Page 1

Installation manual

Greenline HC

6 720 641 855-01.1I

HC 22 / HC 33

6 720 645 504 (2011/04) en

Page 2

Contents

6 720 645 504 (2011/04) en

2

Contents

1 Key to symbols and safety instructions . . . . . . . 4

1.1 Explanation of symbols . . . . . . . . . . . . . . . 4

1.2 Safety precautions . . . . . . . . . . . . . . . . . . 4

2 Included in the delivery . . . . . . . . . . . . . . . . . . . 5

3 Installation and transport tools . . . . . . . . . . . . . 6

4 Lifting the heat pump . . . . . . . . . . . . . . . . . . . . . 7

5 Product details . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1 Application area . . . . . . . . . . . . . . . . . . . . 8

5.2 Type overview . . . . . . . . . . . . . . . . . . . . . . 8

5.3 Type plate . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.4 Transport and storage . . . . . . . . . . . . . . . . 8

5.5 Transport locking devices . . . . . . . . . . . . . 8

5.6 Positioning the heat pump . . . . . . . . . . . . 8

5.7 Checks before installation . . . . . . . . . . . . 8

5.8 Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.9 CAN-BUS . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.10 Handling circuit boards . . . . . . . . . . . . . . 10

6 Heating, general . . . . . . . . . . . . . . . . . . . . . . . . 11

6.1 Circuits for heating . . . . . . . . . . . . . . . . . 11

6.2 Control methods for heating . . . . . . . . . . 11

6.3 Time control for heating . . . . . . . . . . . . . 11

6.4 Operating modes . . . . . . . . . . . . . . . . . . . 12

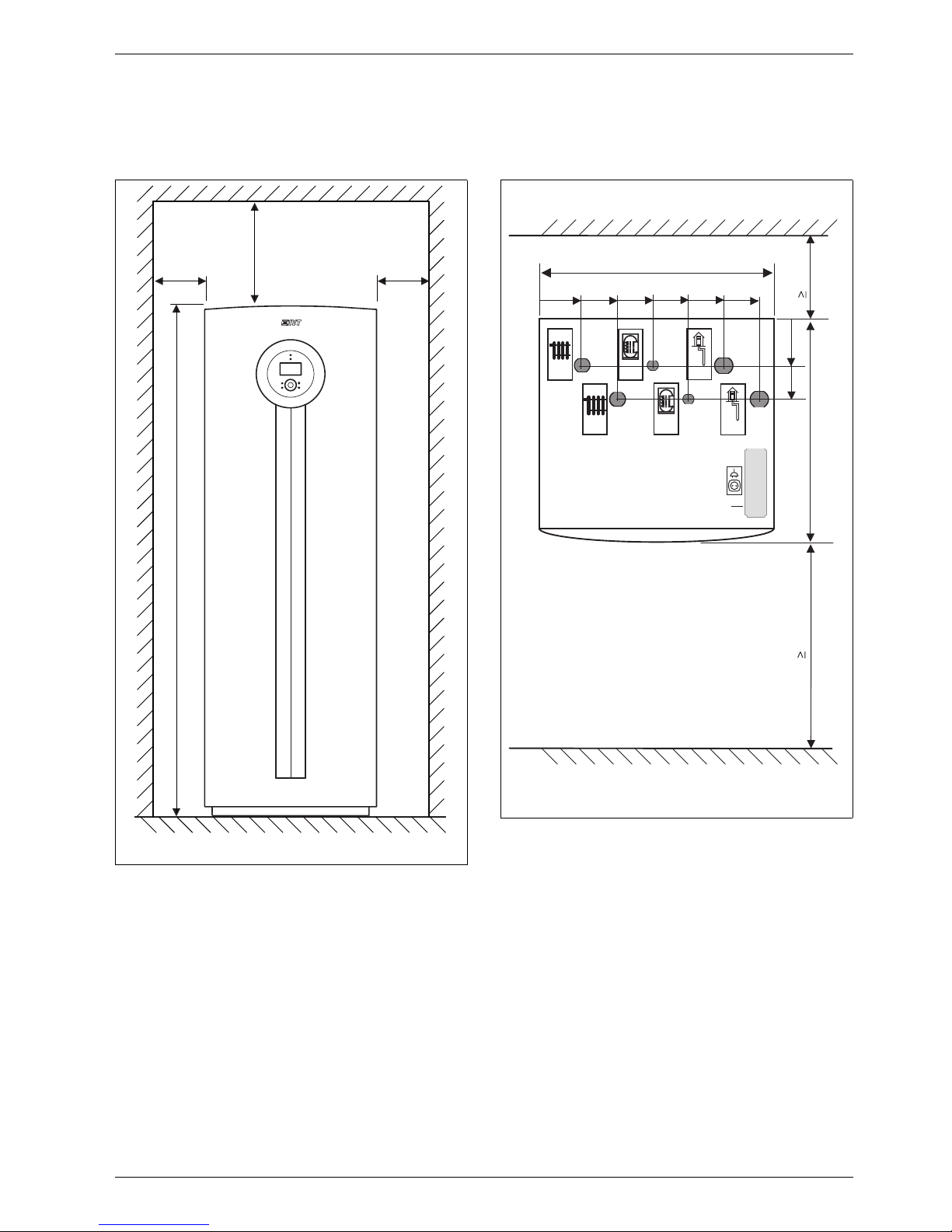

7 Dimensions and clearance . . . . . . . . . . . . . . . . 13

7.1 HC 22 - 33 . . . . . . . . . . . . . . . . . . . . . . . . 13

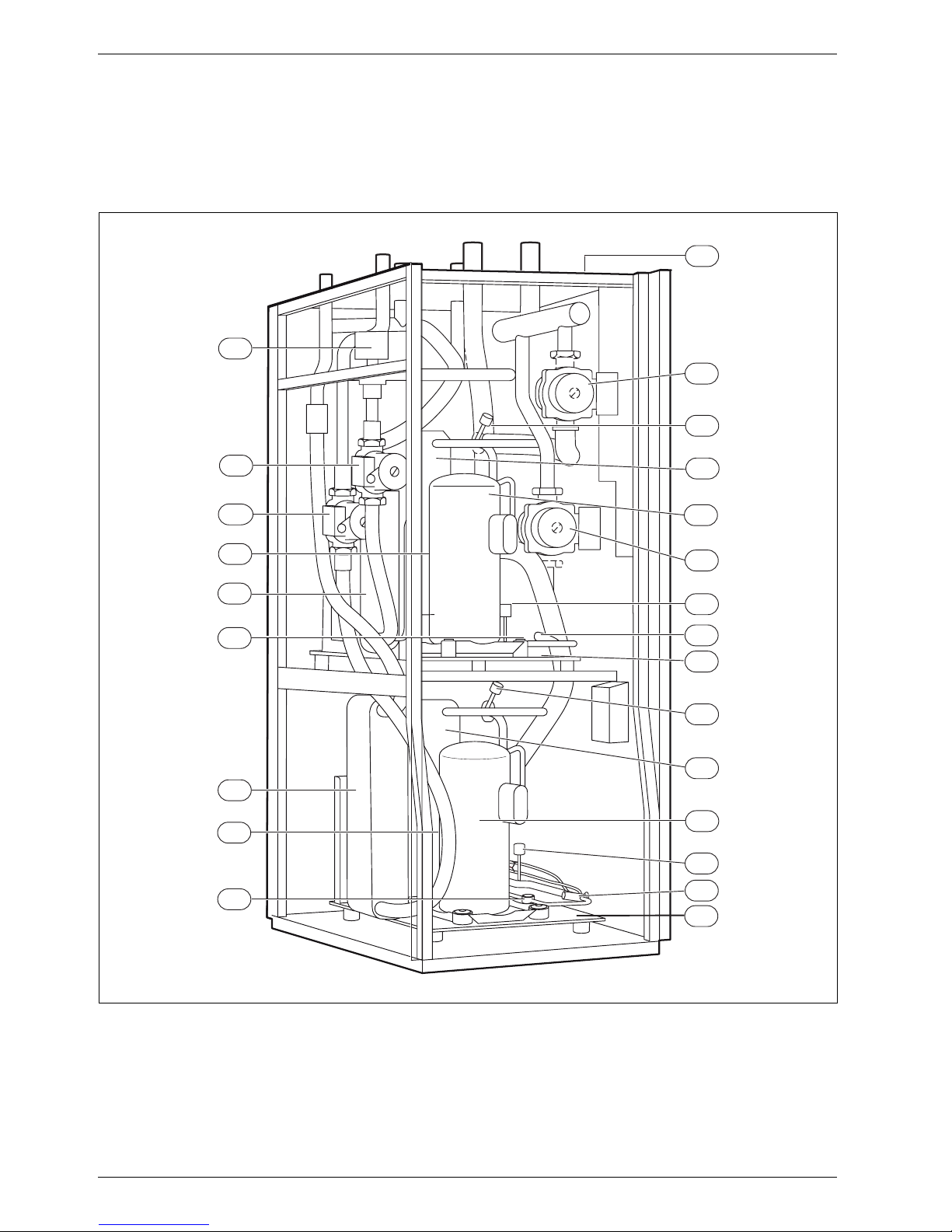

8 Technical information . . . . . . . . . . . . . . . . . . . . 14

8.1 Component parts . . . . . . . . . . . . . . . . . . 14

8.2 System solutions . . . . . . . . . . . . . . . . . . . 15

8.3 Functional description of system

solutions . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.4 Technical information . . . . . . . . . . . . . . . 22

