Iwaki FS-100NF User Manual

Read this manual before use of product

IWAKI

Pneumatic Drive Bellows Pump

FS-100NF

Instruction Manual

Thank you for selecting IWAKI's Pneumatic Drive Bellows Pump the FS-100NF series.

This instruction manual deals with “Safety Section” “Product outline” “Installation

Section” “Operation Section” and “Maintenance Section”.

Please read through this manual carefully to ensure the optimum performance, safety and

service of the FS-100NF series.

Contents

Before use of the FS-100NF series pumps

IMPORTANT INSTRUCTIONS

Safety Section (Instructions to prevent accidents)

..................................................................

.................................

1

2

PRODUCT OUTLINE

1. Unpacking and Inspection

2. Operation Principle

3. Identification Codes

4. Specifications

5. Outer Dimensions/Mass

6. Names of Parts and Structure of Pump

7. Description on Body and Label

INSTALLATION SECTION

1. Before Use

2. Installation, Piping, and Wiring

OPERATION SECTION

1. Preparation

2. Pump Operation

3. Points to Be Observed in Operation

MAINTENANCE SECTION

1. Causes of Trouble and

Troubleshooting

2. Maintenance and Inspection

3. Consumable Parts

..............................................................................

....................................

...............................................

..............................................

.......................................................

.......................................

..........................

......................................................................

.........................................................

...........................

.........................................................................

.........................................................

.................................................

...................

.....................................................................

..................................................

...............................

..............................................

................

5

6

6

7

7

8

9

10

11

12

14

25

26

26

27

28

29

31

31

This instruction manual should be kept on hand by the end user for quick reference.

If you have any questions, contact us or your nearest dealer.

Before use of the FS-100NF series pumps

Important!

● Composite effective cross section area of exhaust piping should be 43.5

mm2 or more. Use a general quick exhaust valve which is made from aluminium with the pressure resistance of 0.7MPa or more.

● Use of the FDC-1, FD or AC-1 controller is recommended. Note that the

electropneumatic regulator is not applicable for the FDC-1 and FD controllers.

● The maximum stroke speed is limited for the prevention of bellows rupture.

See the table below.

Supply air pressure (MPa)

Max. stroke speed (spm)

0.196 - 0.686

100

● Differential pressure between supply air pressure and exhaust pressure is

limited for the prevention of bellows rupture. See below.

Supply air pressure (MPa)

Differential pressure (MPa)

0.196 - 0.686

0.41

Important Instruction

For the Safe and

Correct Handling of the pump

●

"Safety Instruction" section deals with important details about handling of the product. Before

the use of the pump, read this section carefully for the prevention of personnel injury or loss.

●

Observe the instructions accompanied with "WARNING" or "CAUTION" in this manual. These

instructions are very important for protecting pump users from dangerous situations.

●

The symbols on this instruction manual have the following meanings:

Nonobservance or misapplication of the contents of

WARNING

“Warning” section could lead to a serious accident

which may result in death.

Nonobservance or misapplication of the contents of

CAUTION

“Caution” section could lead to a personal injury or

damage to the product.

Types of Symbols

Indicates that “Warning” or “Caution” must be exercised. Inside this triangle, a con-

crete and practical image provided as a warning or caution message is depicted.

Indicates a prohibited action or procedure. Inside or near this circle, a concrete and

practical image of the activity to be avoided is depicted.

Indicates an important action or procedure which must be performed or carried out

without fail. Failure to follow the instructions herein can lead to malfunction or

damage to the pump.

- 1 -

Safety section

WARNING

●

Look around

Make sure there is no one around the pump when connecting the power

cable. Any power supply switch is not provided on the pump. Connecting

the power cable, the a solenoid valve starts to supply the air and the pump

starts to run.

●

Do not remodel the pump

Never remodel the pump. We are not responsible for any injury or damage

due to modification.

●

For specified application only

Use of the pump in any application other than those clearly specified may

result in injury or damage. Use the pump strictly in accordance with the

pump specifications and application range.

●

Do not drain

Do not drain chemicals directly onto the ground or a waste channel.

Disposal of chemicals should be in accordance with an applicable law.

●

Do not come in contact with the products

When the pump is sending a high temperature liquid of 50 deg.C or more,

the surfaces of the pump and piping become hot. Do not touch with the bare

hand. Wear protective gloves.

CAUTION

●

Do not exceed the specified voltage

Do not supply any power voltage other than specified one. Otherwise, a fire

or electric shock may result.

●

Wear protectors

Be sure to wear protective gear (protective goggles, cap, mask, acid-resistant gloves) when working on the pump. Rinse the pump with pure water in

advance.

