Page 1

Installation Manual

Rego 5101

ok

6 720 641 739-37.1I

6 720 645 172 (2010/07) en

Page 2

Table of Contents

6 720 645 172 (2010/07) en

2

Table of Contents

1 Key to symbols and safety precautions . . . . . . . 3

1.1 Explanation of symbols . . . . . . . . . . . . . . . 3

1.2 Safety precautions . . . . . . . . . . . . . . . . . . 3

2 I/O connections . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Panel overview . . . . . . . . . . . . . . . . . . . . . 5

3.2 Status lamp . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 On/Off button . . . . . . . . . . . . . . . . . . . . . . 5

3.4 Menu display . . . . . . . . . . . . . . . . . . . . . . . 5

3.5 Return button . . . . . . . . . . . . . . . . . . . . . . 5

3.6 Navigation buttons . . . . . . . . . . . . . . . . . . 5

3.7 Alarm button . . . . . . . . . . . . . . . . . . . . . . . 5

3.8 Initial menu . . . . . . . . . . . . . . . . . . . . . . . . 6

3.9 Finding desired function and changing

values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.10 Operating information . . . . . . . . . . . . . . . . 8

3.11 Access levels . . . . . . . . . . . . . . . . . . . . . . . 9

4 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Communication . . . . . . . . . . . . . . . . . . . . 10

4.2 Settings\Addressing . . . . . . . . . . . . . . . . 11

4.3 Settings\Room temperature . . . . . . . . . . 11

4.4 Settings\Additional heat . . . . . . . . . . . . . 14

4.5 Settings\Hot water . . . . . . . . . . . . . . . . . 18

4.6 Settings\Accessories . . . . . . . . . . . . . . . . 21

4.7 Settings\Circulation pumps . . . . . . . . . . 24

4.8 Settings\Collector circuit . . . . . . . . . . . . 25

4.9 Settings\External control . . . . . . . . . . . . 25

4.10 Settings\General alarm . . . . . . . . . . . . . . 25

4.11 Settings\Inversions . . . . . . . . . . . . . . . . . 25

4.12 Settings\Sensor calibration . . . . . . . . . . 26

4.13 Function test . . . . . . . . . . . . . . . . . . . . . . 26

4.14 Quick restart . . . . . . . . . . . . . . . . . . . . . . 26

4.15 Read out . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.16 Quick log-out . . . . . . . . . . . . . . . . . . . . . . 27

4.17 Factory reset . . . . . . . . . . . . . . . . . . . . . . 28

5 Information/Alarms . . . . . . . . . . . . . . . . . . . . . 29

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2 Alarm categories . . . . . . . . . . . . . . . . . . . 29

5.3 Status lamp . . . . . . . . . . . . . . . . . . . . . . . 29

5.4 Alarm list and Alarm history . . . . . . . . . . 29

5.5 Acknowledgement of alarms . . . . . . . . . . 29

5.6 Alarm functions . . . . . . . . . . . . . . . . . . . . 30

5.7 Resistance table PT1000 temperature

sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Page 3

Key to symbols and safety precautions

6 720 645 172 (2010/07) en

3

1 Key to symbols and safety precautions

1.1 Explanation of symbols

Warnings

Signal words indicate the seriousness of the hazard in

terms of the consequences of not following the safety

instructions.

• NOTICE indicates possible damage to property or

equipment, but where there is no risk of injury.

• CAUTION indicates possible injury.

• WARNING indicates possible severe injury.

• DANGER indicates possible risk to life.

Important information

Additional symbols

1.2 Safety precautions

General

B Re ad t h e guide c are f u lly and kee p it t o hand fo r fu t u re

use.

Installation and commissioning

B The heat pump may be installed and put into

operation only by a qualified installer.

Risk of damage due to operator error

Operator errors can result in injury and damage to

property.

B Ensure that children never operate this appliance

unsupervised or play with it.

B Ensure that only personnel who can operate this

appliance correctly have access to it.

Service and maintenance

B Only qualified personnel may carry out repairs.

Incorrect repairs can lead to serious risks to the user,

and a reduction in savings.

B Only use original spare parts.

B Service and maintenance must be carried out annually

by an authorised service representative.

Safety instructions in this document are

framed and identified by a warning triangle

which is printed on a grey background.

Electrical hazards are identified by a

lightning symbol surrounded by a warning

triangle.

Notes contain important information in

cases where there is no risk of personal

injury or material losses and are identified

by the symbol shown on the left. They are

bordered by horizontal lines above and

below the text.

Symbol Meaning

B a step in an action sequence

Æ a reference to a related part in the

document or to other related documents

• a list entry

– a list entry (second level)

Tab. 1

Page 4

I/O connections

6 720 645 172 (2010/07) en

4

2 I/O connections

Temperature inputs PT1000 HP

Ai1 E11.T1 Flow E21

Ai2 E10.T2 Outdoor E21

Ai3 E4x.T3 Hot water E2x

Ai4 T6 Hot gas E2x

Ui1 T8 Heat transfer fluid

out (flow from heat

pump)

E2x

Ui2 T9 Heat transfer fluid

in (return to heat

pump)

E2x

Ui3 T10 Collector circuit in E2x

Ui4 T11 Collector circuit out E2x

Tab. 2 Temperature inputs PT1000

Potential-free, digital inputs 24Vac HP

Di1 IND/SSM

E11.G1

Signal circulation

pump heating

system

E21

Di2 B11 EVU / External

control

E2x

Di3 E71.E1.B31

E51.B11

E2.F21

Thermostat

Differential

pressure monitor

Additional heat

alarm

E21

Di4 E1 IND Operating reply

compressor

E2x

Di5 G2.F13 Motor cut-out heat

transfer fluid pump

E2x

Di6 G3.F13 Motor cut-out

collector circuit

pump

E2x

Di7 RLP Low pressure

switch

E2x

Di8 RHP High pressure

switch

E2x

Di7+

8

K11 Safety switch E2x

Tab. 3 Potential-free, digital inputs 24Vac

Analogue outputs 0-10Vdc HP

Ao1 E71.E1.Q71

E51.Q51

Additional heat

mixing valve,

heating system

E21

Ao2

Ao3

Ao4 G2 Heat carrier pump E2x

Ao5 G3 Collector circuit

pump

E2x

Tab. 4 Analogue outputs 0-10Vdc

Digital outputs 230Vac HP

Do1 E1 Compressor E2x

Do2 E71.E1

E2.E1

Start additional heat

Internal electric

additional heat stage

1

E2x

Do3 E2.E2 Internal electric

additional heat stage

2

E2x

Do4

E4x.Q1x

Q21

3-way valve hot water

External

Internal

E2x

Tab. 5 Digital outputs 230Vac

Digital outputs potential-free (inverted) HP

Do5 E11.G1 Circulation pump,

heating system

E21

Do6 E71.E1.G71

E31.G33

Circulation pump

mixed additional

heat

External collector

circuit pump

E21

E2x

Do7 P2 General alarm (A/

AB)

E2x

Tab. 6 Digital outputs potential-free (inverted)

Accessories Quantity HP

Mixing valve/Pool/Room

sensor (Multi-regulator)

0-9 E21

Tab. 7 Accessories

Page 5

Control panel

6 720 645 172 (2010/07) en

5

3 Control panel

Settings for the control of the heat pump are made with

the control unit's control panel, which also provides

information about current status.

Each heat pump is set using its control unit.

