Greenline HT Plus

C and E

User Guide

Art. no: 290410-9 Version: 1.0

FOR THE USER

INDEX

3

Manual for Heat pump Greenline HT Plus C and E

IVT Industrier AB, 2004-06-27

Article number: 290410-9

Version 1.0

Copyright © 2004. IVT Industrier AB. All rights reserved.

This manual contains copyright protected information that is the property of IVT Industrier AB. No part of this document may be copied or forwarded, electronically or mechanically,

without prior, written permission from IVT Industrier AB. This includes photographing and translation to another language.

Thank you for choosing a heat pump from

IVT Industrier

We hope that our heat pump meets your expectations and gives you many years of energy saving. We want you and

your family to enjoy a good economy at the same time as you actively safeguard the environment. We have taken today’s

demands on heat pumps into consideration and believe that your Greenline HT Plus will give you many useful functions in

the future. Your heat pump features an advanced control unit that monitors and controls the temperature in the house and

contributes towards improved overall economy. The heat pump Greenline HT Plus has, for example, a holiday function,

that's to say the heat pump can be set at a “low level” while you are away on holiday.

IVT is the leading heat pump manufacturer in the Nordic Countries. More than every second heat pump comes from IVT.

We have worked with solutions to reduce energy consumption on the environment’s terms for more than 30 years. Today

we can present the widest range of heat pumps for effi cient energy saving in all types of housing and properties.

Johnny Wärnelöv

Managing director IVT Industrier AB

4

Contents

FOR THE USER .................................................................................................... 5

Important information ....................................................................................... 5

This is how your heat pump works ..................................................................... 6

Technology in and around the heat pump ................................................................................................................6

Component parts of the heat pump .................................................................... 8

Control unit Rego 637 ..................................................................................... 10

The control unit’s two methods to control the heat pump ........................................................................................11

The control panel ............................................................................................ 12

Buttons and lamps ................................................................................................................................................12

Menu dial .............................................................................................................................................................13

How to use the control panel .................................................................................................................................13

Basic functions (Customer level 1) ................................................................... 13

Menu outline for Basic functions (Customer level 1) .............................................................................................14

Select scrolling information on the menu display ...................................................................................................14

Set the heating ......................................................................................................................................................15

Set the desired room temperature .......................................................................................................................... 18

Set the heat pump for extra hot water .................................................................................................................... 18

Heating and hot water settings ..............................................................................................................................19

Read the temperatures on the heat pump ...............................................................................................................19

Extra functions (Customer level 2) ................................................................... 21

Menu outline for Extra functions (Customer level 2) .............................................................................................21

Temperature settings ............................................................................................................................................22

Set extra heat curve with mixing valve ..................................................................................................................23

Hot water settings .................................................................................................................................................24

Timer control ........................................................................................................................................................24

Reading operating times on the heat pump and additional heat ............................................................................25

Set the time and date ............................................................................................................................................26

Alarms given by the heat pump .............................................................................................................................27

Return to factory settings .......................................................................................................................................27

Maintenance ................................................................................................... 28

Opening the front cover .........................................................................................................................................28

Sight glass .............................................................................................................................................................28

Expansion vessel ...................................................................................................................................................29

Particle fi lter ......................................................................................................................................................... 29

Checking the protective anode ...............................................................................................................................30

Savings .......................................................................................................... 31

What to do if a fault occurs .............................................................................. 32

Dimmed menu display ..........................................................................................................................................32

Fuses and reset buttons on the heat pump .............................................................................................................. 33

All alarms .............................................................................................................................................................33

Technical information ...................................................................................... 40

The heat pump's factory settings ............................................................................................................................40

Sensor table ...........................................................................................................................................................40

Technical information ...........................................................................................................................................41

Index ............................................................................................................. 42

Table of Contents

5

Note

It is important as the user that you

read through this chapter.

Under no circumstances may the user

make settings that are designed for

the installer. This can cause serious

malfunction of the heat pump.

Important information

The heat pump Greenline HT Plus represents a new generation of heat

pumps from IVT Industrier. It contains numerous functions to control the

temperature and production of hot water in the house. The control unit

Rego 637 is the brains of the heat pump. Rego 637 includes a control and

monitoring function that stores important settings about the heat pump's

operation and maintenance. The settings are made by the installer and the

user via a control panel on the front of the heat pump. Settings intended

for the user, are presented under the headings Basic functions and Extra

functions.

When the heat pump has been installed and started there are a number of

points you should check regularly. This may concern an alarm triggering

or performing basic maintenance actions. First of all you should perform

these actions yourself. This manual describes each step in detail. If the

problem remains you should contact your dealer.

For the user

6

FOR THE USER

This is how your heat pump works

The heat pump Greenline HT Plus represents a new generation of heat pumps from IVT Industrier. The heat pump has

been manufactured for easy and reliable use as well as to provide your house with inexpensive and environment friendly

heating. The easiest way to describe how a heat pump works is to say it works like a refrigerator, however, the other way

round. In a refrigerator heat is moved from the inside to the outside. In a heat pump heat stored in the ground, rock or

water, is moved into the house. The heat pump collects a few degrees of the stored solar energy. The heat is led into the

house via a hose. The temperature is then increased in the heat pump and the heat is distributed to the house’s heating

system.

The heat pump collects stored solar energy

Boiling point in relation to the

pressure:

The boiling point of different liquids

varies with pressure, the higher the

pressure, the higher the boiling point.

For example, water boils at +100ºC

at normal pressure. Double the pressure and water boils at +120ºC. Half

the pressure and water then boils at

+80ºC. The refrigerant in the heat

pump acts in the same way, the boiling

point changes when the pressure

changes. However, the boiling point of

the refrigerant is as low as approximately -40ºC at atmospheric pressure.

Consequently, it is also suitable for

low heat source temperatures.

Note

Rock heat Soil heat Lake heat

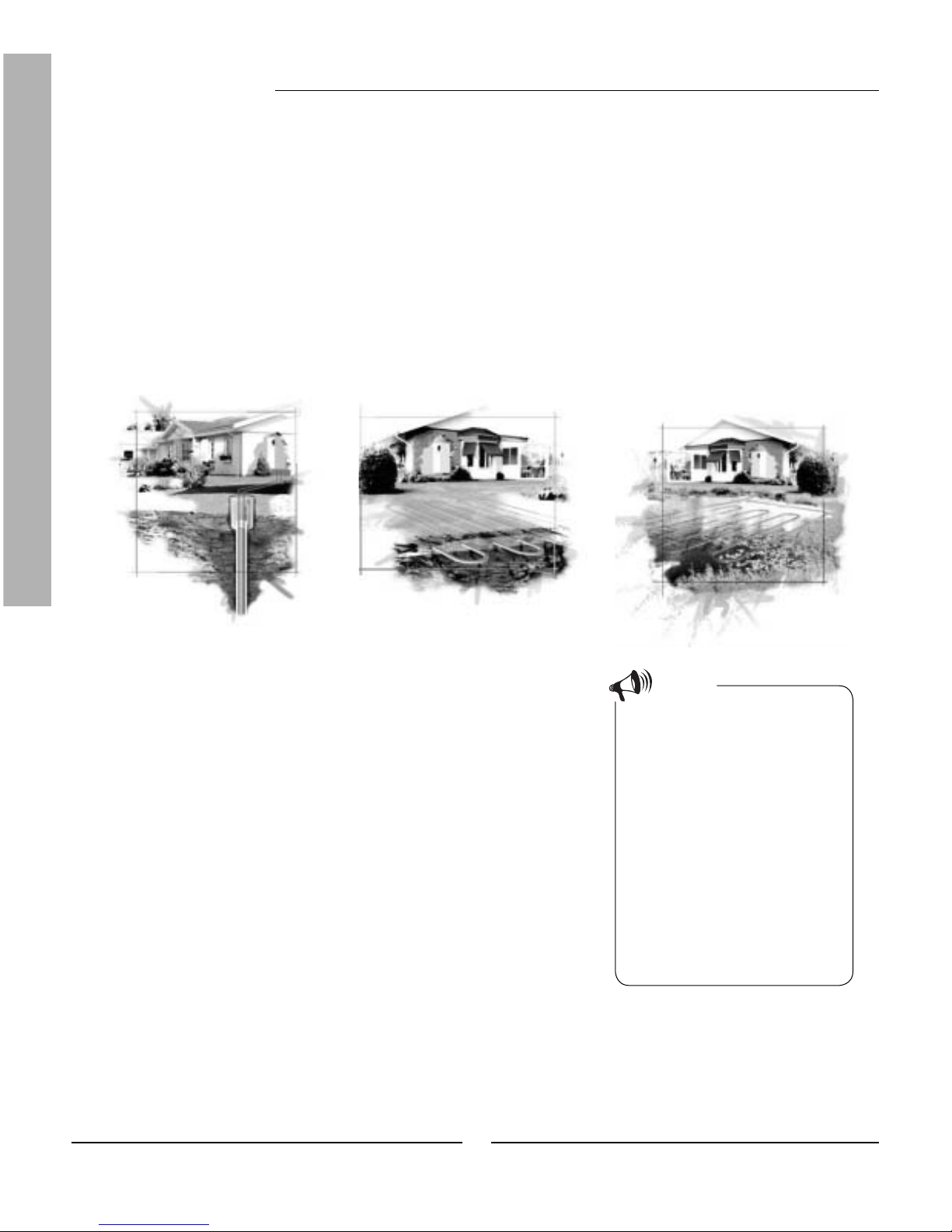

The heat pump consists of four main parts:

1. Evaporator

Evaporates the refrigerant to gas and at the same time transfers the

heat from the heat transfer fl uid to the refrigerant circuit.

2. Condenser

Condenses the gas to fl uid again and transfers the heat to the heating

system.

3. Expansion valve

Lowers the pressure of the refrigerant.

4. Compressor

Increases the pressure of the refrigerant.

These four main parts are linked in three circuits. A refrigerant circulates

in the heat pump, which in some parts of the circuit is in a liquid state and

in other parts in a gas state. Read more about the properties of the refrigerant in the sidebar to the right.

See the detailed description of the technologies used in the heat pump on

the next page.

