IVT Optima 600-1700, Optima 600, Optima 900, Optima 1100, Optima 1400 Installation Manual

...Page 1

IVT Optima 600-1700

Mixed additional heat

Installation Guide

Art. no: 12343 Version 1.0

Page 2

Installation Guide IVT Optima 600 – 1700 Mixed additional heat

IVT Industrier AB, 2007/09

Article number: 12343

Version 1.0

Copyright © 2007. IVT Industrier AB. All rights reserved.

This manual contains copyright protected information that is the property of IVT Industrier AB. No par t of this document may be copied or forwarded, electronically or mechanically,

without prior, written permission from IVT Industrier AB. This includes photographing and translation to another language.

Page 3

3

Table of Contents

Innehåll

FOR THE INSTALLER ..................................................................................................... 5

Important information for the installer ............................................................................ 6

Checklist .......................................................................................................................6

What the shipment includes ...........................................................................................7

General .........................................................................................................................8

Transporting and storage .........................................................................................................................................8

Positioning the heat pump ........................................................................................................................................8

Minimum and maximum working temperatures ......................................................................................................9

The heating installation’s different methods of control .............................................................................................. 9

Defrosting method ....................................................................................................................................................9

Location of the temperature sensors ........................................................................................................................10

CANbus ..................................................................................................................................................................11

Detailed pictures connection area ...........................................................................................................................12

Dimensions, clearance and plumbing connections ..........................................................14

Optima 600-1100 ...................................................................................................................................................14

Optima 1400-1700 .................................................................................................................................................15

Control cabinet, Accessory unit electric/oil-fi red boiler ............................................................................................ 16

Double-shelled hot water heater ..............................................................................................................................16

Fit the particle fi lter ...............................................................................................................................................16

Connecting to the heating system ..................................................................................17

Flushing the heating system ....................................................................................................................................17

Connecting the heat pump to the heating system .....................................................................................................17

Connecting three-way valve ....................................................................................................................................17

Heat carrier pump G2 ............................................................................................................................................17

Connection principles .............................................................................................................................................18

Filling the heating system ....................................................................................................................................... 19

Connecting to the power supply .................................................................................... 20

Accessories .............................................................................................................................................................20

Safety switch and earth-fault breaker ......................................................................................................................21

Emergency operation ..............................................................................................................................................21

Wiring diagram Optima 600-1100 .......................................................................................................................22

Wiring diagram Optima 1400-1700 .....................................................................................................................23

Wiring diagram Control cabinet ............................................................................................................................ 24

Wiring diagram Accessory unit .............................................................................................................................25

External connections diagram ................................................................................................................................26

External connections Heat pump ............................................................................................................................27

External connections Control cabinet ....................................................................................................................28

External connections Accessory unit ......................................................................................................................29

Installer and service menu (I/S) ...................................................................................30

Menu overview ............................................................................................................ 31

Commissioning ............................................................................................................34

Start the heat pump ...............................................................................................................................................34

Start up .................................................................................................................................................................34

Other settings .........................................................................................................................................................37

Important points to check after commissioning ....................................................................................................... 37

Timers ........................................................................................................................ 38

Alarm functions ...........................................................................................................39

Page 4

4

Technical information ..................................................................................................40

Factory settings ......................................................................................................................................................40

Technical information ............................................................................................................................................43

Sound levels ...........................................................................................................................................................44

Sensor table ..................................................................................................................................................... 44

Table of Contents

Page 5

5

This guide provides the heat pump installer with a description of how the heat

pump and the hot water heater, if used, are installed and commissioned. The

installation section consists of a plumbing part and an electrical par t. It also

provides technical data such as measurements, wiring diagrams and installer

menus. We hope that you read through this guide carefully and that you

respect all notes and warning texts.

Note

It is important that as the installer you also read through the User guide for the

heat pump. Here you will fi nd the information necessary to get a comprehensive

understanding of the heating installation.

Contents:

Important information for the installer

Checklist

What the shipment includes

General

Dimensions, clearance and plumbing connections

Connecting the heating installation to the heating system

Connecting the heating installation to the power supply

External connections

Commissioning

Technical information

Important information for the installer

For the Installer

Page 6

6

This manual gives you all the information necessary to install the heat

pump. The guide is divided into several parts in the order in which installation and commissioning must be carried out.

Before starting the installation:

The heat pump may be temporarily tilted with the compressor

downwards. It must never be laid down or transported horizontally.

Check that plumbing connections in the heat pump are intact and have

not shaken loose during transport.

If the heat pump is used in a system with fan-assisted radiators, the

water volume in the system is very small. During defrosting, the heat

pump draws some of the energy from the heating system, cooling

it down. It is therefore important that the fans in the fan-assisted

radiators run during defrosting, alternatively are connected to a tank of

approximately 100 litres.

Wiring should be kept as short as possible to protect the system from

downtime, for example during a thunderstorm.

Before the commissioning the heating system must be filled up and

completely vented.

Important information for the installer

Checklist

The following checklist will give you a general description of how the installation

should be carried out.

1. Position the heat pump on a solid base.

2. Install the incoming and outgoing pipes for the heat pump.

3. Install the drainage pipe for the heat pump.

4. Install the new hot water heater, hot water sensor and three-way valve if used.

5. Install G2 heat carrier pump.

6. Install a mixing valve if not already installed.

7. Fit the particle filter.

8. Connect the heat pump to the heating system.

9. Install the control cabinet and the accessory unit for electric/oil-fired boiler.

10. Install the flow sensor, outdoor sensor, and room sensor if used.

11. Connect the CANbus wiring between the heat pump and the control cabinet.

12. Connect the heating installation to the power supply via a safety switch and

any earth fault breaker.

13. Fill and vent the heating system before commissioning.

14. Commission the heating installation by making all the necessary settings on

the control panel.

15. Check the heating installation after commissioning.

Warning

For reasons of safety the main power

supply must be disconnected before

working on the heat pump.

!

Note

Only qualifi ed installers may carry

out the installation. The installer must

follow applicable rules and regulations and recommendations from the

supplier.

Important information to the installer / Checklist

Page 7

7

What the shipment includes

The following components are included in the delivery of the heat pump:

Circlip pliers

Quantity: 1

Particle fi lter with screen

Quantity: 1

Rubber feet

Quantity: 4

What the shipment includes

The following components are included in Rego 800 Mixed additional heat:

Control cabinet

Flow/Tank sensor T2 with cable

Quantity: 1

(supplied with control cabinet)

Accessories (not included in delivery):

Room sensor T5

Soft starter

Heating cable: 2m / 30W

3m / 45W

5m / 75W

Three-way valve

Circulation pump G2:

600-1100 Wilo Star RS 25/4

1400-1700 TOP S25/75

Shut off valves for G2 Cu 28 (2 x)

Mixing valve

Accessory unit electric/oil-fi red boiler

Includes:

User Guide

Quantity: 1

Installation Guide

Quantity: 1

Hot water heater:

(600-1100) Double shelled: IVT 300/160 (T3 included)

(1400-1700) Coil tank: IVT 320 or IVT 520 (T3 is an accessory)

Tube sensor hot water heater (T3)

Outdoor sensor T2 with cable

Quantity: 1

(supplied with control cabinet)

Page 8

8

Positioning the heat pump

The heat pump is located outdoors. It contains a number of sensitive

parts. It is impor tant that it stands on a flat and solid base, for example,

concrete slabs on ground insulation.

The installer should take sound propagation into consideration when

positioning the heat pump. See more information under the heading

Technical information/Sound levels.

Pipe routing between the heat pump and the existing heating system

should be as short as possible. The outdoor pipes must be insulated.

The heat pump produces condensation and melted ice during the

defrosting process. It is therefore important to lead off this water from

the heat pump to a floor drain inside the house.

Note that the drainage pipe must slope towards and run out above the

floor drain. This will keep the drainage pipe free of frost as air is drawn

from inside the house. In those cases the drainage pipe is released into

the surface water outdoors, the pipe must be fitted with a heating cable

(accessory) to avoid freezing. A suitable output is 10-20 W/metre. The

cable can be connected to terminals in the heat pump. See External

connections.

The heat pump must be positioned so that air is not prevented from

passing through the evaporator. Minimum distance to a wall is

300 mm. Avoid positions which result in circulation of cold air because

this decreases the heat pump output.

