IWAKI EHN-B21SH, EHN-C21SH, EHN-C31SH, EHN-B11SH, EHN-SH Series Instruction Manual

...

EHN-SH

Instruction Manual

IWAKI

Electromagnetic Metering Pump

Read this instruction manual before use of product

Thank you for choosing the EHN type electromagnetic metering

pump.

This instruction manual consists of "Safety Section", "Outline

Section", "Installation Section", "Operation Section" and

"Maintenance Section", and deals with the correct installation,

operation, maintenance and troubleshooting procedures.

Please read through this manual carefully to ensure the optimum

performance, safety and service of your pump.

Contents

Instruction for safety

Outline of product 1. Unpacking and inspection

Installation 1. Before installation

Operation 1. Operation

Maintenance Instruction for safety

Exploded view

Outline dimension

...........................................................................

............................

2. Principle of operation

3. Model identification

4. Specif ication

5. Operating function

6. STOP function

7. O ve rview

2. Precaution on handling

3. Installation

4. Tubing

5. Electrical wiring

2. Operation of controller

1. Troubl esh oot ing

2. Maintenance and inspection

3. Wear parts

4. Dismantlement and assembly

..................................................................................

............................................................................

...................................................

.................................................

....................................................

..............................................

...................................................

..................................

.....................................

................................................

.......................................

.............................................

......................................

..........................

...................................

..........................

......................................

...........................................

........................

.......................

10·11

14~18

19~23

24~35

42·43

44·45

1~3

8·9

10

12

13·14

36

37

37

38

Instruction for safety

For the Safe and

Correct Handling of the Pump

●

"Safety Instruction" section deals with important details about

the handling of the product. Before the use of controller, read

through this section carefully for the prevention of personnel

injury or loss.

●

Observe the instructions accompanied with "WARNING" or

"CAUTION" in this manual. These instructions are very impor-

4

4

5

6

7

8

36

tant to avoid dangerous situations.

●

The symbols on this instruction manual have the following

meanings:

Nonobservance or misapplication of the

Warning

Caution

contents of the “Warning” section could

lead to a s er i ou s a cc i de nt w h ic h m ay

result in death.

Nonobservance or misapplication of the

contents of the “Caution” section could

lead to the personal injury to users or

serio us d a m ag e t o t he p ro d uc t.

Types of Symbols

Indicates a prohibited action or procedure. Inside or near this circle, a concrete and practical image of the activity to be avoided is

depicted.

Indicates an important action or procedure which must be performed or carried out without fail. Failure to follow the inst ructions

herein can lead to malf unction or damage to the pump.

- 1 -

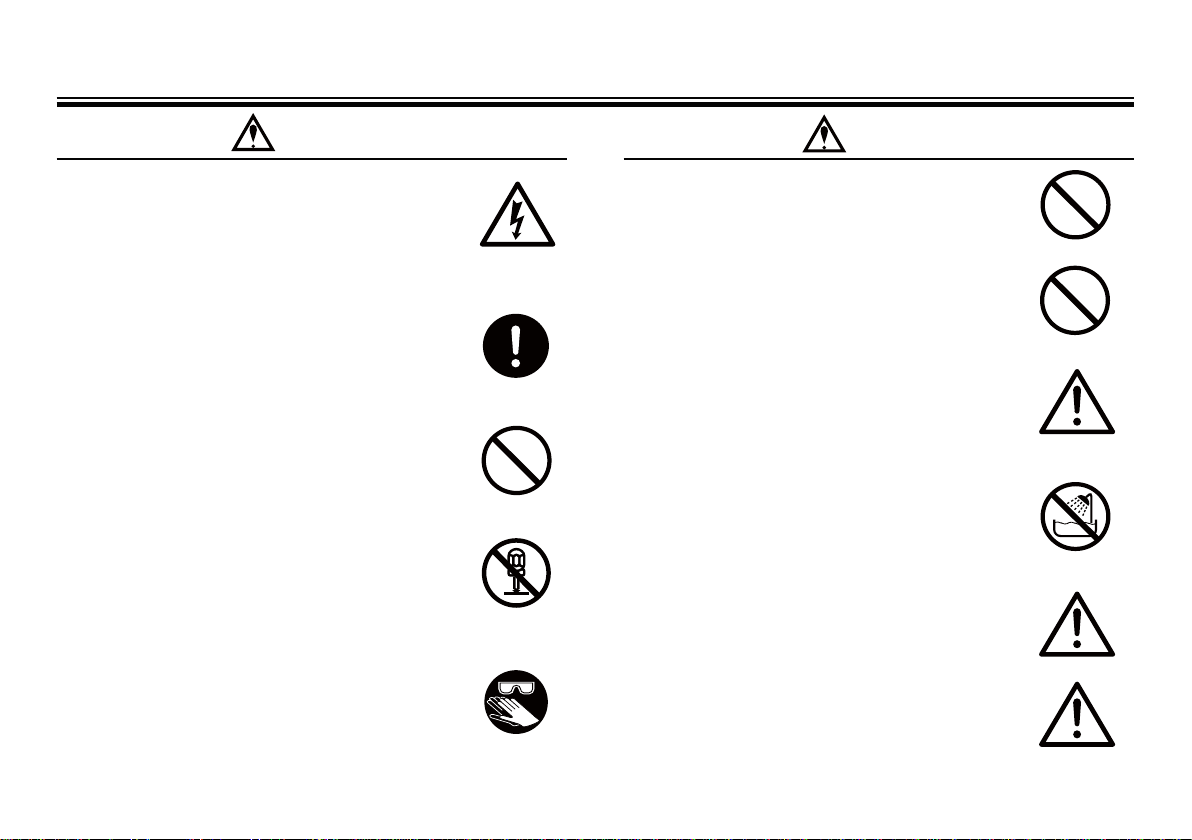

Electrical Shock

Prohibited

No Remodeling

Wear protective

gear

Prohibited

Do not wet

or dampen

Instruction for safety

Caution

Warning

• Turn off power

Working on the pump with power ON may cause an elec-

trical shock. Before work ing on the pump, make sure to

discon nect the power cord in order to stop the pump and

other related devices.

• Terminate operation

Detecting or becoming aware of any dangerous sig n or

abnormal condition, stop the operation immediately and

resta rt it from the beginning.