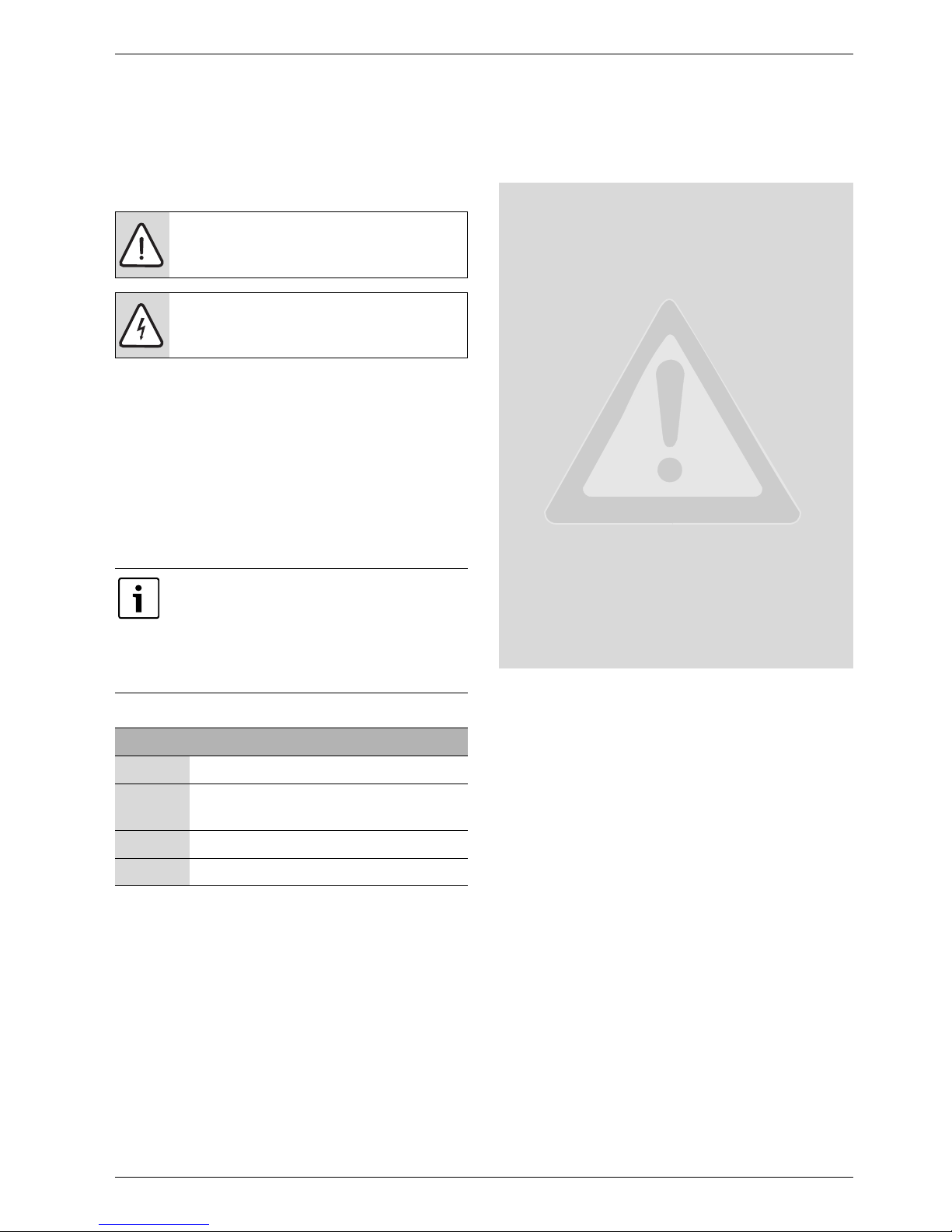

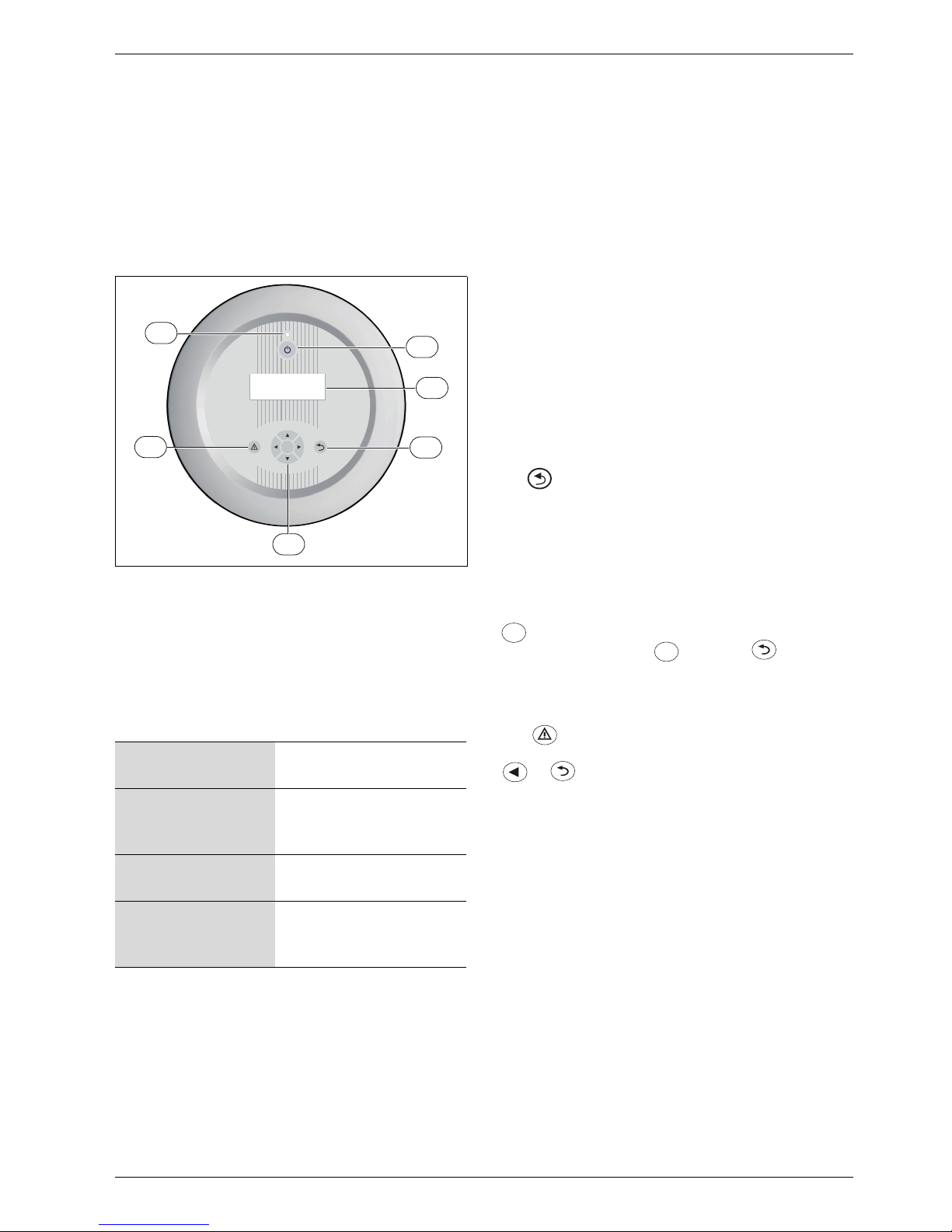

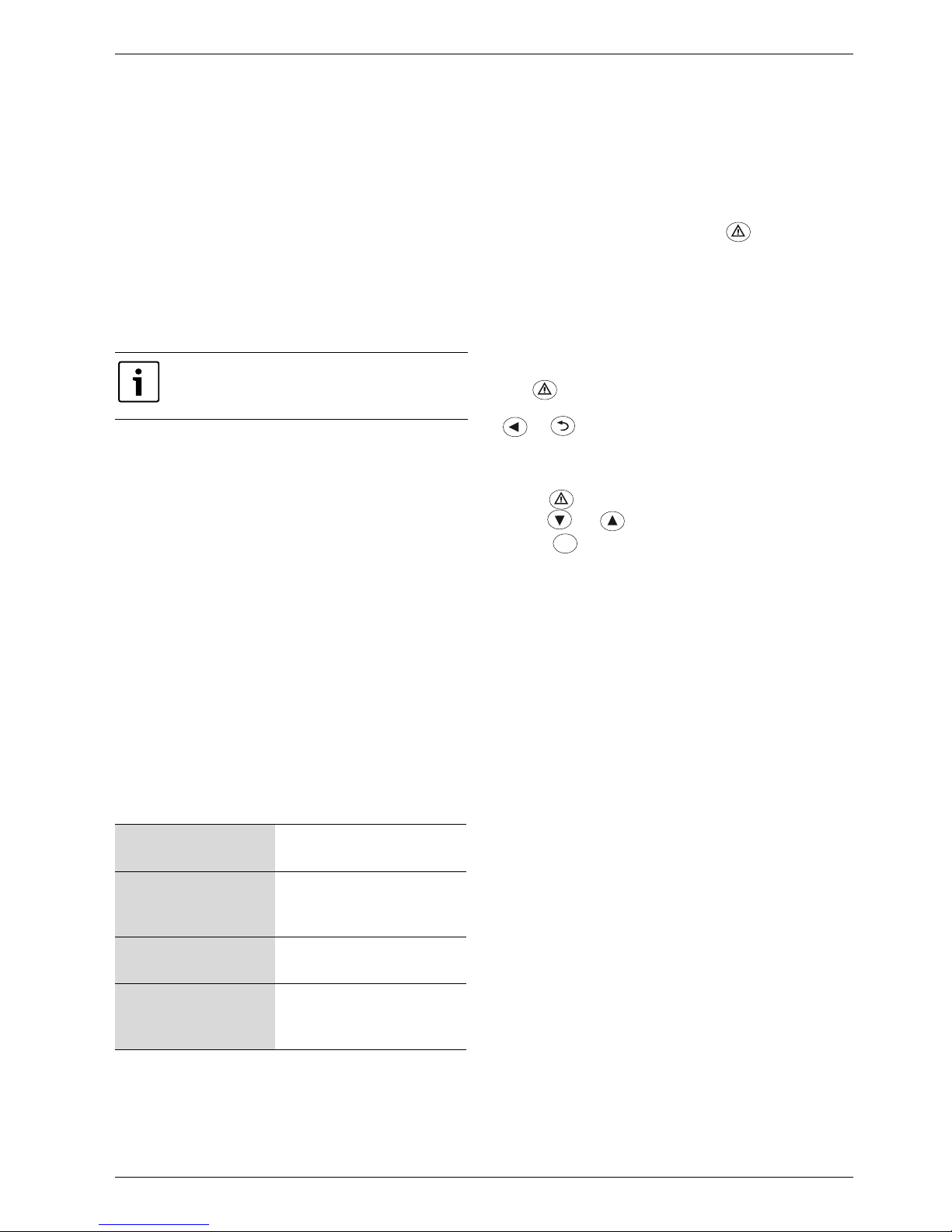

3.1 Panel overview

Fig. 1 Control panel

1 Status lamp

2 On/Off button

3 Menu display

4 Return button

5 Navigation buttons

6 Alarm button

3.2 Status lamp

The status lamp indications apply to the heat pump the

lamp is placed on.

3.3 On/Off button

Use the On/Off button to switch the heating installation

on and off.

When Off: The menu window shows Standby. The heat

system circulation pump E11.G1 keeps running.

Communication between the heat pumps is not

affected.

3.4 Menu display

Use the menu display in order to:

• See information from the heat pump.

• See available menus.

• Change set values.

3.5 Return button

Use to:

• Go back to the previous menu level.

• Leave a setting display without changing the set

value.

3.6 Navigation buttons

Use the arrows to navigate between the menus. Press

to initiate a value change, then use the arrows to

change the value. Press to save or to return

without saving.

3.7 Alarm button

Use to show the alarm list (status lamp lights/

flashes red). To return to the previous position, press

or .

Alarms activated in a certain pump are shown in the heat

pump in question.

The lamp lights green. The control unit is

activated.

The lamp flashes green

slowly.

The control unit is

switched off/stand-by

mode (Off).

The lamp flashes red. An alarm is active or has

not been acknowledged.

The lamp lights red. The alarm has been

acknowledged but the

alarm cause remains.

Tab. 8 Lamp functions

ok

3

4

2

1

5

6

6 720 641 739-06.1I

ok

ok

Page 6

Control panel

6 720 645 172 (2010/07) en

6

3.8 Initial menu

B To see the initial menu when the menu window is

unlit, press .

B Press for 5 seconds to become logged in as a

Customer (Æ Chapter 3.11, page 9).

The Initial menu shows the pump in question (E21),

date, time and outdoor temperature.

B Press to show the current operating information.

B Press to move to the top menu level (Customer).

The Initial menu looks the same in all heat pumps

irrespective of the heat pump's designation.

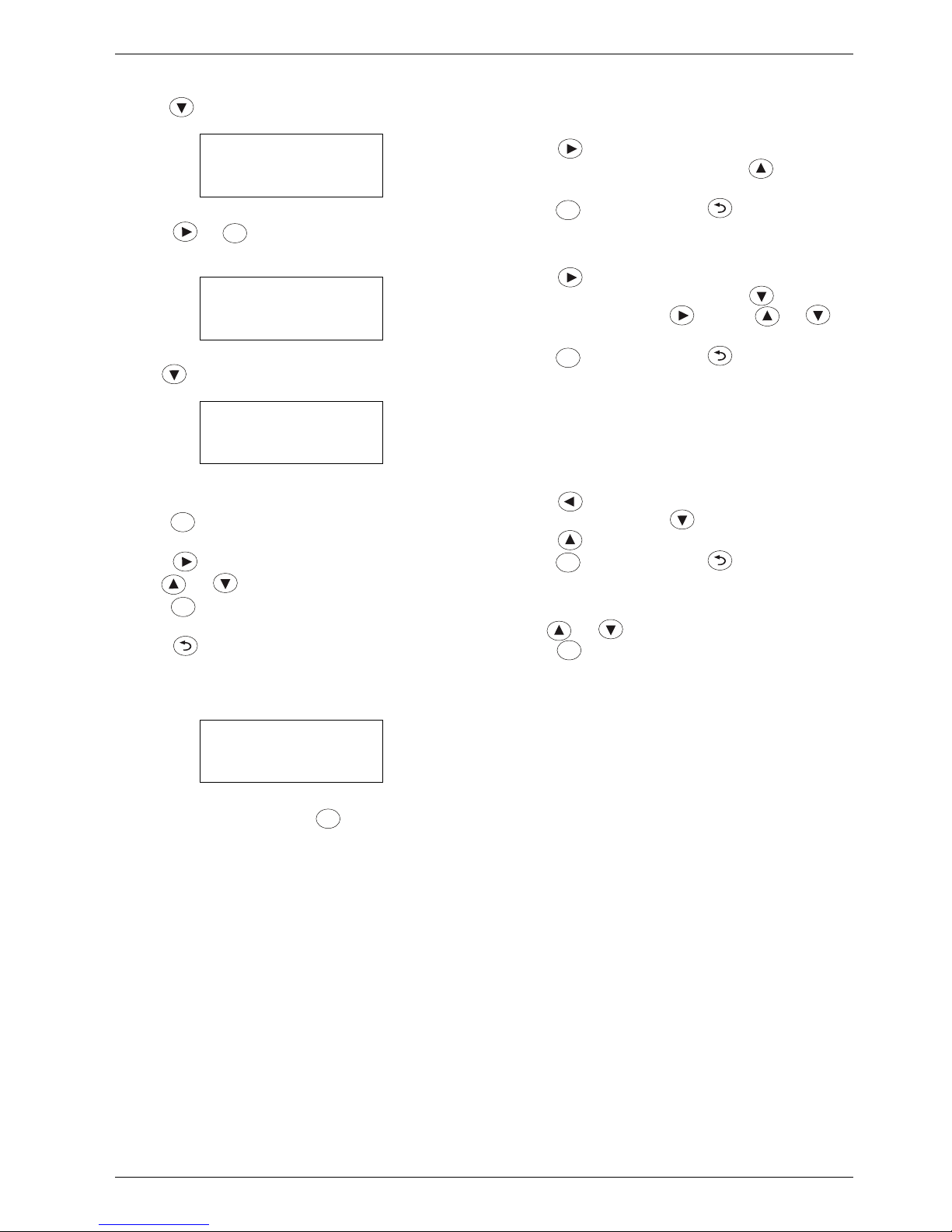

3.9 Finding desired function and changing

values

The menu overview shows the main functions that are

reached using the navigation buttons and .

B Press in the Initial menu to move to the top

menu level (Customer).

B Use and to scroll between the available

menus at menu level.

Navigate between the menus

Change a value, e.g. heat curve at 0 °C

The heat curve is only accessible in E21.

B Go to:

B Press or to go to the next menu under Room

temperature.

