IWAKI EWN-B16 VC, EWN-C16 VC, EWN-C21 VC, EWN-C31 VC, EWN-C36 VC Instruction Manual

...

2008 IWAKI CO., LTD.

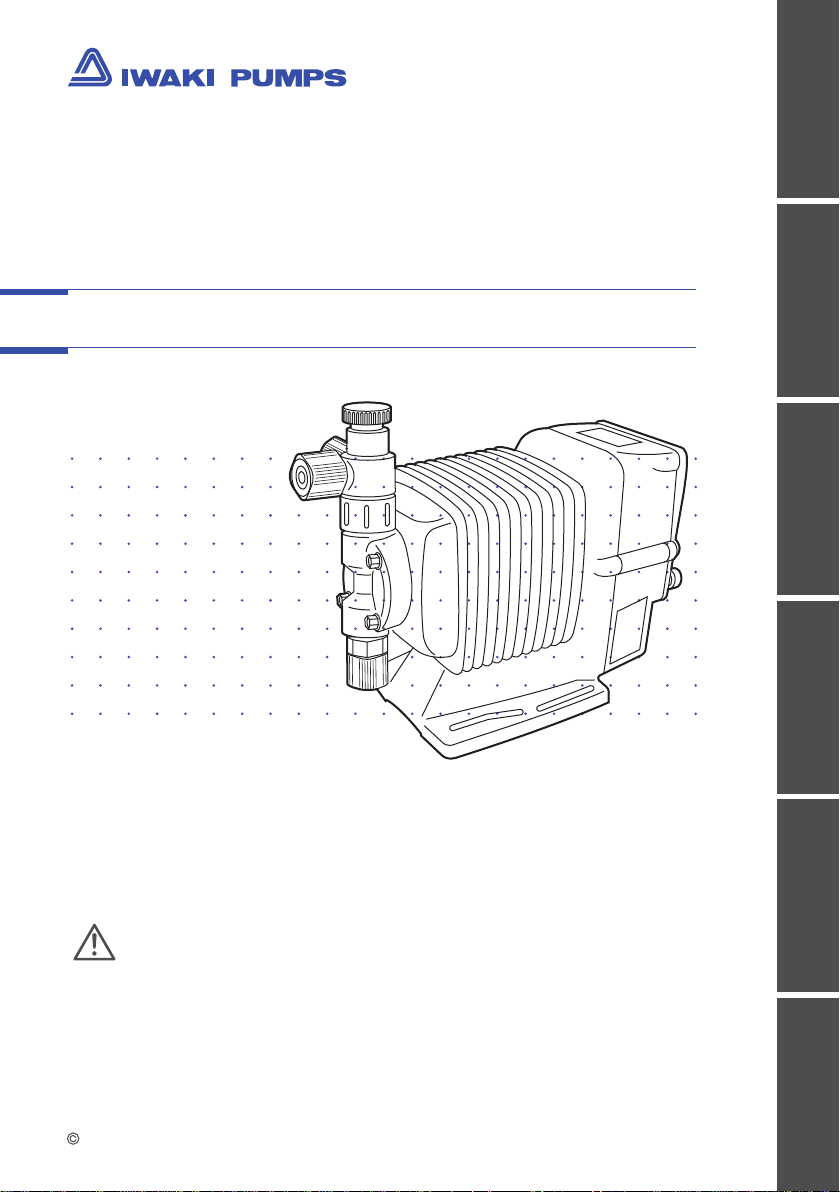

Iwaki

Electromagnetic Metering Pump

EWN-R (Standard)

Safety instructions

Overview Installation Operation Maintenance Specication

Instruction manual

Thank you for choosing our product.

Please read through this instruction manual before use.

This instruction manual describes important precautions and

instructions for the product. Always keep it on hand for quick

reference.

Order conrmation

After unpacking, check the following points. Contact us or your nearest

distributor if the delivery is imperfect.

a. Check if the delivery is as per order.

Check the nameplate to see if the information such as discharge capacity,

discharge pressure and power voltage

are as per order.

b. Check if the delivery is damaged or deformed.

Check for transit damage and loose bolts.

2

Order conrmation

Contents

Order conrmation ............................................................................................. 2

Safety instructions .......................................................................6

Warning ............................................................................................................. 7

Caution .............................................................................................................. 8

Precautions for use ........................................................................................10

Overview ......................................................................................12

Introduction .....................................................................................................12

Pump structure & Operating principle .........................................................12

Features .......................................................................................................14

Operational functions...................................................................................14

Part names.......................................................................................................19

Pump............................................................................................................19

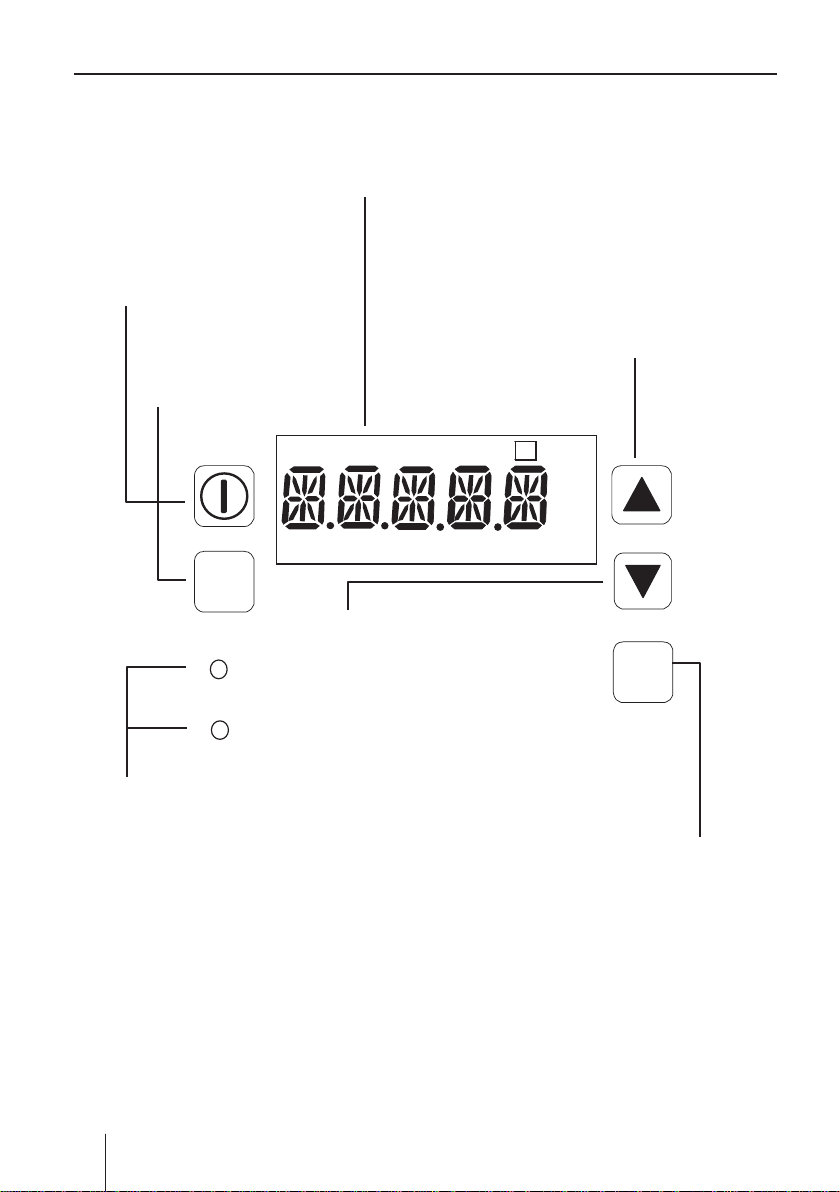

Operational panel .......................................................................................20

Basic displays & Pump states ................................................................21

Identication codes ....................................................................................... 23

Pump/Drive units ........................................................................................ 23

Installation ..................................................................................25

Pump mounting .............................................................................................. 25

Pipework .........................................................................................................26

Tube connection ......................................................................................... 26

Check valve mounting ................................................................................ 28

Wiring .............................................................................................................. 30

Power voltage/Earthing .............................................................................. 30

Signal wire connection................................................................................ 32

Connections .......................................................................................... 34

Contents

3

Operation .....................................................................................37

Before operation .............................................................................................37

Points to be checked ...................................................................................37

Retightening of pump head xing bolts .......................................................37

Use of hexagon wrench instead of a torque wrench ............................. 38

Degassing ................................................................................................... 38

Flow rate adjustment ...................................................................................41

Stroke rate adjustment ...........................................................................42

Stroke length adjustment....................................................................... 44

Before a long period of stoppage (One month or more) ............................. 45

Operation programming ............................................................................... 45

Programming ow ....................................................................................... 46

Manual operation ........................................................................................ 48

EXT operation ............................................................................................. 49

EXT mode .............................................................................................49

EXT mode programming ....................................................................... 50

User mode ..................................................................................................59

STOP/Pre-STOP function .....................................................................60

STOP/Pre-STOP function cancellation ................................................. 62

OUTPUT function .................................................................................. 64

ANA-V/-R selection ...............................................................................66

Buffer ON/OFF selection ....................................................................... 68

PIN number entry ...................................................................................70

Keypad lock .................................................................................................72

Keypad lock activation ............................................................................73

Keypad lock release ...............................................................................73

Calibration mode .........................................................................................74

Unit change ..................................................................................................75

spm indication ..............................................................................................75

4

Contents

Maintenance ................................................................................76

Troubleshooting ............................................................................................. 77

Inspection ....................................................................................................... 79

Daily inspection ...........................................................................................79

Periodic inspection ......................................................................................79

Wear part replacement .................................................................................. 80

Wear part list ............................................................................................... 80

Before replacement .....................................................................................81

Valve set replacement .................................................................................81

Discharge valve set dismantlement/assembly .......................................81

Suction valve set dismantlement/assembly ..........................................83

Spacer set replacement (Auto degassing type) ....................................84

Air vent valve set replacement (Auto degassing type) .......................... 85

Diaphragm replacement .............................................................................85

Exploded view ................................................................................................ 88

Pump head, Drive unit & Control unit .........................................................88

Pump head ................................................................................................. 89

EWN-[B09•B11•B16•B21•C16•C21] [VC•VH•PC•PH•TC] ..................... 89

EWN-[B31•C31•C36] [VC•VH•PC•PH•TC] ............................................ 90

EWN FC .................................................................................................91

EWN C31PC/P6-V ................................................................................ 92

EWN SH/SH-H/SH-H2 .......................................................................... 93

EWN with an Automatic air vent ............................................................ 94

Specications/Outer dimensions ................................................................ 95

Specications .............................................................................................95

Pump unit ..............................................................................................95

Power cable ............................................................................................97

Pump colour ...........................................................................................97

Outer dimensions........................................................................................ 98

Contents

5

Safety instructions

Requirement

Read through this section before use. This section describes

important information for you to prevent personal injury or

property damage.

■ Symbols

In this instruction manual, the degree of risk caused by incorrect use is noted

with the following symbols. Please pay attention to the information associated

with the symbols.

WARNING

CAUTION

Indicates mishandling could lead to a fatal or

serious accident.

Indicates mishandling could lead to personal

injury or property damage.

A symbol accompanies each precaution, suggesting the use of "Caution", "Pro-

hibited actions" or specic "Requirements".

Caution marks Prohibited mark Requirement mark

Caution

Electrical

shock

Prohibited

Do not rework

or alter

Wear

protection

Grounding

Export Restrictions

Technical information contained in this instruction manual might be treated

as controlled technology in your countries, due to agreements in international

regime for export control.

Please be reminded that export license/permission could be required when this

manual is provided, due to export control regulations of your country.

