IVT Greenline D14, Greenline D16, Greenline D20, D40, Greenline E20 Manual To Installation, Commissioning And Maintenance

...Page 1

Guide to installation,

commissioning and maintenance

Gr eenline D14-D40

Gr eenline E14-E25

Article nr: 290430-9 Version: 4.0

Page 2

2

Page 3

3

Important information

This guide is designed to describe the operation, installation and maintenance of

the heat pump as comprehensively as possible. The description has been written

as far as possible so that it can be followed step by step.

Please note that the guide consists of three separate parts, therefore it is especially important that the installation contractor reads the entire manual before

commencing installation.

The guide is in two parts, one for the user and one for the installer. The table of

contents sets out clearly the various sections of the manual.

Warning! The Rego 600 control unit contains an advanced settings level which

should only be accessed by the installer. The end user should never change any

settings on this level, since this might cause problems with the operation of the

heat pump.

• Before the heat pump is commissioned, the heating system and the heat pump

must be filled and vented.

• Hot and cold connections might need checking after delivery.

• If the heat pump has to be carried down steps or stairs it can be tilted temporar-

ily with the compressor downwards, but never for long periods.

• The heat transfer fluid system must be in operation when venting the system.

See chapter on refilling the heat transfer circuit.

• Three phase heat pumps incorporate an alarm if the phasesare incorrectly wired.

IVT Industrier AB

October 2003

Page 4

4

PAGES FOR THE HOUSE OWNER

Table of Contents

Important information ............................................................................................................. 3

This is how your heat pump works: ......................................................................................... 7

Heat pump technology .............................................................................................................................................7

Heat pump components ............................................................................................................8

Greenline 14-16 .......................................................................................................................................................... 8

Greenline 20-40 .......................................................................................................................................................... 9

Principle.................................................................................................................................. 10

Principle of heating and hot water control .............................................................................................................. 10

Power failures.......................................................................................................................................................... 10

Three different operating modes ............................................................................................ 10

Operating mode A (E and D series) ......................................................................................................................... 10

Operating mode B (D series only) ........................................................................................................................... 10

Operating mode C (D series only) ........................................................................................................................... 10

Controls.................................................................................................................................... 11

Curve control (operating modes A and B) ............................................................................................................... 11

Room sensor (operating modes A and B)................................................................................................................ 11

Fixed temperature (operating mode C only) ............................................................................................................ 11

Control panel .......................................................................................................................... 12

Control panel buttons and displays ........................................................................................................................ 12

How to use the control panel .................................................................................................................................. 13

Examples of scrolling information on the display .................................................................................................... 13

Basic functions and settings at customer level 1 .................................................................. 14

Temperature settings ............................................................................................................................................. 1 4

Extra hot water ...................................................................................................................................................... 14

Reading temperatures ........................................................................................................................................... 14

Extra functions and settings at customer level 2 .................................................................. 15

Line 1

Room sensor influence .......................................................................................................................................... 15

Holiday function ................................................................................................................................................... 15

Remote control ...................................................................................................................................................... 15

Summer disconnection .......................................................................................................................................... 15

Line 2

Interval for hot water peak ................................................................................................................................... 15

Line 4

Timer control ......................................................................................................................................................... 16

Line 7

Display, operating times ....................................................................................................................................... 17

Line 10

Setting the clock ................................................................................................................................................... 17

Line 11

Checking stored alarms ........................................................................................................................................ 17

Line 12

Reset to factory settings ........................................................................................................................................ 17

Page 5

5

PAGES FOR THE INSTALLER

Setting the heating ................................................................................................................. 18

How to increase or reduce the heating in your house ............................................................................................ 18

The appearance of the heat curve ........................................................................................................................... 18

Fine-tuning ............................................................................................................................................................. 19

Fixed temperature (D series only) ......................................................................................... 20

Setting the heating at fixed temperature .................................................................................................................. 20

Simple tips for saving ............................................................................................................. 20

Utilising the heat pump in the right way ................................................................................................................. 20

All sensor temperatures .......................................................................................................... 21

Description of all the temperature you can see ....................................................................................................... 21

If something goes wrong ........................................................................................................ 22

Alarm examples and what to do .............................................................................................................................. 22

If the control panel is dark ...................................................................................................................................... 22

All the alarms visible in the control panel ............................................................................................................... 23

Emergency operation, E series ............................................................................................... 27

How to activate emergency operation .................................................................................................................... 27

Maintaining your heat pump ................................................................................................. 27

Working on the heat pump ..................................................................................................................................... 27

Normal maintenance ................................................................................................................................................ 27

Where the various parts are located ...................................................................................... 28

Greenline 14-16 ........................................................................................................................................................ 28

Greenline 20-40 ........................................................................................................................................................ 29

What the shipment includes ................................................................................................... 30

Standard components ............................................................................................................................................. 30

Accessories ............................................................................................................................................................ 30

General .................................................................................................................................... 30

Temperatures .......................................................................................................................................................... 30

Particle filter ............................................................................................................................................................ 30

Transportation ........................................................................................................................................................ 30

Positioning the heat pump ...................................................................................................................................... 30

Dimensions and connections ................................................................................................. 31

Pipe and electrical connections in Greenline 14-16 ................................................................................................. 31

Pipe and electrical connections in Greenline E20-E25 ............................................................................................. 32

Pipe and electrical connections in Greenline D20-D40 ............................................................................................ 33

Collector.................................................................................................................................. 34

Collector hose ......................................................................................................................................................... 34

Bending diameter .................................................................................................................................................... 34

Maximum lengths .................................................................................................................................................... 34

Connecting the collector to the heat pump ............................................................................................................. 35

Ground water system .............................................................................................................................................. 35

Connecting the heat pump to the heating system ................................................................. 36

General .................................................................................................................................................................... 36

Function E14-E25, work tank and coil tank (outline diagram) ................................................................................. 37

Function E14-E25, radiators and double shelled electric water heater (outline diagram) ........................................ 38

Function D14-D40, oil-fired boiler, radiators and coil tank (outline diagram) ......................................................... 39

Function D14-D40, new electric boiler, radiators and coil tank (outline diagram).................................................... 40

Connecting the 3-way valve, D series ..................................................................................................................... 41

Page 6

6

Filling ..................................................................................................................................... 41

Filling the radiator system ...................................................................................................................................... 41

Filling of heat transfer fluid .................................................................................................................................... 41

Electrical connections ............................................................................................................ 43

Circuit diagram, Greenline D14-D16. Factory connections ..................................................................................... 43

Circuit diagram, Greenline E14-E16. Factory connections ...................................................................................... 44

Circuit diagram, Greenline D20-D40. Factory connections ..................................................................................... 45

Circuit diagram, Greenline E20. Factory connections ............................................................................................. 46

Circuit diagram, Greenline E25. Factory connections ............................................................................................. 47

External connections in the E series ....................................................................................................................... 48

External connections in the D series ...................................................................................................................... 49

Connecting the general alarm ................................................................................................................................. 50

Connecting the external input ................................................................................................................................ 50

Connecting the load guard .................................................................................................................................... 50

Control unit Rego 600 ............................................................................................................ 51

Installer/service settings ......................................................................................................................................... 51

Installer/service menu ............................................................................................................ 51

Joint displays for operating modes A, B and C ...................................................................................................... 51

Adapting the heating curve .................................................................................................................................. 51

Clock setting of additional heat ........................................................................................................................... 51

Select operating mode .......................................................................................................................................... 51

Manual control ..................................................................................................................................................... 51

Quick restart of heat pump .................................................................................................................................... 52

Selecting external controls ................................................................................................................................... 52

Choice of language ............................................................................................................................................... 52

Selecting operating modes for heat carrier pump, G2 (P2) ................................................................................. 52

Selecting operating modes for heat transfer pump, G3 (P3) (natural cooling) .................................................. 52

Version number display......................................................................................................................................... 52

Extra sensor acknowledgement ............................................................................................................................ 52

Timer reading ......................................................................................................................................................... 53

Status of the timers when checking the plant ....................................................................................................... 53

Setting additional timers ...................................................................................................................................... 53

Commissioning the heat pump .............................................................................................. 54

Navigating the menu list ........................................................................................................................................ 54

General ................................................................................................................................................................... 55

Manual testing the functions ................................................................................................................................. 55

Operation with additional heat only ....................................................................................................................... 55

Putting into operation, operating mode A (D and E series) .................................................................................... 55

Putting into operation, operating mode B (D series only) ...................................................................................... 57

Putting into operation, operating mode C (D series only) ...................................................................................... 59

Important points to check ...................................................................................................................................... 60

Technical information ............................................................................................................ 60

Table of factory settings ........................................................................................................................................ 60

Technical spec. ...................................................................................................................................................... 61

Table of selected output in display P5.2 ................................................................................................................ 61

Sensor table ........................................................................................................................................................... 61

Page 7

7

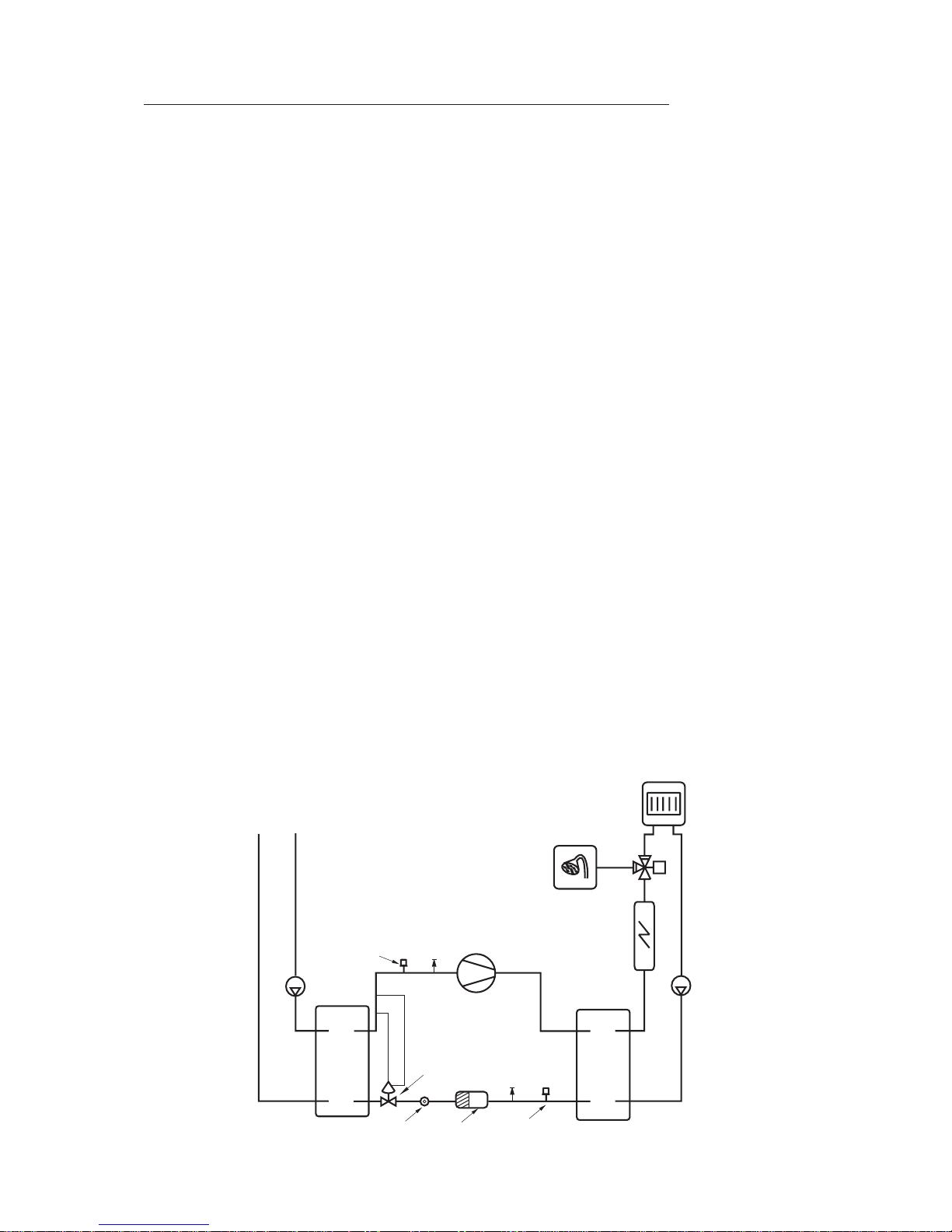

Rock/Ground/Lake

Heating

system

Hot water

3-way valve

(E series only)

