Page 1

TopPage

AYXP12FRN

SERVICE MANUAL

SPLIT TYPE

ROOM AIR CONDITIONER

MODELS

CONTENTS

CHAPTER 1. SPECIFICATION

[1] SPECIFICATION............................................ 1-1

[2] EXTERNAL DIMENSION............................... 1-2

[3] WIRING DIAGRM .......................................... 1-3

[4] ELECTRICAL PARTS .................................... 1-3

CHAPTER 2. EXPLAMATION OF CIRCUIT AND OPERATION

[1] BLOCK DIAGRAMS....................................... 2-1

[2] MICROCOMPUTER CONTROL SYSTEM........ 2-3

[3] FUNCTION..................................................... 2-8

CHAPTER 3. FUNCTION AND OPERATION OF PROTECTIVE PROCEDURES

[1] PROTECTION DEVICE FUNCTIONS AND

OPERATIONS................................................ 3-1

[2] AIR CONDITIONER OPERATION IN

THERMISTOR ERROR ................................. 3-3

INDOOR UNIT

AY-XP12FR-N

OUTDOOR UNIT

AE-X12FR-N

In the interests of user-safety (Required by safety regulations in some

countries) the set should be restored to its original condition and only

parts identical to those specified should be used.

[3] THERMISTOR TEMPERATURE CHAR-

ACTERISTICS...............................................3-5

[4] HOW TO OPERATE THE OUTDOOR

UNIT INDEPENDENTLY ...............................3-7

[5] GENERAL TROUBLESHOOTING CHART........3-7

[6] MALFUNCTION (PARTS) CHECK METH-

OD .................................................................3-9

[7] OUTDOOR UNIT CHECK METHOD........... 3-11

[8] TROUBLESHOOTING GUIDE ....................3-14

CHAPTER 4. REFRIGERATION CYCLE

[1] FLOW FOW REFRIGERANT ........................4-1

[2] STANDARD CONDITION ..............................4-1

[3] TEMPERATURE AT EACH PART AND

PRESSURE IN 3-WAY VALVE ......................4-1

[4] PERFORMANCE CURVES...........................4-2

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

AYXP12FRN

AYXP12FRN

CHAPTER 1. SPECIFICATION

Service Manual

[1] SPECIFICATION

1. AY-XP12FR-N – AE-X12FR-N

MODEL INDOOR UNIT OUTDOOR UNIT

ITEMS AY-XP12FR-N AE-X12FR-N

Cooling capacity(Min. > Max.) kW 3.5 (0.9 - 4.0)

Heating capacity(Min. > Max.) kW 4.2 (0.9 - 6.0)

Moisture removal(at cooling) Liters/h 1.1

Electrical data

Phase Single

Rated frequency Hz 50

Rated voltage V 230

Rated current ✩

(Min - Max.)

Rated input ✩

(Min - Max.)

Power factor ✩ Cool % 91

Compressor Type Hermetically sealed rotary type

Refrigerant system Evaporator Louver Fin and Grooved tube type

Noise level

(at cooling)

Fan system

Drive Direct drive

Air flow quantity

(at cooling)

Fan Cross flow fan Propeller fan

Connections

Refrigerant coupling Flare type

Refrigerant tube size Gas, Liquid 1/2", 1/4"

Drain piping mm O.D φ18

Others

Safety device Compressor: Thermal protector

Air filters Polypropylene net (Washable)

Net dimensions Width mm 790 780

Net weight kg 10 37

NOTE: The condition of star”✩” marked item are ‘ISO5151’ : 1994(E), contition T1.

Cool A 4.3 (0.8 - 6.0)

Heat A 4.5 (0.7 - 7.5)

Cool W 900 (150 - 1300)

Heat W 970 (130 - 1700)

Heat % 94

Model 5RS092XDF

Oil charge 320cc (RB68A or Freil Alphc 68M)

Condenser Corrugate Fin and Grooved tube type

Control Expansion valve

Refrigerant (R410A) 1000g

De-lce system Micro computer controled reversed systems

High dB(A) 43 49

Low dB(A) 39 –

Soft dB(A) 27 –

High m3/min. 10.7 30.2

Low m3/min. 9.3 –

Soft m3/min. 6.0 –

Fan motors: Thermal fuse

Fuse, Micro computer control

Height mm 278 540

Depth mm 198 265

1 – 1

Page 3

[2] EXTERNAL DIMENSION

1. Indoor unit

AYXP12FRN

198790

278

2. Outdoor unit

58

INVERTERAIRCONDITIONER

540

780

175

12

37.5

58

18.5

22.0

135

4.5

72

299

14

324

265

540

1 – 2

165

81

136

Page 4

AYXP12FRN

[3] WIRING DIAGRM

1. Indoor unit

2. Outdoor unit

[4] ELECTRICAL PARTS

1. Indoor unit

DESCRIPTION MODEL REMARKS

Indoor fan motor MLB084 DC Motor

Indoor fan motor capacitor – –

Transformer – –

FUSE1 – QFS-GA062JBZZ (250V, 3.15A)