Avoid falling snow and eaves drop. In some cases a protective roof may

be necessary. The roof should then be installed at least 1.5 m above the

heat pump to avoid the recirculation of cold air.

General

Transporting and storage

The heat pump should always be transported and stored in an upright

position. Otherwise the suspension fi ttings inside the compressor can be

damaged. If the heat pump must be tilted during entry to the installation

site, this should be done for as short a time as possible.

The heat pump must not be stored at temperatures below 0ºC.

Note

The amount of condensation water

can, during days of high humidity,

amount to 30-40 litres.

General

Page 9

9

Maximum working temperatures

The heat pump can work with a maximum return temperature of approximately 59ºC. If the temperature rises above this value the heat pump will

stop for reasons of technical safety.

The maximum fl ow temperature from the heat pump or additional heater is

limited to 65ºC.

Minimum working temperatures

The heat pump stops if the outdoor temperature falls below approx -20ºC.

All heat production then occurs in the existing electric/oil-fi red boiler.

The heat pump starts automatically when the outdoor temperature climbs

above approx -20ºC.

The heating installation’s different methods

of control

The control unit uses different methods to control the heating installation.

These are: Control with an outdoor sensor and Control with an outdoor

sensor supplemented with a room sensor.

More information about the control methods can be found in the User

Guide for Optima.

General

Minimum and maximum working temperatures

Defrosting method

The principle of defrosting in the heat pump is known as hot gas defrosting. During defrosting, the fl ow in the refrigerant circuit is reversed by

means of an electrically-controlled four-way valve. The compressed gas

from the compressor is fed into the top of the evaporator, causing the ice

on the outside to melt. During this process, the heating water is cooled

slightly. Hot gas is sprayed into the evaporator and sensor T11 ensures that

the process functions correctly. The time required for defrosting depends

on the amount of ice and the outdoor temperature.

There is also a fan defrost function, which means that hot air blows

upwards through the fan to prevent it freezing solid.

Page 10

10

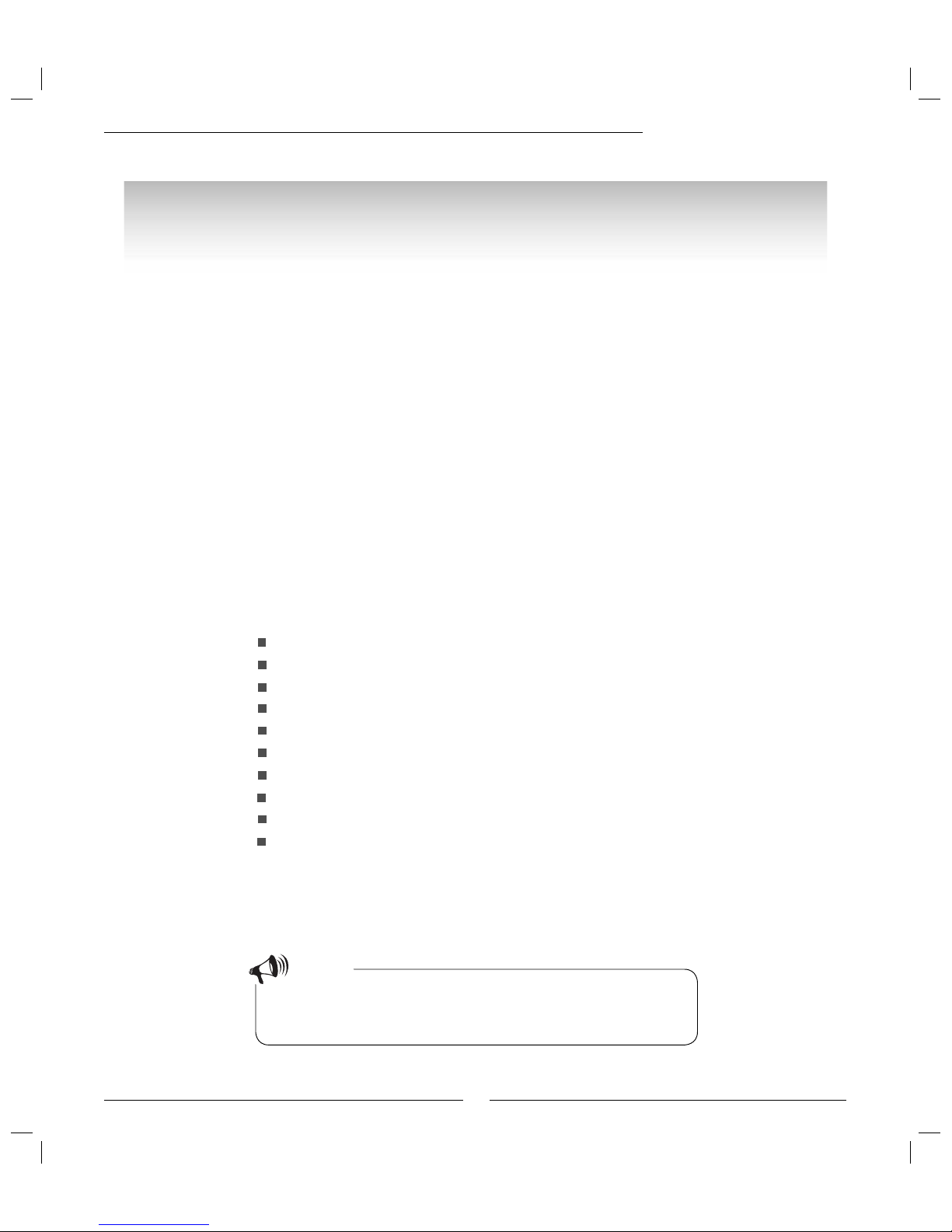

General

T1 Flow sensor

T2 Outdoor sensor

T3 Hot water sensor (if hot water heater is installed)

