IVT GreenlineC, GreenlineE, GreenlineD Manual To Installation, Commissioning And Maintenance

Page 1

Guide to installation,

commissioning and maintenance

Article nr: 290407-9 Version: 5.1

Greenline

C, D and E

Page 2

3

Important information

This guide was designed to describe the operation, connection and maintenance of the

heat pump as comprehensively as possible. As far as possible, the description has been

written so that it can be followed step by step.

Please not that the guide consists of three separate series so it is especially important

that the installation contractor reads the entire manual before commencing installation.

The guide is in two parts, one for the user and one for the installer. The table of contents sets out clearly the various sections of the manual.

Warning! The Rego600 control unit contains an advanced settings level which should

only be accessed by the installer. The end user must never change any settings on this

level, since this might have serious consequences for the operation of the heat pump.

• Before the heat pump is commissioned, the heating system and the heat transfer fluid

system, as well as the heat pump itself, must have been filled and vented. The heat

transfer fluid system must be filled with antifreeze (-15°C).

• Hot and cold connections might need checking after delivery.

• If the heat pump has to be carried down steps or stairs it can be leaned temporarily

with the compressor downwards, but never for longer periods.

• The heat transfer fluid system must be in operation when venting the system. See

chapter on refilling the heat transfer circuit.

• The control unit measures the phase sequence and alarms if the power is connected

wrongly (only 3-phase units).

IVT Industrier AB

June 2003

Page 3

4

PAGES FOR THE HOUSE OWNER

This is how your heat pump works:_____________________________________________ 7

Heat pump technology _______________________________________________________________________ 7

Heat pump components ______________________________________________________ 8

C series components ________________________________________________________________________ 8

D and E series components ___________________________________________________________________ 9

Principle _________________________________________________________________ 10

Principle of heating and hot water control ______________________________________________________ 10

Power failures ____________________________________________________________________________ 10

Three different operating modes ______________________________________________ 10

Operating mode A (not for C, D and E series) ___________________________________________________ 10

Operating mode B (D series only) _____________________________________________________________ 10

Operating mode C (D series only) _____________________________________________________________ 10

Controls _________________________________________________________________ 11

Curve control (operating modes A and B) _______________________________________________________ 11

Room sensor (operating modes A and B) _______________________________________________________ 11

Fixed temperature (operating mode C only) _____________________________________________________ 11

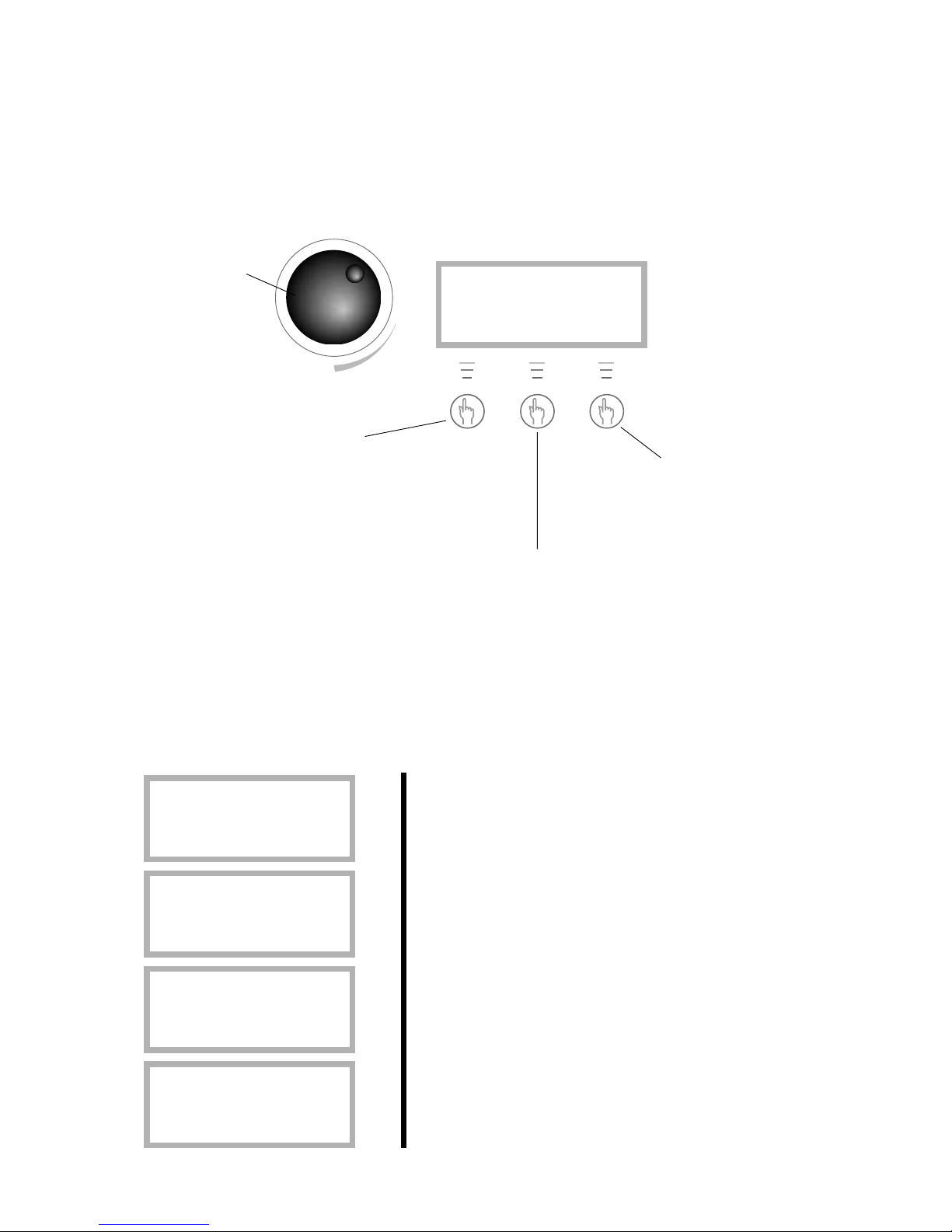

Control panel _____________________________________________________________12

Control panel buttons and displays ____________________________________________________________ 12

How to use the control panel _________________________________________________________________ 13

Examples of scrolling information ____________________________________________________________ 13

Basic functions at customer level 1 ____________________________________________ 14

Heating and extra hot water _________________________________________________________________ 14

Temperatures _____________________________________________________________________________ 14

Extra functions ____________________________________________________________ 15

Line 1

Room sensor affect ________________________________________________________________________ 15

Holiday function __________________________________________________________________________ 15

Remote control ___________________________________________________________________________ 15

Summer mode ____________________________________________________________________________ 15

Line 2

Interval for hot water peak __________________________________________________________________ 15

Line 4

Clock settings ____________________________________________________________________________ 16

Line 7

Display, operating times ____________________________________________________________________ 17

Line 10

Setting the clock __________________________________________________________________________ 17

Line 11

Alarm logging of all alarms _________________________________________________________________ 17

Line 12

Reset to factory settings ____________________________________________________________________ 17

Table of Contents

Page 4

5

Setting the heating _________________________________________________________ 18

How to increase or reduce the heating in your house ______________________________________________ 18

Fixed temperature (D series only) _____________________________________________ 20

Setting the heating at fixed temperature ________________________________________________________ 20

Simple tips for saving _______________________________________________________20

Utilising the heat pump in the right way ________________________________________________________ 20

All sensor temperatures _____________________________________________________ 21

Description of all temperatures _______________________________________________________________ 21

If something is wrong ______________________________________________________ 22

Alarm examples and what to do ______________________________________________________________ 22

If the control panel is dark ___________________________________________________________________ 22

All alarms _______________________________________________________________________________ 23

Maintaining your heat pump _________________________________________________ 27

Working on the heat pump __________________________________________________________________ 27

Normal maintenance _______________________________________________________________________ 27

Control safety anode _______________________________________________________________________ 28

Where the various parts are located ___________________________________________ 28

The various parts in the C series ______________________________________________________________ 28

The various parts in the D and E series _________________________________________________________ 29

Notes ____________________________________________________________________ 64

What the shipment includes __________________________________________________ 30

Standard components ______________________________________________________________________ 30

Accessories ______________________________________________________________________________ 30

General __________________________________________________________________ 30

Temperatures _____________________________________________________________________________ 30

Particle filter _____________________________________________________________________________ 30

Transportation ____________________________________________________________________________ 30

Positioning the heat pump ___________________________________________________________________ 30

Dimensions and connections _________________________________________________ 31

Dimensions and connections, C series _________________________________________________________ 31

Dimensions and connections, D and E series ____________________________________________________ 32

Collector _________________________________________________________________ 33

Collector hose ____________________________________________________________________________ 33

Bending diameter _________________________________________________________________________ 33

Maximal lengths __________________________________________________________________________ 33

Connecting the collector to the heat pump ______________________________________________________ 34

Switching to side mounting of the fluid transfer system ___________________________ 35

Ground water system _______________________________________________________________________ 37

Connecting to the heating system _____________________________________________ 37

General _________________________________________________________________________________ 37

Connecting the C series to the heating system and operating mode A _________________________________ 38

Connecting the D series to the heating system and operating mode A _________________________________ 39

Connecting the E series to the heating system and operating mode A__________________________________ 40

Connecting the D series to the heating system and operating mode B _________________________________ 41

Connecting the D series to the heating system and operating mode C _________________________________ 42

Connecting the 3-way valve _________________________________________________________________ 43

PAGES FOR THE INSTALLER

Page 5

6

Filling ___________________________________________________________________ 43

Filling the radiator system ___________________________________________________________________ 43

Filling of heat transfer fluid __________________________________________________________________ 43

Electrical connections ______________________________________________________ 45

Circuit diagram Greenline C series. Factory connections ___________________________________________ 45

Circuit diagram Greenline D series. Factory connections ___________________________________________ 46

Circuit diagram Greenline E series. Factory connections ___________________________________________ 47

Working switch ___________________________________________________________________________ 48

Earth fault breaker _________________________________________________________________________ 48

External connections in the C and E series. _____________________________________________________ 48

External connections in the D series ___________________________________________________________ 49

Connecting the general alarm ________________________________________________________________ 50

Connecting the external input ________________________________________________________________ 50

Connecting the load guard ___________________________________________________________________ 50

Control unit Rego600 ______________________________________________________ 51

Installer/service settings ____________________________________________________________________ 51

Installer/service menu ______________________________________________________51

Joint displays for operating modes A, B and C ___________________________________________________ 51

Adapting the heat curve _____________________________________________________________________ 51

Clock setting of additional heat _______________________________________________________________ 51

Manual control ___________________________________________________________________________ 51

Quick restart of heat pump __________________________________________________________________ 52

Selecting external controls __________________________________________________________________ 52

Choice of language ________________________________________________________________________ 52

Selecting operating modes for heat carrier pump, P2 ______________________________________________ 52

Selecting operating modes for heat transfer pump, P3 (natural cooling) _______________________________ 52

Version number display _____________________________________________________________________ 52

Extra sensor acknowledgement _______________________________________________________________ 52

Timer reading ____________________________________________________________________________ 53

Status of the timers when checking the plant_____________________________________________________ 53

Setting additional timers ____________________________________________________________________ 53

Reset to factory settings ____________________________________________________________________ 53

Commissioning the heat pump _______________________________________________ 54

Navigating the menu list ____________________________________________________________________ 54

General _________________________________________________________________________________ 55

