34

Commissioning .........................................................................................................................................35

Before a long period of stoppage (One month or more) ..........................................................................35

Perform a calibration ..................................................................................................................................36

Calibration process ..................................................................................................................................37

Operation programming .............................................................................................................................39

Programming ow ....................................................................................................................................40

Menu screen ............................................................................................................................................41

EXT mode selection ............................................................................................................................42

Calibration ...........................................................................................................................................44

Signal input setting ..............................................................................................................................45

Analogue output setting ......................................................................................................................46

Alarm output setting (OUT 1) <Mechanical relay> ..............................................................................47

Alarm output setting (OUT 2) <PhotoMOS relay> ..............................................................................49

Data logging ........................................................................................................................................50

Programming of other functions ..........................................................................................................51

Operation .....................................................................................................................................................54

Manual operation .....................................................................................................................................54

EXT operation ..........................................................................................................................................54

AUX function ............................................................................................................................................55

Priming function .......................................................................................................................................55

Keypad lock ..............................................................................................................................................56

4

Contents

Keypad lock activation ........................................................................................................................56

Keypad lock release ............................................................................................................................56

Emergency stop ..................................................................................................................................56

Maintenance .............................................................................57

Troubleshooting ..........................................................................................................................................58

Pump ...................................................................................................................................................58

Error messages ...........................................................................................................................................59

Inspection ....................................................................................................................................................59

Daily inspection ........................................................................................................................................59

Periodic inspection ...................................................................................................................................59

Wear part replacement ...............................................................................................................................60

Wear part list ............................................................................................................................................60

Before replacement ..................................................................................................................................62

Valve set replacement ..............................................................................................................................62

Diaphragm replacement ...........................................................................................................................63

Exploded view .............................................................................................................................................67

Pump head, Drive unit & Control unit .......................................................................................................67

Pump head ...............................................................................................................................................68

IX-C150 TC N ......................................................................................................................................68

IX-C150 TC FA ....................................................................................................................................69

IX-C150 S6 N ......................................................................................................................................70

IX-C150 S6 FA ....................................................................................................................................71

IX-C060 TC N .....................................................................................................................................72

IX-C060 TC FA ....................................................................................................................................73

IX-C060 S6 N ......................................................................................................................................74

IX-C060 S6 FA ....................................................................................................................................75

Specications/Outer dimensions ..............................................................................................................76

Specications ...........................................................................................................................................76

Pump ...................................................................................................................................................76

Power cable ........................................................................................................................................76

Body colour .........................................................................................................................................76

Control unit ..........................................................................................................................................77

Outer dimensions .....................................................................................................................................78

IX-C060/-C150 TC/TE N-TB ...............................................................................................................78

IX-C060/-C150 TC/TE FA-TB .............................................................................................................79

IX-C060/-C150 TC/TE N-RF ...............................................................................................................80

IX-C060/-C150 TC/TE FA-RF .............................................................................................................81

IX-C060/-C150 S6 N-TB .....................................................................................................................82

IX-C060/-C150 S6 FA-TB ...................................................................................................................83

IX-C060/-C150 S6 N-RF .....................................................................................................................84

IX-C060/-C150 S6 FA-RF ...................................................................................................................85

Contents

5

Safety instructions

Read through this section before use. This section describes important

information for you to prevent personal injury or property damage.

■ Symbols

In this instruction manual, the degree of risk caused by incorrect use is noted with the follow-

ing symbols. Please pay attention to the information associated with the symbols.

Indicates mishandling could lead to a fatal or serious injury

WARNING

CAUTION

A symbol accompanies each precaution, suggesting the use of "Caution", "Prohibited actions"

and specic "Requirement".

accident.

Indicates mishandling could lead to personal injury or prop-

erty damage.

Caution marks Prohibition mark Requirement mark

Caution

Electrical

shock

Prohibition

Do not remodel

Requirement

Wear

protectors

Earthing

Export Restrictions

Technical information contained in this instruction manual might be treated as controlled tech-

nology in your countries, due to agreements in international regime for export control.

Please be reminded that export license/permission could be required when this manual is

provided, due to export control regulations of your country.

Safety instructions

6

Electrical

shock

Requirement

Safety instructions

WARNING

Turn off power before service

Risk of electrical shock. Be sure to turn off power to stop the pump and

related devices before service is performed.

Couper l’alimentation électrique de la pompe avant intervention

Intervenir sur la pompe sans avoir au préalablement coupé l’alimentation

électrique peut déclencher des décharges électriques. Avant d’entreprendre

n’importe quel type d’intervention, veillez à mettre la pompe et tout dispositif

connexe hors tension à l’aide de l’interrupteur prévu à cet effet.

Stop operation

If you notice any abnormal or dangerous conditions, suspend operation

immediately and inspect/solve problems.

Arrêter le fonctionnement

Si vous détectez une anomalie ou des signes suspects et inhabituels

pendant le fonctionnement, interrompez immédiatement les opérations et

inspectez, résolvez les problèmes.

Prohibition

Do not remodel

Wear

protectors

Do not use the pump in any condition other than its intended purpose

The use of the pump in any conditions other than those clearly specied

may result in failure or injury. Use this product in specied conditions only.

Se conformer uniquement aux applications prévues

La pompe doit être utilisée conformément à l’usage pour lequel elle a été

prévue et dans le respect de ses caractéristiques techniques. Toute utilisa-

tion non conforme peut entraîner un incident ou endommager le dispositif.

Do not modify the pump

Alterations to the pump carries a high degree of risk. It is not the manufacturer's

responsibility for any failure or injury resulting from alterations to the pump.

Ne pas modier la pompe

Ne jamais modier une pompe sous peine de causer un incident grave.

Iwaki ne pourra en aucun cas être tenu responsable d’un incident ou de

dégâts survenus à la suite d’une modication du dispositif.

Wear protective clothing

Always wear protective clothing such as an eye protection, chemical re-

sistant gloves, a mask and a face shield during disassembly, assembly or

maintenance work. The specic solution will dictate the degree of protec-

tion. Refer to MSDS precautions from the solution supplier.

Porter un équipement de protection

Toujours porter un équipement de protection (lunettes, gants ré-

sistants aux produits chimiques, masque, casque) durant le démontage,

l’assemblage et la maintenance.

Le travail effectué dictera le degré de protection. Référez-vous au MSDS

de la solution proposée par le fournisseur.

Prohibition

Prohibition

Do not damage the power cable

Do not pull, knot, or crush the power cable. Damage to the power cable

could lead to a re or electrical shock if cut or broken.

Ne pas endommager le câble électrique

Ne pas tirer ou faire un nœud avec le câble électrique. Endommager un

câble électrique pout provoquer une incendie ou une décharge électrique.

Do not operate the pump in a ammable atmosphere

Do not place explosive or ammable material near the pump.

Ne pas utiliser la pompe dans une atmosphère explosive

Pour votre sécurité, du matériel dangereux ou inammable ne doit pas

être placé près de la pompe.

WARNING

7

Risk of electric shock

This pump is supplied with a grounding conductor and grounding-type

attachment plug. To reduce the risk of electric shock, be certain that it is

connected only to a properly grounded, grounding type receptacle.

Electrical

shock

Requirement

Prohibition

Risque de choc électrique

La pompe est fournie avec un conducteur pour mise à la terre et une prise

courant. An de réduire le risque de choc électrique, veillez à ce que la

terre soit correctement raccordée.

CAUTION

Qualied personnel only

The pump should be handled or operated by qualied personnel with a

full understanding of the pump. Any person not familiar with the product

should not take part in the operation or maintenance of the pump.

Opérateur qualié uniquement

La pompe doit être manipulée ou utilisée par du personnel qualié con-

naissant parfaitement la pompe. Tout autre personne étrangère ne doit

pas prendre part à l’utilisation ou à la maintenance de la pompe.

Use specied power only

Do not apply power other than that specied on the nameplate. Otherwise,

failure or re may result. Ensure the pump is properly grounded.

Utilisez une tension appropriée uniquement

Ne pas appliquer une autre tension que celle spéciée sur la plaque sig-

nalétique sinon, il peut en résulter une panne ou une incendie. Assurezvous également de la mise à la terre de la pompe.

Prohibition

Caution

Prohibition

Keep electric parts and wiring dry

Risk of re or electric shock. Install the pump where it can be kept dry.

Ne mouillez pas les parties électriques ou les câbles

Risque d’incendie ou de décharge électrique. Installez la pompe dans un

endroit sec.

Ventilation

Fumes or vapors can be hazardous with certain solutions. Ensure proper

ventilation at the operation site.

Ventilation

Manipuler un produit toxique ou odorant peut provoquer une intoxication.

Prévoyez une ventilation sufsante à l’endroit de la manipulation.

Do not install or store the pump:

• In a ammable atmosphere.

• In a dusty/humid environment.

• Where ambient temperature can exceed 0-50ºC (32-122°F).

• In direct sunlight or wind & rain.

N’installez ou ne stockez pas la pompe dans les endroits suivantes:

• Dans une atmosphère inammable

• Dans un endroit poussiéreux ou humide.

• Dans une place où la température n’est pas comprise entre 0 et 50 °C.

• Directement sous le soleil, le vent ou la pluie.

8

This pump has been evaluated for use with water only.

Cette pompe a été testée uniquement avec de l'eau.

Caution

CAUTION

Spill precautions

Ensure protection and containment of solution in the event of plumbing or

pump damage (secondary containment).

Safety instructions

Requirement

Prohibition

Earthing

Electrical

shock

Déversement accidentel

Prenez des mesures protectrices contre tout incident résultant d’un débit

trop important de la pompe ou d’une casse de tuyauterie.

Do not use the pump in a wet location

The pump is not waterproof. Use of the pump in wet or extremely humid

locations could lead to electric shock or short circuit.

N’utilisez pas la pompe sous l’eau

La pompe n’est pas complètement étanche. Utiliser la pompe dans l’eau

ou dans un endroit très humide peut créer une décharge électrique ou un

court-circuit.

Grounding

Risk of electrical shock! Always properly ground the pump. Conform to lo-

cal electric codes.

Mise à la terre

Veillez à ne pas faire fonctionner la pompe sans avoir au préalable prévu

une mise à la terre. Celle-ci permettra d’éviter d’éventuelles décharges

électriques. Vériez que le câble de mise à la terre est bien branché.

Install a GFCI (earth leakage breaker)

An electrical failure of the pump may adversely affect other devices on the

same line. Purchase and install a GFCI (earth leakage breaker) separately.

Détecteur de fuites à la terre

Un problème électrique peut affecter défavorablement le dispositif. Achet-

ez et installez un détecteur de fuites à la terre.

Requirement

Prohibition

Requirement

Preventative maintenance

Follow instructions in this manual for replacement of wear parts. Do not

disassemble the pump beyond the extent of the instructions.

Remplacement des pièces usées

Suivez les instructions de ce manuel pour remplacer les pièces usées. Ne

démontez pas la pompe au-delà des instructions.

Do not use a damaged pump

Use of a damaged pump could lead to an electric shock or death.

N’utilisez pas une pompe endommagée

Utiliser une pompe endommagée peut provoquer une décharge électrique

ou la mort.

Disposal of a used pump

Dispose of any used or damaged pump in accordance with local rules and

regulations. If necessary, consult a licensed industrial waste disposal company.

Elimination des pompes usées

Elle doit se faire en conformité avec les règles locales en vigueur (consult-

ez une entreprise certiée et spécialisée).

Check pump head bolts

Liquid may leak if any of the M8/M5 pump head bolts become loose. Remove

the bolt cover and tighten the bolts diagonally and evenly by 12N•m (IX-C150)

or 3.5N•m (IX-C060) before initial operation and at regular intervals.

Caution

Serrez la tête de pompe

Il pourrait y avoir une fuite de liquide si les 8 boulons M8/M5 du corps de

pompe ne sont pas bien serrés. Enlevez le cache boulon et resserrez les

boulons diagonalement et uniformément (12N•m: IX-C150, 3.5N•m: IXC060) avant la première utilisation et à intervalles réguliers.

CAUTION

9

Precautions for use

• Electrical work should be performed by a qualified electrician. Otherwise,

personal injury or property damage could result.