T5 Room sensor

T6 Sensor compressor temperature

T8 Sensor heat transfer fluid out

T9 Sensor heat transfer fluid in

T10 Sensor condenser temperature

T11 Sensor refrigerant temperature evaporator

T12 Sensor air temperature evaporator

Location of the temperature sensors

Optima Electric/oil-

fi red boiler

Hot water

heater

Page 11

11

General

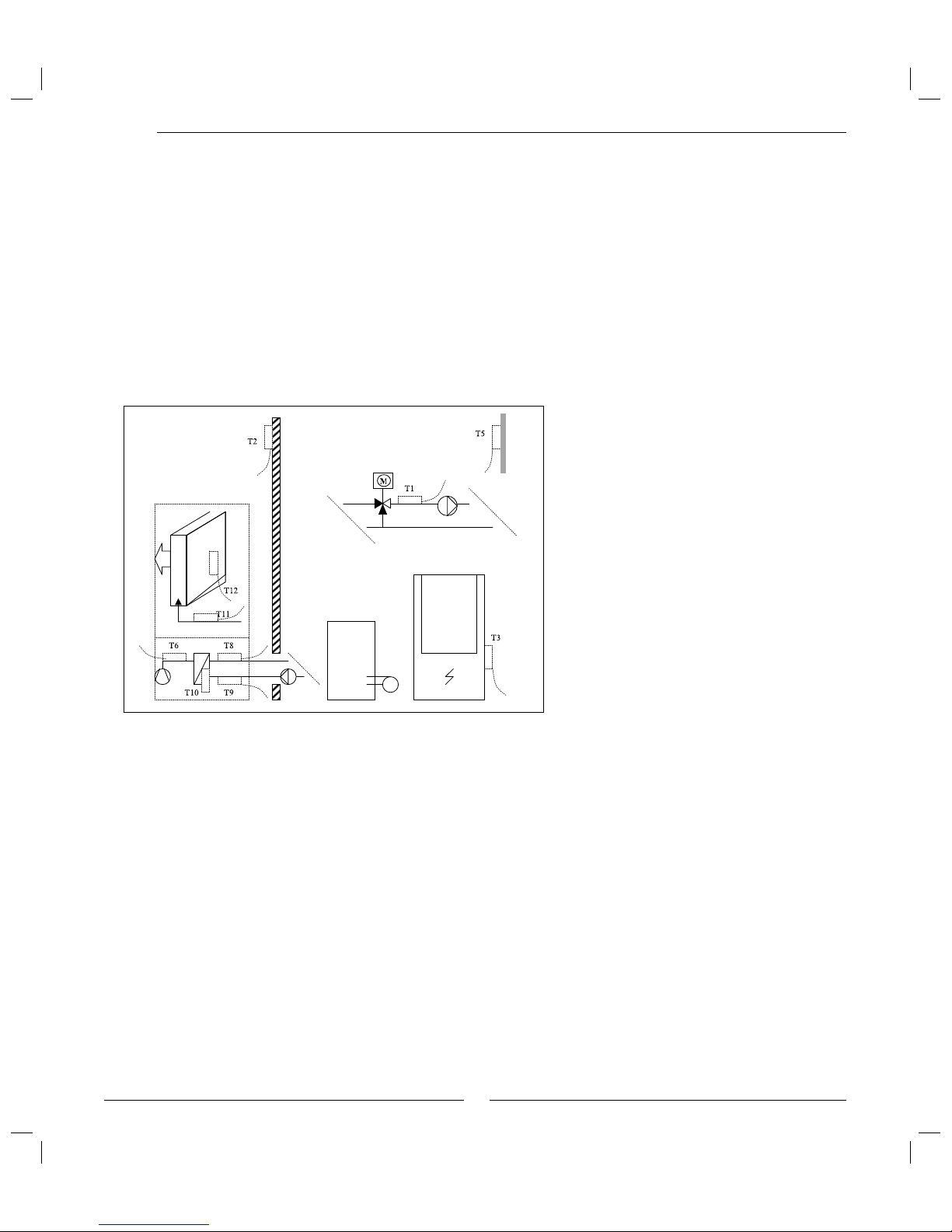

In Rego 800 the different circuit boards are connected by a communications cable, CANbus. CAN is an abbreviation of Controller Area Network

and is a two wire system for communication between the microprocessor

based modules/circuit boards. These are connected in series.

The heat pump has one circuit board (IOB circuit board). The accessor y

unit electric/oil-fi red boiler has one circuit board (IOB circuit board).

Other circuit boards (CPU, PSU and IOB circuit boards) are in the control

cabinet.

Suitable cable for external laying (connection between the circuit

boards) is cable ELAQBY 2x2x0.6. The cable must be twisted pair and

screened. The screen must only be earthed at one end and to the chassis

(not to a circuit board). Maximum cable length is 20 m.

The CANbus cable must not be laid alongside power supply cables. It may

be laid alongside sensor cables.

In the connection area of the heat pump the external CANbus cable must

be laid so that it does not come into contact with high current connections

(230/400V).

The connection between the circuit boards is by four wires since the

12V-supply between the circuit boards must also be connected. The circuit

boards have markings for both the 12V and CANbus connections.

Warning

Do not mix up the 12V and CANbus connections! If 12V (or other

incorrect voltage) is supplied to the

CANbus contacts the processors in the

CANbus are destroyed. Check, therefore, that the four cables are connected

to the contacts with the corresponding

marking on the circuit boards in the

accessory unit and the heat pump.

Switch S1

The switch is used to mark the start and end of a CANbus loop. This

means that the IOB circuit board in the heat pump and the accessory unit

circuit board must be terminated using S1, which must be in position Ter m.

Ensure that this is the case and that all other switches are in the opposite

position.

CANbus

Warning

The CANbus cable must be screened

and laid separately from the power

cable to prevent interference in the

CANbus communication.

Screen

Warning

Handle the circuit boards with great

care. They are sensitive to ESD (Electrostatic discharge), which can cause

faults in electronic components.

Page 12

12

General

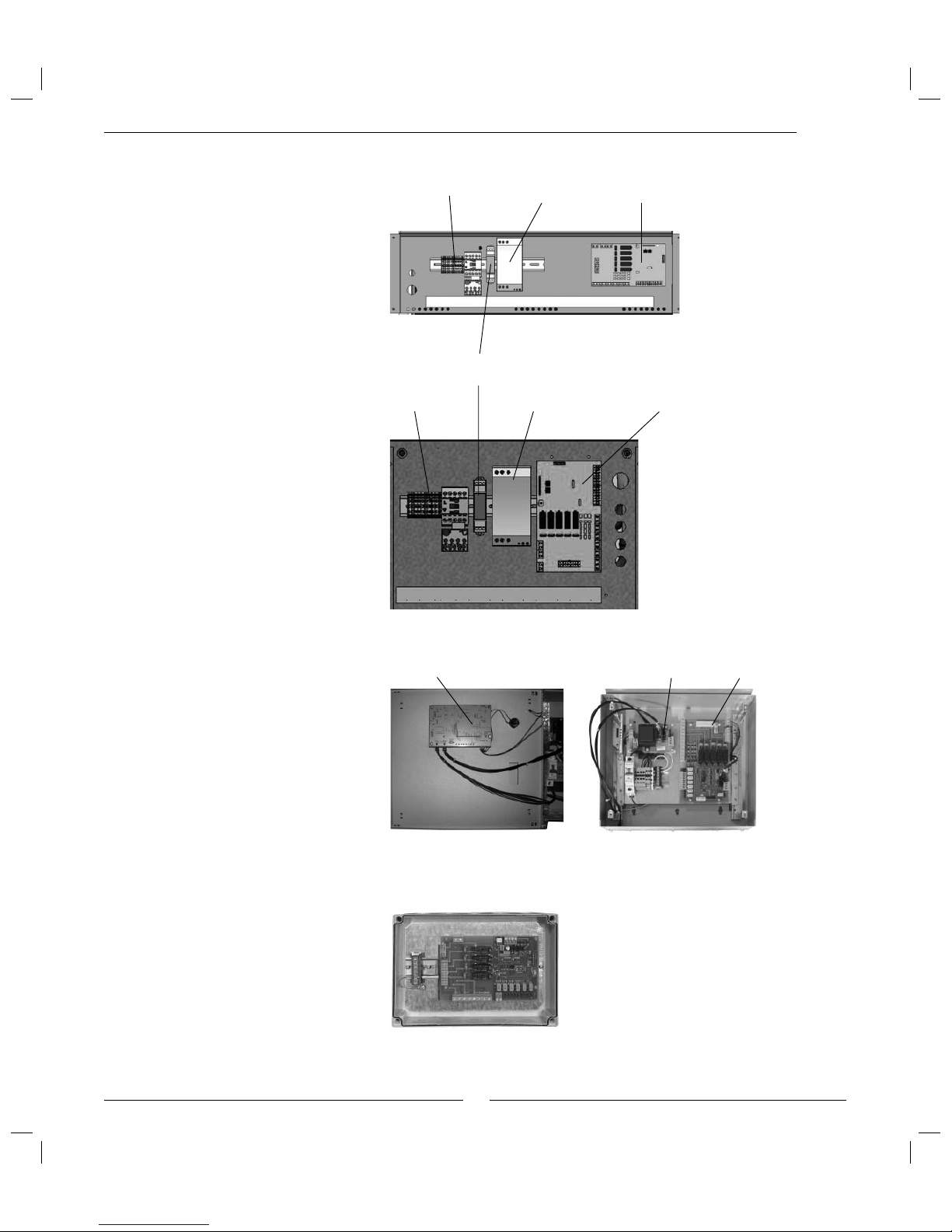

Detailed pictures connection area

Optima 600 - 1100

Optima 1400 - 1700

High pressure

pressostat

Service

connection

Compressor

Expansion valve

Four-way valve

Service

connection

Non-return

valve

Low pressure

pressostat

Drying fi lter

Sight glass

Condenser

Venting nipple

High pressure switch Drying fi lter Sight glass Service

connection

Service

connection

Compressor

Condenser

Expansion valve

Four-way valve

Non-return

valve

Low pressure

pressostat

Suction

accumulator

Page 13

13

Accessory unit electric/

oil-fi red boiler

General

Control cabinet

IOB board

PSU board

CPU board (mounted on the

inside of the door)

Electrical cabinet Optima

600-1100

(above the compressor)

Electrical cabinet Optima

1400-1700

(left-hand side of heat pump)