Manual testing ____________________________________________________________________________ 55

Operation with additional heat only ___________________________________________________________ 55

Putting into operation, operating mode A (C, D and E series) _______________________________________ 55

Putting into operation, operating mode B (D series only) ___________________________________________ 57

Putting into operation, operating mode C (D series only) ___________________________________________ 59

Important points to check ___________________________________________________________________ 60

Table of factory settings ____________________________________________________________________ 60

Technical information ______________________________________________________60

Table of selected output in display 5.2 _________________________________________________________ 60

Technical specifications ____________________________________________________________________ 61

Sensor table ______________________________________________________________________________ 61

Service journal ____________________________________________________________ 62

Page 6

7

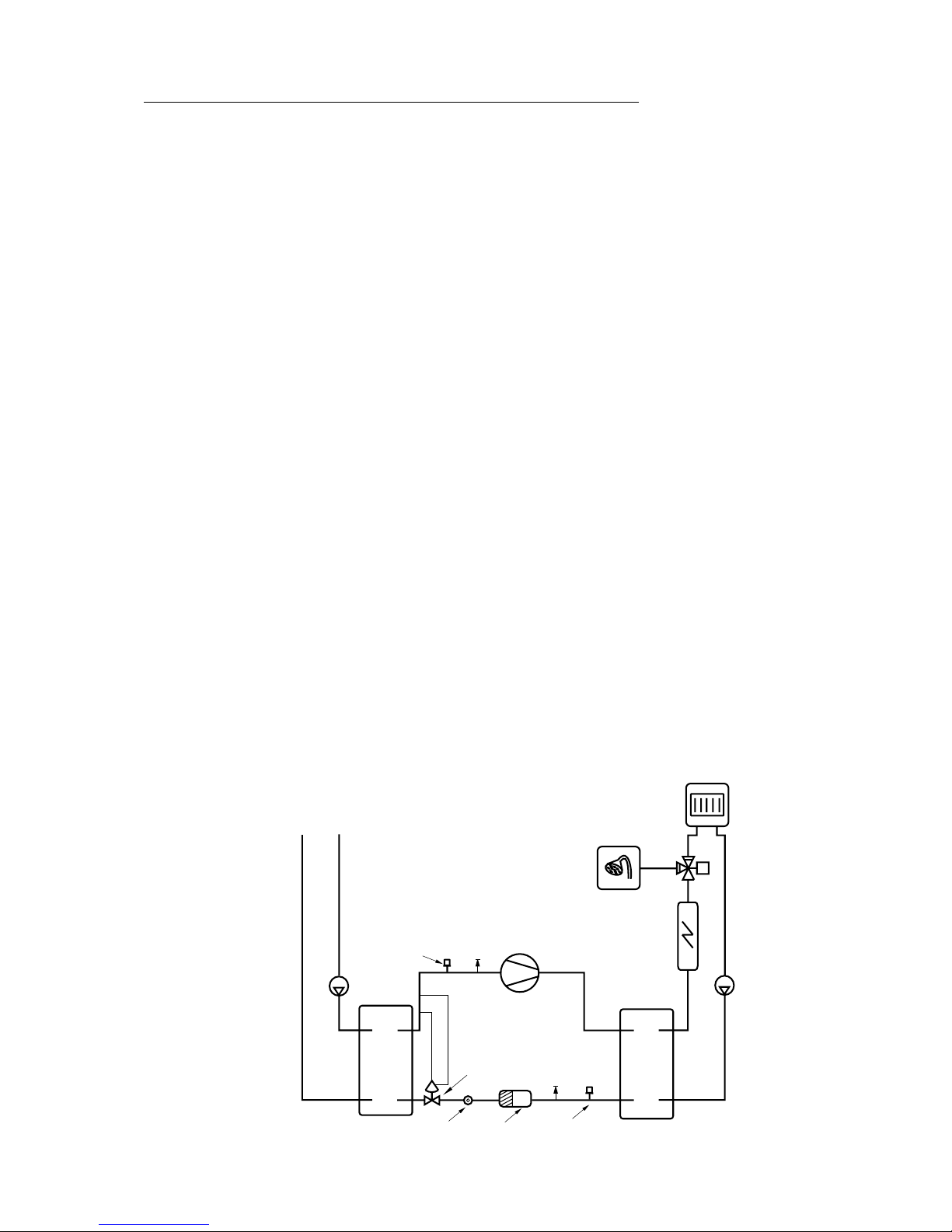

This is how your heat pump works:

Heat pump technology

The compressor, which is driven by an electric motor, forces the refrigerant into the heat pump

condenser as a gas at about 100°C. The gas and the water from the radiator system pass through the

condenser, which is a fully-welded stainless steel heat exchanger. When the hot gas is cooled by the

circulating water, it condenses (changes to liquid). As it does so, it provides energy for the heating

system or the hot water. After the condensor, the refrigerant, which is now in liquid form, continues

through a drying filter and a tank. The filter collects any moisture in the system and the tank is used as

an expansion vessel for the refrigerant to ensure there is always the correct amount in the condenser.

After the filter, the refrigerant passes through a sight glass. The sight glass is used to check the amount

of refrigerant in the system. In normal operation there should be no bubbles in the sight glass. However, bubbles may appear for short periods, mainly on rapid changes between hot water and radiator

operation and when the heat pump starts or stops.

After the sight glass the refrigerant goes to an expansion valve. The valve acts as a flow restrictor

between the high and low pressure sides of the system. The valve, which has a sensor (bulb) just

before the compressor, releases the right amount of liquid into the next heat exchanger, the evaporator.

In the evaporator, the liquid meets the circulating heat transfer fluid coming from the energy source in

the ground or bore hole. In this process, the liquid turns to gas (evaporates) under low pressure, which

uses heat. The heat is extracted from the the ground or bore hole free of charge.

After passing through the evaporator, the refrigerant is once more in the form of a gas (vapour). The

expansion valve sensor constantly checks that the evaporator is performing optimally, in order to use

as much free energy as possible. The gaseous refrigerant then goes to the suction side of the compressor, where it is compressed again. This completes the refrigerant circuit.

To protect the heat pump, pressure switches are fitted on the high and low-pressure sides of the system. These shut down the heat pump if the pressure in the system reaches an abnormal value. This is

dealt with in more detail in the section on troubleshooting.

Rock/Ground/Lake

Heating system

Hot water 3-way valve

(not D)

Pressure switch

Heat

transfer

fluid

pump

Compressor

Immersion

heater

(not D)

Evaporator

Heat

transfer

pump

Sight glass

Expansion valve

Pressure switch

CondenserFilter

Page 7

8

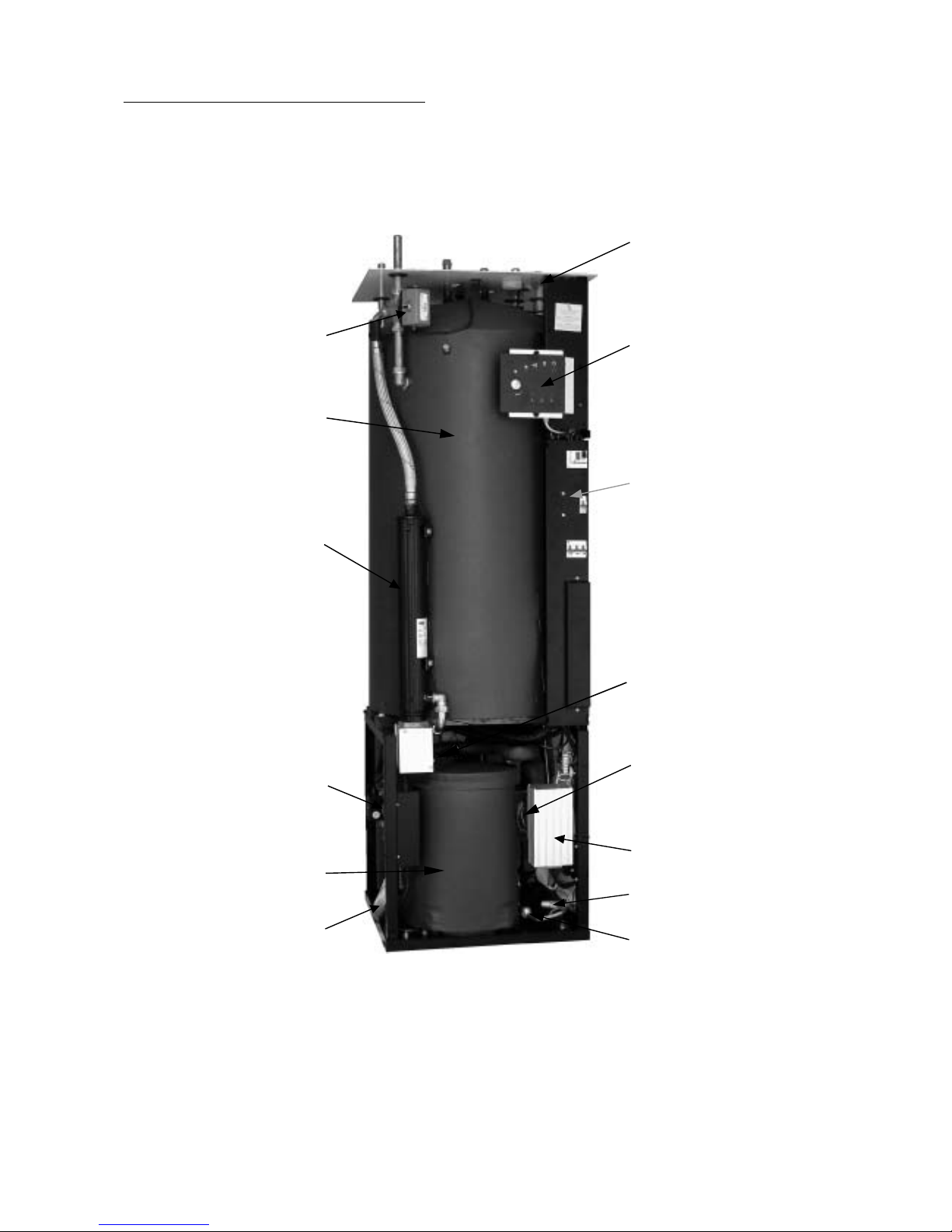

C series components

Please note: The picture shows a 1-phase unit.

3-way valve that switches

between heating and

domestic hot water.

Double-shelled

hot water heater.

Immersion heater.

Reset button for overheat

protection on the immersion heater.

Circulation pump on

the hot side.

Flexible hoses on the hot side

for vibration free operation.

Frequency adapted sound-

proof cover on compressor.

Electrical connection.

Control panel with large

display.

Enclosed electrical box

with motor protection

reset and circuit breaker

for heat pump and immersion heater.

Control unit Rego600.

Insulated corrosion

protected circulation

pump for the heat transfer

fluid system.

Expansion valve.

Sight glass.