●

Qualified operator only

The pump must be operated by operator(s) who has trained in the safe

operation of the pump.

●

Power OFF

Be sure to turn off the power before starting a maintenance/repair work.

Make sure no one turns on the power while working on the pump, otherwise

it may result in a serious accident. If your work field is noisy or dark, let other

people know about the situation by displaying a notice such as "POWER

OFF(Maintenance)" near the power switch.

- 2 -

Safety section

CAUTION

●

Storage limit

Risk of fire and/or health damage. Do not instal or store the pump in explosive atmosphere, dusty place, or corrosive gas (such as chlorine gas).

●

Keep ventilation

When handling a toxic liquid or odorant, keep your working site ventilation.

Always wear protective gear (protective mask, goggles, gloves, etc.).

●

Pump disposal

Any used or damaged pump must be disposed of in accordance with local

laws and regulations. Consult a licensed industrial waste products disposing

company.

●

Return

Before return drain a chemical from the pump and clean the inside with

water for safe transportation.

●

Stroke speed/Supply air pressure/Liquid temperature

The maximum stroke speed is 100spm at an air pressure between 0.196 -

0.686 MPa. Do not continuously run the pump beyond the operating range,

otherwise the pump may be deformed or damaged. The permissible liquid

temperature is between 5-60deg.C. Any operation beyond the permissible

liquid temperature can lead to the deformation of the bellows.

Supply air pressure range

Max. stroke speed

●

Permissible differential pressure in the bellows

Do not operate the pump continuously beyond 0.41 MPa. The life of bellows

may shorten.

Supply air pressure range

Differential pressure on bellows

●

Prohibited liquids

Do not operate the pump with the following liquid.

• Liquid easily crystallizes

• Liquid containing slurry

• Solvent naphtha

0.196 - 0.686 MPa

100 spm

0.196 - 0.686 MPa

0.41 MPa

●

Liquids to be handled with care

• Stripper

• Solvent-type liquid

• Fuming sulfuric acid

• Fuming nitric acid

- 3 -

Safety section

CAUTION

●

Static electricity

When low electric conductivity liquids such as ultra-pure water and fluor

inactive liquid (e.g. FluorinertTM) are handled, the static electricity may generate in the pump and may cause static discharge. Take countermeasures to

remove the static electricity.

●

Ambient temperature

Use this product between 0 - 40 deg.C. of surrounding temperature.

●

When stopping the pump

• Before stopping the pump, first release discharge side pressure.

Otherwise, the bellows may be deformed due to discharge side pressure.

• Do not close any valves right after stopping the pump. The resulting impact

pressure may deform the bellows or the connecting plate.

●

Pump at halt

• Do not supply air to both the right and left air-supply ports at the same time

to prevent the bellows from becoming deformed.

• Do not have the pump unused with any chemical in the bellows for a long

period. Some chemical can penetrate the bellows and corrode metal material.

●

Composite effective cross section area

Composite effective cross section area should be 43.5 mm2 or more.

●

Air exhaust port

Do not narrow the air exhaust port (for example by reducing the tube bore).

The residual pressure in the pump may deform the bellows.

●

During pump operation

• Make sure all the valves on both suction and discharge side piping are

open.

●

Note for the electrode

The electrode occasionally fails to detect leakage depending on operating

condition. Contact IWAKI for detail.