Technology in and around the heat pump

This is how your heat pump works

7

FOR THE USER

Heat transfer fl uid in. A hose is connected here that collects the stored solar energy from, e.g., the soil or

rock. The hose contains a heat transfer fl uid, which is a mixture of water and anti-freeze. The fl uid collects

the heat from the rock and with the help of the HTF pump leads it into the heat pump and the evaporator. The

temperature is then approximately 0ºC.

In the evaporator the heat transfer fl uid meets the refrigerant. At this stage the refrigerant is in a fl uid state

and is at approximately -10ºC. When the refrigerant meets the zero degree heat transfer fl uid it starts to boil.

It then forms a vapour, which is led into the compressor. The temperature of the vapour is 0ºC.

The pressure of the refrigerant increases in the compressor and the vapour temperature rises from 0ºC to

approximately +100ºC. The warm gas is then forced into the condenser.

The condenser is the heat pump's heat emitting part. Here the heat is transferred to the house’s heating

system (radiators and fl oor heating) and the hot water system. The vapour is cooled in the condenser and

becomes fl uid. The pressure in the refrigerant is still high when it is led on to the expansion valve.

The refrigerant pressure is then lowered in the expansion valve. At the same time, the temperature also drops

to approximately -10ºC. When the refrigerant has passed through the valve and the evaporator it changes to

vapour again.

In heat transfer fl uid out, the heat transfer fl uid is led out from the heat pump to the rock to collect new stored

solar energy. The temperature of the fl uid is approximately -3ºC.

1

2

3

4

5

6

Floor heating

Radiator

Fan-assisted

radiator

Heat pump

Rock

Soil

0ºC

-3ºC

0ºC +100ºC

+65ºC

+57ºC

-10ºC

1

6

2 3 4

5

Heat carrier pump

Heat

transfer pump

This is how your heat pump works

"The hot side"

"The cold side"

8

FOR THE USER

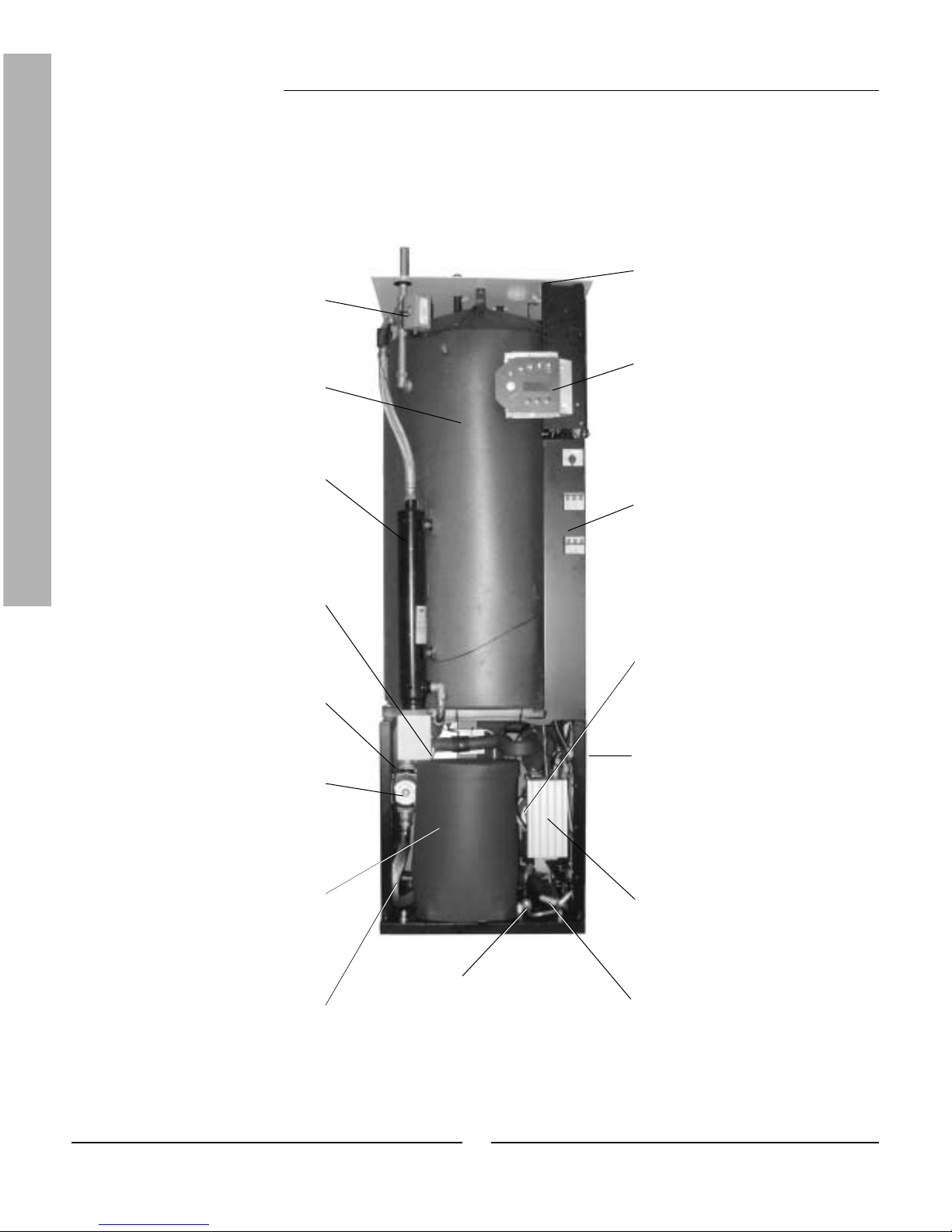

Component parts of the heat pump

Three-way valve

The valve switches between

heating the heating water and hot

water.

Hot water heater

The cylinder is double-shelled

and holds approximately 165 litres

of hot water and 60 litres of the

heating water.

Electric cassette

The electric cassette is used

to provide extra output in cold

weather conditions, with large

water consumption and at hot

water peaks.

Reset button

Press in the button if the overheat

protector on the electric cassette

has tripped. The button is located

on the side.

Heat carrier pump

The pump ensures the heating

water circulates within the heating

system.

Compressor

The compressor increases the

pressure of the refrigerant.

The temperature of the vapour

increases from 0ºC to approximately +100ºC. The compressor is

insulated to decrease the noise

level.

Socket

Connections for the mains supply

as well as sensors.

Control panel

The control panel has a background lit menu display with four

rows of text information, three

buttons and a dial.

Distribution box

The distribution box is enclosed.

It houses a reset function for the

motor cut-out as well as miniature

circuit-breakers (MCB) for the

heat pump and electric cassette.

Heat transfer fl uid pump

The pump is insulated and

features an anti-corrosive fi nish.

It ensures the heat transfer fl uid

circulates from, e.g. the rock to

the heat pump.

Control unit Rego 637

The control unit is enclosed. It

controls and monitors all heat

pump functions.

Expansion valve

Lowers the pressure of the

refrigerant that is to enter the

evaporator and collect energy

from, e.g. the rock.

Sight glass

Sight glass to check the level in the

refrigerant circuit. Air bubbles must not

form in the sight glass when the heat

pump is running. However, there might

be bubbles when the heat pump is started

and stopped.

Flexible hoses

The hoses counteract vibrations in

the heat pump.

IVT Greenline HT Plus C

Evaporator

The evaporator evaporates the

refrigerant to gas and transfers

heat from the heat transfer fl uid to

the refrigerant circuit (behind the

heat pump).

Condenser

The condenser condenses the

vapour to fl uid again and transfers

the heat to the heating system.

Component parts of the heat pump

9

FOR THE USER

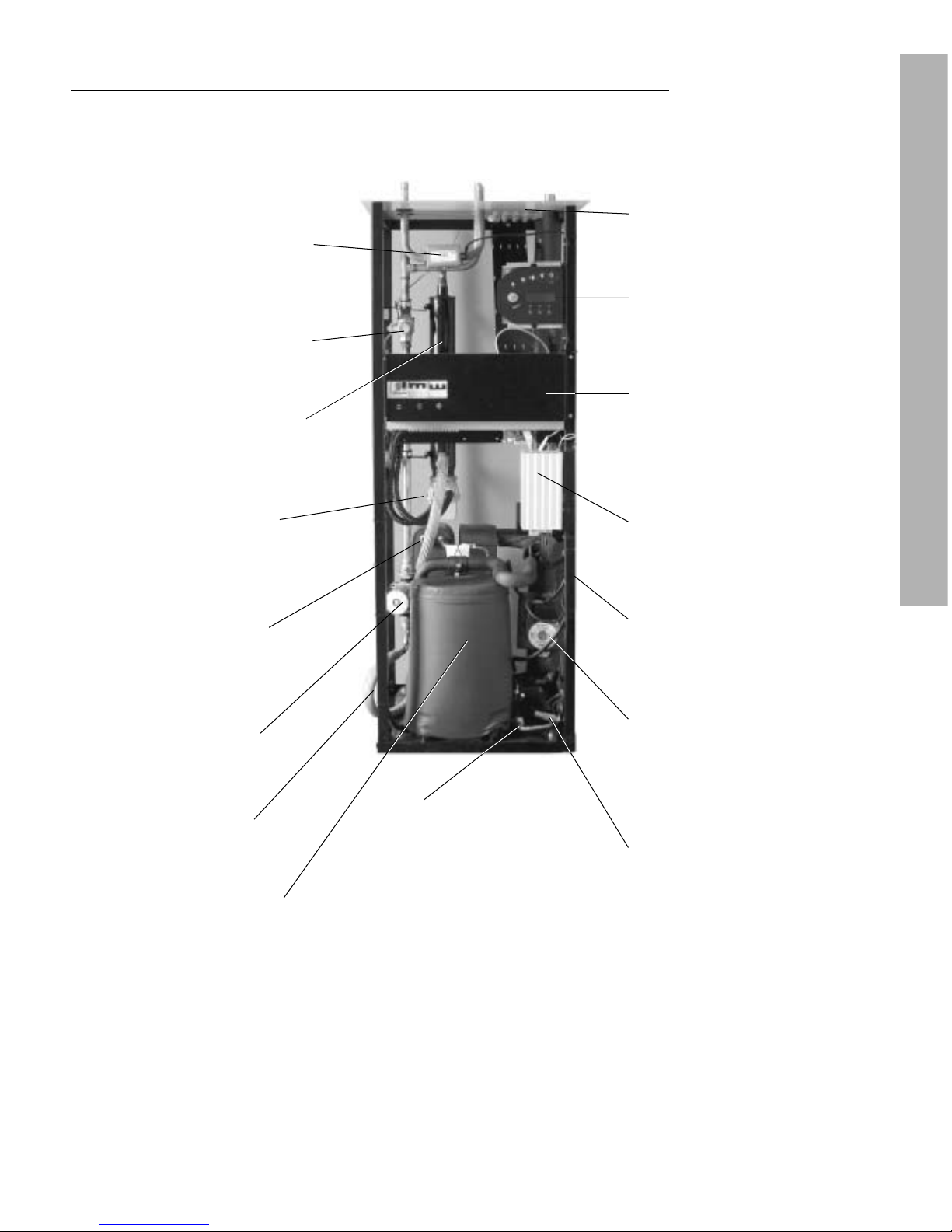

IVT Greenline HT Plus E

Reset button

Press in the button if the overheat

protector on the electric cassette

has tripped. The button is located

on the side.