Rego 5101 E21

2010-03-01 14:23

Outd. -2:0 °C Menu>

Info

Tab. 9 Initial menu

ok

ok

>Room temperature

Hot water

Temperatures

Language

Tab. 10 Menu level 1 (part 1)

Language

Date/Time

>Access level

Tab. 11 Menu level 1 (part 2)

Button Function

Go to the next menu level for a menu

marked with >.

Return to the previous menu level.

Scroll between the menus at the same

level.

Tab. 12 Menu navigation

>Room temperature

Hot water

Temperatures

Language

Tab. 13 Menu level 1 (part 1)

>Summer/winter op.

Heat curve

Parallel offset

Hysteresis

Tab. 14 Room temperature 1

ok

ok

ok

Page 7

Control panel

6 720 645 172 (2010/07) en

7

B Press so that Heat curve is marked.

B Press or to go to the next menu level for

Heat curve.

B Use till the below is shown:

The value 35 ° shall be changed to 37 °.

B Press to come to the first adjustable value, which

is 3 in 35 °. The digit is marked and flashes.

B Press so that digit 5 in 35 ° is marked.

B Use or to change 5 to 7.

B Press to save the value. The cursor is now on the

next adjustable value in the window.

B Press one or more times to cancel an initiated

change.

After change to 37 ° the window looks like this:

Digit 3 in 38 ° is marked. Press to keep the value

and continue navigating.

Other ways of changing a value

Increase the number of digits in a value:

B Press so that the cursor is placed to the right of

the last digit in the value, and press until the

desired value is shown.

B Press to save the value or one or more times

to return without saving.

Place a decimal point in a value:

B Press so that the cursor is placed to the right of

the last digit in the value, and press . A decimal

point is included. Press and use or to

set the desired value for the decimal.

B Press to save the value or one or more times

to return without saving.

When the value has been saved, it can be presented

as a whole number, even though one or more

decimals have been added. The value in the control

unit is always the saved value.

Change to/from a negative value:

B Press to mark the position in front of the first

digit in the value. Press to include a minus sign,

press to remove a minus sign.

B Press to save the value or one or more times

to return without saving.

Change a text value:

B Use or to show the available alternatives.

Press when the desired value is displayed.

Summer/winter op.

>Heat curve

Parallel offset

Hysteresis

Tab. 15 Room temperature 2

Heat curve

Outd. Flow

20 ° 20 °

15 ° 24 °

Tab. 16 Heat curve 1

Heat curve

Outd. Flow

0 ° 35 °

-5 ° 38 °

Tab. 17 Heat curve 2

Heat curve

Outd. Flow

0 ° 37 °

-5 ° 38 °

Tab. 18 Heat curve 3

ok

ok

ok

ok

ok

ok

ok

ok

Page 8

Control panel

6 720 645 172 (2010/07) en

8

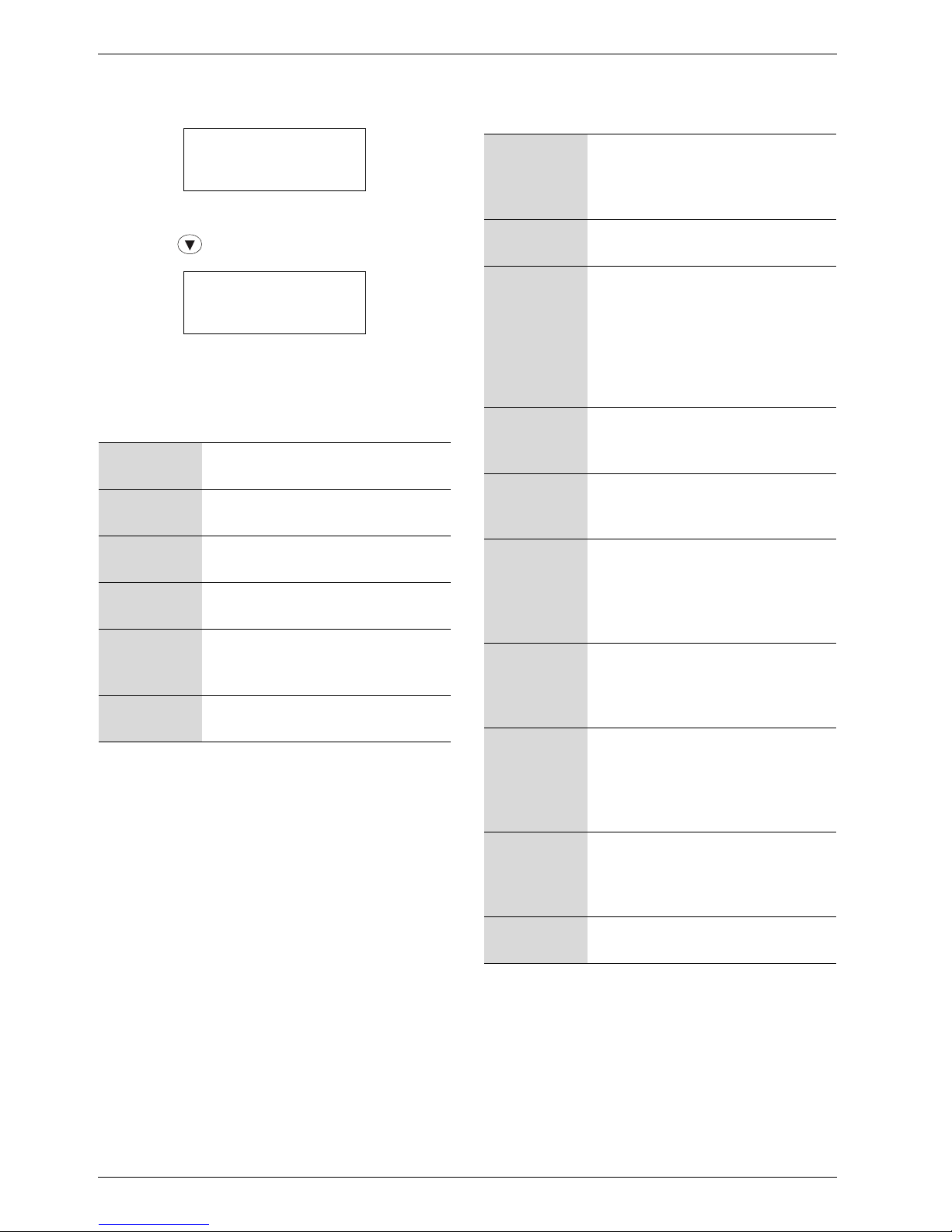

3.10 Operating information

Under Info there is operating information that is reached

by pressing in the initial menu.

Operating mode: Winter operation or Summer

operation.

Demand: Shows one of the following:

Status compressor: Shows one of the following:

Rego 5101 E21

2010-03-01 14:23

Outd. -2:0 °C Menu>

Info

Tab. 19 Initial menu

Operating mode

Demand

Status compr. Time

Tab. 20 Info 1

No demand No demand for heating, hot water or

external start of the compressor.

Heating

demand

Heating demand

Hot water

demand

Hot water demand

Therm.

disinfection

Thermal disinfection

External

operation

An external unit has demanded

operation of the heat pump,

compressor and/or additional heat.

Manual

operation

Function test underway.

Tab. 21 Need

Blocked The compressor is blocked by a

tripped safety function. Information

is stored in Alarm history available at

installer level.

External

blocking

The compressor is blocked via

external control.

Off The compressor is not running.

E11.G1 is running in case of winter

operation or anti-seizure operation.

Q21/E4x.Q1x is active in case of

emergency operation, summer or

anti-seizure operation. Additional

heat is not in operation.

Press. equal. The compressor restart timer is

counting down. The time remaining

in seconds is shown.

Start-up When a demand occurs, G2 and G3

start first and run for 30 seconds to

verify function.

Checking After start-up the temperatures T6,

T8, T9, T10, T11 are checked for 3

minutes to ensure that they can

manage the protection

temperatures.

Compressor The compressor starts. T6 must rise

to a minimum of 10K above T8

within 3 minutes, otherwise the

compressor stops.

Operation The compressor runs as long as the

demand remains or external start is

active. No safety functions have

tripped, and there is no external

stop.

Stopping The compressor has stopped in this

situation. G2 and G3 run for 2

minutes. The time remaining in

seconds is shown.

Oper.+

Add.heat

Both the compressor and the

additional heat are in operation.

Tab. 22 Status compressor

Page 9

Control panel

6 720 645 172 (2010/07) en

9

B Use for more information under Info.

Shows the actual value for a given sensor and the set

point for E11.T1.

Shows the actual value and stop temperature for the hot

water sensor as well as the mixing valve position. Is only

shown in heat pumps that produce hot water.

Shows the actual value for the given sensors.

0 = Off, 1 = On (Æ Chapter 2, page 4 for information on

I/O-connections).

Shows present utilisation in % (Æ Chapter 2, page 4 for

information on I/O-connections).

B Use several times to return to the Initial menu.

Information is also available at different places in the

menus, e.g. under Temperatures at the top menu level.

3.11 Access levels

Log in must be done per heat pump.

Log in as a customer:

B Press for 5 seconds in the Initial menu.

Log in as installer:

B Enter password mmdd under Access level.

mm = current month

dd = current day

E.g.: 0315 = 15th March.

Logging out:

B Use function Quick log-out on installer level or wait.

External sensors

E11.T1 35:2 °C

E11.T1 spv 36.2 °C

E10.T2 3.9 v °C

Tab. 23 External sensors 1

External sensors

E41.T3 56.4 °C

Stop 57.0 °C

E41.Q11 Off

Tab. 24 External sensor 2

Internal sensors

T6 87.0 ( °C)

T8 36.2 T10 5.0

T9 29.2 T11 2.0

Tab. 25 Internal sensors

Status digital I/O

vvvvv1 2 3 4 5 6 7 8

In: vv0 0 0 1 1 1 1 1

Out: 1 0 0 0 1 0 1

Tab. 26 Status digital I/O

Status analogue out

Ao1: 0.0 (%)

Ao2: 0.0 Ao4: 64:3

Ao3: 0.0 Ao5: 52.8

Tab. 27 Status analogue out

Program version

x.x– x– xx

Tab. 28 Program version

Not logged in See a small number of settings.

Customer See and change customer settings.

Logging out after 10 min.

Installer According to the Customer and see

and change more settings. Logging

out after 30 min.

Tab. 29 Access levels

ok

Page 10

Settings

6 720 645 172 (2010/07) en

10

4 Settings

After logging on as installer (Æ Chapter 3.11, page 9)

Installer is displayed directly under Access level on the

top menu level. Menu line Communication is displayed

before Access level.