• For specified application only

The use of the pump in any application other than those

clearly specified may result in inju ry or damage to the

pump. Use the pump within specifications and applica-

tion range.

• No remodeling

Never try to modif y the pump. Ser ious accidents may

result. We are not responsible for any accident or damage

due to modification without first obtaining permission or

instructions from Iwaki.

• Wear protectors

Always wear protective clothing, eye protection and

gloves before any dismantlement/assembly of the pump

or maintenance.

Caution

• Qualified operators only

Any operation of the pump is permitted to only t he per-

son with a enough understanding of the pump.

• Specified power only

Do not apply any power other than specif ied one on the

nameplate. Otherwise damage or fire will may happen.

• Pay attention to dry running

Do not r un pump dry for more than 30 minutes. The bolt

on the pump head may loosen and result in liquid leak-

age. Install the pump so that dry running can not occu r.

Take extra care not to run the pump dry unintentionally

for more than 30 minutes for air elimination.

• Do not wet or dampen

If any electric part or wiring gets wet with the liquid

spilled over accidentally, a fi re or electrical shock may

be caused. Install the system in a place free f rom liquid

spillage or leakage.

• Ventilate

Poisoning may result when handling toxic or odorous

liquid. Ventilate the operating site suff iciently.

• Spill-out accident

Protective measures should be taken against any acciden-

tal spill-out or leakage of the operating liquid as a result

of unexpected damage on the pump or the related piping.

Prohibited

Caution

Caution

- 2 -

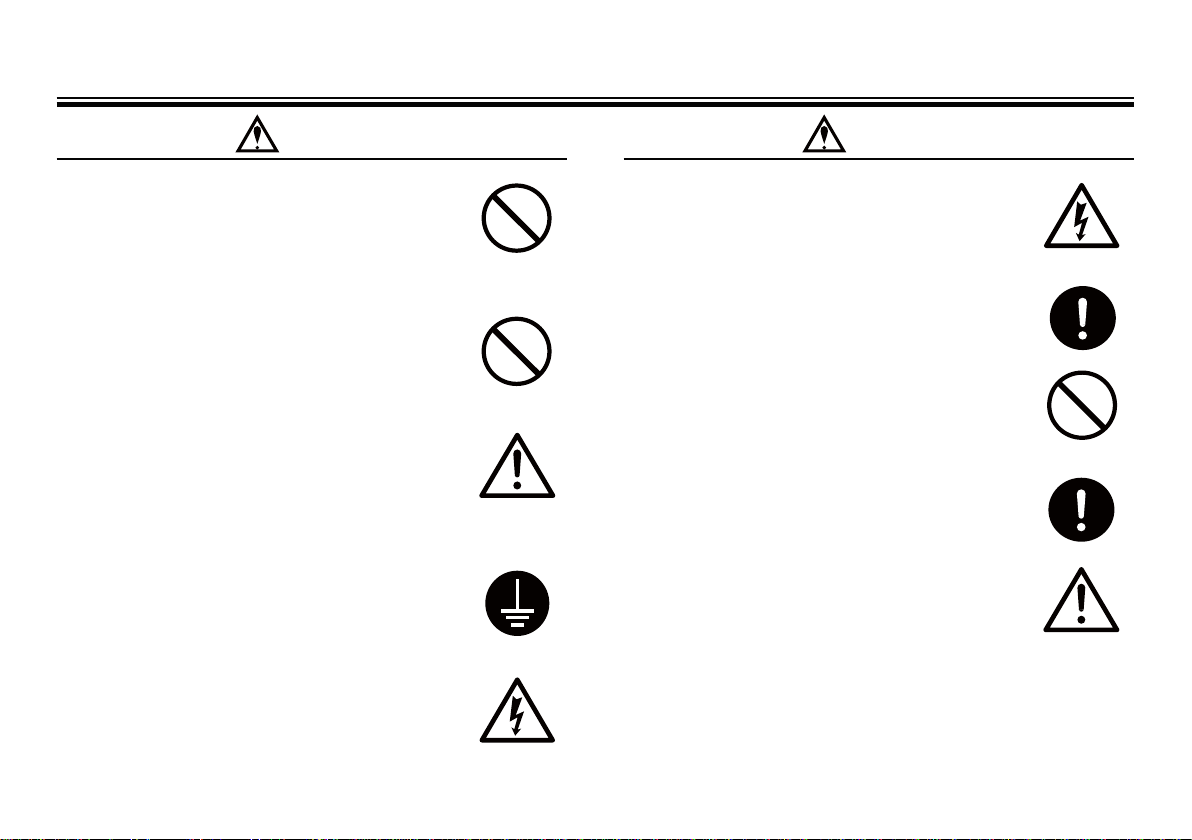

Prohibited

Caution

Prohibited

Electrical Shock

Electrical Shock

Prohibited

Instruction for safety

Caution

Caution Caution

• Limited operating site and storage

Do not install or store the pump in the following places:

* Flammable gas or material is used or stored.

* Ambient temperat ure is extremely high (40 dig.C or

higher) or ext remely low (0 dig.C or lower).

• Do not place the pump close to water

The pump is not water-proof construction. If the pu mp

is used in a place where liquid is splashed on pump or at

humid place, electrical shock or short-circuit may happen.

• Do not damage or change power cable

Do not scratch, damage, process, or pull the power cable

forcibly. An extra load onto the cable, such as heati ng

the cable or placing something heavy on the cable, may

damage the cable and finally cause a fire or an electrical

shock.

• Arrange grounding

Be su re to connect grounding wire before operation.

Other wise, an electrical shock may result. Make sure the

grounding wire is connected with the grounding terminal.

• Install an earth leakage breaker (option)

Pu mp operation without using an earth leakage breaker

may cause a n electrical shock. Purchase an optional leak-

age breaker and install in the system.

Grounding

• Handling of the power cable

Use of a defective or damaged power cable may result in a

fire or electrical shock. Handle the power cable carefully.

• When replacing parts

Replace the consumable parts by following the descrip-

tions in the instr uction manual. Do not disassemble the

pump beyond the extent shown on the instruction manual.

• Damaged pump

Never operate a damaged pump. A damaged pump may

cause leakage or electrical shock.

• Disposal of used pump

Dispose of the used or damaged pump in accordance with

the relevant local laws and regulations. (Consult a licensed

industrial waste products disposing company.)