Le raccordement électrique de la pompe doit être effectué par du person-

nel qualié sinon, il pourrait y avoir un dommage corporel ou incorporel.

• Do not install the pump:

–In a ammable atmosphere.

–In a dusty/humid place.

–In direct sunlight or wind & rain.

–Where ambient temperature can exceed 0-50ºC (32-122°F).

Ne pas installer la pompe dans les endroits suivants:

–Dans une atmosphère inammable

–Dans une atmosphère poussiéreuse ou humide.

–Sous les rayonnements du soleil, dans le vent ou sous la pluie.

–La température ambiante doit être comprise entre 0 et 50°C.

• Select a level location, free from vibration, that won't hold liquid. Anchor

the pump with four M8 bolts so it doesn't vibrate. If the pump is not in-

stalled level, output may be affected.

Choisissez un endroit où il n’y a pas de vibrations et où le liquide peut

s’évacuer. Fixez la pompe à l’aide de visses M8 de façon à ne pas avoir de

vibrations. Si la pompe est inclinée, le débit peut être réduit.

• When two or more pumps are installed together, vibration may be signifi-

cant, resulting in poor performance or failure. Select a solid foundation

(concrete) and fasten anchor bolts securely to prevent vibration during

operation.

Caution

Si plusieurs pompes sont installées ensemble, elles interagissent et les

vibrations peuvent devenir importantes, ce qui engendre des performances

médiocres ou des ratures. Choisissez un endroit solide et xez les boulons

correctement pour évitez les vibrations pendant le fonctionnement.

• Allow sufficient space around the pump for easy access and maintenance.

Prévoyez de l’espace autour de la pompe pour faciliter l'accès et la mainte-

nance.

• Install the pump as close to the supply tank as possible.

Installez la pompe le plus près possible du tank de produit.

• When handling liquids that generate gas bubbles (sodium hypochlorite or

hydrazine solution), install the pump in a cool and dark place. Flooded suc-

tion installation is strongly recommended.

Installez la pompe dans une place froide à l’abri du soleil lorsqu’il s’agit

du dosage de produits dégazant tels que l’hypochlorite de sodium ou

l’hydrazine. Mettre la pompe en charge est vivement recommandé.

• The suction line I.D. should be equal to or wider than the I.D. of the pump.

La ligne d’aspiration doit être plus large que l’entrée de la pompe.

• Build up a flooded suction system for the viscous liquid delivery of

300mPa•S or more.

Caution

Caution

Caution

Caution

Caution

Pour les liquides ayant une viscosité supérieure ou égale à 300 mPa.s il

faut mettre la pompe en charge.

Precautions for use

10

Caution

• Use measures to keep the pump connections free from stress. Weight and

thermal expansion/contraction of the piping can stress connection points.

Safety instructions

La pompe ne doit pas être soumise à des effets éventuels de dilation ou de

contraction du pipe dus à un stress thermique.

• Overload protection will stop pump operation when discharge pressures

reach 1.3 to 2 times higher than the pump maximum. If the discharge line

cannot conservatively handle the maximum pressure, use a relief valve to

safely depressurize the discharge line.

Un dispositif de protection en cas de surcharge doit pouvoir arrêter le dos-

age quand la pression au refoulement s’élève de 1,3 à 2 fois le maximum

admis. Installez une vanne de sécurité pour relâcher la pression de la ligne

de refoulement si la ligne de refoulement ne peut pas supporter de haute

pression.

• Use care handling the pump. Do not drop. An impact may affect pump

performance. Do not use a pump that has been damaged to avoid the risk

of electrical damage or shock.

Veillez à ne pas laisser tomber la pompe sur le sol. Un impact important

pourrait réduire les performances de la pompe. Ne pas utiliser une pompe

endommagée sinon il pourrait y avoir un courant de fuite ou une décharge

électrique.

• The pump has a rating of IP65 equivalent, but is not waterproof. Do not op-

erate the pump while wet with solution or water. Failure or injury may result.

Immediately dry off the pump if it gets wet.

Caution

Caution

Le pompe est IP65 équivalent mais n’est pas complètement étanche. Ne

pas laisser la pompe couverte de liquide pompé ou sous la pluie. Il pour-

rait y avoir des ratés ou préjudices. Si la pompe a été mouillée, sechez-la

directement.

• Do not close discharge line during operation. Solution may leak or piping

may break. Install a relief valve to ensure safety and prevent damaged

plumbing.

Ne fermez pas la ligne de refoulement lorsque la pompe est en fonctionne-

ment sinon il pourrait y avoir des fuites de liquide ou la tuyauterie pourrait

céder. Installez une soupape de sécurité pour des raisons de sécurité et

pour éviter tout dommage de la tuyauterie.

• Solution in the discharge line may be under pressure. Release the pres-

sure from the discharge line before disconnecting plumbing or disassembly

of the pump to avoid solution spray.

Le liquide au refoulement peut être sous pression. Relâchez la pression

du refoulement avant de démonter la pompe ou d’enlevez le tubage pour

éviter tout jet de liquide.

• Wear protective clothing when handling or working with pumps. Consult

solution MSDS for appropriate precautions. Do not come into contact with

residual solution.

Portez un équipement de sécurité lorsque vous manipulez la pompe. Consultez le MSDS pour utilisez les précautions appropriées. Evitez tout con-

tact avec le liquide chimique.

Caution

Requirement

Requirement

Caution

• Do not clean the pump or nameplate with a solvent such as benzine or

thinner. This may discolour the pump or erase printing. Use a dry or damp

cloth or a neutral detergent.

Ne nettoyez pas la pompe ou la plaque signalétique à l’aide d’un solvant

comme le benzène ou le white spirit. Cela pourrait décolorer la pompe ou

effacer l’impression. Utilisez un tissu sec ou mouillé avec de l’eau ou un

détergent neutre.

Benzine

Precautions for use

Thinner

11

Overview

Pump characteristics, features and part names are described in this

section.

Introduction

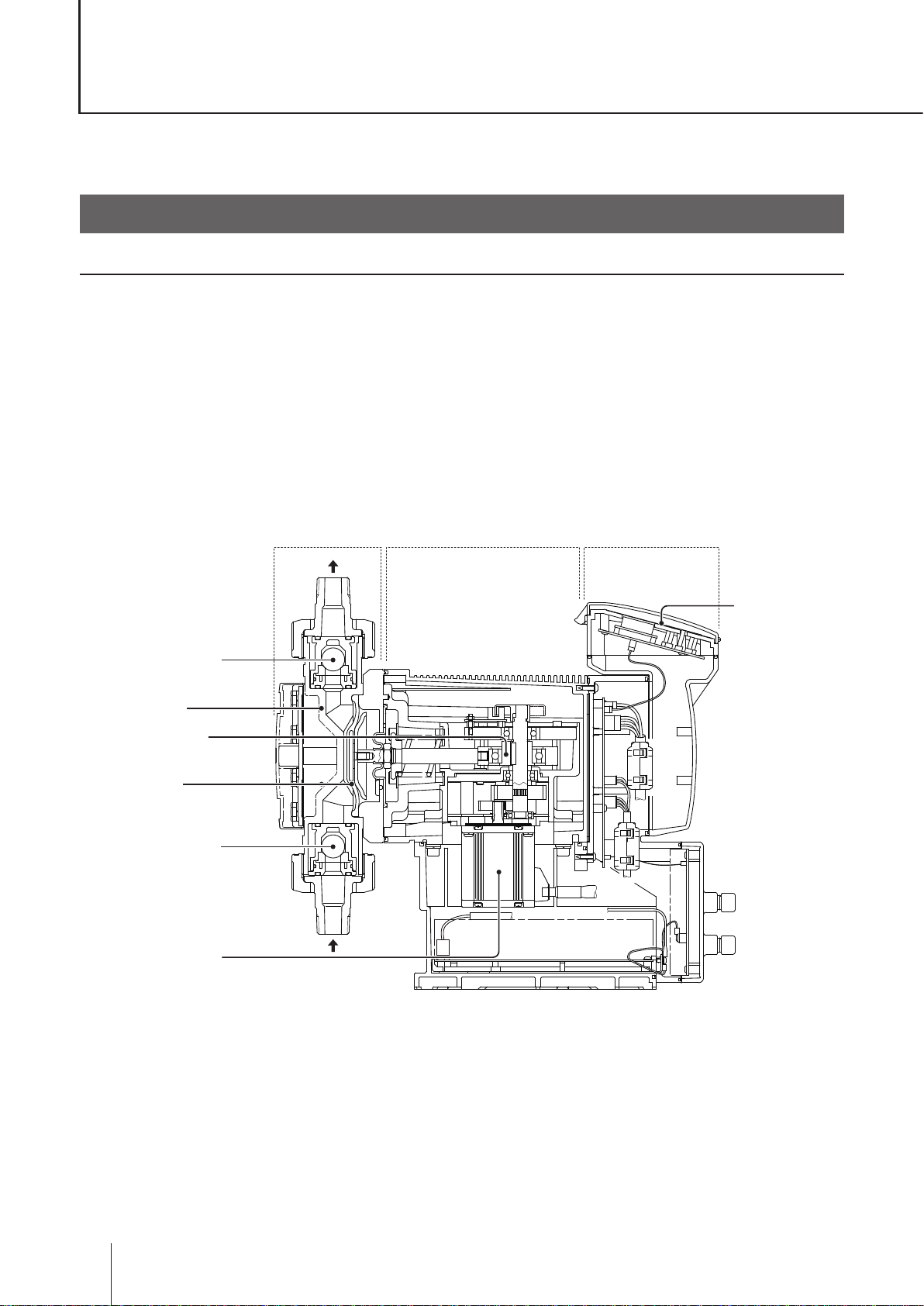

Pump structure & Operating principle

The IX series are diaphragm pumps with a brushless DC (BLDC) motor and feature a high turndown ratio &

automatic controls.

Principle of operation

In the IX series design, a BLDC motor rotation controls the ow rate.

Motor rotation is transmitted to an eccentric cam through a reduction gear and then converted to reciprocating

motion. Volumetric change occurs in the pump chamber as the diaphragm moves back and forth and liquid is

pumped because of the suction and discharge check valves. Discharge speed changes the ow rate while the

suction speed remains the same at any ow rate.

Control unitPump head Drive unit

Pump head valve

(discharge side)

Pump head

Eccentric cam

Diaphragm

Pump head valve

(suction side)

Brushless motor

OUT

Keypads

IN

12

Introduction

Features

● High turndown ratio

Use of a BLDC control motor enables accurate control with a wide turndown ratio.

● High repeatability

Highly-efcient valve design and accurate discharge-/suction-speed controls assure the high repeatability of

chemical dosing (±1%).

● Energy-saving design

Use of helical gears and an assist spring reduces power consumption by 70% compared to our existing me-

tering pump designs (spring back).

● Automatic control

The IX can automatically run along with analogue-, pulse-, batch- or interval batch-operation programming.

● Multivoltage operation

The IX series can be used in all countries thanks to the universal power voltage (100-240VAC).

● Safety design

A diaphragm rupture detection ensures user safety and a pressure overload detection protects the pump and

pipework from an accidental discharge line pressure rise.

● Ingress protection rating of IP65

Overview

Operational functions

Manual mode

Run/stop the pump by key operation. The ow rate can be changed by the up and the down keys at any time

during operation or stop. The operation LED lights in green colour during operation. See page 54 for detail.

Key operation

(Push key)

Run

Pump operation

Stop

Run

Stop

Operational functions

13

EXT mode

■ Analogue proportional control

ANA. P (analogue preset) programming (see page 42 & 54)

Select a proportional control pattern. 4 - 20mA, 20 - 4mA, 0 - 20mA and 20 - 0mA are available. During opera-

tion, the display shows the current ow rate. To show the current value, push the key. To return to the ow

rate display, push the key.

Max

b

d

Flow rate

[L/H]

c

a

Min

0 4 20

4-20mA analogue signal

Example of use: pH control in a water treatment system

Supply tank

pH meter

Electrode

The left graph shows the flow rate at each

pattern.

a. 4 - 20mA

b. 20 - 4mA

c. 0 - 20mA

d. 20 - 0mA

* The ow rate falls to 0mL/H if the pump runs

beneath the minimum rate.