Under Installer are the following main functions:

• Settings

• Function test

• Quick restart

• Read out

• Quick log-out

• Factory reset

All settings are made under Settings. This section

includes:

• Addressing

• Room temperature

• Additional heat

• Hot water

• Accessories

• Circulation pumps

• Collector circuit

• External control

• General alarm

• Inversions

• Sensor calibration

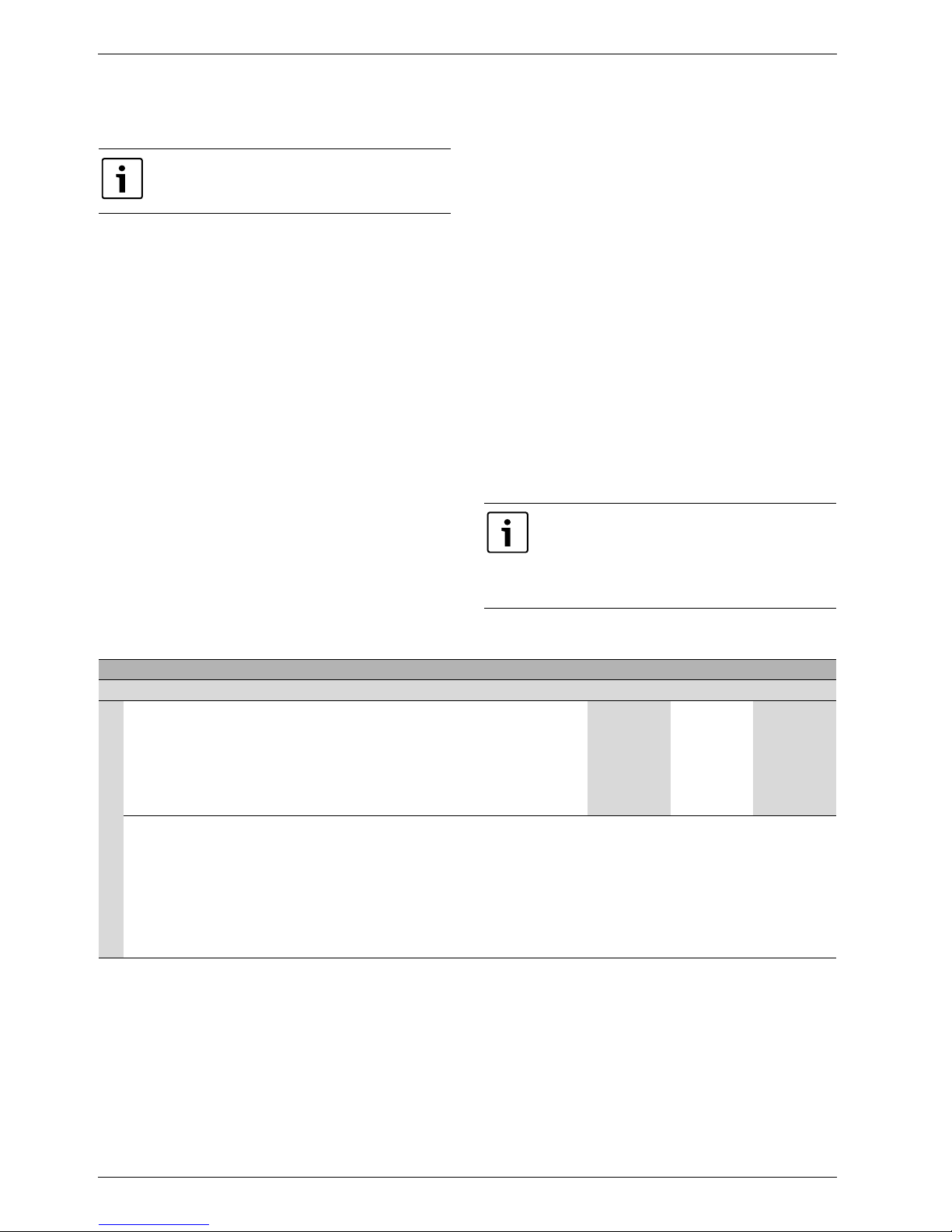

Menu tables

The available functions and settings are shown in the

following menu tables.

Factory: Pre-set values, most of which can be changed.

Range: Gives available setting alternatives or possible

value limitations.

HP: Gives the heat pump in which the function is

available.

4.1 Communication

Settings at customer level are in the User

Manual for Greenline HE.

Always set E21 first. Most settings are made

here because for example Additional heat

and accessories are connected to this heat

pump. The settings in E21 also affect other

heat pumps.

Setting Factory Range HP

Communication

Modbus server

Address:

Speed:

1,8,N,2

1

19200 bps

1-247

2400

4800

9600

19200

E2x

B Set the valid address for the heat pump. Each heat pump must have a unique address.

The function is used for monitoring/control from external equipment (3rd party). Data is retrieved separately from all units

that are to be monitored. The communication is Modbus/RTU, RS485.

Operation times, operating status, alarm status, temperatures, set point values, limit values etc are read off via

communication. The set point values can be changed and the heat pump can be force started and force stopped.

The settings do not affect the heat pump operation or cooperation.

Tab. 30 Communication

Page 11

Settings

6 720 645 172 (2010/07) en

11

4.2 Settings\Addressing

4.3 Settings\Room temperature

Setting Factory Range HP

Addressing

Heat pumps

Number:

This HP:

1

E21

1- 9

E21- E29

E21

E2x

B Set the number of heat pumps in E21.

B State the valid designation of the heat pump in each heat pump in accordance with the system drawing.

By setting Number and This HP all cooperation, addressing and port setting is arranged automatically.

Tab. 31 Addressing

Setting Factory Range HP

Room temperature

Summer/winter

op.

Summer operation

Start:

T2 >

in

17 °C

180 min

E21

Winter operation

T2 <

in

15 °C

300 min

E21

Winter operation

Direct start:

T2 < 7 °C

E21

B Set the outdoor temperature that is required for changeover to summer operation, and the delay

that applies.

B Set the outdoor temperature that is required for changeover to winter operation, and the delay

that applies.

B Set the outdoor temperature at which winter operation shall start directly, without a delay.

Delays prevent repeated stops and starts of the heating system circulation pump when the outdoor

temperature fluctuates above and below the limit.

Basic setting Basic setting

DOT

Min

Max

-35 °C

20 °C

60 °C

E21

The factory settings refer to radiator systems. For underfloor heating systems only, 35 °C is

recommended as the highest flow set point. Other applications may require other values.

B Set the minimum outdoor temperature for the heat curve (DOT), and the lowest and highest flow

temperature set points.

Heat curve E21

The flow temperature set points at different outdoor temperatures are automatically calculated using

the values in Basic setting, Æ Chapter 4.3.1 for example on heat curve for radiator systems and

underfloor systems. Values can be changed individually, for example adjusting the heat curve at 0 °C.

Parallel offset

Parallel offset 0 K E21

B Enter by how many degrees the flow temperature at the curve's outdoor temperatures shall be

adjusted down or up.

Tab. 32 Room temperature

Page 12

Settings

6 720 645 172 (2010/07) en

12

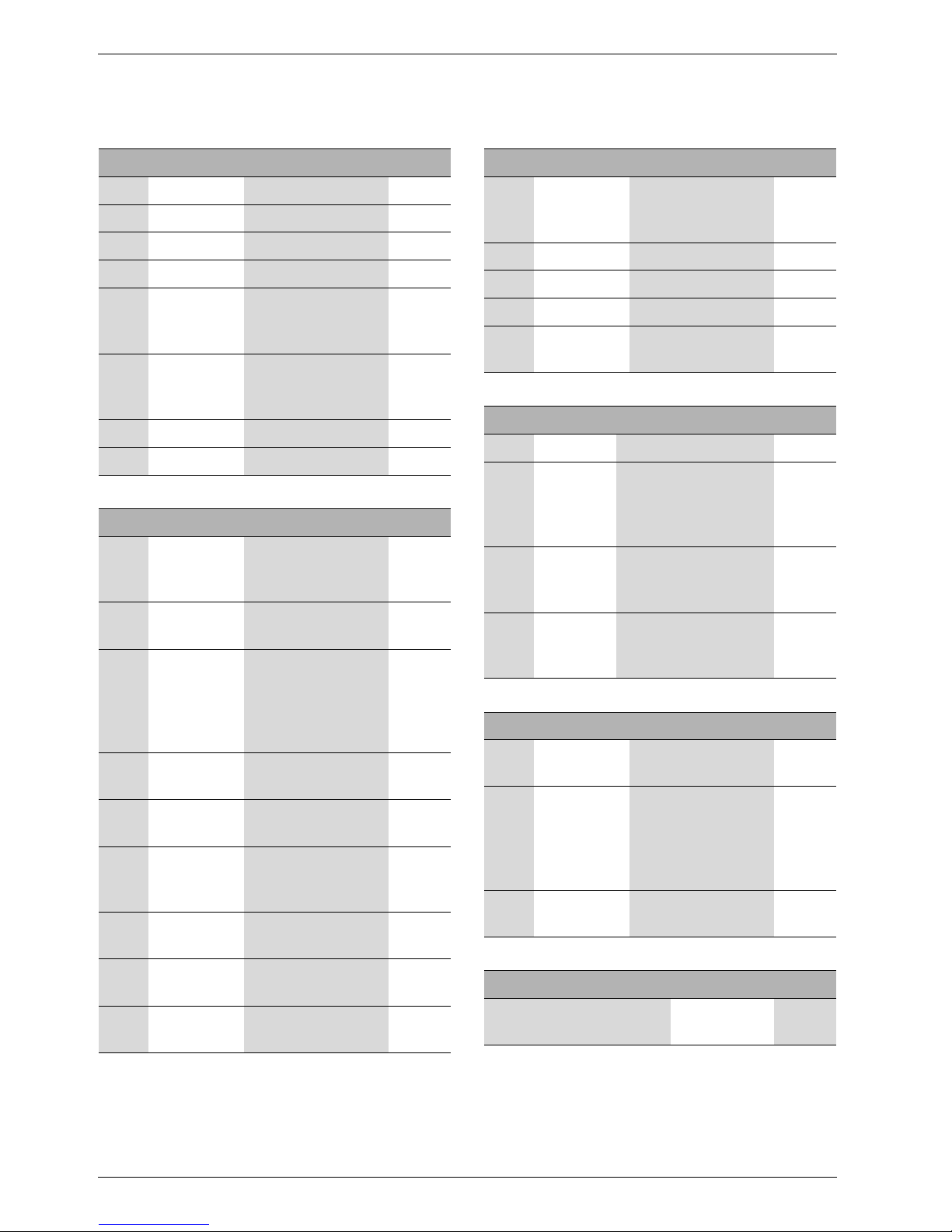

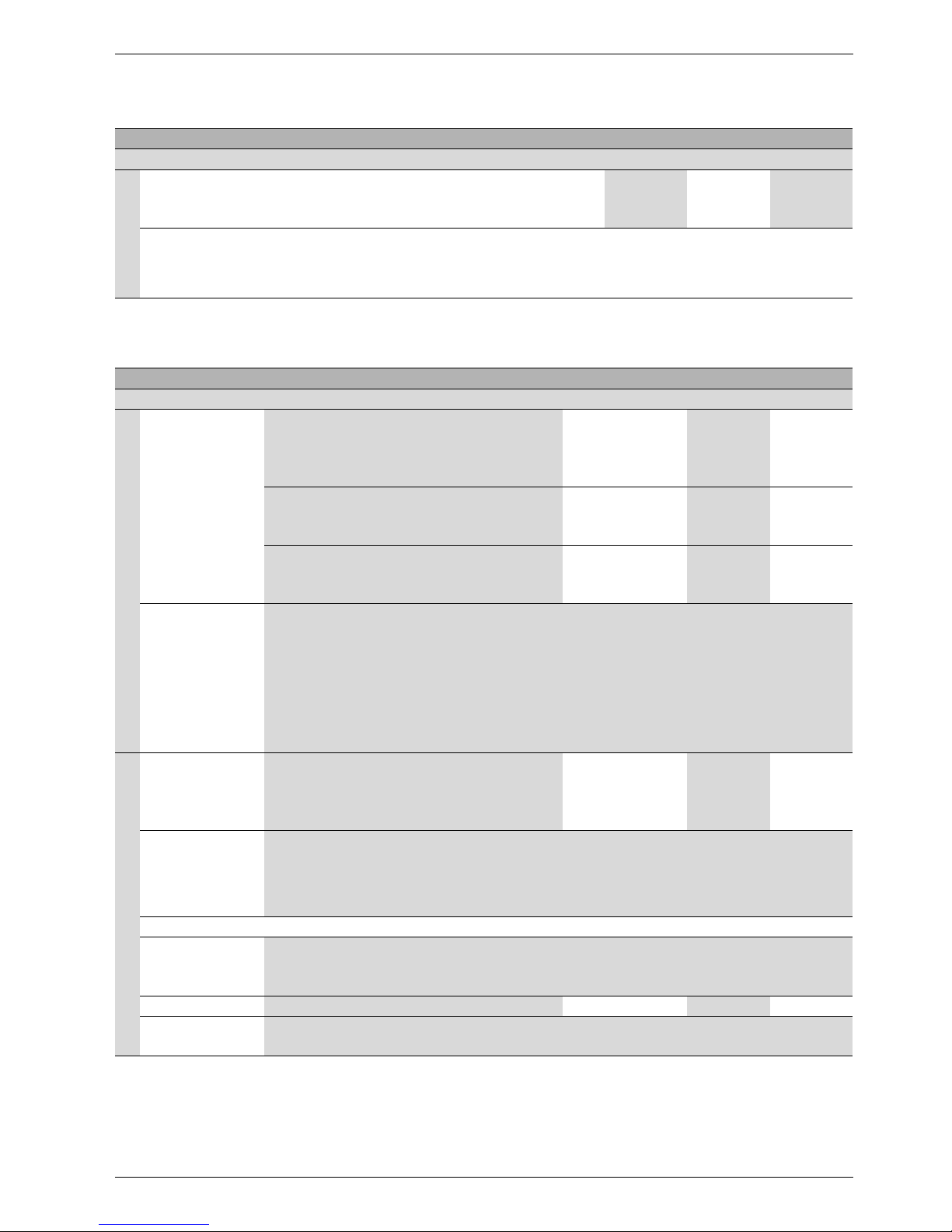

4.3.1 Heat curve

The heat pump operates by holding flow temperature

E11.T1 in relation to outdoor temperature E10.T2

according to the set heat curve.