Page 8

9

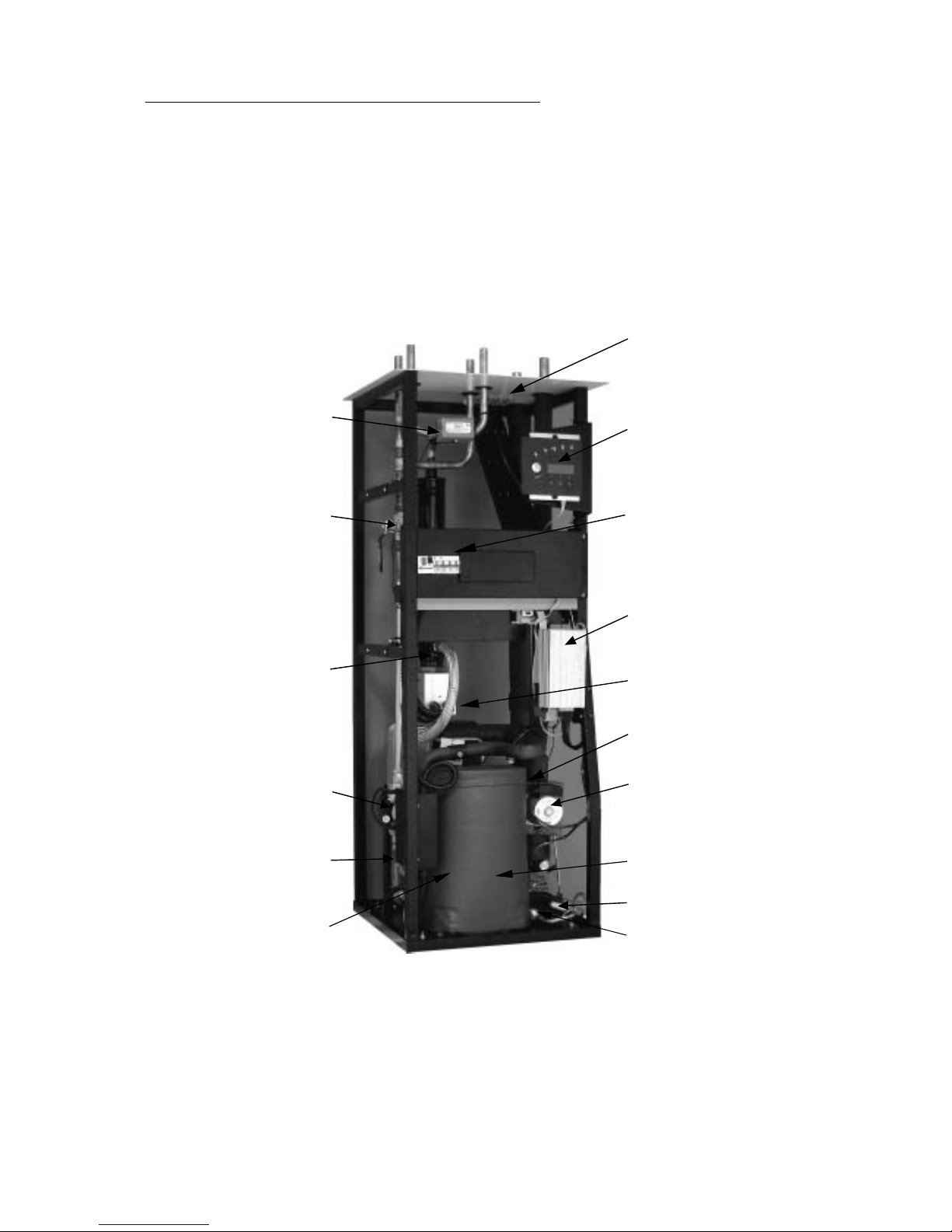

D and E series components

Please note: The picture is of the E series, 1-phase.

The D series has two connections on the hot side and does not include a 3-way valve and immersion

heater. The particle filter is supplied separately and is mounted outside the heat pump.

3-way valve that changes

between heating and

domestic hot water.

Cleanable particle

filter with cut-off.

Immersion heater.

Reset button for overheat protection on the

immersion heater.

Circulation pump

on the hot side.

Flexible hoses on the

hot side for vibration

free operation.

Frequency adapted

soundproof cover.

Electrical connection.

Control panel with

large display.

Enclosed electrical box with

motor protection reset and

circuit breaker for heat pump

and immersion heater.

Control unit Rego600.

Heat exchanger.

Insulated corrosion protected

circulation pump for the heat

transfer fluid system.

Compressor.

Expansion valve.

Sight glass.

Page 9

10

Principle

Principle of heating and hot water control

Your heat pump is fitted with a Rego600 control unit to guarantee you maximum savings and many

years of service. The unit, which has advanced monitoring functions, controls the heating and hot

water in your home. This ensures that all vital functions are monitored and that, if problems arise, the

heat pump is shut down before it is damaged.

When the heat pump is not able to meet the heating requirements, additional heat is connected that

together with the heat pump provides the required temperature. The Greenline C and E series has a

built-in immersion heater that can be connected in three steps. Factory setting is 2/3 electrical output.

The additional heat only provides the output that the heat pump cannot generate and in this way can

never take over heating the house completely. When the heat pump is once more able to meet the

heating demand, the additional heat is automatically switched off. An oil-fired boiler is normally used

to provide additional heat for the Greenline D series. In which case Rego600 controls the oil-fired

boiler and the existing mixing valve.

The heat pump is connected to the heating system’s return flow. The water is heated in the heat pump

and is then fed back to the heating system. While the heat pump is heating the water in the immersion

heater, the heating system is disconnected temporarily through the 3-way valve. A sensor in the hot

water cylinder makes sure that priority is always given to heating the hot water. When the water in the

cylinder reaches the required temperature, heat is once more supplied to the heating system.

Power failure

If the power supply fails, the control unit remembers all its settings and re-starts the heat pump when

the power returns.

Three different operating modes

The control unit can be used for three different operating modes: A, B and C. Please note that the C

series can only utilise operating mode A. The three operating modes are also outlined under Installer.

Operating mode A (C, D and E series)

This is the factory set operating mode based on an outdoor sensor that sends signals to the heat pump

control unit and controls it through an adjustable control curve. Water heating takes priority over

space heating. As well as operating the heat pump, Rego600 can also regulate other heat curves with a

mixing valve, e.g. through a combination of radiator and floor heating systems. An immersion heater is

used for additional heat.

Operating mode B (D series only)

Used when additional heat is from an oil-fired boiler. Operation is the same as for operating mode A.

Rego600 cannot control other heat curves in this operating mode.

Operating mode C (D series only)

Used in exceptional cases, it does not provide optimal operation for the heat pump because it always

works with a high temperature, or Fixed Temperature. This is most commonly used together with

existing electric boilers. This mode of operation is based on the existing electric boiler’s heater being

kept warm by the heat pump and by utilising the existing immersion heater in the boiler.

Page 10

11

Controls

The control unit operates the heat pump in three ways. We call them Curve Control, Room Sensor and

Fixed Temperature. Below follows a brief description.

Curve control (operating modes A and B)

This is the most common mode and is also the factory setting. This means that the heat pump adjusts

the heat in the house based on the outdoor temperature so that the radiator temperature increases as the

outdoor temperature reduces. An outside sensor sends signals to the control unit, which automatically

adjusts the supply of heat to the radiators. To set the temperature of a radiator for a certain outdoor

temperature, you can choose between a number of different curves on the control unit. This maximises

savings, since the heat pump never needs to work at a higher temperature than necessary. The heat

pump only delivers the maximum temperature when heating the hot water. Normally, hot water heating

accounts for 20% of the total annual requirement.

Room sensor (operational modes A and B)

A room sensor can be connected to the heat pump. It sends signals to the control unit and in this way

affects the curve control. The amount of affect the room sensor has on the curve control can be set on

the control panel. The room sensor is normally only used in combination with an outdoor sensor; when

a fan-assisted radiator is used in houses with electric radiators or a fire place, or in houses that are

wind sensitive.

Fixed temperature (operating mode C only)

This control technique is rarely used, and does not offer optimum savings from the heat pump. The

principle is that the heat pump is switched on and off by the built-in return sensor and always works

up to its maximum working temperature. The most common use for this control technique is when

there is a relatively new electric boiler and the heat pump is connected to it. The heat pump heats the

hot water cylinder in the boiler, and any additional heat required is provided by the boiler’ immersion

heater. There are unfortunately not many electric boilers on the market that are suitable for use in

conjunction with a heat pump.

Page 11

12

Control panel

Control panel buttons and displays

The control panel is the heart of your heat pump installation. From the control panel, instructions are

sent to the Rego600 control unit, which ensures that the house is uniformly heated. All settings are

carried out here and the display shows the settings that have been set.

Rego600 K1

020301 12.00.00 Fr

Heat Info Menu

The heat pump is in

operation when this

lamp is lit.

This lamp is lit when

the heat pump needs

additional heat.

This lamp is lit when

hot water is being

heated. It blinks during

hot water peaks and

additional hot water.

This lamp blinks when

a fault has occurred.

This switch is used to

turn the heat pump on

and off. The heat pump

is in operation when

the lamp is lit. The heat

pump is off when it

blinks.

This shows you

which user level

you are in.

This display

shows information

such as text and

temperatures.

Press once to come to

the complete menu for

settings and temperatures.

Press once for

continuous information about operation

conditions for the heat

pump and additional

heat.

Press once for a short

cut to the heat

settings.

This knob is used

to navigate the

menu and to

change settings.

Page 12

13

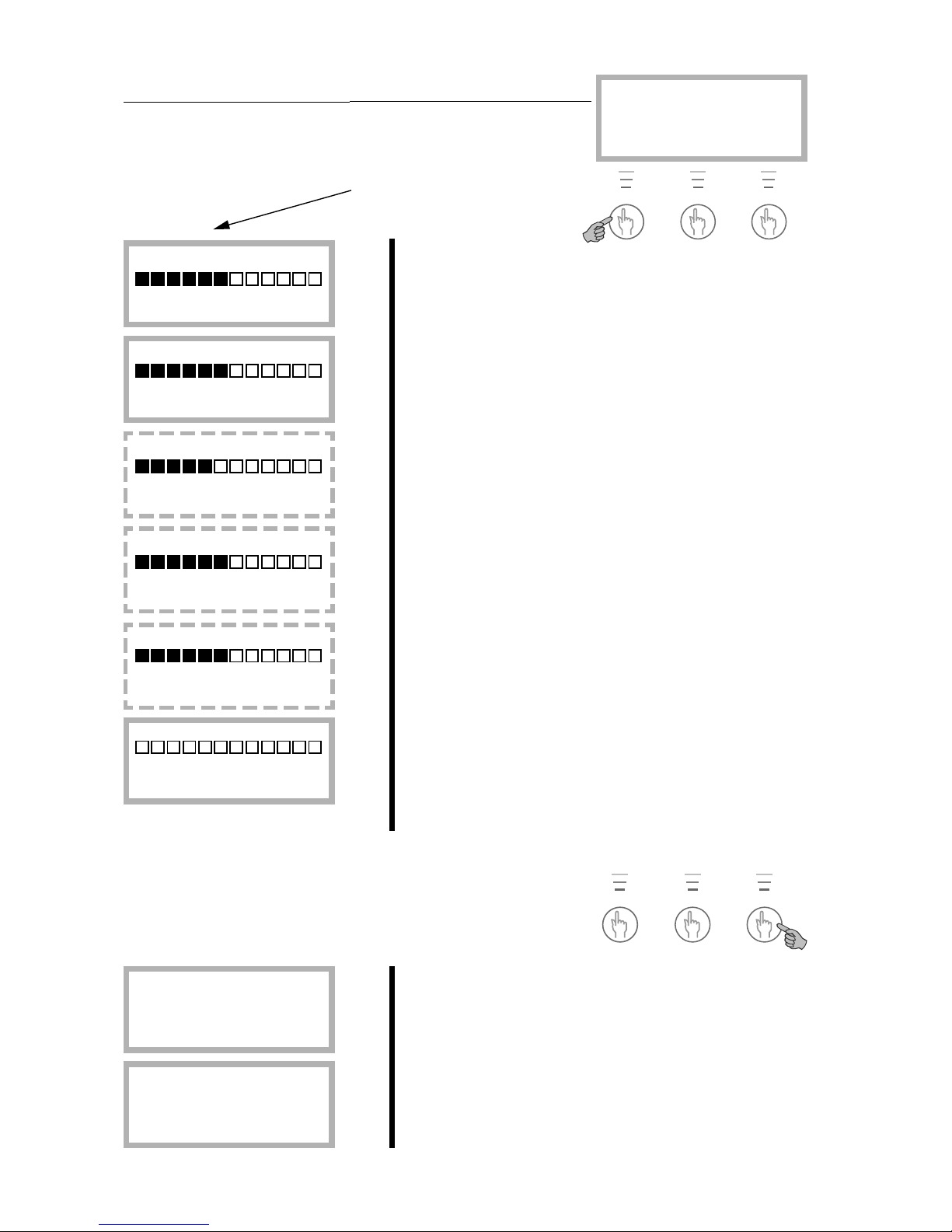

How to use the control panel

With three buttons and a knob you can navigate to the various displays for settings and readings. The

last line at the bottom of the display contains information about the functions of the buttons in the

current display. If you choose Heat or Info the display you have chosen to stay in will always remain.