• Tightening torque of the pump head

Leakage may occur when the pump head fixing bolts are

loose. Make sure that the pump head is secured by tighten-

ing the 4 f ixing bolts diagonally at the first operation.

Tightening torque

EHN-B11 • 21 • C21 : 2.16N•m

EHN- C31 • 36 : 2.55N•m

- 3 -

Outline of product

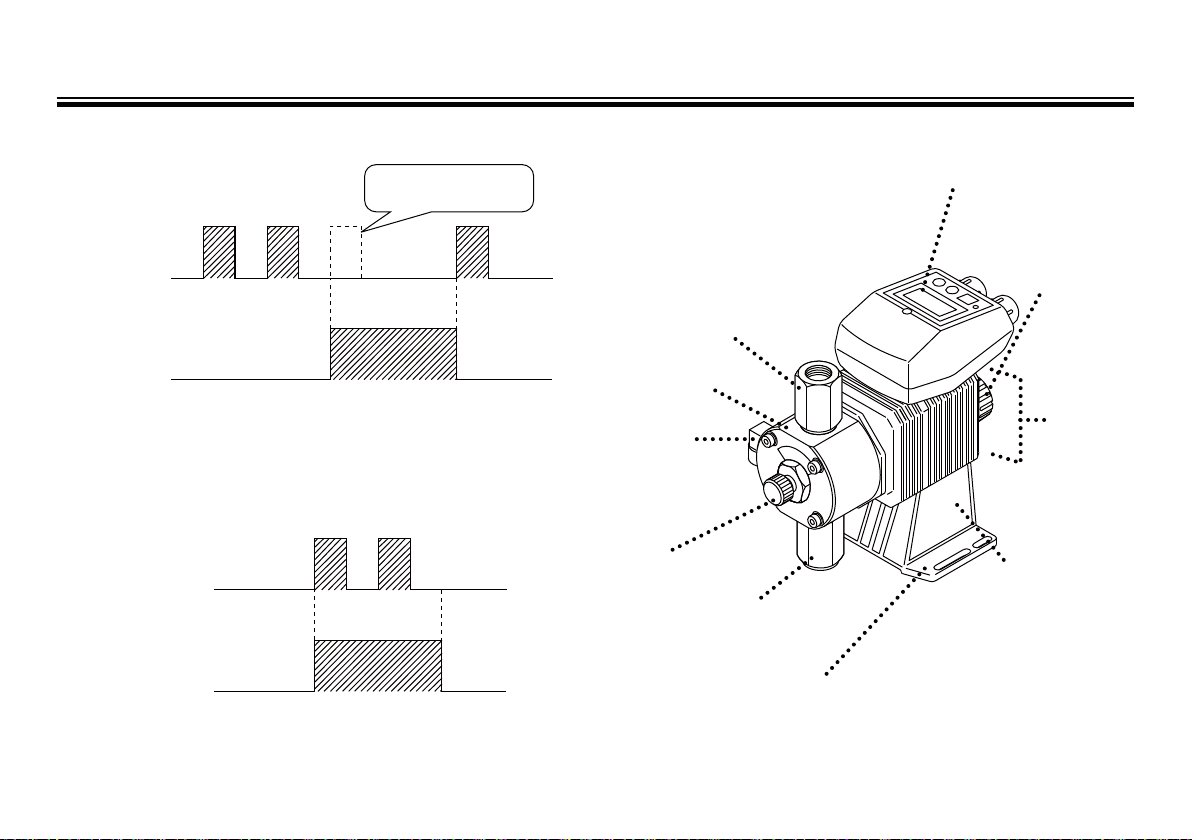

Control unit

Pump head

Driving unit

Stroke length

adjusting knob

Plunger

Diaphragm

Spring

1. Unpacking and inspection

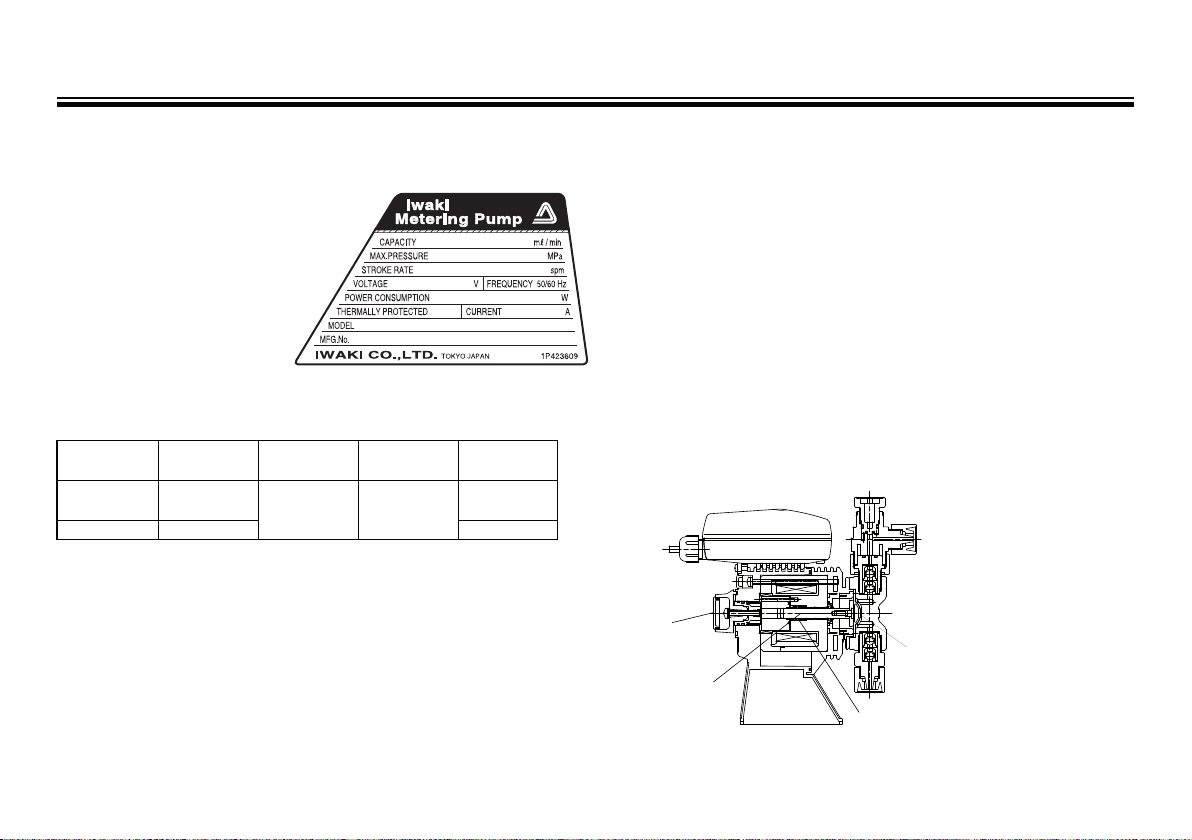

1) Check the model code, discharge capacity, discharge

pressure and voltage etc.

shown on nameplate to

confirm the pump is in your

specification.