The appearance of the heat curve depends on settings

for the minimum outdoor temperature (DOT, factory

setting -35 °C), lowest flow set point (factory setting

20 °C) and highest flow set point (60 °C). This heat

curve is appropriate for radiator systems.

Fig. 2 Radiator system

When the factory setting is changed, the heat curve is

redrawn automatically. Any adjustments to the curve

disappear.

The curve is set in E21 and applies to all heat pumps.

Example of a floor heating curve:

Fig. 3 Floor heating

Hysteresis Hysteresis

Min

Max

Time factor

2 K

8 K

30

E2x

Hysteresis

Actual v.

E11.T1

Set point

Display K

Display °C

Display °C

E2x

The factory settings refer to heating systems with normal flow. For low flow systems Min 3 K, Max 16

K is recommended. For high flow systems (floor heating) Min 1 K, Max 4 K is recommended.

B Set the minimum and maximum hysteresis and time factor for hysteresis reduction after start/stop.

Current hysteresis, as well as actual value and set point for E11.T1 are shown.

Attenuation

E10.T2

Attenuation E10.T2 2h E21

The function means that the set point for the flow temperature is successively adjusted with respect

to the set point at the current outdoor temperature. This reduces the effect of brief fluctuations in

outdoor temperature.

B Set the time for the flow temperature set point to reach the current curve value.

Deviation E11.T1

Deviation E11.T1 10 K E21

B Set how much lower/higher than the set point T1 must be for 30 min to give an alarm

(Æ Chapter 5.6.32, page 34).

Setting Factory Range HP

Tab. 32 Room temperature

6 720 614 789-15.3I

T

1(˚C)

T2(˚C)

20 15 10 5 0 -5 -10 -15 -20 -25 -30 -35

80

70

60

50

40

30

20

10

6 720 641 739-54.1I

T

1(˚C)

T2(˚C)

20 15 10 5 0 -5 -10 -15 -20 -25 -30 -35

80

70

60

50

40

30

20

10

Page 13

Settings

6 720 645 172 (2010/07) en

13

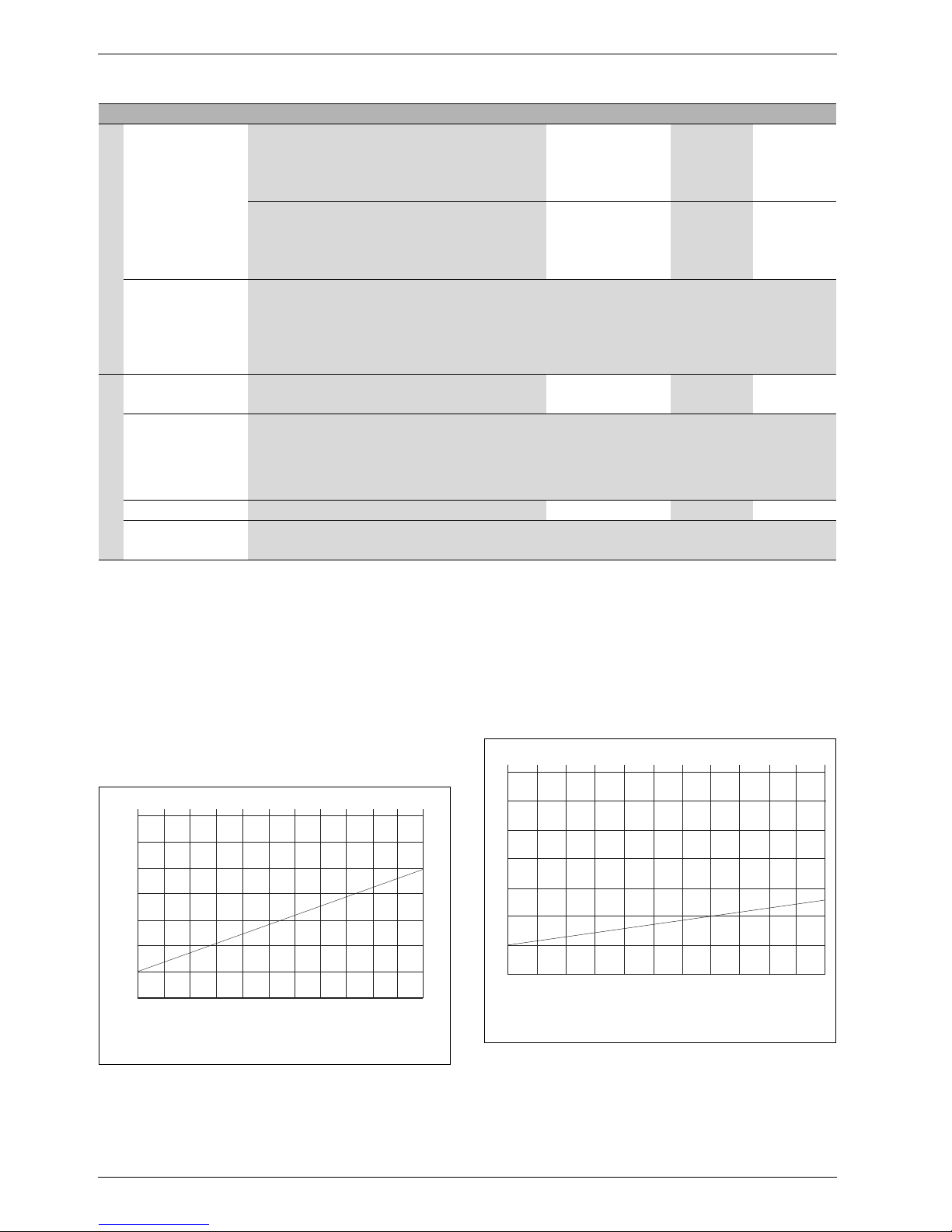

B Draw in your own curve:

Fig. 4 Own curve

4.3.2 Hysteresis

Hysteresis floats between a max value and a min value.

A time factor determines the time it takes to go from

maximum to minimum value.

The values are set in each heat pump. The current

hysteresis is calculated and displayed in each heat pump

as well as E11.T1's actual value and set point value. The

heat pump that has been out of operation the longest

starts first, that which has operated longest stops first.

4.3.3 Heating demand

The heating demand is activated in each heat pump

when E11.T1 falls below the heat curve set point with

current hysteresis. The heating demand is deactivated

when E11.T1 exceeds the set point with current

hysteresis.

Hot water mode and external control are superior

functions.

No heat is produced in summer operation, apart from for

a pool if applicable.

6 720 641 739-53.1I

T

1(˚C)

T2(˚C)

20 15 10 5 0 -5 -10 -15 -20 -25 -30 -35

80

70

60

50

40

30

20

10

Page 14

Settings

6 720 645 172 (2010/07) en

14

4.4 Settings\Additional heat

The tables display the settings for different types of

additional heat:

• Internal add. heat E2 (3 step)

• District heating E51

• Modulated add. heat E71

• Mixed add. heat E71

B Read more about additional heat (Æ Chapter 4.4.1 -

4.4.7).

Setting Factory Range HP

Additional heat

Additional heat type No additional heat

Comp. + add. heat

No additional heat

Internal add. heat

District heating

Modulated add. heat

Mixed add. heat

Only additional heat

Comp. + add. heat

Only compressor

E21

B Set applicable Additional heat type and desired additional heat operation. In Internal add.

heat is shown:

Settings

Start E2.E1

Hysteresis

Delay

Actual v.:

3 K

180 °min

Display, can be changed

E21

Start E2.E2

Delay

Actual v.:

60°min

Display, can be changed

Start E2.E3

Delay

Actual v.:

60°min

Display, can be changed

Stop E2.E1

Delay

Actual v.:

10°min

Display, can be changed

Stop E2.E2

Delay

Actual v.:

5°min

Display, can be changed

Stop E2.E3

Delay

Actual v.:

5°min

Display, can be changed

Settings

Max no. of steps in:

Heating:

Hot water:

2

2

0, 1, 2, 3

0, 1, 2, 3

B Set conditions for when respective stages must connect/disconnect.

B Set how many steps may be used as a maximum for heating mode and hot water mode.

ECO-drive

ECO-drive

Start

Stop after

No

22:00

6 hr

No, Yes

00:00 - 23:59

E21

B Indicate Yes if activation of the additional heat is to be delayed during a set time period.

The delay increases by 25% for the first stage.

Tab. 33 Internal electric additional heat

Page 15

Settings

6 720 645 172 (2010/07) en

15

Setting Factory Range HP

Additional heat

Additional heat type No additional heat

Comp. + add. heat

No additional heat

Internal add. heat

District heating

Modulated add. heat

Mixed add. heat

Only additional heat

Comp. + add. heat

Only compressor

E21

B Set applicable Additional heat type and desired additional heat operation. In District heating

is shown:

Settings

Start E51

Hysteresis

Delay

Actual v.:

3 K

180 °min

Display, can be changed

E21

Stop E51

Delay

Actual v.:

10°min

Display, can be changed

PID E51

P:

I:

D:

T1, Sp, Out

1

100

0

Display

B Set conditions for engaging/disengaging the additional heat.

B Set values for mixing valve control.

Actual and set point value for T1 is shown. In addition the output signal is shown in %.

ECO-drive

ECO-drive

Start

Stop after

No

22:00

6 hr

No, Yes

00:00 - 23:59

E21

B Indicate Yes if activation of the additional heat is to be delayed during a set time period.

The delay increases by 25%.

Tab. 34 Additional heat District heating

Page 16

Settings

6 720 645 172 (2010/07) en

16

4.4.1 Internal add. heat

The internal additional heat has three steps, E2.E1 (4.5

kW), E2.E2 (4.5 kW) and E2.E3 (6.75 kW). When all

stages are connected a total of 15.75 kW is obtained. A

degree minute calculation is used to activate each stage.

E2.E1: The compressor is running and E11.T1 does not

reach its set point value. Calculation of difference

between E11.T1 set point value – set Hysteresis (3 K)

and E11.T1 actual value are added continuously. When

the sum reaches the value set in Delay (180 °min) stage

1 is activated.

E2.E2: Stage 1 is connected and E11.T1 does not reach

its set point value. Calculation of difference between

E11.T1 set point value – set Hysteresis (3 K ) and E11.T1

actual value are added continuously. When the sum

reaches the value set in Delay (60 °min) stage 2 is

activated.

E2.E3: Stage 2 is connected and E11.T1 does not reach

its set point value. Calculation of difference between

E11.T1 set point value – set Hysteresis (3 K ) and E11.T1

actual value are added continuously. When the sum

Setting Factory Range HP

Additional heat

Additional heat type No additional heat

Comp. + add. heat

No additional heat

Internal add. heat

District heating

Modulated add. heat

Mixed add. heat

Only additional heat

Comp. + add. heat

Only compressor

E21

B Set applicable Additional heat type and desired additional heat operation. In Modulated add.

heat and Mixed add. heat is shown:

Settings

Start E71

Hysteresis

Delay

Actual v.:

3 K

180 °min

Display, can be changed

E21

Stop E71

Delay

Actual v.:

10°min

Display, can be changed

PID E71

P:

I:

D:

T1, Sp, Out

1

100

0

Display

B Set conditions for engaging/disengaging the additional heat.

B Set values for mixing valve control.

Actual and set point value for T1 is shown. In addition the output signal is shown in %.

Alarm delay

Alarm delay 30 min E21

The function is only displayed at Mixed add. heat.

B Set with what time alarm External add. heat out of order is to be delayed (Æ Chapter 5.6.25,

page 33).

ECO-drive

ECO-drive

Start

Stop after

No

22:00

6 hr

No, Yes

00:00 - 23:59

E21

B Indicate Yes if activation of the additional heat is to be delayed during a set time period.