Heat carrier pump

The pump ensures the heating

water circulates within the heating

system.

Compressor

The compressor increases the

pressure of the refrigerant.

The temperature of the vapour

increases from 0ºC to approximately +100ºC. The compressor is

insulated to decrease the noise

level.

Socket

Connections for the mains supply

as well as sensors.

Control panel

The control panel has a background lit menu display with four

rows of text information, three

buttons and a dial.

Distribution box

The distribution box is enclosed.

It houses a reset function for the

motor cut-out as well as miniature

circuit-breakers (MCB) for the

heat pump and electric cassette.

Heat transfer fl uid pump

The pump is insulated and features

an anti-corrosive fi nish. It ensures

the heat transfer fl uid circulates

from, e.g. the rock into the heat

pump.

Control unit Rego 637

The control unit is enclosed. It

controls and monitors all heat

pump functions.

Expansion valve

Lowers the pressure of the refrigerant that is to enter the evaporator

and collect energy from, e.g. the

rock.

Sight glass

Sight glass to check the level in the

refrigerant circuit. Air bubbles must

not form in the sight glass when the

heat pump is running. However, there

might be bubbles when the heat

pump is started and stopped.

Flexible hoses

The hoses counteract

vibrations in the heat pump.

Evaporator

The evaporator evaporates the

refrigerant to gas and transfers

heat from the heat transfer fl uid to

the refrigerant circuit (behind the

heat pump).

Particle fi lter

The fi lter can be opened for easy

cleaning. It also has a shut off

function.

Electric cassette

The electric cassette is used

to provide extra output in cold

weather conditions, with large

water consumption and at hot

water peaks.

Three-way valve

The valve switches between

heating the heating water and hot

water.

Condenser

The condenser condenses the

vapour to fl uid again and transfers

the heat to the heating system.

Component parts of the heat pump

10

FOR THE USER

Control unit Rego 637

The control unit Rego 637 is the brains of the heat pump. It makes sure the

heat pump gives the best energy savings and that it runs for many years.

The control unit controls and monitors the heating and hot water supply in

your house. The monitoring function is especially important. It shuts down

the heat pump in the event of operational disturbances so that no critical

parts are damaged.

Additional heat gives more output

When the heat pump can not manage to heat the house by itself, for

example, if there is a considerable drop in the outdoor temperature, the

control unit ensures the additional heat source is connected. Together

the heat pump and additional heat guarantee the right temperature in the

house. Additional heat in the Greenline HT Plus is provided by a built

in electric cassette. Additional heat can never completely take over the

heating from the heat pump. It only adds the output necessary for the heat

pump to be able to produce the right temperature. When the heat pump

can once again manage heating on its own the additional heat is automatically disconnected.

Hot water is given priority over heating water

In a house with water based heating a difference is made between heating

water and hot water. The heating water is for radiators/fl oor heating

and hot water is for showers and taps. Hot water is heated in a hot water

cylinder. The hot water cylinder is fi tted with a sensor that senses the

temperature of the hot water. In Greenline HT Plus C there is a hot

water cylinder inside the heat pump while Greenline HT Plus E has an

external hot water heater. The heating water passes through the hot water

cylinder’s outer shell and heats up the hot water cylinder’s inner tank. The

control unit makes sure the heating of hot water is always given priority

over the heating of the heating water. This means you never need to be

without hot water. The control unit controls a three-way valve that switches

between heating the heating water and hot water. Once the hot water

has been heated the three-way valve switches so that the heating water is

heated.

Control unit

Rego 637

Electric

cassette

(additional

heat)

Three-way

valve

Double-shelled

hot water heater

Heating water

Hot water

Control unit Rego 637

11

FOR THE USER

The control unit’s two methods to control

the heat pump

The control unit uses two different methods to control the heat pump.

These two methods are: Control with an outdoor sensor and Control with an

outdoor sensor supplemented with a room sensor.

Control with an outdoor sensor

Control with an outdoor sensor is the most common method used by the

control unit to control the heat pump. When the heat pump is delivered it

is set for this control method. A sensor is fi tted on the outside wall of the

house. It sends signals to the control unit in the heat pump. Control with

an outdoor sensor means that the heat pump automatically regulates the

heating in the house depending on the outdoor temperature. If the outdoor

temperature drops, i.e. it becomes colder; the radiators inside the house

will become warmer.

You determine the temperature of the radiators, in relation to the outdoor

temperature, with the help of a number of settings such as selecting the

heat curve on the control unit. A lower curve gives higher energy savings.

Control with an outdoor sensor supplemented

with a room sensor

Control with an outdoor sensor supplemented with a room sensor means

that you also place a sensor in a central position inside the house. This is

connected to the heat pump and provides the control unit with information

about the room temperature. The signals affect the control unit’s settings

(curves) and ensure the heat pump gives the best possible energy savings.

This control method is used when factors other than the outdoor temperature infl uence the indoor temperature. Examples include the use of a stove

or fan-assisted radiator, or if the house is sensitive to the wind.

It is only the room where the room

sensor is located that can infl uence

regulation of the temperature.