Pressure switch

Heat transfer

fluid pump

Compressor max

Electric water heater

(E series only)

Evaporator

Heat

carrier pump

Sight

glass

Expansion valve

Pressure

switch

CondenserFilter

This is how your heat pump works

Heat pump technology

The compressor, which is driven by an electric motor, forces the heat transfer fluid into the heat

pump condenser as a gas at about 100°C. The gas and the water from the radiator system pass

through the condenser, which is a fully-welded stainless steel heat exchanger. When the hot gas is

cooled by the circulating water, it condenses (changes to liquid). As it does so, it provides energy for

the heating system or the hot water. After the condenser, the refrigerant, which is now in liquid form,

continues through a drying filter and a tank. The filtercollects any moisture in the system and the tank

is used as an expansion vessel for the heat transfer fluid to ensure there is always the correct amount

in the condenser.

After the filter, the heat transfer fluid passes through a sight glass. The sight glass is used to check the

amount of heat transfer fluid in the system. In normal operation there should be no bubbles in the

sight glass. However, bubbles may appear for short periods, mainly on rapid changes between hot

water and radiator operation and when the heat pump starts or stops.

After the sight glass the heat transfer fluid goes to an expansion valve. The valve acts as a flow

restrictor between the high and low pressure sides of the system. The valve, which has a sensor

(bulb) just before the compressor, releases the right amount of liquid into the next heat exchanger, the

evaporator. In the evaporator, the liquid meets the circulating heat transfer fluid coming from the

energy source in the ground or bore hole. In this process, the liquid turns to gas (evaporates) under

low pressure, which uses heat. The heat is extracted from the outside air free of charge.

After passing through the evaporator, the heat transfer fluid is once more in the form of a gas (vapour). The expansion valve sensor constantly checks that the evaporator is performing optimally, in

order to use as much free energy as possible. The gaseous refrigerant then goes to the suction side of

the compressor, where it is compressed again. This completes the heat transfer fluid circuit.

Pressure switches are fitted on the high and low-pressure sides of the system to protect the heat

pump. These shut down the heat pump if the pressure in the system reaches an abnormal value. This

is dealt with in more detail in the section on troubleshooting.

Page 8

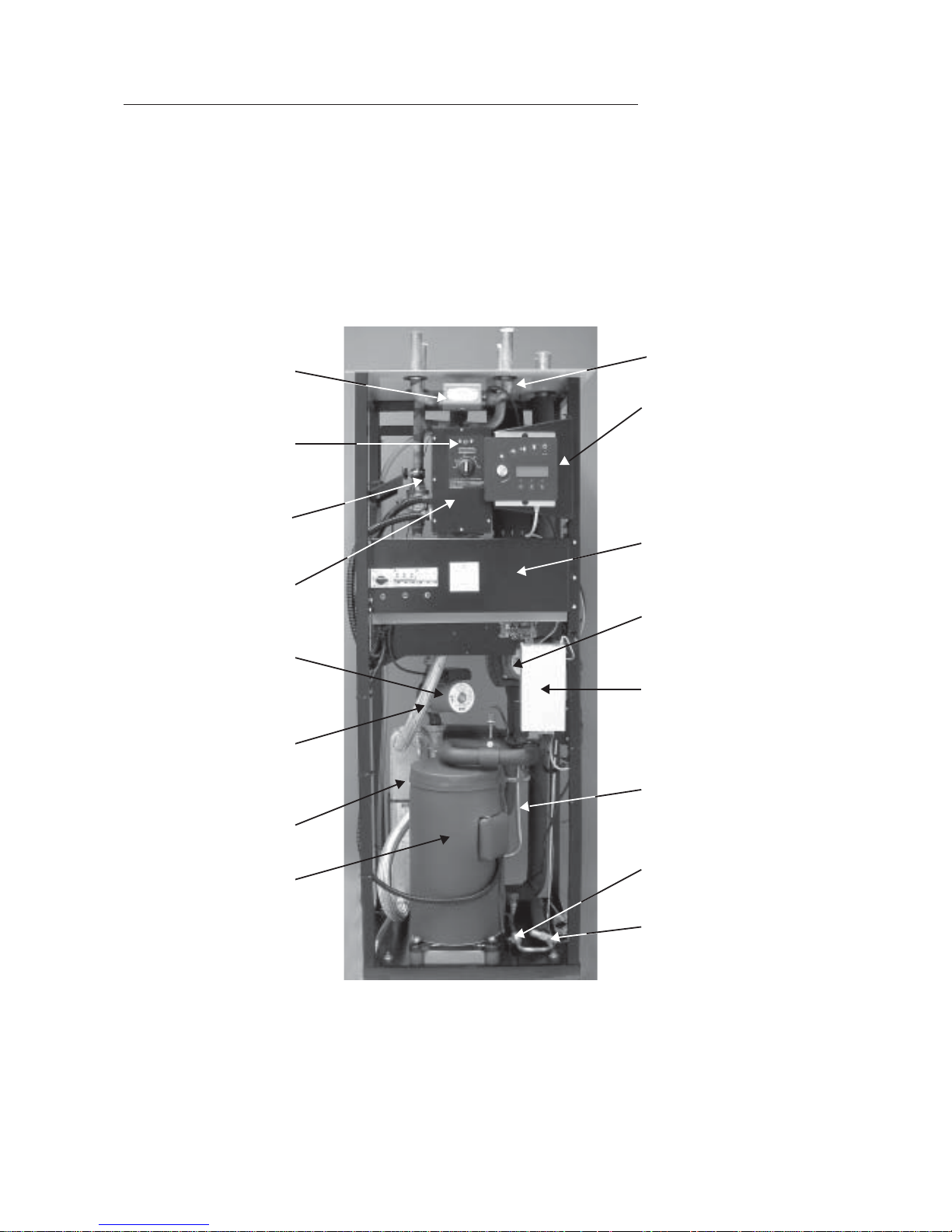

8

3- way valve that

alternates between

heating and hot water.

Reset buttonfor over-

heat protectionon the

electric heater.

Cleanable particle filter

with cut-off.

Electric boiler.

Circulation pump on

the hot side (G2 (P2)).

Flexible hoses on the

hot side for vibration

free operation.

Condenser.

Compressor with

frequency adapted

soundproof cover.

Electrical connections.

Control panel with

large display.

Sealed electrical box

with resetting of the

motor cutout and

circuit breaker for heat

pump and electric

heater.

Circulation pump on

the cold side

(G3 (P3)).

Control unit Rego 600.

Evaporator.

Sight glass.

Expansion valve.

Greenline 14 and 16 components

NOTE: The picture is of the E series

The D series has two connections on the hot side and does not include a 3-way valve and electric

water heater. The particle filter is supplied separately and is mounted outside the heat pump.

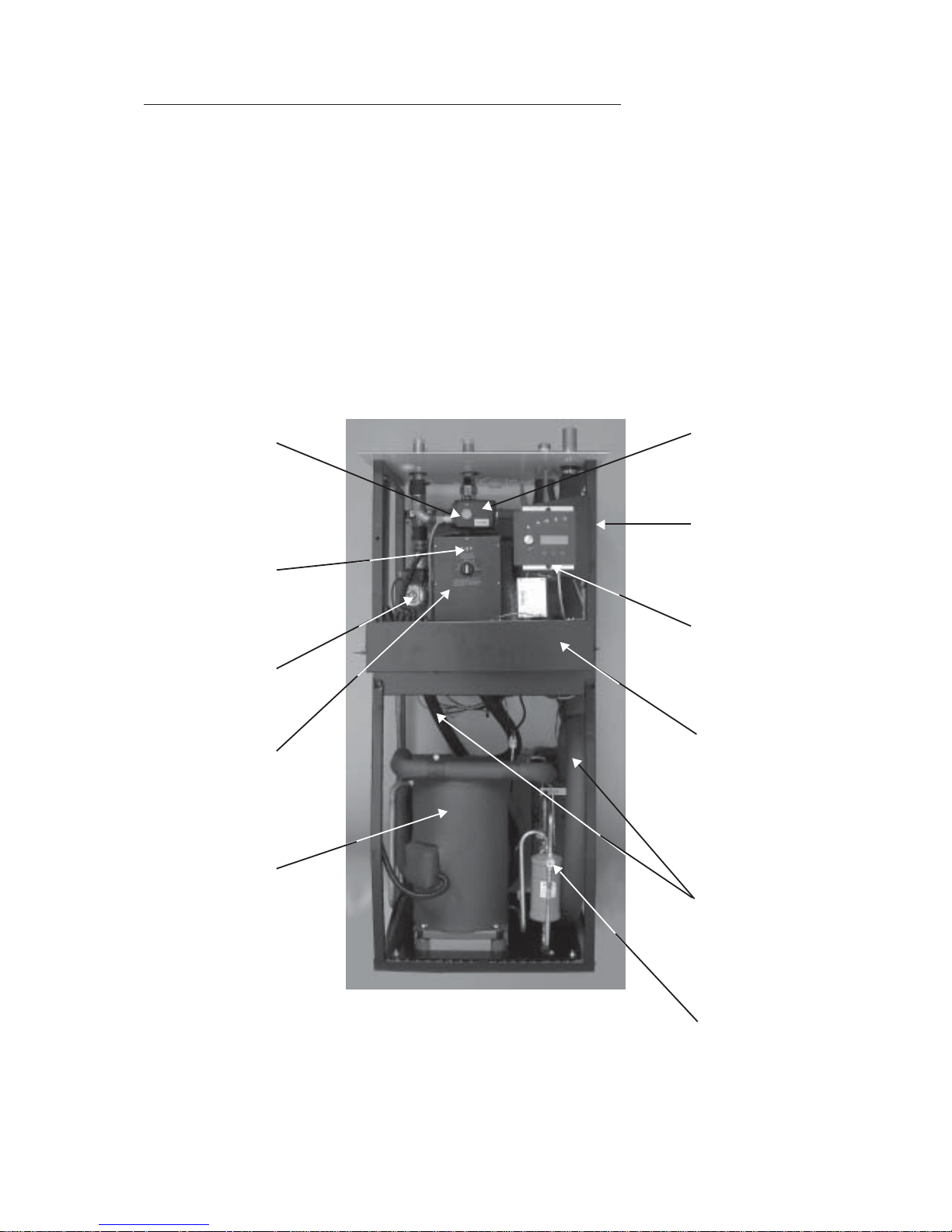

Page 9

9

3- way valve that

alternates between

heating and hot

water.