Electrical

connections

Soft starter IOB card

Electrical

connections

Soft starter IOB card

Phase sequence relay

Page 14

14

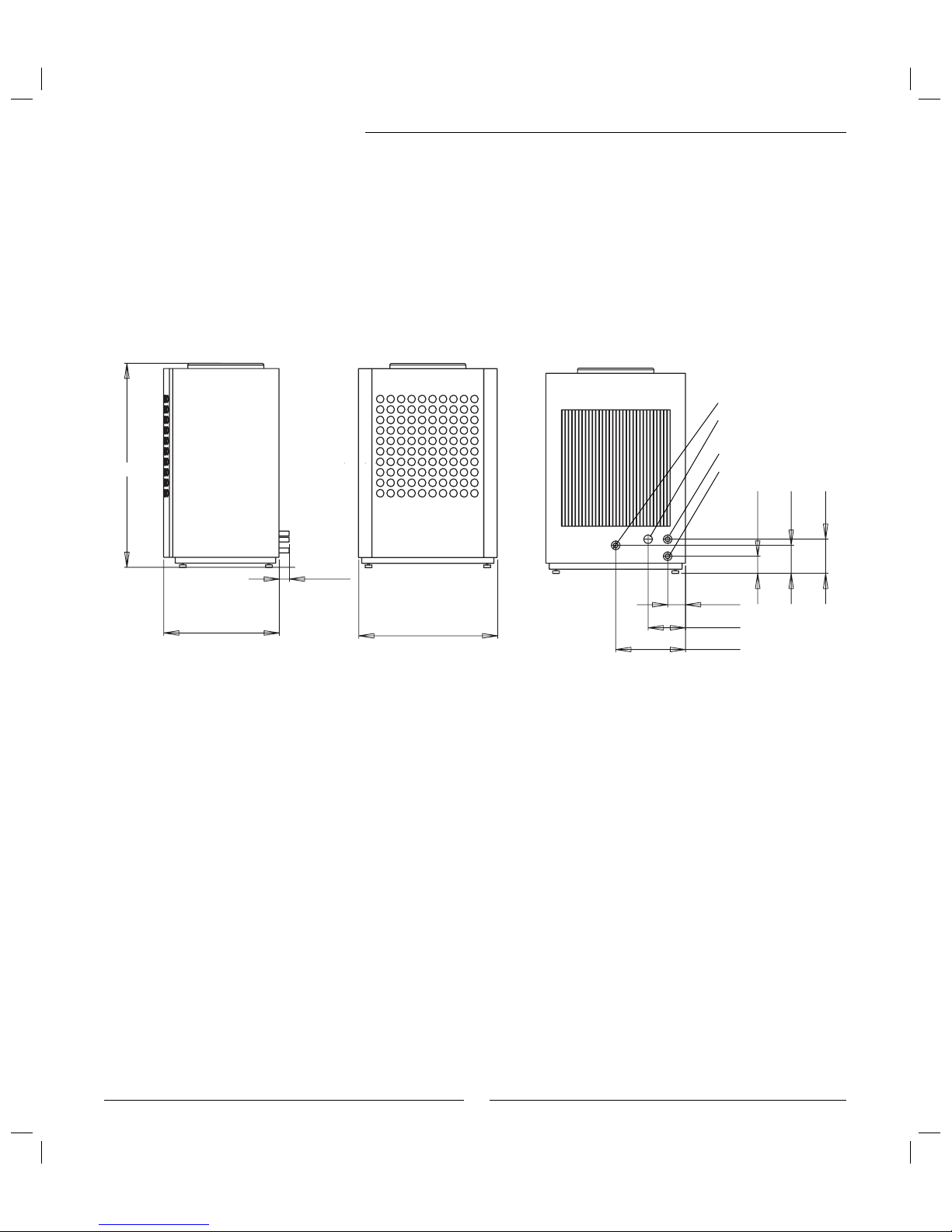

Dimensions, clearance and plumbing connections

Dimensions, clearance and plumbing connections

Front

Left-hand side

To heating system

(Hose 1 inch internal thread)

Draining, plastic pipe 32 mm

Back

Electric lead-ins

640

1190

60

820

411

220

105

101

165

201

Optima 600-1100

Required installation space for the heat pump.

Minimum distance from the pump to the wall is 300 mm.

Minimum distance in front of the pump 1000 mm, to the sides 500 mm.

If a roof is installed it must be positioned at least 1.5 m above the heat

pump to avoid the recirculation of cold air.

From the heating system

(Hose 1 inch internal thread)

Page 15

15

Optima 1400-1700

Dimensions, clearance and plumbing connections

Required installation space for the heat pump.

Minimum distance from the pump to the wall is 300 mm.

Minimum distance in front of the pump 1000 mm, to the sides 500 mm.

If a roof is installed it must be positioned at least 1.5 m above the heat

pump to avoid the recirculation of cold air.

705

920

1660

From above

Right-hand sideBack

1 Heat transfer fl uid out external G25

2 Heat transfer fl uid in external G25

3 Drainage external G25

Right

Left

Front

1

2

3

Page 16

16

Dimensions, clearance and plumbing connections

Control cabinet, Accessory unit

electric/oil-Þ red boiler

The units must be wall mounted indoors close to the other indoor components.

Control cabinet

Accessory unit

Double-shelled hot water heater

See the documentation for the hot water heater. See also Connection

principles.

Fit the particle Þ lter

The task of the particle fi lter is to fi lter out dir t before it can enter the heat

pump. Consequently, the particle fi lter supplied with the heat pump should

always be fi tted on the incoming hot pipe. It should be fi tted as close to the

heat pump as possible and be horizontal.

Page 17

17

Connecting to the heating system

Connecting to the heating system

Flushing the heating system

It is important that all previously mentioned preparations have been

carried out before the heat pump is connected to the heating system. Also

ensure the pipe system has been well fl ushed before it is connected to the

heat pump. Flushing protects the heat pump from contamination.

The heat pump is a part in a heating system. Faults in the heat pump can

be caused by poor water quality in the radiators/underfl oor coils or that air

is penetrating the system continuously. Oxygen causes corrosion products

in the form of magnetite and sediment. Magnetite has a grinding effect on

the heat pump pumps, valves and components with turbulent fl ows such

as the condenser. Heating systems which require regular fi lling or where

the heating water is not clear when drained, requires remedial measures

before the installation of a heat pump, for example the heating system must

be fi tted with fi lters and vents. Do not use any water treatment additives

except agents for raising the pH level.

An intermediate heat exchanger is sometimes necessary to protect the

heat pump.

Connecting the heat pump to the heating

system

Use the information in section Dimensions, clearances and plumbing connections to connect the different parts of the heating unit.

In addition, to avoid vibration transfer between the heat pump and the pipe

system we recommend fi tting fl exible hoses at the inlet and outlet of the

heat pump.

Between the heat pump and the house we recommend 28 mm copper

pipe for lengths of less than 20 metres. The pipes must be insulated with a

material, such as Armafl ex, which cannot absorb moisture. Venting valves

must be provided on the pipes. Short outdoor pipes reduce heat losses.

Connecting three-way valve

Connect a 3-way valve if the hot water heater is to be included. A description how to connect a ESBE type three-way valve is given to the right.

The ESBE 3-way valve must be installed on the return line according to the

system solution. Some 3-way valves are designed to be located on the fl ow

line. If such a valve is used, install it on the fl ow line

Heat carrier pump G2

Connect G2 and the shut off valves. The fl ow across G2 must be set slightly

lower than the fl ow across G1.

Note

Only qualifi ed installers may carry out

the installation. The installer should

observe applicable r ules and regulations and recommendations from the

supplier.

Port A:

From hot water

heater.

Port B:

From heating

system

Port AB: To heat pump

Page 18

18

Q Shut off valve

Q Safety valve outlet

Q Control valve with motor

T Temperature sensor

E Double-shelled water heater with electric element

E Oil-Þ red boiler/Electric boiler

E Heat pump

C Expansion tank

W Filter/Screen

G Pump

G Fan

W Filter valve

W Domestic hot water

W Inlet/outlet

Pipe (Arrow denotes direction of ß ow)

Crossing pipes

T-piece

Optima with electric/oil-fi red boiler and hot water heater

Connection principles

The principle is based on liquid condensation and additional heat from an electric/oil-fi red boiler using a mixing valve.

The control unit controls the heat pump using the outdoor sensor T2 and the return sensor T1 according to the set heat

curve. When the heat pump is unable to meet the heating requirements, the electric/oil-fi red boiler starts automatically and together with the heat pump provides the required temperature. Hot water is prioritised and controlled by a

sensor, T3 in the heater. While the water is heating in the hot water heater, the heating system from the heat pump is

disconnected temporarily through a three-way valve. If the electric/oil-fi red boiler is in operation it provides the required

temperature to the heating system. When the hot water is heated the heat pump continues the heat production.