9 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

10 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

10.1 Collector system . . . . . . . . . . . . . . . . . . . 25

10.2 Heating system . . . . . . . . . . . . . . . . . . . . 25

10.3 Siting the appliance . . . . . . . . . . . . . . . . . 26

10.4 Pipework preparations . . . . . . . . . . . . . . 26

10.5 Flushing the heating system . . . . . . . . . . 26

10.6 Setting up . . . . . . . . . . . . . . . . . . . . . . . . 26

10.7 Heat insulation . . . . . . . . . . . . . . . . . . . . . 26

10.8 Removing the front panel . . . . . . . . . . . . 26

10.9 Temperature sensor installation . . . . . . . 27

10.10 Filling the heating system . . . . . . . . . . . . 27

10.11 Filling the hot water circuit . . . . . . . . . . . 27

10.12 Filling the collector system . . . . . . . . . . . 27

11 Electrical connections . . . . . . . . . . . . . . . . . . . . 30

11.1 Connecting the heat pump . . . . . . . . . . . 30

11.2 Phase guard . . . . . . . . . . . . . . . . . . . . . . . 30

11.3 Screed drying . . . . . . . . . . . . . . . . . . . . . . 30

11.4 Electrical connection wiring diagram . . . 31

11.5 External connections . . . . . . . . . . . . . . . . 36

11.6 Other wiring diagrams . . . . . . . . . . . . . . . 37

11.7 Connection of additional heat alarm . . . . 45

11.8 Connection of hot water electric heater . 45

11.9 Connection of circulation pump

E41.E1.G1 . . . . . . . . . . . . . . . . . . . . . . . . .46

11.10 Connection of low energy pump E11.G1 . 46

12 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

12.1 Panel overview . . . . . . . . . . . . . . . . . . . . . 47

12.2 On/Off button . . . . . . . . . . . . . . . . . . . . . 47

12.3 Status lamp . . . . . . . . . . . . . . . . . . . . . . . 47

12.4 Menu display . . . . . . . . . . . . . . . . . . . . . . 47

12.5 Menu button and menu dial . . . . . . . . . . . 47

12.6 Return button . . . . . . . . . . . . . . . . . . . . . 47

12.7 Mode button . . . . . . . . . . . . . . . . . . . . . . 47

12.8 Info button . . . . . . . . . . . . . . . . . . . . . . . . 47

13 Start up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

14 Installer menus . . . . . . . . . . . . . . . . . . . . . . . . . 49

14.1 Access to the functions on Installer level 49

14.2 Compressor fast restart . . . . . . . . . . . . . . 49

14.3 Temperature sensor . . . . . . . . . . . . . . . . . 49

Page 3

Contents

6 720 645 504 (2011/04) en

3

15 Menu overview . . . . . . . . . . . . . . . . . . . . . . . . . 50

16 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

16.1 Room temperature . . . . . . . . . . . . . . . . . 57

16.2 Hot water . . . . . . . . . . . . . . . . . . . . . . . . 68

16.3 Holiday . . . . . . . . . . . . . . . . . . . . . . . . . . 71

16.4 Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

16.5 External control . . . . . . . . . . . . . . . . . . . 73

16.6 Installer . . . . . . . . . . . . . . . . . . . . . . . . . . 74

16.7 Additional heat . . . . . . . . . . . . . . . . . . . . 80

16.8 Safety functions . . . . . . . . . . . . . . . . . . . 83

16.9 General . . . . . . . . . . . . . . . . . . . . . . . . . . 83

16.10 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

16.11 Access level . . . . . . . . . . . . . . . . . . . . . . . 85

16.12 Return to factory settings . . . . . . . . . . . . 85

17 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

17.1 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

17.2 Control unit and room sensor alarm lamp 86

17.3 Alarm display . . . . . . . . . . . . . . . . . . . . . . 86

17.4 Alarm buzzer at alarm . . . . . . . . . . . . . . . 86

17.5 Acknowledgement of alarms . . . . . . . . . . 86

17.6 Alarm timer, alarm mode . . . . . . . . . . . . 86

17.7 Alarm categories . . . . . . . . . . . . . . . . . . . 87

17.8 Alarm window . . . . . . . . . . . . . . . . . . . . . 87

17.9 Alarm functions . . . . . . . . . . . . . . . . . . . . 88

17.10 Alarm log . . . . . . . . . . . . . . . . . . . . . . . . . 96

17.11 Alarm history . . . . . . . . . . . . . . . . . . . . . . 96

18 Factory settings . . . . . . . . . . . . . . . . . . . . . . . . 97

18.1 Return to factory settings . . . . . . . . . . . . 97

18.2 Factory values . . . . . . . . . . . . . . . . . . . . . 97

19 Function check . . . . . . . . . . . . . . . . . . . . . . . . 102

19.1 Refrigerant circuit . . . . . . . . . . . . . . . . . 102

19.2 Filling pressure in collector circuit . . . . 102

19.3 Setting heating system operating

pressure . . . . . . . . . . . . . . . . . . . . . . . . . 102

19.4 Operating temperatures . . . . . . . . . . . . 103

20 Environmental protection . . . . . . . . . . . . . . . . 104

21 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 105

22 Commissioning protocol . . . . . . . . . . . . . . . . . 106

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Page 4

Key to symbols and safety instructions

6 720 645 504 (2011/04) en

4

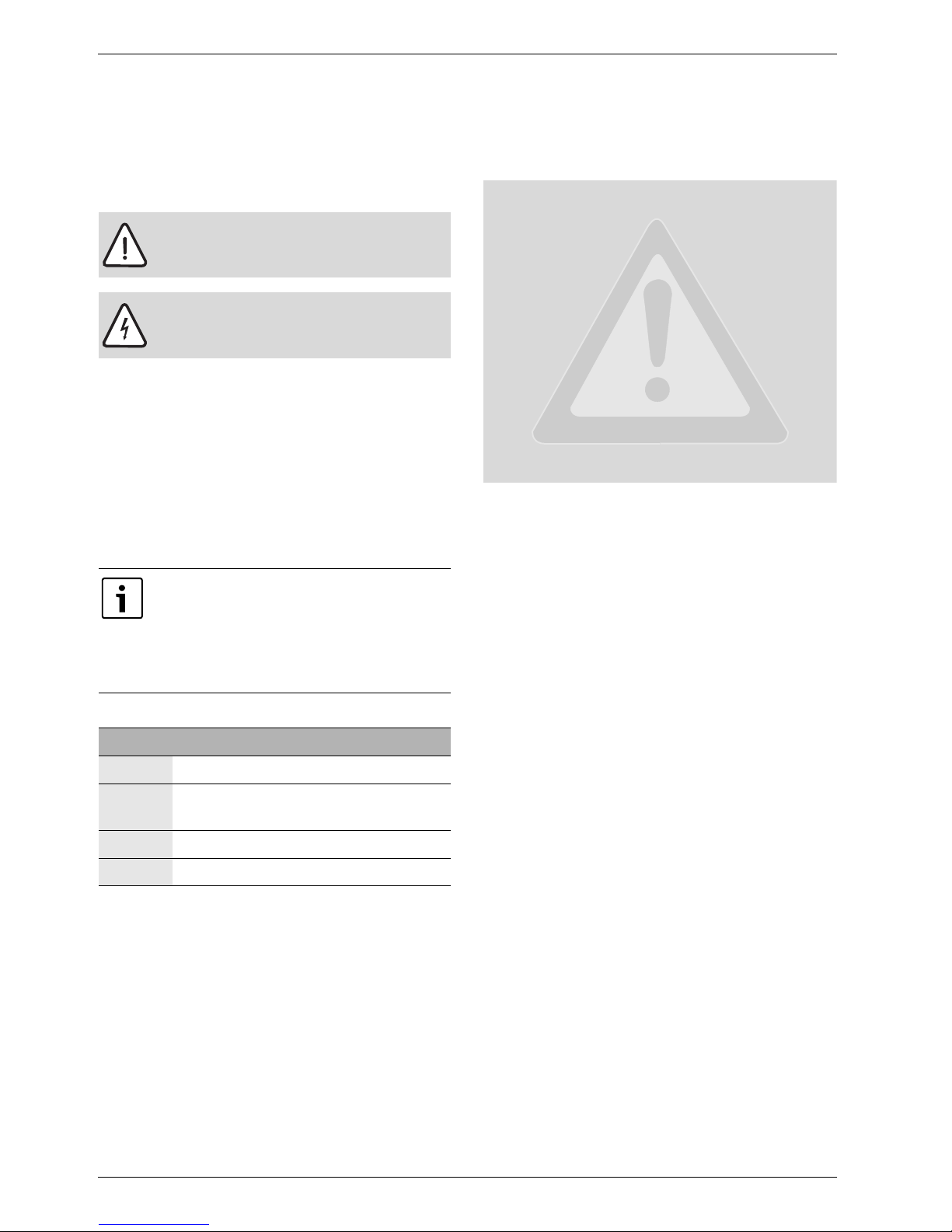

1 Key to symbols and safety instructions

1.1 Explanation of symbols

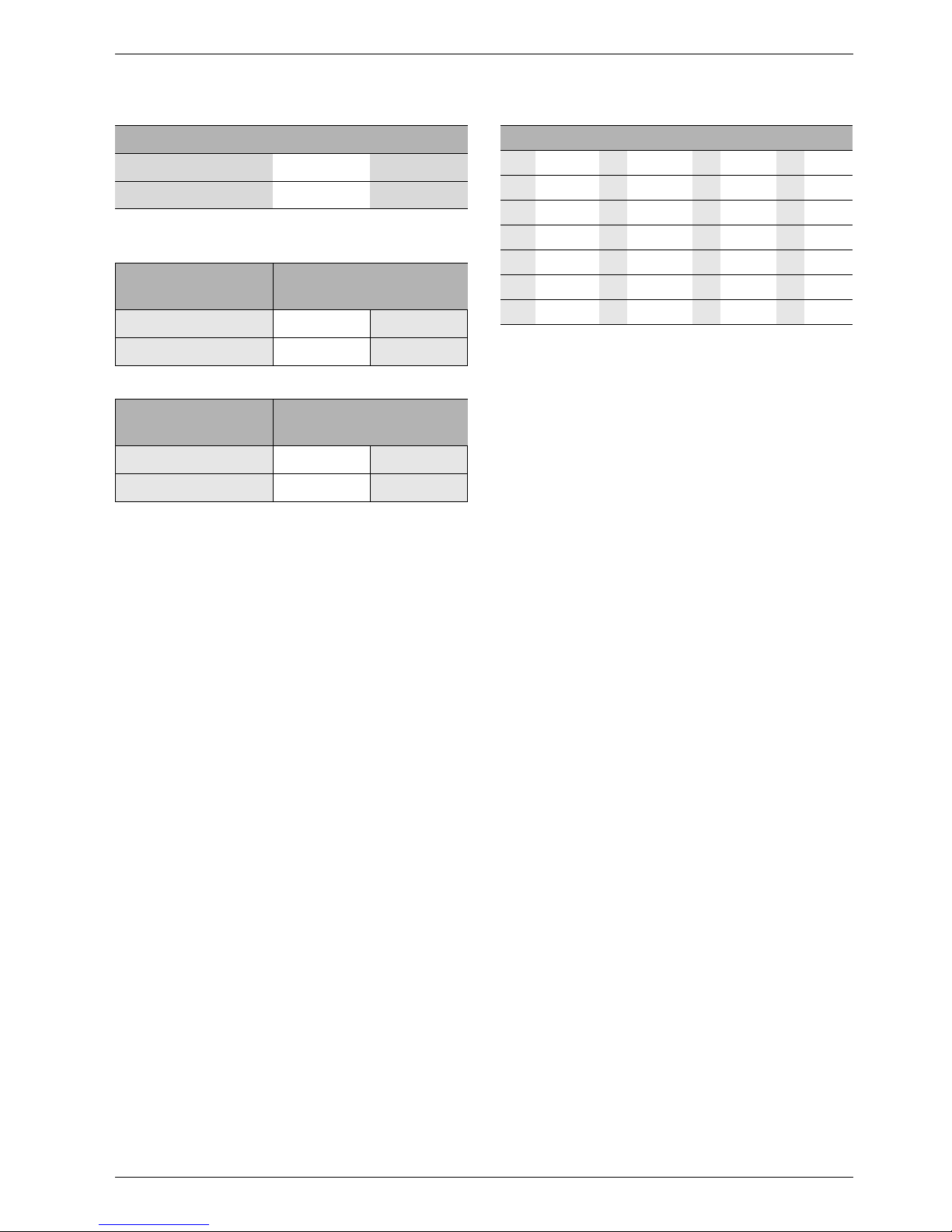

Warning symbols

Signal words indicate the seriousness of the hazard in

terms of the consequences of not following the safety

instructions.

• NOTICE indicates possible damage to property or

equipment, but where there is no risk of injury.

• CAUTION indicates possible injury.

• WARNING indicates possible severe injury.

• DANGER indicates possible risk to life.

Important information

Additional symbols

1.2 Safety precautions

General

B Read the gu ide carefu lly and keep i t to hand for fu tur e

use.

Installation and commissioning

B The heat pump may be installed and put into

operation only by a qualified installer.

Service and maintenance

B Only qualified personnel may carry out repairs.

Incorrect repairs can lead to serious risks to the user,

and a reduction in savings.

B Only use original spare parts.

B Service and maintenance must be carried out annually

by an authorised service representative.

Safety instructions in this document are

framed and identified by a warning triangle

which is printed on a grey background.

Electrical hazards are identified by a

lightning symbol surrounded by a warning

triangle.

Notes contain important information in

cases where there is no risk of personal

injury or material losses and are identified

by the symbol shown on the left. They are

bordered by horizontal lines above and

below the text.

Symbol Meaning

B a step in an action sequence

a reference to a related part in the docu-

ment or to other related documents

• a list entry

– a list entry (second level)

Tab. 1

Page 5

Included in the delivery

6 720 645 504 (2011/04) en

5

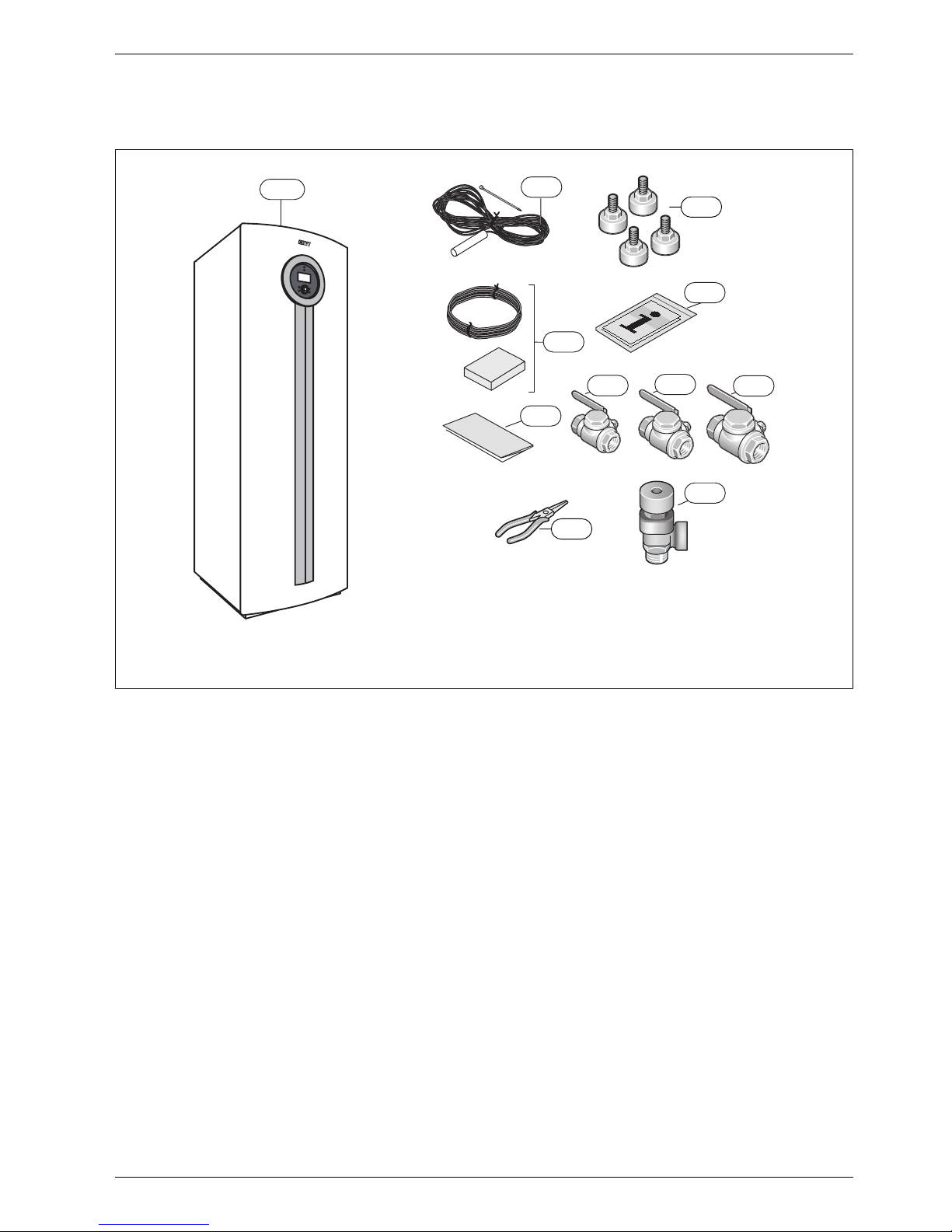

2 Included in the delivery

Fig. 1

1 Heat pump

2 Flow sensor

3 Adjustable feet

4 Outdoor sensor

5 Warranty Card

6 Guides

7 Particle filter for hot water

8 Particle filter for the heating system

9 Particle filter for the collector circuit

10 Pliers for particle filter

11 Safety valve, 4 bar

11

1

2

4

5

6

10

3

6720645504-01.1I

9

8

7

Page 6

Installation and transport tools

6 720 645 504 (2011/04) en

6

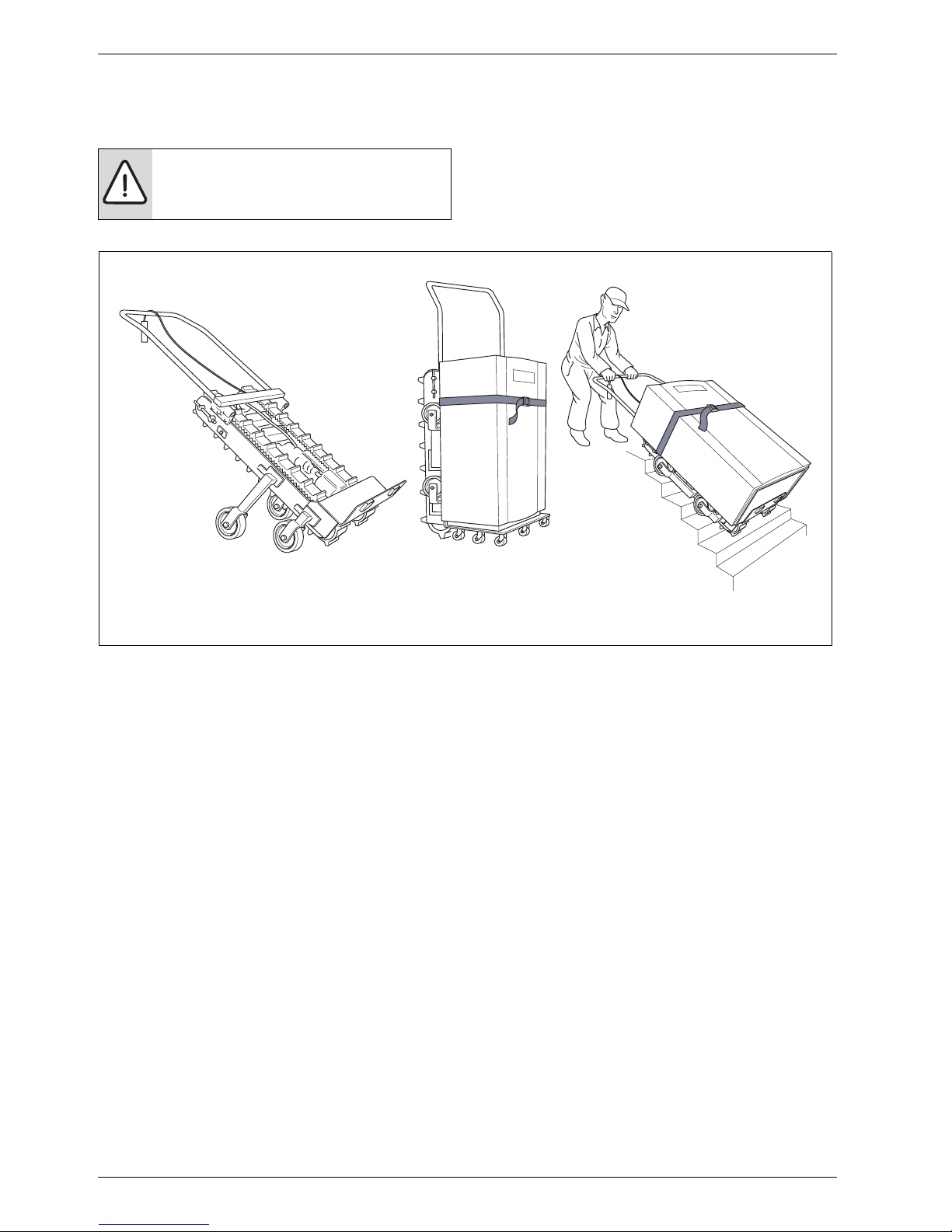

3 Installation and transport tools

The heat pump may be transported only with a handling

trolley/lift truck .

Fig. 2 Example of a handling trolley/lift truck that can be used during installation of a heat pump

DANGER: Personal injuries may occur. The

heat pump weighs between 330 and 360 kg.

B Never lift the heat pump by hand.