6

Safety instructions

WARNING

shock

Turn off power before work

Risk of electrical shock. Be sure to turn off power to stop the pump

and related devices before work.

Stop operation

On sensing any abnormality or danger, suspend operation immedi-

ately and inspect/solve problems.

Do not use the pump in anything other than a specied purpose

The use of the pump in any purpose other than those clearly speci-

ed may result in failure or injury. Use this product in a specied

condition.

Do not modify the pump

Remodelling the pump carries a high degree of risk. We are not

responsible for any failure or injury results from remodelling.

Safety instructions

Electrical

Requirement

Prohibition

Do not remodel

Wear protective clothing

Always wear protective clothing such as an eye protection, chemi-

cal resistant gloves, a mask and a work cap during dismantlement,

assembly or maintenance work.

Do not damage a power cable

Do not pull or knot a power cable or place a heavy stuff on it. Dam-

age to the cable could lead to a re or electrical shock.

Do not use the pump in a ammable atmosphere

Do not place dangerous or ammable goods near the pump for your

safety.

protectors

Prohibition

Prohibition

WARNING

Wear

7

CAUTION

A qualied operator only

The pump must be handled or operated by a qualied person with a

full understanding of the pump. Any person who is not familiar with

this product should not take part in operation or management.

Use a specied power only

Do not apply any power other than the one specied on the nameplate.

Otherwise, failure or re may result. Also, be sure to earth the pump.

Do not run pump dry

Do not run pump dry for more than 30 minutes (even when the

pump runs for degassing). Otherwise, the pump head xing screws

may loosen and liquid may leak. Optimise your system in order for

the pump not to run dry. If the pump runs dry for a long period (for

more than 30 minutes), the pump head and the valve cases may

deform by friction heat and consequently leakage results.

Requirement

Prohibition

Caution

Do not wet electric parts or wiring

Risk of re or electrical shock. Install the pump free from liquid spill.

Observe an applicable MSDS

Take account of installation environment. Chemicals should be

controlled in accordance with a MSDS.

Do not install or store the pump in the following places where...

• Under a ammable atmosphere or in a dusty/humid place.

• Ambient temperature exceeds 40ºC or falls below 0ºC.

• Under direct sunlight or wind & rain.

Countermeasure against efux

Take protective measures against an accidental chemical overow

results from pump or piping breakage.

8

CAUTION

Prohibition

Caution

Prohibition

Requirement

Do not use the pump in a water place

Requirement

Caution

Caution

The pump is not totally waterproof. The use of the pump in water or

high humidity could lead to electrical shock or short circuit.

Earthing

Risk of electrical shock. Always earth the pump.

Install an earth leakage breaker

An electrical failure of the pump may adversely affect related devices. Purchase and install an earth leakage breaker separately.

Wear part replacement

Follow instructions in this manual for wear part replacement. Do not

dismantle the pump beyond the extent of the instructions.

Do not use a damaged pump

Using a damaged control unit could lead to an electric leak or shock.

Safety instructions

Prohibition

Earthing

Prohibition

Disposal of the used pump

Dispose of any used or damaged pump in accordance with relevant regulations. Consult a licensed industrial waste products disposing company.

Tighten the pump head

Liquid may leak if pump head xing bolts are loose. Tighten the

bolts evenly to the following torque in diagonal order before initial

operation. Periodically retighten them for the prevention of leakage.

Tightening torque

EWN - B11 /-B16/-B21/-C16/-C21 : 2.16 N•m

EWN-B31/-C31/-C36 : 2.55 N•m

Solution compatibility

This pump has been evaluated for use with water only. The suitability of this pump for use with liquids other than water, such as acid

and alkaline, is the responsibility of the user. For liquids other than

water, select the best-suited liquid end material combination using a

chemical compatibility chart.

Requirement

Caution

CAUTION

9

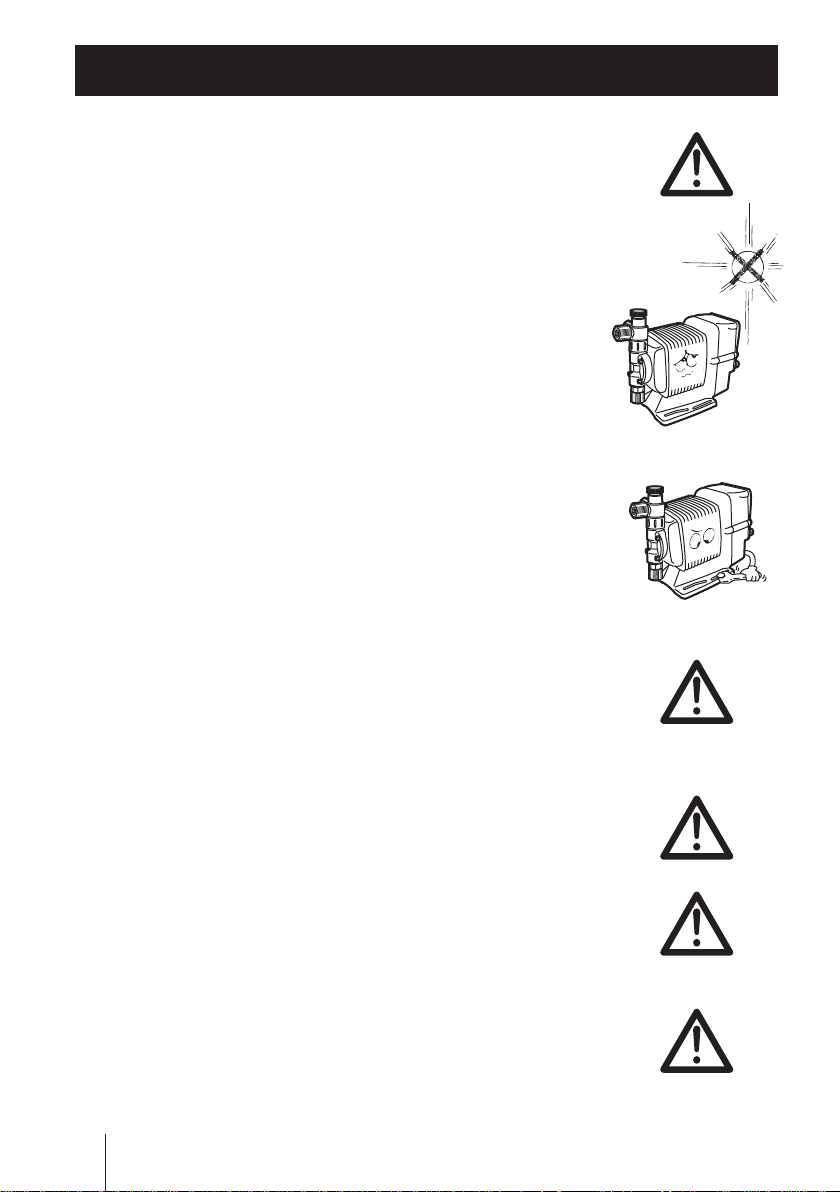

Precautions for use

• Electrical work should be performed by a qualied opera-

tor. Otherwise, personal or property damage accident may

result.

• Do not install the pump in the following places where...

–Under a ammable atmosphere or in a dusty/humid place.

–Under direct sunlight or wind & rain.

– Ambient temperature exceeds 40ºC or falls below 0ºC.

Protect the pump with a cover when installing it out of

doors.

• Select a level location where is free from vibration and liq-

uid can't stay. Anchor the pump with M5 bolts so as not to

vibrate. If the pump is installed at a tilt, a ow may reduce.

• When two or more pumps are installed, the pump opera-

tion interacts each other and vibration becomes signicant,

resulting in poor performance or failure of internal electri-

cal devices. Select an installation location where tolerates

vibration to enough degree.

Caution

Caution

• Keep an ample working area around the pump for inspec-

tion and maintenance.

• Install the pump as close to a supply tank.

• Install the pump in a cool and dark place when handling

liquids that readily generate gas bubbles such as sodium

hypochlorite or hydrazine solution. Flooded suction applica-

tion is strongly recommended for these liquids.

10

Precautions for use

Caution

Caution

Caution

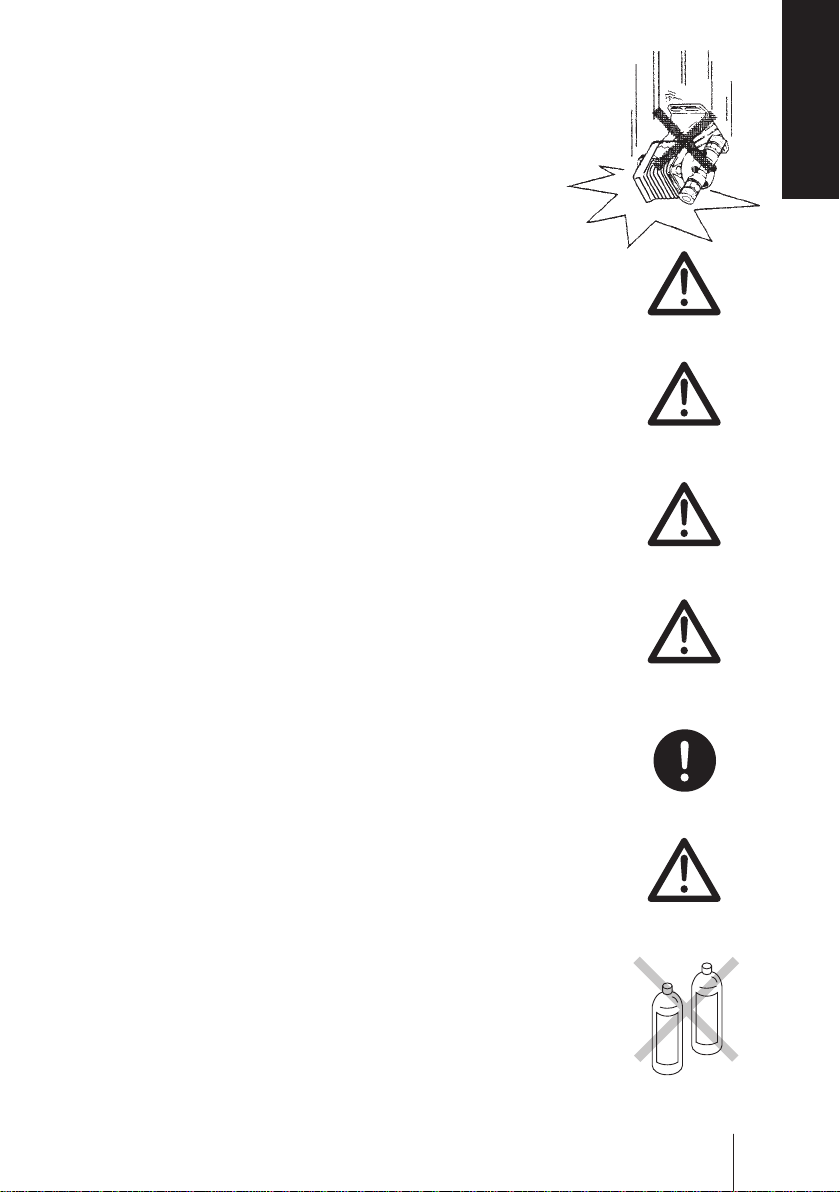

• Be careful not to drop the pump onto the oor. A strong

impact may reduce pump performance. Do not use a pump

which has once damaged. Otherwise an electrical leak or

shock may result.

• The pump is a light water-/dust-proof structure of IP65, but

is not totally waterproof. Do not have the pump wet with the

liquid handled or rainwater.

• Never wet the pump head, control unit and drive unit. Oth-

erwise, failure or an accident may result. Immediately wipe

off liquid if the pump has got wet.