Hot water mode when the heat pump is not operating:

The heat pump stops automatically at outdoor temperatures below approximately -10ºC and cannot then produce hot

water. The electric element in the hot water heater (IVT 300/160) is then automatically activated by the control unit and

the hot water heater will thus maintain a high temperature. The temperature is adjustable using the thermostat on the

electric element.

Connected sensors:

T1 Flow sensor

T2 Outdoor sensor

T3 Hot water sensor (accessor y)

T5 Room sensor (accessory)

T8 Sensor heat transfer fl uid out

T9 Sensor heat transfer fl uid in

Connecting to the heating system

Mixing valve

Three-way valve

Hot water

Cold water

Particle

fi lter

Heating

system

Outdoor sensor

Room sensor,

accessory

Note

If a hot water heater is not included,

connect the cold and hot water pipes to

the electric/oil-fi red boiler.

Page 19

19

Connecting to the heating system

Warning

The hot water heater must always be

fi lled and pressurised before the heating system is fi lled.

The installation must not, under any

circumstances, be switched on without

water.

Venting nipple (only Optima 600-1100)

Optima 600-1100

Filling the heating system

After fl ushing the heating system the hot water heater must be fi lled with

water. The heating system is then fi lled.

This is what to do:

1. Open and close the tap between the cold water system and the heating

system in short time inter vals.

2. Read the pressure on the expansion tank pressure gauge.

3. Vent the system and refill to the correct pressure.

Page 20

20

Connecting to the power supply

Check that cables and printed circuit boards are intact. High and low

current cables should be routed separately in order to avoid interference

on the sensors.

The heat pump control unit is mounted in the control cabinet. Connect

additional heat equipment to the accessory unit. The compressor, fan,

sensors, pressure switches, etc. are connected to the heat pump’s junction

box. The cable between the control cabinet, accessory unit and heat

pump’s electrical box is routed according to the diagram External connec-

tions diagram.

The following sensors are to be connected during installation: T1 Flow

sensor, T2 Outdoor sensor, T3 Hot water sensor (accessory), T5 Room sensor

(accessory).

Install the fl ow sensor T1 in direct contact with the fl ow pipe.

Accessories

Hot water sensor T3

When IVT 300/160 is used T3 is already installed on the heater. The sensor

is connected according to External connections Control cabinet. Note that

300/160 must be supplemented with a 6 kW electric element, see separate

guide.

Room sensor T5

The room sensor is placed centrally in the house and is connected

according to External connections Control cabinet.

Soft starter

The compressor can be equipped with a soft starter to reduce the inrush

current. The soft star ter is fi tted on the heat pump and is connected

according to Wiring diagram Optima.

Heating cable

A drainage pipe from the heat pump’s drip collector may need to be fi tted

with a heating cable. See Accessories under What the shipment includes?

for information about lengths. The heating cable is according to External

connections Heat pump.

Connecting to the power supply

Warning

Handle the circuit boards with great

care. They are sensitive to ESD (Electrostatic discharge), which can cause

faults in electronic components.

Page 21

21

Safety switch and earth-fault breaker

Safety switch

All heating installations must be isolated by a safety switch.

Earth-fault breaker

If the heating installation is to be connected across an earth-fault breaker

then a separate earth-fault breaker for the heating installation is recommended. Comply with applicable regulations.

Emergency operation

The heat pump is equipped with emergency operation which means that

the additional heater takes over the heat production in the event of faults in

the control unit. Read more about emergency operation in the User Guide.

On the OPB circuit board there is switch, S4, which can be activated for

emergency operation, see under heading Wiring diagram Accessory unit.

Connecting to the power supply

Page 22

22

Wiring diagram Optima 600-1100

Connecting to the power supply

B1: Phase sequence monitor

E3: Crankcase heating

E4: Any heating cable

F1: Miniature circuit breakers

G3: Fan

K1: Contactor compressor

M1: Compressor

MB2: Motor cut-out compressor

Q3: Four-way valve

R1: Soft starter

S1: Termination switch

HP: High pressure switch

LP: Low pressure switch

T6: Compressor hot gas

T8: Heat transfer ß uid out

T9: Heat transfer ß uid in

T10: Condenser

T11: Evaporator temperature

T12: Air intake

To Control cabinet

Blue

Brown

Black

G3

S1 must be in "Term" position on

the Þ rst and last circuit board in

the CANbus loop.

1) Strap

Page 23

23

Connecting to the power supply

Wiring diagram Optima 1400-1700

B1: Phase sequence monitor

E3: Crankcase heating

E4: Any heating cable

F1: Miniature circuit breakers

G3: Fan

K1: Contactor compressor

M1: Compressor

MB2: Motor cut-out compressor

Q3: Four-way valve

R1: Soft starter

S1: Termination switch

HP: High pressure switch

LP: Low pressure switch

T6: Compressor hot gas

T8: Heat transfer ß uid out

T9: Heat transfer ß uid in

T10: Condenser

T11: Evaporator temperature

T12: Air intake

U1: Brown

U2: Red

V1: Blue

V2: Grey

W1: Black

W2: Orange

L1: Black

L2: Brown

L3: Grey

PE: Yellow green

Diagram fan motor M2

High speed

Optima 1300

Low speed

Optima 1000

To Control cabinet

S1 must be in "Term" position on

the Þ rst and last circuit board in

the CANbus loop.

1) Strap

Page 24

24

Wiring diagram Control cabinet

Connecting to the power supply

F1: Miniature circuit-breaker

F2: Miniature circuit-breaker

G1: Pump for heating system

G2: Heat carrier pump

L1: LED operation/alarm

Q1: Any three-way valve

S1: Termination switch

S2: On/Off

S3: Switch emergency operation

K: Any additional heat WH

T1: Flow sensor

T2: Outdoor sensor

T3: Any hot water sensor

T5: Room sensor, accessory

To Heat pump

To Accessory unit

Open

Strap

S1 must be in "Term" position on

the Þ rst and last circuit board in

the CANbus loop.

Page 25

25

Wiring diagram Accessory unit

Connecting to the power supply

Open

Strap

Close

To Control cabinet To Control cabinet

Do1: Starting additional heat (oil-Þ red boiler/electric element) heating system.

PLEASE NOTE: Maximum relay output load, 1800W resistive, 600W inductive,

cos

ϕ >0,4. At greater loads, an intermediate relay must be installed, not

included.

H1: Any additional heat alarms. Closing during operation causes alarm Fault on

additional heat heating system.

Q2: Mixing valve.

S4: Switch emergency operation (starting oil-Þ red boiler/electric element)

Function Emergency operation:

Switch S3 on the control cabinet starts the heating system’s pump G3 and

heat carrier pump G2.

Switch S4 on the accessory unit is used for starting the oil-Þ red boiler or the

electric element.

If the emergency operation function is to be used, the pre-installed cables

from switch S4 must be connected to the OPB circuit board according to wiring

diagram (L and Do1).

NOTE! An electric element must have overheat protection with built-in

thermostat.

S1 must be in "Term" position on

the Þ rst and last circuit board in

the CANbus loop.

Page 26

26

External connections diagram

Connecting to the power supply

Control cabinet

Accessory unit electric/

oil-fi red boiler

Heat pump

Open

Open

E4: Heating cable in draining pipe, accessory

G1: Pump for heating system

G2: Heat carrier pump

Q1: 3-way valve, accessory

Q2: Mixing valve, accessory

K: Contactor any electrical additional heat in the hot water heater

Do1: Starting additional heat (oil-Þ red boiler/electric element). PLEASE NOTE:

Maximum relay output load, 1800W resistive, 600W inductive, cos ϕ >0,4.

At greater loads, an intermediate relay must b installed, not included.

S4: Switch emergency operation. Pre-installed switch connected by installer if

the function is required.

H1: Any additional heat alarm

T1: Flow sensor

T2: Outdoor sensor

T3: Hot water sensor, accessory

T5: Room sensor, accessory

Optima 600-1100, Optima 1400-1700

Close

NOTE! If the emergency operation

function is to be used, the electric

element’s overheat protection must

have a built-in thermostat.