Note

Control unit Rego 637

12

FOR THE USER

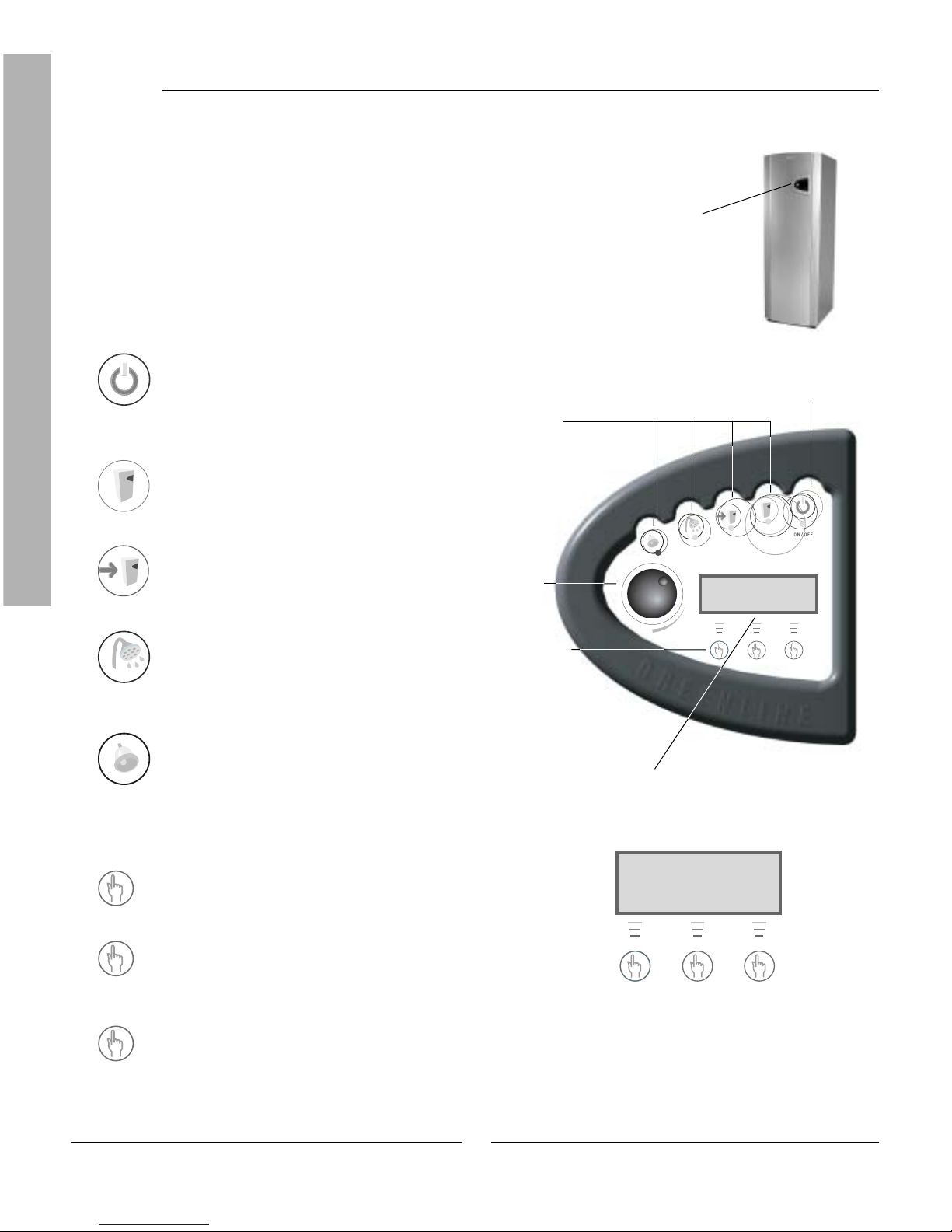

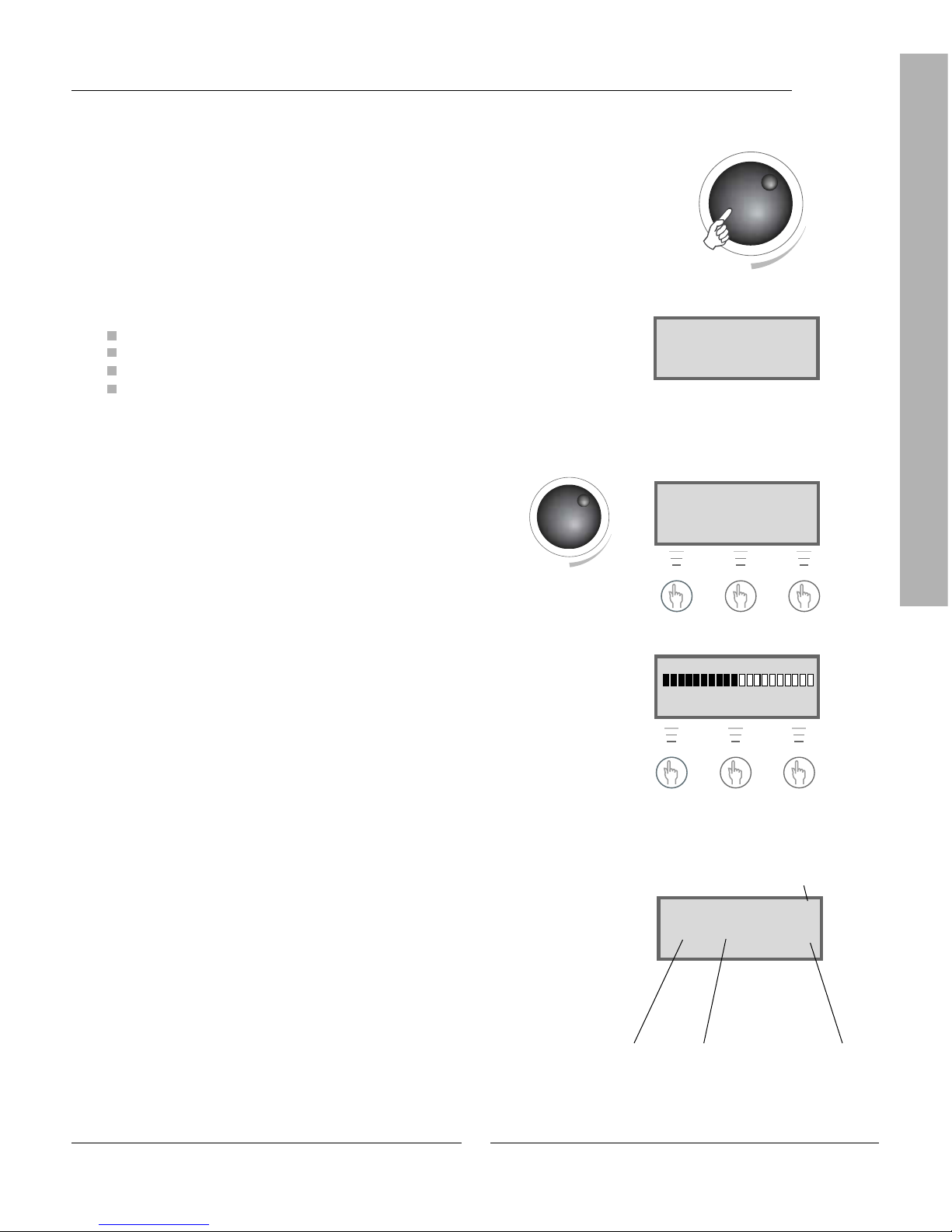

The control panel

All settings are made from the control panel. It also displays heat production statistics and information about different alarms. When you have

made your settings, the control panel makes sure they are saved in the

control unit Rego 637 to carr y out your wishes.

Control panel

Menu dial

Status lamps

Power switch (ON/OFF)

Buttons and lamps

Power switch (ON/OFF)

You start and stop the heat pump using the power

switch button.

Lamp on: The heat pump is on.

Lamp fl ashes: The heat pump is off.

Operating status

Lamp on: The heat pump (compressor) is

operational.

Additional heat status

Lamp on: The heat pump is using additional heat

from, e.g. an electric cassette.

Hot water status

Lamp on: The heat pump is heating water in the

cylinder.

Lamp fl ashes: The heat pump has a hot water

peak or is producing extra hot water.

Alarm status

Lamp fl ashes: A fault has occurred in the heat

pump.

Lamp on: The alarm has been acknowledged, but

the fault remains.

Heat

Heat

Pressing once gives a shortcut to the most

frequent temperature settings.

Info

Pressing once gives continuous information about

the heat pump’s and additional heat’s operating

conditions.

Menu

Press once to enter the main menu.

The main menu contains all setting menus and

temperature displays.

Info

Menu

Menu display

Menu buttons

Control panel

Rego 637 K1

040622 16:08:15 Tu

Heat Info Menu

Rego 637 K1

040622 16:08:15 Tu

Heat Info Menu

13

FOR THE USER

Rego 637 K1

040622 16:08:15 Tu

Heat Info Menu

Control panel

Menu dial

The menu dial is used to scroll through the menu display windows. Turn

the menu dial clockwise (to the right) to move down through the menus.

Turn the menu dial anti-clockwise (to the left) to move up through the

menus. You also determine the values of different settings by using the

dial.

The menu display gives you information and the chance to make settings.

You can:

Choose different temperature and hot water settings.

Choose extra hot water and the holiday function.

See alarm causes and receive corrective instructions.

Obtain operating statistics.

How to use the control panel

The principle of the control panel is based on the user using three

menu buttons and a menu dial to move between the different

menus and settings. On the lower row of the menu display you will

always see information about the signifi cance of the buttons. The

function of the buttons changes depending on which window you

are currently in.

Example

If, from the initial menu, you press the Heat button, you will access

the menu Temp. incr. / decr.. In this menu you can increase and

decrease the heating in the house. Note that the signifi cance of the

buttons has now changed. You can either return to the initial menu

by pressing the Return button or you can choose to change the

heating setting in the house by pressing the Adjust button. If you

press the Adjust button you can increase or decrease the heating in

the house by using the menu dial. Save your adjustment by pressing

the Save button.

Initial menu display

+

Initial menu

Initial menu

Time Date

Customer level 1

Day

Basic functions ( Customer level 1)

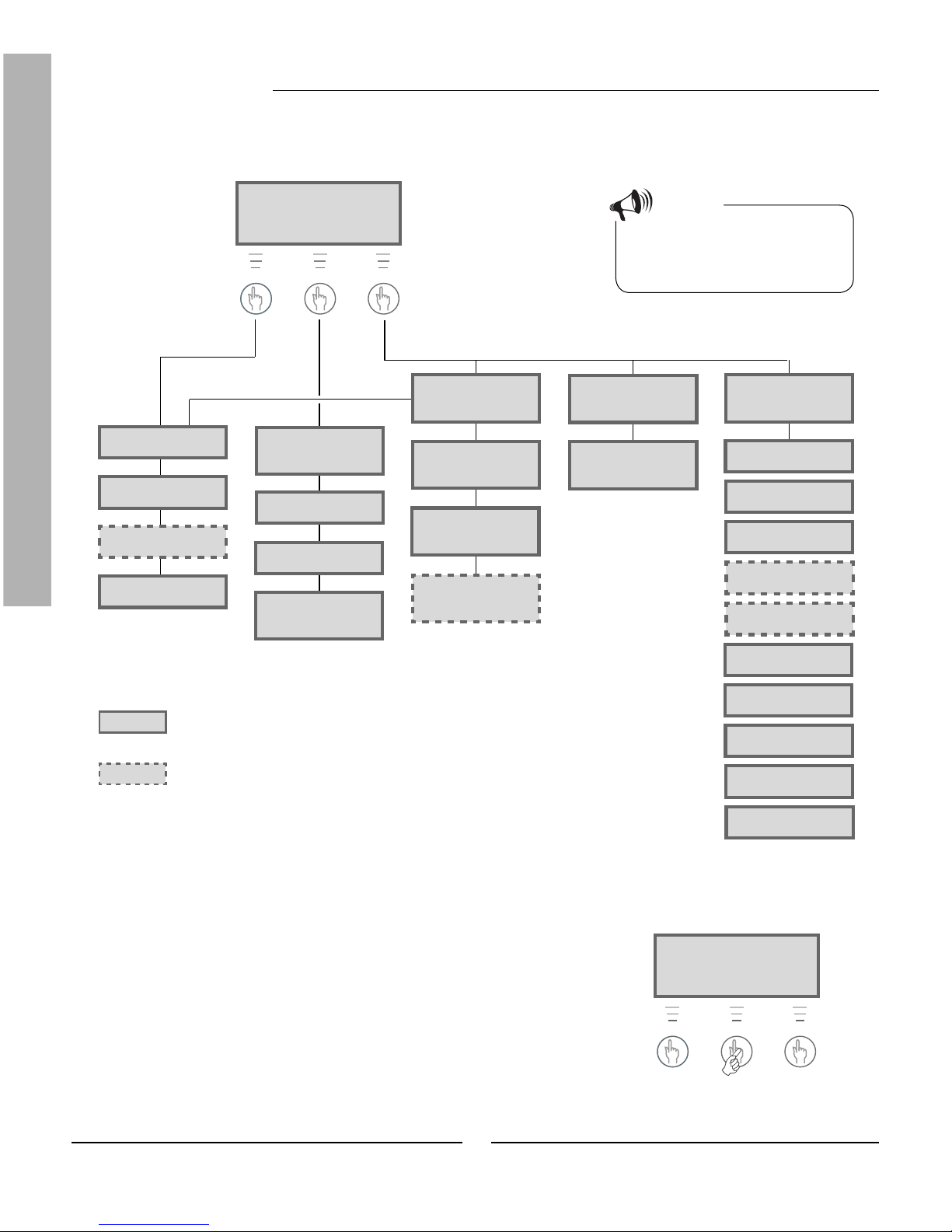

Basic functions (Customer level 1) are the functions most frequently used

and the ones you have the most benefi t of. You reach the basic functions

by pressing one of the Heat, Info or Menu buttons in the initial menu.