• Do not close a discharge line during operation. Otherwise,

liquid may leak or tubing may break.

Safety instructions

Caution

Caution

Caution

• Do not remove the control unit. Note that an applicable con-

trol unit differs with each drive unit. Do not attach a control

unit to a different drive unit. Otherwise, an electrical circuit or

the drive unit may fail.

• Release pressure from a discharge line before dismantling

the pump or removing tubing. Otherwise, chemical liquid

gushes out.

• Be careful not to come in contact with residual liquid.

• Do not clean the pump or nameplate with a solvent such

as benzine and thinner. This may discolour the pump or

erase printing. Use a dry cloth or a wet cloth with water

or neutral detergent.

Precautions for use

Caution

Requirement

Caution

Thinner

Benzine

11

Overview

The information such as characteristics, features and part

names are described in this section.

Introduction

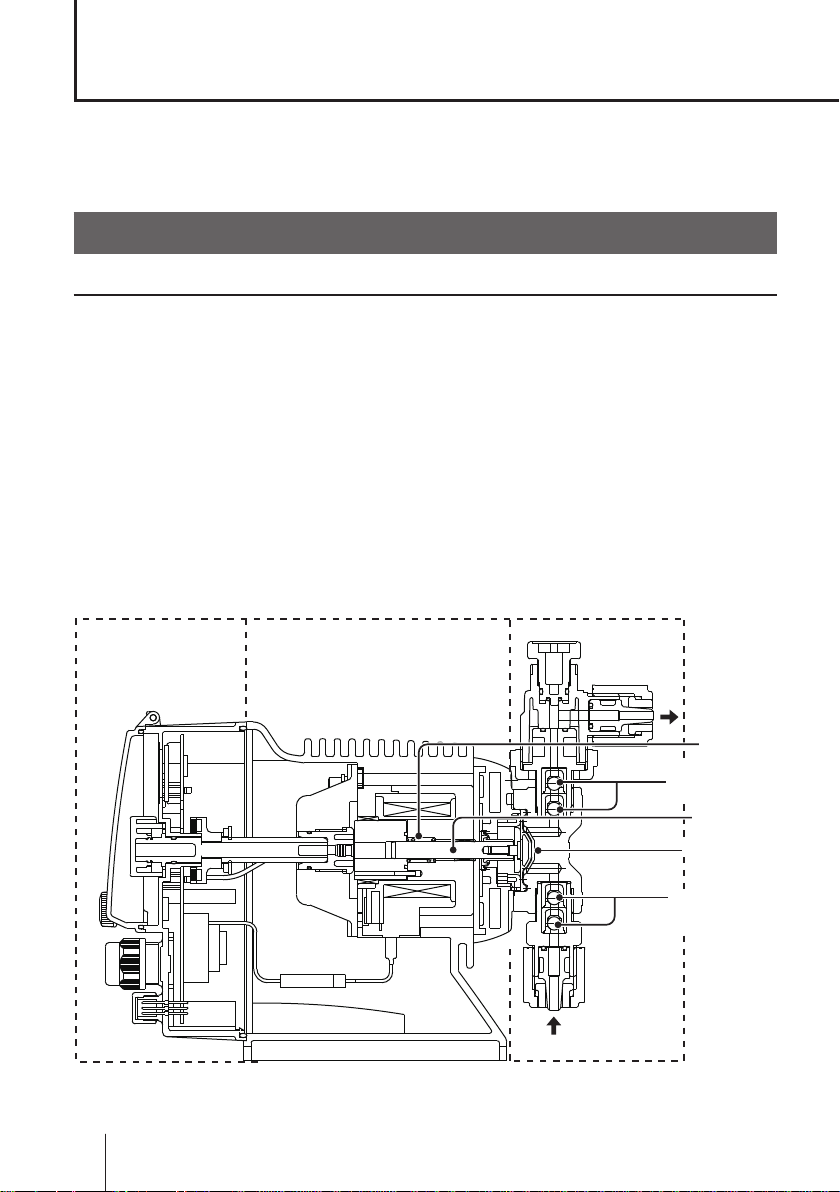

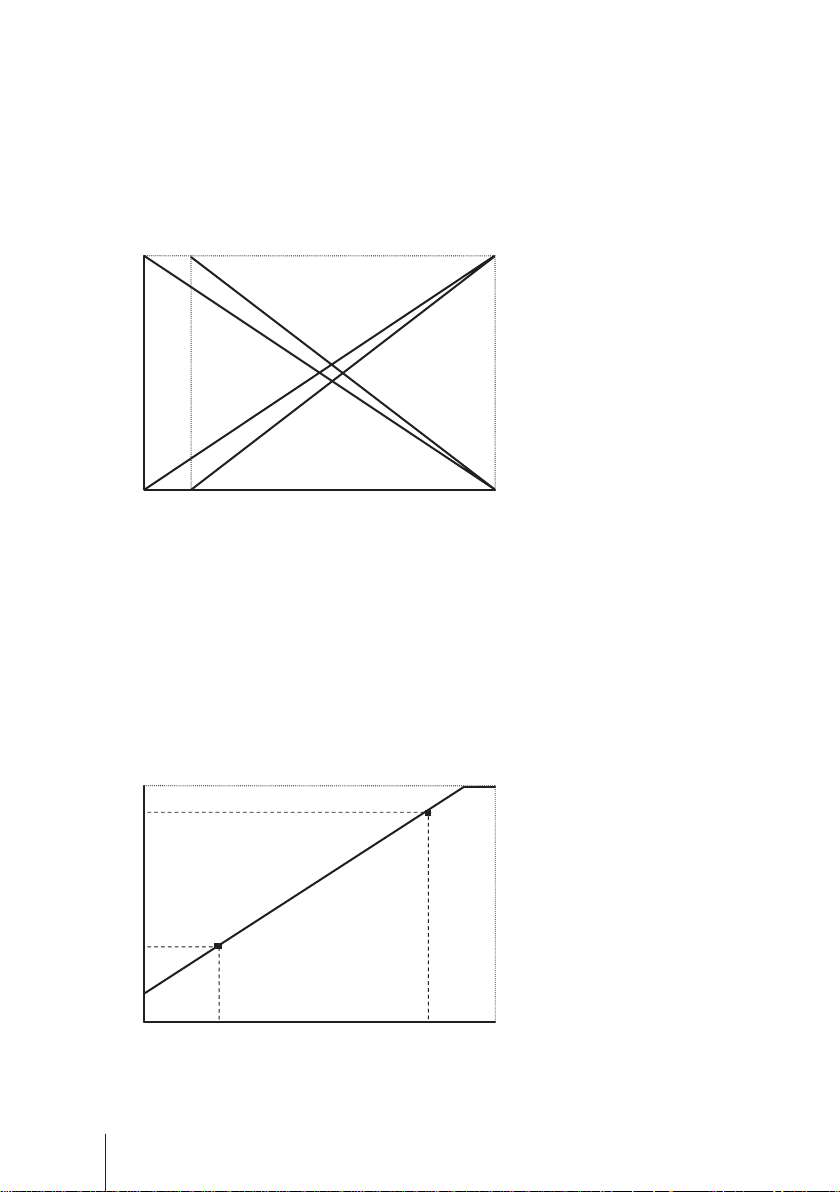

Pump structure & Operating principle

The EWN series is a diaphragm metering pump which consists of a pump

head, drive unit and control unit. A diaphragm is directly driven by electromagnetic force.

Principle of operation

The pulse signal controls the electromagnetic force and spring force in order

to make reciprocating motion. The reciprocating motion is transferred to a

diaphragm through a plunger and then volumetric change occurs in the pump

head. This action transfers liquid along with pump head valve action.

Control unit Pump headDrive unit

12

Introduction

OUT

Spring

Pump head valve

(Discharge side)

Plunger

Diaphragm

Pump head valve

(Suction side)

IN

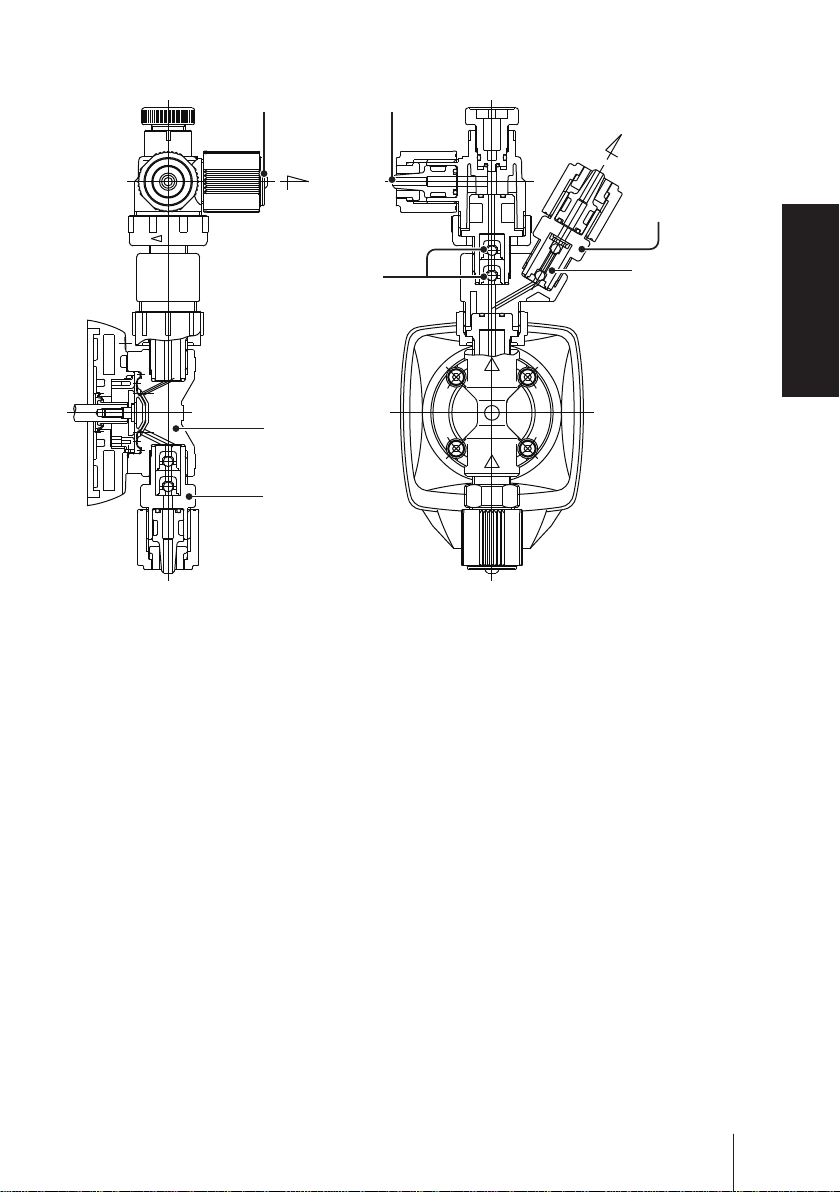

● Auto degassing system

Discharge port Air vent port

AIR

OUT

Automatic air

vent valve body

LOCK

Pump head valve

Air vent valve

Pump head

Suction port

• Once air is entrained through the suction port, the working pressure difference

between the pump head valve and the air vent valve separates entrained air

from liquid.

• Entrained air is expelled to open air through the automatic air vent valve body.

• Only liquid is delivered to a discharge line through the discharge port. Note a

small amount of liquid is expelled with entrained air.

Overview

Introduction

13

Features

Pump operation

● Multivoltage operation

The EWN-R series is a multivoltage type (100-240VAC) and can be selected

without concern for local power voltage.

● High turndown ratio

Digitally-controlled stroke rate range is 0.1-100%. The stroke length shifts for

a ne ow adjustment.