6 720 616 938-22.1I

Page 7

Lifting the heat pump

6 720 645 504 (2011/04) en

7

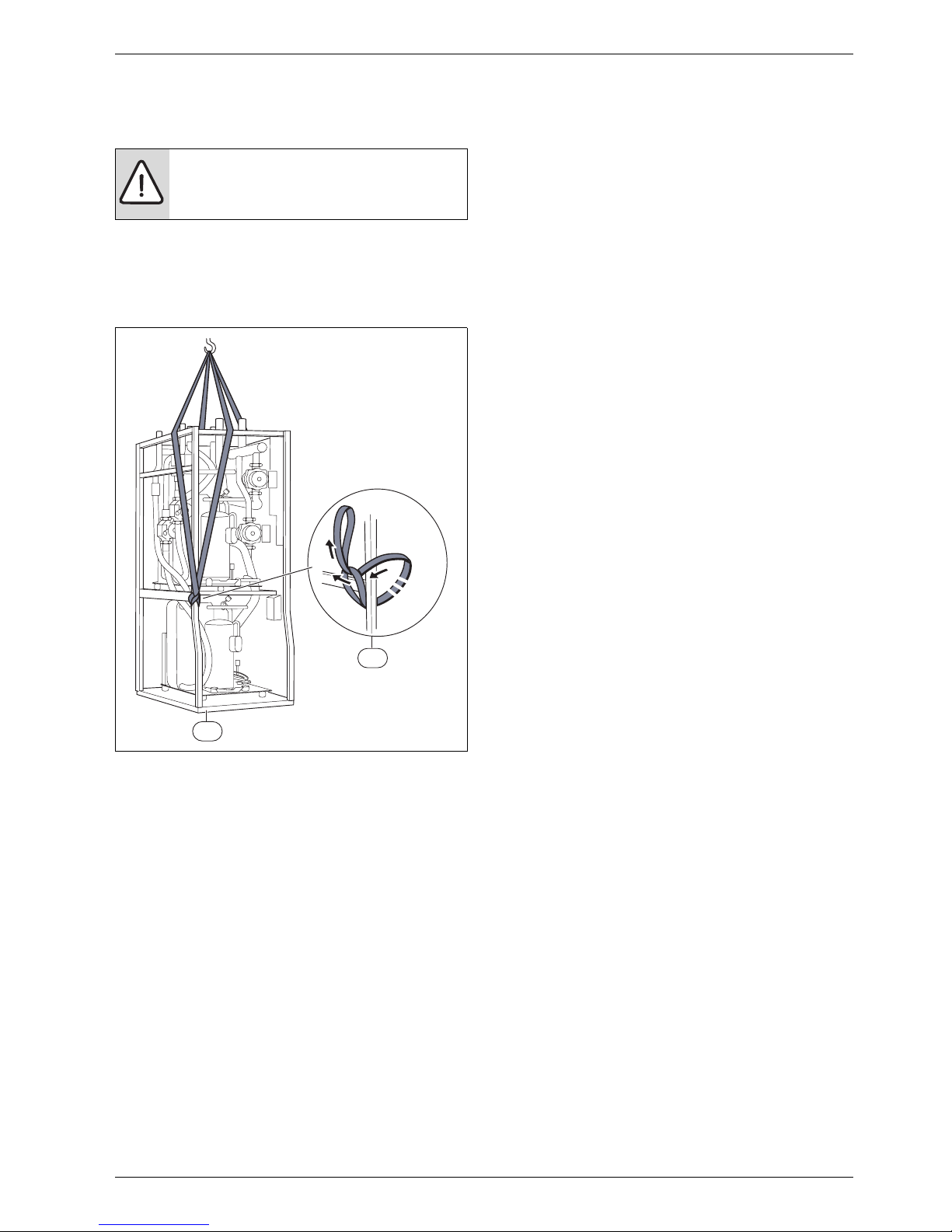

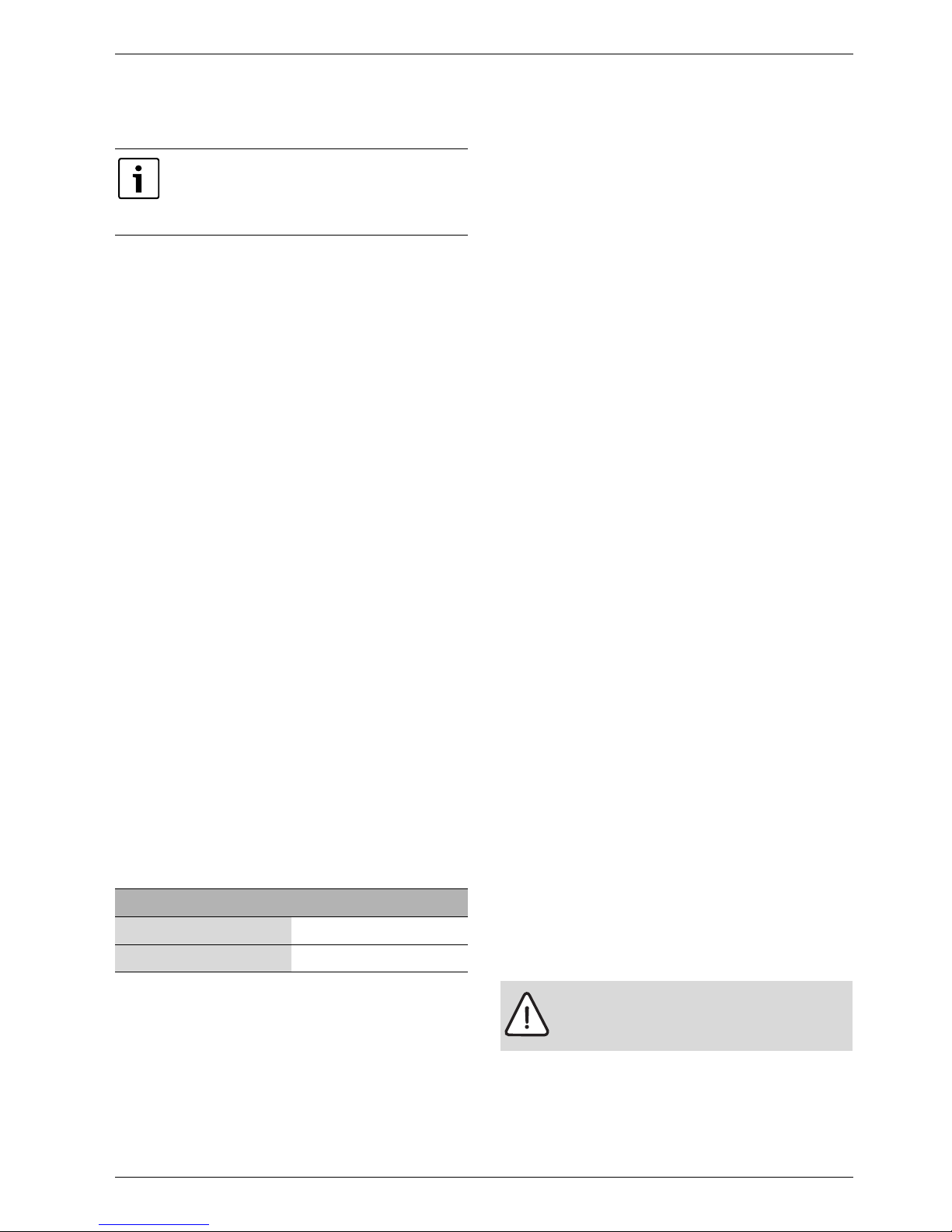

4 Lifting the heat pump

Remove the packaging and the transport pallet from the

heat pump. Dismantle also the front and side plates

before lifting the heat pump into the building.

Fig. 3 HC22-33 with lifting belts

1 HC 22-33 with lifting belt on opposite sides

2 Attach the lifting belts to the heat pump according to the

figure

DANGER: Personal injuries may occur. The

heat pump weighs between 330 and 360 kg.

B Never lift the heat pump by hand.

x 2

1

2

6 720 645 504-02.1I

Page 8

Product details

6 720 645 504 (2011/04) en

8

5 Product details

HC 22-33 are ground source pumps designed to be

supplemented with an external hot water heater.

5.1 Application area

The heat pump must only be used in a closed hot water

heating system according to BS EN 12828.

Other forms of use are not permitted. We take no

responsibility for damage occurring due to nonpermitted use.

5.2 Type overview

HC Ground source heat pump

kW Heat output 0/35 (EN 14511)

5.3 Type plate

The type plate is located on the roof plate of the heat

pump. Information about the heat pump's output, part

number, serial number and date of manufacture is stated

there.

5.4 Transport and storage

The heat pump should always be transported and stored

in an upright position. However, the heat pump may be

tilted temporarily, but must not be laid down.

The outer cover plates should be removed to avoid

damage if the heat pump is transported without the

supplied transport pallet.

The heat pump must not be stored at temperatures

below -10 °C.

5.5 Transport locking devices

The heat pump is furnished with transport locking

devices which prevent damage during transportation.

Unscrew the transport locking devices installed next to

the vibration dampers on the heat pump ( figure 9).

5.6 Positioning the heat pump

B The heat pump is placed indoors, on a level and stable

surface that withstands a weight of at least 400 kg.

B Adjust the rubber feet so the heat pump does not

lean.

B The ambient temperature around the heat pump must

be between 10 °C and 35 °C.

B The installer should take noice transfer to adjacent

areas into consideration when positioning the heat

pump.

B There must be a drain in the room where the heat

pump is placed. This ensures that water can easily be

carried away if there is a leak.

5.7 Checks before installation

B Installation of the heat pump should be performed by

a qualified installer.

B Before the heat pump is commissioned, the heating

system, hot water cylinder and the collector circuit

system, including the heat pump, must be filled and

vented.

B Check that all pipe connections are intact and have

not shaken loose during transportation.

B Wiring should be kept as short as possible to protect

the system from downtime, for example during a

thunderstorm.

B Heat pump installation, energy drilling and collector

installation must follow applicable regulations.

B Check the water quality ( page 24, VDI 2035).

5.8 Checklist

1. Position the heat pump on an even base. Adjust the

height using the adjustable feet.

2. Fit the valves, particle filters and a filling unit.

3. Install the incoming and outgoing pipes for the heat

pump, as well as the expansion vessel.

4. Connect the heating unit to the heating system.

5. Install the outdoor sensor and possible room sensors.

6. Fill and vent the heating and collector systems before

commissioning.

7. Carry out the external connections.

8. Connect the heating installation to the power supply.

9. Commission the heating installation by making all the

necessary settings on the control panel.

10. Check the heating installation after commissioning.

11. Top up more collector circuit fluid, if required.

Only qualified installers may carry out the

installation. The installer must follow

applicable rules and regulations and

recommendations from the supplier.

HC HC 22 HC 33

kW 21,0 33,8

Tab. 2 Type overview

Each heat pump installation is unique. The

following checklist will give you a general

description of how the installation should

be carried out.

Page 9

Product details

6 720 645 504 (2011/04) en

9

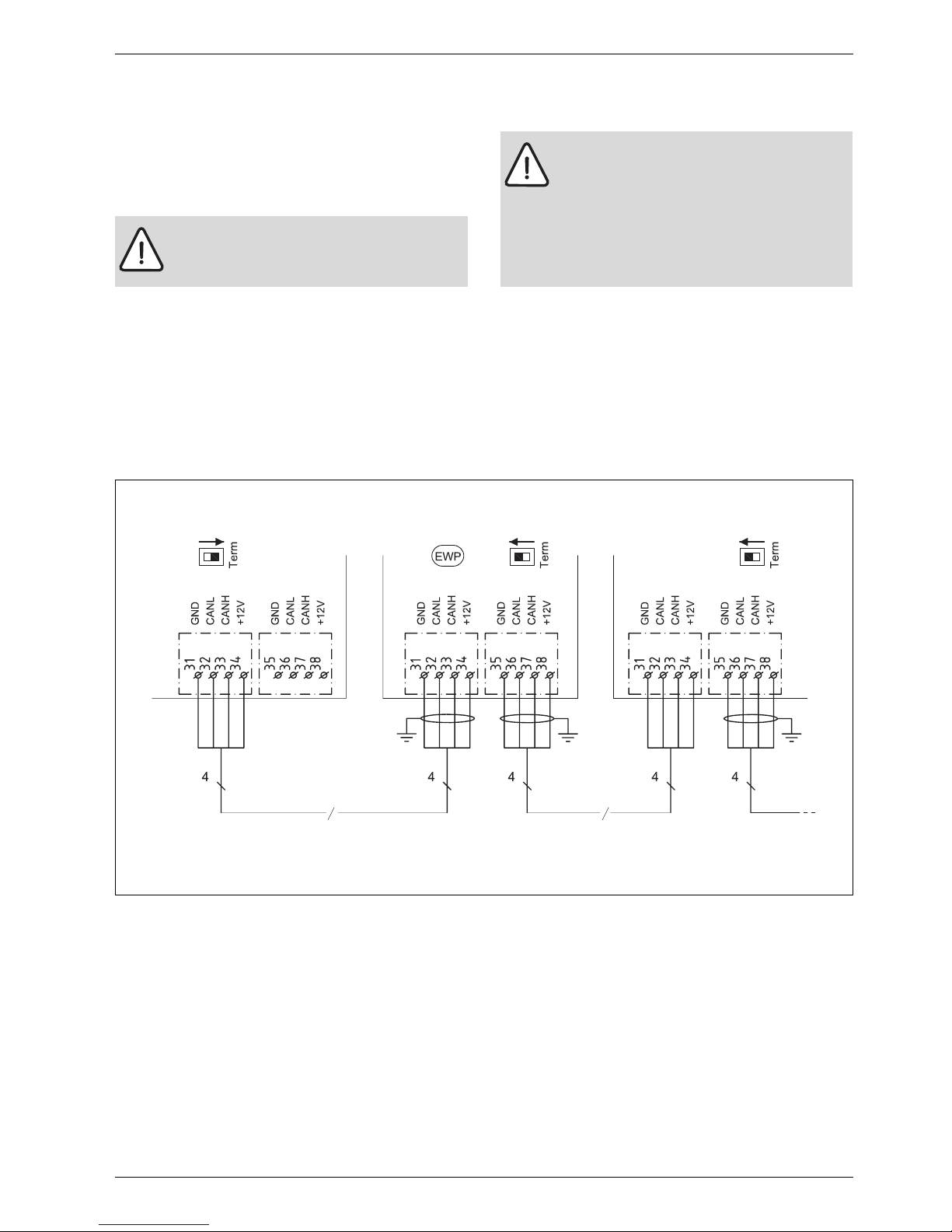

5.9 CAN-BUS

The various circuit boards in the heat pump are joined by

a communications cable, CAN-BUS. CAN (Controller

Area Network) is a two-wire system for communication

between microprocessor based modules/circuit boards.

Suitable cable for external laying is cable LIYCY (TP)

2x2x0.5. The cable must be twisted pair and screened.

The screen must only be earthed at one end and to the

chassis.

Maximum cable length is 30 m.

CAN-BUS cable must not be laid alongside power supply

cables. Minimum distance 100 mm. They may be laid

alongside sensor cables.

The connection between the circuit boards is by four

wires, because the 12V-supply between the circuit

boards must also be connected. The circuit boards have

markings for both the 12V and CAN-BUS connections.

Switch Term is used to mark the start and end of a CANBUS loop. Ensure that the correct circuit board is

terminated and that all other switches are in the

opposite position.

Fig. 4

GND Earth

CANL CAN low

CANH CAN high

+12V Connection 12V

EWP Heat pump

CAUTION: Interference.

B The CAN-BUS cable must be screened

and laid separately from the power cable.

CAUTION: Do not mix up the 12V and CANBUS connections!

The processors are destroyed if 12V is

connected to the CAN-BUS.

B Check that the four cables are connected

to the contacts with the corresponding

marking on the circuit board.

6 720 614 967-31.2I

CAN-BUS

CAN-BUS

Page 10

Product details

6 720 645 504 (2011/04) en

10

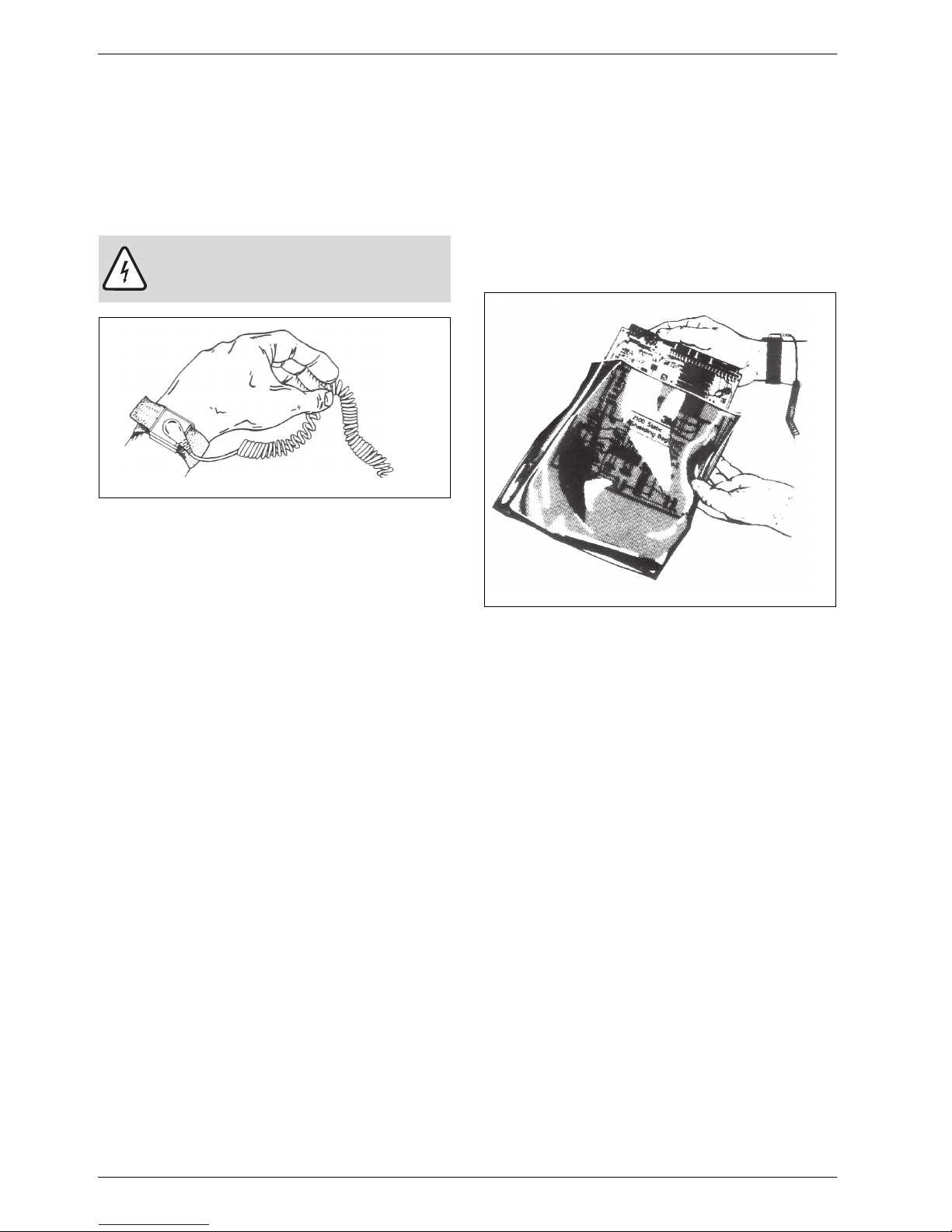

5.10 Handling circuit boards

Circuit boards with control electronics are sensitive to

discharges of static electricity (ESD – ElectroStatic

Discharge) when handled. To prevent damaging the

components, special care is therefore required when

handled.