Examples of scrolling information

Here are some of the displays you see if you choose scrolling information with the Info button:

Heat pump is not operating.

The heat pump is producing hot water and you see the

current temperature and the temperature it stops at.

The heat pump and additional heat is in operation.

A need for heat has arisen and the heat pump is waiting for

the reset time to count down to zero.

STANDBY

No rad heat required

No hotwater required

HOT WATER MODE

Heat pump only

Stop temp 47.5°

Present temp 42.0°

HEAT RAD MODE

Compr. + Add. heat

Stop temp 45.0°

Present temp 44.0°

HEAT RAD REQ

Heat pump starts

in 320 seconds

Press “Heat” once and

you come to the shortcut

for heat settings. You can

choose to stay in which

display you want.

Press “Info” once and you receive continuous information about what

the heat pump is doing and at which temperature it stops. You can

choose to remain in this display and always receive this information.

Press the middle button again to return to the first display.

Press “Menu” once and

you come to the main

menu for settings or

temperature readings.

With the knob

you navigate up

and down between the displays or change

the settings.

Rego600 K1

020301 12:00:00 Fr

Värme Info Meny

Page 13

14

Basic functions (at customer level 1)

Heating and extra hot water

Press Heat to come to the short cut to the heat settings. These displays

are then available.

House heating settings in areas 0 to 10. See more detailed

description in Heat Settings chapter.

Fine adjustment settings in areas -10 to +10. See more

detailed description in Heat Settings chapter.

Here you can set the heat in areas 0 to 10 if you use an extra

heat curve with a mixing valve.

Here you set the fine adjustment of the mixing valve curve

in –10°C to 10°C.

If a room sensor is connected you can set the required room

temperature here. At customer level 2 you can set how

much you want the sensor to affect the heating system.

You can temporarily increase the hot water temperature

with the electric water heater here. The heat pump first

increases it to around 50° and then the electric water heater

to around 65°. The electric heater starts again at 60° and

increases the temperature to 65° in set time. The area is 148 hours and when the set time has passed, the normal

operation is resumed.

Temperatures

Press “Menu” to come to the main menu. Where you can also

carry out heat settings and see the temperatures. These

displays are then available.

The radiator temperature settings you make in the short cut

to Heat you can also make in line 1 and hot water setting in

line 2.

In line 3 you can see all the temperatures where sensors are

connected.

With

extra

sensor

only

With

extra

sensor

only

With

extra

sensor

only

Operating

mode A

only

Extra DHW:

1hr 20hrs 48hrs

Return Adjust

Room temperature

10° 20° 30°

Return Adjust

Mix. valve fine-tune

-10° 0,0° 10°

Return Adjust

Mix. valve incr/decr

0 4 10

Return Adjust

Temp. fine-tune

-10° 0,0° 10°

Return Adjust

Temp. incr. / decr.

0 4 10

Return Adjust

Main menu

Monitor all

temperatures 3

Return Select

Main menu

Indoor temperature

settings 1

Return Select

Rego600 K1

020312 12.00.00 Ti

Heat Info Menu

Page 14

15

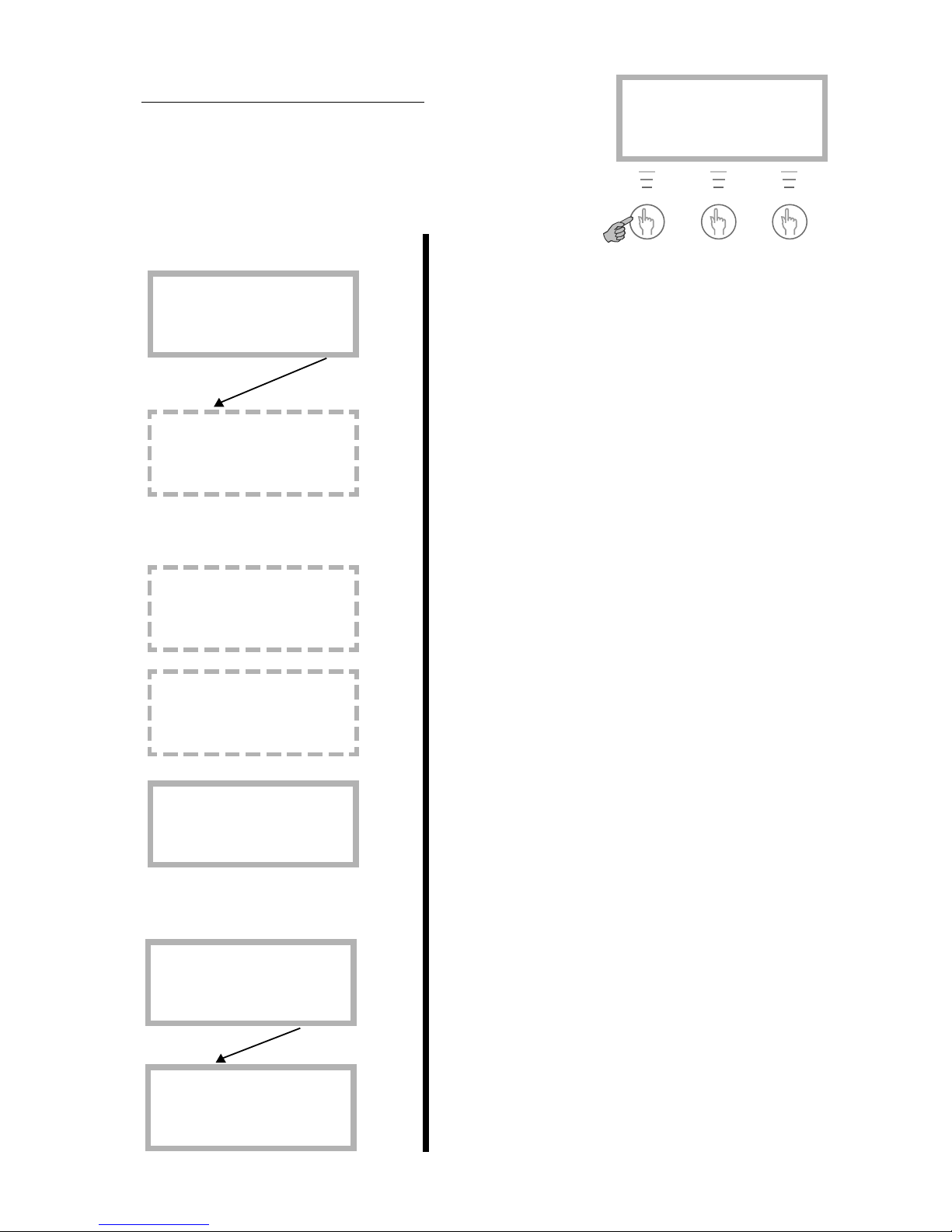

Enhanced functions

As user you have access to extra functions. Keep the Heat button

pressed down for five seconds and go into Menu to gain access to

these displays. You will automatically return to level 1 again after

30 seconds.

Keep the button pressed down for 5 seconds.

You have pressed Menu and are on row 1. Press “Select”

and turn the knob and the displays scroll up. You can then

choose to enter the display you require. Each display has a

number.

With a room sensor installed you can set the value of how

much you want it to affect the outdoor sensor. A high value

gives more affect from the room sensor. Please note the

room sensor only fine tunes the heat curve. It is therefore

important that you set the basic settings for the heat curve

and fine tuning from the start.

If a room sensor is installed you can set the number of days

that the room temperature is lowered to 15°C here. The

temperature is not adjustable and it does not affect the hot

water. Normal operation is resumed when the period is

over.

If a room sensor and remote control is installed you can set

the required room temperature here. You can then use the

telephone to increase the temperature to normal.

This equipment is available as an accessory.

At this set temperature the heat pump only produces hot

water.

Line 1

Only

with

extra

sensor

and at

operating

mode A

only

With extra

sensor

only

With extra

sensor ,

remote

control

and at

operating

mode A

only

At

operating

modes A

and B

only

At

operating

mode A

only

Using the knob you have moved to the hot water settings in

row 2.

Setting for intervals for the continual raising of the hot

water temperature. If you choose for example7 days, the

temperature is raised using the electric water heater once a

week to around 65°C (Operating mode A with electric

water heater only).

Line 2

Hot water setting

Interval for

hot water peak 2.2

Return Select

Main menu

Adjusting the hot

water settings 2

Return Select

Temperature settings

Setting of summer

disconnection 1.14

Return Select

Temperature settings

Remote control

temperature 1.13

Return Select

Temperature settings

Setting of holiday

function 1.12

Return Select

Temperature settings

Setting of room

sensor infl. 1.11

Return Select

Main menu

Indoor temperature

settings 1

Return Select

Rego600 K2

020312 12.00.00 Ti

Heat Info Menu

Page 15

16

Line 4

You have now moved to timer control settings line 4.

Here you can set the times day for day that you want to

utilise the clock settings. You can set all the weekdays

independent of each other. Press “Select”.

The example describes how you set Monday between 22:00

and 06:00. Press “Adjust”.

There is now a cursor under Monday. Turn the knob and mo

becomes Mo. Monday is now activated.

Now set the clock setting for between 22:00 and 06:00 in

the morning. Press the right arrow button until the cursor is

under the first 00. Turn the knob until 22:00 appears. Press

the button twice more (the cursor moves two steps to the

right) and turn the knob until 06:00 appears. Press the right

arrow button once more and the arrow is replaced by Save.

Press “Save” to set the timer controls.

You can now do the same for all the other days of the week

you want to timer control. Use the knob in this display to

come to the other days.

In display 4.1.1 you set how much you want the temperature

to be raised or lowered in the above time zone settings. If

you choose for example -5°C, the heating system temperature is lowered by 5°C.

In display 4.3 you can disconnect the hot water completely

during e.g. peak rate times. This is done in the same way as

with the heat pump time controls.