● Waterproof and dustproof structure (IP65)

With the aim of improving resistance to exposure to liquid, the control unit is

installed on the back of the pump and the control panel is protected with a

cover as standard equipment. A rubber gasket is provided between the pump

head and the bracket to prevent water from entering from the periphery of

the pump head.

* This pump is not completely water resistant. Protect the pump with a cover when

installing it out of doors.

Operational functions

● Manual operation (see page 48)

The start/stop of the pump by key operation

Key operation

(Push key)

*Manual operation can be done at any time during operation or stop.

● EXT operation (see page 49)

The pump operation by the external signal.

The external operation is available after multiplier or divisor programming.

14

Introduction

Run Run

Stop

Stop

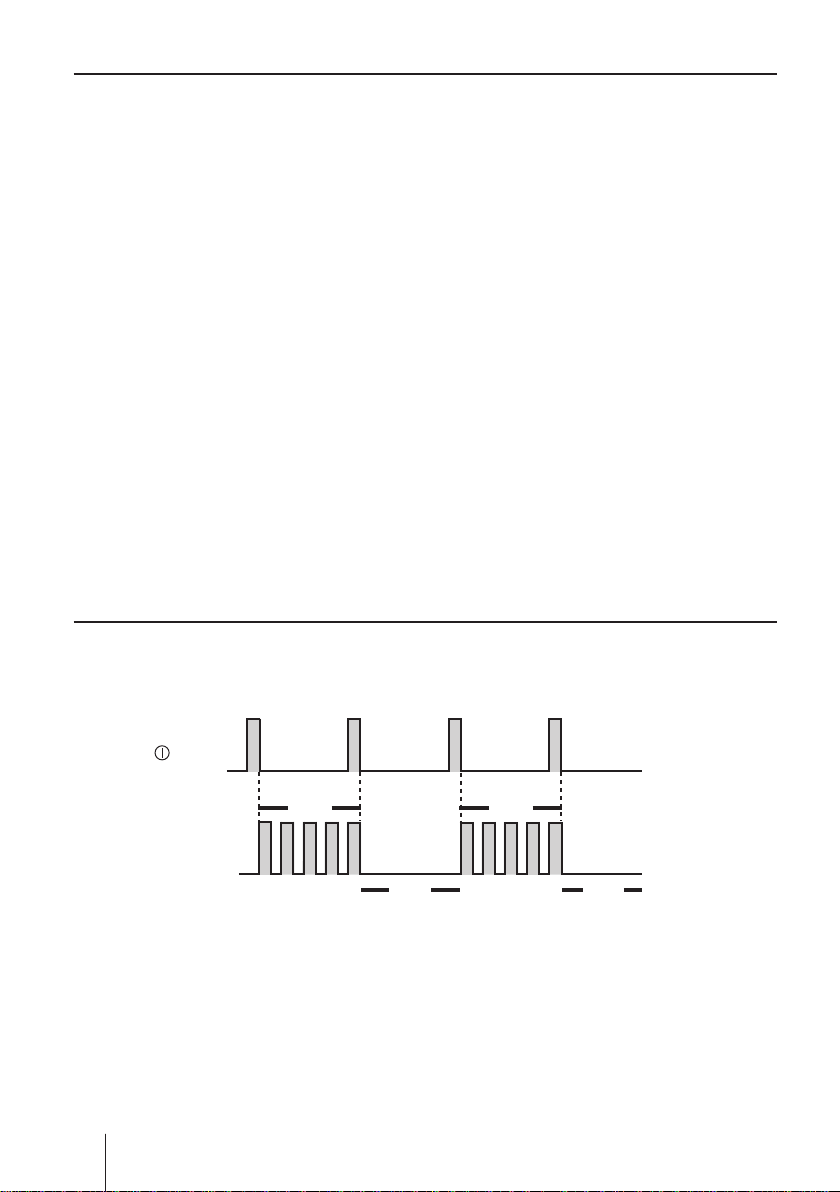

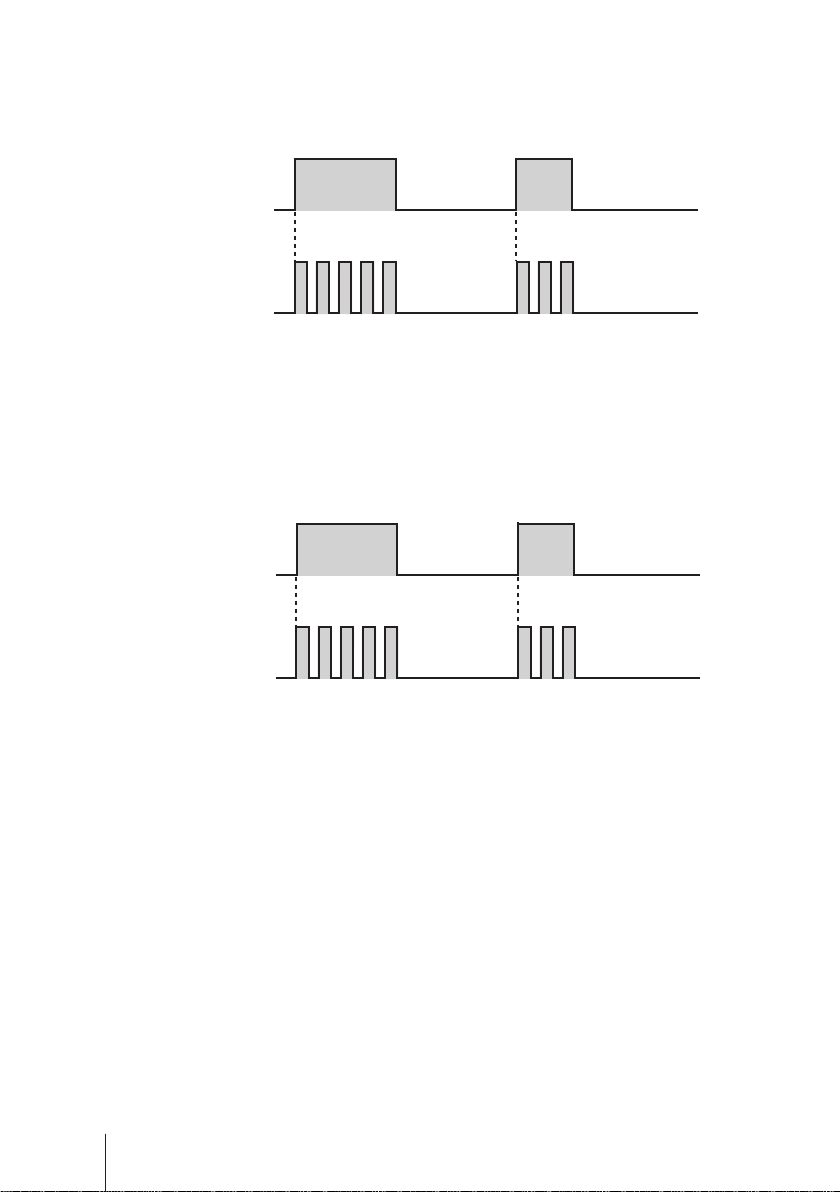

Multiplier programming (See page 51)

1-9999 shots can be programmed to one pulse signal.

*In the EXT operation, the pump runs at the manual operation stroke rate.

*The pump makes one shot per pulse when the multiplier is programmed to 1.

Example) When the multiplier is programmed to 5, the pump makes ve

shots per signal.

Pulse signal input

Pump operation

1 2 3 4 5 1 2 3 4 5

A buffer works when the pump receives an external signal before the pro-

grammed shots per signal is completed.

Pulse signal input

Pump operation

1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3

*The buffer stores the external signals for up to 65535 shots.

Overview

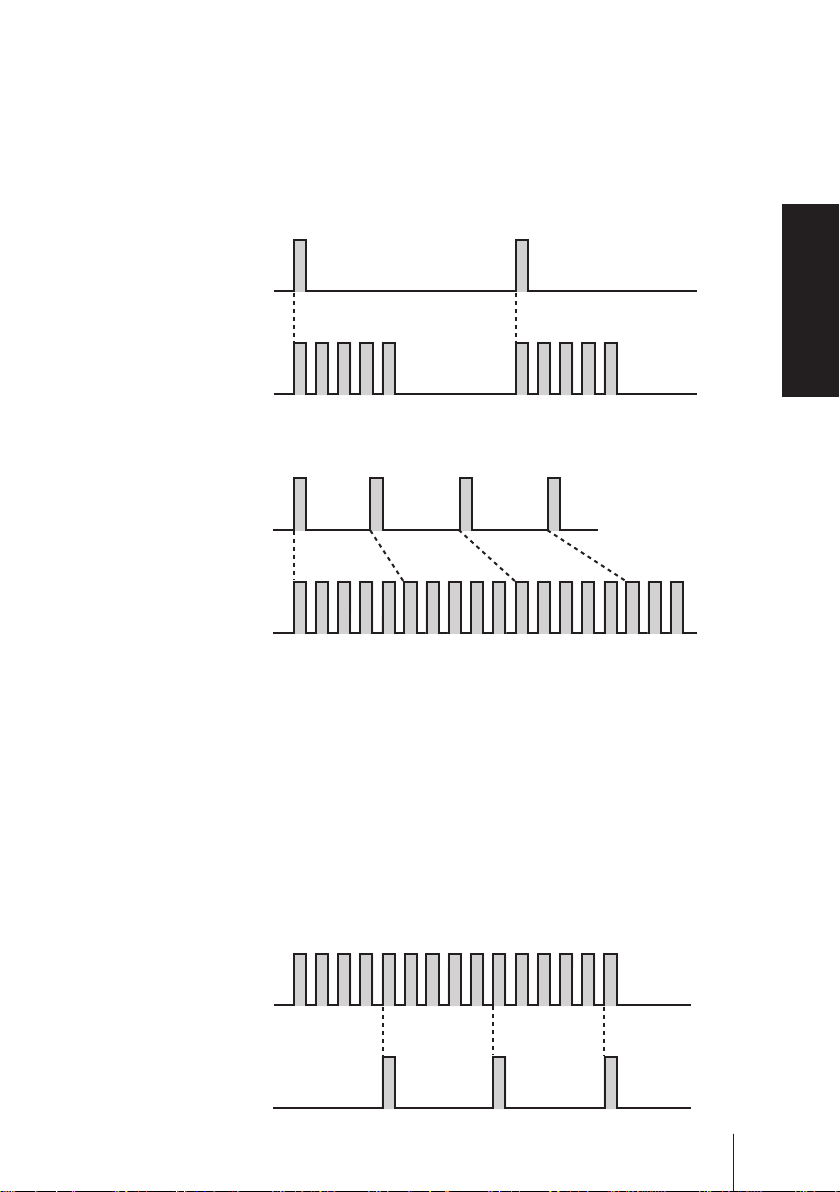

Divisor programming (See page 53)

1-9999 pulse signals can be programmed to make one shot.

* The pump can not run over a programmed stroke rate (max. 100%) even if a divisor

is set to run the pump faster.

*The pump makes one shot per pulse when a divisor is programmed to 1.

Example) When a divisor is programmed to 5, the pump makes one shot per

5-signal.