The designation K1 in the upper right corner indicates you are in Basic

functions - Customer level 1.

Rego 637 K1

040622 16:08:15 Tu

Heat Info Menu

Rego 637 K1

040622 16:08:15 Tu

Heat Info Menu

Temp. incr. / decr.

0 5,0 10

Return Adjust

14

FOR THE USER

Basic functions - Customer level 1

The menu display is standard on all

heat pumps.

=

=

Temp. fi ne-tune

Page 17

The menu display is only shown on

the heat pump in combination with an

extra sensor or for a specifi c model of

Greenline HT Plus.

Temp. incr. / decr.

Page 16

Room temperature

Page 18

Extra hotwater

Page 18

STANDBY

No rad heat required

No hotwater required

Page 15

HOTWATER MODE

Heat pump only

Page 15

HEAT RAD MODE

Compr. + Add. heat

Page 15

HEAT RAD REQ

Heat pump starts

in #### seconds

Page 15

Main menu

Indoor temperature

settings 1

Page 19

Temperature settings

Temp. incr. / decr.

range 0-10 1.1

Page 16

Temperature settings

Temp. fi ne-tune

range -10/+10 1.2

Page 17

Temperature settings

Setting of room

temperature 1.10

Page 18

Main menu

Adjusting the hot

water settings 2

Page 19

Hot water setting

Duration of

add. hot water 2.1

Page 18

Main menu

Monitor all

temperatures 3

Page 19

Temperature readings

Return radiator GT1

Temperature readings

Out GT2

Temperature readings

Hot water GT3

Temperature readings

Shunt, fl ow GT4

Temperature readings

Room GT5

Temperature readings

Compressor GT6

Temperature readings

Heat trfl uid out GT8

Temperature readings

Heat tr fl uid in GT9

Temperature readings

Ht trfl d(coll)inGT10

Temperature readings

Httrfl d(coll)outGT11

Page 20

Note

Each menu is numbered in the lower

right-hand corner; this indicates which

main display it is associated to.

Select scrolling information on the menu

display

If you press the Info button in the initial menu you will receive continuous

information about the heat pump's operation and working temperatures.

This is what to do:

1. Press the Info button in the initial menu.

Here follows a few of the windows displayed:

Menu outline for Basic functions (Customer level 1)

Rego 637 K1

040622 16:08:15 Tu

Heat Info Menu

Rego 637 K1

040622 16:08:15 Tu

Heat Info Menu

15

FOR THE USER

The heat pump is in standby mode.

The heat pump is producing hot water. You see at which temperature

the heat pump will stop and the present temperature. Note that the stop

temperature is read at the bottom of the cylinder. The hot water is a few

degrees warmer.

The heat pump and additional heat are running.

The heat pump has received signals that it should produce heating. It now

waits for the restart time to countdown to zero.

Return to the initial menu by pressing one of the buttons or turn the dial.

Basic functions - Customer level 1

Set the heating

It is easy to set the heating level on the heat pump. However, before we

explain how to do this it is important to understand the relation between

the outdoor temperature, return temperature and heat curve slope. The

easiest way to explain the relation is with a heat curve.

Heat curve

You use the heat curve to help set the indoor temperature you would

like. The heat pump is controlled by the outdoor temperature. When the

weather becomes colder the heat pump ensures more heating is produced

automatically.

Return temperature:

The return temperature is the temperature of the water that returns to the

heat pump from the radiators. The water led out from the heat pump to the

heating system is normally 7-10ºC higher than the return temperature.

When the outdoor temperature is -10ºC and curve 4 is set, the pump

attempts to keep the return water at approximately 40ºC. If instead the

temperature is 35ºC, the fl ow water is heated until the return water is warm

enough.

Outdoor temperature:

The outdoor temperature determines how much heating the heat pump

should produce. A sensor placed outdoors sends signals to the control unit,

which then adjusts the heat pump.

Cur ve slope:

You can change the curve slope to increase or decrease the heating in the

house. The scale is between 0-10.

On delivery the heat pump curve

slope is set to position 4. This means

that the return temperature is +35ºC

when it is 0ºC outdoors.

Note

STANDBY

No rad heat required

No hotwater required

HOTWATER MODE

Heat pump only

Stop temp 53,0°

Present temp 42,0°

HEAT RAD MODE

Compr. + Add. heat

Stop temp 45,0°

Present temp 44,0°

HEAT RAD REQ

Heat pump starts

in 320 seconds

16

FOR THE USER

In cold weather (below -5ºC):

If you are not satisfi ed with the indoor temperature when it is colder than

-5ºC outdoors, you need to change the slope of the heat curve. This is what

to do:

1. Press the Heat button in the initial menu.

2. Press the Adjust button.

3. Turn the menu dial clockwise to increase the heating.

Turn the menu dial anti-clockwise to lower the heating.

(Adjust in small increments, 0.5-1.0 units is usually enough.)

4. Save the new value by pressing the Save button.

Basic functions - Customer level 1

Dashed line:

If the return temperature exceeds 57ºC an alarm is given and the compressor switches off. The heat pump star ts automatically when the return

temperature drops.

Curve slope:

2-4 Normal setting for fl oor hea-

ting.

4-6,5 Normal setting for radiators.

7-10 Abnormal high setting.

From the heat curve we see that curve slope 4 gives a return temperature

of +35ºC when it is 0ºC outdoors. If the

outdoor temperature drops we can see

that the return temperature increases.

The colder the outdoor temperature

the higher the return temperature. At

an outdoor temperature of approximately -30ºC we see the curve slope has

reached the limit value (+57ºC) for the

return temperature.

You should wait at least two days

when increasing or decreasing the

heating before making a new adjustment.

At outdoor temperatures around 0ºC

you should “adapt the heat curve” to

obtain the desired indoor temperature. Read how to “adapt the curve” in

the section Extra functions - Customer

level 2 / Temperature settings / Adapting the heat curve.

Note

Change the curve slope

The heat pump’s production of heat is adjusted by increasing or decreasing

the curve slope in the Temp. incr. / decr. menu. This is especially effective

in cold weather conditions.

Return temperature (ºC) Curve slope (0-10)

Outdoor temperature (ºC)

Temp. incr. / decr.

0 4,0 10

Return Adjust

Temp. incr. / decr.

0 5,0 10

Return Save

17

FOR THE USER

Basic functions - Customer level 1

Fine-tune the heat curve

The heat curve can also be fi ne-tuned. Fine-tuning means that you offset

the heat curve in parallel. Fine-tuning is done from the Temp. fi ne-tune

menu. The diagram for fi ne-tuning shows how the dashed line has been

offset upwards in parallel. This means the heating has been fi ne-tuned in a

positive direction and the heat pump will be instructed to maintain a higher

temperature on the return water at all outdoor temperatures.

Outdoor temperature (ºC)

Return temperature (ºC)

By using the menu dial on the control panel

the fi ne-tuning line has been moved up so the

heat pump produces more heat.

In warm weather (above +5ºC):

If you are not satisfi ed with the indoor temperature when it is warmer than

+5ºC outdoors, you should offset the cur ve in the Temp. fi ne-tune menu.

This is what to do:

1. Press the Heat button in the initial menu.

2. Turn the menu dial clockwise until you reach the menu

Temp. fi ne-tune.

3. Press the Adjust button.

4. Turn the menu dial clockwise to increase the heating.

Turn the menu dial anti-clockwise to lower the heating.

(Adjust in small increments, 0.5-1.0 units is usually enough.)

5. Save the new value by pressing the Save button.

Temp. fi ne-tune

-10° 0,0 10°

Return Adjust

18

FOR THE USER

Set the desired room temperature

If you have a room sensor connected to the heat pump you can set the

temperature in the room from the Room temperature menu. From Extra

functions (Customer level 2) you can also set how much you want the

sensor to infl uence the heating system.

This is what to do:

1. Press the Heat button in the initial menu.

2. Turn the menu dial clockwise until you reach the menu Room tempera-

ture.

3. Press the Adjust button.

4. Turn the menu dial clockwise to increase the room temperature.

Turn the menu dial anti-clockwise to lower the room temperature.

5. Save the new value by pressing the Save button.

Room temperature

10° 20,0 30°

Return Adjust

Note

The example describes how to set the

required room temperature with the

help of a connected room sensor. The

range is 10ºC to 30ºC.

Set the heat pump for extra hot water

You can obtain extra hot water by temporarily increasing the temperature

of the water in the hot water cylinder. The temperature increase is effected

with the help of the heat pump's electric cassette. A higher water temperature gives more hot water when, for example, a large number of people

wish to shower. The heat pump fi rst makes sure that the water reaches a

temperature of 50-55ºC. The electric cassette then continues to heat the

water to approximately 65ºC. You choose how long the function should run

using the Extra hotwater menu. This is what to do:

1. Press the Heat button in the initial menu.

2. Turn the menu dial clockwise until you reach the menu Extra

hotwater.

3. Press the Adjust button.

4. Turn the menu dial clockwise to choose the number of hours that the

electric cassette should be on (e.g. 24 hours).

5. Save the value by pressing the Save button.

When the set time has elapsed you

must repeat the setting to get extra

hot water again.

Note

Basic functions - Customer level 1

Extra hotwater

1h 24h 48h

Return Adjust

Extra hotwater

1h 24h 48h

Return Save

19

FOR THE USER

Basic functions - Customer level 1

Heating and hot water settings

Move to the temperature settings for heating on customer level 1 like this:

1. Press the Menu button in the initial menu.

2. Press the Select button and scroll through the heating menus with the

menu dial.

Move to the temperature settings for hot water on customer level 1 like

this:

1. Turn the menu dial clockwise until you reach the menu Adjusting the

hot water settings.

2. Press the Select button and scroll through the hot water menus using

the menu dial.

Read the temperatures on the heat pump

There are several different temperature sensors in the heat pump. Each

sensor plays an important par t in the heat pump's daily operations. It may,

for example, adjust the heat production so that the pump does not become

overheated. Proceed as follows to read the temperatures on the heat pump:

1. Press the Menu button in the initial menu.

2. Turn the menu dial clockwise until you reach the menu Monitor all

temperatures (menu 3).