- 4 -

PRODUCT OUTLINE

1. Unpacking and Inspection ................. 6

2. Operating Principle ........................... 6

3. Identification Codes .......................... 7

4. Specifications .................................... 7

5. Outer Dimensions/Mass ................... 8

6. Names of Parts and

Structure of Pump ............. 9

7. Description on Body and Label ....... 10

- 5 -

OUT

IN

Bellows Air chamber

Compression

Air supply

Pump head

Suction

Air exhaust

OUT

IN

Compression

Air supply

Suction

Air exhaust

: Liquid flow

: Air supply flow

Suction/compression: Created by bellows stroke

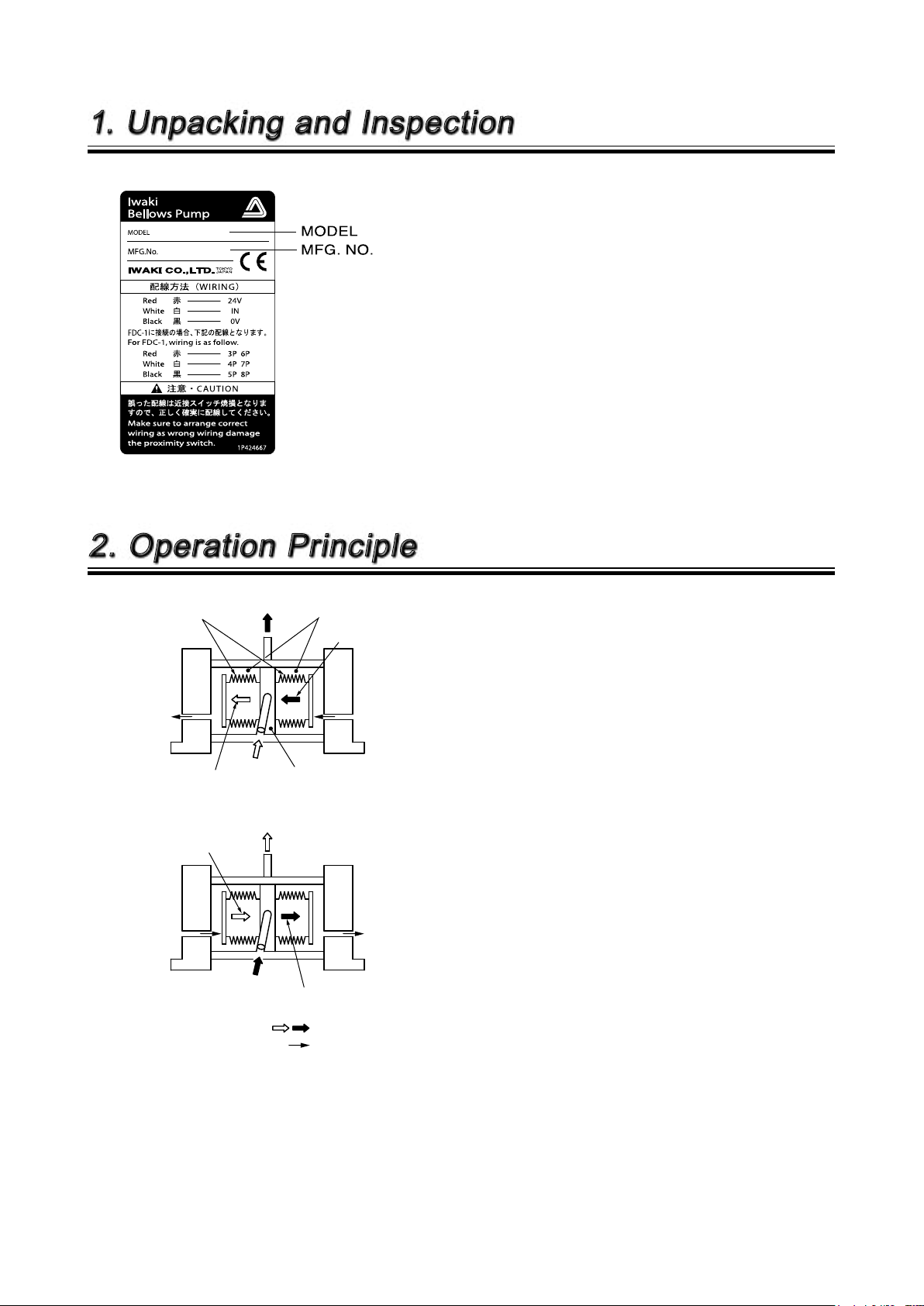

1. Unpacking and Inspection

After unpacking the product, check the following points to ascertain that the product is

exactly as you ordered. If you find anything

wrong, please contact your dealer.

[1] Does the model indicated on the nameplate

[2] Are there any transit damage?

[3] Are all optional items such as controller deliv-

[4] Regarding the quick exhaust valve, use alu-

2. Operation Principle

represent what you ordered?

ered with the pump?

minium one with the pressure resistance of

0.7MPa or more.

Our pneumatic drive pumps are designed for

semiconductor manufacturing and chemical dosing processes. And wet-ends are all

fluororesin.

The pump unit consists of two air chambers

and a pair of bellows. The bellows are reciprocated by supply air and make pumping action

continuously.

[1] A liquid is sucked into the pump head through

an inlet when the bellows expand (suction

motion).

[2] The liquid is then pumped through an outlet

when the bellows contract (discharge motion).