Pulse signal input

1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

Pump operation

Introduction

15

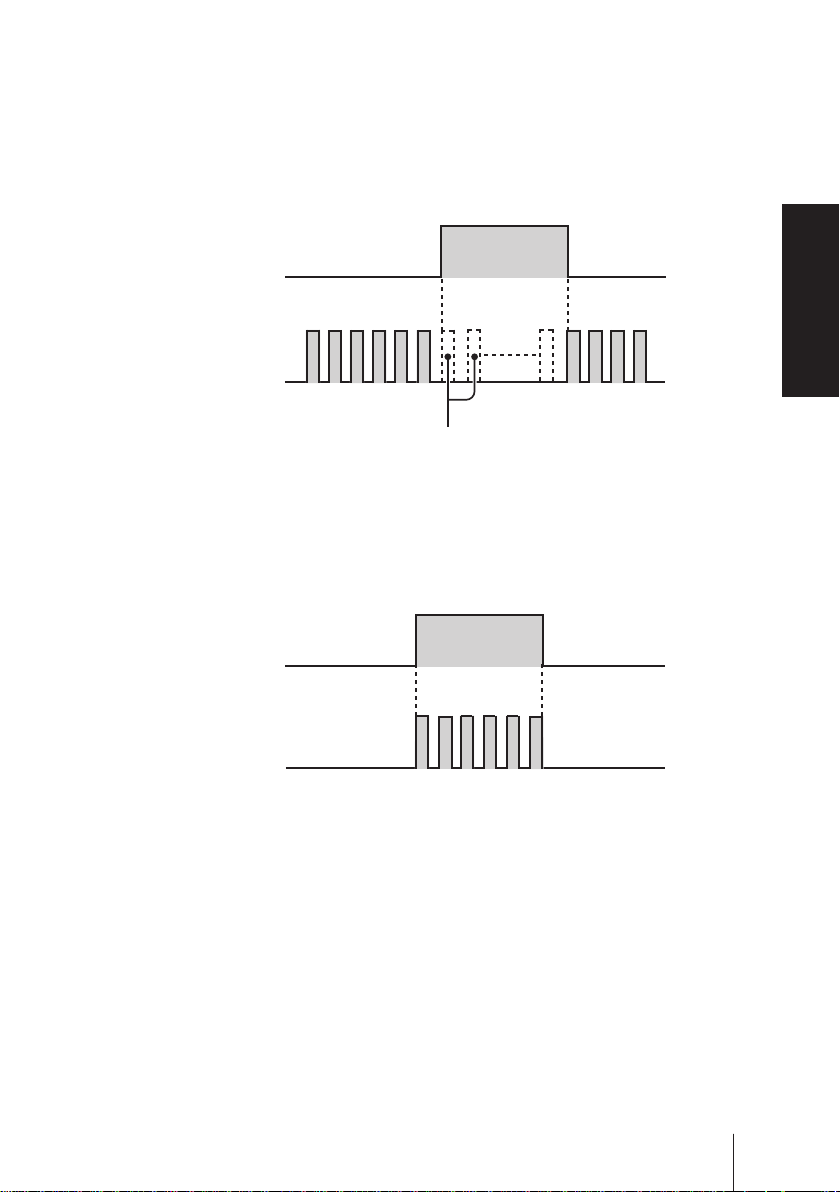

ANA. R (analogue rigid) programming (See page 57)

The pump increases/decreases a flow rate in proportion to 0-20mA. Four (4-

20, 20-4, 0-20, 20-0) programs are provided.

In "4-20" or "20-4" program a disconnection sensor works to stop the pump

as a current value falls below 4mA ("DISCN" blinks on the screen). Check

wiring as necessary. Pushing the start/stop key, this state is released.

100%

0 4

b

d

c

a

20mA

Condition

The left graph is in the following

programs.

a. 4-20 (Default setting)

b. 20-4

c. 0-20

d. 20-0

ANA. V (analogue variable) programming (See page 55)

The pump increases/decreases a flow rate in proportion to 0-20mA.

Setting two points can draw a straight line. Depending on the position of the

two points, 0 % may not come at 0mA in some cases. When a stroke rate

could become over 100% at some mA due to the setting, pump speed is lim-

ited to 100%.

100%

85

P2

Condition

The left graph is in the following

setting.

P1 = 6 mA, 30%

P2 = 17 mA, 85%

30

0 6

16

Introduction

P1

20mA

17

● STOP function (See page 60)

The start/stop of the pump can be controlled by the external signal.

When "NOR. OP" is selected...

The pump stops while receiving the external signal via the STOP terminal.

*The pump resumes operation when the STOP signal is released.

STOP signal input

Run Run

Pump operation

Stop

The pump stops running while

the STOP signal is inputted.

When "NOR. CL" is selected...

The pump runs while receiving the external signal via the STOP terminal.

*The pump stops operation when the stop signal is released.

STOP signal input

Run

Pump operation

Stop Stop

Overview

● Pre-STOP function (See page 60)

When "NOR. OP" is selected...

The STOP LED lights orange while the pump is receiving the external signal

via the Pre-STOP terminal (a contact is closed). Note the pump does not

stop running.

When "NOR. CL" is selected...

The STOP LED stops lightening while the pump is receiving the external

signal via the Pre-STOP terminal (a contact is closed).

Introduction

17

● AUX function (See page 40)

The pump runs at the maximum stroke rate while receiving the external sig-

nal via the AUX terminal. Use this function for degassing.

Pulse signal input

Pump operation

1 2 3 4 5 1 2 3

● Priming function (See page 40)

The pump runs at the maximum stroke rate while both the UP and DOWN

keys are pressed. Use this function for degassing.

Press Press

▲+▼ keys

Pump operation

1 2 3 4 5 1 2 3

● OUTPUT function (See page 64)

Signals can be sent via the output terminal in sync with manual operation.

The terminal can be set to on or off.

18

Introduction

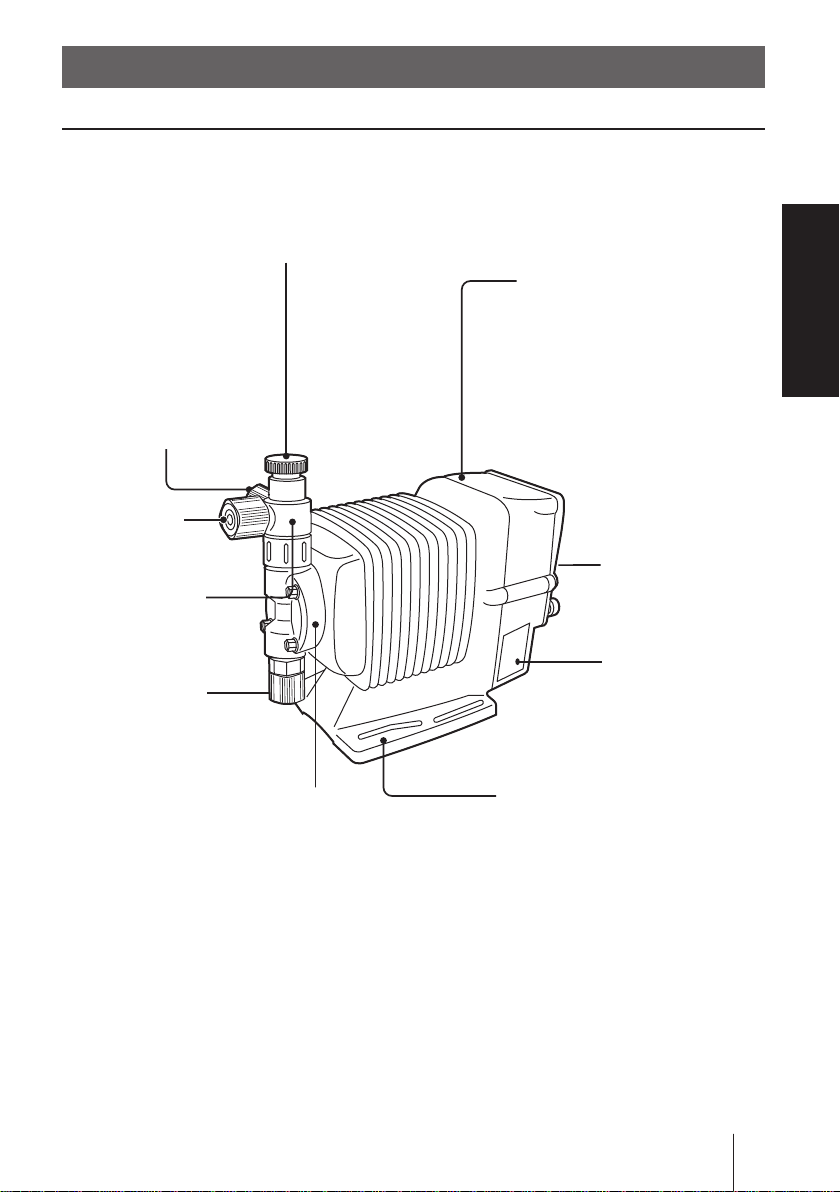

Part names

Pump

Adjusting screw

Used for opening the air vent port.

Air vent por t

Always connect a tube.

Be sure to return the tube

end to a supply tank or a

cont ainer.

The air vent port can

rotate 90 degrees.

Outlet

Air vent body

Inlet

Pump head

Overview

Control unit

Used for the start/stop of the

pump and stroke rate adjustment/programming.

Stroke length

adjusting knob

Used for adjusting

a flow rate.

Nameplate

Describes the

pump specifications.

Base

Always fix with bolts.

Part names

19

Operational panel

Display

An operational status, a selected mode and

a programmed value are shown here.

START/STOP key

Used for starting/stopping

the pump operation.

EXT key

Used for entering the

EXT mode.

UP key

Used for increasing numeric values or selecting a programming

mode.

MAN DIV MULT ANA. RV P

OVER P1 2 LOCK Err Disp SET

EXT

DOWN key

Used for decreasing numeric

values or selecting a program-

ON

STOP

LED

Lights as the pump is turned

on and blinks at each shot.

ming mode.

!

spm

L/h

mA

DISP

DISP key

Used for checking flow information or changing units.

20

Part names

■

MULT

ANA. R

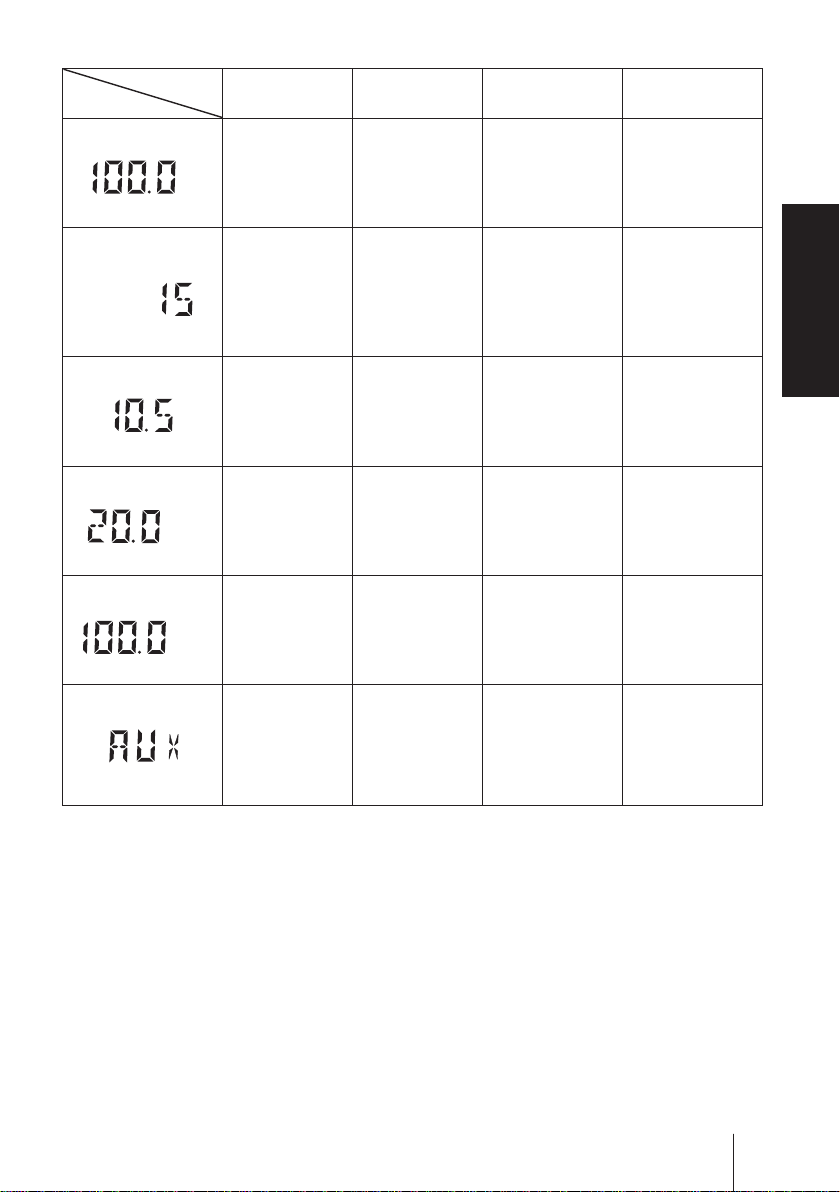

Basic displays & Pump states

STOP LED

lights red

MAN

%

DIV

― ―

%

%

ANA. V

%

―

― ―

― ―

― ―

― ― ―

ON LED lights

orange

Manual wait

state. Display

shows stroke

rate in %.