2) Check if accessories are

attached.

a. Check valve or back pres-

sure valve : One piece

Model

CS-1S 0.2

CS-1SL

Set press.

MPa

Connection Wet-end material

SUS316

RC1/4

Hastelloy C

PTFE

Applied pump

model

EHN-B11ּ21

EHN-C21ּ31

EHN-C360.05

3) Check if the product is not damaged and any parts are not lost in

transit. Check that any bolts or nuts are not loosened.

If you find any abnormality, ask us.

2. Principle of operation

IWAKI electromagnetic metering pump the EHN series is a diaphragm metering pump which consists of a pump head, driving unit,

and control unit. A diaphragm is directly driven by electromagnet

force.

A reciprocating motion is made by a spring and electromagnetic

force generated by pulse current coming from a control unit. The

reciprocating motion is transferred to a diaphragm through a plunger

and makes volumetric change in a pump chamber. Pumping action is

obtained by volumetric change and by valve action in pump head.

- 4 -

Outline of product

3. Model identification

Pump : EHN - B 11 SH 9 R -

□□

1 2 3 4 5 6 7

1. Series

EHN multi voltage type

2. Driving unit code (Average power consumption)

B : 20W C : 24W

3. Diaphragm effective diameter

11 : 10mm 21 : 20mm

31 : 30mm 36 : 35mm

4. Wet-end material

Code Pump head Valve Valve seat Gasket

SH SUS316

Mate rial code EPDM: Ethylene-propylene-diene-methylene P TFE: Poy tetr aflu ro ethylene

Hastelloy C

SUS316 PTFE

Diaphragm

PTFE

+

EPDM

(Not wet-end)

5. Connection hose diameter code

9: Rc1/4 Female screw

6. Controller function code

R: Standard type

7. Special type code

01 ~ 99 : Non standard material, Non standard connection, etc.

Control unit : EHNC - B R -

□□

1 2 3 4

1. Control unit type

EHNC: Multi voltage type (with crimp contact)

2. Driving unit code

B or C

3. Controller function code

R: Standard type

4. Special type code

01 ~ 99 : Non standard specification.

- 5 -

Outline of product

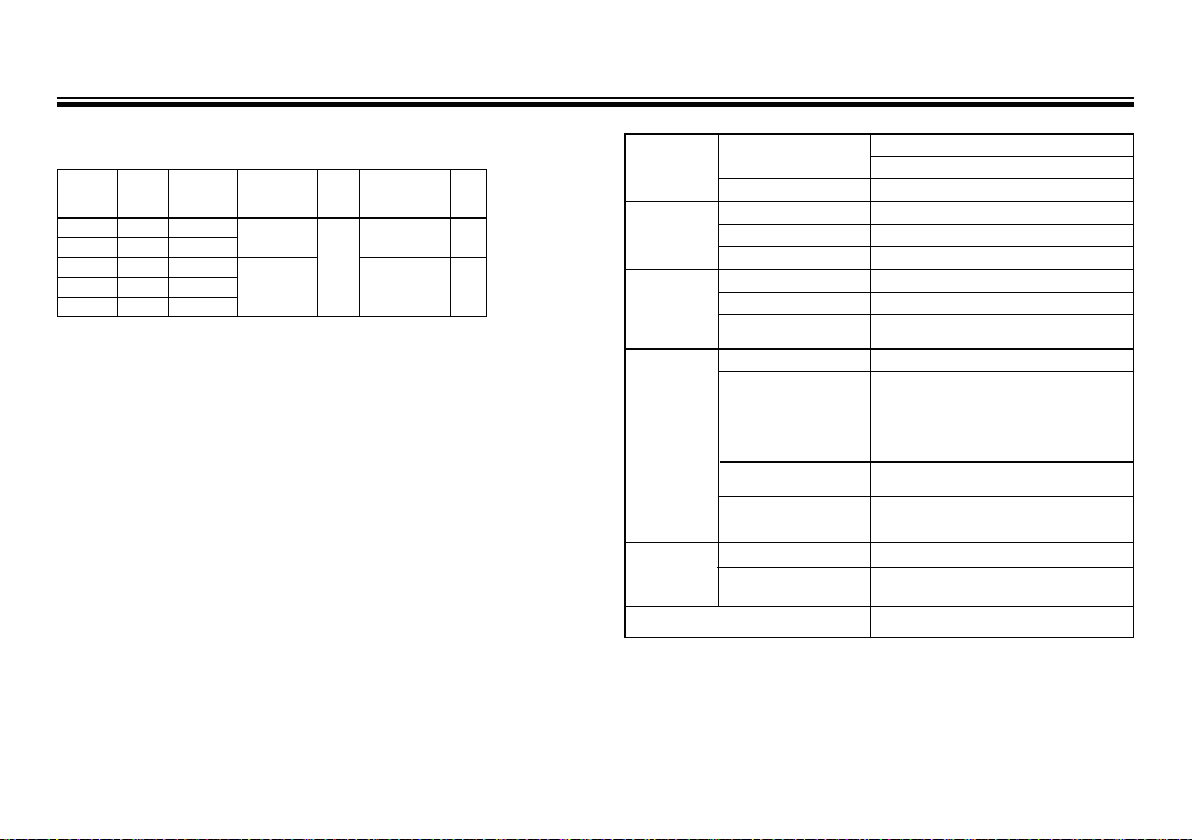

4. Specification

4-1. Pump specification

Disch.

capacity

ml/min

notice.

Max. disch.

Model

EHN-B11 38 1.0

EHN-B21 100 0.4

EHN-C21 130 0.7

EHN-C31 270 0.35

EHN-C36 410 0.2

Note1. Per formance is obtained by pumping clean water at ambient temp in the

rated voltage.