Reset button for

overheat protec-

tion on the electric

water heater.

Circulation pump

(G2 (P2)) on the

hot side.

Electric boiler.

Frequency

adapted sound-

proof cover.

Electrical connections.

Control panel with

large display.

Circulation pump

on the cold side

(G3 (P3)).

Sealed electrical

box with resetting

of the motor cutout

and circuit breaker

for heat pump and

electric heater (the

box is shown

folded up).

Flexible hoses on

the hot and cold

sides for vibration

free operation.

Sight glass.

Greenline 20 – 40 components

NOTE: The picture is of the E series

The D series has two connections on the hot side and does not include a 3-way valve and electric

water heater. The particle filter is supplied separately and is mounted outside the heat pump.

Page 10

10

Principle

Principle of heating and hot water control

Your heat pump is fitted with a Rego 600 control unit to guarantee you maximum savings and many

years of service. The unit, which has advanced monitoring functions, controls the heating and hot

water in your home. This ensures that all vital functions are monitored and that, if problems arise, the

heat pump is shut down before it is damaged.

When the heat pump is not able to meet the heating requirements, supplementary heat is connected

that together with the heat pump provides the required temperature. The Greenline E series has a

built-in electric heater that can be connected in three steps. The supplementary heat only provides

the output that the heat pump cannot generate and in this way can never take over heating the house

completely. When the heat pump is once more able to meet the heating demand, the supplementary

heat is automatically switched off. An oil-fired boiler is normally used to provide supplementary heat

for the Greenline D series. In which case Rego 600 controls the oil-fired boiler and the existing mixer

valve.

The heat pump is connected to the return line of the heating system so that it always receives the

coldest water. The water is heated in the heat pump and is then fed back to the heating system.

While the heat pump is heating the domestic hot water by using the electric water heater, the heating

system is disconnected temporarily through the three-way valve. A sensor in the hot water cylinder

makes sure that priority is always given to heating the hot water. When the water in the cylinder

reaches the required temperature, heat is once more supplied to the heating system.

Power failures

If the power supply fails, the control unit remembers all its settings and re-starts the heat pump when

the power returns.

Three different operating modes

The control unit can be used for three different operating modes: A, B and C. The three operating

modes are described schematically in the Installer chapter.

Operating mode A (D and E series)

This is the factory setting, based on an outdoor sensor and controls the heating temperature through

an adjustable control curve. Water heating takes priority over space heating. As well as operating

the heat pump, Rego 600 can also regulate other heat curves with a mixing valve, e.g. through a

combination of radiator and floor heating systems. An electric water heater is used for additional

heat.

Operating mode B (D series only)

Used when additional heat is from an oil-fired boiler. Operation is the same as for operating mode A.

Rego 600 cannot control other heat curves in this operating mode.

Operating mode C (D series only)

Used in exceptional cases, it does not provide optimal operation for the heat pump because it always

works with a high temperature, or “Fixed Temperature”. This is often used in operation with one or

more accumulator tanks. The tank is always kept at a high temperature and the hot water is often

heated in one or more coils.

Page 11

11

Controls

The control unit operates the heat pump in three ways. We call them Curve Control, Room Sensor

and Fixed Temperature. Below follows a brief description.

Curve control (operating modes A and B)

This is the most common mode and is also the factory setting. With curve control, the heat pump

adapts the heating inside the house on the basis of the outside temperature. An outside sensor sends

signals to the control unit, which automatically adjusts the supply of heat to the heating system. This

maximises savings, since the heat pump never needs to work at a higher temperature than necessary.

The heat pump only delivers the maximum temperature when heating the hot water. Normally, hot

water heating accounts for 20% of the total annual energy requirement.

Room sensor (operational modes A and B)

A room sensor can be connected to the heat pump. It sends signals to the control unit and in this way

affects the curve control. The sensor influences the curve control and the amount of influence can be

set on the control panel. Normally, room sensors are only used when a fan-assisted radiator is used

in a house with direct electric heating or when a wood-burning stove is used in the house or where

the house is effected by wind chill or solar gain.

Fixed temperature (operating mode C only)

This control technique is rarely used, and does not offer optimum savings from the heat pump. The

principle is that the heat pump is switched on and off by the built-in return sensor and always works

up to its maximum working temperature. The normal area of use for this is together with existing

accumulator tanks.

Page 12

12

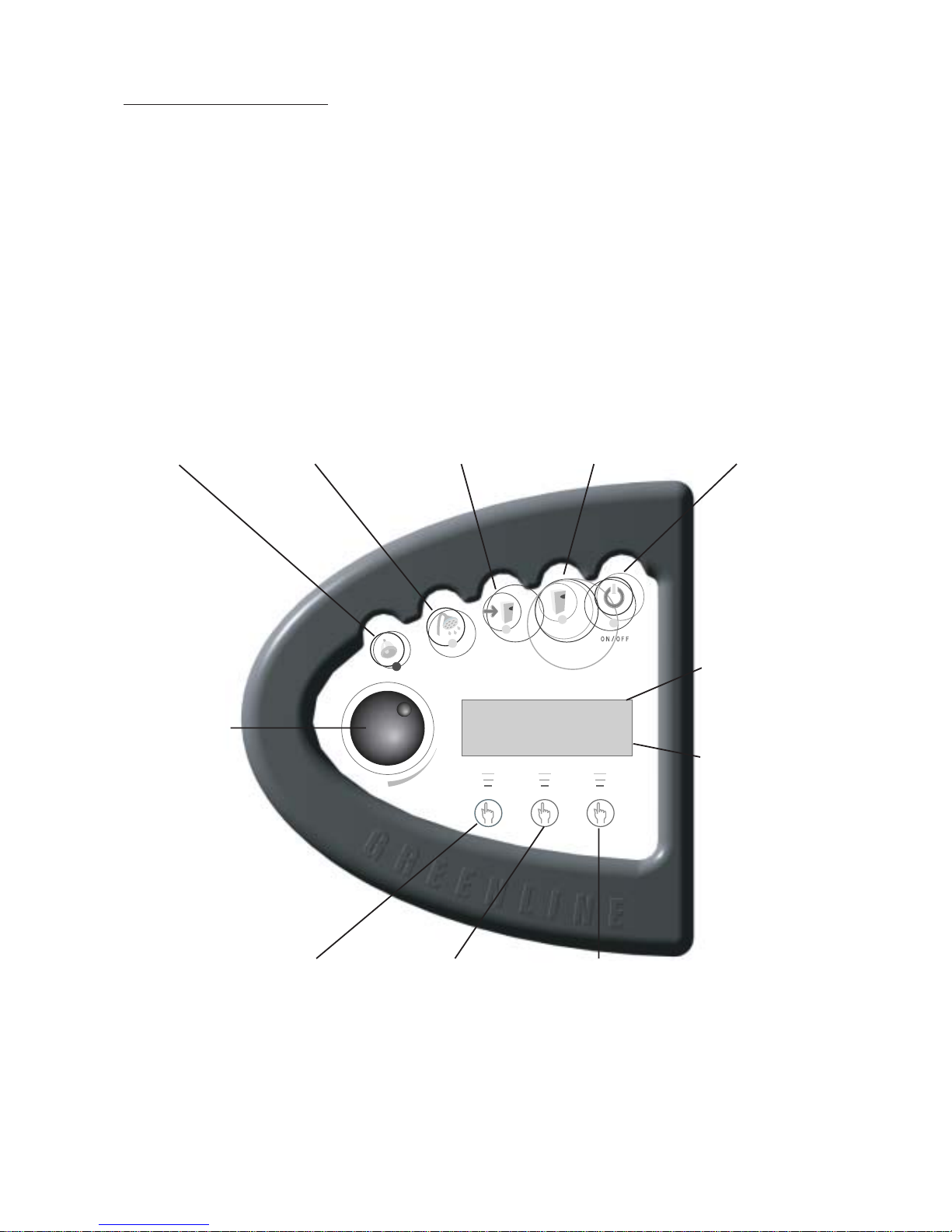

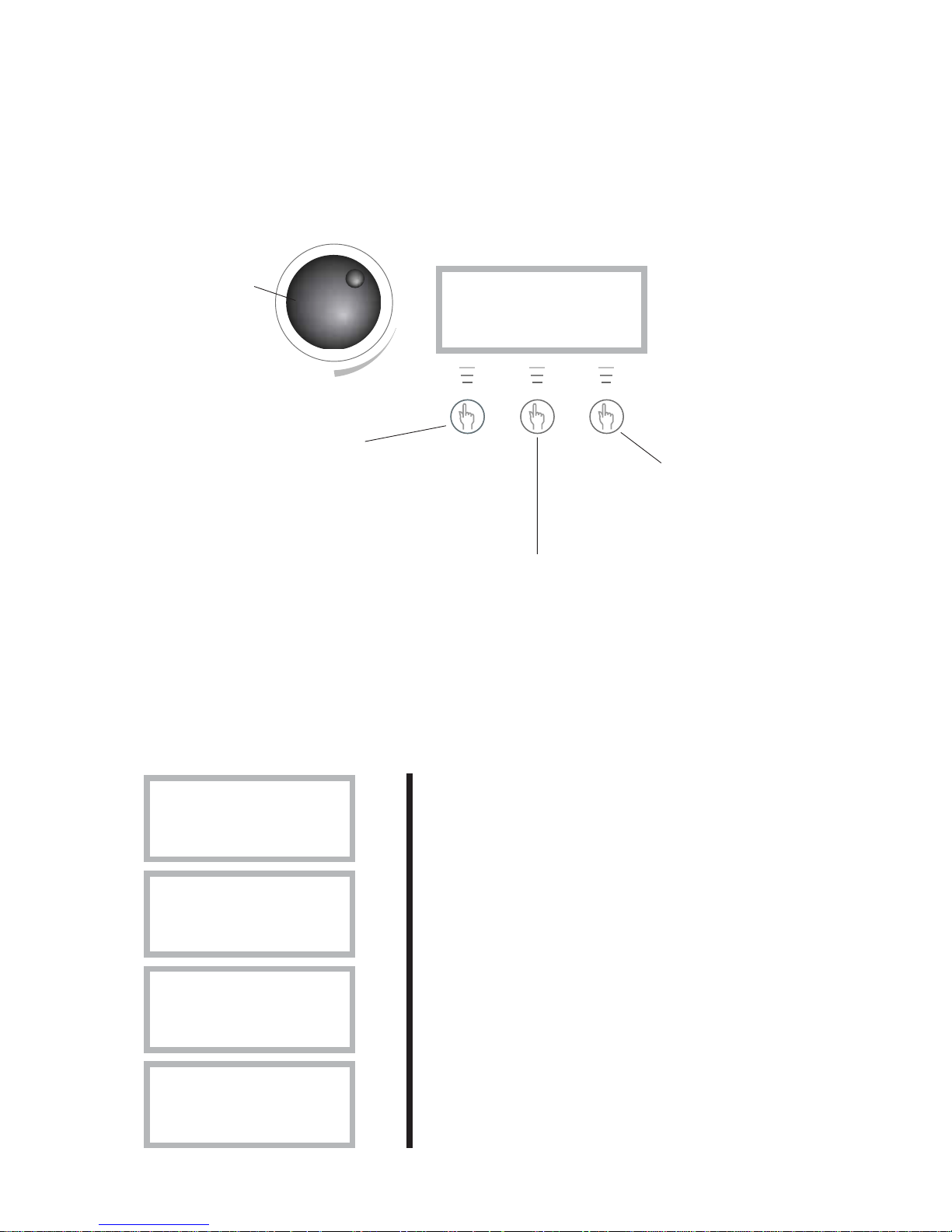

Control panel

Control panel buttons and displays

The control panel is the heart of your heat pump installation. From the control panel, instructions are

sent to the Rego 600 control unit, which ensures that the house is uniformly heated. All settings are

carried out here and the display shows the settings that have been set.