* The pump does not run over the maximum ow

rate at any current value.

4-20mA signal

Pump

14

Operational functions

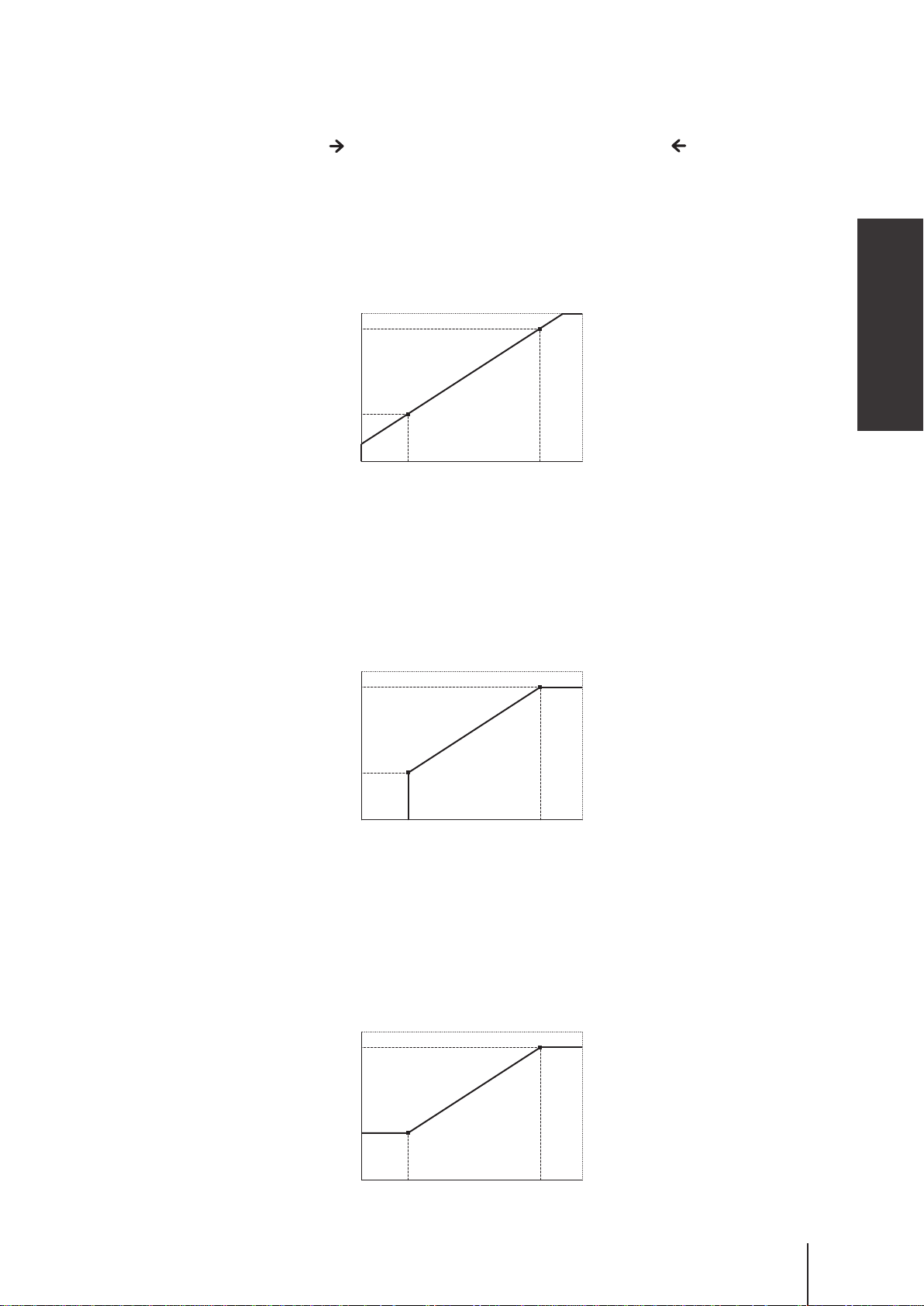

ANA. V (analogue variable) programming (see page 42 & 54)

The pump increases/decreases a stroke/ow rate in proportion to 0-20mA. Determine the operational behav-

iour by programming two set points and choosing one of the LINEAR, BOX and LIMIT patterns.

To show the current value, push the key. To return to the ow rate display, push the key.

<LINEAR>

A stroke/ow rate changes with a current value by a programmed line.

Condition:

Set Point 1 (SP.1) = Ampere : 6mA, Flow rate : 45L/H

Set Point 2 (SP.2) = Ampere : 17mA, Flow rate : 127L/H

150L/H

127L/H

SP.2

Overview

45L/H

0 6

SP.1

17

20mA

<BOX>

A stroke/ow rate changes with a current value by a programmed line. The rate does not exceed the Set Point

2 but then falls to 0 before the Set Point 1.

Condition:

Set Point 1 (SP.1) = Ampere : 6mA, Flow rate : 45L/H

Set Point 2 (SP.2) = Ampere : 17mA, Flow rate : 127L/H

150L/H

127L/H

45L/H

SP.1

0 6

17

SP.2

20mA

<LI M IT>

A stroke/ow rate changes with a current value by a programmed line. The rate does not falls below the Set

Point 1 or exceed the Set Point 2.

Condition:

Set Point 1 (SP.1) = Ampere : 6mA, Flow rate : 45L/H

Set Point 2 (SP.2) = Ampere : 17mA, Flow rate : 127L/H

150L/H

127L/H

45L/H

SP.1

0 6

17

SP.2

20mA

Operational functions

15

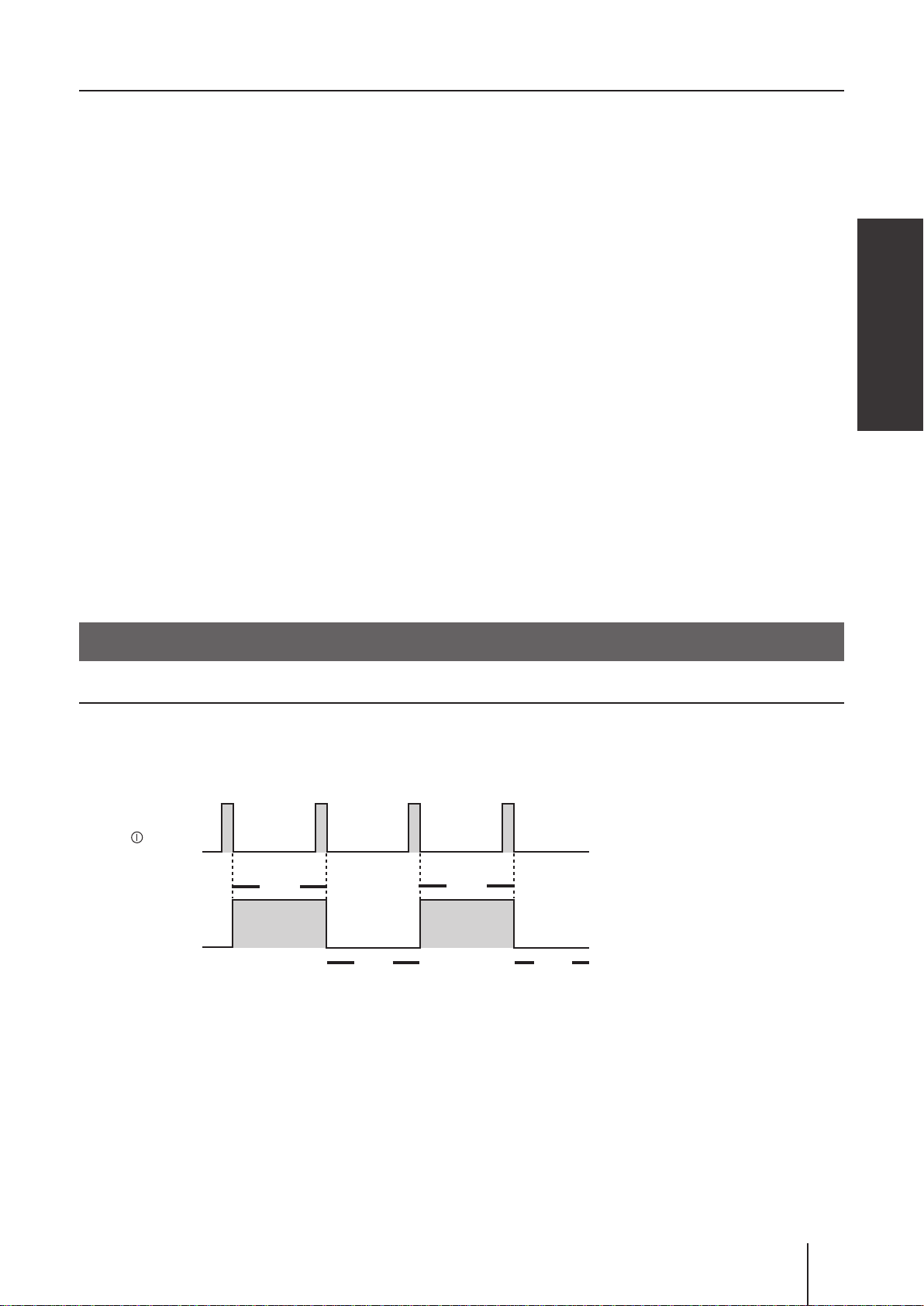

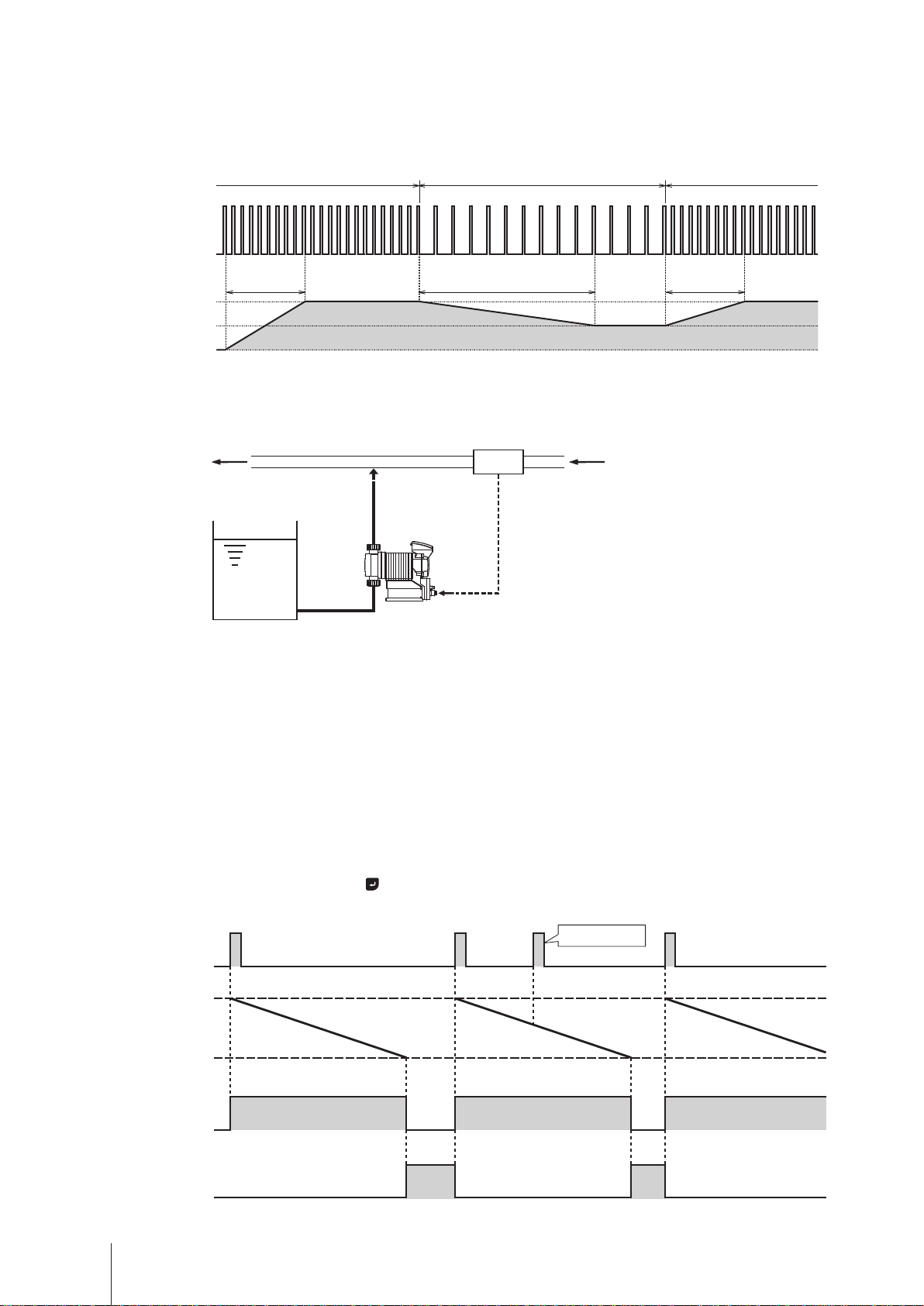

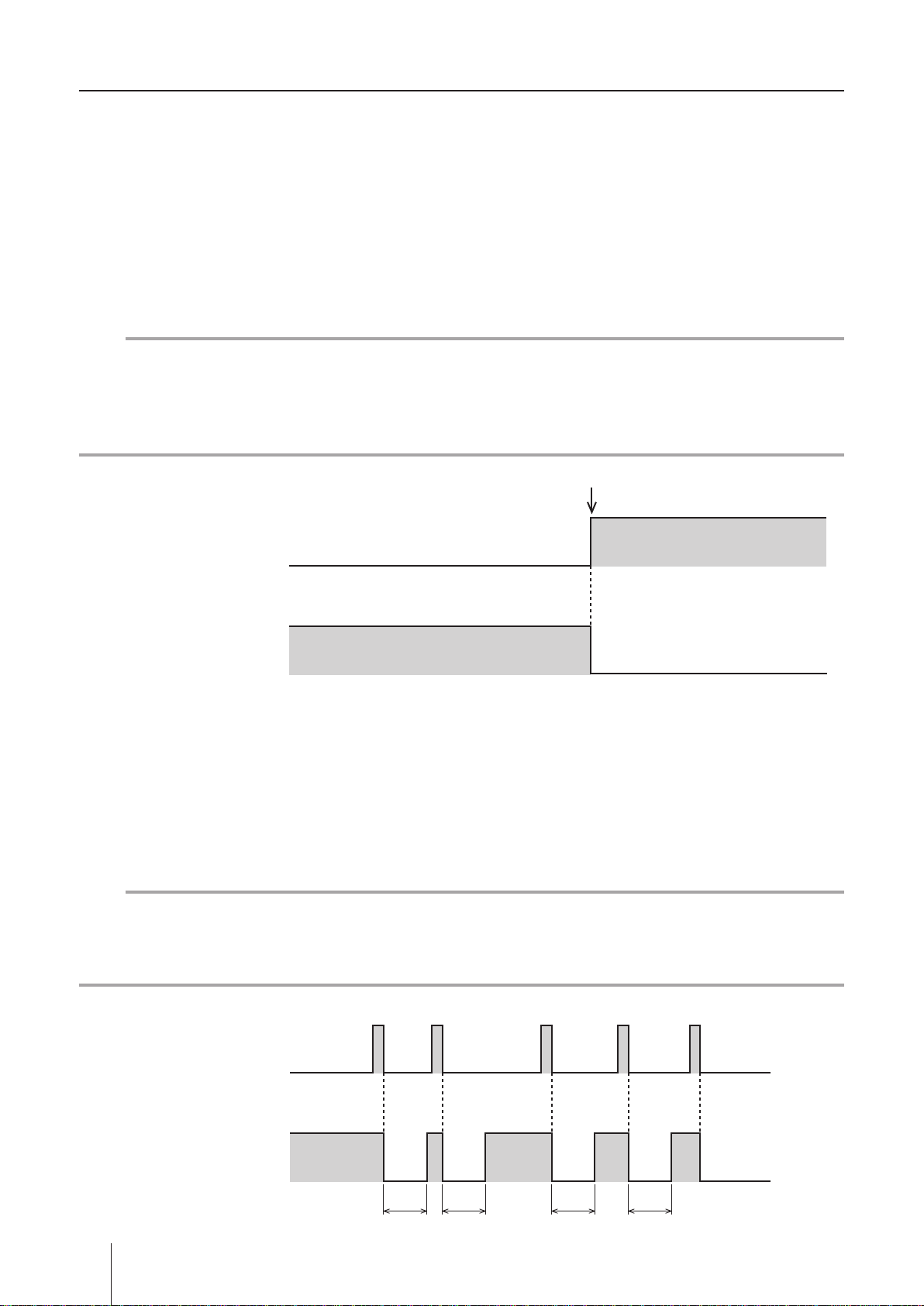

■ Pulse control (see page 42 & 54)

The ow rate is automatically controlled by the ow volume (ml) per pulse and the pulse signal frequency from a

ow meter.

* It takes about 10 pulses for the IX to catch up with the change of the frequency.

10Hz 5Hz 10Hz

Pulse signal

Flow rate at 10Hz

Fow rate at 5Hz

0

Example of use: Chemical dosing in a sewage treatment system

Flow meter

Flow

Supply tank

Pulse signal

Pump

■ Batch control (see page 42 & 54)

The IX discharges a programmed ow volume per pulse and stops when it is completed. The programmed or

remaining ow volume is shown on the controller until it has reduced to zero. In this control mode, the pump

runs at the MAN speed (the pump speed in the manual mode). The pump behaviour can change depending on

the setting of the buffer. See below.

When the buffer is OFF:

Any input of the external pulse signal will be cancelled when the pump is activated for the earlier pulse input.

The next dosing becomes ready after the programmed ow volume has been completed.

*Note the control stops immediately when the key is pushed once.

Cancelled

Pulse input

Programmed

flow volume

Pump

Signal out

(batch comp alarm)

Operational functions

16

Run

Stop

Run

Run

Stop

Example of use: Chemical dosing in a production line system

Supply tank

Pump

Pulse

signal

Proximity switch

When the buffer is ON:

Every time the external pulse signal is inputted, the programmed ow volume per pulse is accumulated (max

65535 pulses) even when the pump is activated for the earlier pulse input.

*The control stops immediately and all the pulse accumulation is cleared when the key is pushed once.

Pulse input

Overview

Flow volume for

Programmed

flow volume

Pump

Signal out

(batch comp alarm)

the next signal

Run

Run

Stop Stop

Pulse input by the key:

Instead of the pulse signal input, pushing the key can start or stop the batch control. In this case, the pump

behaves as the control with the buffer OFF even when the buffer is set to ON in the batch control mode.

key

Programmed

flow volume

Pump

Run

Run

Stop Stop

Stop

Operational functions

Run

17

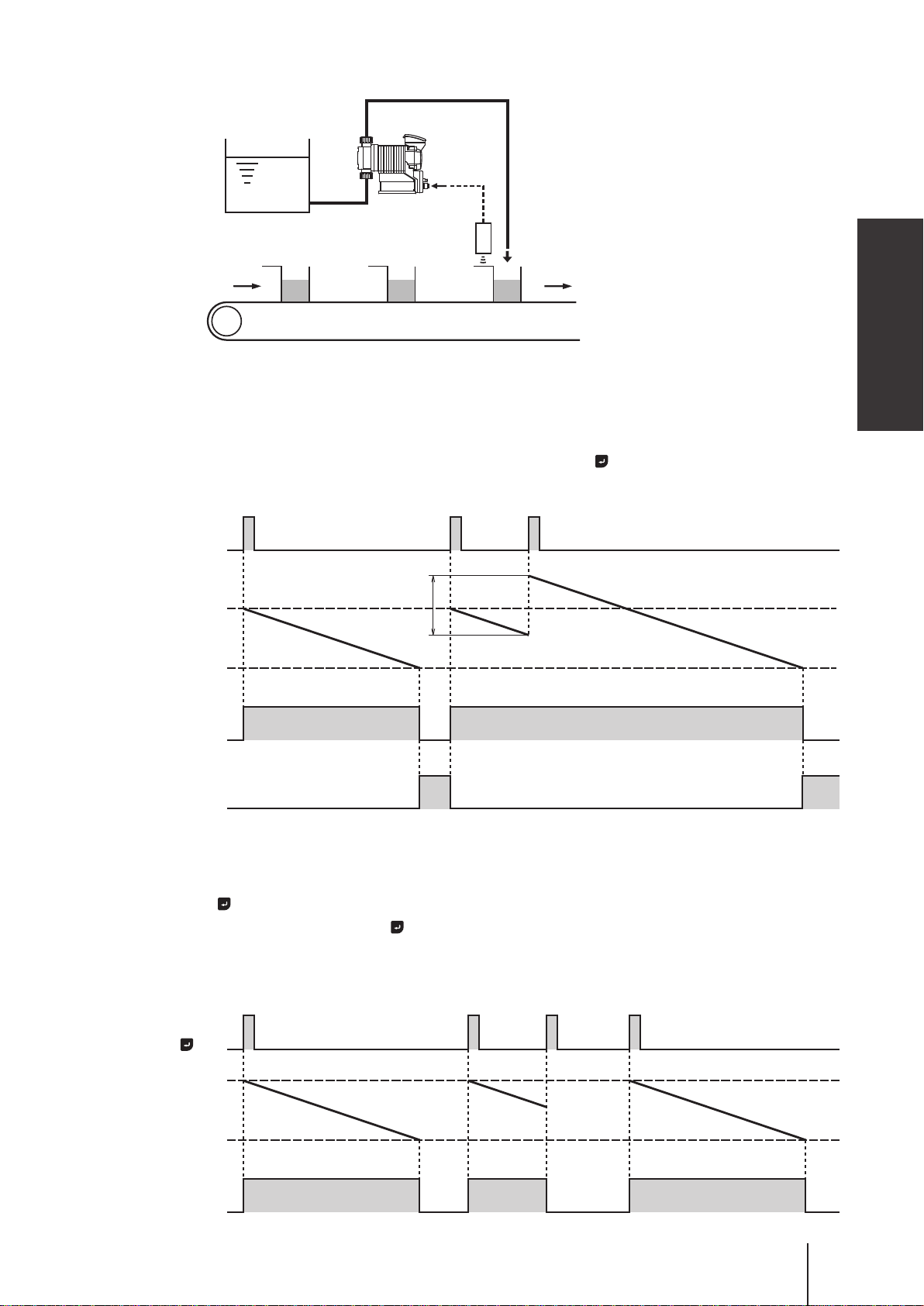

■ Interval batch control (see page 42 & 54)

To make an interval batch control, set a date and time interval and the ow volume. The IX discharges the pro-

grammed ow volume at a set interval. In the diagram below, the interval is set to 1 hour.

* The pump runs at the MAN speed. The control is triggered by either the external pulse signal or the push of the key.

Push the

key to stop the control when it is triggered by the key.

Time

Pulse signal/

Push of

key

Flow

1 hr

2 hr 3 hr

Example of use: Water transfer for a sprinkler system

Pump

Supply tank (water) Pulse signal

AUX function

The pump runs at the AUX speed while receiving the external signal via the AUX terminal. See page 51.

* This function works only when the pump is running in either MAN or EXT mode (see page 40.). The pump returns to the

MAN or EXT mode once the AUX signal stops.

AUX signal

Pump operation

RunStop RunStop

Priming function

The pump runs at the MAN speed (or the maximum stroke rate with default setting) while both the UP and

DOWN keys are pressed. Use this function for priming or degassing. Release both the keys to stop the pump.

See page 55 for detail.

* This function is available at any time except when the pump is in the MAN/EXT selection or menu selection (see page 40.).