2. Discharge capacity on the table are obtained at max. discharge pressure

(100% stroke length, 360 spm stroke rate.). When discharge pressure

is low, the pump discharges liquid much more than discharge capacity

shown as above.

3. Permissible ambient temperature : 0 ~ 40 deg. C

4. Permissible liquid temperature : 0 ~ 40 deg. C

5. Permissible voltage fluctuation: Within ±10% of the rated voltage

● Ask us for special cases such as transferring slurry liquid or so.

● Specification may be changed for product improvement without prior

press.

MPa

Stroke length

mm

(%)

0.5~1.0

(50~100)

0.5~1.25

(40~100)

Stroke

rate

spm

1~360

Average power

consumption

W

20

24

Mass

kg

2.4

4.1

4-2. Control unit

Operation

mode

Stroke rate

STOP input

EXT input

Display

Power source voltage

Note 1: Max. charged voltage to the contact is 12V and 5mA current. If the con-

tact such as relay is used, its applicable load should be 5mA or below.

Note 2: The input signals over the upper limit stroke rate are stored up to 255

signals.

Note 3: The residual input signals over 360 spm are cancelled.

Note 4: Do not apply any voltage other than the specified one. It causes the

pump failure. Allowable power voltage is between AC90 - 264V.

Mode

Switching Key operation

Set range 1 ~ 360 spm

Set method Up or down key

Memory function By non-volatile memory

When M - OFF Pump stops when contact signal comes.

When M - ON Pump runs when contact signal comes.

Input signal

Upper limit stroke rate Stroke rate indication of manual mode

Pump operation

Input signal

Dividing ratio/Multiply

ratio setting range

Figures

Pump movement

EXT(Pule dividing or multiply )

Potential free contact or open collector

1 input signal : "n" pumping(s)

"n" input signal(s) : 1 pumping

When "n" is 1, the pump starts synchronized operation

Potential free contact or open collector

(Blinks synchronous with pump operation)

AC100V~240V, 50/60Hz Note 4

Manual

Note 1

(Pulse multiply) Note 2

(Pulse dividing) Note 3

Note 1

1~999

(Dividing or multiply)

4 digits LCD

Green LED (one)

- 6 -

Outline of product

Pump operation

Operation Operation

Stop

Key operation

EXT input(Multiply)

×

n operation (n=5)

External pulse

Pump operation

1

2 3 4

5 1 2

3

4 5

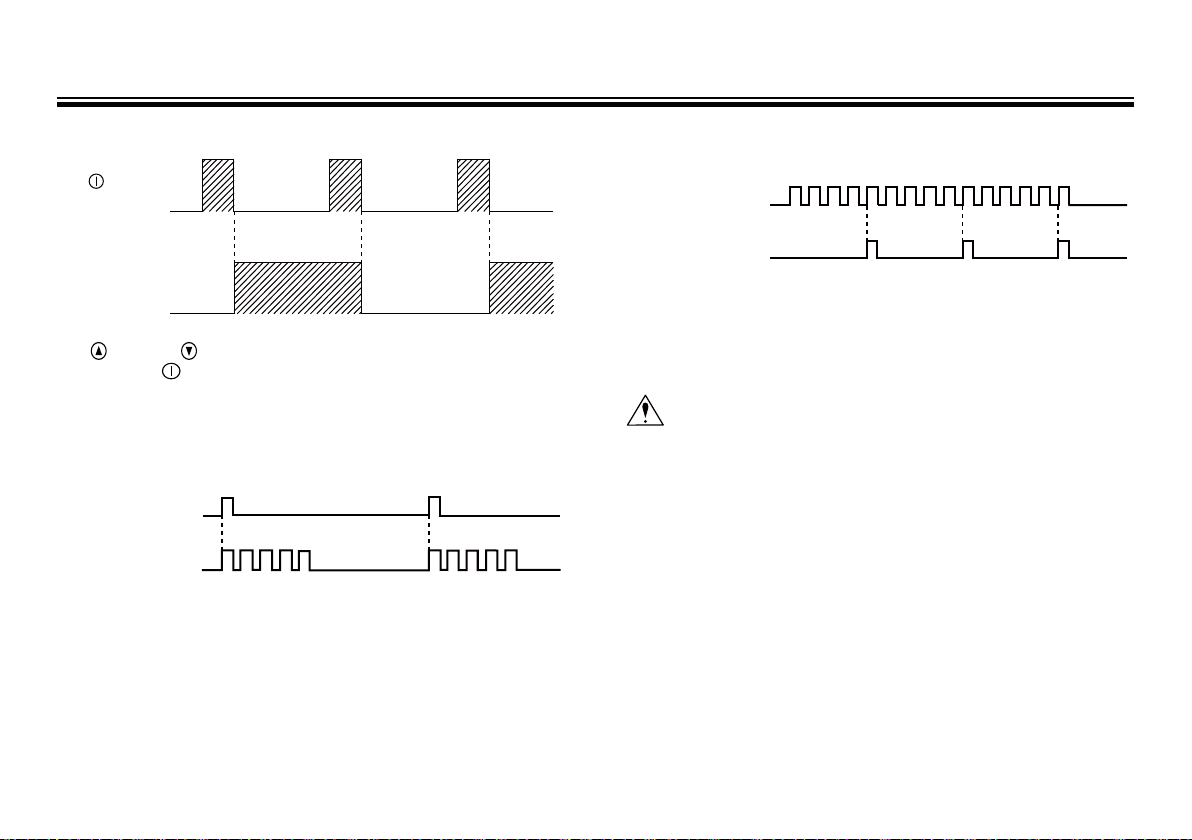

5. Operating function

5-1. Manual operation

Use (UP) and (DOWN) keys to set a stroke rate between 1 ~

360 spm. Use (Stop/start) key to start/stop the pump. Stroke rate

can be adjusted when the pump runs or stops.

5-2. EXT operation

EXT input (Multiply) when a set number of pumping is 5

EXT input operation (Pulse multiply)

Pump operates with a set number of pumping between 1~999 for a

external pulse signal. The preset stroke rate in manual operation is

applied as the upper limit stroke rate in EXT operation. The pulse

signals which come while pumping for the set number of times for

a external pulse signal are stored up to 255 pulses. When the set

number of pumping is set to 1, pump operates synchronously with a

external pulse in the ratio of 1:1.