Not

operating

mode C

Clock setting

Clock setting DHW

accord. to clock 4.3

Return Select

Clock setting

Setting level

heat pump +/- 4.1.1

Return Select

Clock setting HP 1

Mo 22:00-06:00

Return Adjust

Clock setting HP 1

Mo 22:00-06:00

^^

Cancel <- ->

Clock setting HP 1

Mo 00:0000:00 ^^

Cancel ->

Clock setting HP 1

Mo 00:00-00:00

Return Adjust

Clock setting

Clock setting HP

accord. to clock 4.1

Return Select

Main menu

Timer control

settings 4

Return Select

Page 16

17

Line 7

Not

operating

mode C

In line 7 you can read the running times for the heat pump

and additional heat. Press “Select” to enter these menus.

Here you can see how many hours the heat pump has been in

operation.

This shows the distribution of the heat pump between hot

water and heating in percentage.

Here you can see how many hours the additional heat has

been in operation.

This shows the distribution of the additional heat between

hot water and heating in percentage.

You can set the clock to the correct time if it is wrong.

Line 11 shows a record of the alarms that may have occurred

on your heat pump. You can see the type of alarm and when

it occurred. An * in the display means the alarm is still

active.

If you want to change your settings at customer levels 1 and

2 you can return to factory settings on line 12.

Please note: If you at the level for installer/service when you

choose factory settings, the installer must carry out a new

start-up of the plant with new settings. The installer/service

level is for installer only. As end-user you must never go into

this level!

Not

operating

mode C

Line 10

Line 11

Line 12

Main menu

Return to

factory settings 12

Return Select

Main menu

Alarm logging

of all alarms 11

Return Select

Main menu

Clock, setting

time and date 10

Return Select

Op. time readings

Distribut. add. heat

DHW-Rad in % 7.4

Return Select

Op. time readings

Add. heat in operat.

number of hours? 7.3

Return Select

Op. time readings

Distribution HP

DHW-Rad in % 7.2

Return Select

Op. time readings

Heat pump in operat.

number of hours? 7.1

Return Select

Main menu

Op. time readings on

HP and add. heat 7

Return Select

Page 17

18

Setting the heating

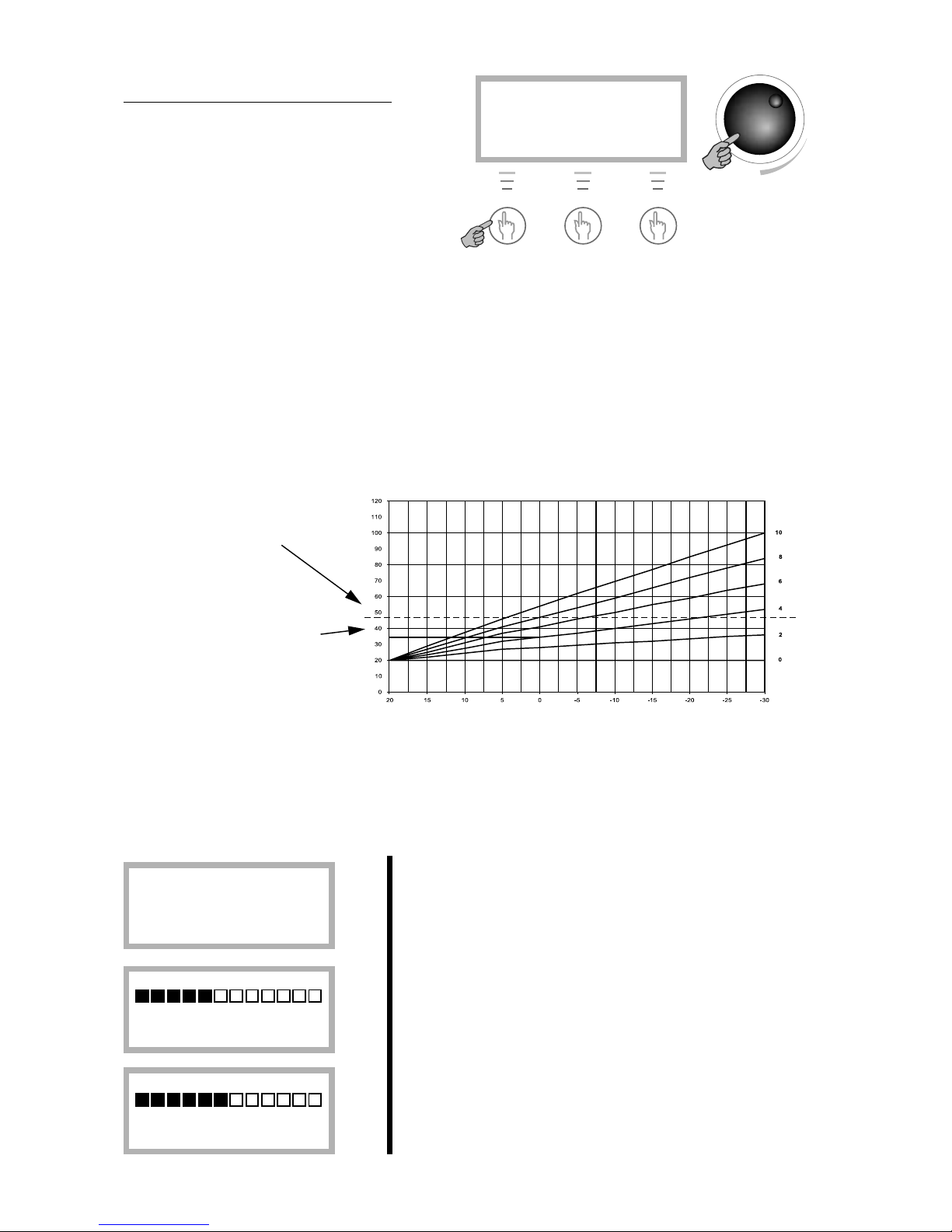

In the Temperature increase/decrease display

you use the knob to change the heat curve.

The lines show how the return temperature

varies with the outdoor temperature for

different settings. The colder the weather the

warmer the heating system. Curve 4 is the

factory setting and in the example you can see

that this gives a return temperature of around

35

o

C at an outdoor temperature of 0oC.

The example describes how to change the heat curve in the Heating increase/decrease menu.

Please note that a high value could cause the heat pump to stop if the return temperature is too high.

Heat curve

Radiator return

temperature

Setting

Outdoor temperature

The appearance of the heat curve

The limit for when the

heat pump stops for too

high a return temperature.

The line shows that if heat

curve 4 is chosen, the heat

pump stops at around 35

o

C

when the outdoor temperature

is 0

o

C.

Cold weather:

If the indoor temperature is too low or too high during cold

weather, you use Temp. incr./decr. to change it.

Press “Heat”.

The set value is shown in the display. In the shape of a bar

but also as a digit. The area is between 0 and 10. Press

“Adjust”.

Turn the knob to the right to increase, to the left to decrease.

The example shows how you increase the value to 5. Turn

the knob until 5 appears in the display. The new value now

appears in the display. Press “Save” to save the new value.

Rego600 K1

020312 12.00.00 Ti

Heat Info Menu

Temp. incr. / decr.

0 4 10

Return Adjust

Temp. incr. / decr.

0 5 10

Return Save

Rego600 K1

020312 12.00.00 Ti

Heat Info Menu

Please note that the flow temperature is then around 7-10oC warmer. During the first winter, the heat

curve must be set up so that the temperature in the house is pleasant whatever the weather. The heat curve

should preferably be adjusted at a low temperature under 3

o

C. You should wait two days after adjusting

before carrying out any readjustments. Also note that a lower curve setting gives a lower runnig cost.

Page 18

19

Warm weather:

If the indoor temperature is too low or too high during warm

weather, you use fine tuning to change it. You come to

“Temp. fine-tune” by pressing “Heat” and turning the knob

to the right.

Fine tuning can be set in areas –10°C to 10°C. You change

the fine tuning in the same way as “Temp. increase/decrease” as described on the previous page.

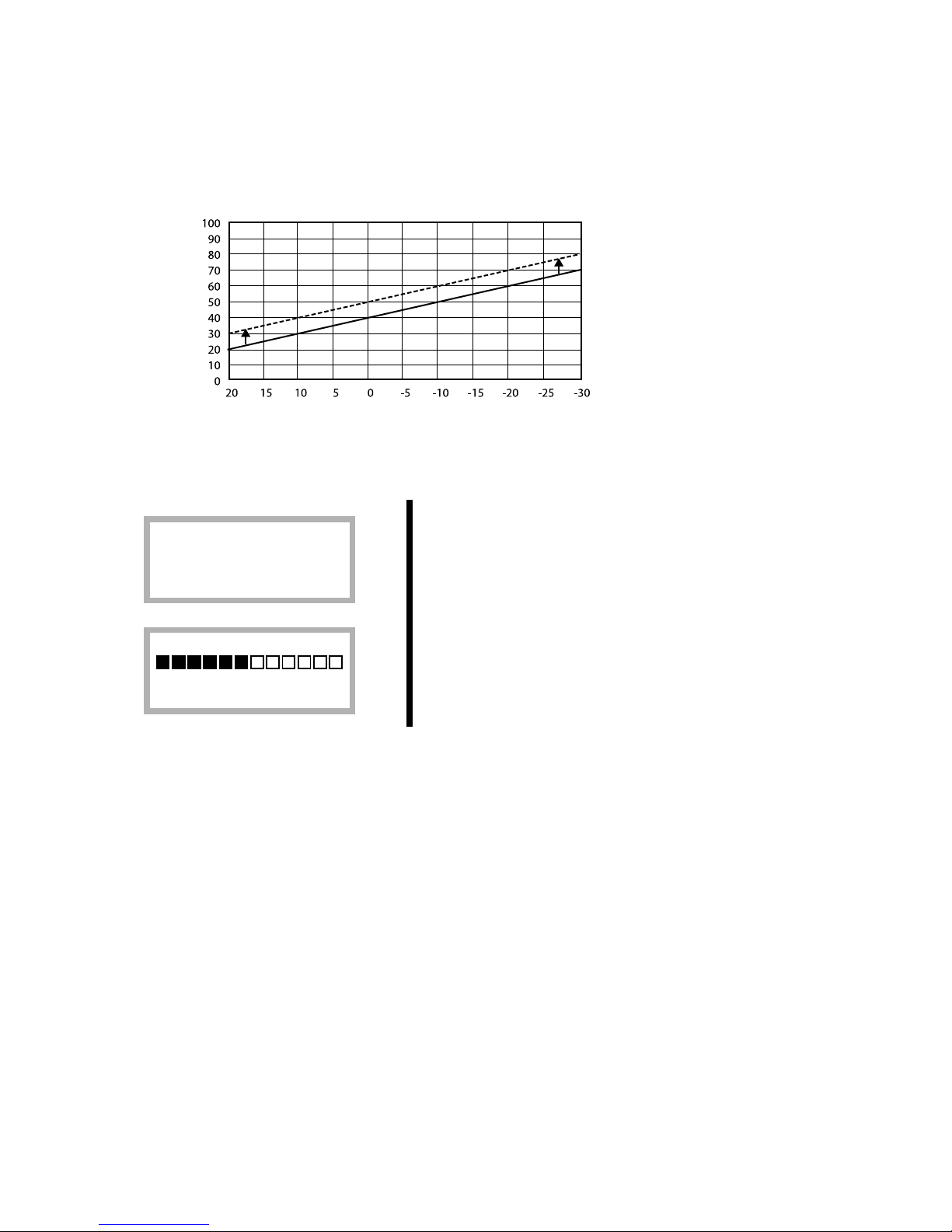

The heat curve can also be fine tuned. You do this in the Temp. fine tune display. The dotted line illustrates how the parallel offset has been turned towards plus. The entire curve moves upwards, in contrast

to increasing the slope, when only the slope changes.