FUSE2 – QFS-GA063JBZZ (250V, 2A)

2. Outdoor Unit

DESCRIPTION MODEL REMARKS

Compressor 5RS092XDF D.C. brush-less motor

Outdoor fan motor ML-A902 DC Motor

Outdoor fan motor capacitor – –

Fu4 – QFS-GA064JBZZ(250V, 1A)

Fu3 – QFS-GA051JBZZ(250V, 2A)

Fu2 – QFS-GA052JBZZ(250V, 3.15A)

Fu1 – QFS-CA001JBZZ(250V, 20A)

Fu5, 6 – QFS-CA002JBZZ(250V, 15A)

1 – 3

Page 5

AYXP12FRN

CHAPTER 2. EXPLAMATION OF CIRCUIT AND OPERATION

Service Manual

[1] BLOCK DIAGRAMS

1. Indoor unit

AYXP12FRN

CPU

DC power supply circuit

Fan motor PWM control circuit

Rotation pulse input circuit

AC clock circuit

Remote controller signal reception circuit

Buzzer drive circuit

CPU reset circuit

CPU oscillator circuit

Room temp. detect circuit

Heat exchanger pipe thermo circuit

EEPROM

Select circuit

Serial I/O circuit

Power supply relay drive circuit

2A

Rectification circuit

Fuse

Indoor fan motor

Fan motor pulse detect

Wireless remote control operation

Audible operation confirmation

Room temp. thermistor

Heat exchanger pipe thermistor

Louvre angle, fan speed

Wireless, preheat, Model select

Indoor/outdoor control signal I/O

Outdoor unit power supply on/off control

3.15A

AC power

Fuse

Unit-unit wiring

(AC power and

serial signals)

Serial signals

Sub

CPU

Auto restart circuit

Test run circuit

Auxiliary mode

Power on circuit

Cluster generator drive circuit

Louvre motor drive circuit(upper)

Louvre motor drive circuit(lower)

LED drive circuit

Test run (forced operation)

Auxiliary mode button ON/OFF

Self diagnostics, fault diagnosis

Cluster generator

Flow direction control (louver motor upper)

Flow direction control (louver motor lower)

LED display

2 – 1

Page 6

AYXP12FRN

2. Outdoor unit

CPU

AC clock circuit

Pulse amplitube modulation circuit

Power supply circuit

CPU oscillator circuit

DC overvoltage detection circuit

Outdoor fan drive circuit

4-way valve relay drive circuit

DC overcurrent detection circuit

Power transistor module drive circuit

Serial I/O circuit

CPU reset circuit

Position detection circuit

AC overcurrent detection circuit

Compressor thermo circuit

Heat exchanger pipe thermo circuit

Outdoor temp. thermo. circuit

Smoothing

circuit

15A

protection

IGBT

Power factor

converter circuit

Outdoor fan

4-way valve

Power transistor module

Compressor

Current transformer

Compressor thermistor

Heat exchanger pipe thermistor

Outdoor temperature thermistor

Filter

circuit

20A

protection

3.15A

protection

15A

protection

Unit-unit wiring (AC power

and serial signals)