EXT input (Dividing) when a set number of pumping is 5

EXT input(Dividing) /n operation (n=5)

External pulse

1 2 3 4 5

1 2 3 4 5 1 2 3 4 5

Pump operation

EXT input operation (Pulse dividing)

Pump operates with a pumping for external pulse signals. The preset

stroke rate in manual operation is applied as the upper limit stroke

rate in EXT operation. Residual input signals over 360 spm are

cancelled. When the set number of external signals is set to 1, pump

operates synchronously with a external pulse in the ratio of 1:1.

Caution

When the set number of external pulse signals for a pumping

is set to 1 in pulse dividing operation, pump operation can be

unstable due to the residual signal cancellation function but it

is not malfunction of pump. Set the number of pumping for a

external pulse signals to 1 for 1:1 operation in the pulse multiply

operation.

- 7 -

Outline of product

6. STOP function

6-1. M – OF setting

Pumps does not operate

because of STOP signal.

Pump operation

STOP signal

The pump stops while STOP signal is comming(contact closed).

The pump starts running when STOP signal is stopped.

6-2. M – ON setting

Pump operation

STOP signal

Pump operates while STOP signal comes (contact closed). The pump

operates in EXT mode while STOP signal is coming.

7. Ove r view

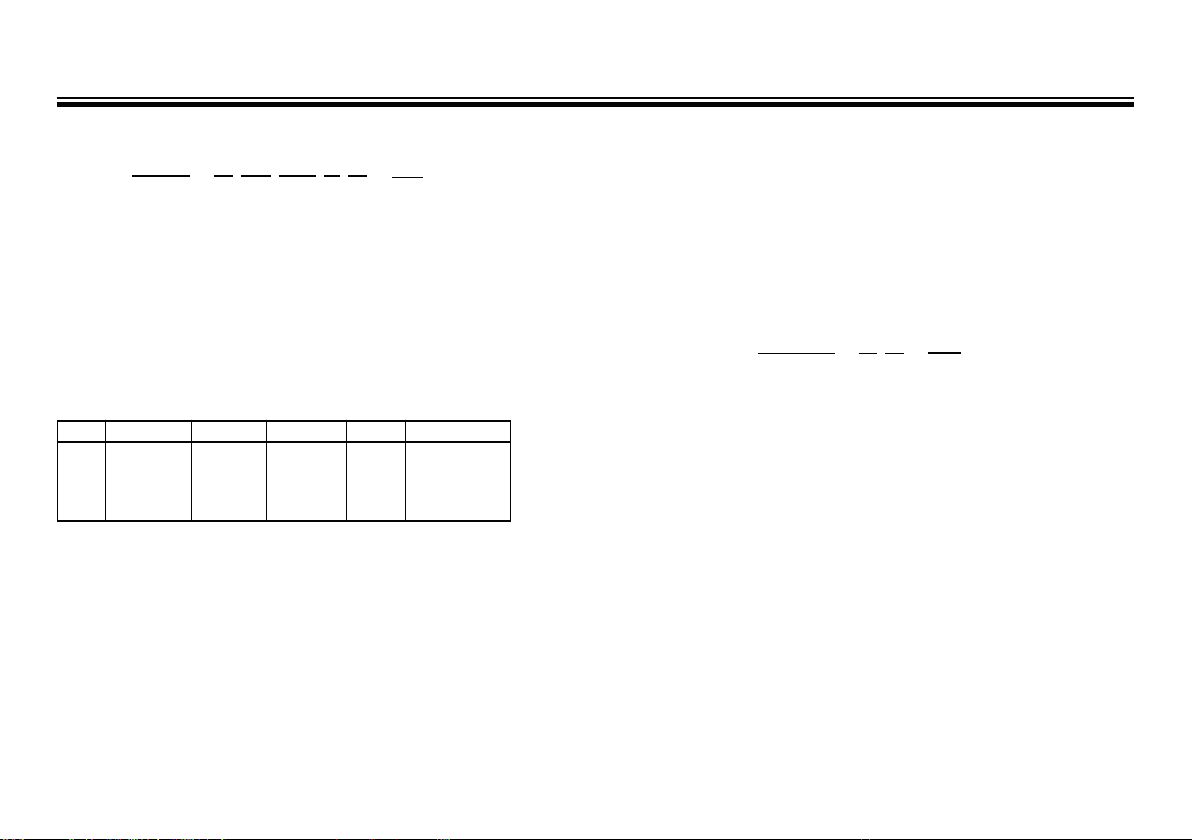

7-1. Overview of pump

Discharge port

Pump head

Bleed port

Be sure to connect

a tube and return it

to the suction

side tank.

Adjusting

screw

Suction port

Control unit

For the pump operation,

the flow rate adjustment

and the st roke rate

adjustment·setting.

Stroke length

adjustment

knob

Driving unit

Pay attention

to mounting

location.

Do not have

them wet.

Nameplate

Use the pump

according to the

specif ication on

the nameplate.

Base

Fix base with screws.