Rego600 K1

020312 12.00.00 Ti

Heat Info Menu

Temp. fine-tune

-10° 0,0° 10°

Return Adjust

The dotted line illustrates

how the fine tuning adjustment has been turned

towards plus.

Fine tuning adjustment

Radiator return

temperature

Outdoor temperature

Page 19

20

Fixed temperature (D series only)

If the heat pump is set at operating mode C with a fixed temperature, then it can only be engaged and

disengaged by the built-in return sensor. There are two displays available for this mode. Please note

that if a mixing valve is connected to the heat pump, the Temp. incr/decre and Temp. fine tune displays

control the settings for the mixing valve opening to the heating system.

To adjust the engaging and disengaging temperature, press

“Menu” followed by “Select”. You are now in line 1.

Use the knob to navigate to display 1.16 and press “Select”.

The factory setting is 48°C. Please note that this concerns

the return temperature to the heat pump. The temperature

from the pump is normally 5-10C higher. Settings above

48°C are not allowed for technical reasons.

You can also set the difference between starting and

stopping the heat pump in display 1.17. The factory setting

is 5°C. A lower setting gives more frequent starts and stops

for the heat pump. Press “Select” to adjust.

Simple tips for saving

The lower you can keep the temperature of the radiators in the house, the better your heating economy

will be. So take make sure not to set your heat curve too high. Operate your heating system as efficiently as possible by making sure that the entire surface of your radiators or your underfloor heating

coils are kept hot.

Thermostatic valves on your radiators or underfloor heating may have a negative effect on your

heating system because they restrict the flow so that the system has to compensate with a higher water

temperature. If thermostat valves are fitted, they should be fully opened, except in bedrooms, where

they can be turned down slightly.

Temperature settings

Return thermostat

stop temp sett. 1.16

Return Select

Return thermos. stop

30° 48,0° 50°

Return Adjust

Temperature settings

Return thermostat

hysteresis set 1.17

Return Select

Rego600 K1

020312 12.00.00 Ti

Heat Info Menu

Page 20

21

All sensor temperatures

Below are the various sensor temperatures that are visible under line 3 in the control panel. Note that

not all the sensors are standard but are available as accessories for different areas of use. To get there

press ”Menu” in the control panel and then turn the knob to line 3. Then press ”Select”.

Shows the temperature of the heating system return flow.

This varies depending on the outdoor temperature.

Shows the outdoor temperature.

Shows the temperature in the outer container of the electric

water heater’s bottom part. This temperature is around 5°C

lower than the temperature in the hot water tank.

If an extra mixing valve is used for e.g. floor heating then

the flow pipe is visible on the circuit. It varies with the

outdoor temperature.

If a room sensor is used, you see the temperature of the

room where the sensor is located.

The sensor shows the working temperature of the compressor. It varies between around 70°C and 125°C.

The sensor shows the outgoing temperature from the heat

pump. It varies depending on the outdoor temperature and if

the heat pump is in hot water production mode.

The sensor shows the ingoing temperature to the heat pump.

It varies as mentioned above. Please note that for safety

reasons the heat pump stops when this shows a temperature

of more than 48°C.

The sensor shows the temperature from the bore hole or the

ground. It normally varies between -5°C and 8°C throughout

the year.

The sensor shows the temperature to the bore hole or the

ground. It is normally 1.5°C till 5°C lower than heat transfer

in.

Line 3

Standard

Standard

Only in Cserie

Accessories

Accessories

Standard

Standard

Standard

Standard

Standard

Temperature readings

Return radiator GT1

Off ##,#° Now ##,#°

Return

Temperature readings

Out GT2

###,#°

Return

Temperature readings

Hot water GT3

Off ##,#° Now ##,#°

Return

Temperature readings

Shunt, flow GT4

Tgt ##,#° Now ##,#°

Return

Temperature readings

Room GT5

Tgt ##,#° Now ##,#°

Return

Temperature readings

Compressor GT6

###,#°

Return

Temperature readings

Heat trfluid out GT8

###,#°

Return

Temperature readings

Heat tr fluid in GT9

###,#°

Return

Temperature reading

Ht trfld(coll)inGT10

###,#°

Return

Temperature reading

Httrfld(coll)outGT11

###,#°

Return

Page 21

22

If something is wrong

The control unit provides a lot of information about faults and how to remedy them. The control unit

incorporates advanced functions to monitor and protect your heat pump. This means there is no risk

involved in resetting an alarm. If a fault persists, you should contact the installer.

Alarm examples and what to do

If the control panel is dark

Possible faults:

• The fuses or MCBs (miniature circuit-breakers) in your fuse box.

This is what to do: Check the fuse (or MCB) for your heat pump. If the small plate at the bottom of

the fuse has come off, the fuse has blown and must be replaced. If you have MCBs, and they have

tripped, move the switch to the up position.

Note that the heat pump cannot restart until after 15 minutes. This delay is needed for technical

reasons!

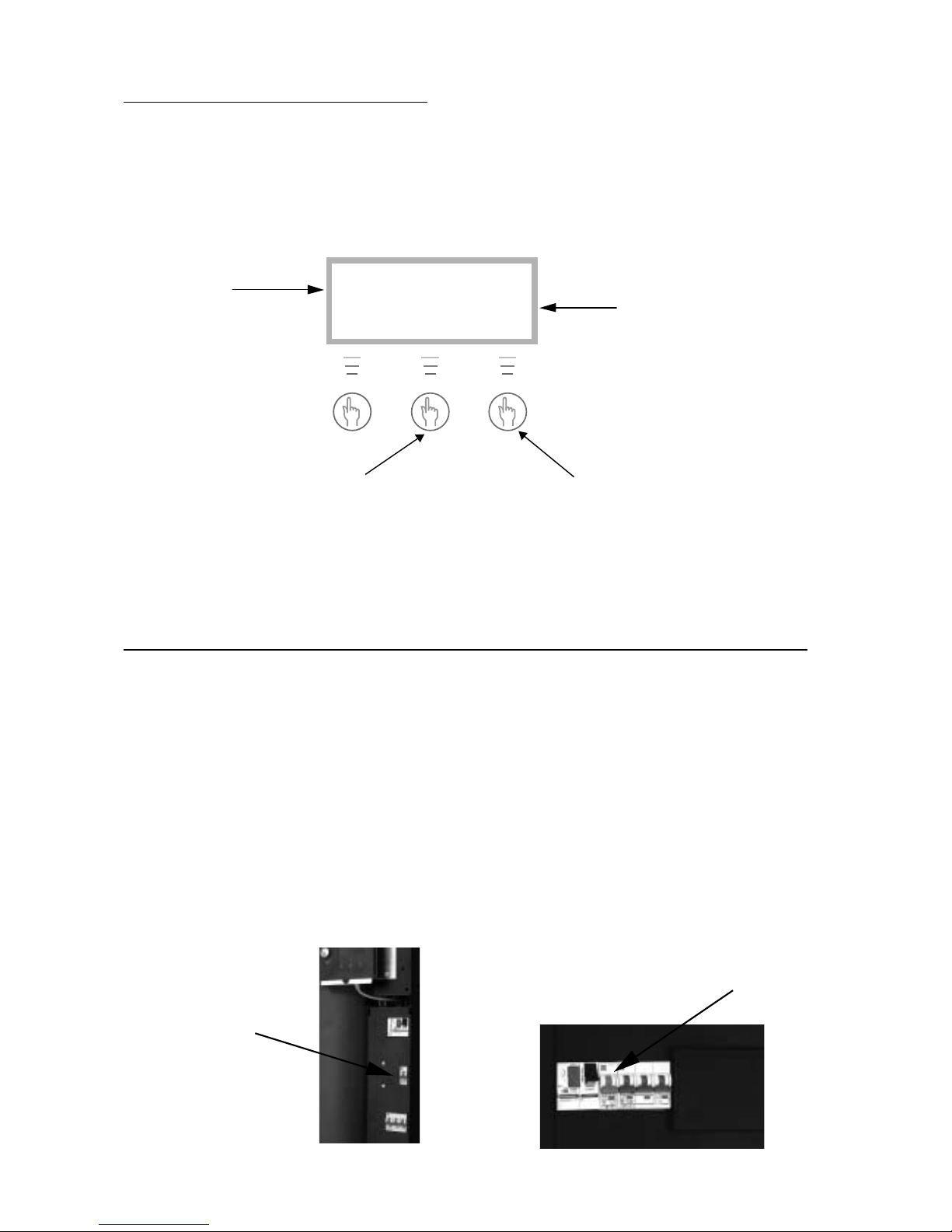

• If the heat pump MCB has tripped, this is what to do:

Press ”Ackn” and the fault is remedied,

the alarm lamp goes off and the heat

pump starts again within 15 minutes. If

the lamp is lit with a steady glow then

the alarm is remedied but the fault

remains. If several alarms have triggered, use the knob to navigate to them.

If you press ”Info” and then turn

the knob you will see information about the possible causes

and how you can remedy the

fault yourself.

ALARM

Power failure

020312 16.08.15

Info Ackn.

Time and date for when the

fault occurred.

Cause

On D and E series:

Reset by pushing the

toggle to the up position.

The C series

Reset by pushing the

toggle to the up position.

Page 22

23

All alarms

Below is a description of the alarms that can appear in the menu display. The description gives an idea

of what the fault is and what you yourself can check and remedy. An alarm can sometimes occur

temporarily so there is never any risk with resetting it. If a fault persists, you should contact the

installer.

The description sometimes refers to a heat pump component. Pages 28 and 29 have details of where to

find the components.

COMPRESSOR MOTOR CUTOUT SWITCH ALARM

To reset the alarm:

Reset the motor cutout by pressing in the black button (position

2) Then press ”Ackn”. NOTE: The lamp goes out even if the

motor cutout has not been reset. (Model C4 have built-in

temperature protection in the compressor that resets automatically when the temperature has reduced).

ALARM (MB1)

Compr. circ. switch

020312 16.08.15

Info Ackn.

Probable causes and actions:

• Sporadic fault or overloading of the power supply.

Action: Reset the motor cutout and wait and see. (Not model C4)

• The current setting of the motor cutout is too low. The compressor’s current intensity varies during

summer/winter operation. (Not model C4)

Action: Contact the installer.

• Contactor or cutout faulty, or loose electrical connections to the compressor.

Action: Contact the installer.

• Compressor faulty.

Action: Contact the installer.

ALARM (MB2)

HTF circ-pump switch

020312 16.08.15

Info Ackn.

HEAT TRANSFER FLUID CIRCULATION PUMP

SWITCH ALARM

To reset the alarm: Press ”Ackn”. (11 kW-models have built-in

motor cutout in the pump that resets automatically after a period

of time. The MB2-alarm is not shown in other models). Note

that the lamp goes out even if the motor cutout has not been

reset.

Probable causes and actions:

• The pump has stopped because of contaminants.

Action: If the pump has an air vent screw it can be loosened and the pump restarted with a screwdriver.

• Fault in the pump’s electric motor.

Action: Contact the installer.

• Temporary fault.

Action: If the fault persists, contact the installer.