The delay increases by 25%.

Tab. 35 Modulated additional heat, Mixed additional heat

Page 17

Settings

6 720 645 172 (2010/07) en

17

reaches the value set in Delay (60 °min) stage 3 is

activated.

Disconnection: Stage 3 is disconnected when the degree

minute calculation for the difference between E11.T1

actual value and E11.T1 set point value reaches the set

Delay (5 °min). The same applies to stage 2. Stage 1 is

disconnected when the degree minute calculation

reaches the set Delay (10 °min).

The additional heat demand ceases when all stages are

disconnected.

When the internal additional heat is activated the max

limit for T8 is increased to 75 °C. The limit is reset to

65 °C when the additional heat is disconnected.

4.4.2 Modulated add. heat E71

The external additional heat is controlled with 0-10V and

regulated using a PID regulator to maintain the E11.T1

set point value.

A degree minute calculation is used for connection/

disconnection.

Connection: E11.T1 does not reach its set point value.

Calculation of difference between E11.T1 set point

value – set Hysteresis (3 K) and E11.T1 actual value are

added continuously. When the sum reaches the value set

in Delay (180 °min) the additional heat is activated.

The output signal from the PID regulator controls how

much additional heat shall be produced.

Disconnection: The additional heat is disconnected

when the degree minute calculation for the difference

between E11.T1 actual value and E11.T1 set point value

reaches the set Delay (10 °min). The calculation starts

when the output signal from the PID regulator is 0.

4.4.3 Mixed add. heat E71

The external additional heat Q71 mixing valve is

controlled with 0-10V and regulated using a PID

regulator to maintain the E11.T1 set point value.

A degree minute calculation is used for connection/

disconnection.

Connection: E11.T1 does not reach its set point value.

Calculation of difference between E11.T1 set point

value – set Hysteresis (3 K) and E11.T1 actual value are

added continuously. When the sum reaches the value set

in Delay (180 °min) the additional heat is activated.

The additional heat and any internal circulation starts.

When the thermostat E71.E1.P111 acknowledges that

the additional heat has reached its operating

temperature mixing commences.

The output signal from the PID regulator controls how

much additional heat shall be produced.

Disconnection: The additional heat is disconnected

when the degree minute calculation for the difference

between E11.T1 actual value and E11.T1 set point value

reaches the set Delay (10 °min). The calculation starts

when the output signal from the PID regulator is 0.

4.4.4 District heating E51

Differential pressure switch E51.B11 at the district

heating heat exchanger must indicate the correct

direction of flow to permit opening of mixing valve Q51.

Q51 is controlled with 0-10V and regulated using a PID

regulator to maintain the E11.T1 set point value.

A degree minute calculation is used for connection/

disconnection.

Connection: E11.T1 does not reach its set point value.

Calculation of difference between E11.T1 set point

value – set Hysteresis (3 K) and E11.T1 actual value are

added continuously. When the sum reaches the value set

in Delay (180 °min) the additional heat is activated.

The output signal from the PID regulator controls how

much additional heat shall be produced.

Disconnection: The additional heat is disconnected

when the degree minute calculation for the difference

between E11.T1 actual value and E11.T1 set point value

reaches the set Delay (10 °min). The calculation starts

when the output signal from the PID regulator is 0.

4.4.5 Additional heat alarm

On alarm from the additional heat all degree minute

calculations are reset.

4.4.6 Additional heat operation

Normally Comp. + add. heat applies. When Only

additional heat is set the additional heat is activated

instead of the compressor during a heat demand.

In Internal add. heat the additional heat is also activated

during a hot water demand.

4.4.7 Hysteresis E11.T1

When an additional heat demand exists the hysteresis

for E11.T1 is held at its maximum.

4.4.8 PID regulator

P factor regulation is used.

Page 18

Settings

6 720 645 172 (2010/07) en

18

4.5 Settings\Hot water

Setting Factory Range HP

Hot water

Hot water type No hot water No hot water

Local sensor

Communicated

Previous HP

E2x

Not E21

When the heat pump is to produce hot water:

B Enter how the heat pump is to control hot water production.

B Select Local sensor when there is a locally connected hot water cylinder with local sensor to

measure the hot water temperature.

B Select Previous HP when the heat pump receives values for the hot water temperature from

the previous heat pump.

B Select Communicated when the heat pump has all information about the hot water

temperature and start/stop limits via communicating (Modbus) control (Æ Chapter 4.1,

page 10).

Temperatures

Actual v.:

Start:

Stop:

Max temperature:

Display

53 °C

57 °C

Display

E2x

B Set start and stop values for hot water production.

The factory settings refer to heat pumps with Local sensor. In Previous HP 2 K lower

temperatures are recommended. In Communicated the values have no meaning.

Max temperature displays the calculated possible highest hot water temperature.

Tab. 36 Hot water

Page 19

Settings

6 720 645 172 (2010/07) en

19

Settings

(Hot water type =

Local sensor)

Settings

Alarm setting

Alarm limit:

Delay

45 °C

30 min

E2x

B Set with what time alarm Low temperature T3 hot water is to be delayed (Æ Chapter 5.6.34,

page 34).

Settings

Valve:

Emergency operation:

External

No

External, Internal

No, Yes

E2x

B Enter type of three-way valve to get the correct designation in the control unit.

External = E4x.Q1x, Internal= Q21

B Indicate Yes if Emergency operation for hot water should be able to occur in event of

problems, Æ Chapter 4.5.3, page 20 for description of the function.

Settings

Monitor E11.T1:

Set point - T1 >

Delay

No

10 K

10 min

No, Yes

E2x

B Select Yes when the heat pump must monitor E11.T1 during hot water production.

B Enter the maximum number of degrees (K) the flow temperature T1 may be below its set point

value.

B Enter how long the flow temperature must be below the set limit before the heat pump

changes to heating mode.

At more than one heat pump all heat pumps except E21 switch to heating mode 2 degrees (K)

below E21's limit (10 K-2 K = 8 K at 10 K factory value ).

Settings

Heat protection:

T1 - Set point>

T1 increase >

No

10 K

15 K

No, Yes

E2x

B Select Yes when the heat pump must monitor E11.T1 during hot water production.

B Enter the maximum number of degrees (K) the flow temperature T1 may exceed its set point

value and how many degrees (K) T1 may increase during hot water production.

When both conditions are fulfilled the heat pump gives an alarm Problem with E4x.Q1x 3-way

valve or Problem with Q21 3-way valve (Æ Chapter 5.6.21, page 33).

Therm. disinfection

(Hot water type =

Local sensor)

Therm. disinfection

Day:

Start:

Number of steps:

No

02:00

1

No, Yes

None, Day, All

00:00 - 23.59

1, 2, 3

E21

B Select Yes if thermal disinfection is to occur. Indicate frequency and time of start.

B Select number of stages for the internal electric additional heat that is to be used by the

function.

The function can only occur in heat pumps with internal electric additional heat. It starts

according to settings and is active until T3 exceeds 70 °C or has operated for three hours. If

70 °C is not reached in that time an alarm is given Therm. disinfection unsuccessful

(Æ Chapter 5.6.43, page 35), and a new attempt is made on the next occasion.

TwinKick

(Hot water type =

Local sensor)

TwinKick No No, Yes E21

(installation

with 1 HP)

B Select Yes if the function should be active.

After heating mode a hot water demand is initiated if the hot water is lower than half the

difference to the stop limit. After hot water production a heating demand is initiated if the flow

temperature is lower than one degree below the set point value. Hysteresis is set to maximum.

Setting Factory Range HP

Tab. 36 Hot water

Page 20

Settings

6 720 645 172 (2010/07) en

20

4.5.1 Hot water temperatures

A start temperature and a stop temperature is set for

E4x.T3. If the sensor is local T9 is automatically set to

the same stop temperature in the heat pump.

Highest permitted stop temperature for hot water

decreases when T11 (heat transfer fluid out) in the heat

pump falls below - 2 °C. If necessary the control unit also

adjusts the start temperature so that it is below the stop

temperature by at least 2 K.

4.5.2 Hot water demand

Hot water demand arises when T3 falls below its start

temperature and ceases when T3 exceeds its stop

temperature. With a local sensor, T9 must also exceed

the stop limit.

4.5.3 Emergency operation, hot water

If the function is activated and local sensor T3 is not

working, hot water production is switched over to

emergency mode. 120 minutes after the previous hot

water production, the 3-way valve switches over to hot

water and a start signal is given to G2. This happens

whether the compressor is running or not. If T9 is below

the T3 start temperature, hot water demand is activated,

otherwise the 3-way valve changes back to its previous

position. The hot water demand ceases when T9

exceeds its and T3's joint stop temperature.

Page 21

Settings

6 720 645 172 (2010/07) en

21

4.6 Settings\Accessories

Accessory Multiregulator is used as a room sensor or a

mixing valve regulator. How the regulator is used in the

system is determined by selecting the function for each

accessory unit in the control unit. Accessory 1 must have

physical address 21, which is set in the unit during

installation. Accessory 2 must have physical address 22

etc.

B Set the physical address of the respective accessories

and connect the accessories before settings in the

control unit.

Setting Factory Range HP

Accessories

Accessories

Number:

Set unit

0

x

0-9

E21

B Set each accessory.

Accessories x

Select function:

Room sensor

Active room sensor

Fixed sp heating

Own heat curve

E11 heat curve

Fixed sp cooling

Pool

E21

B Select the correct function for each accessory installed.

B Use and to scroll through the settings.

In Room sensor Room sensor

Actual v.:

Display

E21

In Active room

sensor

Active room sensor

Actual v.:

Set point:

Average:

Display

22 °C

Display

E21

B Set the set point value for the room temperature.

With several active room sensors their average value is calculated and shown. This value together with

the factor set in Room temp. influence is used to affect E11.T1's heat curve.

In Fixed sp

heating

Fixed sp heating

Actual v.:

Set point:

Settings> Fixed sp heating

P:

I:

Deviation:

Pump:

Display

0°C

0

0

0 K

Off Winter, Summer, Off, On

E21

B Set the fixed set point value that must apply.

B Set appropriate values for P and I.

B Set the temperature deviation that shall cause an alarm Accessory x temp. deviation

(Æ Chapter 5.6.51, page 36).

B Enter pump function. Winter means that the accessory circulation pump is in operation during winter

operation.

The unit uses an externally connected sensor to control a 0-10V connected mixing valve to maintain

the stated fixed set point value.

Tab. 37 Accessory

Page 22

Settings

6 720 645 172 (2010/07) en

22

In Own heat

curve

Own heat curve

Actual v.:

Set point:

Settings> Own heat curve

P:

I:

Deviation:

Pump:

Display

0°C

0

0

0 K

Off Winter, Summer, Off, On

E21

B Set the heat curve that shall apply for the unit in Set point curve.

B Set appropriate values for P and I.

B Set the temperature deviation that shall cause an alarm Accessory x temp. deviation

(Æ Chapter 5.6.51, page 36).

B Enter pump function. Winter means that the accessory circulation pump is in operation during winter

operation.

The unit uses an externally connected sensor to control a 0-10V connected mixing valve to maintain

the set point value according to settings in Set point curve.

In E11 heat

curve

E11 heat curve

Actual v.:

Offset:

Settings> E11 heat curve

P:

I:

Deviation:

Pump:

Display

0 K

0

0

0 K

Off Winter, Summer, Off, On

E21

B Set appropriate values for P and I.

B Set the temperature deviation that shall cause an alarm Accessory x temp. deviation

(Æ Chapter 5.6.51, page 36).

B Enter pump function. Winter means that the accessory circulation pump is in operation during winter

operation.

The unit uses an externally connected sensor to control a 0-10V connected mixing valve to maintain

the set point value according to the heat curve for E11.T1.

In Fixed sp

cooling

Fixed sp cooling

Actual v.:

Set point:

Settings> Fixed sp cooling

P:

I:

Deviation:

Pump:

Display

0°C

0

0

0 K

Off Winter, Summer, Off, On

E21

B Set the fixed set point value that must apply.

B Set appropriate values for P and I.

B Set the temperature deviation that shall cause an alarm Accessory x temp. deviation

(Æ Chapter 5.6.51, page 36).