- 8 -

Outline of product

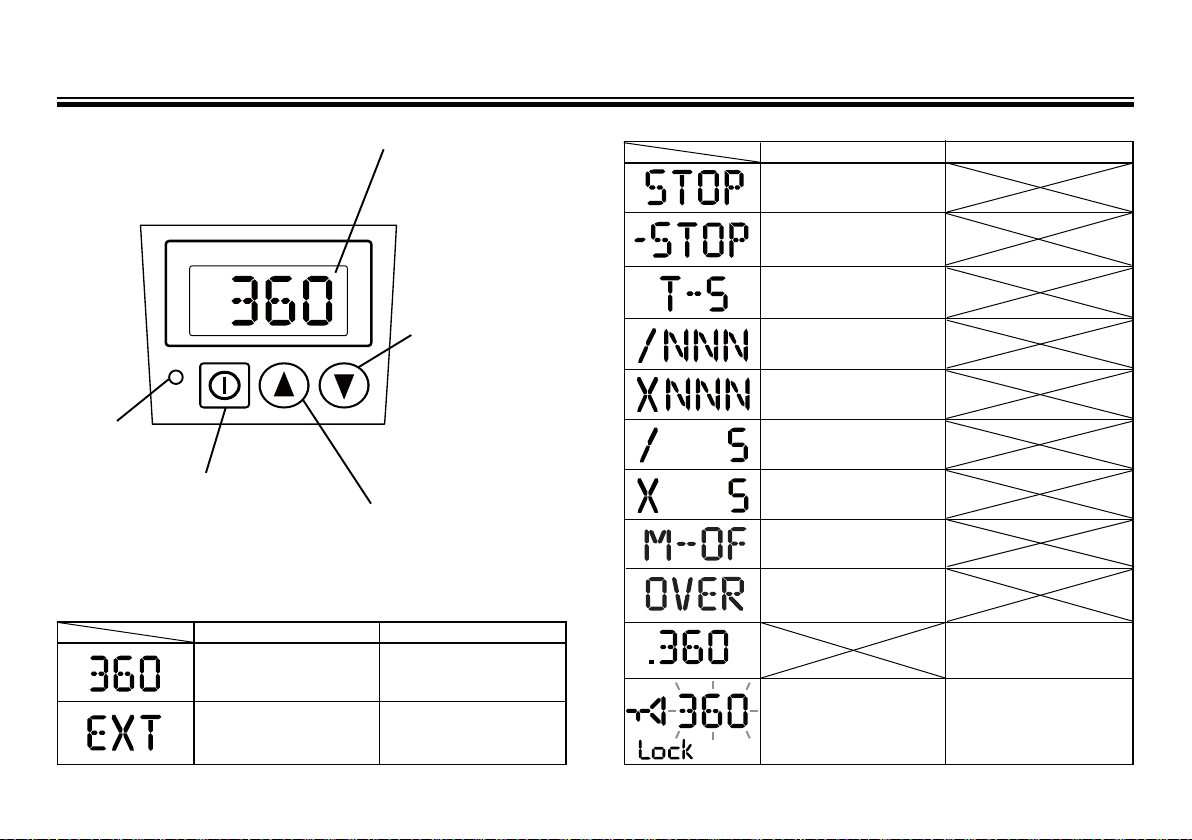

ON

STROKE RATE

Start/Stop key

Use this key to

start/stop the pump.

Down key

Pu sh t his key t o

ch ange mo de or

se tt ing val ue.

Display

Operation state or

ea ch setting value a re

displayed.

Up key

Pu sh t his key t o

ch ange mo de or

se tt ing val ue.

7-2. Overview of controller

ON lamp lights ON lamp blinks

The pump is waiting in

manual operation mode.

The pump is in E XT mode.

EXT setting can be done.

The pump is running in

manual operation mode. The

stroke rate blinks, too.

The pump is running in EXT

mode.

7-3. Basi c disp lay.

( )

- 9 -

ON lamp lights.

The pump is stopped by

STOP signal..

The pump is stopped in

manual waiting mode while

STOP signal comes.

Chattering is being set.

T-10 or T-50 is displayed

other than T-5.

Pulse dividing mode is

selected in EXT setting.

Pulse multiply mode is

selected in EXT setting.

The dividing ratio of EXT mode

is being set. The left display

shows 1 pum ping for 5 pulses .

The multiply ratio of EXT mode

is being set. The left display

shows 5 pumpings for a pulse.

STOP function is set to

M-OF. M-ON is displayed

when M- ON is selected.

EXT input signals exceed the

pump uppe r limit spm in EX T

mode. Pum p operates at its

upper limit spm.

Key is locked. Key operations are ineffective in this

state. Release the key lock

function before operation.

ON lamp blinks.

Pump is running in pulse dividing/multiply operation for external input pulses. The indication

shows spm .

Key is locked. Key operations are ineffective in this

state. Release the key lock

function before operation.

Installation

1. Before installation

"Strictly observe the following points."

Operators and maintenance service staff must read the instr uction

manual thoroughly before installing the products. Do not operate the

pump system unless all of the contents in this manual are completely

understood.

Warning

●

Turn off power

Working with power ON may cause an electrical shock. Before

working on the pump, make sure turn off main power.

●

Terminate operation

On detecting or becoming aware of any dangerous sign or abnor-

mal condition in operation, terminate the operation immediately

and start it from the beginning again.

●

Specified power only

Be sure to connect earth wire. Do not apply any power other than

specified power on nameplate.

●

Keep the pump away from heat or flame

Do not place any dangerous materials or flammable objects near

the pump for the prevention of fire or accident.

●

Damaged pump

Never operate any damaged pump. A damaged pump may cause

leakage or electrical shock.

2. Precaution on handling

●

Dropping the pump or subjecting

it to strong impacts may result in

faulty performance. Handle the

pump with care.

●

When installing the pump, avoid

places where...

• The pump is exposed to direct

sunlight or rain.

• Ambient temperature is 40 deg.

C or more.

• Relative humidity is 85% or

more.

Though the pump has a simple

waterproof and dustproof structure,

do not install it outdoor.

●

Select an installation site convenient

for future maintenance and inspection, and fix the pump on a flat

floor free of vibrations.

- 10 -

Installation

Prohibited

Prohibited

Benzine

Thinner

●

Ventilate.

Poisoning may result when

toxic or odorous liquid is used.

Ventilate the operating site sufficiently.

●

Do not wet or dampen.

If an electric part or wiring gets

wet with the liquid spilled over

accidentally, a fire or electrical

shock may be caused. Install

the system in a place free from

liquid spillage or leakage.

●

Install an earth leakage

breaker (option).

Pump operation without an

earth leakage breaker may lead

to an electrical shock. Purchase

an optional leakage breaker and

install in the system.

●

The control unit can be

detached, however, do not

detach it unless it is not

required. Never use the detached

control unit with other pump

models.

Caution

- 11 -

●

Grounding.

Risk of electrical shock. Do

not operate the pump without

grounding.

●

Limited operating site and

storage

Do not install or store the

pump in the following places:

• Flammable gas or material is

used or stored.

• Ambient temperature is

extremely high (40 deg.C or

higher) or extremely low (0

deg.C or lower).

• Under direct sunlight or

rainwater

• Relative humidity is 85% or

more.

●

Cleaning

Do not wipe the pump body

or the nameplate with a cloth

soaked with solvent such as

benzene, thinner, or kerosene.

Coating may be removed or

colour may be changed. Use

a dry cloth or a cloth soaked

with water or neutral detergent.

Installation

3. Installation

Caution

Detecting or becoming aware of a dangerous sign or abnor-

mal condition in operation, stop the operation and take the

procedure from the top.