EEPROM

LED drive circuit

Test mode circuit

Expansion valve drive circuit Expansion valve

Suction temp. thermo. circuit Suction pipe thermistor

2-way valve temp. thermo. circuit 2-way valve thermistor

LED

2 – 2

Page 7

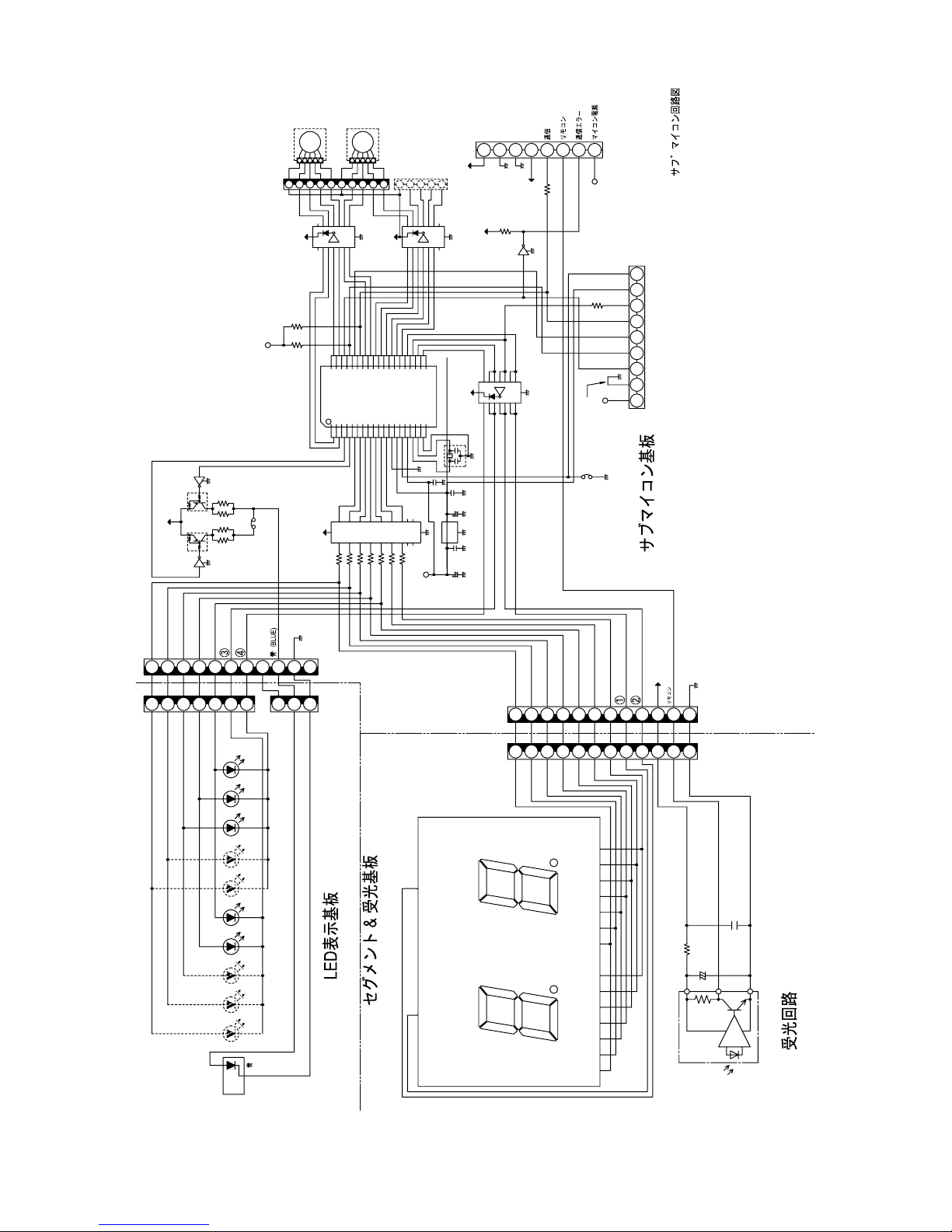

[2] MICROCOMPUTER CONTROL SYSTEM

1. Indoor unit

1.1. Electronic control circuit diagram

AYXP12FRN

1

12V

CNA

BCN5

FU1

3.15A - 250V

RHRE

C23

275V

0.01μ

1W

R76

100

12V

E

D3

C53~C56

250V4700p

C54C53

C56

C55

R1

3.3

FU2

C35

5

1

D15

D1FL20U

10KF

R22 R3

11KF

ZD1

ST03D - 200

65432

TR1

R13

100K

12V

5V

1

1

1

D1N60

5W

1M

R2

2A - 250V

2KV

C12

9

C43

N

1

3W

3W

R75

C1

33p

D21

D1FL20U

R5

30KF

100V

100pF

D14

25V

R10

2

IN

RY1

3

365

3

11K

11K

SSR

3.3K

200K

R26

1/2W

DB1

D2SBA60

450V 120μ

1/2W1M1/2W

RF

D20

D1FL20U

2

C2

50V

100μ

C5

50V

ZD5

15V

101112

D2S6M

470μ

1.5K

2

1

3

OUT

CLUSTER

GENERATOR

5

6

(CLUSTER)

CONNECTOROF JOINT

910

R20

1/4W

R23

910

1/4W

39K

R24

R25

200K

1/2W

NR1

C14 275V 0.1μ

R19A 1/2W 470K

R19 1/2W 470K

NF1

C45 275V 0.1μ

DC15V

IC7

KIA7815API

Q9

D

KRA106S

1SR139

5V

L2

3

IC3

4

MR1712

R65

1500p

D2

D1FL20U

1

C49

C48

250V

10000p

C7

10V

D1

D1FS4

R6

L1

100K

10μH

1K

R9

C4

PC6

2

1

PC817XP3

R80

1.2K

2.4KFR82.4KF

N

N

S

CONNECTOROF JOINT

100μ

35V

C46

0.1μ

25V

C50

0.1μ

50V

C47

4

1

3.3K

R66

100K

R73

1234

CN80

R7

15KF

4

PC6

470μ

C44

10V

220μ

50V

0.1μ

R11

RA

RG R40RBRC

D8

7

(FANMOTOR)