Rego600 K1

020301 12.00.00 Fr

Heat Info Menu

The heat pump is in

operation when this

lamp is lit.

This lamp is lit when

the heat pump needs

additional heat.

This lamp is lit when

hot water is being

heated. It blinks

during hot water

peaks and additional

hot water.

This lamp blinks

when a fault has

occurred.

This switch is used

to turn the heat pump

on and off. The heat

pump is in operation

when the lamp is lit

The heat pump is off

when it blinks.

This dial is used to

navigate the menu

and to change

settings.

This shows you

which user level

you are in.

This display

shows information such as text

and temperatures.

Press once to come

to the complete

menu for settings

and temperatures.

Press once for

continuous information about operation

conditions for the

heat pump and

additional heat.

Press once for a

short cut to the

heating settings.

Page 13

13

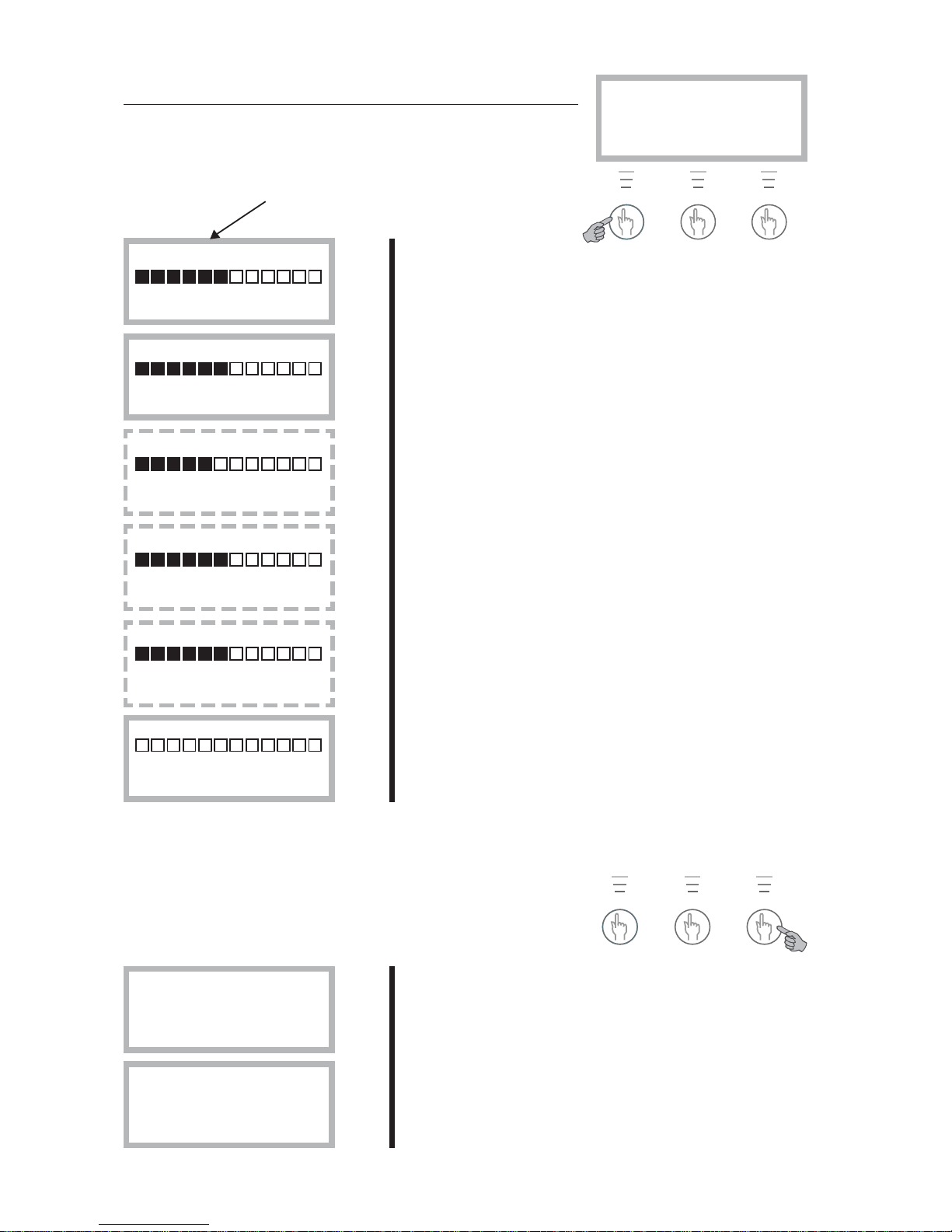

Examples of scrolling information

Here are some of the displays you see if you choose

scrolling information with the “Info” button:

Heat pump is not operating.

The heat pump is producing hot water and you see the

current temperature and the temperature it stops at.

The heat pump and additional heat is in operation.

A need for heat has arisen and the heat pump is waiting for

the reset time to count down to zero.

STANDBY

No rad heat required

No hot water

required

HOTWATER MODE

Heat pump only

Stop temp 47.5°

Present temp 42°

HEAT RAD MODE

Compr. + Add. heat

Stop temp 45°

Present temp 44°

HEAT RAD REQUIRED

Heat pump starts

in 320 seconds

How to use the control panel

With the help of three buttons and a dial you can navigate to the various displays for settings and

readings. The last line at the bottom of the display contains information about the functions of the

buttons in the current display. If you choose “Heat” or “Info” the display you have chosen to stay in

will always remain.

Press “Heat” once more

and you come to the

shortcut for heat settings.

You can choose to stay in

which display you want.

Press “Info” once and you receive continuous information about what

the heat pump is doing and at which temperature it stops at. You can

choose to remain in this display and always receive this information.

Press the middle button again to return to the first display.

Press “Menu” once and

you come to the main

menu for settings or

temperature readings.

With the dial you

navigate up and

down between

the displays or

change the

settings.

Rego600 K1

020301 12:00:00 Fr

Heat Info Menu

Page 14

14

House heating settings in areas 0 to 10. See more detailed

description in “Heat Settings” chapter.

Fine adjustment settings in areas -10°C to 10°C. See more

detailed description in “Heat Settings” chapter.

Here you can set the heat in areas 0 to 10 if you use an

extra heat curve with a mixing valve.

Here you set the fine adjustment of the mixing valve curve

in –10°C to 10°C.

If a room sensor is connected you can set the required

room temperature here. On customer level 2 you can set

how much you want the sensor to affect the heating system.

You can temporarily increase the hot water temperature

with the electric water heater here. The heat pump first

increases it to around 50°C and then the electric water

heater to around 65°C. The electric heater starts again at

60°C and increases the temperature to 65°C in the set

time. The area is 1-48 hours and when the set time has

elapsed the settings must be repeated in order to receive

extra hotwater.

With extra

sensor

only.

With

extra

sensor

only.

With

extra

sensor

only.

Operating mode

A only.

The radiator temperature settings you make in the short cut

to “Heat” can also be made on row 1 and for the hot water

setting on row 2.

In row 3 you can see all the temperatures where sensors

are connected.

Main menu

Monitor all

temperatures 3

Return Select

Main menu

Indoor temperature

settings 1

Return Select

Extra hotwater

1h 0h 48h

Return Adjust

Room temperature

10° 20° 30°

Return Adjust

Mix. valve fine-tune

-10° 0,0° 10°

Return Adjust

Mix. valve incr/decr

0 4 10

Return Adjust

Temp. fine-tune

-10° 0,0° 10°

Return Adjust

Temp. incr. / decr.

0 4,0 10

Return Adjust

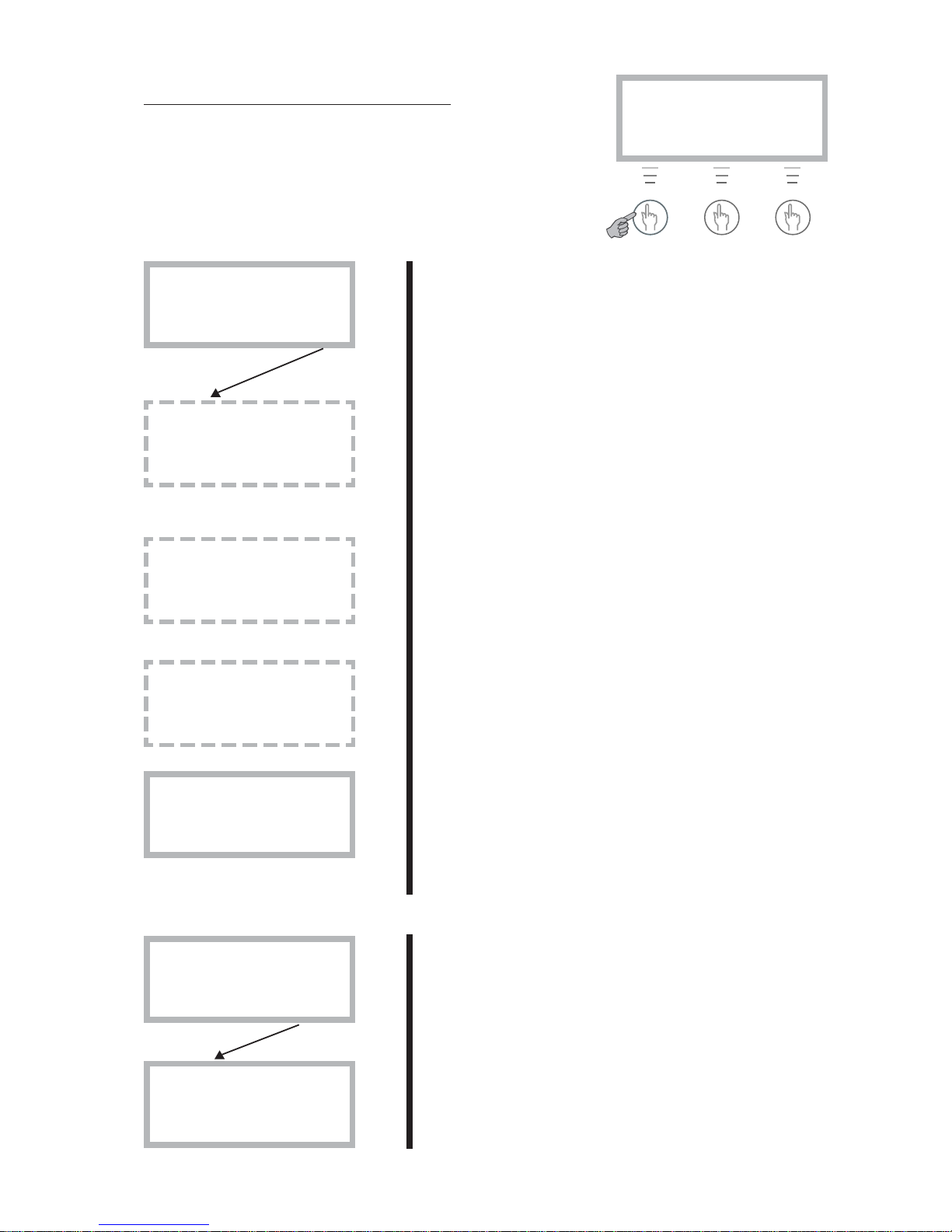

Basic functions (customer level 1)

Heating and extra hot water

Press “Heat” to come to the short cut to the heat settings. These

displays are then available.