●

Installation

Install the pump at a site where

ambient temperature does not

exceed 40 deg.C and relative

humidity does not exceed 85%.

(There should be no dew condensation in the control unit.)

The site must be selected keeping in mind ease and efficiency

for maintenance and inspection

work.

Do not expose the pump to

sunlight or rainwater. Cover the

pump when placing it outside.

●

Place the pump as close to the

suction tank as possible.

Caution

●

If the pump is used to feed any

liquid that generates air bubbles easily (Hydrazine solution,

etc.), it must be positioned in

a cool, dark place away from

direct sunlight.

When using a tank, realize a

flooded suction system.

●

Anchoring pump

Select a flat floor free of liquid

splash for installation of the

pump. Use M5 bolts to f irmly

anchor the pump so as not to

allow any vibration.

- 12 -

Installation

Fig.C

5m

Suction side tank

Discharge side tank

Bleed port

Check valve

OUT

IN

Fig.B

Discharge

Suction

Return the end

tube to a tank.

Adjusting screw

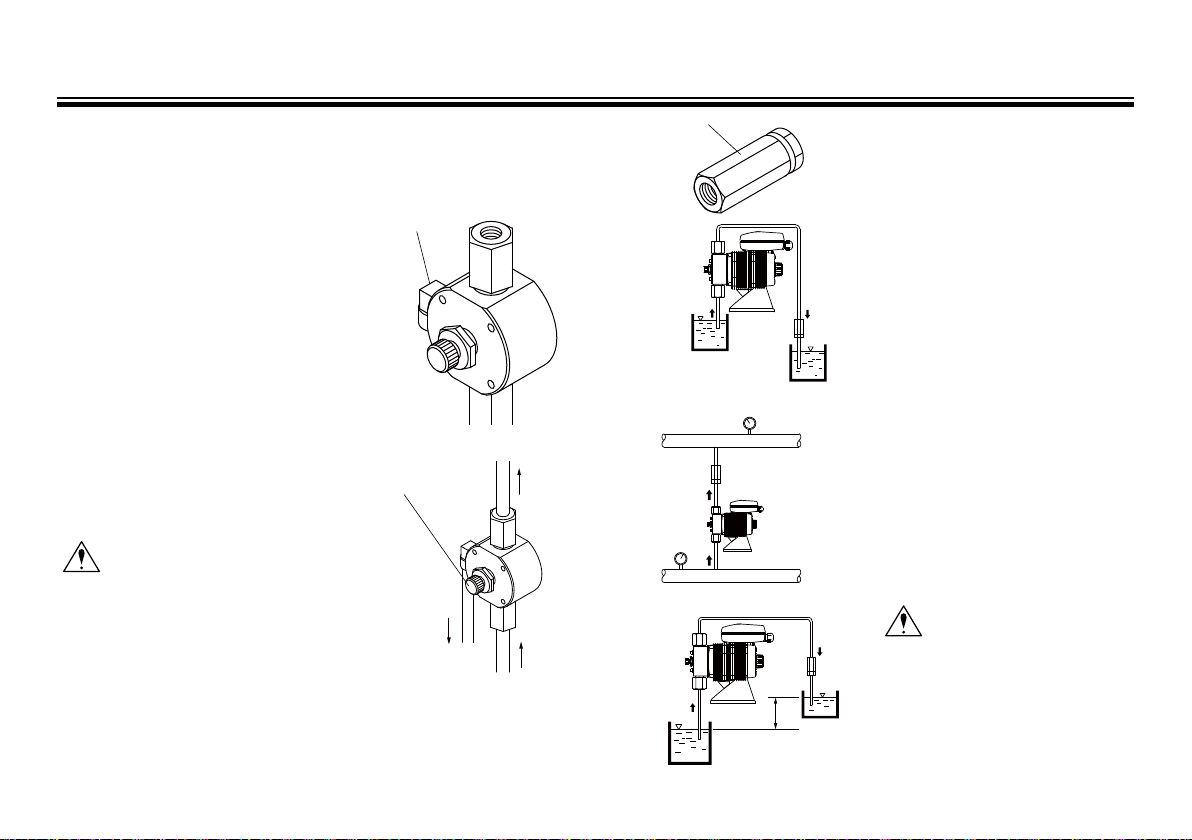

4. Tubing

1) Tape the air bleeding union

(Attached to the pump) and screw it

in the pump head.

2) Have the piping short and less

bends as much as possible to reduce

flow resistance.

3) The fitting bore is Rc1/4 female

thread. Be sure to connect each

connection on both suction/discharge piping to eliminate liquid/

air leakage.

4) Piping for air elimination.

Be sure to return the end of hose to

a tank or container after connecting a hose to the bleed port.

Caution

Regarding the SH type, discharge

pressure can not be fully opened

by the adjusting screw. Install a

discharge valve on discharge pipe

for opening pressure.

- 13 -

Suction side tank

Fig.A

5) Mounting check valve

A check valve is packed to

avoid over feeding. Be sure to

install the check valve in following condition.

a. Suction side liquid level is

higher than discharge side

liquid level. (See Fig. A)

Injection point is below

suction side liquid level at

atmospheric pressure.

Discharge side tank

b. Suction side pressure is

higher than that of injection

point. (See Fig. B.)

c. Difference of liquid level in

height is 5 meters or less,

even if discharge side liquid

level is higher than suction

side. (See Fig. C.)

Caution

Periodically wash or replace

the check valve with new one

because it may be clogged by

crystal.

Installation

Power

When power is charged at a setting When power is charged gradually

ON

OFF

Power

ON

OFF

d. Discharge pressure (Pipe

resistance, discharge head or

so) is below 0.13MPa. (Load

pressure is 0.049MPa for C36).

• The check valve should be

installed at discharge tube end at

least 1 meter away from pump.

5. Electrical wiring

Caution

Electrical works must be done by a qualified person. We are

not responsible for any injury and damage by any person

other than a qualified person,

5-1. Wiring of power source

1) Confirm that main power source is tur ned off before wiring.

2) Wiring must be done according to your electrical works standard

using good wiring equipment/device.

Caution

Power voltage should be charged at a sitting via switch or

relay. Otherwise malfunction of CPU may happen.

For selecting a relay, refer to P16 which mentions the precaution

when pump is controlled by relay ON/OFF.

- 14 -

Loading...

Loading...