Press & hold

Pump operation

RunStop Stop

Press & hold

Run Stop

Operational functions

18

STOP functions

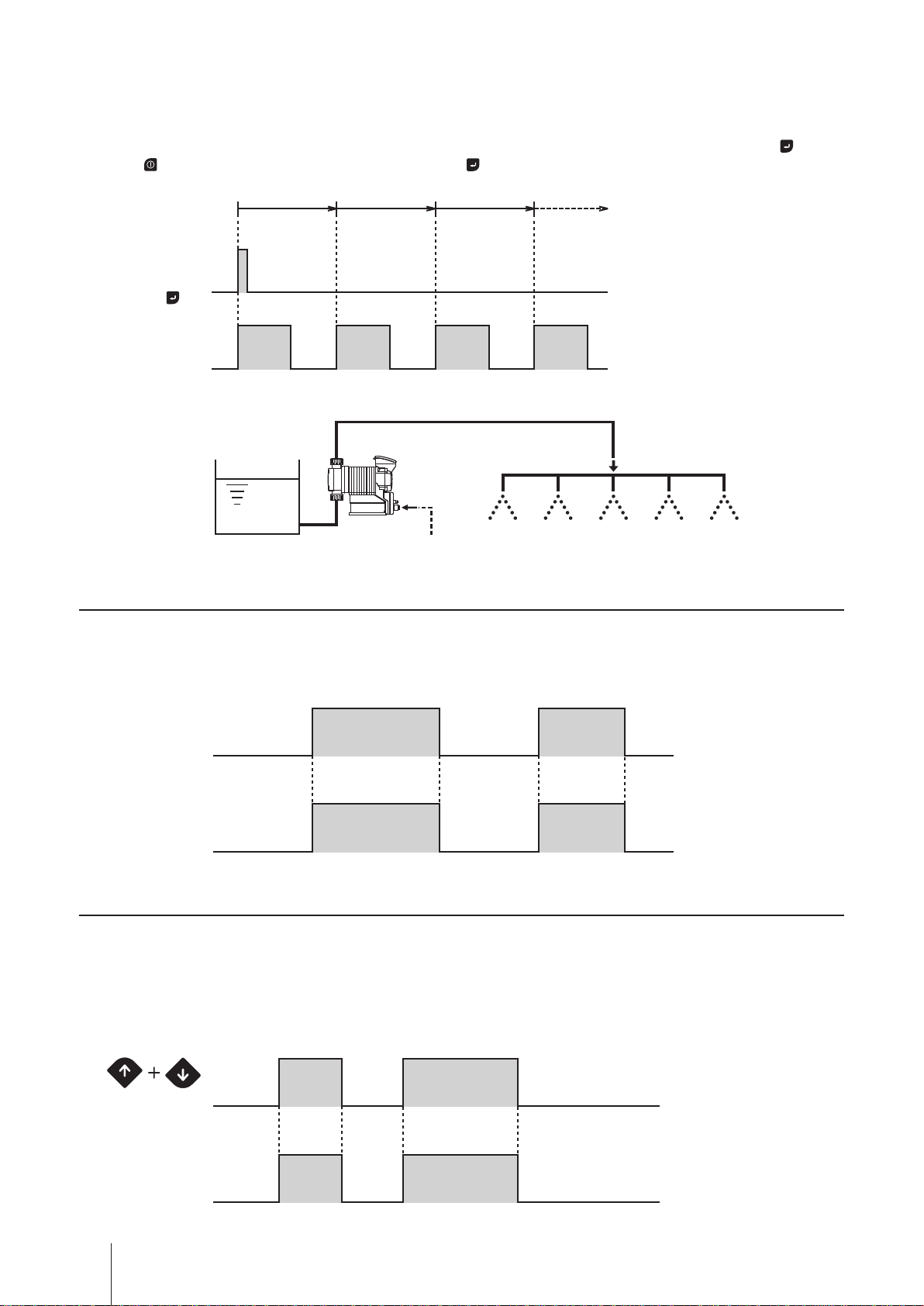

■ STOP function (see page 45)

The start/stop of operation can be controlled by the signal from a level sensor. The operation LED changes

from green to red colour when the pump is receiving the Pre-STOP signal from a level sensor in operation.

See page 32 "STOP IN" for wiring diagram.

Example of use: Liquid level monitoring

Flow

LED lights

in red

Pump OFF

Liquid is below the minimum level

The pump stops when liquid has fallen below the minimum level.

STOP signal

Level sensor

Overview

■ Pre-STOP function (see page 45)

Liquid level in the supply tank can be monitored by the signal from a level sensor. The operation LED changes

from green to orange colour when the pump is receiving the Pre-STOP signal from a level sensor in operation.

See page 32 "STOP IN" for wiring diagram.

Example of use: Liquid level monitoring

Flow

LED lights

in orange

Pump

ON

Liquid is near the minimum level

The operation LED lights in orange colour to inform a user that liquid comes

close to the minimum level in a supply tank.

Pre STOP

Level sensor

signal

Analogue output function

The pump transmits the 0-20mA analogue signal in proportion to the preset ow rates. See page 46.

Operational functions

19

Protective functions

■ Interlock function (see page 32 & 47)

Interlock function works in the same way as the STOP function but uses a preference circuit. Use this function

for emergency stop.

■ Diaphragm rupture detection (see page 45)

The pump stops right after a built-in sensor detects a leak in the compartment at the back of the diaphragm.

In this condition, the operation LED lights in red colour. Replace a broken diaphragm as necessary. See page

63 for diaphragm replacement. To release this error condition, push the start/stop key (or the ESC key under

Probus control.).

NOTE

This capacitance sensor does not work properly if liquid conductivity is 1mS/m or below. Before sending pure

water, oil or any other low-conductivity liquid, check the conductivity to see if it meets the minimum level. If it

is not satised, replace the diaphragm immediately when a leak is found from the drain port. Otherwise, the

pump may fail.

A leak is detected.

ON

Leak detection

OFF

Pump operation

Run Stop

■ Pressure overload/Failed rotation control detection

The pump stops when a built-in pressure sensor detects 1.3-2.0 times higher discharge pressure than the

maximum level or when the hole IC which monitors the motor rotation has failed. In either condition, the operation LED ashes in red colour. The pump resumes operation 30 seconds after the stoppage due to the pres-

sure overload. If the overload has recurred 5 times consecutively, the pump will not resume operation any more

and will keep still. Push the start/stop key to release these error conditions.

NOTE

The activation of this function means the discharge pressure has risen 1.3-2.0 times higher than the maxi-

mum allowable level of the pump. Set up a relief valve to protect the related devices on the discharge line

from the possible pressure rise as necessary.

ON

Overload detection

1 2 3 4 5times

Pump operation

20

Operational functions

OFF

Run Stop

30sec 30sec 30sec 30sec

■ Alarm output function (see page 47)

Enable or disable the output of the batch completion, STOP, Pre-STOP, interlock, diaphragm rupture detection,

pressure overload detection, and/or drive error detection functions which is preset to the Alarm OUT 1 and 2,

or the output of the volume proportional pulse preset only to the Alarm OUT 2. See page 33 "Alarm OUT (DIN

connector)" for wiring diagram.

Alarm OUT 1 (OUT 1) : Mechanical relay output (no voltage contact 1a×1 250VAC 3A, resistive load)

Alarm OUT 2 (OUT 2) : PhotoMOS relay output (no voltage contact 1a×1 24VAC/DC 0.1A, resistive load)

Other functions

■ Suction speed setting (see page 51)

Suction speed is adjustable by 4 levels depending on liquid property. Reduce suction speed so as to reduce

inertia resistance for the delivery of viscous liquid or to prevent cavitation for gaseous liquid. Select 100% (de-

fault), 75%, 50% or 25%.

■ Maximum ow rate setting (see page 51)

The maximum allowable ow rate of the IX can be reduced if necessary. The default setting of the IX-C150 is

150L/H and the IX-C060 is 60L/H.

Overview

■ Diaphragm position adjustment (see page 51)

A pump shaft expands or contracts for easy diaphragm replacement. Select "MAX OUT Pos." through the

"Other Features" menu in order to extend the pump shaft to the maximum. Select "MAX IN Pos." to contract it

to the minimum and mount the pump head. See page 63 "Diaphragm replacement" for detail.

■ Anti chattering programming (see page 51)

Program a pulse recognition time for the IX not to be adversely affected by chattering or noise. Factory default

setting is 5 msec. This means the pump recognizes the pulse length of 5 msec or more. The other options are

1 and 2 msec and should be selected for the shorter pulse length, however, note the shorter the recognition

time is, the more susceptible to the interference of noise the pump becomes. Note the maximum allowable

input frequency of the IX is 100Hz.

■ Output logic setting (see page 51)

Select "normally open" or "normally closed" for the Alarm OUT 1 (OUT 1) and 2 (OUT 2) outputs.

■ Flow unit setting (see page 51)

Select L/H or GPH for the ow rate indication.

■ Language setting (see page 51)

Select your language through the language selection.

■ Keypad lock (see page 56)

The IX-C is shipped with the access codes at default values (00000). In order to prevent against unauthorized

tampering, you will need to change the access codes to your own values.

■ Default setting

Power on the pump while pressing the ESC key to recall default setting. Note the ow volume per shot ob-

tained through the calibration process (see page 37) remains the same.

Operational functions

21

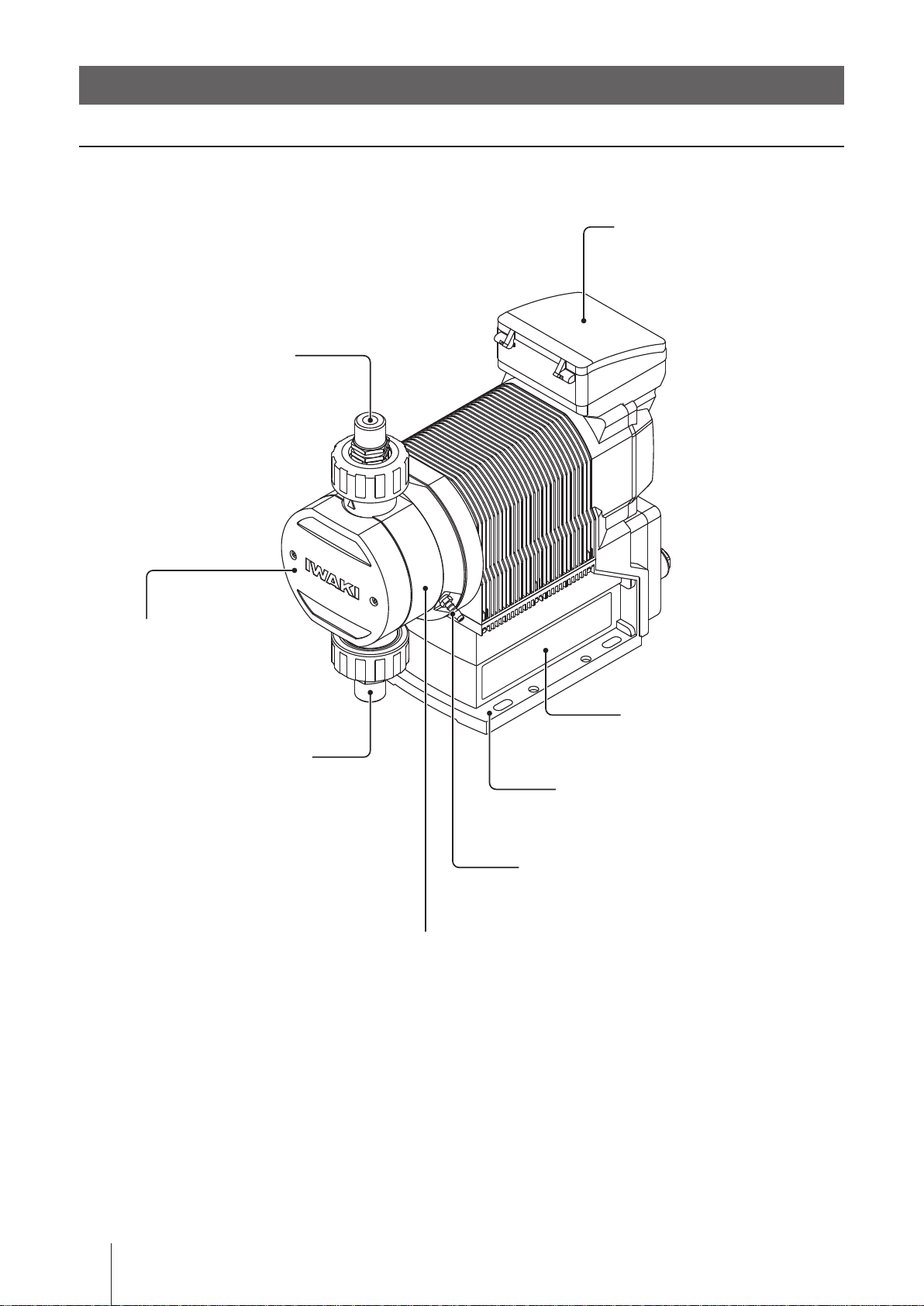

Part names

Pump

Control unit

Used for the start/stop of the pump

and operation control/program-

ming. See next page for detail.