Rego600 K1

020301 12:00:00 Fr

Heat Info Menu

Temperatures

Press “Menu” to come to the main menu. Where you can also carry

out heat settings and see the temperatures. These displays are then

available.

Page 15

15

You have pressed “Menu” and are on row 1. Press “Select” and turn the dial and the display will scroll. You can

then choose to enter the display you require. Each display

has a number.

With a room sensor installed you can set the value here how

much you want it to affect the outdoor sensor. A high value

gives more effect from the room sensor. Please note the

room sensor only fine tunes the heat curve. It is therefore important that you set the basic settings for the

heat curve and fine tuning from the start.

If a room sensor is installed you can utilise the holiday mode

function, you can set the number of days that the room

temperature is lowered to 15°C here. The temperature is

not adjustable and it does not affect the hot water. Normal

operation is resumed when the period is over.

If a room sensor and remote control is installed you can set

the required room temperature here. You can then use the

telephone to increase the temperature to normal.

This equipment is available as an accessory.

At this set temperature the heat pump only produces hot

water.

Line 1

With extra

sensor and

in operating

mode A

only

With extra

sensor

only

With extra

sensor,

remote

control

and in

operating

mode A

only

Operating

mode A

and B only

Operating

mode A

only

Using the dial you have moved to the hot water settings in

row 2.

Setting intervals for the continual raising of the hot water

temperature. If you choose for example 7 days, the temperature is raised using the electric water heater once a

week to around 65°C (Operating mode A with electric

water heater only).

Line 2

Hot water setting

Interval for

hot water peak 2.2

Return Select

Main menu

Adjusting the hot

water settings 2

Return Select

Temperature settings

Setting of summer

disconnection 1.14

Return Select

Temperature settings

Remote control

temperature 1.13

Return Select

Temperature settings

Setting of holiday

function 1.12

Return Select

Temperature settings

Setting of room

sensor infl. 1.11

Return Select

Main menu

Indoor temperature

settings 1

Return Select

Enhanced functions

As a user you have access to enhanced functions. Keep the

“Heat” button pressed down for five seconds and go into ”Menu”

to gain access to these displays. You will automatically return to

level 1 again after 30 seconds.

Keep the button pressed

down for 5 seconds.

Rego600 K2

020301 12:00:00 Fr

Heat Info Menu

Page 16

16

Line 4

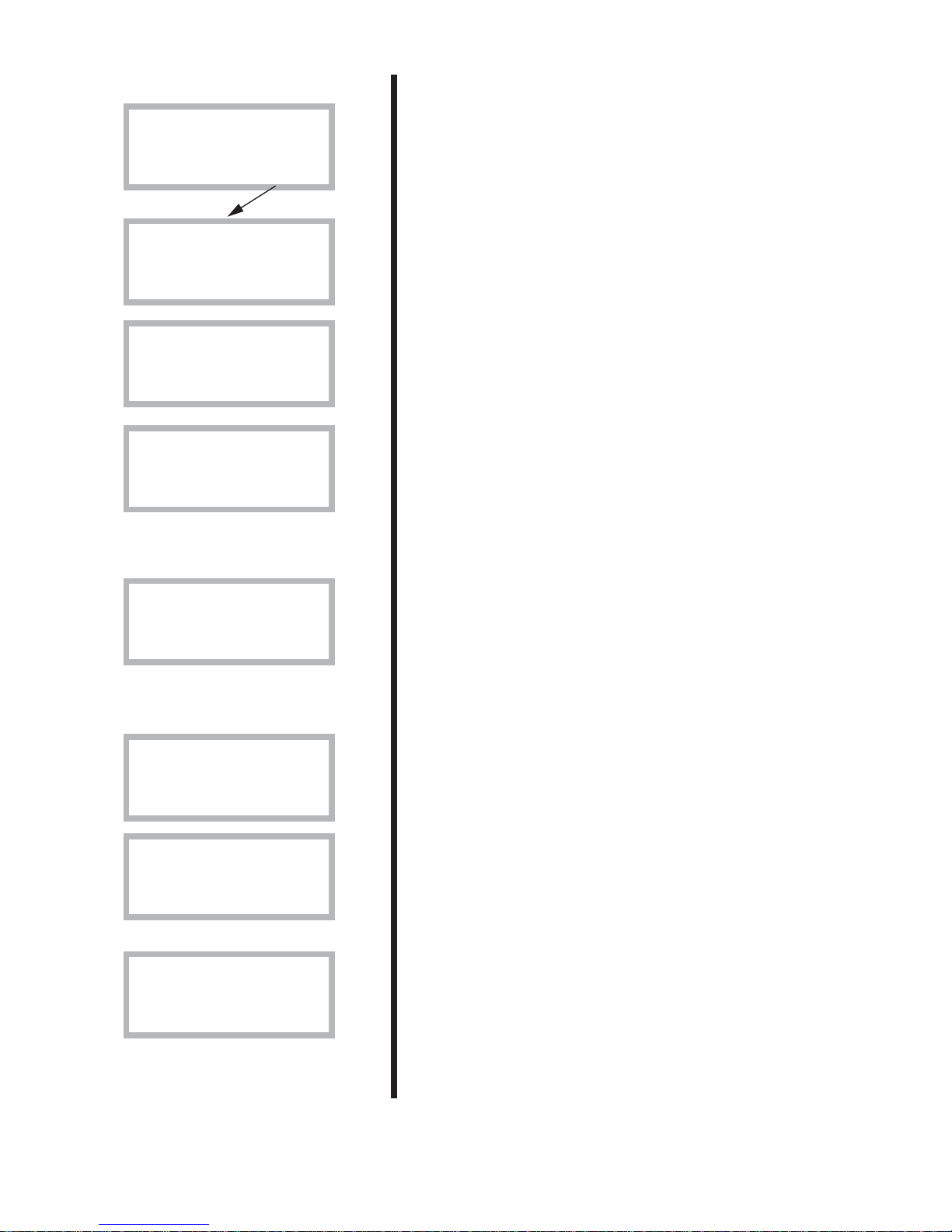

You have now moved to timer control settings line 4.

Here you can set the times, day for day, that you want to

utilise the clock settings. You can set all the weekdays

independently of each other. Press “Select”.

The example describes how you set Monday between

22:00 and 06:00. Press “Adjust”.

There is now a cursor under Monday. Turn the dial and mo

becomes Mo. Monday is now activated.

Now set the clock setting to between 22:00 and 06:00 in

the morning. Press the right arrow button until the cursor is

under the first 00. Turn the dial until 22:00 appears. Press

the button twice more (the cursor moves two steps to the

right) and turn the dial until 06:00 appears. Press the ”right

arrow” button once more and the arrow is replaced by

“Save”. Press “Save” to set the timer controls.

You can now do the same for all the other days of the

week you want to timer control. Use the dial in this display

to access other days.

In display 4.1.1 you set how much you want the temperature to be raised or lowered in the above time zone settings. If you choose, for example, –5°C the heating system

temperature is lowered by 5°C.

In display 4.3 you can disconnect the hot water completely

during e.g. peak rate times. This is done in the same way as

with the heat pump time controls.

Not

operating

mode C

Tidsstyrning

Tidsstyrning tillsk.

enligt klocka 4.2

Tillbaka Välj

Clock setting

Setting level

heat pump +/- 4.1.1

Return Select

Clock setting HP 1

Mo 22:00-06:00

Return Adjust

Clock setting HP 1

Mo 22:00-06:00

^^

Cancel <- ->

Clock setting HP 1

Mo 00:00-00:00

^^

Cancel ->

Clock setting HP 1

mo 00:00-00:00

Return Adjust

Clock setting

Clock setting HP

accord. to clock 4.1

Return Select

Main menu

Timer control

settings 4

Return Select

Page 17

17

Line 7

Not

operating

mode C

Not

operating

mode C

Line 10

Line 11

Line 12

Main menu

Return to

factory settings 12

Return Select

Main menu

Alarm logging

of all alarms 11

Return Select

Main menu

Clock, setting

time and date 10

Return Select

Op. time readings

Distribut. add. heat

DHW-Rad in % 7.4

Return Select

Op. time readings

Add. heat in operat.

number of hours? 7.3

Return Select

Op. time readings

Distribution HP

DHW-Rad in % 7.2

Return Select

Op. time readings

Heat pump in operat.

number of hours? 7.1

Return Select

Main menu

Op. time readings on

HP and add. heat 7

Return Select

In line 7 you can read the running times for the heat pump

and additional heat. Press “Select” to enter these menus.

Here you can see how many hours the heat pump has been

in operation.

This shows the distribution of the heat pump between hot

water and heating as percentages.

Here you can see how many hours the additional heat has

been in operation.

This shows the distribution of the additional heat between

hot water and heating as percentages.

You can set the heat pump’s clock to the correct time if it is

wrong on line 10.

Line 11 shows a record of the alarms that may have occurred on your heat pump. You can see the type of alarm

and when it occurred. An * in the display means the alarm is

still active.

If you want to change your settings at customer levels 1 and

2 you can return to factory settings on line 12.

Please note: If you are on the installer/service level when

you choose factory settings, the installer must carry out a

new start-up of the plant with the new settings. The installer/

service level is for installer only. As an end-user you should

never go into this level!

Page 18

18

Cold weather:

If the indoor temperature is too low or too high during cold

weather, you use Temp. incr./decr. to change it.

Press “Heat”.

The set value is shown on the display; in the shape of a bar

but also as a digit. The range is between 0 and 10. Press

“Adjust”.

Turn the dial to the right to increase, to the left to decrease.

The example shows how you increase the value to 5. Turn

the dial until 5 appears on the display. The new value now

appears on the display. Press “Save” to save the new

value.

Rego600 K1

020301 12.00.00 Ti

Heat Info Menu

Temp. incr. / decr.

0 4 10

Return Adjust

Temp. incr. / decr.