Fig. 5 Bracelet

Damage is usually latent, and a circuit board can operate

impeccably during commissioning but show signs of

problems later. Charged objects may only be

problematic if they are in close proximity to the

electronics. Keep a distance of at least one metre from

expanded polystyrene, protective plastic and other

packaging, synthetic material (e.g. fleeces) and similar

before starting work.

A condition for good ESD protection is a groundconnected bracelet when handling electronics. This

bracelet must be put on before opening the screened

metal bag/packaging or before exposing an installed

board. The bracelet must be worn until the circuit board

is enclosed in its screen packaging or closed electric

box. Replaced, returned circuit boards must be handled

in the same way.

Fig. 6

CAUTION: Never grasp a circuit board

without wearing a ground-connected

bracelet.

6 720 614 366-24.1I

6 720 614 366-25.1I

Page 11

Heating, general

6 720 645 504 (2011/04) en

11

6 Heating, general

6.1 Circuits for heating

• Circuit 1; the first circuit is included by default in the

control unit and is controlled by the installed flow

sensor, possibly in combination with an installed

room sensor.

• Circuit 2 (mixed); control of circuit 2 is also included

by default in the control unit and only needs to be

supplemented with a mixing valve, circulation pump

and flow sensor and possibly with an additional room

sensor.

• Circuit 3-4 (mixed); control of up to 2 additional

circuits is optional. Each circuit is then fitted with a

mixing valve module, circulation pump, flow sensor

and a possible room sensor.

6.2 Control methods for heating

• Outdoor sensor; a sensor is fitted on the outside wall

of the house. The sensor sends signals to the control

unit in the heat pump. Control with an outdoor sensor

means that the heat pump automatically regulates the

heating in the house depending on the outdoor

temperature. The customer determines the

temperature of the heating system in relation to the

outdoor temperature by setting the heat curve on the

control unit.

• Outdoor sensor and room sensors (one room sensor

per circuit is possible); Control with outdoor sensor

supplemented with room sensor(s) means that one

(or several) sensors are mounted in a central location

inside the house. They are connected to the heat

pump and provide the control unit with information

about the current room temperature. The signal

affects the flow temperature. For example, it falls

when the room sensor indicates a higher temperature

than the one set. Room sensors are used when factors

other than the outdoor temperature influence the

indoor temperature of the house. For example, this

can be when a stove or fan-assisted radiator is used in

the house, or if the house is sensitive to the wind or

exposed to direct sunlight.

6.3 Time control for heating

• Program control; The control unit offers a possibility

to define two individual programs for time control of

the heating.

• Holiday; the control unit has a program for holiday

mode, which means that during the selected period

the room temperature changes to a lower or higher

level. The program also allows switching off hot water

production.

• External control; the control unit can make settings

for external control, which means that the

preselected function is performed when the control

unit senses an input signal.

Circuit 1 must always be installed and used.

Circuits 2 through 4 cannot have a higher

flow temperature than circuit 1. This means

that underfloor heating on circuit 1 cannot

be combined with radiators on another

circuit. Room temperature reduction for

circuit 1 can affect other circuits in some

cases.

When the Use temperature from circuit

with highest temperature function under

Circuit 1 is used, the heat curve for Circuit

1 does not need to be adapted to the mixed

circuits. The heat pump automatically

selects the highest flow temperature set

point value.

It is only the room where the room sensor is

located that can influence regulation of the

temperature for the relevant heating circuit.

Page 12

Heating, general

6 720 645 504 (2011/04) en

12

6.4 Operating modes

• Without additional heat; the heat pump is sized so as

to cover at least 100 % of the peak output of the

house.

– This choice is not in the control, choose Mixed

additional heat at Start-up and thereafter Block

additional heat in the menu for additional heat

( Chapter 16.7).

• With electrical additional heat; the heat pump is

sized to cover less than the peak output of the house.

An additional electric heat source covers the

difference. The additional electric heat source is

controlled by a 0-10 V signal which is connected to

the mixing valve output E71.E1.Q71 on the PEL board

( Chapter 11.6.5). Otherwise, the control of the

additional electric heat source functions in the same

way as the control of the mixed additional heat

source. The mixing valve control delay should be set

to 0, since it unnecessarily extends the start delay of

the additional heat ( Chapter 16.7).

• With mixed additional heat; mixed additional heat

source which is allowed to work in parallel with the

heat pump. Connection E71.E1.Q71

( Chapter 11.6.3). The additional heat is also used

in alarm mode.

For production of extra hot water and hot water peak,

an additional electric heat source is required in the

hot water heater.

For all operating modes shall Mixed

additional heat be used.

An additional electric heat source should

always be installed in the hot water heater if

the heat pump should supply more than 2

flats.

If an oil/gas boiler is used as a mixed

additional heat source, the boiler can be

installed in such a way as to generate hot

water, extra hot water and hot water peak.

In this case, an additional electric heat

source is not required in the hot water

heater.

Page 13

Dimensions and clearance

6 720 645 504 (2011/04) en

13

7 Dimensions and clearance

7.1 HC 22 - 33

Fig. 7 Front view

Fig. 8 Top view

All dimensions are stated in mm.:

A Collector circuit out

B Collector circuit in

C Return, hot water heater

D Flow, hot water heater

E Heat transfer fluid in

F Heat transfer fluid out

G Electrical connections

≥100 ≥350

≥600

1640

6 720 645 504-03.1I

E

B

A

F

C

D

700

810

300

135

230

1200

G

100

200

300

400

500

600

6 720 614 967-8.2I

Page 14

Technical information

6 720 645 504 (2011/04) en

14

8 Technical information

8.1 Component parts

8.1.1 HC 22 - 33

Fig. 9

1 Type plate

2 Collector circuit pump

3 Heat carrier pump

4 Low pressure switch

5 Condenser

6 Compressor (1 and 2)

7 Evaporator

8 Sight glass

9 High pressure switch

10 Expansion valve

11 3-way valve

12 Drying filter

13 Transport locking devices (2) and Vibration dampers (2)

6 720 614 967-5.1I

8

5

5

3

3

8

11

12

12

2

4

2

6

9

4

6

9

10

13

1

7

7

10

13

Page 15

Technical information

6 720 645 504 (2011/04) en

15

8.2 System solutions

8.2.1 System solution explanations

Detailed system solutions can be found in

the product's planning documentation.

E10

E10.T2 Outdoor sensor

Tab. 3 E10

E11 Circuit 1

E11.C101 Expansion vessel

E11.C111 Buffer tank

E11.F101 Safety valve

E11.F111 Automatic air vent

E11.G1 Heating circuit pump

E11.P101 Pressure gauge

E11.P111 Thermometer

E11.P112 Thermometer

E11.Q101 Shut-off valve

E11.Q102 Shut-off valve

E11.R101 Non-return valve

E11. T1 Flow sensor

E11.TT Room sensor

Tab. 4 E 11 Circuit 1

E12 Circuit 2

E12.G1 Heating circuit pump

E12.P112 Thermometer

E12.Q101 Shut-off valve

E12.Q102 Shut-off valve

E12.Q11 Mixing valve

E12.R101 Non-return valve

E12.T1 Flow sensor

E12.T5 Room sensor

Tab. 5 E12 Circuit 2

E21 Compressor 1

E21 Heat pump

E21.F111 Automatic air vent

E21.G2 Heat carrier pump

E21.G3 Collector circuit pump

E21.Q102 Shut-off valve

E21.Q21 3-way valve

E21.R101 Non-return valve

E21.R102 Non-return valve

E21.T8 Heat transfer fluid out

E21.T9 Heat transfer fluid in

E21.T10 Collector circuit in

E21.T11 Collector circuit out

E21.V102 Filter

Tab. 6 E21 Compressor 1

E22 Compressor 2

E22 Heat pump

E22.F101 Safety valve

E22.G2 Heat carrier pump

E22.G3 Collector circuit pump

E22.Q101 Shut-off valve

E22.Q21 3-way valve

E22.R101 Non-return valve

E22.R102 Non-return valve

E22.T8 Heat transfer fluid out

E22.T9 Heat transfer fluid in

E22.T10 Collector circuit in

E22.T11 Collector circuit out

E22.V101 Filter

Tab. 7 E22 Compressor 2

Page 16

Technical information

6 720 645 504 (2011/04) en

16

E31 Collector circuit

E31 Collector circuit, compressor 1

E31.C101 Expansion vessel

E31.F101 Safety valve

E31.F102 Safety valve

E31.F111 Automatic air vent

E31.Q21 Ball valve filling unit

E31.Q22 Ball valve filling unit

E31.Q23 Shut-off valve

E31.Q24 Shut-off valve

E31.V101 Filter

Tab. 8 E31 Collector circuit

E41 and E42 Domestic hot water tank 1 and 2

E41 Hot water heater 1

E41.E1 Hot water electric heater

E41.E1.G1 Circulation pump

E41.F101 Safety valve

E41.F102 Safety valve

E41.G6 Circulation pump hot water

E41.P111 Thermometer

E41.P112 Thermometer

E41.Q101 Shut-off valve

E41.Q104 Shut-off valve

E41.Q105 Shut-off valve

E41.Q106 Shut-off valve

E41.Q111 Balancing valve

E41.R101 Non-return valve

E41.R102 Non-return valve

E41.T3 Hot water sensor

E41.V41 Hot water

E41.W41 Cold water

E42 Hot water heater 2

Tab. 9 E41, E42 DHW tank 1, 2

E71 Additional heat

E71 Additional heat

E71.E1.F101 Safety valve

E71.E1.F111 Automatic air vent

E71.E1.G71 Circulation pump

E71.E1.P111 Thermometer

E71.E1.P101 Pressure gauge

E71.E1.Q1Q1 Shut-off valve

E71.E1.Q1Q2 Shut-off valve

E71.E1.Q71 Mixing valve

Tab. 10 E71 Additional heat

Page 17

Technical information

6 720 645 504 (2011/04) en

17

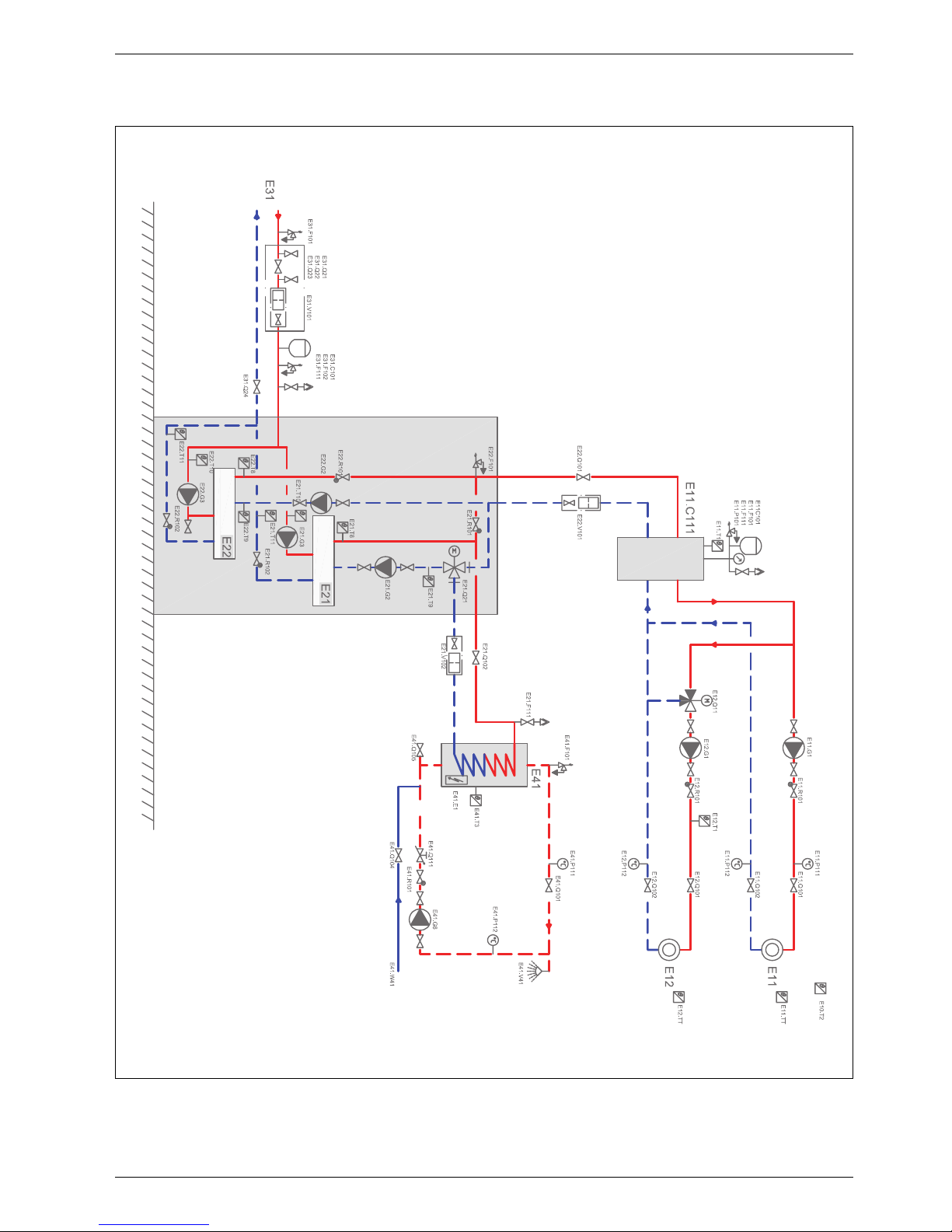

8.2.2 System solution without additional heat

Fig. 10 Heating circuit and buffer tank without additional heat (

Chapter 8.2.1, 8.3)