ON LED lights

green

―

EXT(Multiply)

mode. The

pump is waiting

for the external

signal.

EXT(Divide)

mode. The

pump is waiting

for the external

signal.

EX T(ANA.

R) mode. The

pump is waiting.

EX T(ANA.

V) mode. The

pump is waiting.

ON LED blinks

green

The pump

is running in

manual mode.

Display shows

stroke rate in %.

EXT(Multiply)

mode. The

pump is making

the displayed

# of shots per

signal.

EXT(Divid e)

mode. The

pump is running

at the displayed

stroke rate.

EX T(ANA.

R) mode. The

pump is running

at the displayed

stroke rate.

EX T(ANA.

V) mode. The

pump is running

at the displayed

stroke rate.

AUX mode.

The pump

is running at

the maximum

stroke rate.

Overview

Part names

21

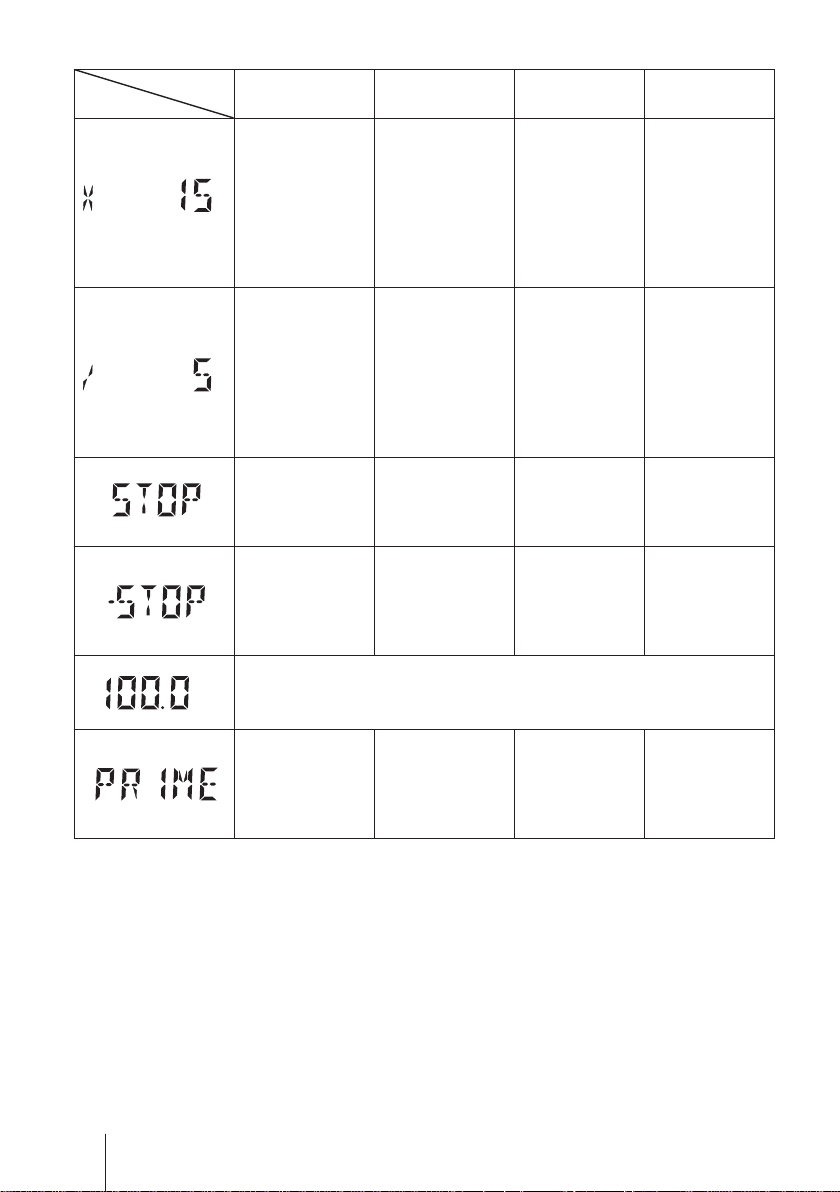

STOP LED

LOCK

SET

MULT

lights red

ON LED lights

orange

ON LED lights

green

ON LED blinks

green

EXT(Multiply)

programming

mode. The

SET

―

pump is set

to make the

displayed #

― ―

of shots per

signal.

EXT(Divid e)

programming

DIV

―

mode. The

pump is set

to make one

― ―

shot for the

displayed # of

signals.

Operation stop

by the STOP

signal. ON LED

― ― ―

lights green.

STOP signal

input in the

manual wait

― ― ―

state. ON LED

lights orange.

MAN

Keypads are locked. Keypad operation is ineffective in this state.

Release keypad lock before operation.

%

22

Part names

PRIME mode.

The pump

― ― ―

is running at

the maximum

stroke rate.

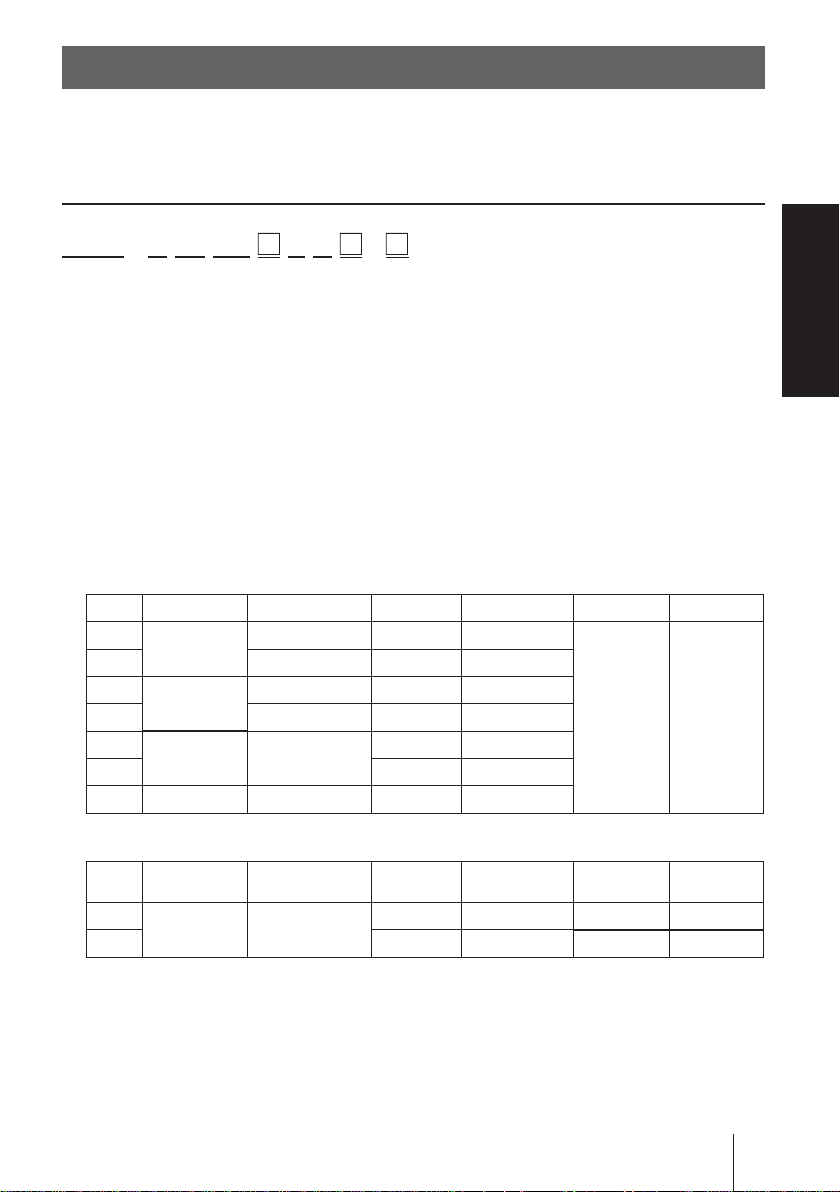

Identication codes

The model codes of the pump/drive units and the control unit represent the following information.

Pump/Drive units

EWN - B 11 VC

E R -

a b c d e f g h i

a. Series name

EWN: Multivoltage electromagnetic metering pump

b. Drive unit (Average power consumption)

B: 20W

C: 24W

c. Diaphragm effective diameter

09: 8mm 11: 10mm 16: 15mm

21: 20mm 31: 30mm 36: 35mm

d. Wet end materials

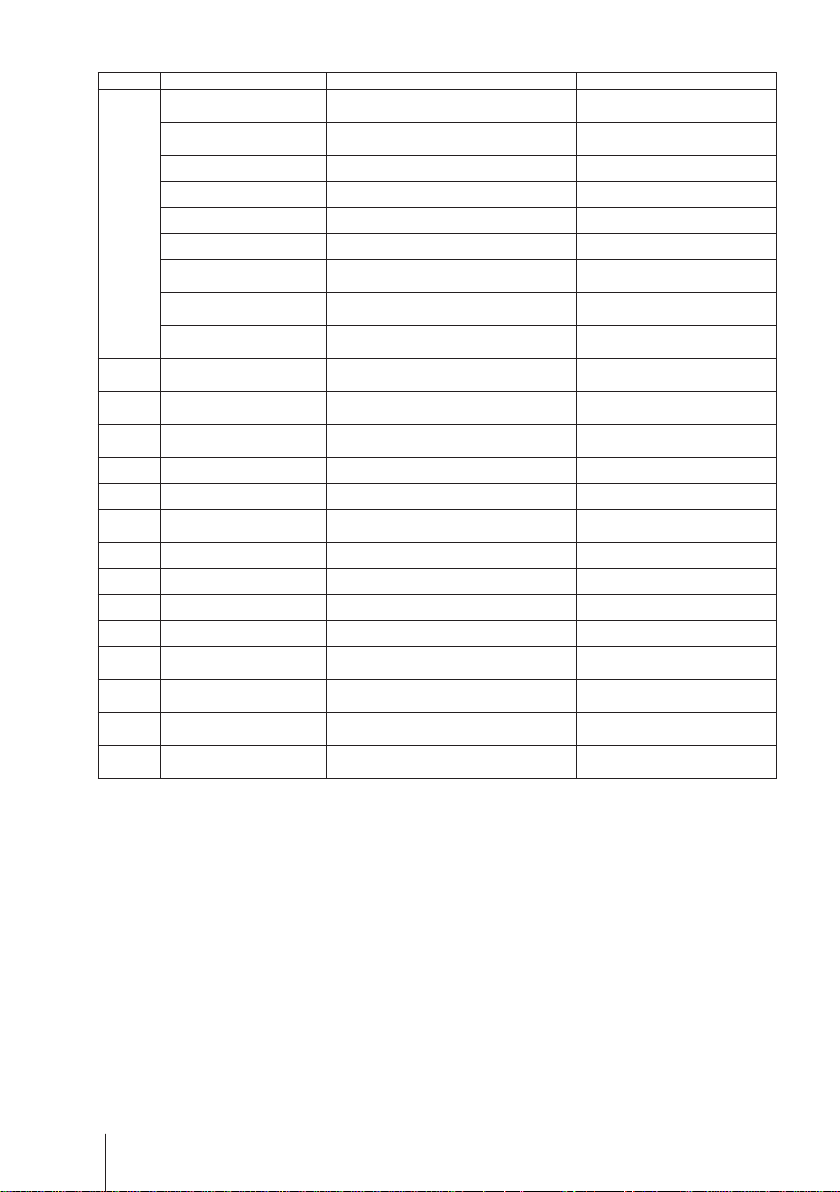

Code Pump head Valve O ring Valve seat Gasket Diaphragm

VC

VH HC276 EPDM EPDM

PC

PH HC276 EPDM EPDM

FC

TC FKM FKM

SH SUS316 HC276 SUS316

PVC

GFRPP

PVDF CE

CE FKM FKM

CE FKM FKM

PCTFE

―

―

PTFE

Overview

PTFE

+ EPDM

Automatic air vent (Auto degassing type)