Unhook the cover to open it. Push

down until it clicks once to close it.

Outlet

Bolt cover

Take out the cover to

remove the pump head.

Inlet

Pump head

Nameplate

Describes the pump specifi-

cations.

Base

Always anchor it with bolts.

Drain port (Vent hole)

Chemical liquid will be released from here.

* Do not plumb this drain port to a supply tank

with sodium hypochlorite or any other strong

acid. Make sure this port "breathes" in a clean

atmosphere.

22

Part names

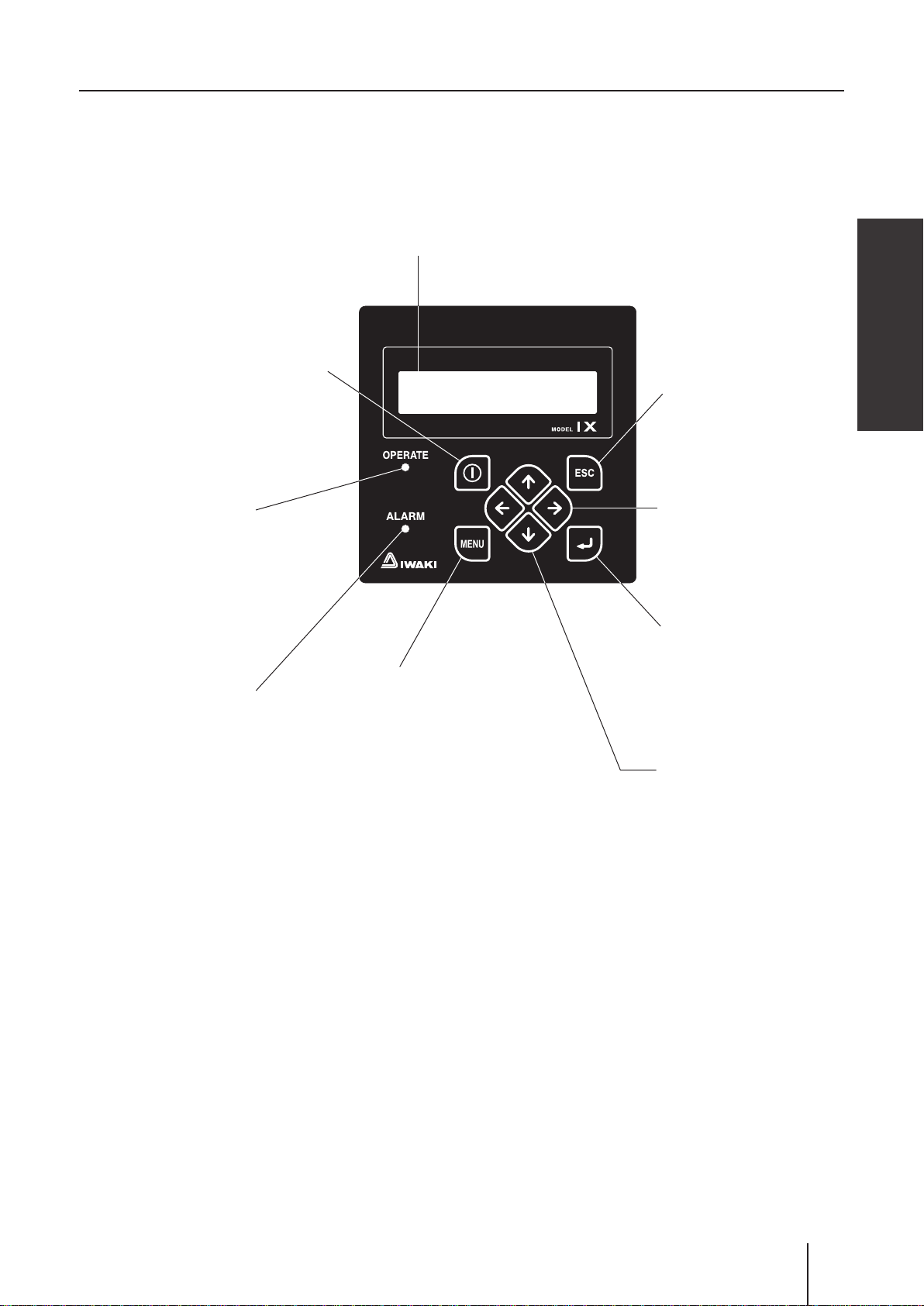

Operation panel

Start/Stop key

Used for starting/stopping the pump

operation or moving back to the MAN/

EXT selection.

Display

An operational status, a selected mode

and programmed values are shown here.

Overview

ESC key

Used for cancelling pro-

gramming and moving back

to a previous menu.

Operation LED

Lights in green in operation

and in red during stoppage,

programming, error conditions.

Lights in orange as Pre-STOP

signal is entered. See page 24.

ALARM LED

Lights to notice the damaged diaphragm, the inter-

lock activation or so.

MENU key

Used in the MAN/EXT

selection screen for calling

up the menu screen.

Left/Right key

Used for moving through

items. Press and hold both

keys for 3 seconds to dis-

able keypads.

Enter key

Used for making a deci-

sion in the menu screen or

MAN/EXT selection.

UP/DOWN key

Used for changing numeric

values or selecting a programming mode.

The pump enter the priming

mode while both the keys

are pressed.

Part names

23

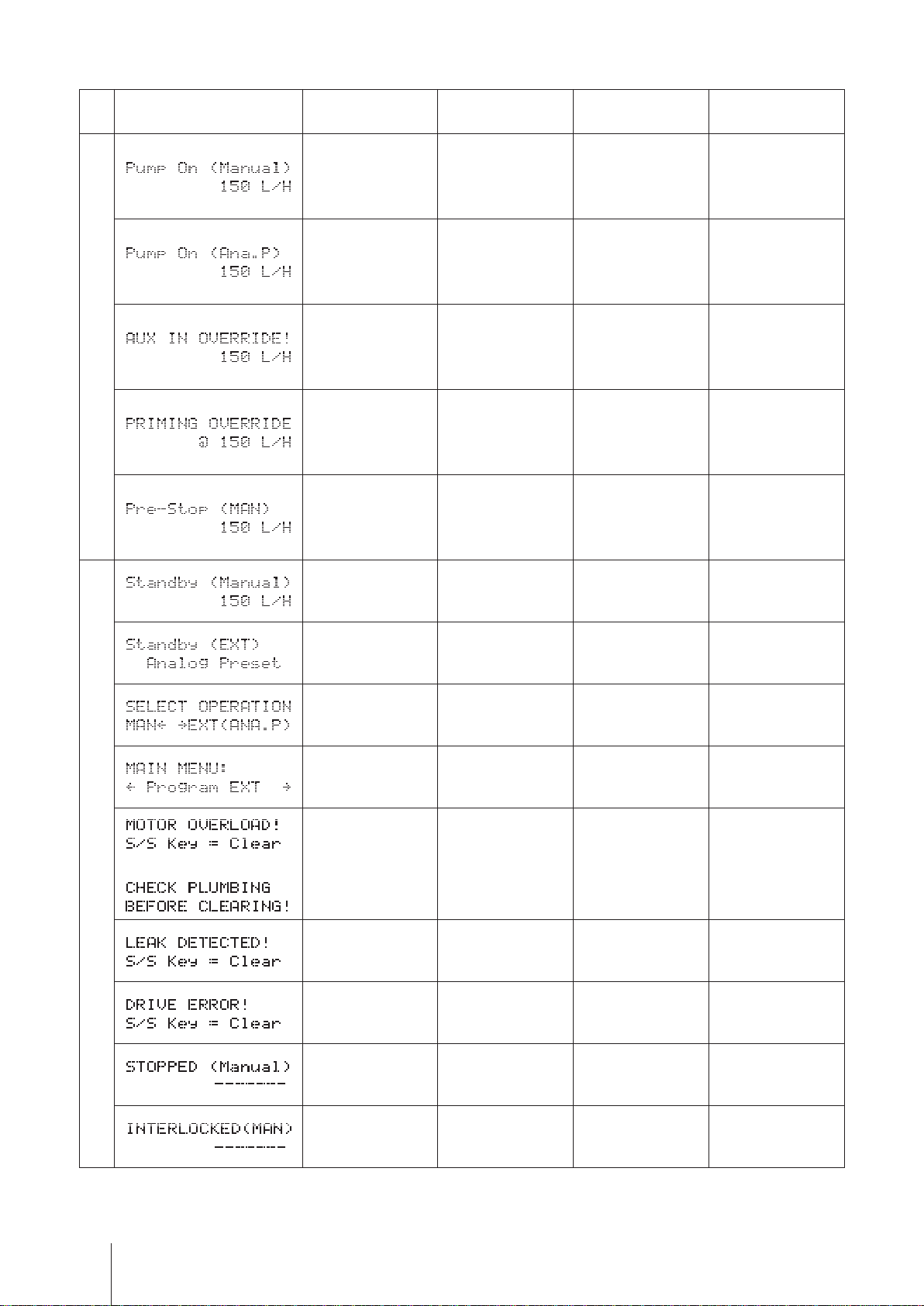

■ Basic displays & Pump states

Display

Operation LED

lights in red

Operation LED

lights in green

Operation LED

lights in orange

ALARM LED

lights in red

Operation

―

―

― AUX operation ― ―

―

― ―

A wait state in

manual mode

Operation in

manual mode

Operation in EXT

mode (Analogue

control)

Operation in prim-

ing mode

― ― ―

― ―

― ―

― ―

Pre-STOP func-

tion is active.

Pre-STOP func-

tion is active.*

A wait state in

EXT mode (ana-

logue control)

MAN/EXT selec-

tion

Menu screen ― ― ―

Pressure overload

Stop

or

protection is ac-

tive.

Diaphragm is bro-

ken.

Failed rotation

control is detected.

Operation stop in

manual mode

― ― ―

― ― ―

Pressure overload

― ―

― ―

― ―

― ―

protection is ac-

tive.*

Diaphragm is bro-

ken (Alarm OUT 1

default setting).*

Failed rotation

control is detect-

ed.*

Operation stop in

manual mode*

― ― ―

* The Alarm LED becomes active when a function is allocated to the Alarm OUT 1 or 2.