6 720 616 938-23.1I

Page 18

Technical information

6 720 645 504 (2011/04) en

18

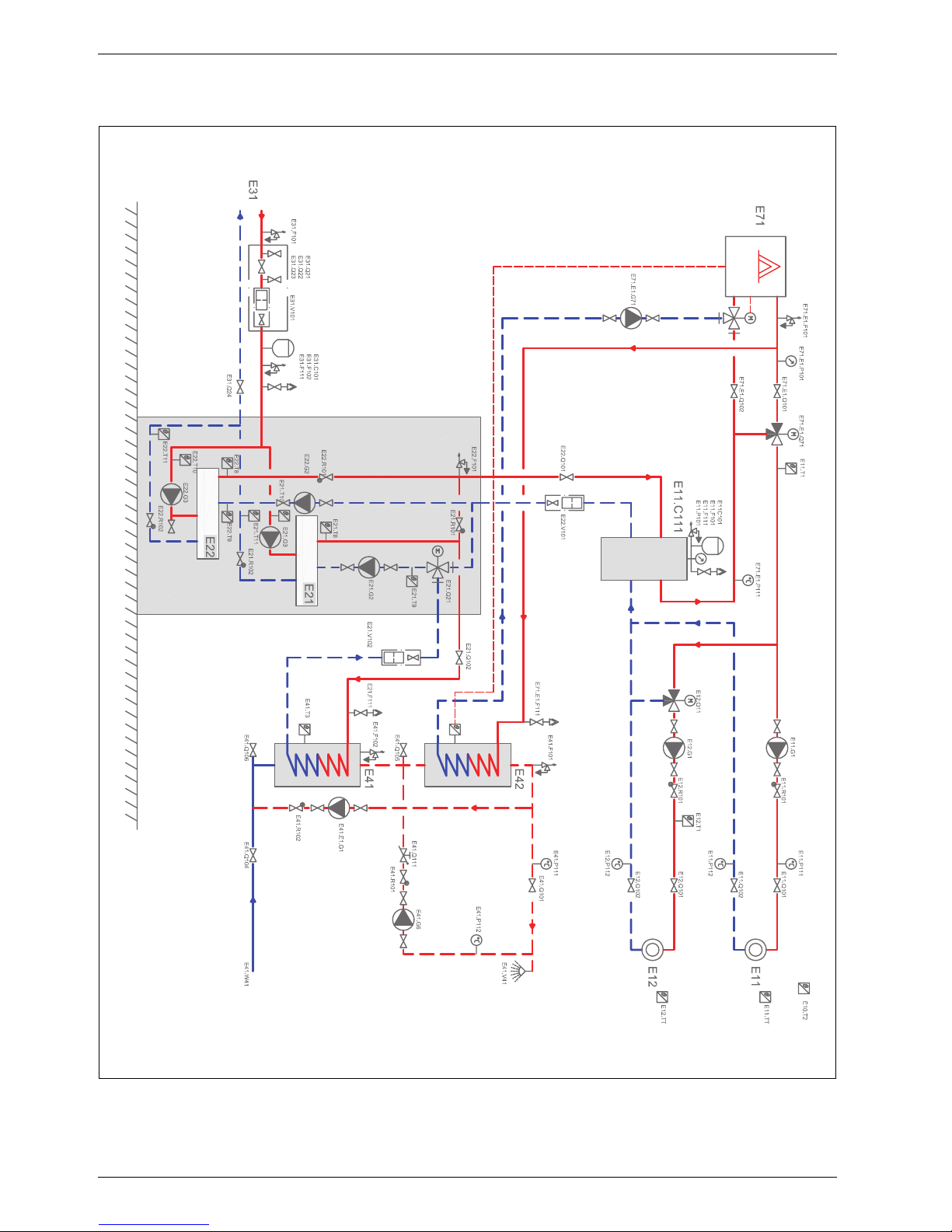

8.2.3 System solution with mixed additional heat

Fig. 11 Heating circuit, buffer tank and mixed additional heat (

Chapter 8.2.1, 8.3)

6 720 616 938-26.1I

Page 19

Technical information

6 720 645 504 (2011/04) en

19

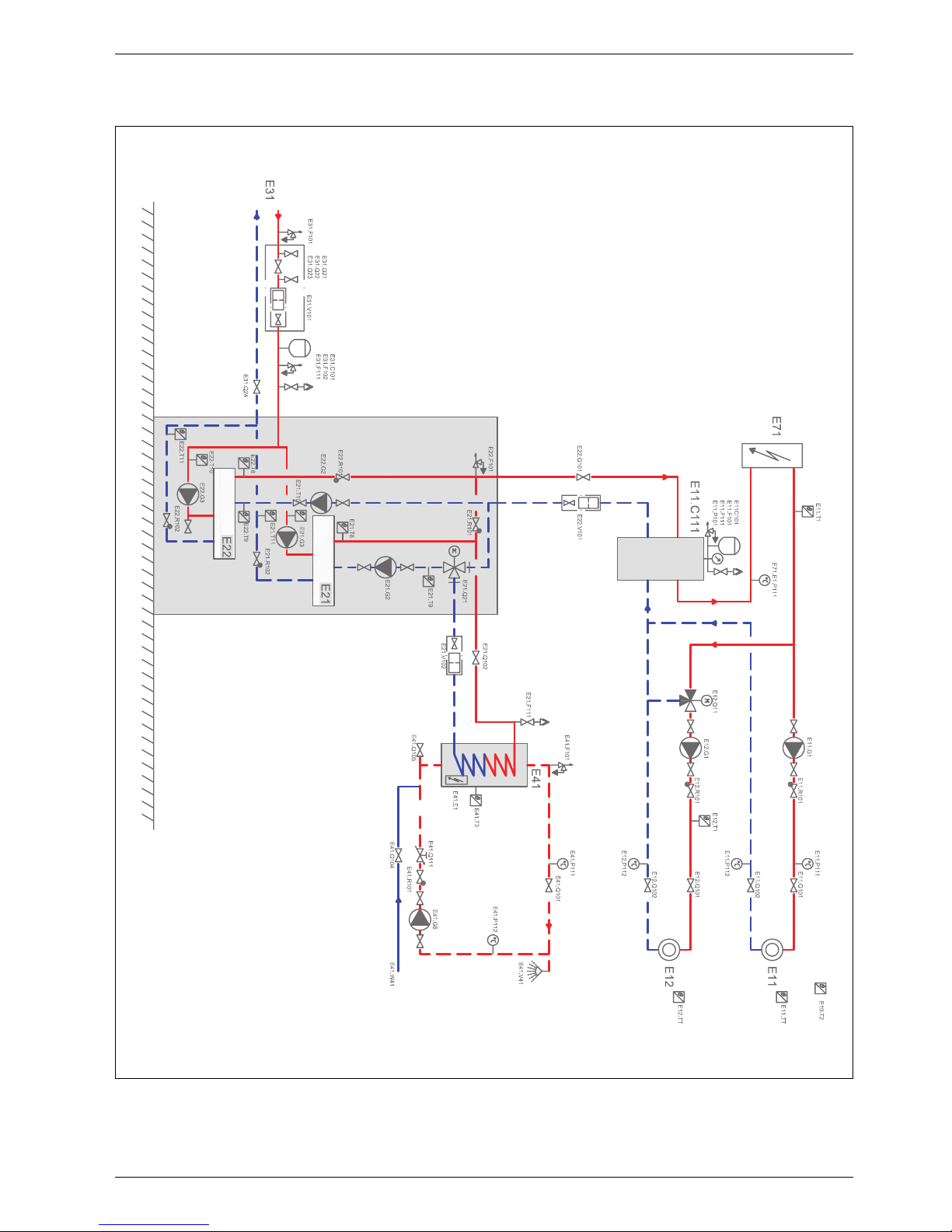

8.2.4 System solution with electric additional heat

Fig. 12 Heating circuit, electric additional heat and buffer tank (

Chapter 8.2.1, 8.3)

6 720 616 938-25.1I

Page 20

Technical information

6 720 645 504 (2011/04) en

20

8.3 Functional description of system solutions

System without additional heat ( Chapter 8.2.2)

Heating

Heat for E11 is taken directly from buffer tank E11.C111.

Heat for E12 is taken from buffer tank E11.C111 and is

shunting to the set temperature using mixing valve

E12.Q11. The heat pump supplies heat to E11.C111 and

keeps the temperature set on E11.T11 by starting one

compressor at a time when the temperature is too low

and stopping one compressor at a time when the

temperature is too high.

Hot water

When the temperature in hot water heater E41.T3 falls

below the set limit, E21.Q21 switches over to water

heating and compressor E21 starts. Water heating

continues until the temperature of E21.T8 exceeds the

set stop limit.

Pump control

E11.G1 and E12.G1 start at low outdoor temperature

and stop at high outdoor temperature. E21.G2 and

E21.G3 are in operation when compressor E21 is in

operation. E22.G2 and E22.G3 are in operation when

compressor E22 is in operation. E41.G6 is in operation

at set times.

System with mixed additional heat

( Chapter 8.2.3)

Additional heat and heat pump work in parallel

Heat for E11 is taken directly from buffer tank E11.C111,

with possible afterheating by E71. Heat for E12 is taken

from buffer tank E11.C111, with possible afterheating by

E71, and is released by shunting at the set temperature

using mixing valve E12.Q11. The heat pump supplies

heat to E11.C111 in order to keep the temperature set

on E11.T11 by starting one compressor at a time when

the temperature is too low and stopping one

compressor at a time when the temperature is too high.

If the heat pump does not manage to supply the set

temperature by itself, additional heat E71.E1.Q71 is

activated and regulates E11.T1 to the set temperature.

Additional heat and heat pump work separately

When the heat pump is responsible for all of the heating,

it supplies heat to E11.C111 and keeps the temperature

set on E11.T11 by starting one compressor at a time

when the temperature is too low and stopping one

compressor at a time when the temperature is too high.

When the heat pump is in operation, boiler E71 is

responsible for all of the heat production. Heat for E11

is taken from buffer tank E11.C111 or from E71. Heat for

E12 is taken from buffer tank E11.C11 or from E71 and

is shunted to the set temperature using mixing valve

E12.Q11. Switch between heat pump and additional

heat operation can result from low outdoor temperature,

temporary stop of the energy supply to the heat pump or

activation of external input for blocking the heat pump.

Hot water

The hot water is preheated in E41 which is heated by the

heat pump. When the temperature in hot water heater

E41.T3 falls below the set limit, E21.Q21 switches over

to water heating and compressor E21 starts. Water

heating continues until the temperature of E21.T8

exceeds the set stop limit. The hot water is afterheated

in E42 which is heated by additional heat E71. The

heating of the hot water circulation via E41.G6 is done

completely by E42. Additional heat E71 exercises full

control and regulation of the temperature in hot water

heater E42.

Pump control

E11.G1 and E12.G1 start at a low outdoor temperature

and stop at a high outdoor temperature. E21.G2 and

E21.G3 are in operation when compressor E21 is in

operation. E22.G2 and E22.G3 are in operation when

compressor E22 is in operation. E41.G6 are in operation

at the set times. E41.E1.G1 ( Chapter 11.9) is

controlled by the heat pump and is used for thermal

disinfection of E41.

High temperature systems

In some heating systems the return temperature may at

times exceed 55 °C. In such cases the heat pump stops

(T9 > 55 °C) and restarts when E11.T1 becomes less

than 65 °C.

Page 21

Technical information

6 720 645 504 (2011/04) en

21

System with electric additional heat

( Chapter 8.2.4)

Heating

Heat for E11 is taken directly from buffer tank

E11.C111, with possible afterheating by E71. Heat for

E12 is taken from buffer tank E11.C111, with possible

afterheating by E71, and is shunted to the set

temperature using mixing valve E12.Q11. The heat pump

supplies heat to E11.C111 and keeps the temperature

set on E11.T11 by starting one compressor at a time in

the heat pump when the temperature is too low and

stopping one compressor at a time when the

temperature is too high. If the heat pump does not

manage to supply the set temperature by itself,

additional heat is activated, controlling the output via 010 V signal so as to keep the set temperature.

Hot water

When the temperature in hot water heater E41.T3 falls

below the set limit, E21.Q21 switches over to water

heating and compressor E21 starts. Water heating

continues until the temperature of E21.T8 exceeds the

set stop limit.

Pump control

E11.G1 and E12.G1 start at low outdoor temperature

and stop at high outdoor temperature. E21.G2 and

E21.G3 are in operation when compressor E21 is in

operation. E22.G2 and E22.G3 are in operation when

compressor E22 is in operation. E41.G6 is in operation

at set times.

This system solution is also suitable for 010V output-controlled gas/oil-fired boiler.

Enter Yes for Acknowledge hot water

additional heat (Chapter 16.7) in all

system solutions.

Page 22

Technical information

6 720 645 504 (2011/04) en

22

8.4 Technical information

8.4.1 HC 22 - 33

Unit HC 22 HC 33

Liquid/water operation

Emitted output / COP (0/35) EN14511

1)

1) The indicated values are measured according to WPZ test methods.

kW 21.0/4.4 33.8/4.2

Emitted output / COP (0/45) EN14511

1)

kW 19.9/3.5 31.6/3.2

Emitted output / COP (0/35) EN255

1)

kW 21.6/4.8 34.2/4.4

Emitted output / COP (10/35) EN255

1)

kW 26.4/5.8 41.7/5.2

Max. cooling effect (0/35) kW 17 26

Max. cooling effect (10/35) kW 23 34

Collector circuit

Connection, collector circuit DN40, 1½ “

Working pressure collector circuit max/min bar 4 / 0.5

Incoming temperature collector circuit max/min °C 22 / -5

Outgoing temperature collector circuit min. °C -8

Mixture Ethylene glycol max/min % 35 / 30

Nominal flow collector circuit (max deviation 15%) l/s 1.3 2.3

Permitted ext. pressure drop collector circuit kPa 65 44

Heating system

Buffer tank connections DN 32, 1¼ “

Tap hot water connections DN 25, 1“

Nominal flow hot water (max deviation 15%) l/s 0.28 0.45

Working pressure heating system max/min bar 4 / 0.5

Flow buffer tank max/min l/s 0.74/0.52 1.1/0.82

Max. ext. pressure drop buffer tank at max. flow kPa 30 20

Max. ext. pressure drop buffer tank at min. flow kPa 40 40

Compressor

Step 1 (no. 1) Mitsubishi Scroll

Step 2 (no. 2) Mitsubishi Scroll

Max. flow temperature (no. 1/no. 2) °C 65/65

Refrigerant R 407C (no. 1/no. 2)

2)

2) Global Warming Potential, GWP

100

= 1526

kg 2,4/2,4 2,6/2,6

Sound level

3)

3) The sound level is the acoustic energy that the heat pump emits and is not affected by the surroundings. On the other hand, the

sound pressure level is affected by the surroundings and is approx. 11dBA lower when measured at a distance of 1 m in a free

field.

dBA 51 53

Electrical data

Electrical connection (acc. to EN 60204-1) 400V 3N~50Hz

Fuse gL- gG / characteristic D (automatic) A 25 32

Max. short-circuit impedance soft starter Ω 0,42 0,47

Max. operating current A 17 22,3

Start current with soft starter A 29 30

Nominal output (0/50) kW 6,7 10,8

Nominal output (0/35) kW 5,5 8,7

Maximum effect kW 10,5 14,1

Collector circuit pump output at max. speed (no. 1/no. 2) W 310/310 390/390

Collector circuit pump output at min. speed (no. 1/no. 2) W 290/290 360/360

Heat carrier pump output at max. speed (no. 1/no. 2) W 91/91 124/124

Heat carrier pump output at min. speed (no. 1/no. 2) W 49/49 61/61

General

Dimensions (height x depth x width) mm 700 x 750 x 1620

Weight kg 330 351

Tab. 11 Teknisk information

Page 23

Technical information

6 720 645 504 (2011/04) en

23

8.4.2 Motor cut-out compressor

8.4.3 Circulation pumps

8.4.4 Measurement values for temperature sensors

Compressor HC 22 HC 33

No. 1 8 A 13 A

No. 2 8 A 13 A

Tab. 12 Motor cut-out settings, compressor

Collector circuit pump

(G3)

HC 22 HC 33

No. 1 Wilo TOP-S 30/10 TOP-S 30/10

No. 2 Wilo TOP-S 30/10 TOP-S 30/10

Tab. 13 Built-in collector circuit pumps

Heat carrier pump

(G2)

HC 22 HC 33

No. 1 Wilo RS-25/6 RS-25/7

No. 2 Wilo RS-25/6 RS-25/7

Tab. 14 Built-in heat carrier pumps

°C Ω

T...

°C Ω

T...

°C Ω

T...

°C Ω

T...