Air vent valve

Code

VC

VH HC276 HC276 EPDM EPDM

guide A

PVC PVC

Material code

PVC : Transparent polyvinyl chloride GFRPP :

PVDF : Polyvinylidene diuoride EPDM : Ethylene-propylene rubber

FKM : Fluorine-contained rubber PTFE : Polytetrauoroethylene

HC276 : HASTELLOY C276 SUS316 : Austenite stainless steel

CE : Alumina ceramics PCTFE : Polymonochlorotriuoroethyle

Air vent valve

guide B

Valve Separate pin Valve seat O ring

CE Titanium FKM FKM

Glassber-reinforced polypropylene

Identication codes

23

e. Tube connection bore

No. Hose size (ID×OD) Wet end materials Pump model

ø4×ø6*²

ø6×ø8*²

ø9×ø12 VC/VH/PC/PH EWN-31 & -36

ø10×ø12 TC EWN-31 & -36

No

code*¹

1 ø4×ø9

2 ø4×ø6

3 ø6×ø8

4 ø8×ø13 VC/VH/PC/PH EWN-31 & -36

6 ø10×ø12 VC/VH/PC/PH EWN-31 & -36

7 ø1/4"×ø3/8 "

8 ø3/8"×ø1/2" VC/VH/PC/PH/TC EWN-31 & -36

9 Rc1/4 VC/VH/PC/PH/TC/VC-C/VH-C

23 ø6×ø12 VC EWN -11/-16/-21/-31 & -36

24 ø5×ø8 VC/TC/VC- C EWN-09/-11/-16 & -21

1/27

2/27

3/27

7/27

ø6×ø12 VC-C/VH-C EWN-09/-11/-16 & -21

Rc 1/4 FC/SH/SH-H/SH-H2 EWN-11/-16/-21/-31 & -36

IN: ø15×ø22

OUT: ø9×ø12

IN/AIR: ø4×ø6*²

OUT: R1/4

IN/AIR: ø6×ø8*²

OUT: R1/4

IN: ø4×ø9

OUT: R1/4

IN: ø4×ø6

OUT: R1/4

IN: ø6×ø8

OUT: R1/4

IN: ø1/4"×ø3/8"

OUT: R1/4

*¹ ø4×ø6 and ø6×ø12 are equipped to the EWN-09/-11/-16/-21 (VC-C type).

*² European standard hose size is ø4×ø6. Australian standard hose size is ø6×ø8

(VC/VH/PC/PH/TC/VC-C/VH-C/VC-A/VH-A).

VC/VH/PC/PH/TC/VC-C/VH-C/

VC-A/VH-A

VC/VH/PC/PH/TC/VC-C/VH-C/

VC-A/VH-A

PC/P6-V EW N-31

PC/PH-H/PH-H2 EWN-11 & -16

PC/PH-H/PH-H2 EWN-11 & -16

VC/VH/PC/PH/VC-C/ VH-C/

VC-A/VH-A

VC/VH/PC/PH/VC-C/ VH-C/

VC-A/VH-A

VC/VH/PC/PH/TC/VC-C/VH-C/

VC-A/VH-A

VC/VH/PC/PH/TC/VC-C/VH-C/

VC-A/VH-A

PC/PH-H EWN-11 & -16

PC/PH-H EWN-11 & -16

PC/PH-H EWN-11 & -16

PC/PH-H EWN-11 & -16

EWN-09/-11/-16 & -21

EWN-09/-11/-16 & -21

EWN - 09 /-11/-16 & -21

EWN-09/-11/-16 & -21

EWN-09/-11/-16 & -21

EWN-09/-11/-16 & -21

EWN-09/-11/-16/-21/-31 & -36

f. Power cable

E: European type A: Australian type

g. Control unit function

R: Standard

h. Special version

C: High compression type H: High pressure type

V: High viscosity type A: Auto degassing type

i. Special conguration

H: High pressure type (2MPa)

24

Identication codes

Installation

This section describes the installation of the pump, tubing and

wiring. Read through this section before work.

Observe the following points when installing the pump.

• Be sure to turn off power to stop the pump and related devices before work.

• Upon sensing abnormality or danger, stop work immediately. Remove

problems before resuming work.

• Do not place dangerous or ammable goods near the pump for your safety.

• Risk of an electrical leak or shock. Do not use a damaged pump.

Pump mounting

Select an installation location and mount the pump.

Necessary tools

• Four M5 bolts (pump mounting)

• Adjustable wrench or spanner

Installation

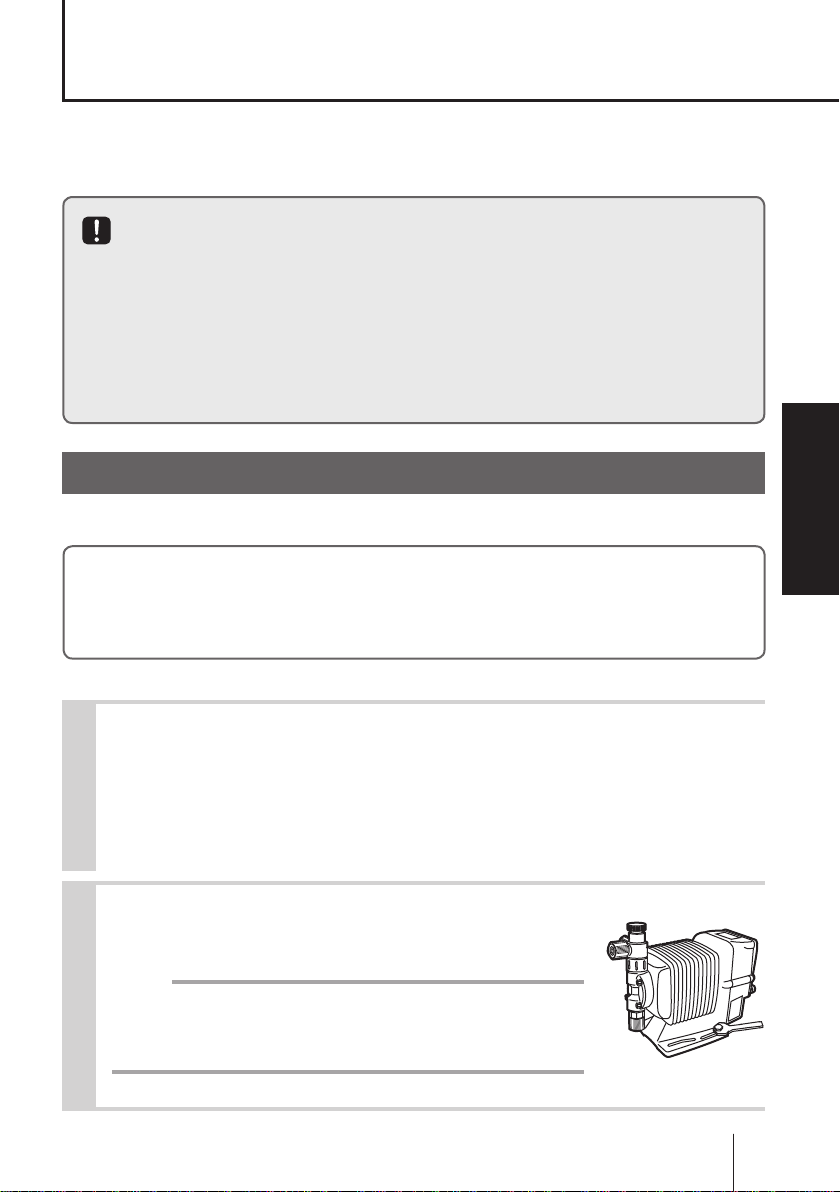

Select a suitable place.

1

Always select a at oor free of vibration. See page 10 for detail.

Flooded suction is recommended when handling a gaseous liquid such

as sodium hypochlorite.

Anchor the pump by the M5 bolts.

2

Be sure to x the pump at four points.

NOTE

Install the pump horizontally. If the pump is installed at a

tilt, a ow may reduce.

Pump mounting

25

Pipework

Connect tubes to the pump and install a check valve.

Before operation

• Cut the tube ends at.

Necessary tools

• Adjustable wrench or spanner

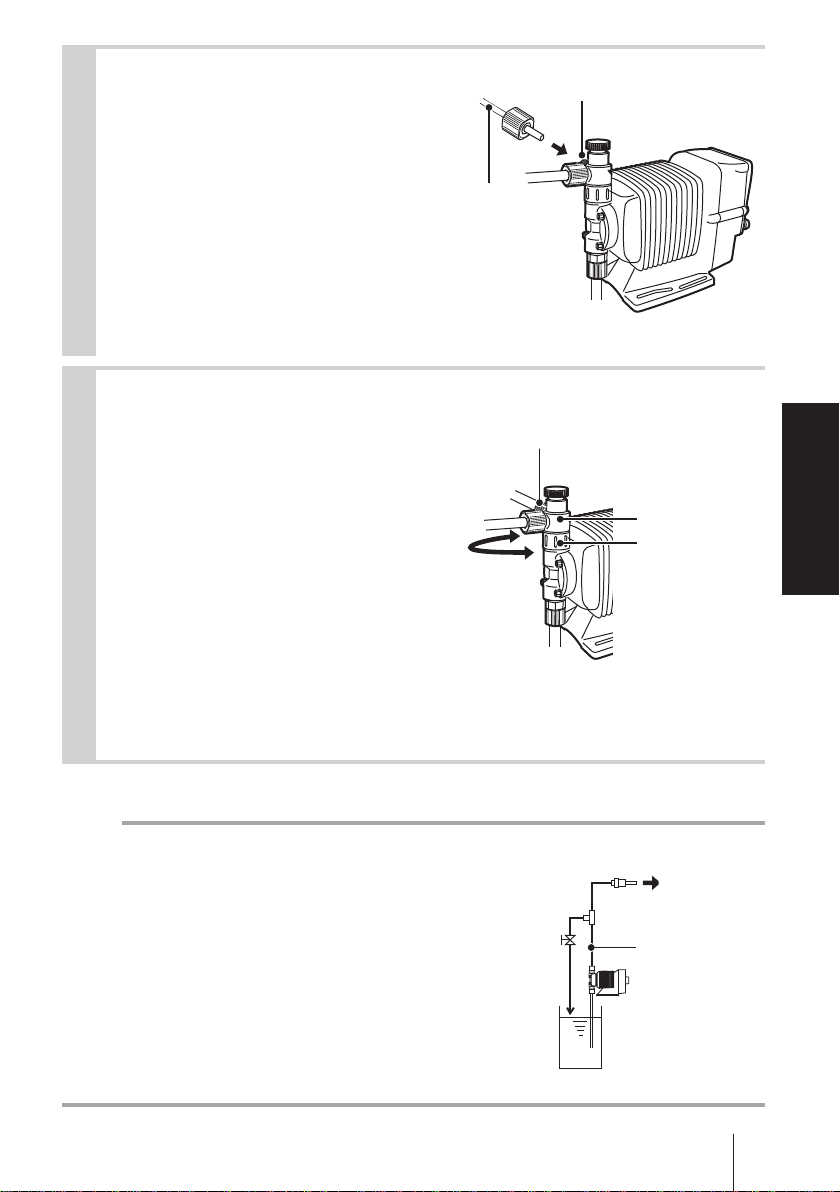

Tube connection

a. Pass a tube into the tting nut and

hose stopper and then slide it down to

the hose adapter as far as it will go.

b. Fit the tube end (hose adapter) to the

tting. Then hand tighten the tting nut.

c. Retighten the tting nut by turning it

180 degrees with an adjustable wrench

or spanner.