Safety switch not included.

Optima 600/900/1100: 10A

Optima 1400/1700: 16A

Page 27

27

External connections Heat pump

Power supply:

Connect to terminals L1, L2, L3, N and PE.

CANbus:

Communication cable between the circuit boards in the control

cabinet, heat pump and accessory unit. Connect to terminals GND,

CANL, CANH and 12V. See more under section CANbus.

E4, Heating cable:

The drainage pipe from the heat pump’s discharge water vessel may

need to be fi tted with a heating cable. The heating cable is connected

to terminals Do4, N. See section Accessories.

Warning

Connecting to the power supply

Note

S1 must be in position Term here and

on the accessory unit board.

To Control cabinet

Do not mix up the 12V and CANbus connections! If 12V (or other

incorrect voltage) is supplied to the

CANbus contacts the processors in the

CANbus are destroyed.

Page 28

28

Connecting to the power supply

External connections Control cabinet

Power supply:

Connect to terminals L1, L2, L3, N and PE and then further feed

to the heat pump. Connect further supply to the accessor y unit on

terminals 1, N and PE.

CANbus:

Communication cable between the circuit board in the control

cabinet, heat pump and optional unit. Connect to terminals GND,

CANL, CANH and 12V. See more under section CANbus.

T1, Flow sensor: Connect to terminals Ai1 and GND.

T2, Outdoor sensor: Connect to terminals Ai2 and GND.

T3, Hot water sensor: Accessory. Connect to terminals Ai3 and GND.

T5, Room sensor: Accessory. Connect if room sensor infl uence is

required. Connect to terminals Ai4 and GND.

G1, Heating system pump: Connect to terminals Do1 and N.

G2, Heat carrier pump: Connect to terminals Do2 and N.

Q1, Three-way valve: Accessory. Connect to terminals L, Do3 (Open)

and N.

K: Any contactors for the hot water heater’s electric element can be

connected to terminals Do4 and N.

Open

To Heat pump

To Accessory unit

Warning

Strap

Do not mix up the 12V and CANbus connections! If 12V (or other

incorrect voltage) is supplied to the

CANbus contacts the processors in the

CANbus are destroyed.

Page 29

29

Connecting to the power supply

External connections Accessory unit

Power supply:

Connected to terminals L, N and PE.

CANbus:

Communication cable between the circuit boards in the control

cabinet, heat pump and accessory unit. Connect to terminals GND,

CANL, CANH and 12V. See more under section CANbus.

Q2, Mixing valve:

Connect to terminal Do2 (Open), N (Zero) and Do3 (Close).

H1, Any additional heat alar m:

Closing during operation causes alarm Fault on additional heat for

heating system.

Do1, Starting additional heat:

Connect the cable to electric or oil-fi red boiler contactor. Only connect

when a hot water heater is included. NOTE: Maximum relay output

load, 1800W resistive, 600W inductive. At greater loads, an

intermediate relay must be installed, not included.

Warning

Do not mix up the 12V and CANbus connections! If 12V (or other

incorrect voltage) is supplied to the

CANbus contacts, the processors in the

CANbus are destroyed.

To Control cabinet

Strap

Open

Close

Note

S1 must be in position Term here and on

the IOB circuit board in the heat pump.

Page 30

30

Installer and service menu (I/S)

Warning

The installer and service menu (I/S) is

only for installers. Under no circumstances may the user access this level.

Installer and service menu

First read aboutCommissioning.

As the installer you have your own section of menus for settings, e.g. for

commissioning and maintenance.

The User Guide for the heat pump contains a complete description of how

the control panel functions and of all customer functions under Menu and

Advanced menu. Read it before you start.

A four digit access code is required to access the I/S menus.

This is what to do:

1. Press the menu dial for approximately five seconds to get to Advanced

menu.

2. Select Access level.

3. Enter the four digit access code using the menu dial and press the

menu dial to confirm. The access code is the present date given as two

digits for the month and two digits for the date (for example 0920).

Access = service is shown in the display. Press the dial to get to Menu.

Under Menu there are now both customer functions and I/S functions.

To reach Advanced menu press the menu dial for approximately five

seconds.

4. Return to customer level by selecting Access level in Advanced menu

and enter 0000 as access code.

The control unit automatically returns to customer level after approxi-

mately 120 minutes.

Page 31

31

Menu overview

Here you fi nd the upper levels for all functions under Menu and Advanced

menu. All setting functions can also be found in the table Factory settings,

see Technical information.

Menu overview

Menu

Fast restart of heat pump?

I/S

Start up

Setting the clock I/S

Connected extra sensors I/S

Manual operation I/S

Additional heat options I/S

Language I/S

Correct sensor I/S

Fan defrost interval I/S

Fan defrost time I/S

Forced defrost I/S

Block crankcase heater at high outdoor temperature I/S

Anti-jamming mode time I/S

Alarm buzzer signal length I/S

T1 Set point value maximum I/S

Display I/S

Room temperature setting (T5)

K

Temperature increase/decrease (no T5)

K

Temperature increase/decrease

settings (no T5)

I/S

Limit value for V or H

Much colder/warmer, change

Colder/warmer, change

Temperatures

K

Page 32

32

Menu overview

Advanced menu

Temperature

Heating system temperature K

Room sensor settings (T5) K

Time limited settings K

Heating season K

Heating, maximum operating time at hot water requirement K

Shut down protection, change over hot water to heating I/S

Compressor working area settings I/S

Hot water

Extra hot water K

Hot water peak K, I/S

Hot water temperature K, I/S

Time control hot water K

Hot water additional heat I/S

Temperatures

Shows temperatures, inputs, outputs

Correct sensor

I/S

Defrost settings

T12 - T11 settings I/S

Maximum outdoor temperature I/S

T11 Maximum temperature I/S

Maximum time I/S

Delay after compressor start I/S

Minimum time between defrosts I/S

Compressor pressure equalisation time I/S

4-way valve pressure equalisation time I/S

Forced defrost I/S

Heating cable time after defrost I/S

Fan defrost

Timers

Shows timers K, I/S

Additional heat settings

Start delay I/S

Time control additional heat I/S

Additional heat options I/S

Connected electrical capacity (shows present value) I/S

Page 33

33

Menu overview

Setting the clock

Set date

Set time

Alarm

Alarm log K, I/S

Alarm history I/S

Warning log I/S

Access level

K, I/S

Return to factor y settings

K, I/S

Deactivate alarm buzzer

K

Program version

K, I/S

Page 34

34

Commissioning

Commissioning

Before commissioning the heating system must be fi lled up and completely

vented. Check that there are no leaks.

As many radiators as possible should be fully open when connecting to an

existing water system. When connecting to an underfl oor heating system

at least half of all the fl oor coils should be open. When connecting to a

fan-assisted radiator system the fans are started fi rst and then the taps on

the fan-assisted radiators are opened fully.

Start the heat pump

1. Connect the mains and press the ON/OFF switch on the control panel.

A language selection window is shown.

2. Start by selecting the language to be applied to the menu windows.

The selected language automatically becomes the factory setting, that

is, is not changed by Return to factory settings. To change language

go to Language under Start up. Available: Dansk, Deutsch, English,

Français, Norsk, Suomi, Svenska,

Čeština.

3. Select Setting the clock.

Select Set date and adjust the date (yy-mm-dd) if it is not correct. Select

Set time to adjust the time if it is not correct.

4. Activate the installer and service menu, see Installer/service menu.

Start up

When you have entered the access code and are in Menu select the

function Start up.

All functions for carr ying out the basic settings in the heating installation

are gathered in the start up menu. Carry out/go through these in turn.

Setting the clock

See Start the heat pump.

Page 35

35

Connected extra sensors

The control unit senses which extra sensors (T3 hot water, T5 room sensors) have

been installed and displays which are acknowledged when you select Connected

extra sensors.

Manual operation

Make a check of all the functions before you commission the heating installation.

You can manually start and stop the pumps and valves from the menu Manual

Operation. Select Yes to activate.

NOTE! The function is deactivated by selecting No in Manual Operation.

Additional heat options

Additional heat only blocks the start of compressor and fan. Heating and hot water

is supplied via the additional heater.

Block additional heat blocks the additional heat function, but not during alarm

mode, hot water peak, extra hot water or operation with additional heat only.