–40 154300 –5 19770 30 3790 65 980

–35 111700 0 15280 35 3070 70 824

–30 81700 5 11900 40 2510 75 696

–25 60400 10 9330 45 2055 80 590

–20 45100 15 7370 50 1696 85 503

–15 33950 20 5870 55 1405 90 430

–10 25800 25 4700 60 1170

Tab. 15 Measurement values for temperature sensors

Page 24

Regulations

6 720 645 504 (2011/04) en

24

9Regulations

The following regulations and requirements must be

observed:

• The responsible power supply company's local

regulations and requirements, including the

corresponding special rules (TAB)

• BImSchG, Section 2 on installations which do not

require permits

• TA Lärm Technical Instruction on Noise Protection -

(general regulation in accordance with the Federal

Emission Control Act)

• National building regulations

• EnEG (Energy Saving Act)

• EnEV (German regulations on energy saving thermal

insulation and energy saving building design)

• EN 60335 (Safety of electric and similar household

appliances)

part 1 (General requirements)

Part 2-40 (Particular requirements for electrical heat

pumps, air-conditioners and dehumidifiers)

• EN 12828 (Heating systems in buildings. Design for

water-based heating systems)

• DVGW, Wirtschafts- und Verlagsgesellschaft, Gas-

und Wasser GmbH - Josef-Wirmer-Str. 1–3 53123 Bonn

– Worksheet W 101

Guidelines for drinking water protection areas;

part I: protection areas for groundwater

• The following DIN standards:DIN 1988, TRWI

(Technical Regulations for Drinking Water

Installations),DIN VDE 0100, Part 701 (Installation of

High-Power Equipment with Rated Voltages up to

1000 V, Rooms with Bath or Shower),DIN 4751

(Heating Systems; Safety Systems for Water Heating

Systems with Flow Temperatures up to 110 °C),DIN

4807 (Expansion Vessels)Beuth-Verlag GmbH Burggrafenstraße 6 -10787 Berlin

– DIN 1988, TRWI (Technical Regulations for

Drinking Water Installations)

– DIN 4108 (Thermal Insulation and Energy Economy

in Buildings)

– DIN 4109 (Sound Insulation in High Buildings)

– DIN 4708 (Central Hot Water Installations)

– DIN 4807 and EN 13831, respectively (Expansion

Vessels)

– DIN 8960 (Refrigerants -Requirements and

Symbols)

– DIN 8975-1 (Refrigerating Plants - Safety Principles

for Design, Equipment and Installation Interpretation)

– DIN VDE 0100, (Installation of High-Power

Equipment with Rated Voltages up to 1000 V)

– DIN VDE 0105 (Operation of Power Installations)

– DIN VDE 0730 (Regulations for Devices with

Electromotive Drive for Domestic Use and Similar

Purposes)

• VDI guidelines, Verein Deutscher Ingenieure e.V. -

P.O. Box 10 11 39 - 40002 Düsseldorf

– VDI 2035 Sheet 1

1)

: Prevention of damage in water

heating installations and scale formation in

domestic hot water supply installations and water

heating installations

– VDI 2035 Sheet 2

2)

: Prevention of water corrosion

in the heating system

– VDI 2081 Sound production and reduction in

ventilation systems

– VDI 2715 Noise reduction at domestic hot water

and central heating systems

– VDI 4640 Thermal use of the underground,

Sheet 1: Fundamentals, approvals, environmental

aspects;

Sheet 2: Ground source heat pump systems

• Austria:

– örtliche Bestimmungen und regionale

Bauordnungen

– Vorschriften der Versorgungsnetzbetreiber (VNB)

– Vorschriften der Wasserversorgungsunternehmen

– Wasserrechtsgesetz von 1959 in gültiger Fassung

– ÖNORM H 5195-1 Verhütung von Schäden durch

Korrosion und Steinbildung in geschlossenen

Warmwasserheizungsanlagen bis 100 °C

– ÖNORM H 5195-2 Verhütung von Frostschäden in

geschlossenen Heizungsanlagen

• Switzerland: kantonale und örtliche Vorschriften1

1) If the drinking water has a higher °dH than what is indicated in

VDI 2035, a water softener must be installed in the filling pipe

to the heating system - this in order to guarantee the function

of the heat pump. However, when the hardness is already

greater than 3 °dH, the performance of the heat pump will

deteriorate with time because of the lime deposits left on the

heat exchanger surfaces.

2) The standard discusses the problems but does not set any limit

values. This is why, we supplement with the following values:

Oxygen content, O

2

-0.5-1 mg/l. Carbon dioxide content, CO2 <1 mg/l. Chloride, Cl - <100 mg/l. Sulphate, SO4 - <100 mg/l. If

the drinking water exceeds the limit values for chloride or

sulphate content, an ion exchange filter must be installed in

the filling pipe for the heating system. Do not use any water

treatment additives except agents for raising the pH level, keep

the water clean.

Page 25

Installation

6 720 645 504 (2011/04) en

25

10 Installation

10.1 Collector system

Installation and filling

Installation and filling of the collector system should

comply with applicable laws and regulations. Soil used

for refilling around the collector hose must not contain

stones or other sharp objects. Pressure test the

collector system before refilling to ensure that the

system is watertight.

When cutting the collector, it is important that no dirt or

gravel enters the system. This can cause blockages in the

heat pump and damage components.

Condensation insulation

Condensation insulation should be mounted on all parts

of the collector circuit system.

Filling unit

A filling unit is required and should be installed close to

the collector circuit inlet.

Vents

To avoid operational disturbances because of air

bubbles, a microbubble separator with a venting nipple

is required and should be installed between the filling

unit and the heat pump.

Expansion vessel, safety valve, pressure gauge

The expansion vessel, safety valve and pressure gauge

are to be provided by the dealer.

Membrane expansion vessel in the collector circuit

Select membrane expansion vessel according to:

The values apply at a pre-pressure of 0.5 bar.

Antifreeze/Corrosion preventative

Freeze protection until –15 °C should be ensured. We

recommend the use of ethylene glycol.

10.2 Heating system

Flow over the heating system

When the heat pump works with a buffer tank, there can

be significant variations in the flow into the heating

system. However, there must be a certain minimum flow,

which is solved by:

In the event of a radiator system, the setting for the

radiator thermostats must be limited to a minimum

temperature of 18°C.

In the event of a floor heating system, a minimum water

flow must be guaranteed by ensuring that there are

circuits without room temperature control or with a

bypass in the floor heating distributor.

This guarantees cooling of the heating system's

circulation pump and correct measurements of the flow

sensor. A slight increase in flow rate above the minimum

flow is accepted.

Expansion vessel

Select expansion vessel in accordance with BS

EN 12828.

Particle filter

A particle filter for the heating system is included in the

delivery and should be installed on the connection for

heat transfer fluid in (heating system return).

A particle filter for the collector circuit is included in the

delivery and is installed between the filling unit and the

heat pump close to the connection for collector circuit

in.

A particle filter for hot water is included in the delivery

and should be installed on the connection for hot water

return.

See also the system solutions ( Chapter 8.2).

Ethylene glycol

Glycol is not normally used in the heating system. In

special cases, where increased protection is required,

glycol can be added with a maximum concentration of

15%. Heat pump performance will however decrease.

Safety valve

Pursuant to EN 12828, a safety valve should be used.

The safety valve must be installed vertically.

Only qualified installers may carry out the

installation. The installer must follow

applicable rules and regulations and

recommendations from the supplier.

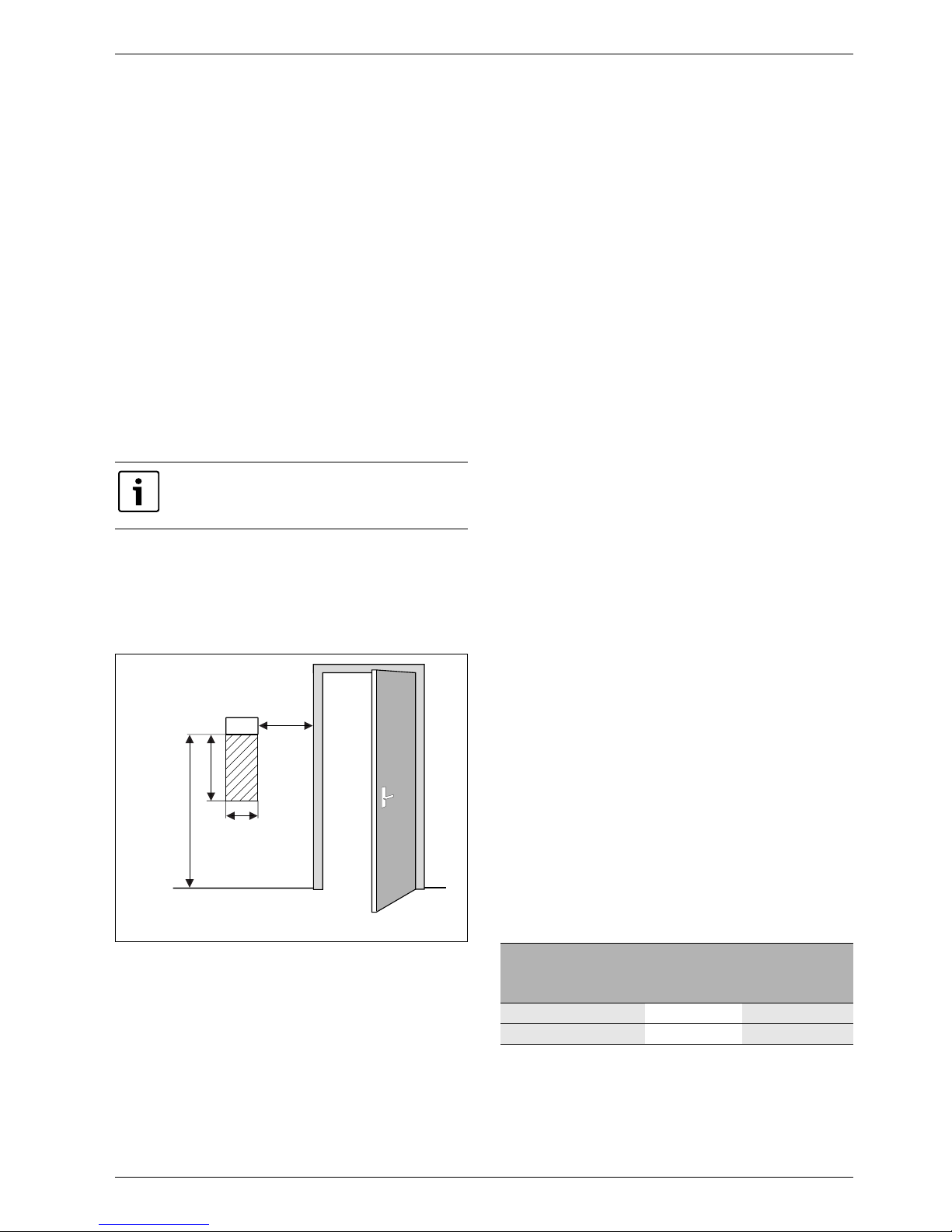

Model Volume

HC 22 25 litres

HC 33 35 litres

Tab. 16 Volume membrane expansion vessel

WARNING:

B No other anti-freeze may be used in the

heating system.

Page 26

Installation

6 720 645 504 (2011/04) en

26

10.3 Siting the appliance

Noice transfer to adjacent areas must be taken into

consideration when choosing a position for the heat

pump ( Chapter 8.4 for sound levels).

10.4 Pipework preparations

B Connection pipes for the collector system, heating

system and possible hot water should be installed in

the premises to the heat pump location.

B An expansion vessel, a safety group and a pressure

gauge should be mounted in the heating circuit

(accessories).

B Mount a filling unit at a suitable place in the collector

circuit close to the inlet.

10.5 Flushing the heating system

The heat pump is a part in a heating system. Faults in the

heat pump can be caused by poor water quality in the

radiators/floor loops or air penetrating the system

continuously.

Oxygen causes corrosion products in the form of

magnetite and sediment.

Magnetite has a grinding effect on the heating system's

pumps, valves and components with turbulent flows

such as the condenser.

Heating systems which require regular filling or where

the heating water is not clear when drained, require

remedial measures before the installation of a heat

pump, for example the heating system must be fitted

with filters and vents.

Do not use any water treatment additives except agents

for raising the pH level. Recommended pH value is 7.5 –

9.

An intermediate heat exchanger is sometimes necessary

to protect the heat pump.

10.6 Setting up

B Remove packing, taking care to observe the

instructions on the packing.

B Remove the supplied accessories.

B Install the supplied adjustable feet and adjust the

height.

10.7 Heat insulation

All heat conducting pipes must have suitable heat

insulation, applied to current standards.

10.8 Removing the front panel

B Loosen the screws, tilt the front panel outwards and

take it off.

Fig. 13

WARNING:

B Never block the safety valve outlet.

CAUTION: The heat pump may become

damaged in the event of dirt or other

particles in the pipework.

B Flush out the system to remove all dirt

residues.

CAUTION: The heat pump may become

damaged in the event of dirt or other

particles in the pipework.

B Flush out the system to remove all dirt

residues.

1.

1.

2.

6 720 614 967-4.1I

Page 27

Installation

6 720 645 504 (2011/04) en

27

10.9 Temperature sensor installation

10.9.1 Flow sensor T1

B Operation mode without additional heat with buffer

tank. Install the sensor in the upper part of the tank.

See the installation manual for the buffer tank.

B Operation mode mixed additional heat (including

electric additional heat). Install the sensor in contact

with the flow pipe immediately after the mixing valve

(Q71) or after the additional electric heat.

10.9.2 Outdoor sensor T2

B Install the sensor on the coldest side of the house

(the north side). It must be protected from direct

sunlight, ventilation air or anything that can affect the

temperature measurement. The sensor must not be

installed directly beneath the roof.

10.9.3 Room sensor T5 (accessory)

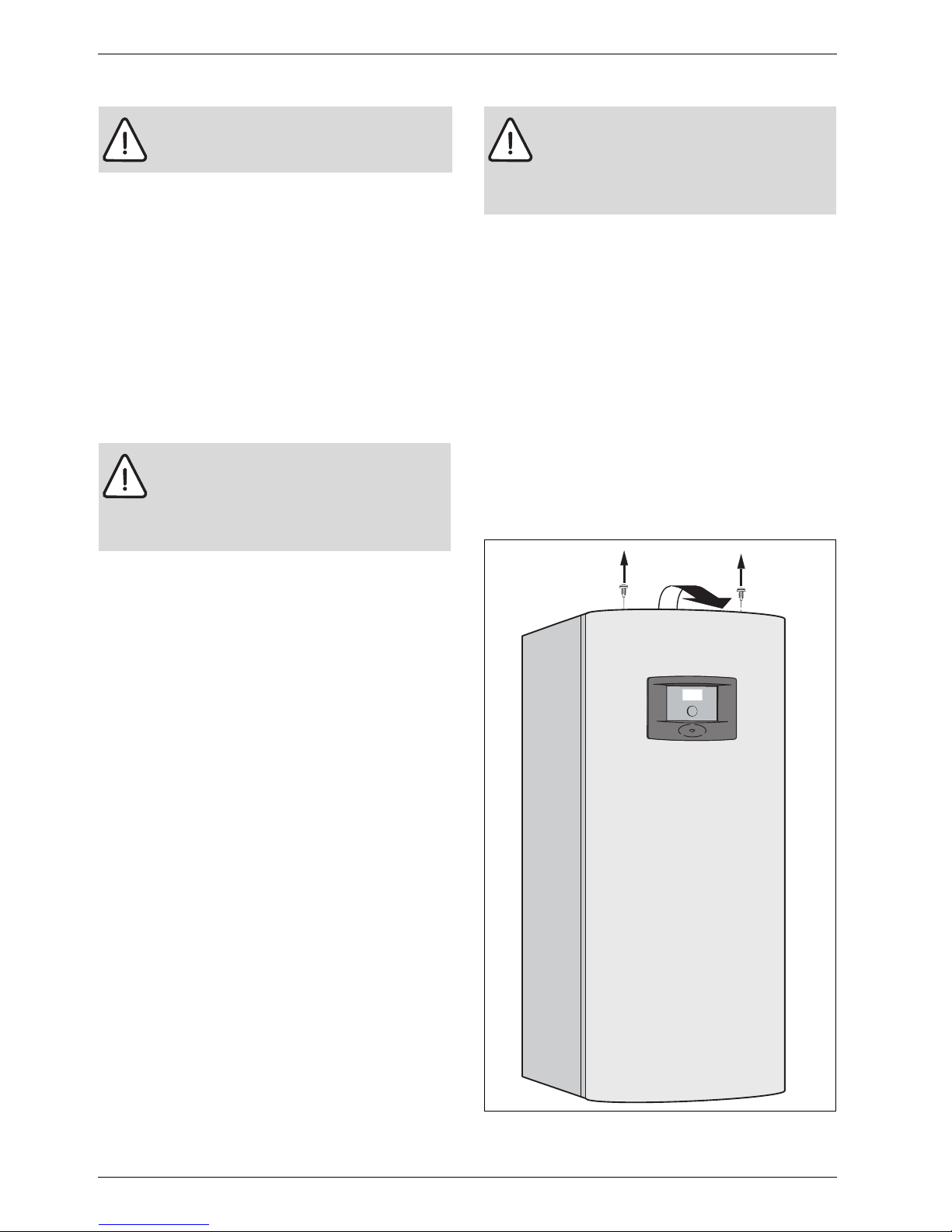

Installation location requirements:

• If possible, interior wall without drafts or heat

radiation.

• Unimpeded circulation of room air under room sensor

T5 (dotted area in figure 14 must be kept clear).

Fig. 14 Recommended installation location for room

sensor T5

10.10 Filling the heating system

B Open the heating system's valves.

B Open the tap on particle filter E22.V101 of the heating

system. Open valve E22.Q101.

B Fill up the heating system until the appropriate

pressure for the installation is reached. The maximum

permitted pressure is 4 bar.

B Vent the heating system.

B Drain some water out of buffer tank E11.C111 in

order to flush away possible particles from the tank.

Check and clean the particle filter if necessary.

B Check the pressure of the system and refill to the

appropriate pressure.

B Repeat the steps above if there is a lot of dirt in the

filter or tank.

B Check all connections for leaks.