* The plastic tting nut may be broken if it is

tightened too much.

Tube end (Side view)

Tube

Fitting nut

Hose

stopper

Slide it

down

Hose

adapter

Fitting

Connect tubes into the inlet and

1

outlet.

26

Pipework

Tube

Tube

Outlet

Inlet

Connect an air bleed tube into the

2

air vent port.

Route back the other tube end to a

supply tank or a container.

For the auto degassing type, con-

nect another air bleed tube into the

automatic air vent valve body as

well.

Determine an air vent port direction.

3

The air vent port can rotate 90 de-

grees.

a. Turn the lock nut anticlockwise.

b. Adjust the direction of the air vent

port.

c. Hand-tighten the lock nut, holding

the air vent body A.

d. Turn the lock nut 90 degrees

clockwise further with an adjustable

wrench or spanner.

Tube

Air vent port

Air vent port

Installation

Air vent body A

Lock nut

NOTE

The air vent port is not provided to the EWN-

FC type. Purchase and install an air vent valve.

Air vent

valve

Check valve

Three way joint

Discharge line

Pump

Pipework

27

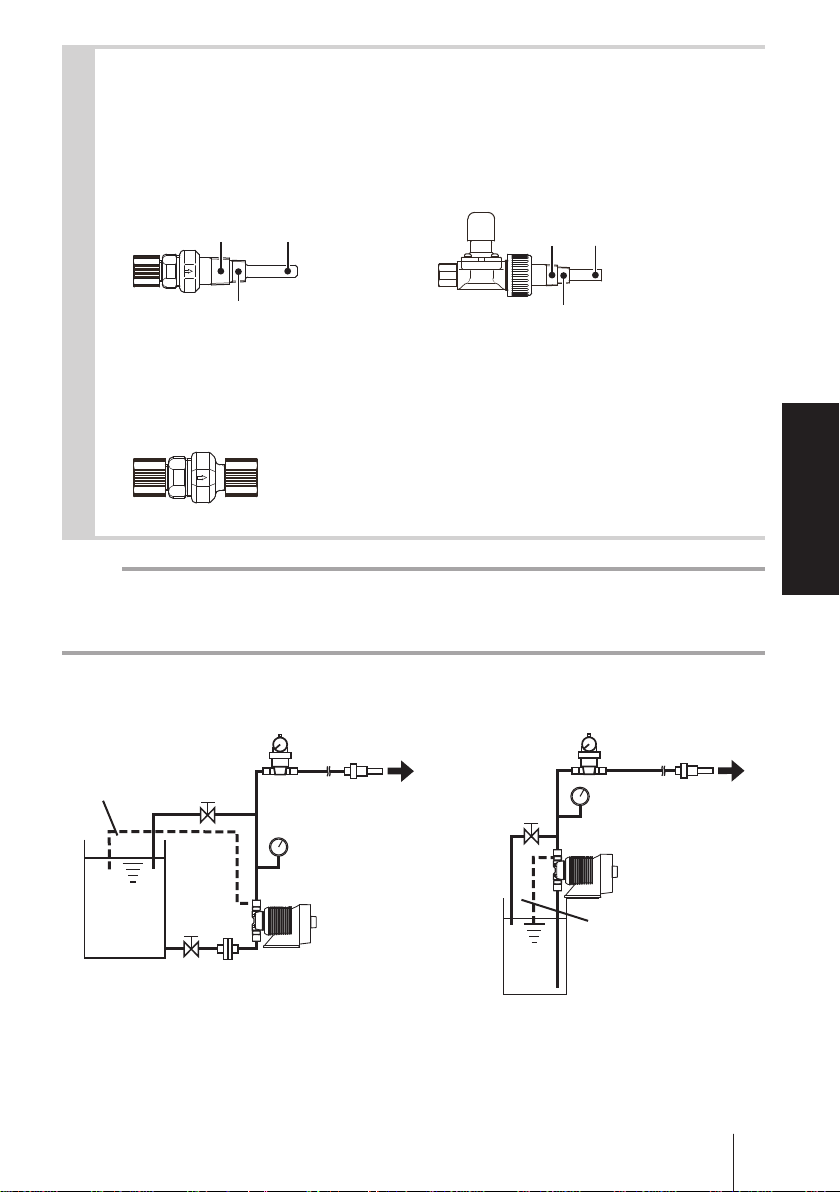

Check valve mounting

Install an optional check valve to the EWN (or a back pressure valve to the FC

type) for the prevention of a back ow, siphon and overfeeding.

In the following cases be sure to install the check valve.

• A suction side liquid level is higher than a discharge side (See the diagram

below). Or an injection point is below a suction side liquid level at atmospher-

ic pressure.

Suction side

Discharge side

• The elevation difference between two liquid levels is ve meters or below,

even if a discharge side liquid level is higher than a suction side.

5m or below

Discharge side

Suction side

• A suction side pressure is higher than a discharge side pressure.

• A discharge pressure (including pipe resistance and discharge head) is below

0.13MPa. (0.049MPa for B31 and C36).

28

Pipework

Mount a check valve at the discharge tube end.

1

* The CAN/CBN check valve and the BVC back pressure valve have R1/2 and

R3/8 thread connections as well as a tube connection. Cut off and adjust the

connection length to t the check valves into tubing.

CAN check valve BVC back pressure valve

Outer dia Ф9R1/2

R3/8

* The CBN check valve of which the both ends are tube connections is also

available. Contact us or your nearest distributor.

CBN check valve

Outer dia Ф12R1/2

R3/8

NOTE

Periodically clean or replace a check valve with new one for the prevention of crystal

clogging.

Tubing layout

Flooded suction application Suction lift application

Accumulator/Chamber

Air vent line

Accumulator/Chamber

Check valveCheck valve

Installation

Pump

Pump

* Flooded suction is recommended when handling a gaseous liquid such as sodium

hypochlorite. For the auto degassing type, keep a suction lift at 1m or below. Other-

wise, the air vent valve may not function. Before resuming operation, always perform

degassing by using the adjusting screw.

Air vent line

Pipework

29

Wiring

Wiring for a power voltage and an external signal.

Observe the following points during wiring work.

• Electrical work should be performed by a qualied operator. Always ob-

serve applicable codes or regulations.

• Observe the rated voltage range, or the electrical circuit in the control

unit may fail.

• Do not perform wiring work while electric power is on. Otherwise, an

electrical shock or a short circuit may result. Be sure to turn off the power

before wiring work.

• Be careful for electric power not to be turned on during work.

• Replacement of a power cable should be conducted by a manufacturer,

his agency or a skilled person. Otherwise, an accident may result.

Necessary tools

• Adjustable wrench or spanner • Phillips screw driver

• Precision screw driver

Power voltage/Earthing

Check that the main power is turned off.

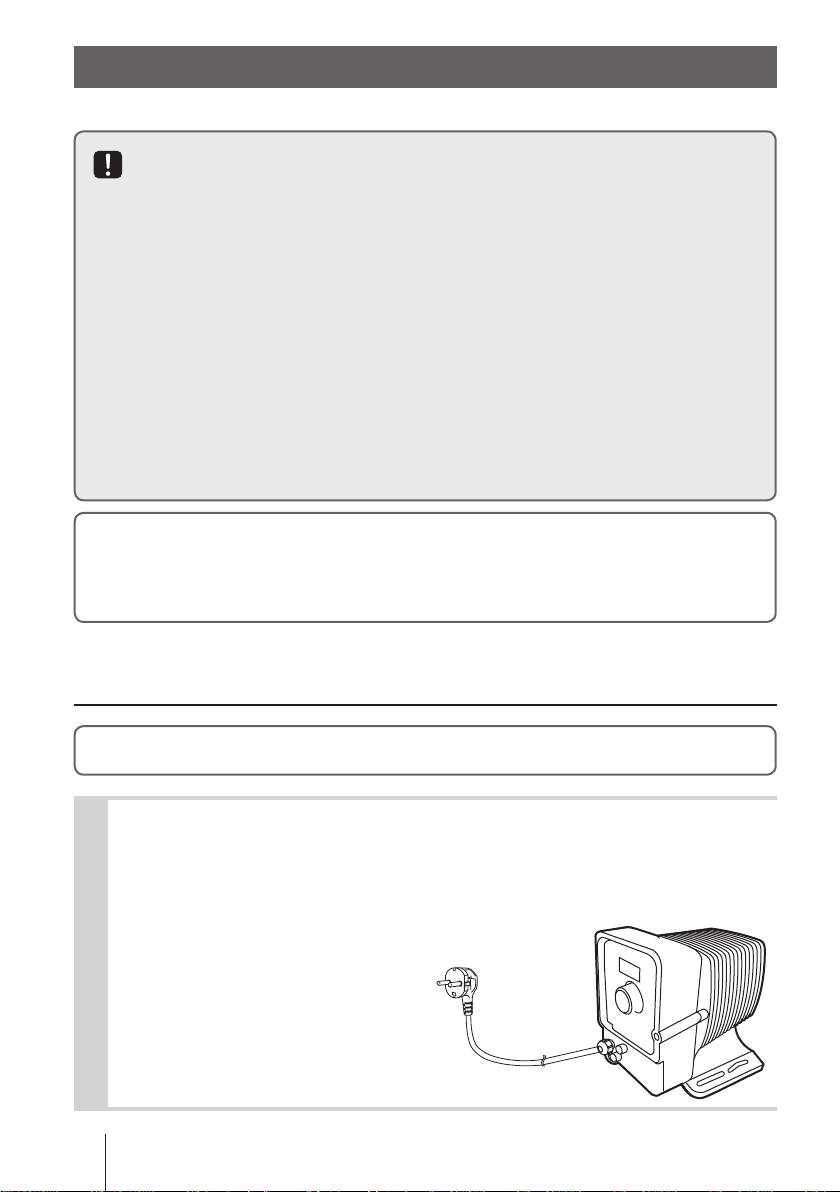

Insert the plug all the way seated in a jack.

1

This product have two power wires and one earth

wire, and is classied as class Ι.

*Make sure the earth plug is seated in securely as well.

30

Wiring

Loading...

Loading...