3. Press the Select button.

4. Turn the menu dial to scroll through all the heat pump's temperature

sensors. See the next page.

Note

Each menu is numbered in the lower

right-hand corner; this indicates which

main display it is associated to.

Rego 637 K1

040622 16:08:15 Tu

Heat Info Menu

Main menu

Indoor temperature

settings 1

Return Select

Main menu

Adjusting the hot

water settings 2

Return Select

Main menu

Monitor all

temperatures 3

Return Select

20

FOR THE USER

All the temperature sensor menus

All the windows associated with the heat pump's temperature sensors are

presented below. Note that you cannot make any settings in these menus,

only read the current values. Some menus are standard for all models of

Greenline HT Plus while others are only available in combination with

different accessories.

The sensors give an alarm if the temperature is outside of the permitted

interval/values.

Note

All sensors are not included as

standard on the heat pump, some are

available as accessories for different

application areas. See more information under respective menus.

The menu shows the temperature in the heating system’s return, i.e. the water from the

radiators back to the heat pump in heating mode. This temperature varies depending on the

outdoor temperature.

The menu shows the outdoor temperature. Some deviation compared to the true temperature

may occur due to thermal radiation from the house to the installed outdoor sensor.

The menu shows the set and present temperature in the lower section of the outer container in

the hot water cylinder/heater. The temperature is approximately 5ºC lower than the temperature of the hot water inside the inner container.

The menu only applies together with a fl ow sensor. If an extra curve with mixing valve is used,

for example, for a fl oor heating system, you can see the temperature on the fl ow water in the

circuit. The temperature varies with the outdoor temperature.

The menu only applies together with a room sensor. The menu shows the set point value and

present temperature in the room where the sensor is fi tted.

The menu shows the compressor’s working temperature. The temperature varies between

70ºC and 125ºC during operations.

The menu shows the temperature of the radiator water as it leaves the heat pump. It varies

depending on the outdoor temperature and whether the heat pump is in hot water production

mode.

The menu shows the temperature of the water that is led into the heat pump. It varies

depending on the outdoor temperature and whether the heat pump is in hot water production

mode. The heat pump stops at 54ºC for reasons of safety.

The menu shows the temperature of the heat transfer fl uid that is led into the heat pump from

the bore hole or the ground. It can vary between -5ºC to +8ºC during a season.

The menu shows the temperature of the heat transfer fl uid that is led out of the heat pump to

the bore hole or the ground. Normally, during operations, it is 1.5 - 5.0 degrees lower than the

heat transfer fl uid that is led into the heat pump.

Basic functions - Customer level 1

Temperature readings

Return radiator GT1

Off 21,3

O

Now 21,7

O

Return

Temperature readings

Out GT2

14,0°

Return

Temperature readings

Hot water GT3

Set 51,0°

Now 46,0°

Return

Temperature readings

Shunt, fl ow GT4

Tgt 40,3° Now 43,0°

Return

Temperature readings

Room GT5

Tgt 20,0°

Now 19,5°

Return

Temperature readings

Compressor GT6

90,0°

Return

Temperature readings

Heat trfl uid out GT8

45,0°

Return

Temperature readings

Heat tr fl uid in GT9

22,0°

Return

Temperature readings

Ht trfl d(coll)inGT10

0,0°

Return

Temperature readings

Httrfl d(coll)outGT11

-4,0°

Return

21

FOR THE USER

Extra functions ( Customer level 2)

In the section Basic functions (Customer level 1) we presented the

functions that you will probably use the most and which you will receive

the most benefi t from. However, there are numerous extra functions that

you can use to control your heat pump. This can, for example, include

activating the heat pump’s holiday function or setting the time and date.

If no settings are made on Customer level 2 (K2), the menu display will

automatically return to Customer level 1 (K1) after 30 minutes. Proceed as

follows to access the extra functions on Customer level 2:

1. Press the Heat button until Access = CUSTOMER2 is displayed

2. Press the Menu button to open the Main menu. From Customer level 2

you also have access to all Customer level 1 functions.

Note

From Customer level 2 you also have

access to all the basic functions on

Customer level 1.

Only the most frequently used menus

in Customer level 2 are shown in the

menu outline. All the menus cannot be

presented due to space limitations. Use

the dial to scroll through the menus.

Press the Heat button until Access

= CUSTOMER2 is displayed.

( Initial menu)

Extra functions - Customer level 2

The menu display is standard

on all heat pumps.

=

=

The menu display is only

shown on the heat pump in

combination with an extra

sensor or for a specifi c model of

Greenline HT Plus.

Heat curve adjust.

(break) 1.3

Page 22

Main menu

Indoor temperature

settings 1

Page 23

Mix. valve incr/decr

range 0-10 1.5

Page 23

Mix. valve fi ne-tune

range -10/+10 1.6

Page 23

Adjusting mix. valve

curve (break) 1.7

Page 23

Setting of room

sensor infl 1.11

Page 22

Setting of holiday

function 1.12

Page 22

Remote control

temperature 1.13

Page 22

Setting of summer

disconnection 1.14

Page 22

Main menu

Adjusting the hot

water settings 2

Page 24

Interval for

hot water peak 2.2

Page 24

Main menu

Timer control

settings 4

Page 24

Clock setting HP

accord. to clock 4.1

Page 24

Setting level

heat pump +/- 4.1.1

Page 25

Clock setting DHW

accord. to clock 4.3

Page 25

Main menu

Op. time readings on

HP and add. heat 7

Page 25

Heat pump in operat.

number of hours? 7.1

Page 26

Add. heat in operat.

number of hours? 7.3

Page 26

Distribut. add. heat

DHW-Rad in % 7.4

Page 26

Main menu

Clock, setting

time and date 10

Page 27

Main menu

Alarm logging

of all alarms 11

Page 27

Main menu

Return to

factory settings 12

Page 27

Menu outline for Extra functions (Customer level 2)

Rego 637 K2

040622 16:08:15 Tu

Heat Info Menu

Rego 637 K2

040622 16:08:15 Tu

Heat Info Menu

Distribution HP

DHW-Rad in % 7.2

Page 26

22

FOR THE USER

Temperature settings

Proceed as follows to access the temperature settings for the heating on

Customer level 2:

1. Press the Heat button until Access = CUSTOMER2 is displayed.

2. Press the Menu button.

3. Press the Select button and scroll through the menus with the menu

dial.

Adapting the heat curve

You can "break" the heat curve up or down every fi fth outdoor degree.

For example, you can make a hump in the curve at 0ºC. The purpose of

breaking the curve is to be able to infl uence the heat pump's heat production at extra sensitive outdoor temperatures.

Room sensor infl uence

The menu is only shown for heat pumps having a room sensor installed.

You use the menu to set how much the room sensor shall infl uence the

heat curve. A higher value will have a greater effect. Please note that the

room sensor only fi ne-tunes the heat curve. Consequently, it is impor tant

the basic setting of the heat curve’s slope and fi ne-tuning are correct.

Holiday function

The menu is only shown for heat pumps having a room sensor installed.

The holiday function gives you the possibility to choose a number of days

when the room temperature will be lowered to 15ºC (the temperature is

not adjustable). When the days have passed the heat pump returns to the

normal heating setting. Hot water production is not affected by the holiday

function.

Remote control

The menu is only shown for heat pumps having a room sensor installed. In

addition, special remote control equipment is needed. This equipment is

available as an accessory. You can switch between the remote control mode

and normal mode using a telephone.

Summer disconnection

The function means the heat pump only produces hot water when the

outdoor temperature rises above the set value.

Extra functions - Customer level 2

Main menu

Indoor temperature

settings 1

Return Select

Temperature settings

Heat curve

adjust. (break) 1.3

Return Select

Temperature settings

Setting of room

sensor infl . 1.11

Return Select

Temperature settings

Setting of holiday

function 1.12

Return Select

Temperature settings

Remote control

temperature 1.13

Return Select

Temperature settings

Setting of summer

disconnection 1.14

Return Select

23

FOR THE USER

Set extra heat curve with mixing valve

If you have fl oor heating combined with radiators you should set an extra

heat curve with mixing valve. The mixing valve is a valve that lets water

through in different amounts. It prevents the fl oor from becoming too hot

and destroying the fl ooring. The menu is only displayed when there is an

extra fl ow sensor, T4 (GT4), on the heat pump. You set the extra heat cur ve

using two menus: Mix. valve incr/decr and Mix. valve fi ne-tune.

Increase or decrease the mixing valve

1. Press the Heat button until Access = CUSTOMER2 is displayed.

2. Press the Heat button.

3. Turn the menu dial clockwise until you reach the menu Mix. valve

incr/decr.

4. Press the Adjust button.

5. Turn the menu dial clockwise to choose a higher heat curve.

Turn the menu dial anti-clockwise to choose a lower heat curve.

6. Save the new value by pressing the Save button.

Note

The initial position of the fl oor heating circuit is heat curve 2.

The scale covers the range 0 to 10.

Extra heat curve with mixing valve

only works with an extra fl ow sensor

T4 (GT4).

Fine-tune the mixing valve

1. Press the Heat button until Access = CUSTOMER2 is displayed.

2. Press the Heat button.

3. Turn the menu dial clockwise until you reach the menu Mix. valve

fi ne-tune.

4. Press the Adjust button.

5. Turn the menu dial clockwise to set an upward, parallel offset on the

curve.

Turn the menu dial anti-clockwise to set a downward parallel offset on

the curve.

6. Save the new value by pressing the Save button.

Note

In the example we describe how to

fi ne-tune the extra heat cur ve. The

scale covers the range -10ºC to +10ºC.

Extra functions - Customer level 2

Mix. valve incr/decr

0 2,0 10

Return Adjust

Mix. valve fi ne-tune

-10° -0,0° 10°

Return Adjust

24

FOR THE USER

Timer control

Open the setting menus for timer control like this:

1. Press the Heat button until Access = CUSTOMER2 is displayed.

2. Press the Menu button.

3. Turn the menu dial clockwise until you access the menu Timer control

settings (menu 4).

4. Press the Select button and scroll through the menus using the menu

dial.

Clock setting of the heat pump according to clock

The function Clock setting HP accord. to clock is for those who want the heat

pump to produce different amounts of heat at different times of the day

and on different days of the week. This allows you to make further energy

savings.