10.11 Filling the hot water circuit

B Remove the cover of particle filter E21.V102. Position

the filter in an intermediate position.

B Position the 3-way valve E21.Q21 for heat production.

B Open shut-off valve E21.Q102 a bit and fill the circuit

carefully.

B Position the filter in operating mode and refit the

cover.

B Open the shut-off valve completely and perform

manual operation of the 3-way valve E21.Q21 in both

heating and hot water mode for venting.

B Check the pressure of the heating system and fill up,

if necessary, to a maximum of 4 bar.

B Check all connections for leaks.

10.12 Filling the collector system

The collector system is filled with collector circuit fluid

which must guarantee antifreeze protection down to

–15 °C. We recommend a mixture of water and glycol.

A rough estimate of the amount of collector circuit fluid

that is required in relation to the length of the collector

system and the inner diameter of the pipe can be made

using table 17.

It is only the room where the room sensor is

located that can influence regulation of the

temperature for the relevant heating circuit.

6 720 614 366-34.1I

0,3 m

0,3 m

0,6 m

1,2 - 1,5 m

T5

Inner diameter

Volume per metre

Single pipes

Double U

pipes

28 mm 0.62 l 2.48 l

35 mm 0.96 l 3.84 l

Tab. 17 Amount of collector circuit fluid

Page 28

Installation

6 720 645 504 (2011/04) en

28

The following description of filling presupposes the use

of the filling station accessory. Follow corresponding

steps if other equipment is used.

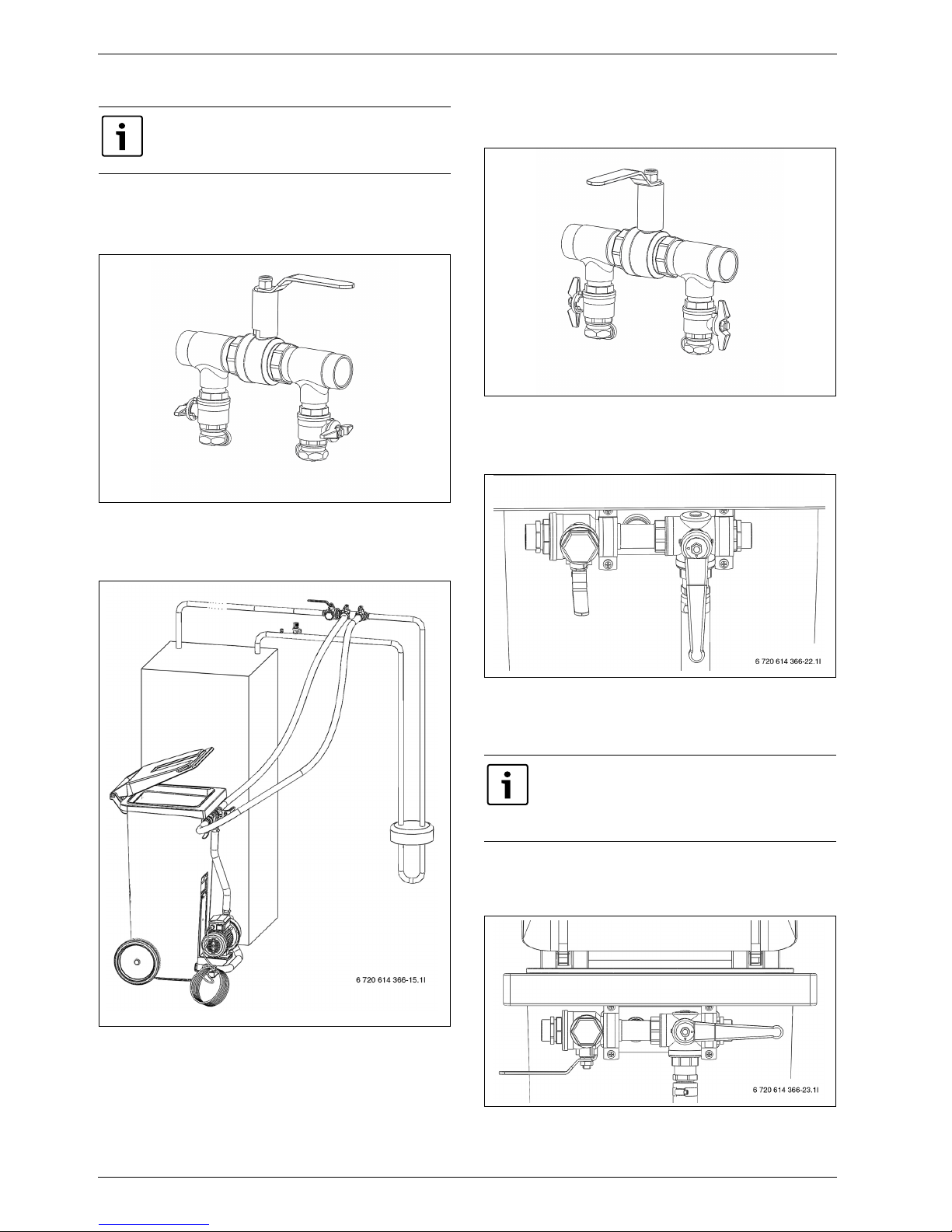

Fig. 15 Example of a filling unit

B Connect two hoses from the filling station to the

filling unit ( Figure 16).

Fig. 16 Filling with filling station

B Fill the filling station with collector circuit fluid. Fill

water before you fill antifreeze.

B Turn the valves on the filling unit so that they are in

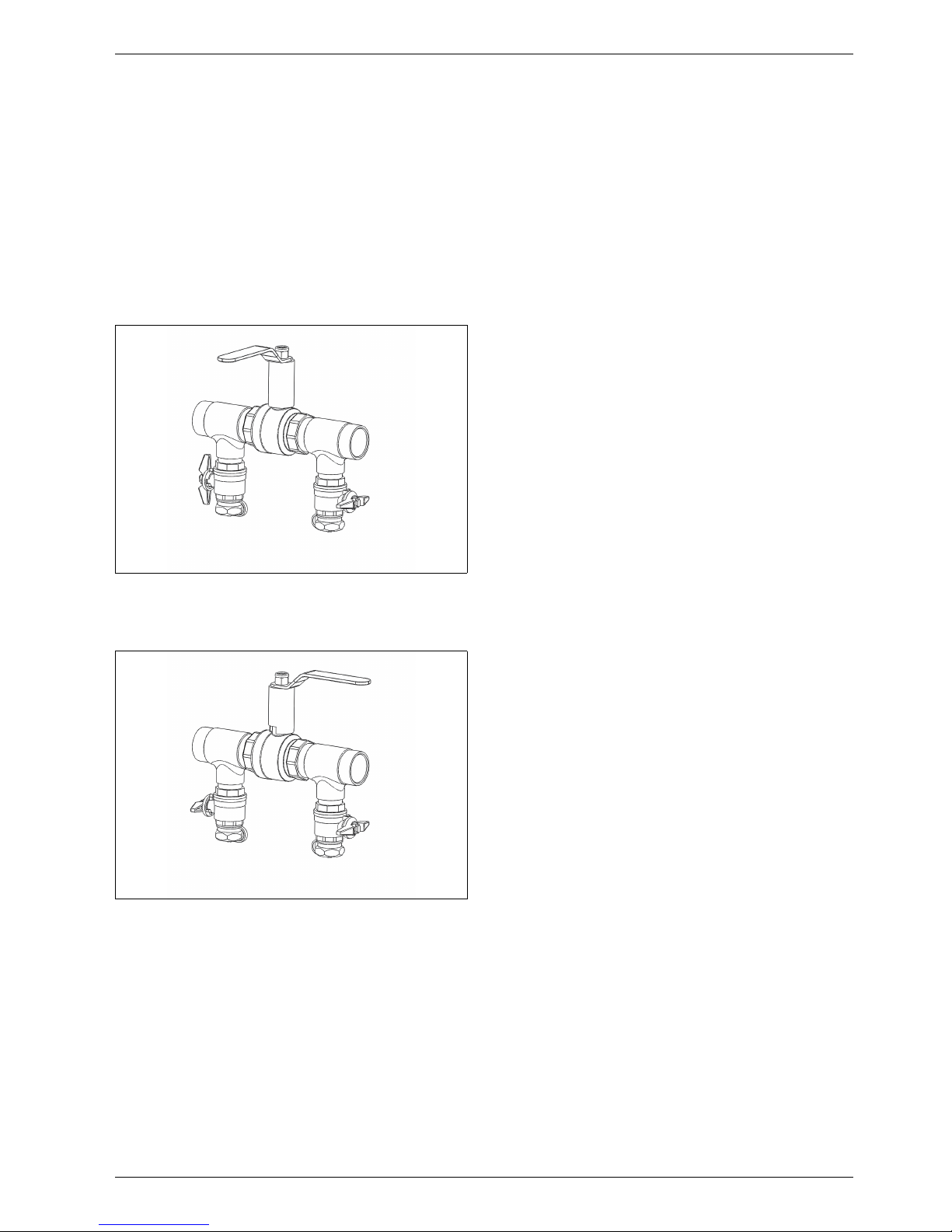

filling position ( Figure 17).

Fig. 17 Filling unit in filling position

B Turn the valves on the filling station so that they are

in mixing position ( Figure 18).

Fig. 18 Filling station in mixing position

B Start the filling station (pump) and mix the collector

circuit fluid for at least two minutes.

B Turn the valves on the filling station to filling position

and fill the circuit with collector circuit fluid

( Figure 19).

Fig. 19 Filling unit in filling position

Double U pipes, each of which consists of

two descending and two ascending pipes,

are most often used as a rock collector.

6720614967-32.1I

Repeat the following steps for each circuit.

One circuit at a time is filled with collector

circuit fluid. Keep the valves closed in the

other loops during the process.

6720614967-35.1I

Page 29

Installation

6 720 645 504 (2011/04) en

29

B When the fluid level has fallen to 25% in the filling

station, the pump should be stopped and more

collector circuit fluid should be filled and mixed.

B When the circuit is full and air no longer comes from

the return pipe, the pump should be run again for at

least 60 minutes (the fluid should be clear and should

not contain any bubbles).

B The circuit must be pressurized when venting is

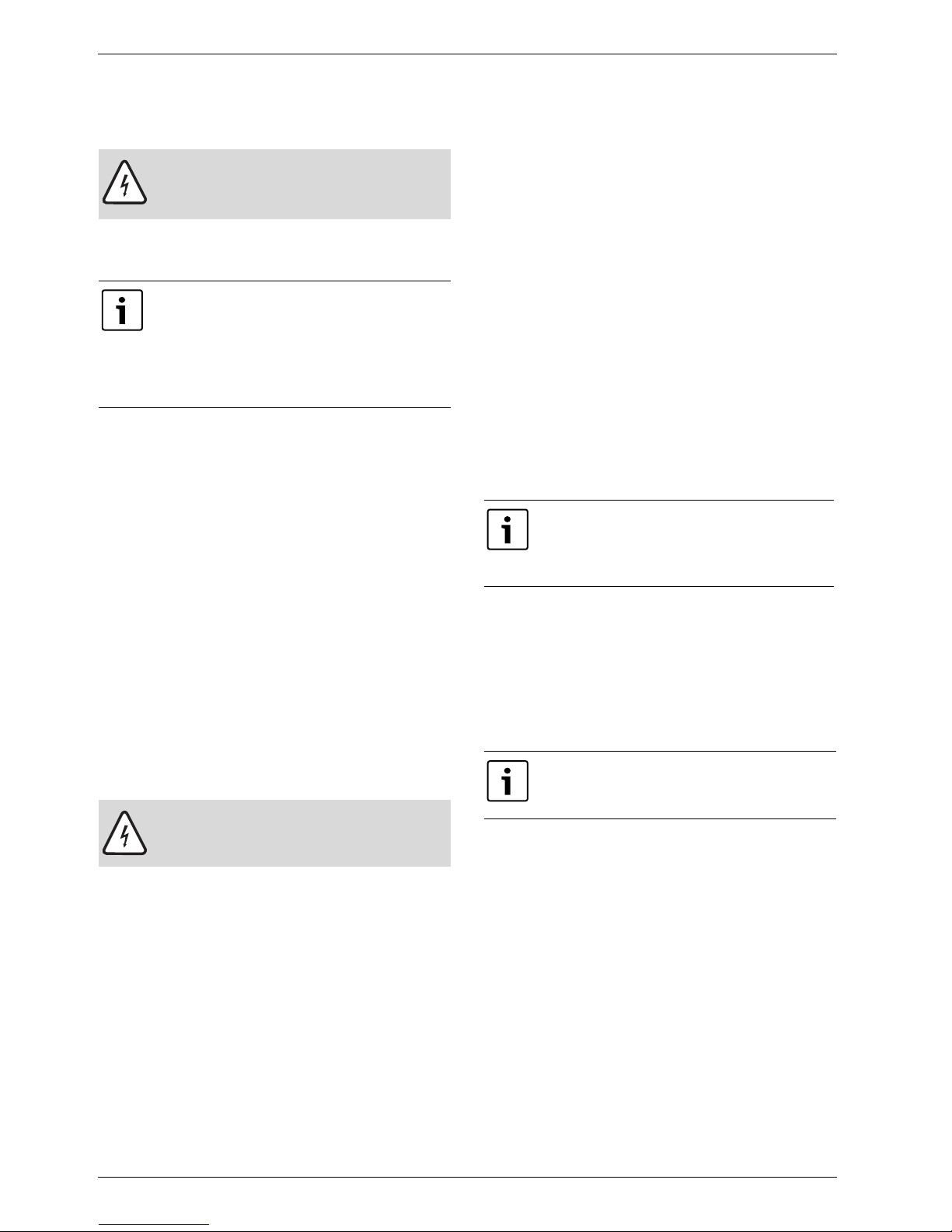

complete. Turn the valves on the filling unit to

pressure increase position and pressurize the circuit

to 2.5 to 3 bar ( Figure 20).

Fig. 20 Filling unit in pressure increase position

B Turn the valves of the filling unit to normal position (

Figure 21) and turn off the pump on the filling station.

Fig. 21 Filling unit in normal position

B Disconnect the hoses and insulate the filling unit.

If other equipment is used, the following is required,

among other things:

• A clean container with capacity for the amount of

collector circuit fluid that is required

• An additional container for collection of contaminated

collector circuit fluid

• Submerged pump with filter, flow capacity of min.

6m

3

/h, pressure height of 60 to 80 m

• Two hoses, Ø 25 mm

6720614967-34.1I

6720614967-32.1I

Page 30

Electrical connections

6 720 645 504 (2011/04) en

30

11 Electrical connections

All regulation, control and safety devices on the heat

pump are connected and checked upon delivery.

B According to the applicable regulations for 400 V/

50 Hz connection, a H05VV-... type 5-core cable must

be used as a minimum. Select cable area and cable

type that corresponds to the relevant fuse rating

( Chapter 8.4) and routing method.

B Observe protection measures acc. to VDE regulations

0100 and special regulations of the local power

supply utility.

B Connect the heat pump to the electric box connection

strip according to BS EN 60335 part 1 and via a switch

with a minimum contact distance of 3 mm (e.g. fuses,

LS switch). Other consumers must not be connected.

B Follow the relevant wiring diagram when connecting

an earth breaker. Only connect components that are

approved for each market.

B Observe the colour coding when replacing circuit

boards.

11.1 Connecting the heat pump

B Remove the front panel ( page 26).

B Remove the electric box cover.

B Route the connection cables to the electric box

through the cable gland in the roof plate of the heat

pump.

B Connect the cables according to the wiring diagram.

B Reinstall the electric box cover and the front panel of

the heat pump.

11.2 Phase guard

A phase guard is mounted and connected to the heat

pump in order to monitor the phase sequence to the

compressors during installation ( Figure 33 and 34).

There are three indicator lamps on the phase guard.

When the heat pump is started the first time the

uppermost lamp lights up yellow and the bottom lamp

green. The lamp in the middle flashes red if there is a

phase sequence error and the alarm Phase error E2x.B1

( Chapter 17.9.11) is displayed. If so, change the

phase sequence. The lamp is not lit at correct phase

sequence.

The phase guard also trips on too high or too low

voltage. The lamp in the middle lights red and the alarm

Phase error E2x.B1 ( Chapter 17.9.11) is displayed.

11.3 Screed drying

Screed drying must take place with continuous access to

current. When screed drying is used, the electric

connection should therefore be made in the standard

way, see ( Chapter 11.4).

On completion of screed drying, the EVU signal can be

connected (Chapter 11.4). Enable the EVU signal

according to the settings under menu External control.

The screed drying process is described in

( Chapter 16.6.9).