0 5 10

Return Save

Setting the heating

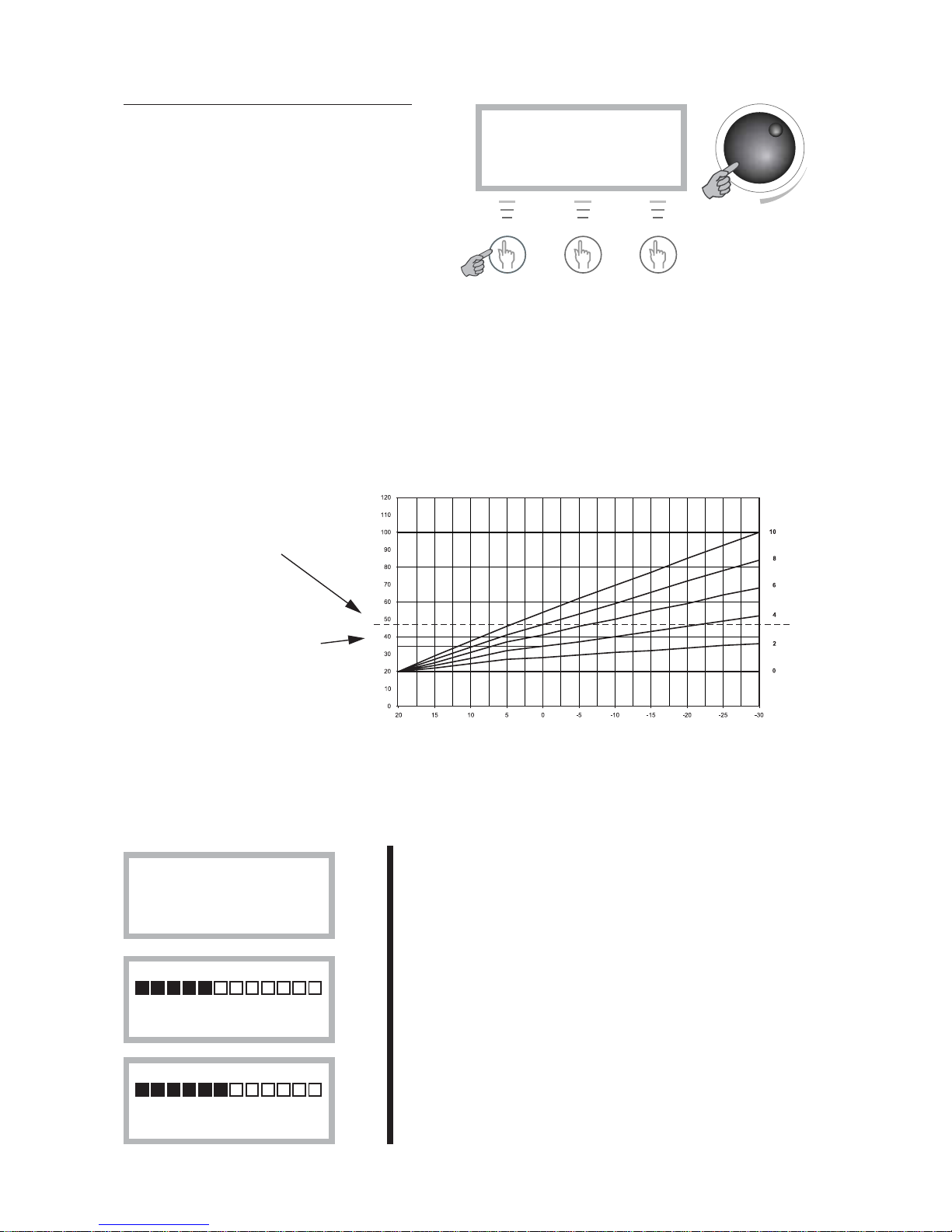

In the Temperature “increase/decrease” display

you use the dial to change the heat curve. The

lines show how the return temperature varies

with the outside temperature for different settings. The colder the weather the warmer the

heating system. Curve 4 is the factory setting

and in the example you can see that this gives a

return temperature of around 35°C at an outdoor temperature of 0°C.

Please note that the flow temperature is then around 7-10°C warmer. During the first winter, the

heating curve must be set up so that the temperature in the house is pleasant whatever the weather. You

should adjust the heating curve when the outdoor temperature is around 0ºC. You should wait two days

after adjusting before carrying out any readjustments.

Rego600 K1

020301 12:00:00 Fr

Heat Info Menu

The example describes how to change the “heat curve” in the Heating increase/decrease menu.

Please note that a high value could cause the heat pump to stop if the return temperature is too high.

Heat curve

Radiator return

temperature

Setting

Outdoor temperature

The appearance of the heat curve

The limit when the heat

pump stops for a too

high a return temperature.

The line shows that if heat

curve 4 is chosen, the heat

pump stops at around 35°C

when the outdoor temperature is 0°C.

Page 19

19

Warm weather (above +5ºC):

If the indoor temperature is too low or too high during

warm weather, you use fine tuning to change it. You come

to Temp. Fine Tuning by pressing “Heat” and turning the

dial to the right.

Fine tuning can be set in areas –10°C to 10°C. You change

the fine tuning in the same way as “Temp. increase/decrease” as described on the previous page.

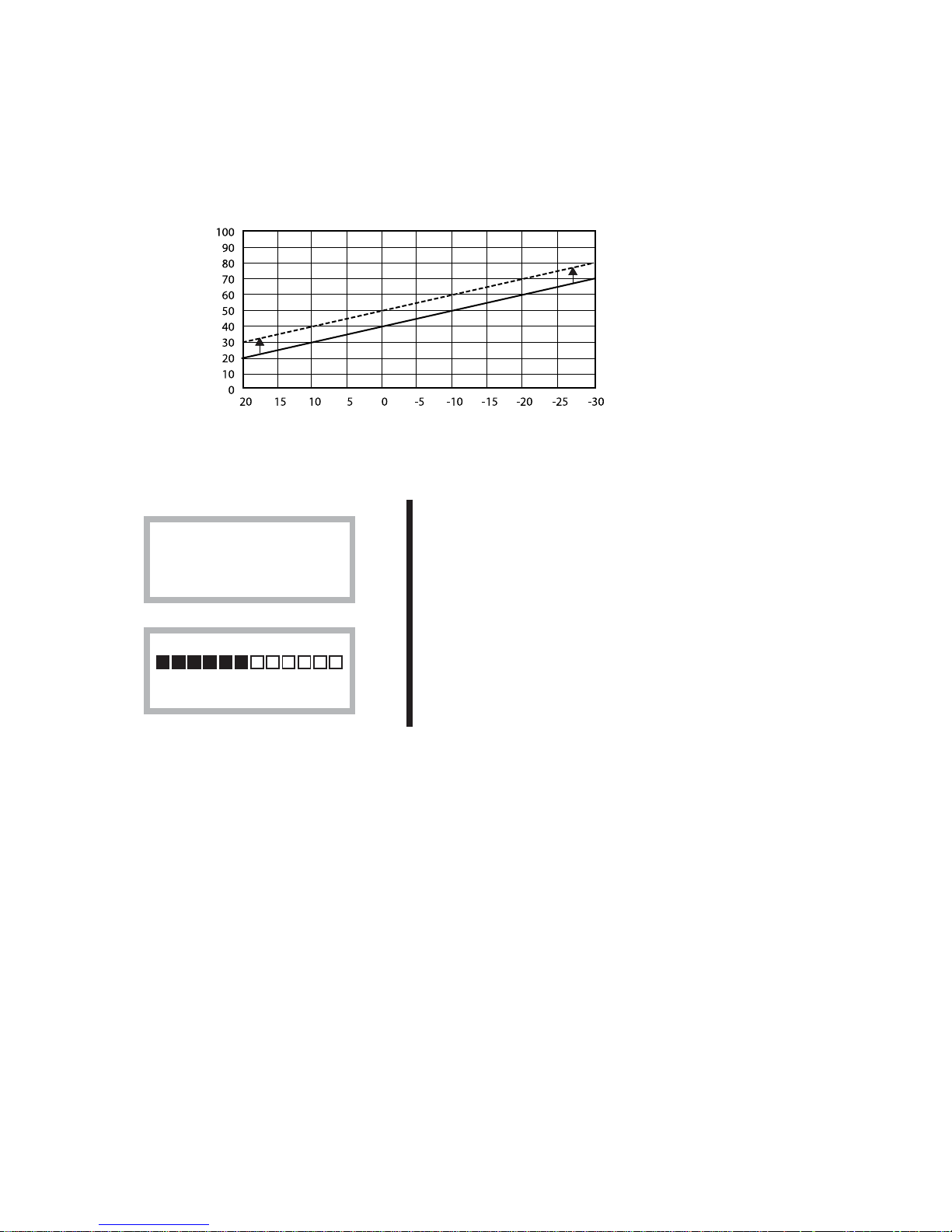

The heat curve can also be fine tuned. You do this in the “Temp. fine tune” display. The dotted line

illustrates how the parallel offset has been turned towards plus. The entire curve moves upwards, in

contrast to increasing the slope, when only the slope changes.

The dotted line illustrates

how the fine tuning adjustment has been turned

towards plus.

Fine tuning adjustment

Radiator return

temperature

Outdoor temperature

Rego600 K1

020301 12:00:00 Fr

Heat Info Menu

Temp. fine-tune.

-10° 0,0° 10°

Return Adjust

Page 20

20

Fixed temperature (D series only)

If the heat pump is set at operating mode C with a fixed temperature, then it can only be engaged

and disengaged by the built-in return sensor. There are two displays available for this mode. Please

note that if a mixing valve is connected to the heat pump, the “Temp. incr/decre” and “Temp. fine

tune” displays control the settings for the mixing valve opening to the heating system.

Rego600 K1

020301 12.00.00 Ti

Heat Info Menu

To adjust the engaging and disengaging temperature, press

“Menu” followed by “Select”. You are now in line 1.

Use the dial to navigate to display 1.16 and press “Select”.

The factory setting is 48°. Please note that this concerns the

engaging temperature to the heat pump. The temperature

from the pump is normally 5-10°C higher. Settings above

48°C are not recommended for technical reasons.

You can also set the difference between engaging and

disengaging the heat pump in display 1.17. The factory

setting is 5ºC. A lower setting results in the heat pump

starting and stopping more frequently. Press “Select” to

adjust.

Simple tips for saving

The lower you can keep the temperature of the heating system in the house, the better your heating

economy will be. So make sure not to set your heat curve too high. It is important that the heating

system is carefully balanced so that all parts or the heat emitters (radiators or underfloor) are at the

same temperature.

Thermostatic valves on your radiators or floor heating may have a negative effect on your heating

system because they restrict the flow so that the system has to compensate with a higher water

temperature. If thermostat valves are fitted, they should be fully opened, except in bedrooms, where

they can be turned down slightly.

Temperature settings

Return thermostat

stop temp sett. 1.16

Return Select

Return thermos. stop

30° 48° 50°

Return Adjust

Temperature settings

Return thermostat

hysteresis set 1.17

Return Select

Page 21

21

All sensor temperatures

Below are the various sensor temperatures that are visible under line 3 in the control panel. Note that

not all the sensors are standard but are available as accessories for different areas of use. To get

there press “Menu” in the control panel and then turn the dial to line 3. Then press “Select”.