- 6 -- 6 -

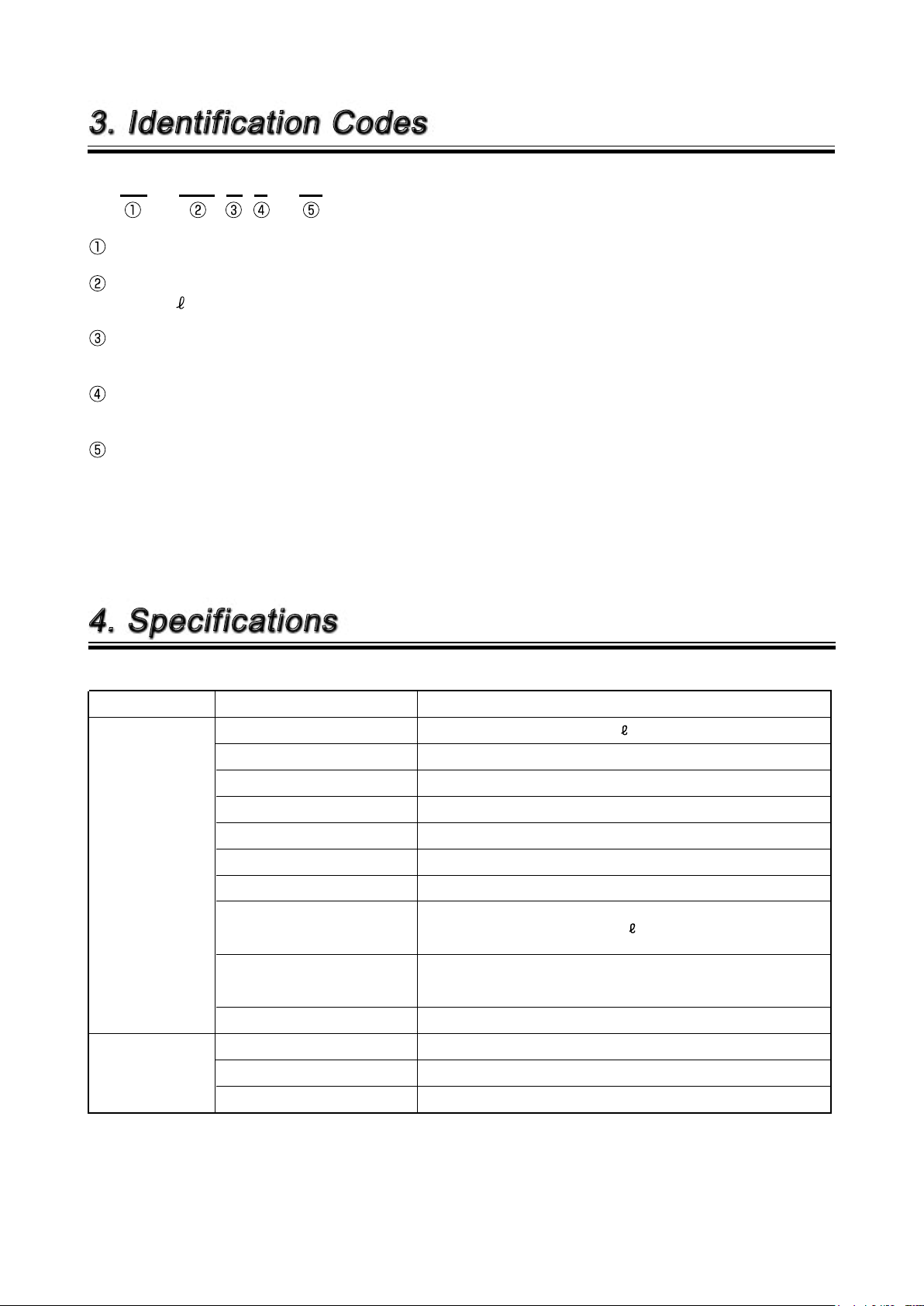

3. Identification Codes

FS - 100 N F - 01

Series code

Maximum discharge volume

100: 100 /min

Operating temperature

N: 5 - 60 deg.C

Pump connection port (discharge port/suction port)

F: Flange type connection (Standard)

Special specifications

No symbol: Standard

01 : Special specifications (01, 02······)

4. Specifications

Item Specifications

Max. discharge volume (Note 1)

Supply air pressure range 0.196-0.686 MPa

Max. stroke speed

Permissible differential pressure

Self-priming ability (Note 2) 1 m

General Specification

Proximity switch

arrangement

Pump connection por t JIS 20K 25A flange

Supply air connection port Rc 1/2"

Max. air consumption

(at max. discharge volume,

max. supply air pressure)

Liquid temp. range (deg.C) 5~60 deg.C

Ambient temp. 0~40 deg.C

Driving method External forced switching of driving air

Type High-frequency type proximity switch

Output NPN DC open/close output

Source voltage DC10V~DC30V

100 /min

100 spm

0.41 MPa

1495 N /min

Note 1. The maximum discharge volume is on pumping clean water at room temperature.