DANGER: Risk of electric shock!

B Switch off the main power supply before

starting work on the electrical part.

The heat pump's electrical connections

must be able to be disabled safely.

B Install a separate safety switch that cuts

all current to the heat pump. A safety

switch for each supply is required for

separate power supplies.

CAUTION: Never grasp a circuit board

without wearing a ground-connected

bracelet ( Chapter 5.10).

The heat pump alone can not produce

enough heating for screed drying. We

recommend using building drying

equipment.

EVU means a special electrical connection

used primarily in countries like Germany and

Austria.

Page 31

Electrical connections

6 720 645 504 (2011/04) en

31

11.4 Electrical connection wiring diagram

11.4.1 Overview of connection between distribution box and heat pump (HC 22 - 33)

Fig. 22 Overview of connection between distribution box and heat pump

1 Power supply to the distribution box

2 Power meter for heat pump, low tariff

3 Tariff control

4 Power meter for the property, 1-phase high tariff

5 Compressor 1 and 2

6 Control unit, E21.G2, E22.G2, EVU, external pumps

7 Collector circuit pump E21.G3, E22.G3

EVU Property's distribution box

EWP Heat pump

*) Strap which is removed in the event of separate power supply

D External power meter

1

2

3

4

5 6

7

EVU

EWP

6 720 618 981-11.1I

EVU means a special electrical connection

used primarily in countries like Germany and

Austria.

Page 32

Electrical connections

6 720 645 504 (2011/04) en

32

11.4.2 Overview of electric box (HC 22 - 33)

Fig. 23 Overview of electric box

1 Electric box heat pump HC 22

2 Electric box heat pump HC 33

E21.F11 Motor cut-out compressor E21

E22.F11 Motor cut-out compressor E22

E21.B1 Phase guard for E21 and E22

E21.F1 Miniature circuit-breaker heat pump

E21.F3 Miniature circuit-breaker E21.G3

E22.F3 Miniature circuit-breaker E22.G3

K1 Contactor compressor E21

K2 Contactor compressor E22

K4 Relay E22.K4

Q1.1/Q1.2 Soft starter E21

Q2.1/Q2.2 Soft starter E22

X1 Terminal block

E21.V1-2 EMC filter

BAS Circuit board

PGB Circuit board

XB1 Circuit board

PEL Low-voltage external terminal board

PHV Terminal board 230 V

6 720 616 938-3.1I

1 2

Page 33

Electrical connections

6 720 645 504 (2011/04) en

33

11.4.3 Overview of circuit boards

Fig. 24 Overview of circuit boards and factory-assembled cables

LCD Display board

BAS Circuit board

PGB Circuit board

XB1 Circuit board

PEL Low-voltage external terminal board

PHV Terminal board 230V

PIL Low-voltage internal terminal board

6 720 616 938-6.1I

Page 34

Electrical connections

6 720 645 504 (2011/04) en

34

11.4.4 Power supply of EVU signal

EVU relay (no. 4, A1, A2, no. 2 Figure 25) with 3 main

contacts and 1 auxiliary contact must be dimensioned in

accordance with the heat pump's fuse rating. The relay

is provided by an electrical fitter or a power company.

Control requires a potential-free contact signal on the

external input (1 / C Figure 25). External input

connected = EVU block active.

During the blocked period, the energy supply cut-off

symbol is displayed in the menu display.

Fig. 25 Blocked period enabled

1 Power meter

2 Tariff control

3 Control unit heat pump

4 Low-tariff

EVU means a special electrical connection

used primarily in countries like Germany and

Austria.

Complete screed drying before connection

of the EVU signal.

B Activate the energy supply cut-off in the

control unit under menu External control

(Chapter 16.5) after drying and

connection of the EVU signal.

2

1

3

4

6 720 614 366-50.2I

Time difference

B Ensure a maximum time difference of 5

seconds between current control and

EVU signal control.

Page 35

Electrical connections

6 720 645 504 (2011/04) en

35

11.4.5 Power supply (HC 22 - 33)

Fig. 26

1 X1 The terminal block in the heat pump

2 The PEL card where the EVU signal is connected

3 PE (protective earth)

Standard design without EVU

The terminal blocks are strapped at the factory to a

common power supply. Connected to PE, 1N, 1L1, 1L2

and 1L3.

Fig. 27 Standard design

1 Supply, Heat pump

Alternative A

The power supply can also be connected as low tariff

from the EVU control unit. During a cut-off period, the

cont rol un it i s sup plie d wit h 1-p hase , L1, high tar iff. They

are connected to PE, 3N and 2L1. Signal from the control

unit via EVU control is connected to terminal blocks 1

and C on the PEL card. During a cut-off period, the

contact is closed. The terminal straps between 1N-3N

and 1L1-2L1 are removed.

Fig. 28 Connections Alternative A

1 Supply, 1-phase L1 to control unit by EVU

2 Supply, heat pump

2

1

3

6720614967-21.1I

EVU means a special electrical connection

used primarily in countries like Germany and

Austria.

1

6 720 616 938-7.1I

6 720 616 938-8.1I

2

1

Page 36

Electrical connections

6 720 645 504 (2011/04) en

36

Alternative B

If the collector circuit pumps should be supplied

separately, they are connected to PE, 2N, 2L2 and 2L3.

Remove all terminal straps.

Fig. 29 Connection alternative B

1 Supply 1-phase L1 to control unit by EVU

2 Supply, heat pump

3 Supply, collector circuit pumps

11.5 External connections

All external connections are made on terminal board PEL

(low current) and PHV (high current):

B High and low current cables should be routed

separately in order to avoid interference on the

sensors (minimum distance of 100 mm).

B Use the following cable area when extending a

temperature sensor cable:

– Up to 20 m long cable: 0.75 to 1.50 mm

2

– Up to 30 m long cable: 1.0 to 1.50 mm

2

6 720 616 938-9.1I

2

3

1

Page 37

Electrical connections

6 720 645 504 (2011/04) en

37

11.6 Other wiring diagrams

11.6.1 Explanations

+ = Open, – = Close

E11 Circuit 1

E10.T2 Outdoor sensor

E11.G1 Circulation pump, heating system

E11.P2 General alarm

E11.S11 External set point value

E11.T1 Flow sensor

E11.TT.P1 Alarm lamp, room sensor

E11.TT.T5 Room sensor, circuit 1

Tab. 18 E 11 Circuit 1

E12 Circuit 2

E12.B11 External input, circuit 2

E12.G1 Circulation pump

E12.TM Dew point sensor

E12.TM.TM5 Room temperature sensor

E12.TM.TM1 Humidity sensor

E12.T1 Flow sensor

E12.TT.P1 Alarm lamp, room sensor

E12.TT.T5 Room temperature sensor

E12.Q11 Mixing valve

Tab. 19 E12 Circuit 2

E21 Compressor 1 (Step 1)

B1 Alarm phase guard (for E21 and E22)

B11 External input 1

B12 External input 2

F3 Circuit breaker, collector circuit pump

F11 Motor cut-out compressor

F12 Motor cut-out collector circuit pump

F51 Fuse 6.3A

F52 Fuse 250mA

G2 Heat carrier pump

G3 Collector circuit pump

K1 Contactor

RHP High pressure switch

RLP Low pressure switch

Q1.1 Soft starter HC 22

Q1.2 Soft starter HC 33

Q21 3-way valve

T6 Hot gas sensor (compressor)

T8 Sensor heat transfer fluid out

T9 Sensor heat transfer fluid in

T10 Sensor collector circuit in

T11 Sensor collector circuit out

E21.B1 Alarm phase guard (for E21 and E22)

E21.E1 Compressor E21

E21.F1 Miniature circuit-breaker heat pump

E21.F3 Miniature circuit-breaker E21.G3

E21.F11 Motor cut-out compressor E21

E21.V1 EMC filter

E21.V2 EMC filter

Tab. 20 E21 Compressor 1 (Step 1)

E22 Compressor 2 (Step 2)

B11 External input 1

B12 External input 2

F3 Circuit breaker, collector circuit pump

F11 Motor cut-out compressor

F12 Motor cut-out collector circuit pump

F13 Compressor cut-out

F51 Fuse 6.3A

G2 Heat carrier pump

G3 Collector circuit pump

K2 Contactor

K3 Contactor, collector circuit pump

RHP High pressure switch

RLP Low pressure switch

Q2.1 Soft starter HC 22

Q2.2 Soft starter HC 33

Q21 3-way valve

T6 Hot gas sensor (compressor)

T8 Sensor heat transfer fluid out

T9 Sensor heat transfer fluid in

T10 Sensor collector circuit in

T11 Sensor collector circuit out

E22.E1 Compressor

E22.F3 Circuit breaker, collector circuit pump

E22.F11 Motor cut-out compressor

E22.F12 Motor cut-out collector circuit pump

E22.F13 Compressor cut-out

E22.V1 EMC filter

Tab. 21 E22 Compressor 2 (Step 2)

E41 and E42 Hot water heater 1 and 2

E41.E1.E1 Hot water electric heater

E41.E1.F21 Overheat protection, hot water electric

heater

E41.F31 Protective anode

E41.G6 Circulation pump hot water

E41.Q1 Mixing valve, hot water

E41.T1 Hot water flow

E41.T3 Sensor, hot water

E42.T3 Sensor, hot water

Tab. 22 E41 and E42 Hot water heater 1 and 2

E71 Additional heat

E71.E1.E1 Allow additional heat

E71.E1.Q71 Additional heat mixing valve

E71.E1.E1.F21 Alarm, additional heat

Tab. 23 E71 Additional heat

Page 38

Electrical connections

6 720 645 504 (2011/04) en

38

11.6.2 Internal wiring diagram

Fig. 30 Internal wiring diagram

6 720 616 938-13.1I

Page 39

Electrical connections

6 720 645 504 (2011/04) en

39

11.6.3 Wiring diagram E21, high current

Fig. 31 Wiring diagram E21, high current

Solid line = factory connected. Dotted line = connected at installation.

6 720 616 938-15.1I

Page 40

Electrical connections

6 720 645 504 (2011/04) en

40

11.6.4 Wiring diagram E22, high current

Fig. 32 Wiring diagram E22, high current

Solid line = factory connected. Dotted line = connected at installation.

6 720 616 938-16.1I

E22.Q21

Page 41

Electrical connections

6 720 645 504 (2011/04) en

41

11.6.5 Wiring diagram E21, low current

Fig. 33 Wiring diagram E21, low current

Solid line = factory connected. Dotted line = connected at installation.

6 720 616 938-18.1I

Page 42

Electrical connections

6 720 645 504 (2011/04) en

42

11.6.6 Wiring diagram E22, low current

Fig. 34 Wiring diagram E22, low current

Solid line = factory connected. Dotted line = connected at installation.

6 720 616 938-19.1I

Page 43

Electrical connections

6 720 645 504 (2011/04) en

43

11.6.7 External connections E21

Fig. 35 External connections E21

Solid line = factory connected. Dotted line = connected at installation.

6 720 616 938-20.1I

Page 44

Electrical connections

6 720 645 504 (2011/04) en

44

11.6.8 External connections E22

Fig. 36 External connections E22

Solid line = factory connected. Dotted line = connected at installation.

6 720 616 938-21.1I

E22.Q21

Page 45

Electrical connections

6 720 645 504 (2011/04) en

45

11.7 Connection of additional heat alarm

Fig. 37 Alarm, additional heat

E71 Additional heat

E71.E1.E1.F21 Alarm, additional heat

A1, A2, 11, 14 Relay

10, C Terminal blocks, PEL board

B Use an intermediate relay on connection of additional

heat alarm E71.E1.E1.F21 to the low-voltage board

( Figure 33) when the alarm signal of the additional

heat is 230V.

11.8 Connection of domestic hot water

electric heater

Fig. 38 Connection, hot water electric heater

PHV1 Circuit board in the control unit

A1,A2, 1-6 Contactor

E41.E1.E1 Hot water electric heater

E41.E1.F21 Overheat protection, hot water electric heater

The electric heater is supplied with its own 3-phase

voltage from the distribution box. Control is exercised

from the control unit via the contactor.

The distribution box supplies the control unit with 1phase 230V on PHV1, terminal board 74.

The outgoing signal to the contactor for control of the

electric heater is on PHV1, terminal board 73.

Connect the alarm signal from phase L1 to PHV1,

terminal board, after the overheat protection. When the

overheat protection is triggered, the voltage on terminal

block 72 disappears and alarm is given in the display.

Acknowledge Hot water electric heater under

Additional heat \ Hot water electric heater.

6 720 616 938-40.1I

6 720 616 938-27.2I

Page 46

Electrical connections

6 720 645 504 (2011/04) en

46

11.9 Connection of circulation pump

E41.E1.G1

Fig. 39 Connection of circulation pump E41.E1.G1

The circulation pump is part of the system solution with

mixed additional heat ( Chapter 8.2.3)

The circulation pump has its own voltage feed from the

distribution box. The pump is controlled from the

control unit. Incoming voltage feed is connected to

terminal block 72 and 74 on PHV1, outgoing voltage feed

on terminal block 73.

The maximum load is 2.6A when cos ϕ = 0.4. For

example, Wilo Star-Z 15 can be used.

11.10 Connection of low energy pump

E11.G1

Fig. 40 Connection of low energy pump E11.G1

When a low energy circulation pump is connected in the

heating circuit an intermediate relay must be used for

pump control.

The relay is connected to terminal blocks 62 and N on

the PHV board (output for E11.G1).

E11.G1 is powered externally.

6 720 616 938-28.1I

6 720 645 810-01.1I

Page 47

Control panel

6 720 645 504 (2011/04) en

47

12 Control panel

Settings for the control of the heat pump are made with

the control unit's control panel, which also provides

information about current status.

12.1 Panel overview

Fig. 41 Control panel

1 On/Off button

2 Mode button

3 Info button

4 Menu dial

5 Status lamp

6 Return button

7 Menu button

8 Menu display

12.2 On/Off button

Use the On/Off button to switch the heat pump on and

off.

12.3 Status lamp

12.4 Menu display

Use the menu display in order to:

• View information from the heat pump.

• View available menus.

• Change set values.

12.5 Menu button and menu dial

Use to get from Initial menu to the menus. Use the

menu dial in order to:

• Navigate the menus and get to the setting displays.

– Turn the dial to see more menus on the same level

or change a set value.

– Press the dial to change to a lower menu level or

save a change.

12.6 Return button

Use to:

• Go back to the previous menu level.

• Leave a setting display without changing the set

value.

12.7 Mode button

Use to change type of operation.

12.8 Info button

Use to see information from the control unit about

operating mode, temperature, program version, etc.

The lamp lights green. The heat pump is running.

The lamp flashes red. There is an alarm which

has not been acknowledged

The lamp lights red. The alarm has been

acknowledged but the

alarm cause remains

Lamp flashes slowly

green, menu window

not lit.

The heat pump is in standby mode

1)

.

1) Stand-by means that the heat pump is running but no

heating or hot water demand exists.

The lamp and menu

display not lit.

No voltage to control unit.

Tab. 24 Lamp functions

menu

mode

i

6 720 641 855-08.1I

5

6

2

8

1

7

4

3

The controller language can be changed

with the -key.

B Press the button in the standard

display for at least 5 s, then select the

required language.

Page 48

Start up

6 720 645 504 (2011/04) en

48

13 Start up

The first time the heat pump is started, a number of

settings are displayed automatically so as to facilitate

putting it in operation.

Before this stage, the heat pump should be installed in

accordance with the previous sections ( Chapter 10,

Chapter 11). Collector circuits, heating circuits and

hot water circuits should be filled and vented.

The settings are also available under ordinary installer

menus.

Language, Country and Operating mode

B Select language for the menus of the control unit

( Chapter 16.9).

B Select Country ( Chapter 16.9).

B Select operating mode (L/W + mixed additional heat)

( Chapter 6.4, Chapter 16.6.1).

Start-up

Review and adjust, as required, the functions below. See

the references for description of the functions.

B Set Heat pump capacity according to the details on

the type plate ( Chapter 5.3 and 16.6.2).

B Set Hot water production for each heat pump

(compressor) ( Chapter 16.2).

B Set Minimum outdoor temperature ( Chapter

16.1.1).

B Set Groundwater if it is installed.

B Set Circuit 1 Heating\ Type of heating system (

Chapter 16.1.2).

B Set Circuit 1 Cooling (if Cooling has been installed,

accessory), see the accessory documentation.

B Set Circuit 2, 3... ( Chapter 16.1.3).

– Mixing valve mode

– Type of heating system

– Mixing valve running time

B Select alternative in Protective anode installed

( Chapter 16.2).

B Set values for Mixed additional heat

( Chapter 16.7).

– Mixing valve running time