Shows the heating system return temperature. This varies

depending on the outdoor temperature.

Shows the outdoor temperature.

Shows the temperature in the outer container of the electric

water heater’s bottom part. This temperature is around 5°C

lower than the temperature in the hot water tank.

If an extra mixing valve is used for e.g. floor heating then

the flow pipe is visible on the circuit. It varies with the

outdoor temperature.

If a room sensor is used, you will see the temperature of the

room where the sensor is located.

The sensor shows the working temperature of the compressor. It varies between around 70°C and 135°C.

The sensor shows the outgoing temperature from the heat

pump. It varies depending on the outdoor temperature and

whether the heat pump is in hot water production mode.

The sensor shows the incoming temperature to the heat

pump. It varies as mentioned above. Please note that for

safety reasons the heat pump stops when this shows a

temperature of more than 48°C.

The sensor shows the temperature from the bore hole or

the ground. It normally varies between -5°C and 8°C

throughout the year.

The sensor shows the temperature to the bore hole or the

ground. It is normally 1.5°C to 5°C lower than heat transfer

in.

Line 3

Standard

Standard

Included

with

the C series

Accessories

Accessories

Standard

Standard

Standard

Standard

Standard

Temperature readings

Return radiator GT1

Off ##,#º Now ##,#º

Return

Temperature readings

Out GT2

###,#°

Return

Temperature readings

Hot water GT3

Off ##,#º Now ##,#º

Return

Temperature readings

Shunt, flow GT4

Tgt ##,#º Now ##,#º

Return

Temperature readings

Room GT5

Tgt ##,#º Now ##,#º

Return

Temperature readings

Compressor GT6

###,#º

Return

Temperature readings

Heat tr fluid out GT8

###,#º

Return

Temperature readings

Heat tr fluid in GT9

###,#º

Return

Temperature readings

Ht tr fld(coll)inGT10

###,#º

Return

Temperature readings

Httrfld(coll)outGT11

###,#º

Return

Page 22

22

If the control panel is dark

Possible faults:

• The fuses or MCBs (miniature circuit-breakers) in your fuse box.

This is what to do:

Check the fuse (or MCB) for your heat pump. If the small plate at the bottom of the fuse has come

off, the fuse has blown and must be replaced. If you have MCBs, and they have tripped, move the

switch to the up position.

Note that the heat pump cannot restart until after 15 minutes. This delay is needed for technical reasons!

• The heat pump MCB has tripped

This is what to do:

Reset the MCB by pushing the switch upwards.

If something is wrong

The control unit provides a lot of information about faults and how to remedy them. Rego 600

incorporates advanced functions to monitor and protect your heat pump. This means there is no risk

involved in resetting an alarm. If a fault persists, you should contact the installer.

Alarm examples and what to do

Press “Ackn” when the fault is remedied, the alarm lamp goes off and the

heat pump starts again within 15 minutes. If the lamp is lit with a steady glow

then the alarm is remedied, but the fault

remains. If several alarms have triggered, use the dial to navigate to them.

If you press “Info” and then turn

the dial you will see information

about the possible causes and

how you can remedy the fault

yourself.

ALARM

Power failure

020301 15:10:18

Info Ackn.

Time and date for

when the fault

occurred.

Cause.

Page 23

23

All alarms

Below is a description of the alarms that can appear in the menu display. The description gives an

idea of what the fault is and what you yourself can check and remedy. An alarm can sometimes

occur temporarily so there is never any risk with resetting it. If a fault persists, you should contact the

installer.

The description sometimes refers to a heat pump component. Pages 28 and 29 have details of where

to find the components. Page 28 is for models 14-16 and page 29 is for models 20-40.

COMPRESSOR MOTOR CUTOUT SWITCH ALARM

To reset the alarm: Reset the motor cutout by pressing in the

black button (position 2). Then press “Ackn.” Note: The lamp

goes out even if the motor cutout has not been reset. (Models

25-40 have built-in temperature protection in the compressor

that resets automatically when the temperature has reduced).

ALARM (MB1)

Compr. circ. Switch

020301 15:10:18

Info Ackn.

Probable causes and actions:

• Sporadic fault or overloading of the power supply.

Action: Reset the motor cutout and wait and see.

• The current setting on the motor cutout is too low. The compressor’s current intensity varies during

summer/winter operation.

Action: Contact the installer.

• Contactor or cutout faulty, or loose electrical connections to the compressor.

Action: Contact the installer.

• Compressor faulty.

Action: Contact the installer.

ALARM (MB2)

HTF c-pump switch

020301 15:10:18

Info Ackn.

HEAT TRANSFER FLUID CIRCULATION PUMP

SWITCH ALARM

To reset the alarm: Greenline 14-16. Press “Ackn.” (Mod-

els 14-16 have built-in motor cutout in the pump that resets

automatically after a period of time). Greenline 20-40. Reset

the circuit breakers (pos 3) or the pump built-in motor cutout

(pos 9) and press Confirm. Note that the lamp goes out even if

the motor cutout has not been reset.

Probable causes and actions:

• The pump has stopped because of contaminants.

Action: If the pump has an air vent screw it can be loosened and the pump restarted with a screwdriver

• Fault in the pump’s electric motor.

Action: Contact the installer.

• Temporary fault.

Action: If the fault persists, contact the installer.

Page 24

24

LOW PRESSURE SWITCH ALARM

To reset the alarm:

Press “Ackn.”

ALARM (LP)

Low pressure switch

020301 15:10:18

Info Ackn.

Probable causes and actions:

• Air in the heating system.

Action: Check the expansion vessel and fill if required. If air is heard continuously in the system,

contact the installer.

• Heat transfer pump has stopped or is set at too low a speed.

Action: Check the pump has not stopped or is set at the wrong speed.

• Particle filter on the cold side is clogged.

Action: Check the particle filter and clean if necessary.

• Not enough refrigerant in the circuit.

Action:Check that bubbles do not appear continuously in the sight glass. Contact the installer.

• Not enough antifreeze in the heat transfer circuit creating ice in the heat exchanger.

Action: Contact the installer.

• Expansion valve faulty (alarms occur at long intervals, about every three or four weeks).

Action: Contact the installer.

HIGH PRESSURE SWITCH ALARM

To reset the alarm:

Press “Ackn.”

ALARM (HP)

High press. switch

020301 15:10:18

Info Ackn.

Probable causes and actions:

• Air in the heating system.

Action: Check the system and vent the radiators if necessary.

• Not enough flow over the heat pump.

Action:Check that the circulation pump has not stopped and that a valve in the system is not closed.

• Particle filter on the hot side is clogged.

Action: Check the particle filter and clean if necessary.

• Heat transfer fluid circuit over-filled.

Action: Contact the installer.

• Drying filter clogged.

Action: Contact the installer.

Page 25

25

ALARM ON COMPRESSOR SUPERHEAT

To reset the alarm:

Press “Ackn.”

Probable causes and actions:

• The working temperature of the compressor is too high.

Action: If the fault persists, contact the installer.

• Sporadic temperature rise due to abnormal operating conditions.

Action:Wait and see.

ALARM (GT6)

Compr. superheat

020301 15:10:18

Info Ackn.

PHASE SEQUENCE FAULT ALARM

To reset the alarm: The alarm does not reset until the

phase sequence has been changed. Then the heat pump

starts automatically.

Probable causes and actions:

• Phase sequence to the heat pump is incorrect.

Action: The phase sequence to the incoming supply must be changed.

POWER FAILURE ALARM

To reset the alarm: The alarm resets itself and the heat

pump starts automatically when the fault has been corrected.

Probable causes and actions:

• One or two phases are missing to the heat pump.

Action:Check the fuse (or MCB) for your heat pump. If the bottom plate is loose then the fuse has

blown and must be changed. If you have MCBs, and they have tripped, move the switch to the up

position.

• The emergency thermostat is not in the 0 position.

Action: Check that the emergency thermostat wheel is turned to the anti-clockwise end position.

ELECTRIC WATER HEATER ALARM

To reset the alarm: Reset the water heater’s MCB (pos

4) or overheat protection (pos 5). Press Ackn.

Probable causes and actions:

• The electric water heater MCB has tripped.

Action:Reset the MCB by pushing the switch upwards. If the fuse blows again then the heater could

be faulty, contact your installer.

• The overheat protection on the electric water heater has tripped.

Action: Reset by pressing the button on heater’s protective cover until it “clicks”. It could depend

on a bad flow over the heater caused by the circulation pump standing still or a clogged particle filter.

Check the circulation pump and particle filter.

ALARM (EK)

Electrical cassette

020301 15:10:18

Info Ackn.

ALARM

Power failure

020301 15:10:18

Info Ackn.

ALARM

3-phase incorrect

020301 15:10:18

Info Ackn.

Page 26

26

ALARM, HIGH RETURN TO THE HEAT PUMP

To reset the alarm: The alarm resets itself and the heat

pump starts automatically when the temperature has

dropped.

ALARM (GT9)

High return HP

020301 15:10:18

Info Ackn.

Probable causes and actions:

The heat pump has a sensor that stops the heat pump for safety reasons when the return temperature is

too high, about 48°C

• The temp. incr/decr dial is set so high that the heating system return temperature is too high.

Action:Reduce the temp. setting.

• The hot water temperature is set too high.

Action: Contact the installer.

• The radiator valves or the underfloor heating system are closed.

Action:Open the valves.

• The flow across the heat pump is greater than the flow in the heating system.

Action: Reduce the speed of the heat pump circulation pump or increase the speed of the main pump

in the heating system. Contact the installer.

SENSOR ALARM

To reset the alarm: The alarm resets itself and the heat

pump starts automatically when the fault has been corrected.

ALARM (GT1)

Sensor return rad.

020301 15:10:18

Info Ackn.

Probable causes and actions:

Alarm if a sensor fault can be indicated for all sensors that are connected to the heat pump. The example shows the alarm for the Return radiator, GT1 sensor. The principle is the same for all sensor alarms.

• Short circuit or broken cable to sensor.

Action: If you have an instrument that can measure resistance, you can check the resistance of the

circuit and compare with the table for sensors in Technical spec. Or contact your installer.

• Faulty sensor.

Action: Contact the installer.

• Faulty connection.

Action: Contact the installer.

• Temporary fault.

Action:Wait and see.

HEAT TRANSFER FLUID SYSTEM OUT MAX

ALARM

To reset the alarm: The alarm resets itself and the heat

pump starts automatically when the temperature has

dropped.

ALARM (GT8)

HTF out max

020301 15:10:18

Info Ackn.

Probable causes and actions:

The heat pump has a sensor that stops the pump for safety reasons when the outgoing temperature is

too high at around 75°C.

• Not enough flow over the heat pump

Action:Check that the circulation pump has not stopped and that a valve in the system is not closed.

• Particle filter on the hot side is clogged.

Action: Check the particle filter and clean if necessary.

Page 27

27

Maintaining your heat pump

Your heat pump normally requires little maintenance, but we recommend occasional checking to

ensure that your heating installation is giving the best possible performance. The description

sometimes refers to a heat pump component. You will find these on page 28 for models 14-16

and page 29 for models 20-40.