NOTE! Normally this is not recommended.

Language

This allows you to change the language to one other than that selected when the

heat pump was fi rst star ted. The selected language automatically becomes the

factory setting, that is, is not changed by Return to factory settings.

Correct sensor

All sensors can be corrected here. The correction value is stated directly in °C.

Normally one should avoid correcting a sensor. The value that is given without

correction is most often the correct one. Correction of maximum 5ºC up or down

is possible.

Fan defrost interval and Fan defrost time

Because weather conditions vary from place to place some factory settings for

defrosting may need adjustment. This particularly applies to locations with high

humidity where there is a risk that the fan will ice up. Fan defrost means that

warm air is blown upwards through the fan.

The fan defrost function is active when the value Fan defrost interval is between

1 and 10, factory setting is 1. The value 1 states that fan defrosting will occur at

each ordinary defrosting. If the value is set to 3 then fan defrost occurs every third

defrost.

Select how long fan defrost should last. The factory setting is 1 min.

Min = 1 and max = 5.

The function is deactivated by selecting 0 in Fan defrost interval.

Temperature limit for fan defrost is set to -5ºC. No fan defrost occurs below this

temperature. This setting can be changed under Fan defrost in the Advanced menu.

Commissioning

Page 36

36

Forced defrost

Forced defrost is used to bypass the timer and temperature conditions for

defrost. Temperature T11 (refrigerant temperature evaporator) must be

below the set stop level for defrosting.

Block crankcase heater at high outdoor temperature

Checked by outdoor sensor T2. When the outdoor temperature exceeds

the set value the crankcase heating in the compressor is deactivated. The

crankcase heater is active when the compressor is idle and the outdoor

temperature is below the set value. Factory setting = 10ºC. Min = 5ºC and

max = 20ºC.

Anti-jamming mode time

At the set time each day the circulation pumps G1 and G2, three-way valve

VXV and fan are run for one minute each, provided that they have not

been in operation during the previous 24 hours. Factory setting = 2, which

means 02:00. Min = 0, max = 23.

Alarm buzzer signal length

In event of an alarm the alarm signal is sounded for the set time if the

signal is not deactivated. The factory setting is 1 minute, max setting is 10

minutes.

T1 Set point value maximum

T1 is set to max, that is 80°C, on delivery. The value may need to be

reduced if only underfl oor heating is used.

Display

The function affects the window contrast and brightness. On deliver y the

max setting 10 is set on both.

Alarm during start up

During start up there may be an alarm regarding Low temperature in

condenser. The cause is that the fi lled water is too cold (colder than +5ºC).

Check the sight glass inside the heat pump. Bubbles may appear in the

sight glass for a few minutes during start up. The bubbles should then

stop. If it bubbles continuously this is a fault symptom which is probably

due to insuffi cient refrigerant.

Sight glass

Commissioning

Page 37

37

Other settings

Go through the heating and hot water settings in the Menu and

Advanced menu and make the necessary changes. For example the

heat curve settings for underfl oor heating need to be lower than the

factory settings. Set appropriate V and H values.

Important points to check after

commissioning

For the installation to perform at its best, it is important to check

the fl ow on the hot side of the heat pump. Usually, the heat carrier

pump has a speed selector switch. This must be set correctly for the

pressure drop in the system. A recommended temperature dif ference

across the heat pump on the hot side is between 5 and 10ºC. The

nominal fl ows provided in Technical data provide a dif ference of 7ºC

in operating mode +7/45ºC. Check this by reading the sensors T9

(heat transfer fl uid in) and T8 (heat transfer fl uid out). These can be

found under Temperatures in the Advanced menu.

When commissioning is carried out at a low outdoor temperature

(below 0ºC) the temperature difference should be between 5ºC and

7ºC.

When commissioning is carried out at an outdoor temperature above

15ºC the temperature difference must be between 8ºC and 10ºC.

The fl ow through the heating system should be suffi cient to keep the

whole radiator warm and thereby increase the heat emitting surface.

This means that the fl ow temperature is kept low.

After testing, vent the heating system again and top up with cold water

if necessary. See Filling the heating system.

Commissioning

Page 38

38

Advanced menu

Extra hot water

Displays the remaining time for requested extra hot water.

Additional heat start

Displays the countdown of the timer for delay of additional

heat.

Mixing valve control delay

Displays the time that the mixing valve function is delayed

after the additional heat timer has counted down.

Alarm mode delay

Displays the remaining time until the additional heat is

activated when an alarm is triggered.

Compressor start

Displays the remaining time of compressor start delay.

Delay before defrost

Displays the remaining time before defrosting is permitted.

T12-T11 reached temperature difference

The heat pump regularly calculates the difference between

T12 and T11. The result is compared to the set point value

which is calculated based on actual outdoor temperature

and settings in Defrost settings\T12-T11 settings\Difference

at +10°C /0°C /-10°C. The timer starts when the dif ference

exceeds the set point value and, if it lies above the set point

value continuous defrosting is permitted to start when the

timer has counted down.

PLEASE NOTE: For defrosting to start the Delay before

defrost must have also counted down.

Defrost

Displays the remaining time before defrosting the evaporator.

Heating cable

Displays the remaining time for the heating cable in the

drainage pipe from the heat pump to be active.

Heating, maximum operating time at hot water requirement

Displays the remaining time before the maximum time in

heating mode is reached if there is a simultaneous hot water

requirement.

Hot water, maximum operating time at heating

requirement

Displays the remaining time before the maximum time

for hot water operation is reached if there is a simultaneous heating requirement.

Heating season change delay

Displays the remaining time until the heating season is

activated in the heat pump.

Blocking low pressure switch

Displays the time remaining when the low pressure

switch is blocked.

Blocking room sensor infl uence

Displays the time remaining when the room sensor is

blocked.

Hot water peak

Displays the remaining time for the hot water peak to be

active.

Hot water peak interval

Displays the time remaining to the next hot water peak.

Timers

There are a number of timers in the control unit.

The statuses for these are shown in the menu Timers.

Page 39

39

Alarm functions

Functions under Alarm:

Alarm log

Alarm history

Warning log

All alarms and warnings are described in the User guide.

At Customer level you have access to alarm information in the alarm log.

As installer you can also:

Delete the Alarm log

Read information in Alarm history

Read information in Warning log

Delete the Warning log

Alarm histor y

Alarm information

Alarms are stored in chronological order. Turn the menu dial to read off all

information about the most recent alarm, continuing to turn will show the

previous alarms.

Alarm information consists of a heading and then detailed information

about the time, temperatures of all sensors and status for each output when

the alarm occurred.

Warning log

The alarm log stores alarms in chronological order.

Deleting Warning log and Alarm log can be appropriate when commissioning has been completed.

Advanced menu

Page 40

40

Technical information

Technical information

Factory settings

The table displays the factory values (F value) of the settings that you, as a customer,

(K) can change via the customer menus Menu and Advanced menu. The functions of

Installer/Service level (I/S) under Menu and Advanced menu in the table are accessed by

the installer after changing the access level.

Menu

Level F value

Fast restart of heat pump?