Part names

24

Interlock function ac-

tivation (Alarm OUT

2 default setting)*

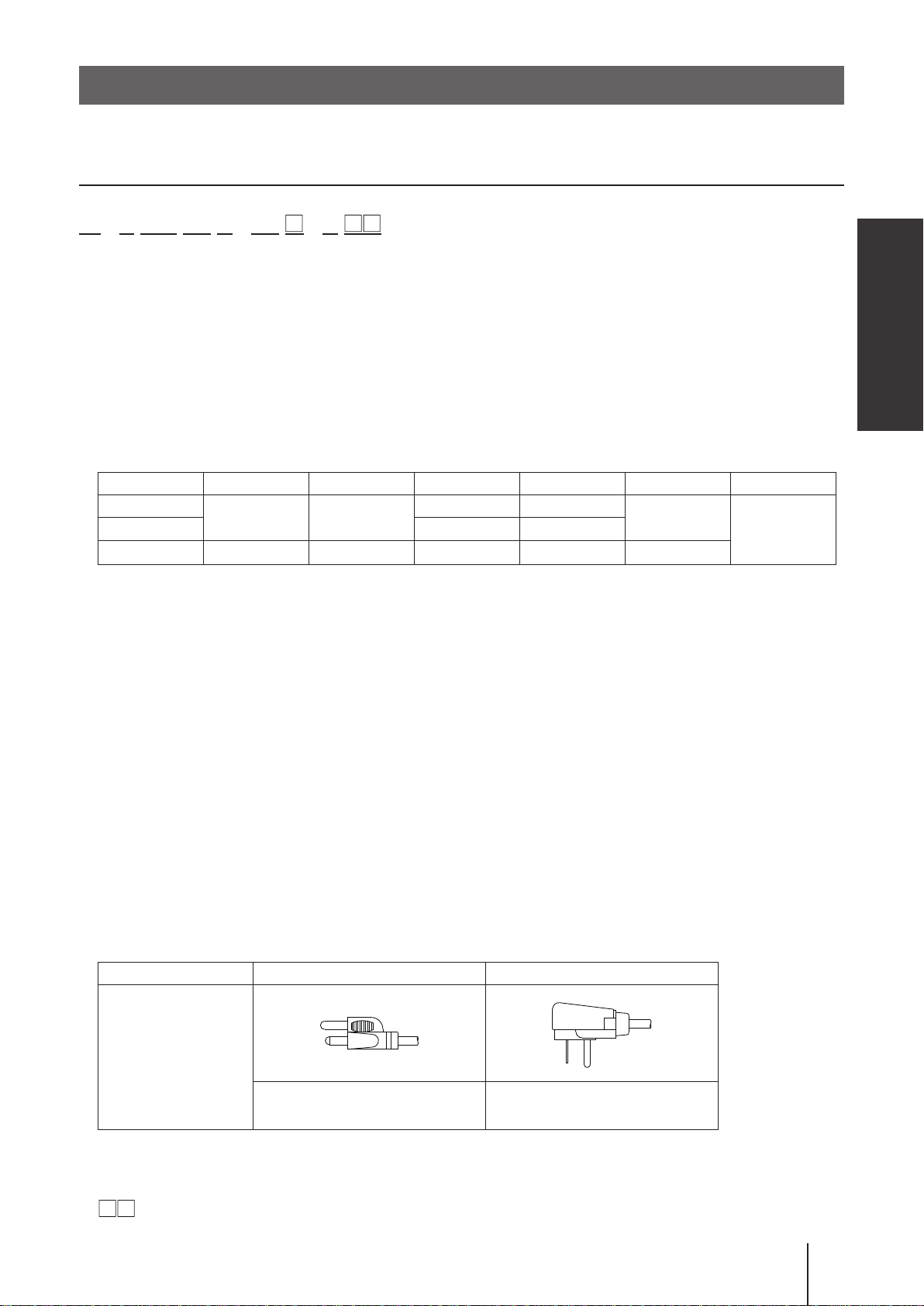

Identication codes

Each code represents the following information.

Pump

IX - C 150 TC N - TB - U

a b c d e f g h i

a. Series name

b. Drive unit

c. Pump unit (Max ow)

150 : 150 [L/H]

060 : 60 [L/H]

d. Wet end materials

Code Pump head Ball valve Valve seat O ring Valve gasket Diaphragm

TC

TE EPDM EPDM

S6 SUS316 SUS316 SUS316

*EPDM is not a wet end.

PVDF CE

FKM FKM

―

―

PTFE

Overview

PTFE+EPDM*

Material code

PVDF : Polyvinylidene diuoride PTFE : Polytetrauoroethylene

EPDM : Ethylene-propylene rubber FKM : Fluorine-contained rubber

CE : Ceramics SUS316 : Austenite stainless

e. Connection

N : NPT thread

FA : ANSI ange

f. Controller housing

TF : Top Front TB : Top Back TR : Top Right TL : Top Left RF : Right Face LF : Left Face

g. Control code

1 : IX-C060

2 : IX-C150

h. Power plug

Code U U2

Plug shape

115V (1950mm length) 230V (1950mm length)

i. Special version

No code : Standard models

: Customized models will be coded.

Identication codes

25

Installation

This section describes the installation of the pump, piping and wiring.

Read through this section before work.

Points to be observed

Observe the following points when installing the pump.

• Risk of electrical shock. Be sure to turn off power to stop the pump and related devices

before service is performed.

If you notice any abnormal or dangerous conditions, suspend operation immediately and

•

inspect/solve problems.

• Do not place explosive or ammable material near the pump.

• Use of a damaged pump could lead to an electric shock or death.

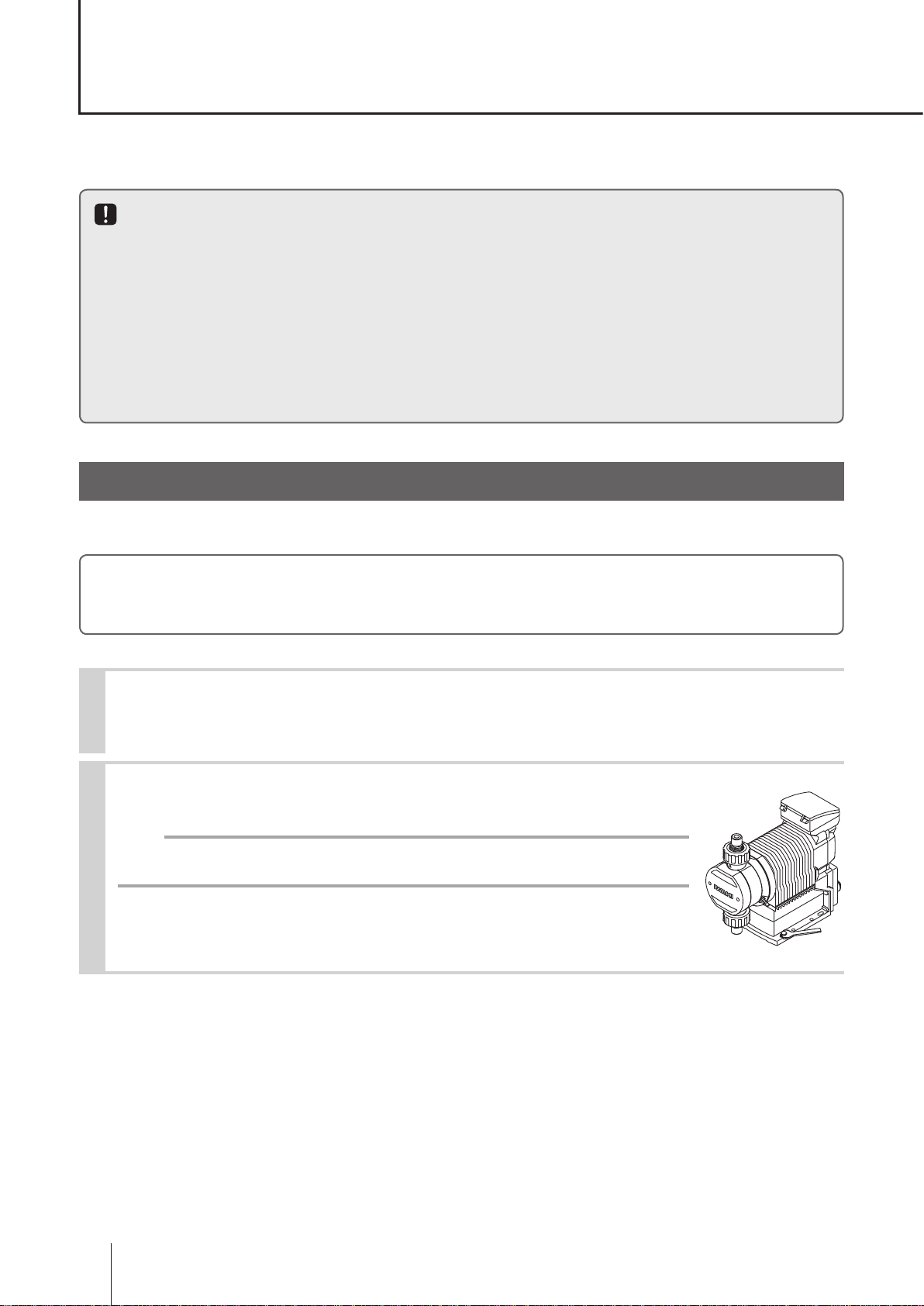

Pump mounting

Select an installation location and mount the pump.

Necessary tools

• Four M8 bolts (pump mounting) • Adjustable wrench or spanner

Select a suitable place.

1

Always select a at oor free of vibrations. See page 10 for detail.

Anchor the pump by four M8 bolts.

2

Be sure to x the pump at four points.

NOTE

Select a level location, or the ow may reduce.