Working on the heat pump

• Switch off the electrical supply before commencing work on the heat pump. Usually there is an

isolating switch on the wall before the heat pump.

• Only an accredited refrigeration company is permitted to work on the heat transfer fluid circuit.

The installation contains gases that may form toxic fumes when combined with discharges and

naked flames. The gas that forms may cause choking even at low concentrations. If it should leak,

evacuate the room until it has been thoroughly aired.

Normal maintenance

Points to check a few times a year:

• Sight glass (pos 7): When the heat pump starts, and during rapid temperature changes, you can

sometimes see bubbles in the liquid in the heat transfer fluid circuit for a minute or so. This is

normal.

If there are always bubbles in the sight glass: Contact the installer.

Sight glass

• Expansion vessel: If the heat pump has a plastic expansion vessel connected to the heat transfer

circuit the level must not fall below 1/3 (the vessel is mounted outside the heat pump).

For low fluid level: With the pump working, remove the lid to the valve at the top of the vessel

and open the valve. Fill with antifreeze or clean water (simplest with a watering can). Shut the

valve again and screw on the lid.

Ball valve with lid

Emergency operation, E series

If a fault occurs that you cannot remedy, the plant can operate in emergency mode. In this mode the

circulation pump and electric heater are started manually by turning the thermostat wheel on the

electric heater. To get both heating and hot water, the 3-way valve must be set at intermediate

position (the 3-way valve is built-in in the E series) WARNING! Must not be activated during

normal operation.

To reset the alarm: Turn the electric heater thermostat wheel to the required temperature (see

following pages, pos 6). Reset the 3-way valve to manual operation in an intermediate position so

that the electric boiler can heat both the heating system and the immersion heater.

PLEASE NOTE: The control panel alarms for a power failure in emergency operations.

Page 28

28

Particle filter

• Particle filter: The particle filters, which are connected on both the hot and cold sides of the heat

pump, protect the heat exchangers from dirt. Sometimes these filters may get clogged and cause

malfunctions.

Do this when checking: Shut down the heat pump with the on/off button on the control panel.

Close the valve and unscrew the sealing cover. Check for dirt in the filter. If necessary, remove the

circlip that retains the filter. The simplest way to do this is by using pliers. Remove the filter and flush

it clean with water. Refit the filter, circlip and cover. Open the valve and start the heat pump. Note

that the particle filters in the E14 and E16 series are mounted inside the heat pump (pos 1). On the

cold side the filter is mounted outside the heat pump.

Where the various components are situated (models 14-16)

The pages, If something goes wrong and Maintaining your heat pump, show various positions in

your heat pump. The picture shows the location of the various components.

The picture is of the E series.

Pos 1

Cleanable particle filter with

shut off lever valve.

Pos 2

Reset, motor cutout com-

pressor.

Pos 3

Reset circuit breaker heat

pump.

Pos 4

Reset circuit breaker

electric water heater.

Pos 5

Reset button for overheat

protection on the electric heater

elements.

Pos 6 (Emergency op, E series)

Turn the thermostat wheel to the

right to manually activate the

electric boiler.

Set the 3-way valve to the

intermediate position by pushing

the grey switch downwards at

the same time as it is pressed

inwards.

WARNING! Must not be

activated during normal operation.

Pos 7

Sight glass

Page 29

29

Pos 6 (Emergency operation, E series)

This is what to do:

• Set the 3-way valve to the intermediate position by turning the wheel

to the side half a turn. Then turn the large wheel to an intermediate

position. Turn the small wheel back to its original position to return to

normal position again.

• Turn the thermostat wheel to the right to manually activate the electric

boiler.

• WARNING! Must not be activated during normal operation.

Pos 5

Reset button for overheat protection on the electric boiler.

Pos 9

Resetting the motor cutout on the heat transfer pump.

Where the various components are situated (models 20-40)

These pages identify the various parts contained in the heat pump. The picture shows the location of

the various components. The picture shows the E series.

Pos 2

Reset, motor cutout compressor.

Pos 3

Reset circuit breaker heat

pump.

Pos 8

Reset, motor cutout heat

transfer fluid pump.

Pos 4

Reset circuit breaker

electric water heater.

(Model E20 has one less

circuit breaker.)

Pos 7

Sight glass.

Page 30

30

What the shipment includes

Standard components

• Heat pump unit with the necessary safety functions and electrical components.

• Factory fitted control unit Rego 600. Rego 600 can be used for simultaneous operation together with

an electric boiler or oil-fired/electric boiler with mixing valve.

• Sensor radiator return, T1 (GT1) (packed separately).

• Sensor out, T2 (GT2) (packed separately).

• Sensor, compressor, T6 (GT6).

• Sensor heat transfer fluid out, T8 (GT8) and sensor heat transfer fluid in, T9 (GT9).

• Sensor heat transfer fluid (collector) in, T10 (GT10) and sensor heat transfer fluid (collector) out,

T11 (GT11).

• Pump for heat transfer out and in and built-in flexible hoses on the heat transfer circuit.

• Particle filter with shut off for heating and heat transfer fluid side (packed separately in D series).

• Expansion vessel and safety valve for heat transfer fluid circuit, only 14-16 (packed separately).

Accessories

• Sensor hot water, T3 (GT3).

• Sensor flow duct mixing curve, T4 (GT4).

• Room sensor, T5 (GT5).

• Expansion vessel for the heat transfer circuit.

General

Temperatures

Note that the heat pump can work to a maximum return temperature of around 48°C. Anything over

this and the heat pump stops for safety reasons. The maximum outgoing temperature from the heat

pump is around 55°C. A higher temperature can be achieved using an electric water heater.

Particle filter

The particle filter supplied must always be fitted in the input pipe of the hot side as close as possible

to the heat pump, and horizontally. For E14 and E16, the filter is mounted on the heat transfer side.

The filters are packed separately on the heat transfer fluid side.

Transportation

The heat pump must always be transported and stored upright and dry. The heat pump can be

placed on its back temporarily when moving to the installation site.

Positioning

Place the heat pump on a flat base and adjust the rubber feet until it is level. Avoid installing the heat

pump close to sensitive walls such as bedroom walls, since the pump produces a certain amount of

noise when running. The room must have a floor drain. Installation must comply with local construction regulations.

Page 31

31

Dimensions and connections (models DE14-16)

(1) Return radiator

(2) Riser radiator

(3) Return electric water

heater (only E)

(4) Riser electric water

heater (only E)

(5) Heat transfer fluid out

(6) Heat transfer fluid in

(7) Electrical connections

(7)

Front

®®

®

®

®

(1)

(2)

(3)

(4)

(6)

(5)

248 385 513

596

571

495

317

121

1500 mm

(1525 mm incl. feet)

®®

®

380

®

Page 32

32

Dimensions and connections (models E20-E25)

(1) Return radiator

(2) Plug

(3) Radiator out

(4) Riser DHWH

(5) Heat transfer fluid in

(6) Heat transfer fluid out

(7) Electrical connections

(7)

Front

(1)

(2)

(3)

(4)

(6)

(5)

1500 mm

(1525 mm incl. feet)

®

(7)

®

539

®

®®

672

583

417

271

®

750

®®®®®

128 296 372 603 700

Page 33

33

Dimensions and connections (models D20-D40)

(1) Return radiator

(2) Riser radiator

(3) Plug

(4) Plug

(5) Heat transfer fluid in

(6) Heat transfer fluid out

(7) Electrical connections

Front

(1)

(2)

(3)

(4)

(6)

(5)

1500 mm

(1525 mm incl. feet)

®

(7)

®

539

®

®®

672

583

417

271

®

750

®®®®®

128 296 372 603 700

(7)

Page 34

34

Greenline 14 200 metres 800 metres

Greenline 16 120 metres 650 metres

Greenline 20

Greenline 25

Greenline 35

Greenline 40

Max. Hose length

with one loop

Heat pump

Max. hose length per coil

with two loops

Collector

Collector hose

The collector hose consists of a thin-walled plastic hose of make Pem 40 x 2.4 DN 6.3. Length and

depth as in IVT’s dimensioning program.

Install the hose rising towards the heat pump to avoid air pockets.

It is vitally important that the filling around the ground coil does not contain stones or other objects

that could damage the coil. The final filling is best carried out after the ground collector has been

pressure tested. Avoid chips or dirt getting into the coil when cutting.

Installation and filling around the collector hose must comply with local regulations. Mark AMA is a

general material and work description issued by Svensk Byggtjänst.

Bending diameter

Minimum bending diameter permitted is 1 metre. Always use an elbow coupling for sharper bends. If

you damage the hose by bending it too sharply you can repair it with a straight connector.

Maximum lengths

Specified pressure falls and hose lengths are based on heat transfer fluid containing ethanol 30% by

volume. Other heat transfer fluids are not recommended because they are sluggish at low temperatures. The table shows the maximum hose length for each heat pump model. The coils can be parallel

connected if the collector’s length exceeds that permitted for a circuit. Note that maximum hose

length per coil is specified for parallel connecting. The table specifies that e.g. a Greenline 14 has a

maximum coil length of 200 metres and for 2 parallel coils the length is 800 metres a coil, a total of

1,600 metres.

Contact IVT

Page 35

35

Connecting the collector to the heat pump

The sketch shows the connection of a collector with two parallel coils. Both coils are connected to

two distributors. Each coil should have a gate valve and a control valve. The control valve is adjusted so that the flow rate is the same in both coils.

The common pipe to the heat pump is fitted with a filling unit, a particle filter and an expansion

vessel. A safety valve is fitted to the outgoing pipe. When filling the heat transfer fluid circuit, one coil

at a time is filled by using these valves.

Heat pump

Filling unit

Safety

valve

Distributor

Filter

Ground, lake

or rock

collector

Ground water system

Application:

Systems using ground water are equipped with an intermediate heat exchanger to eliminate the risk

of freezing. A pump with a non-return valve is placed in the bore hole that via a hose pumps the

water to the intermediate exchanger and then back to an injection well. The circuit to the heat pump

is installed in the normal way with a filling unit and safety valve. The circuit should contain around

30% by volume antifreeze which corresponds to around -15°C.

Exp

Page 36

36

Electrical connections:

The ground water pump is connected to 3 x 400 volt with a motor cutout and a contactor. Power to

contactor CK3(230V) is taken from terminals L and N (P3) in the heat pump. The auxiliary contact

for motor cutout MB3 is series connected with the “MB2” alarm. In this way the ground water pump

starts and stops with the heat pump’s heat transfer fluid pump and during motor cutout MB3, the

heat pump stops and the heat transfer fluid pump alarm shows in the alarm display. NOTE: A

single-phase pump should always be connected with a contactor. It should never be connected to the P3 outlet on the heat pump.

Connecting to the heating system

General

Installation must be carried out by an authorised installer and must follow the current regulations and

recommendations of IVT. The pipework must be flushed before the heat pump is connected to

protect the heat pump from contaminants.

Please note that the connecting instructions are only outlined sketches. For more detailed descriptions please see IVT’s system manual for properties. See IVT’s homepage http://www.ivt.se/.

Recharge wellGroundwater

To the heating system

Intermediate heat

exchanger

The flow in the exchanger must be