Page 23

24

ALARM ON PRESSURE SWITCH LOW

To reset the alarm: Press ”Ackn”.

ALARM (LP)

Low pressure switch

020312 16.08.15

Info Ackn.

Probable causes and actions:

• Air in the heating system.

Action:Check the expansion vessel and fill if required. If air is heard continuously in the system,

contact the installer.

• Heat transfer pump has stopped or is set at too low a speed.

Action: Check the pump has not stopped or is set at the wrong speed.

• Particle filter on the cold side has clogged.

Action: Check the filter and clean if required.

• Not enough refrigerant in the circuit.

Action: Check that bubbles do not appear continuously in the sight glass. Contact the installer.

• Not enough antifreeze in the heat transfer circuit creating ice in the heat exchanger.

Action: Contact the installer.

• Expansion valve faulty (alarms occur at long intervals, about every three or four weeks).

Action: Contact the installer.

HIGH PRESSURE SWITCH ALARM

To reset the alarm: Press ”Ackn”.

ALARM (HP)

High pressure switch

020312 16.08.15

Info Ackn.

Probable causes and actions:

• Air in the heating system.

Action: Check the system and vent the radiators if necessary.

• Not enough flow over the heat pump.

Action: Check that the circulation pump has not stopped and that a valve in the system is not

shut.

• Hot side particle filter clogged.

Action: Check the filter and clean if required.

• Refrigerant circuit over-filled.

Action: Contact the installer.

• Drying filter clogged.

Action: Contact the installer.

Page 24

25

ALARM ON COMPRESSOR SUPERHEAT

To reset the alarm: Press “Ackn”.

Probable causes and actions:

• The working temperature of the compressor is too high.

Action: If the fault persists, contact the installer.

• Sporadic temperature rise due to abnormal operating conditions.

Action: Wait and see.

ALARM (GT6)

Compressor superheat

020312 16.08.15

Info Ackn.

PHASE SEQUENCE FAULT ALARM

(Only 3-phase units)

To reset the alarm: The alarm does not reset until the phase

sequence has been changed. Then the heat pump starts

automatically.

Probable causes and actions:

• Phase sequence to the heat pump is incorrect.

Action: The phase sequence to the incoming supply must be changed.

POWER FAILURE ALARM

To reset the alarm: The alarm resets itself and the heat

pump starts automatically when the fault has been corrected.

Probable causes and actions:

• One or two phases are missing to the heat pump.

Action: Check the fuse (or MCB) for your heat pump. If the small plate at the bottom has come loose

then the fuse is broken and must be replaced. If you have ciruit breakers that have tripped, reset by

pushing the switch upwards.

ELECTRIC WATER HEATER ALARM

To reset the alarm: Reset water heater’s MCB (pos 4) or

overheat protection (pos 5). Press “Ackn”.

Probable causes and actions:

• The electric water heater MCB has tripped

Action: Reset the MCB by pushing the switch upwards. If the MCB trips again then the water heater

is probably faulty, contact the installer.

• The electric water heater overheat protection has tripped

Action: Reset by pressing the button on heater’s protective cover until it clicks. It could depend on a

bad flow over the heater caused by the circulation pump standing still or clogged particle filter. Check

the filter and circulation pump.

ALARM (EK)

Electrical cassette

020312 16.08.15

Info Ackn.

ALARM

Power failure

020312 16.08.15

Info Ackn.

ALARM

3-phase incorrect

020312 16.08.15

Info Ackn.

Page 25

26

ALARM, HIGH RETURN TO THE HEAT PUMP

To reset the alarm: The alarm resets itself and the heat pump

starts automatically when the temperature has dropped.

ALARM (GT9)

High return HP

020312 16.08.15

Info Ackn.

Probable causes and actions:

The heat pump has a sensor that stops the heat pump for safety reasons when the return temperature is too

high, about 48°C.

• The temp. incr/decr knob is set so high that the heating system return temperature goes too high.

Action: Reduce the temp. setting.

• The hot water temperature is set too high.

Action: Contact the installer.

• The radiator or underfloor heating system valves are closed.

Action: Open the valves.

• The flow across the heat pump is greater than the flow in the heating system.

Action: Reduce the speed of the circulation pump in the heat pump or increase the speed of the

mainpump in the heating system. Contact the installer.

SENSOR ALARM

To reset the alarm: The alarm resets itself and the heat pump

starts automatically when the fault has been corrected.

ALARM (GT1)

Sensor return rad.

020312 16.08.15

Info Ackn.

Probable causes and actions:

Alarm if a sensor fault can be indicated for all sensors that are connected to the heat pump. The example

shows the alarm for the Return radiator, GT1 sensor. The principle is the same for all sensor alarms.

• Temporary fault.

Action: Wait and see.

• Short circuit or disconnected to sensor.

Action: If you have an instrument that can measure resistance, you can check the resistance of the

circuit and compare with the table for sensors in Technical spec. If not, contact the installer.

• Faulty sensor or faulty connection.

Action: Contact the installer.

HEAT TRANSFER FLUID SYSTEM OUT MAX ALARM

To reset the alarm: The alarm resets itself and the heat pump

starts automatically when the temperature has dropped.

ALARM (GT8)

Heat tran. fluid out

020312 16.08.15

Info Ackn.

Probable causes and actions:

The heat pump has a sensor that stops the pump for safety reasons when the outgoing temperature is too

high at around 75

o

C.

• Not enough flow over the heat pump.

Action: Check that the circulation pump has not stopped and that a valve in the system is not closed.

• Hot side particle filter clogged.

Action: Check the filter and clean if required.

Page 26

27

Maintaining your heat pump

Your heat pump normally requires little maintenance, but we recommend occasional checking to ensure

that your heating installation give the best possible performance. The description sometimes refers to a

heat pump component. You find these on the following pages.

Working on the heat pump

• Switch off the electrical supply before commencing work on the heat pump. Usually there is an

isolating switch on the wall before the heat pump.

• Only an accredited refrigeration company is permitted to work on the refrigerant circuit. The installa-

tion contains gases that may form toxic fumes when combined with discharges and naked flames. The

gas that forms may cause choking even at low concentrations. If it should leak, evacuate the room

until it has been thoroughly aired.

Normal maintenance

Points to check a few times a year:

• Sight glass (pos 6). When the heat pump starts, and during rapid temperature changes, you can

sometimes see bubbles in the liquid in the refrigerant circuit for a minute or so. This is normal.

If there are always bubbles in the sight glass: Contact the installer.

Sight glass

• Expansion vessel. A plastic expansion vessel is connected to the heat pump heat transfer fluid

circuit. The level of the vessel must not fall below1/3 (the vessel is mounted outside the heat pump).

Too low fluid level: With the pump working, remove the lid to the valve at the top of the vessel and open

the valve. Fill with antifreeze or clean water (simplest with a watering can). Shut the valve again and

screw on the lid.

Ball valve with lid

• Particle filter (pos 1, only built-in in the E series on the hot side). The particle filter, which is con-

nected on both the hot and cold sides of the heat pump protect the heat exchangers from dirt. Some-

times these filters may get clogged and cause malfunctions.

Do this when checking: Shut down the heat pump with the on/off button on the control panel. Close the

valve and unscrew the sealing cover. Check for dirt in the filter. If necessary, remove the circlip that

retains the filter. The simplest way to do this is by using pliers. Remove the filter and flush it clean with

water. Refit the filter, circlip and cover. Open the valve and start the heat pump. Note that the particle

filter in the E series is mounted inside the heat pump. On the cold side and in the C and D series the

filters are outside the heat pump.

Particle filter

Page 27

28

The various parts in the C series

Please note: The picture shows a 1-phase unit.

Control safety anode

(Only for models with stainless hot water cylinder)

At the top of the hot water cylinder, under the insulation, there is an electronic protection anod (standard

feature) Its purpose is to prevent corrosion. The cylinder must be full of water for the anode to work.

If the heat pump is equipped with a magnesium anode, the anode can corrode depending on the water

quality. If its diameter has been reduced to a minimum it must be replaced. This is how you check the

magnesium anode:

1. Shut off the main cold water feed.

2. Turn on a tap to reduce the pressure in the water cylinder.

3. Unscrew the anode and check it.

If the anode is electronic there is a control panel with LEDs where you can see the status of the anode. It

shows a red or a green light. If the LED shows green, the anode is operating and working normally. If

large amounts of hot water are drawn off (when filling a bath for instance) the LED may show a red light

for a short time even though there is no fault. If the LED shows red for more than 10 hours, the anode is

faulty and a service engineer must be called.

Electronic anode Control panel with LEDs Magnesium anode

Pos 2

Reset, motor cutout

compressor.

Pos 3

Reset heat pump breaker

heat pump.

Pos 4

Reset circuit breaker

electric water heater.

Pos 5

Reset button for overheat protection on the

immersion heater.

Pos 6

Sight glass.

Page 28

29

The various parts in the D and E series

Please note: The picture is of the E series, 1-phase.

Pos 1

Cleanable particle filter

with cut-off

Pos 2

Reset, motor cutout

compressor.

Pos 3

Reset circuit

breaker heat pump.

Pos 4

Reset circuit

breaker immersion

heater.

Pos 5

Reset button for

overheat protection

on the immersion

heater.

Pos 6

Sight glass.

Page 29

30

What the shipment includes

Standard components

• heat pump unit with the necessary safety functions and electrical components

• factory mounted control unit Rego600. Rego600 can be used for simultaneous operation

together with an immersion heater or oil-fired or electric boiler with mixing valve.

• sensor radiator return, GT1 (packed separately).

• sensor hot water, GT3 (C series).

• sensor out, GT2 (packed separately).

• sensor, compressor, GT6.

• sensor heat transfer fluid out, GT8.

• sensor heat transfer fluid in, GT9.

• sensor heat transfer fluid (collector ) in, GT10.

• sensor heat transfer fluid (collector ) out, GT11.

• pump for heat transfer fluid and heat transfer circuits.

• built-in, flexible hoses on the heat transfer circuit.

• particle filter with shut off for heating and heat transfer fluid side (packed separately in C

and D series).

• expansion vessel and safety valve for heat transfer fluid circuit (packed separately).

• soundproof cover on compressor

Accessories

• sensor hot water, GT3 (D and E series).

• sensor flow duct mixing curve, GT4.

• room sensor, GT5.

General

Temperatures

Note that the heat pump can work to a maximum return temperature of around 48°C. Anything over

this and the heat pump stops for safety reasons. The maximum outgoing temperature from the heat

pump is around 55°C. A higher temperature can be achieved using an immersion heater.

Particle filter

The particle filter supplied must always be fitted in the input pipe of the hot side as close as possible

to the heat pump, and horizontally. The filter is mounted on the heat transfer side in the E series. The

filters is separately packed on the heat transfer fluid side.

Transportation

The heat pump must always be transported and stored upright and dry. The heat pump can be placed

on its back temporarily for moving into place of installation.

Positioning

Place the heat pump on a flat base and adjust the rubber feet until it is level. Avoid installing the heat

pump close to sensitive walls such as bedroom walls, since the pump produces a certain amount of

noise when running. The room must have a floor drain. Installation must comply with local construction regulations.