Example:

You want to set the heat pump so that it maintains a 5ºC lower radiator

temperature on Mondays between 22:00 and 06:00.

1. Turn the dial clockwise until you access the menu Clock setting HP

accord. to clock (menu 4.1).

2. Press the Select button.

3. Turn the menu dial clockwise to choose the day. Now press the Adjust

button to select the weekday with the symbol ^. Turn the menu dial

clockwise one step to activate the start day. The weekday now has a

capital letter.

4. Press the right-hand arrow (->) until the cursor reaches the fi rst two

zeros (00).

Extra functions - Customer level 2

Hot water settings

Hot water peak

Recurring increase in the hot water temperature

The Interval for hot water peak menu is used to set the interval for a

recurring increase in the hot water temperature. If, for example, you set

the value seven days, the temperature is increased once a week to approximately 65ºC.

Hot water setting

Interval for

hot water peak 2.2

Return Select

Main menu

Indoor temperature

settings 1

Return Select

Main menu

Timer control

settings 4

Return Select

Clock setting

Clock setting HP

accord. to clock 4.1

Return Select

Clock setting HP 1

mo 00:00-00:00

Return Adjust

>

Clock setting HP 1

Mo 00:00-00:00

Return ->

>

Clock setting HP 1

Mo 00:00-00:00

Return ->

>

>

25

FOR THE USER

5. Turn the menu dial until the value 22:00 is displayed.

6. Press the right-hand arrow twice (->) to move the cursor two steps to

the right.

7. Turn the menu dial until the value 06:00 is displayed.

8. Press the right-hand arrow so it is replaced by the Save function.

9. Finish the setting by pressing the Save button.

10. Press the Return button.

11. Turn the menu dial clockwise until you reach the menu Setting level

heat pump +/- (menu 4.1.1).

12. Press the Select button and set the temperature to -5ºC, which is to

apply for the chosen time zone.

13. Finish by pressing the Save button.

Note

If you would like to make the setting

for every day of the week, carry out

the instruction shown in the example

seven times, once for each weekday.

The temperature set under 4.1.1

applies to all active time zones.

Clock setting of the hot water according to clock

The Clock setting DHW accord. to clock (menu 4.3) works in exactly the

same way as Clock setting HP accord. to clock (menu 4.1). You can choose

to completely disable hot water heating to save energy. This is primarily

effective when peak tarif fs are charged. The procedure is the same as in

the previous example. Use this to make your settings.

Reading operating times on the heat pump

and additional heat

Statistics concerning the heat pump and additional heat operations are

stored in the control unit. For example, you can see how many hours they

have been running. To view the operating times for the heat pump and

additional heat:

1. Press the Heat button until Access = CUSTOMER2 is displayed.

2. Press the Menu button.

Extra functions - Customer level 2

Clock setting HP 1

Mo 22:00-06:00

Return <- ->

Clock setting HP 1

Mo 22:00-06:00

Return <- Save

Clock setting HP 1

Setting level heat

pump +/- 4.1.1

Return Select

Clock setting

Clock setting DHW

accord. to clock 4.3

Return Select

Main menu

Indoor temperature

settings 1

Return Select

>

>

26

FOR THE USER

3. Turn the menu dial clockwise until you reach the menu Op time

readings on HP and add. heat (menu 7).

4. Press the Select button and scroll through the menus using the menu

dial.

The number of hours the heat pump has been in

operation

The menu shows the number of hours that the heat pump has been in

operation since the day of installation.

The heat pump’s hot water mode and heating

mode operations as a percentage

The menu show the heat pump's allocation between hot water mode and

heating mode. The allocation is stated as a percentage. Heating mode

refers to heating of the radiator water.

The number of hours additional heat has been in

operation

The menu shows the number of hours additional heat has been in

operation since the day of installation.

Additional heat’s hot water mode and heating

mode operations as a percentage

The menu shows the heat addition's allocation between hot water mode

and heating mode. The allocation is stated as a percentage. Heating mode

refers to heating of the radiator water.

Set the time and date

The heat pump has functions that are dependent on both the clock and

date. Thus it is important that these are correct. This is how you access the

menu Clock, setting time and date:

1. Press the Heat button until Access = CUSTOMER2 is displayed.

2. Press the Menu button.

Extra functions - Customer level 2

Main menu

Op. time readings on

HP and add. heat 7

Return Select

Op. time readings

Heat pump in operat.

number of hours? 7.1

Return Select

Op. time readings

Distribution HP

DHW-Rad in % 7.2

Return Select

Op. time readings

Add. heat in operat.

number of hours? 7.3

Return Select

Op. time readings

Distribut. add. heat

DHW-Rad in % 7.4

Return Select

27

FOR THE USER

3. Turn the menu dial clockwise until you reach the menu Clock, setting

time and date (menu 10).

4. Press the Select button and make your settings using the menu dial

and menu buttons.

Alarms given by the heat pump

You can easily see any alarms given by the heat pump. The menu provides

you with information about the alarm type and when it occurred. If there is

an asterisk (*) in the menu window this means the alarm is still active, i.e.

the cause of the alarm remains. This is how you access the Alarm logging

of all alarms (menu 11):

1. Press the Heat button until Access = CUSTOMER2 is displayed.

2. Press the Menu button.

3. Turn the menu dial clockwise until you reach the menu Alarm logging

of all alarms (menu 11).

4. Press the Select button and scroll using the menu dial between any

alarms that may have previously occurred. Alarms are stored in

chronological order. Read more about the heat pump's alarms under

the heading All alarms.

Return to factory settings

If you want to restore the factory settings on the heat pump you can easily

reset all the settings you have made. This is how you access the Return to

factory settings menu (menu 12):

1. Press the Heat button until Access = CUSTOMER2 is displayed.

2. Press the Menu button.

3. Turn the menu dial clockwise until you reach the menu Return to

factory settings (menu 12).

4. Press the Select button.

5. Return to the factory settings by pressing the Yes button.

When you return to the factor y settings all the adjustments made on

customer levels 1 and 2 are reset such as temperature settings and

time control settings.

Extra functions - Customer level 2

Main menu

Clock, setting

time and date 10

Return Select

Main menu K2

Indoor temperature

settings 1

Return Select

Main menu K2

Indoor temperature

settings 1

Return Select

Main menu

Alarm logging

of all alarms 11

Return Select

Main menu

Return to

factory settings 12

Return Select

28

FOR THE USER

Maintenance

Your heat pump requires a minimum of maintenance, however, we still

recommend some servicing to get optimal performance from your heat

pump. Check the following items a few times during the fi rst year. You

should then check them once or twice a year:

Sight glass

Expansion vessel

Particle fi lter

Protective anode (only models with a stainless steel hot water cylinder)

Maintenance inside the heat pump

Make sure you disconnect the main power supply before opening the heat

pump. Turn off the power switch that precedes the heat pump.

Opening the front cover

On certain models you will need to open the front cover to access some

of the maintenance areas, e.g. the sight glass and particle fi lter. The front

cover is secured at the top by two screws.

This is how you remove the front cover from the heat pump:

1. Unscrew the two screws on the top. See the picture.

2. Tilt the front cover towards you.

3. Lift the front cover up to release the lower edge.

Sight glass

Sometimes when the heat pump has started you can see the fl uid in the

refrigerant circuit bubble for a few minutes in the sight glass. This is

completely normal. However, if it bubbles continuously you should contact

your dealer.

War ning

For reasons of safety the main power

supply must be disconnected before

working on the heat pump.

Only an accredited refrigeration

company is permitted to work on the

heat transfer fl uid circuit.

Remove the front cover by unscrewing the

screws on the top.

Sight glass

Greenline HT Plus E

If the sight glass shows green this means there is no moisture in the

system. If it is yellow there is moisture in the system. If this happens,

contact your dealer.

Maintenance

29

FOR THE USER

Expansion vessel

A plastic expansion vessel is connected to the heat pump heat transfer

circuit (cold side). The level in the vessel should not fall below the

minimum level 1/3. If the fl uid level is too low, contact your dealer. After

discussions with your dealer fi lling can take place as set out below:

The heat pump must be in operation all the time while fi lling.

1. Remove the cover on the valve on top of tank. Now carefully open the

valve (fi gure 1).

2. Check that the valve is fully open (fi gure 2).

3. Fill with anti-freeze or water (to 2/3) with the help of a clean watering

can or the like (fi gure 3).

4. Close the valve and fi nish by screwing on the cover (fi gure 4).

Particle fi lter

The task of a particle fi lter is to ensure no particles or dirt enter the

heat exchangers. Over time the fi lter can become clogged and will need

cleaning. There are particle fi lters on both the hot and cold sides. To clean

the particle fi lters:

1. Shut down the heat pump using the ON/OFF button.

2. Close the valve and unscrew the sealing cap.

3. Loosen the circlip holding the screen in the valve. Use the supplied

circlip pliers.

4. Lift out the screen from the valve and wash clean with water.

5. Refi t the screen, the circlip and sealing cap.

6. Open the valve and start the heat pump using the ON/OFF button.

On the cold side the particle fi lter

is located outside of the heat pump.

It may be concealed by insulation

material or a black box.

On Greenline HT E Plus the hot

side’s particle fi lter is fi tted inside the

heat pump. On Greenline HT Plus C

it is located outside of the heat pump.

Note

Strainer Circlip Sealing cap

max. level

min. level

Figure 1 Figure 2 Figure 3 Figure 4

Particle fi lter

Greenline HT Plus E

Maintenance

30

FOR THE USER

Control box with diode lamps

Electronic anode

Checking the protective anode

Checking the protective anode only applies to stainless steel hot water

cylinders. At the top of the hot water cylinder, under the insulation, there is

a protective anode. The task of the anode is to prevent corrosion so the hot

water cylinder does not corrode away. The hot water cylinder must be fi lled

with water in order for the protective anode to work.

There are two types of protective anodes: a sacrifi cial anode and an

electronic anode.

Sacrifi cial anode

The sacrifi cial anode can corrode depending on the water quality. If the

diameter of the anode has been reduced to a few millimetres it must be

replaced. This is how you check the sacrifi cial anode:

1. Shut off the main cold water supply.

2. Open a tap and let the water run out to reduce the pressure in the hot

water cylinder.