B Enter pump function. Summer means that the accessory circulation pump is in operation during

summer operation.

The unit uses an externally connected sensor to control a 0-10V connected mixing valve to maintain

the stated fixed set point value.

Setting Factory Range HP

Tab. 37 Accessory

Page 23

Settings

6 720 645 172 (2010/07) en

23

4.6.1 PI regulator

For accessories other than Room sensor or Active room

sensor the PI regulator for the mixing valve must be set.

P band regulation is used.

In Pool Pool

Actual v.:

Set point:

Settings> Pool

P:

I:

Deviation:

Pump:

Display

0°C

0

0

0 K

Off Winter, Summer, Off, On

E21

B Set the fixed set point value that must apply.

B Set appropriate values for P and I.

B Set the temperature deviation that shall cause an alarm Accessory x temp. deviation

(Æ Chapter 5.6.51, page 36).

B Enter pump function. Summer means that the accessory circulation pump is in operation during

summer operation.

The unit uses an externally connected sensor to control a 0-10V connected mixing valve to maintain

the stated fixed set point value.

In Own heat

curve

Set point curve E21

B Set the set point value for the circuit flow at different outdoor temperatures. For the heat curve's

lowest outdoor temperature DOT the same value as for E11's heat curve applies.

Room temp.

influence

Room temp. influence 00-10E21

Settings are shown if there is one or more active room sensors installed. With several room sensors,

comparison with the average of the sensor's actual values occurs.

B Set how much a one degree difference in room temperature (actual/average value compared to set

point) shall influence the flow temperature set point for E11.T1.

Example: At 2 K deviation from the set room temperature, the set point for the flow temperature is

changed by 6 K when the influence is set at factor 3. At 0, there is no influence.

Setting Factory Range HP

Tab. 37 Accessory

Page 24

Settings

6 720 645 172 (2010/07) en

24

4.7 Settings\Circulation pumps

Setting Factory Range HP

Circulation pumps

Settings E11.G1 Settings E11.G1

Alarm:

Operating mode:

SSM

Automatic

None, Oper. reply, SSM

Continuous, Automatic

E21

B Set if/how G1 should give an alarm in event of a problem. Alarm Operating error pump G1 can

occur when SSM or Oper. reply (Æ Chapter 5.6.27, page 34).

B Select if G1 should run in continuous or automatic operation.

In Automatic G1 runs in winter operation and is stationary in summer operation, except for

anti-seizure mode.

In the event of an operating fault in E11.G1 and all accessory pumps, all heat production stops

and alarm Oper. error all G1 (category A, Æ Chapter 5.6.1, page 30) is displayed. This alarm is

displayed also in the cases where there is only E11.G1 because all heat production stops.

Settings G2 Settings G2

At Regulating:

Set point T8-T9:

Heat:

DHW:

At Fixed speed:

Fixed speed:

Heat:

DHW:

Regulating

7 K

7 K

100%

100%

Regulating, Fixed speed

5-10 K

5-10 K

30-100%

30-100%

E2x

B Set how G2 should function.

B In Regulating: Set the temperature difference T8-T9 that the heat carrier pump must maintain

in heating mode and hot water mode respectively.

B In Fixed speed: Set the desired speed in %.

Settings G3 Settings G3

At Regulating:

Set point T10-T11:

At Fixed speed:

Fixed speed:

3 K

100%

Regulating, Fixed speed

2-6 K

30-100%

E2x

B Set how G3 should function.

B In Regulating: Set the temperature difference T10-T11 that the collector circuit pump must

maintain.

B In Fixed speed: Set the desired speed in %.

Settings Do6 Settings Do6

Pump function: None

None, E31.G33,

E71.E1.G71

E2x

E21

B Select the alternative applying to Do6 connection.

At E71.E1.G71: The pump starts at the same time as the mixed additional heat and continues for

2 minutes after the additional heat stop.

At E31.G33: The external collector circuit pump starts and stops at the same time as heat pump

collector circuit pump G3.

Tab. 38 Circulation pumps

Page 25

Settings

6 720 645 172 (2010/07) en

25

4.8 Settings\Collector circuit

4.9 Settings\External control

4.10 Settings\General alarm

4.11 Settings\Inversions

Setting Factory Range HP

Collector circuit

Collector circuit T10: Start

T10: Stop

T11: Start

T11: Stop

– 5 °C

– 8 °C

– 5 °C

– 8 °C

– 8 °C – +30 °C

– 8 °C – +30 °C

– 8 °C – +30 °C

– 8 °C – +30 °C

E2x

B Set the suitable values for collector circuit in (T10) and out (T11).

B For rock/earth – 5, – 8, – 5, – 8 °C (factory settings) are recommended.

B 1, 0, 0, – 3 °C is recommended for exhaust air.

B 4, 3, 3, 0 °C is recommended for groundwater.

Tab. 39 Collector circuit

Setting Factory Range HP

External control

External input B11

Select function:

Block all No effect

Block all

Block add. heat

Block compressor

Block hot water

Start comp+add.heat

Start compressor

E2x

B Select the function applicable for how the external input B11 (Di2) must affect the heat pump

when the input closes.

Tab. 40 External control

Setting Factory Range HP

General alarm

General alarm A/B alarm A/B alarm, A alarm E2x

B Select whether the general alarm output Do7 is to be activated for both A and B alarms or only

for A alarms.

Tab. 41 General alarm

Setting Factory Range HP

Inversions

Digital inputs

Di1

Di2

Di3

Normal

Normal

Normal

Normal, Inverted

Normal, Inverted

Normal, Inverted

E2x

B Select Inverted if the unit connected to the input requires it.

Tab. 42 Inversions

Page 26

Settings

6 720 645 172 (2010/07) en

26

4.12 Settings\Sensor calibration

4.13 Function test

4.14 Quick restart

Setting Factory Range HP

Sensor calibration

Sensor calibration

E11.T1

E10.T2

E4x.T3

0.000 K

0.000 K

0.000 K

E21

E21

E2x HW

B Check the sensors and adjust the measurement value if necessary.

Tab. 43 Sensor calibration

Setting Factory Range HP

Function test

Digital outputs Do1 – Do7

Function: Auto

Off, On, Auto

E2x

Analogue outputs

Ao1 – Ao5

Function:

Manual value:

Auto

%

Manual, Auto

E2x

B Function test all inputs and outputs in conjunction with commissioning.

B Set Auto after completed test.

Otherwise an alarm occurs Output in wrong pos after function test (Æ Chapter 5.6.30,

page 34).

The control unit gives a recommended setting for each output in brackets on the fourth line of the

menu window.

Tab. 44 Function test

Setting Factory Range HP

Quick restart

Quick restart

Actual v.:

No

Display

No, Yes E2x

B Select Yes if the restart time for the compressor is to be changed from 10 minutes to 20

seconds.

The time remaining in seconds is shown.

Yes can only be selected when the restart timer is counting at 10 minutes. After changing, the

value automatically resets to No.

Tab. 45 Quick restart

Page 27

Settings

6 720 645 172 (2010/07) en

27

4.15 Read out

4.16 Quick log-out

Read out/Setting HP

Read out

I/O-status Digital inputs E2x

B Read status of the inputs. Displayed as 0 (Off) or 1 (On).

Digital outputs E2x

B Read status of the outputs. Displayed as 0 (Off) or 1 (On).

Analogue inputs E2x

B Read temperatures for the inputs.

Analogue outputs E2x

B Read opening degree/speed in % for the outputs.

Temperatures Internal sensors E2x

B Read off temperatures for sensor T6, T8, T9, T10, T11.

External sensors E2x

B Read temperatures for sensor E11.T1, E10.T2, T3. The set point for E11.T1 and stop

temperature for T3, valve and valve operation mode are also shown.

Operating times Total E2x

B Read the total number of starts and hours for Compressor, Hot water, Winter operation,

Additional heat.

Additional heat is displayed in E21.

Short time E2x

B Read the number of starts and hours for Compressor, Hot water, Winter operation,

Additional heatfor the time after reset.

Additional heat is displayed in E21.

Alarm settings E2x

B Indicate Yesif short run time will be monitored for Heatingand/or Hot water.

Information alarm Short oper. time in heating modeand/or Short oper. time in hot water

modecan now perform (Æ Chapter 5.6.44, 5.6.45, page 35).

Logging Heating, Additional heat, Hot water, etc E2x

B Set a number of hours back in time and see the status/temperatures etc at that point in time.

The values are stored each whole hour and 168 hours (=1 week) are stored.

B Use and to scroll between the different windows.

Additional heat is displayed in E21.

Alarm history Alarm history E2x

B Read all alarms and information messages, the latest is shown first.

B Use and to browse to the required alarm.

The alarm history contains the most recent 20 messages.

Program version Program version E2x

B Read the current program version for the control unit.

Tab. 46 Reading

Setting Factory Range HP

Quick log-out

Quick log-out

Current level:

No

Display

No, Yes E2x

B Indicate Yes to log out and return to the initial menu.

Tab. 47 Quick log-out

Page 28

Settings

6 720 645 172 (2010/07) en

28

4.17 Factory reset

Setting Factory Range HP

Factory reset

Factory reset

Reset:

Confirm:

No

No

No, Yes

No, Yes

E2x

B Indicate Yes to reset all values to the factory setting. Customer settings can be affected if the

heat curve is changed by the reset (E21).

After Yes on Confirm and completed reset Completed is displayed.

Tab. 48 Factory reset

Page 29

Information/Alarms

6 720 645 172 (2010/07) en

29

5 Information/Alarms

5.1 General

The heat pump is equipped with several safety features,

which prevent problems and damage to the equipment.

These include temperature control and operation of

critical parts. In addition, anti-seizure operation of all

circulation pumps and 3-way valve Q21/E4x.Q1x occurs

for one minute if they have not been used for 7 days.

The heat pump reacts to operational disturbances by

providing information or giving an alarm.

5.2 Alarm categories

Some disturbances are more serious than others.

Alarms are therefore categorised.

C: Information that is acknowledged automatically when

the cause disappears. Disturbances are often temporary

and disappear of their own accord.

B: Action must be taken but can wait until normal

working hours. With some alarms, the operation of the

heat pump is restricted until the fault is rectified and the

alarm is acknowledged.

A: Must be rectified immediately to prevent damage to

the system/equipment.

5.3 Status lamp

The status lamp on the control unit is used to show ON/

OFF status for the heat pump but also to show possible

alarms.

With Information (category C) no indication is given.

5.4 Alarm list and Alarm history

When a disturbance occurs, a fault message is stored in

the alarm list and alarm history.

The alarm list is shown by pressing .

The alarm history is shown at installer level under Read

out.

The alarm history contains the last 20 or so alarms and

information messages; the most recent is shown first.

5.5 Acknowledgement of alarms

Use to show the alarm list (status lamp lights/

flashes red). To return to the previous position, press

or .

To acknowledge an alarm:

B Log in.

B Use to show the alarm list.

B Use and to browse to the required alarm.

B Press twice.

Acknowledged is shown in the alarm window and the

alarm is taken from the list when the cause is

remedied/disappears.

If the cause of the alarm disappears but the alarm is not

acknowledged Returned is shown in the alarm window.

Acknowledge the alarm and it is removed from the list.

A disturbance is indicated/stored/

remedied/acknowledged in the heat pump

where it occurred.

The lamp lights green. The control unit is

activated.

The lamp flashes green

slowly.

The control unit is

switched off/stand-by

mode (Off).

The lamp flashes red. An alarm is active or has

not been acknowledged.

The lamp lights red. The alarm has been

acknowledged but the

alarm cause remains.

Tab. 49 Lamp functions

ok

Page 30

Information/Alarms

6 720 645 172 (2010/07) en

30

5.6 Alarm functions

The different error messages that can occur are

presented here, the text and category is indicated in the

heading.

A and B alarms must always be acknowledged after the

cause is rectified in order to restart the heat pump. C

alarms are automatically acknowledged.

5.6.1 Oper. error all G1 (A)

Function: Compressor and additional heat stop.

Activated when all connected circulation pumps for

heating have stopped functioning. The alarm is also

given when E11.G1 is the only circulation pump for

heating and has stopped functioning. Risk of freezing

damage. In the control unit Settings E11.G1\Alarm

(Installer level ) must be set to Oper. reply or SSM in

order for the alarm to occur.