Page 30

31

Dimensions and connections, C series

Dimensions are given in mm

(1) Return radiator

(2) Riser radiator

(3) Cold water in

(4) Hot water out

(5) Heat transfer fluid in

(6) Heat transfer fluid out

Electrical

connections

Front

®®®

®

(1)

(2)

(3)

(4)

(6)

(5)

600

®®

®® ® ®

®

®

®

85 240 360 460 525

85

65

500

600

345

225

40

1770

Page 31

32

Dimensions and connections, D and E series

Dimensions are given in mm

(1) Return radiator

(2) Riser radiator

(3) Return DHWC

(4) Riser DHWC

(5) Heat transfer fluid out

(6) Heat transfer fluid in

The D series does not have

Pos. 3 and 4

Electrical

connections

Front

®®

®

®

®

(1)

(2)

(3)

(4)

(6)

(5)

105 310 505

600

600

510

349

294

239

1500

Page 32

33

Collector

Collector hose

The collector hose consists of a thin-walled plastic hose of make Pem 40 x 2.4 DN 6.3. Length and

depth as in IVT:s dimensioning program.

Install the hose rising towards the heat pump to avoid air pockets.

It is vitally important that the filling around the ground coil does not contain stones or other objects

that could damage the coil. The final filling is best carried out after the ground collector has been

pressure tested. Avoid chips or dirt getting into the coil when cutting.

Installation and filling around the collector hose must comply with local regulations.

Bending diameter

Minimum bending diameter permitted is 1 metre. Always use an elbow coupling for sharper bends. If

you damage the hose by bending it too sharply you can repair it with a pipe joint.

Maximal lengths

Specified pressure drop and hose lengths are based on heat transfer fluid containing 29 volume percent

ethanol. Other heat transfer fluids are not recommended because they give high pressure drop at low

temperatures. The table shows the maximum hose length for each heat pump model. The coils can be

parallel connected if the collector’s length exceeds that permitted for a circuit. Note that maximum

hose length per coil is specified for parallel connecting. The table specifies that e.g. a Greenline 11 has

a maximum coil length of 400 metres and for 2 parallel coils the length is 800 metres a coil, a total of

1,600 metres.

Greenline C4

(hose 32 x 2.5) 180 metres 360 metres

Greenline C4 500 metres 1,000 metres

Greenline C5/D5/E5 500 metres 1,100 metres

Greenline C7/D7/E7 400 metres 800 metres

Greenline C9/D9/E9 400 metres 800 metres

Greenline D11/E11 400 metres 800 metres

Max. hose length

with one loop

Heat pump:

Max. hose length per coil

with two loops

Page 33

34

Connecting the collector to the heat pump

The sketch shows the connection of a collector with two parallel coils. Both coils are connected to two

distributors. Each coil should have a gate valve and a control valve. The control valve is adjusted so

that the flow is the same in both coils.

The joint pipe to the heat pump is fitted with a filling unit, a particle filter and an expansion vessel. A

safety valve is fitted to the outgoing duct. When refilling with the heat transfer fluid circuit, a coil at a

time is filled by shutting both valves completely.

Heat pump

Filling unit

Safety valve

Distributor

Filter

Ground,

lake or

rock

collector

Page 34

35

Switching to side mounting of the heat transfer fluid system

When delivered Greenline Compact is designed for top mounting on the heat transfer fluid (collector)

side. This can be changed to side mounting on the right or left side. The following instructions describe the process step by step. We recommend that rebuilding is completed before placing the heat

pump in its place of installation.

The right side plate has two

connection points. Swap right

and left side plates if you want

to connect on the left side.

Remove the plastic plugs from

the sideplate (1) and put them

in the holes on the roof cover

panel (2).

Remove both the heat transfer fluid pipes that go to the top of

the top plate. Heat transfer fluid in is equipped with a connector

on top of the heat transfer fluid pump. Heat transfer fluid out is

connected to the bottom of the heatexchanger. Note that the

sensor on heat transfer fluid out must first be removed.

The armaflex insulation is removed

from both pipes when removing the

heat transfer fluid pipe from the heat

pump.

Both heat transfer fluid pipes are cut to suit left or right mounting. The following series of pictures provide the exact measurements. The pipes are cut the same whether they are left or right

mounting.

Heat transfer fluid in

Heat transfer fluid out

Heat transfer fluid out

Sensor removed

Heat transfer fluid in

(1)

(2)

Page 35

36

RIGHT MOUNTING

- Heat transfer fluid in is cut as shown in figure A.

- Heat transfer fluid out can be cut as shown in figure B

then a bend and a straight piece of copper pipe can be

soldered in.

The piece of pipe can be taken from the piece that was over

when the pipe was cut.

Do not use compression fittings because of the lack of space in

the heat pump.

LEFT MOUNTING:

- Heat transfer fluid out is cut as shown in figure C then a

bend and a straight piece of pipe are soldered in.

- Heat transfer fluid in is cut as shown in figure D then a

joint and a straight piece of pipe are soldered in.

You can use material that was over when the pipe was cut.

Do not use compression fittings because of the lack of space in

the heat pump.

- When the pipes have been adjusted they are mounted

inplace again.

- The sensor is mounted back on the heat transfer fluid out

with a piece of aluminium tape.

- The armaflex insulation is pushed back onto both pipes. Use

a piece of armaflex tape tocover the pipe properly to avoid

condensation.

The picture on the left shows the heat transfer fluid pipe

mounted on the right before the armaflex insulation is mounted.

Right mounting

Left mounting

View from left and right

D

C

B

A

Soldered

bend

Soldered

bend

Soldered

joint

Straight

section

Straight section

Straight

section

Page 36

37

Intermediate heat exchanger

The flow in the exchanger must be

counterflow. The pipe from the well

is connected to the bottom of the

exchanger so that the flow goes

upwards.

Heat pump

Water source Recharge well

* Model 11 has a built-in motor

cutout in the pump.

Models 5-9 have a clamp mounted

between L and MB2.

Terminal card

Connecting to the heating system

General

Installation must be carried out by an authorised installer and must follow the current rules and recommendations of IVT. The pipework must be flushed before the heat pump is connected to protect the

heat pump from contaminants.

Safety

valve

Filling unit

P8

Ground

water

water pump

Ground water system

Application:

Systems using ground water are equipped with an intermediate heat exchanger to eliminate the risk for

freezing. A pump with a non-return valve is placed in the bore hole that via a hose pumps the water to

the intermediate exchanger and then back to an injection well. The circuit to the heat pump is installed

in the normal way with a filling unit and safety valve. The circuit should contain around 29 volume

percent antifreeze (ethanol or ethylene glycol) which corresponds to around -15

o

C freezing point.

Electrical connections:

The ground water pump is connected to 3 x 400 volt with a motor cutout and a contactor. Power to

contactor CK3(230V) is fetched from terminals L and N (P3) in the heat pump. The auxiliary contact

for motor cutout MB3 is series connected with the MB2 alarm. In this way the ground water pump

starts and stops with the heat pump’s heat transfer fluid pump and during motor cutout MB3, the heat

pump stops and the heat transfer fluid pump alarm shows in the alarm display. NOTE: Single-phase

pumps should always be connected with a contactor. It should never be connected to the P3 outlet in

the heat pump.

Filter

Exp

Page 37

38

Application:

The principle for operating mode A is based on liquid condensation and additional heat from an electric water

heater. The built-in control unit Rego600 controls the heat pump with an outdoor sensor GT2 and return sensor

GT1 according to outdoor compensated control curve. When the heat pump is not able to meet the heating

requirements, additional heat starts that together with the heat pump provides the required temperature. Hot

water is prioritised and controlled by a sensor, GT3 in the hot water heater. While the heat pump is heating the

water in the immersion heater, the heating system is disconnected temporarily through the three-way valve.

Radiotor operation continues when the immersion heater is hot enough.

Rego600 can also control other curves together with a mixing valve. The mixer curve must be set lower than

the curve for the rest of the heating system. This extra function is used e.g. for floor heating systems that

demand a lower temperature.

Connecting the sensors:

External sensors GT1 and GT2 must always be connected. Sensor GT4 is connected if the mixer curve is used

and GT5 if the room sensor is required.

*Acc. tank:

A 100-300-litre accumulator tank is recommended for systems with separate controls for e.g. floor heating, to

ensure good operational times for the heat pump. For this solution, GT1 is mounted in accordance with *GT1.

(X) The distance between both cut offs must not be more than 10 times the dimension of the pipe.

Connecting the C series to the heating system and operating mode A

GT2

GT5

HEATING

SYSTEM

P1, RADIATOR PUMP

GT4

P4

(X)

P2

P3

EXP

GT1

DHW

CW

GT3

*GT1

*ACC. TANK

HEAT PUMP

It is also possible to control other heating

systems with a mixing valve. For a

combination of radiator and floor heating

systems for example.

HEATING SYSTEM WITH MIXING VALVE

Safety valve

FILTER BALL

Page 38

39

Application:

The principle for operating mode A is based on liquid condensation and additional heat from an immersion heater.

The built-in control unit Rego600 controls the heat pump with an outdoor sensor GT2 and return sensor GT1

according to outdoor compensated control curve. When the heat pump is not able to meet the heating

requirements, the water heater starts automatically and together with the heat pump provides the required temperature. Hot water is prioritised and controlled by a sensor, GT3 in the hot water heater. While the heat pump is

heating the water in the immersion heater, the heating system is disconnected temporarily through the 3-way

valve. Radiotor operation continues when the immersion heater is hot enough.

Rego600 can also control other curves together with a mixing valve. The mixer curve must be set lower than the

curve for the rest of the heating system. This extra function is used e.g. for floor heating systems that demand a

lower temperature.

Connecting the sensors:

External sensors GT1 and GT2 must always be connected. GT3 is connected if the heat pump is to produce hot

water. Sensor GT4 is connected if the mixing valve curve is going to be used and GT5 if the room sensor is

required.

*Acc. tank:

A 100-300-litre accumulator tank is recommended for systems with separate controls for e.g. floor heating to

ensure good operational times for the heat pump. For this solution, GT1 is mounted in accordance with *GT1.

(X) The distance between both cut offs must not be more than 10 times the dimension of the pipe.

Connecting the D series to the heating system and operating mode A

HEAT TRANSFER

SYSTEM

P1, RADIATOR PUMP

EXP

*ACC. TANK

Safety

valve

DHW

CW

HEAT PUMP

HOT WATER HEATER

3-way valve

MIXING VALVE

It is also possible to control other heating

systems with a mixing valve. For example,

for a combination of radiator and floor

heating systems.

MIXED HEATING SYSTEM

ELECTRIC WATER HEATER

FILTER BALL

Page 39

40

Application:

The principle for operating mode A is based on liquid condensation and additional heat from an immersion

heater. The built-in control unit Rego600 controls the heat pump with an outdoor sensor GT2 and return sensor

GT1 according to outdoor compensated control curve. When the heat pump is not able to meet the heating

requirements, the water heater starts automatically and together with the heat pump provides the required

temperature. Hot water is prioritised and controlled by a sensor, GT3 in the hot water heater. While the heat

pump is heating the water in the immersion heater, the heating system is disconnected temporarily through the 3way valve. Radiotor operation continues when the immersion heater is hot enough.

Rego600 can also control other curves together with a mixing valve. The mixer curve must be set lower than the

curve for the rest of the heating system. This extra function is used e.g. for floor heating systems that demand a

lower temperature.

Connecting the sensors:

External sensors GT1 and GT2 must always be connected. GT3 is connected if the heat pump is to produce hot

water. Sensor GT4 is connected if the mixer curve is used and GT5 if the room sensor is required.

*Acc. tank:

A 100-300-litre accumulator tank is recommended for systems with separate controls for e.g. floor heating to