Note 2. The self-priming height is on pumping clean water at the maximum stroke speed at room temperature.

- 7 -

- 7 -

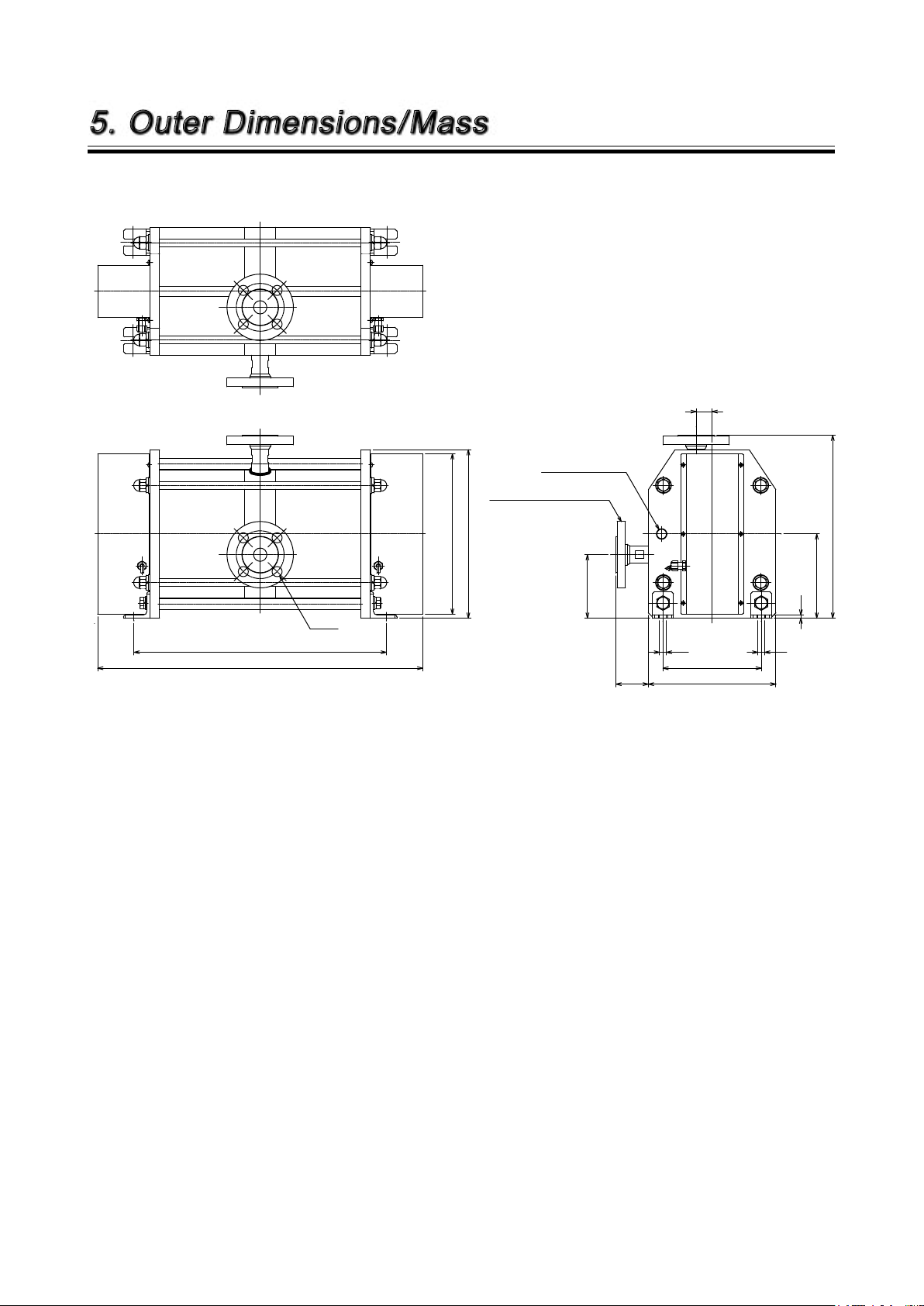

5. Outer Dimensions/Mass

13

13

185

240

(61)

119.5

30

475

612

302

317

158.5

6

344.5

4-ø19

2-JIS20K25A flange or equivalent

Air supply port 2-Rc1/2

FS-100NF Mass : 55.5kg

Unit : mm

- 8 -- 8 -

Loading...

Loading...