I/S No

Start up

--"--\Setting the clock

--"--\ --"--\Set date I/S

yy-mm-dd

--"--\ --"--\Set time I/S

hh:mm:ss

--"--\Connected extra sensors

--"--\ --"--\T3 acknowledged (T3) I/S No

--"--\ --"--\T5 acknowledged (T5) I/S No

--"--\Manual operation I/S No

--"--\Additional heat options

--"--\ --"--\Additional heat only? I/S No

--"--\ --"--\Block additional heat? I/S No

--"--\Language I/S Selected

--"--\Correct sensor I/S 0

--"--\ Fan defrost interval I/S 1 time

--"--\Fan defrost time I/S 1,0 min

--"--\Forced defrost I/S No

--"--\Block crankcase heater at high outdoor

temperature

I/S 10,0ºC

--"--\Anti-jamming mode time I/S 02:00

--"--\Alarm buzzer signal length I/S 1 min

--"--\T1 Set point value maximum I/S 80ºC

Menu

Level F value

--"--\Display

--"--\ --"--\Contrast I/S 10

--"--\ --"--\Brightness I/S 10

Room temperature setting (T5)

K 20,0ºC

Temperature increase/decrease (no T5)

K=

Temperature increase/decrease settings (no T5)

--"--\Limit value for V or H I/S 10ºC

--"--\Much colder/warmer, change I/S 8%

--"--\Colder/warmer, change I/S 3%

Extra hot water

K0 h

Page 41

41

Technical information

Advanced menu

Level F value

Temperature

--"--\Heating system temperature

--"--\ --"--\Heat curve K

V=20,0ºC,

H=55,2Cº

--"--\ --"--\ Hysteresis

--"--\ --"--\ --"--\Maximum K 16,0ºC

--"--\ --"--\ --"--\Minimum K 4,0ºC

--"--\ --"--\ --"--\Time factor K 10

--"--\Room sensor settings (T5)

--"--\ --"--\Room temperature setting K 20,0ºC

--"--\ --"--\Room sensor infl uence

--"--\ --"--\ --"--\Change factor K 5,0

--"--\ --"--\ --"--\Blocking time K 4 h

--"--\Time limited settings

--"--\ --"--\Time control heating

--"--\ --"--\ --"--\Day and time K Off

--"--\ --"--\ --"--\Change in temperature K -10ºC

--"--\ --"--\Holiday

--"--\ --"--\--"--\Date K Off

--"--\ --"--\--"--\Change in temperature K -10ºC

--"--\Heating season

--"--\ --"--\Heating season limit K 18ºC

--"--\ --"--\Delay K 4 h

--"--\--"--\Direct start limit K 10ºC

--"--\Heating, maximum operating time at hot

water requirement

K 20 min

--"--\Shut down protection, change over hot

water to heating

I/S 300 s

Advanced menu

Level F value

Hot water (T3)

--"--\Extra hot water

--"--\ --"--\Number of hours K 0

--"--\ --"--\Stop temperature K 65,0ºC

--"--\Hot water peak

--"--\ --"--\Interval K 0 days

--"--\ --"--\Start time K 03:00

--"--\ --"--\Stop temperature I/S 65,0°C

--"--\Hot water temperature

--"--\ --"--\T8 Stop temperature hot water I/S 59,0°C

--"--\ --"--\In compressor mode

--"--\ --"--\ --"--\T3 Start temperature I/S 49,0°C

--"--\ --"--\ --"--\T9 Stop temperature I/S 54,0°C

--"--\ --"--\In additional heat only mode

--"--\ --"--\ --"--\T3 Stop temperature I/S 56°C

--"--\ --"--\ --"--\T3 Hysteresis I/S 1,0°C

--"--\ --"--\Hot water, maximum operating time at

heating requirement

K 30 min

--"--\Time control hot water K Of f

--"--\Additional heat in water heater

--"--\--"--\ T3 Start value of fset I/S 5,0ºC

--"--\--"--\ T3 Hysteresis I/S 2,0ºC

Temperatures

--"--\Correct sensor I/S 0,0

Defrost settings

--"--\T12 - T11 settings

--"--\ --"--\Time for reached temperature

difference

I/S 60 s

--"--\ --"--\Difference at +10°C I/S 12ºC

--"--\ --"--\Difference at 0°C I/S 8ºC

--"--\ --"--\Difference at -10°C I/S 6ºC

--"--\Maximum outdoor temperature I/S 13ºC

--"--\T11 Maximum temperature I/S 20ºC

--"--\Maximum time I/S 15 min

--"--\Delay after compressor start I/S 10 min

Page 42

42

Technical information

Advanced menu

Level F value

--"--\Minimum time between defrosts I/S 30 min

--"--\Compressor pressure equalisation time I/S 0 s

--"--\4-way valve pressure equalisation time I/S 0 s

--"--\Forced defrost I/S No

--"--\Heating cable time after defrost I/S 15 min

--"--\Fan defrost

--"--\ --"--\Fan defrost interval I/S 1 time

--"--\ --"--\Fan defrost time I/S 1,0 min

--"--\ --"--\Temperature limit I/S -5ºC

Additional heat settings

--"--\Start delay I/S 60 min

--"--\Time control additional heat I/S Of f

--"--\Additional heat options

--"--\ --"--\Additional heat only? I/S No

--"--\ --"--\Block additional heat? I/S No

--"--\Mixing valve settings

--"--\ --"--\Mixing valve delay I/S 20 min

--"--\ --"--\Neutral zone I/S 1,0°C

--"--\ --"--\Running time extension

--"--\ --"--\ --"--\Increase signal extension I/S 1

--"--\ --"--\ --"--\Decrease signal extension I/S 1

--"--\ --"--\Additional heat maximum temperature

--"--\ --"--\ --"--\Mixing valve limitation start

temperature

I/S 47°C

--"--\ --"--\ --"--\Mixing valve force close I/S 48°C

--"--\ --"--\Limitation at temperature increase I/S Yes

--"--\ --"--\Limitation time I/S 20 s

Advanced menu

Level F value

Setting the clock

--"--\Set date K

yy-mm-dd

--"--\Set time K

hh:mm:ss

Alarm

--"--\Alarm log

--"--\ --"--\Delete alarm log? I/S No

--"--\Warning log

--"--\ --"--\Delete warning log? I/S No

Access level

K, I/S K (0)

Return to factor y settings

K, I/S No

Deactivate alarm buzzer

KNo

Page 43

43

Technical information

Dimensions

Control cabinet (WxDxH) mm 335x112x296

Accessory unit (WxDxH) mm 255x100x180

Control cabinet and accessory unit electric/oil-fi red boiler

Technical information

Output data at +7/35º and +7/45º are stated according to the European standard EN 14511.

1)

Dimensions excl. feet, supplied min 20 mm - max 30 mm depending on adjustment

Model IVT Optima 600 900 1100 1400 1700

Emitted/Supplied output at +7/35º kW 5.5 / 1.4 7.2 / 2.0 8.9 / 2.3 12.9 / 3.3 14.3 / 3.9

Emitted/Supplied output at +7/45º kW 5.1 / 1.7 7.0 / 2.4 8.6 / 2.8 12.5 / 4.0 14.1 / 4.7

Heat carrier fl ow nominal l/s 0.19 0.29 0.34 0.47 0.55

Internal pressure drop heat carrier kPa 5 6 7 7 8

Air fl ow m³/h 2200 2200 2200 5500 5500

Electrical consumption fan A 0.44 0.44 0.44 0.7 (400V N3) 0.7 (400V N3)

Electrical supply 400V 3N~ 50Hz

Fuse size AT 10 16

Compressor Scroll

Highest outgoing heat carrier temperature ºC 65

Refrigerant fi lling R-407C kg 2,5 2,6 2,7 3,4 3,5

HTF connection mm Hose 1 inch internal thread external G25

Defrost system Hot gas with four-way valve

Dimensions (WxDxH)

1)

mm 820x640x1190 920x705x1660

Weight kg 140 145 155 160 165

Colour Champagne

Outer casing Galvanised enamelled plate

Page 44

44

Technical information

Sensor table

The table shows all sensor resistance at different temperatures.

Sound levels

The table describes the sound levels stated in sound

pressure level.

Sound pressure level:

Sound pressure level is defi ned as the sound level, which

at an ear level of 1.8 metres, is perceived one metre from

the heat pump. Measured in a sound measurement room

without echo at an outdoor temperature of +7ºC and 50ºC

fl ow temperature.

Example:

When the heat pump is installed outside with free sound

propagation the sound level drops by 6dBa with each

doubling of distance.

Example Optima 600 Optima 1400

Distance Lp - ear (dBa) Lp - ear (dBa)

1 metre 53 59

2 metres 47 53

4 metres 41 47

8 metres 35 41

Heat pump

Sound pressure level

Lp - ear (dBa)

Optima 600 53

Optima 900 53

Optima 1100 53

Optima 1400 59

Optima 1700 59

Temperature (ºC) kΩ

-40 154.300

-35 111.700

-30 81.700

-25 60.400

-20 45.100

-15 33.950

-10 25.800

-5 19.770

0 15.280

5 11.900

10 9.330

15 7.370

20 5.870

25 4.700

30 3.790

35 3.070

40 2.510

45 2.055

50 1.696

55 1.405

60 1.170

65 0.980

70 0.824

75 0.696

80 0.590

85 0.503

90 0.430

Page 45

Page 46

IVT Industrier AB, Sweden

www.ivt.se | mailbox@ivt.se

Loading...

Loading...