3. Unscrew the anode from the heat pump and check its diameter.

Electronic anode

If the protective anode is electronic there is a control box showing the

status of the anode. The diode lamps are either green or red. If green, the

protective anode is operating and working normally. Red can indicate a

fault. When large amounts of hot water are used (e.g. with a bath) the lamp

may show red for a short period without there being a fault. However, if the

red light is on for more than ten hours this indicates the anode is faulty and

you should contact your dealer. If the fault occurs at the weekend you can

wait to the next working day before contacting your dealer.

If the diameter of the anode has been

reduced to a few millimetres it must

be replaced as soon as possible.

Note

Sacrifi cial anode

Maintenance

31

FOR THE USER

Lower the heating.

Open the thermostat valves completely.

Savings

The heat pump's task is to produce heating of the house as cost-effectively

as possible. You can infl uence operating costs by your own settings for the

heat pump. In addition you can infl uence your energy savings by, e.g.

Lowering the indoor temperature.

Opening thermostat valves completely.

Lowering the indoor temperature

The lower the indoor temperature the better the heating economy. So

make sure you do not set the heat curve too high. Use your heating system

in the best possible way by keeping the entire surface of radiators or fl oor

coils warm.

1. Seal windows and doors, but not too tight.

2. When you air the room, do it quickly and with a cross draught.

Opening thermostat valves completely

The thermostat valves on radiators and fl oor coils can have a negative

effect on the heating system by slowing the fl ow and, by doing so, the heat

pump must compensate with a higher temperature. If thermostat valves

are installed they should be opened fully, except in bedrooms or other

areas where a lower temperature is required. In these rooms they can be

somewhat closed.

Savings

32

FOR THE USER

ALARM

Power failure

040622 16:08:15

Info Ackn.

What to do if a fault occurs

The control unit has an advanced monitoring system that gives alarms if

anything unforeseen happens in the heat pump. Most alarms are rectifi ed

by you the user and there is never any risk that you can damage anything

in the heat pump when you reset an alarm.

If a room sensor is installed the lamp on this will come on when the heat

pump gives an alarm.

Example of an alarm:

Info button:

When you press the Info button and turn the menu dial, information is

displayed as well as possible actions to rectify the alarm.

Ackn. button:

When you press the Ackn. button the alarm lamp on the control panel goes

out and the heat pump starts again within 15 minutes if there is a heating

requirement. If the fault has not been rectifi ed the lamp will remain lit.

Should several alarms have occurred on the heat pump, turn the menu dial

clockwise to fi nd out more information about each alarm.

Cause.

Date when the

alarm occurred.

Time when the alarm occurred.

Info Acknowledge

Dimmed menu display

Possible cause 1: Blown fuse in the house’s fuse box/distribution

box.

Action: 1. Check the fuses in the house’s fuse box.

2. Replace the fuse if necessary. If miniature circuit

breakers have tripped these are reset by pushing

up the toggle switch.

3. The heat pump automatically returns to its

operating mode 15 minutes after the fault has

been rectifi ed.

Possible cause 2: The heat pump's miniature circuit-breaker has

tripped.

Action: 1. Reset the heat pump's miniature circuit-breaker

by pushing up the centre toggle switch.

2. The heat pump automatically returns to its

operating mode 15 minutes after the fault has

been rectifi ed.

Miniature circuitbreaker for

Greenline HT Plus C

Miniature circuitbreaker for

Greenline HT Plus E

Note

For technical reasons the heat pump

does not restart until 15 minutes after

a stoppage.

What to do if a fault occurs

33

FOR THE USER

Fuses and reset buttons on the heat pump

Fuse 4

Reset button for the electric cassette

overheat protection.

NOTE! The button must be pressed

in fi rmly.

Fuse 1

Reset switch for motor cut-out

compressor.

Fuse 2

Reset switch for the heat pump’s

miniature circuit-breaker.

Fuse 3

Reset switch for the electric

cassette’s miniature circuit-breaker.

Sight glass

Particle fi lter

Cleanable, with shutoff switch.

Greenline HT Plus C

Greenline HT Plus E

Sight glass

What to do if a fault occurs

Motor cut-out compressor

Motor cut-out HTF pump

Compressor temperature

Low pressure switch

High pressure switch

Electric cassette

Power failure

Phase sequence error

High return to the heat pump

Heat transfer fl uid out max

High heat transfer fl uid delta

Sensor fault

Heat transfer fl uid in under limit and heat

transfer fl uid out under limit

List of all alarms:

All alarms

An alarm can sometimes occur temporarily due to various reasons.

However, there is never a risk involved in resetting an alarm. All

the alarms that can appear in the menu display are described on

the following pages. The descriptions give you an idea about the

nature of the alarm and what you can do to rectify it. The text often

refers to different fuses and reset buttons on the heat pump. These

are shown in the fi gures above.

34

FOR THE USER

Motor cut-out compressor (MB1)

Possible cause 1: Intermittent fault or overload on the power

supply.

Action: 1. Press the Ackn. button.

The alarm indication goes out even if the fault has

not been rectifi ed.

2. Press in the motor cut-out button on the heat

pump. (Fuse 1).

3. Wait for the heat pump to start.

Possible cause 2: Current level (A) on the motor cut-out is set too

low.

The current drawn by the compressor varies during

summer/winter operations.

Action: 1. Contact your dealer.

Possible cause 3: Contactor or cut-out faulty, or loose electrical

connections to the compressor.

Action: 1. Contact your dealer.

Possible cause 4: Compressor error.

Action: 1. Contact your dealer.

Motor cut-out HTF pump (MB2)

(Applies to models C11, E11, E14 and E17)

Possible cause 1: The HTF pump is blocked due to contamination.

Action: 1. Press the Ackn. button.

2. Loosen the venting screw and remove the dirt.

3. Help to start the pump with a screwdriver.

The alarm indication goes out even if the fault has

not been rectifi ed.

Possible cause 2: Faulty electric motor on HTF pump.

Action: 1. Contact your dealer.

Possible cause 3: Temporar y error.

Action: 1. Contact your dealer should repeated faults occur.

The menu display shows:

What to do if a fault occurs

ALARM (MB1)

Compr. circ. Switch

040622 16:08:15

Info Ackn.

The menu display shows:

ALARM (MB2)

HTF c-pump switch

040622 16:08:15

Info Ackn.

The reset switch for the compressor

can be found under heading Fuses

and resetting buttons on the heat

pump.

Note

The alarm indication goes out when

acknowledging the alarm even if the

fault has not been rectifi ed.

Note

35

FOR THE USER

LP in the menu display stands for low

pressure switch.

Note

Low pressure switch (LP)

Possible cause 1: Air in the heat transfer system.

Action: 1. Press the Ackn. button.

2. Check the expansion vessel.

3. Fill with fl uid if necessary.

4. Listen for air in the system. If air is heard constantly, contact your dealer.

Possible cause 2: The particle fi lter on the cold side is clogged.

Action: 1. Check the particle fi lter.

2. Clean the particle fi lter if necessary.

3. Press the Ackn. button.

Possible cause 3: Lack of refrigerant in the heat transfer circuit.

Action: 1. Press the Ackn. button.

2. Wait for the heat pump to start.

3. Check whether it bubbles continuously in the

sight glass.

4. If it bubbles continuously, contact your dealer.

Possible cause 4: The HTF pump has stopped or is set at too low a

speed.

Action: 1. Press the Ackn. button.

2. Check that the pump has not stopped or is set at

the wrong speed.

Possible cause 5: Ice formation in the heat exchanger due to a

lack of anti-freeze in the heat transfer circuit.

Action: 1. Contact your dealer.

Possible cause 6: Faulty expansion valve (the alarm appears in

time periods of 3-4 weeks).

Action: 1. Contact your dealer.

Compressor temperature T6 (GT6)

Possible cause 1: The working temperature of the compressor is

too high.

Action: 1. Press the Ackn. button.

2. Contact your dealer at repeated alarms.

Possible cause 2: Intermittent temperature rise due to abnormal

operating conditions

Action: 1. Press the Ackn. button.

2. Wait and see.

What to do if a fault occurs

The menu display shows:

ALARM (GT6)

Compr. superheat

040622 16:08:15

Info Ackn.

The menu display shows:

ALARM (LP)

Low pressure switch

040622 16:08:15

Info Ackn.

36

FOR THE USER

Pressure switch high (HP)

Possible cause 1: Air in the heating system.

Action: 1. Press the Ackn. button.

2. Check whether there is air in the radiators.

3. Fill the heating system and vent if necessary.

Possible cause 2: Not enough fl ow over the heat pump.

Action: 1. Press the Ackn. button.

2. Check that the heat carrier pump has not

stopped.

3. Check that all the valves are open. The thermostat valves in heating systems should be fully

open and in fl oor heating systems at least half of

the coils should be fully open.

4. Possibly increase the speed of the heat carrier

pump.

Possible cause 3: The particle fi lter on the hot side is clogged.

Action: 1. Press the Ackn. button.

2. Check the fi lter.

3. Clean the fi lter if necessary.

Possible cause 4: The refrigerant circuit is overfi lled.

Action: 1. Contact your dealer.

Possible cause 5: The dr ying fi lter is clogged.

Action: 1. Contact your dealer.

HP in the menu display stands for

high pressure switch.

Note

Increase the speed of the heat carrier pump:

Use a screwdriver or a coin to increase

the speed of the heat carrier pump.

Turn one step anti-clockwise.

Note

Electric cassette (EK)

Possible cause 1: The electric cassette 's miniature circuit-breaker

has tripped.

Action: 1. Press the Ackn. button.

2. Reset the miniature circuit breaker button on the

heat pump (circuit breaker 3) by pushing up the

toggle switch.

3. Contact your dealer if the miniature circuit

breaker trips again.

Possible cause 2: The electric cassette’s overheat protection has

tripped.

Action: 1. Press the Ackn. button.

2. Reset the overheat protector (circuit breaker 4)

by pressing in the button on the electric cassette’s

protective casing. The circuit breaker is reset

when you hear a clicking sound.