Pump mounting

26

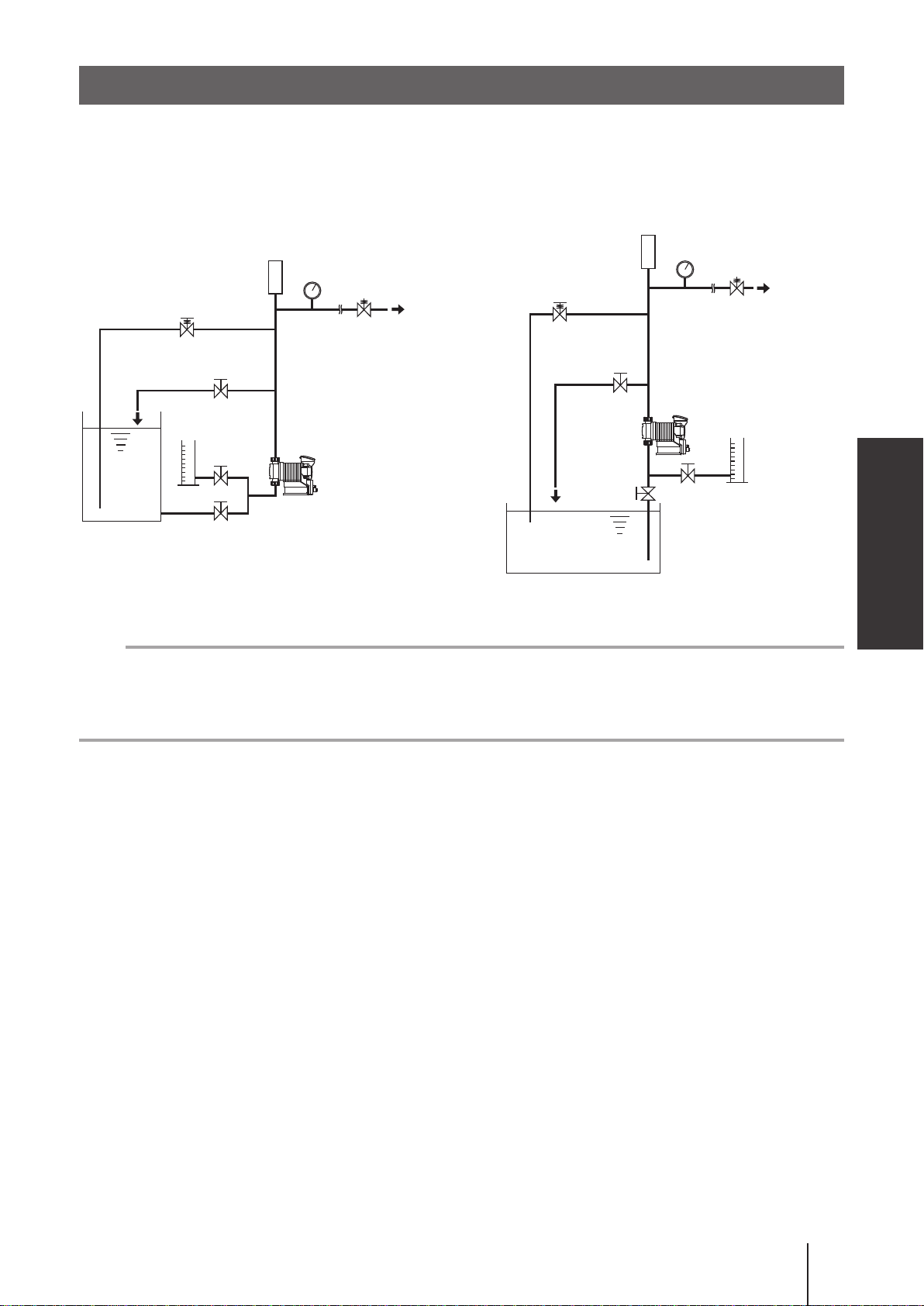

Pipework

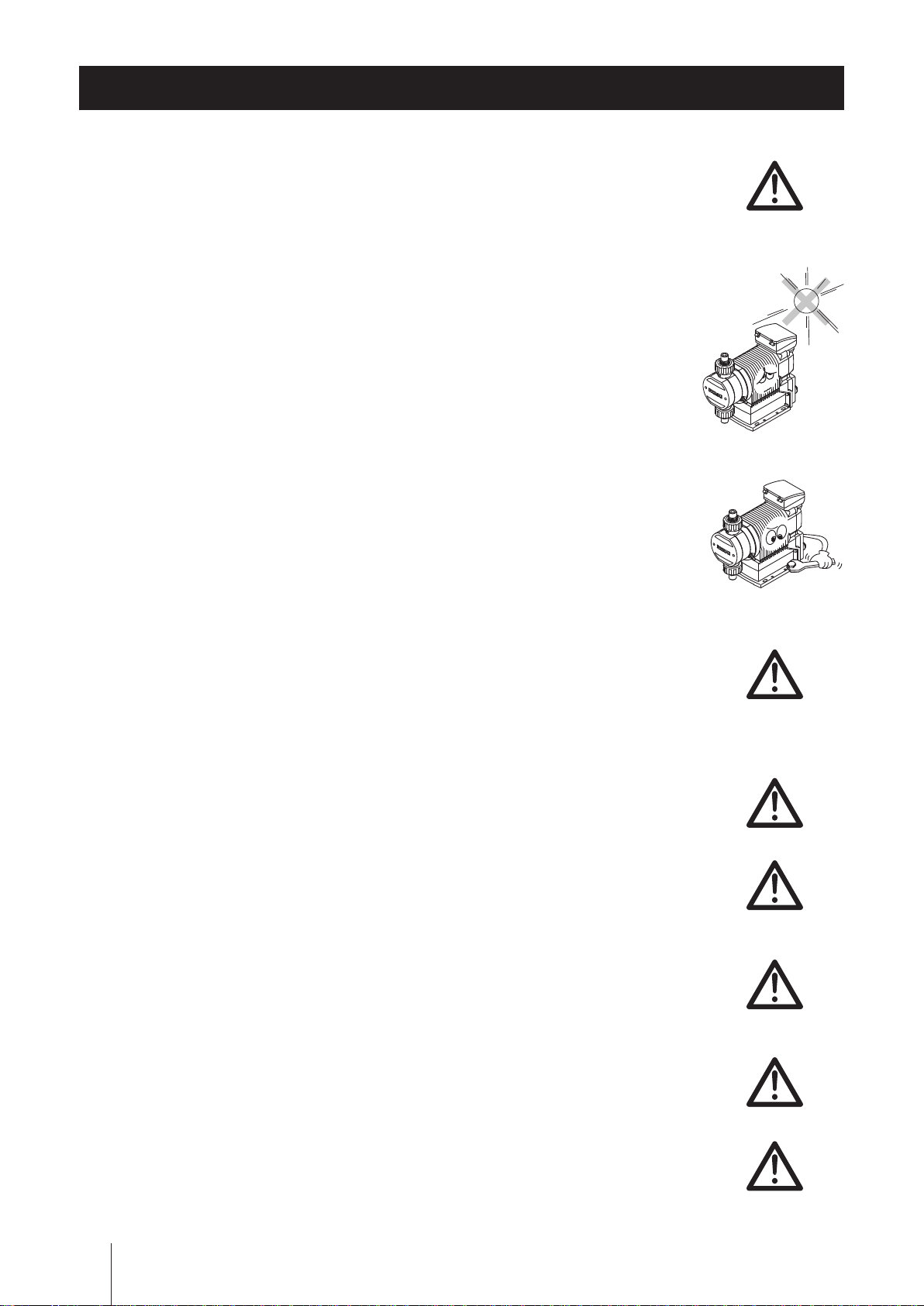

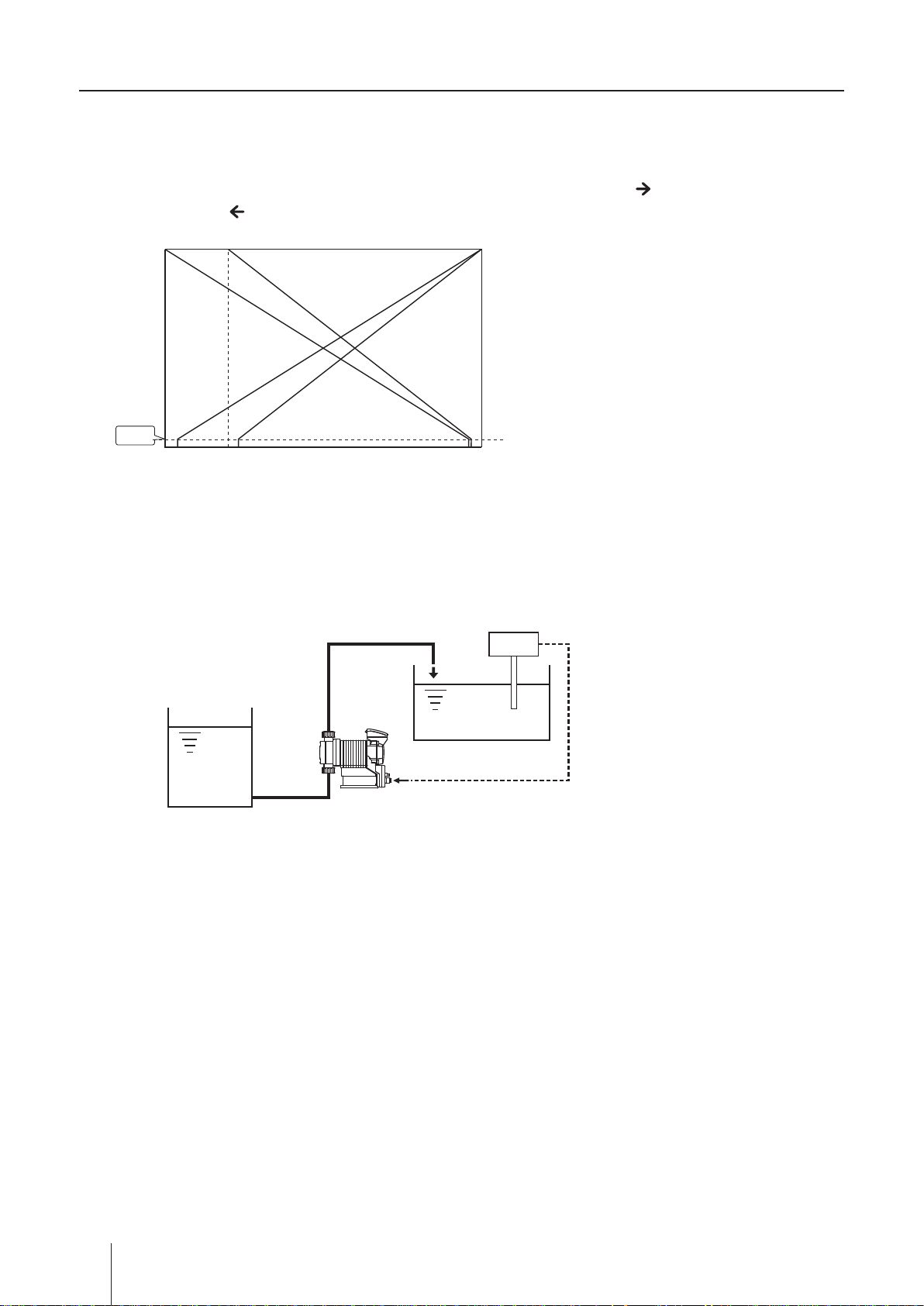

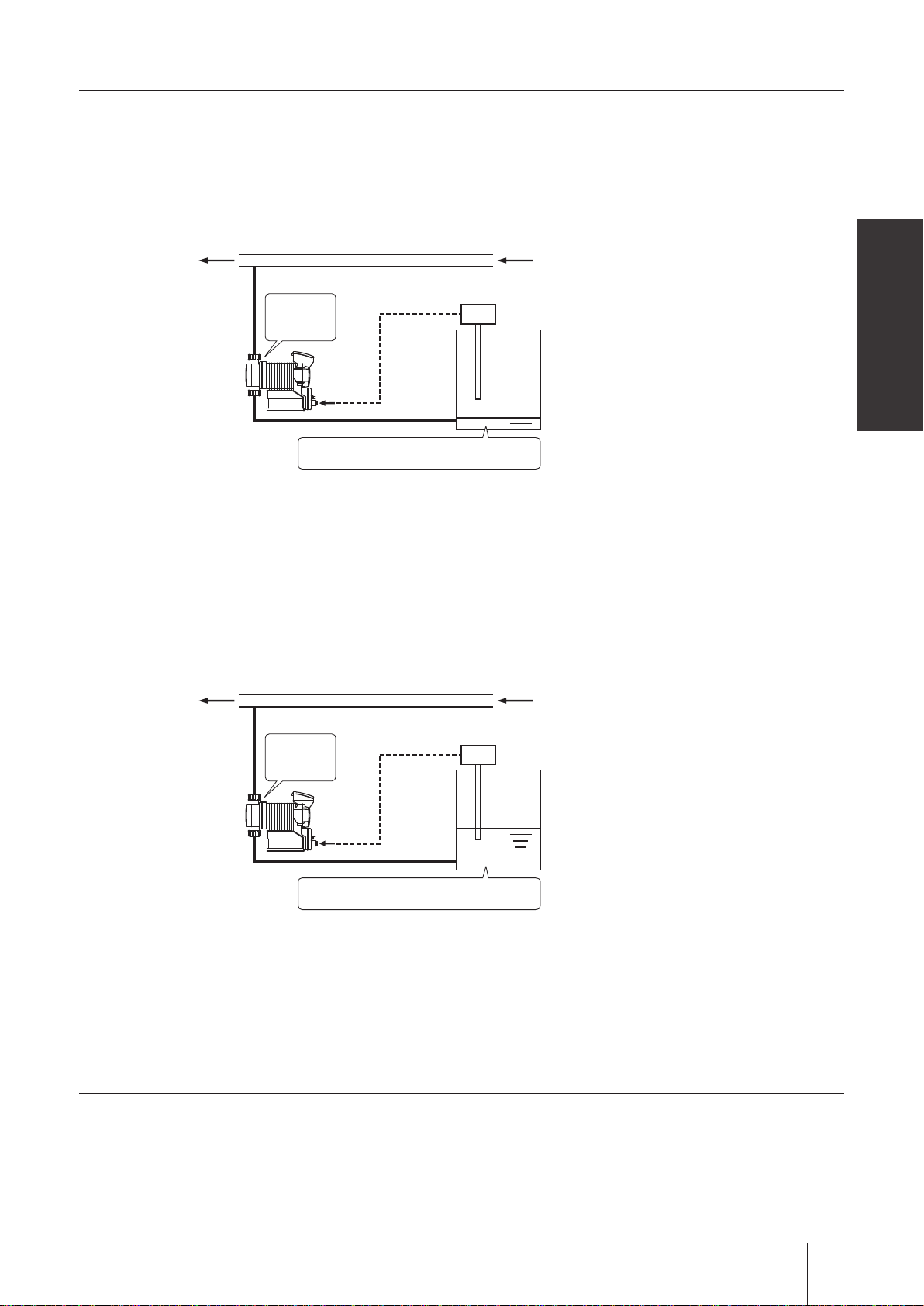

■ Piping layout

Flooded suction application Suction lift application

Accumulator/Chamber

Accumulator/Chamber

Pressure gauge

Relief valve

Back pressure valve

Air vent/drain valve

Calibration

cylinder

Pump

Tank

Relief valve

Air vent/

drain valve

Pump

Pressure gauge

Back pressure valve

Installation

Calibration

cylinder

Tank

NOTE

• The suction line I.D. should be equal to or wider than the I.D. of the pump.

• When handling liquids that generate gas bubbles (sodium hypochlorite or hydrazine solution), install the pump

in a cool and dark place. Flooded suction installation is strongly recommended.

Pipework

27

Loading...

Loading...