Heat pump: E21.

B Check the function of each pump.

B Check connections.

5.6.2 Oper. error compr. and add. heat (A)

Function: No operation response from the compressor.

Additional heat is not functioning. With internal electric

additional heat, the overheat protection has tripped.

With external additional heat, thermostat E71.E1.B31

has not given a signal within 30 minutes of additional

heat operation. Risk of freezing damage.

Heat pump: E21.

B Use the relevant wiring diagram for the heat pump

and follow the operation response signal from the

control unit via connected components.

B Identify where the signal is interrupted incorrectly.

B Check additional heat and overheat protection/

thermostat.

5.6.3 Failure on sensor T1 (B)

Function: The system switches over to control based on

sensor E21.T8. T1's temperature is given with NaN (Not

a Number) in the control unit.

Heat pump: E21.

B Check the installation of the sensor.

B Check the connection, measure the resistance and

compare with the resistance table.

B Replace the sensor if necessary.

5.6.4 Failure on sensor T2 (B)

Function: The outdoor temperature is set to 0 °C, which

means that the heat pump can continue to work, but

heat production is not correct at other outdoor

temperatures. The sensor's value is indicated with NaN

in the control unit.

Heat pump: E21.

B Check the installation of the sensor.

B Check the connection, measure the resistance and

compare with the resistance table.

B Replace the sensor if necessary.

5.6.5 Failure on sensor T3 (B)

Function: Hot water production switches to emergency

operation mode if the heat pump is set for Emergency

operation. The sensor's value is indicated with NaN in

the control unit.

Emergency operation-description (

Æ Chapter 4.5,

page 18).

Heat pump: Heat pump with T3 as local sensor.

B Check that Hot water typeis correctly set in the

control unit.

B Check the installation of the sensor.

B Check the connection, measure the resistance and

compare with the resistance table.

B Replace the sensor if necessary.

5.6.6 Failure on sensor T6 (B)

Function: The compressor is stopped. E21: Additional

heat permitted to start. The sensor's value is indicated

with NaN in the control unit.

Heat pump: All.

B Check the installation of the sensor.

B Check the connection, measure the resistance and

compare with the resistance table.

B Replace the sensor if necessary.

5.6.7 Failure on sensor T8 (B)

Failure on sensor T9 (B)

Function: The sensor's value is indicated with NaN in the

control unit.

Heat pump: All.

B Check the installation of the sensor.

B Check the connection, measure the resistance and

compare with the resistance table.

B Replace the sensor if necessary.

Page 31

Information/Alarms

6 720 645 172 (2010/07) en

31

5.6.8 Failure on sensor T10 (B)

Failure on sensor T11 (B)

Function: The sensor's value is indicated with NaN in the

control unit.

Heat pump: All.

B Check the installation of the sensor.

B Check the connection, measure the resistance and

compare with the resistance table.

B Replace the sensor if necessary.

5.6.9 Operating error compressor (B)

Function: No operation response from the compressor.

E21: Additional heat permitted to start.

Heat pump: All.

B Use the relevant wiring diagram for the heat pump

and follow the operation response signal from the

control unit via connected components.

B Identify where the signal is interrupted incorrectly.

5.6.10 Operating error add. heat (B)

Function: With internal electric additional heat, the

overheat protection has tripped. With external

additional heat, thermostat E71.E1.B31 has not given a

signal within 30 minutes of additional heat operation.

Heat pump: E21.

B Check additional heat and overheat protection/

thermostat.

5.6.11 Operating error pump G2 (B)

Operating error pump G3 (B)

Function: The compressor is stopped. Activated when

the SSM signal from the circulation pump has been

broken for more than 3 minutes. E21: Internal electric

additional heat is permitted to start at operating error

G3.

Heat pump: All.

B Interrupt the current for at least 5 seconds to reset

the alarms (Æ Chapter Resetting the pump alarm in

the installation guide for the heat pump).

B Check that the circulation pump can operate.

B Check the connection for the 0-10V signal.

B Vent the heating system if necessary.

5.6.12 High temp. T6 hot gas (B)

Function: The compressor is stopped because T6 shows

more than 125 °C. Restart is permitted when T6 shows

less than 115 °C. E21: Additional heat permitted to start.

Activated when the corresponding category C-alarm has

occurred more than once during the last 120 minutes.

Heat pump: All.

B Check that the sensor shows a reasonable value.

B Check the connection, measure the resistance and

compare with the resistance table.

B At correct sensor, check that the refrigerant circuit

can dispose of the heat.

5.6.13 Tripped high pressure switch (B)

Function: The compressor is stopped. E21: Additional

heat permitted to start.

Activated when the corresponding category C-alarm has

occurred more than once during the last 120 minutes.

The alarm can also be caused by a faulty system

configuration.

Heat pump: All.

B Check the particle filter and clean if necessary.

B Check the valves.

B Check the heating system pressure, vent if necessary.

B

Check the flow over the condenser.

B Check the pressure switch and its connections.

B Check heat carrier pump G2.

B Ensure that there is no risk of large sudden

temperature increases across the heat pump.

Page 32

Information/Alarms

6 720 645 172 (2010/07) en

32

5.6.14 Tripped low pressure switch (B)

Function: The compressor is stopped. E21: Additional

heat permitted to start.

Activated when the corresponding category C-alarm has

occurred more than once during the last 120 minutes.

Heat pump: All.

B Check the particle filter and clean if necessary.

B Check the valves.

B Check the collector circuit pressure, vent if

necessary.

B Check the flow over the evaporator.

B Check the pressure switch and its connections.

B Check collector circuit pump G3.

5.6.15 High temperature T8 (B)

High temperature T9 (B)

Function: The compressor is stopped. E21: Additional

heat permitted to start.

Activated when the corresponding category C-alarm has

occurred more than once during the last 120 minutes.

T8 > 65 °C and T9 > 59 °C give alarm. Restart at 57 °C.

Heat pump: All.

B Check the particle filter and clean if necessary.

B Check the valves and pipe installation.

B Check that the sensor shows correct temperature,

compare with resistance table.

5.6.16 Low temperature T10 (B)

Low temperature T11 (B)

Function: The compressor is stopped. E21: Additional

heat permitted to start.

Activated when the corresponding category C-alarm has

occurred more than once during the last 120 minutes.

Limit values for alarms are set under Settings\Collector

circuit, factory setting -8 °C (Æ Table 39, page 25).

Restart at -5 °C.

Heat pump: All.

B Check the energy source and its temperature.

B Check the collector circuit.

B Check the particle filter and clean if necessary.

B Check the valves and any distributors.

B Check that the sensor shows correct temperature,

compare with resistance table.

5.6.17 Communication error with E2x (B)

Function: E21 has lost contact with the stated heat

pump.

Heat pump: E21.

B Check the setting for the number of heat pumps

(Æ Table 31, page 11).

B Check the addressing in the stated heat pump

(Æ Table 31, page 11), and the connections between

E21 and the stated heat pump.

B Check the communication cable regarding laying (at

least 100 mm distance to power cables) and any

damage.

B Terminate communication cable at each end as

necessary (use a resistor of 120 Ω, 0.5 W).

5.6.18 Communication error with E21 (B)

Function: The heat pump has lost contact with E21.

Heat pump: All except E21.

B Check that the communication in E21 and the relevant

heat pump is working.

B Check the addressing in the stated heat pump

(Æ Table 31, page 11), and the connections between

E21 and the stated heat pump.

B Check the communication cable regarding laying (at

least 100 mm distance to power cables) and any

damage.

B Terminate communication cable at each end as

necessary (use a resistor of 120 Ω, 0.5 W).

NOTICE: Acknowledgement of pressure

switch alarm without rectifying the fault

results in repeated attempts to start the

compressor. Many start attempts, when

there is no circulation in the refrigerant

circuit, can cause the evaporator to freeze.

At least 24 hours non operation is required

for it to thaw out. It may even be necessary

to replace the evaporator.

B Remedy cause of fault before

acknowledging.

Page 33

Information/Alarms

6 720 645 172 (2010/07) en

33

5.6.19 Communication error with accessory x (B)

Function: E21 has lost contact with the stated

accessory.

Heat pump: E21.

B Check the physical address of the accessory.

B Check the settings for the accessory in E21

(Æ Table 37, page 21).

B Check the connections between E21 and the

accessory.

B Check the communication cable regarding laying (at

least 100 mm distance to power cables) and any

damage.

B Check the power supply.

B Terminate communication cable at each end as

necessary (use a resistor of 120 Ω, 0.5 W).

5.6.20 Problem with hot water production (B)

Function: During previous hot water production, T3 was

still below its start limit when T9 interrupted production

because of risk of High temperature T9. Hot water

production is stopped. The alarm cannot appear if

Failure on sensor T3 is present. Automatic resetting

occurs at midnight.

Heat pump: Heat pump with T3 as local sensor.

B Check the hot water system.

B Check that T3 and T9 show correct temperature,

compare with resistance table.

B Check that the installation is correctly dimensioned.

5.6.21 Problem with Q21 3-way valve (B)

Problem with E4x.Q1x 3-way valve (B)

Function: Hot water production stops because E11.T1 is

10 K above the set point and has increased by 15 K

during hot water mode

The values can be set in Installer level under Hot

water\Settings\Heat protection.

Heat pump: Heat pump with T3 as local sensor.

B Check that the valve can operate and is correctly

connected.

B Check that the system is correctly connected.

B Check that the valve does not leak.

B Check that E11. T1 shows correct temperature,

compare with resistance table.

5.6.22 Start-up attempt interrupted (B)

Function: At compressor start the temperatures and

pressure switches are checked. When one of these is not

approved by the control unit the start attempt is

cancelled. A new start attempt occurs after 20 min if a

demand arises.

Activated when the corresponding category C-alarm has

occurred more than once during the last 120 minutes.

Heat pump: All.

B Check the cause using the temperature log and alarm

history (Æ Table 46, page 27).

5.6.23 Check phase sequence and T6 (B)

Function: The compressor is stopped. Activated if the

hot gas temperature T6 does not exceed T8 heat transfer

fluid out by 10 K within 3 min of compressor start. E21:

Additional heat permitted to start.

Heat pump: All.

At commissioning/During operation:

B Check the direction of rotation of the compressor.

B Check the incoming phase sequence.

B Check that sensors T6 and T8 show the correct

temperature, compare with resistance table.

B Check the connections to the sensors.

B Check the refrigerant circuit.

5.6.24 Internal add. heat overheated (B)

Function: Additional heat operation is stopped.

Overheat protection on the internal additional heat has

tripped.

Heat pump: E21 with internal electric additional heat.

B Reset the overheat protection on the electric

additional heater.

B Check the function of heat carrier pump G2.

B Clean the heating system particle filter if necessary.

B Check the flow in the heating system.

B Check the valves in the heating system.

5.6.25 External add. heat out of order (B)

Function: The additional heat mixing valve is closed. No

signal from the external additional heat thermostat

indicating sufficient heat.

Heat pump: E21 with external additional heat.

B Check that the additional heat is running and has

sufficient temperature.

B Check thermostat E71.E1.B31 and connections.

Page 34

Information/Alarms

6 720 645 172 (2010/07) en

34

5.6.26 Access. x pump out of order (B)

Function: The SSM signal from the circulation pump

connected to the stated accessory is broken.

Heat pump: E21.

B Check that the pump works.

B Check the connections to the pump.

5.6.27 Operating error pump G1 (B)

Function: Activated when the signal from the circulation

pump has stopped. Other G1 pumps work. In the control

unit Settings E11.G1\Alarm (Installer level ) must be set

to Oper. reply or SSM in order for the alarm to occur.

Heat pump: E21.

B Check voltage and safety switches.

B Check the circulation pump's display/alarm indicator

if there is one.

B Check the control signal to G1 and the SSM signal

from G1.

5.6.28 Compressor alarm

Function: The compressor is stopped. E21: Additional

heat permitted to start.

Heat pump: All.

B Check the compressor's miniature circuit breaker and

motor cut-out.

5.6.29 High temperature T10 (B)

High temperature T11 (B)

Function: The compressor is stopped. E21: Additional

heat permitted to start. Activated when the sensor