77

BCN1

Vm

R31

56k

14

PC5

5V

32

PC9

PC817XP3

100μ

50V

C3

5V

3

5V

2W

680

2W

680

2W

680680

2W

2W

680

D1N60

D1N60

D7

DC

5

521

5

10K

R16

R34

6.8k

R57

680

0V

C40

50V

1000p

4

PC7

PC817XP3

1

1K

R81

IC9

PJ431CT

41

FAN

MOTOR

33

312

23

14

23

4.7k

R39

PC1 PC817XP3

C20 250V0.01μ

R38 100k

C19 50V0.047μ

C18 35V100μ

ZD2HZ24-2

2W

2W

11K

11K

R37RD

2.7K

R70

R44

12V

5V

C42

1

2

4

PC3

1

Vs

VccPGGND

C98

C99

6.8k

R33

16V47μ

C21

R32

3

PC817XP3

2

14

3.3k

R29

JPF

32

PC817XP3

R41 56k

32

PC2 PC853HXP

(SERIAL I/O CIRCUIT)

89

BZ

1.8k

1/4W

12V

25V

0.1μ

3

PC81716P

2

C16

50V

0.01μ

C98, C99

1KV 1000p

8.2k

PC4

PC817XP3

R35 10k

680

R30

R27

10K

AC CLOCK

5V

5V

JPS

IC6

16V

C17

10k

R28

R71

4.7K

R36

16V

C22

0.01μ

1k

4.7k

R47

4.7k

R97

KID65004AF

0.01μ

1110

987654321

10

SUB MICRO COMPUTER PWB

7654321

9876

12345

8

123456789

1210 11

1110 12 10 11

987654321

123456789

RECEIVER PWB

7-SEGLED&

BOTTOM

33

LOUVER MOTOR

CIRCUIT DIAGRAM

54 21 54 21

TOP

LOUVER MOTOR

DISPLAY PWB

246

8

10

13579

8765432

POWERSUPPLY OF

SUBMICRO COMPUTER

KRC108S

4.7K

R98

16V

0.01μ

10K

R61

C31

1

CN4

BCN7

10.0KF

16V10μ

RM

49P37

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

JPH

5V

11 12

4.7K

484746454443424140393837363534

P00

P01

P02

P03

P04

P05

P06

P36

P35

P34

P33

P32

P31

P30

VCC

VR

VSS

P67

P66

P65

P64

P63

HOT KEEP

P07

P53

P54

P55

P56

P57

P60

P61

P62

123

4

R52

10K

R53

10K

JPO

(HA CIRCUIT)

AUTO RESTART

5V

FLASH

P10

P52

98765

HAJP

POWERON

BUSY

P11

IC1

P51

10

R95

P12

P13

P47

P50

R91

4.7K

VPP

DRAIN PAN ASS'Y

P14

P15

P16

P44

P45

P46

1514131211

100k

R93

C90

R90

4

321

100K

R69

4.7K

R68

VCC

SCL

P20

P17 33

P21

P22

P23

P24

P25

P26

P27

VSS

XOU

XIN

P40

P41

RST

VSS

P42

P43

16

R92

CN90

SDAOERESET9VSS

4.7k

R45

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

MQ

7654321

8

5V

10k

R48

10K

R94

C27

16V

0.01μ

13

50V

C33

8MHz

AUX.

5V

(TESTRUN)

R87

WIRELESS

1000p

2

47k

R67

SW1

10k

R50

TEST

C37

25V

0.1μ

C26

25V

4.7μ

IC2

RESET

10K

C52

25V

0.1μ

C

50V

0.1μ

OSC1

R85

10K

C57

50V

1000p

R86

10K

JPW

JPP

5V

PREHEAT

(DRAINPAN)

CONNECTOROF JOINT

8

6

43

21

7

5

1

12V

Q11

5V

4.7K

R4

5V

50V

C32

1000p

R17 1K

100μ

10V

C25

5V

0.1μ

25V

C24

1k

R46

4

5

3

6

2

7

1

8

IC10

EEPROM

5V

10.0KF

R96

100

1/4W

R56

100

5V

1/4W

R51

JPT

GND for

KRA101S

1K

R89

R54

10K

12V LINE

Q15

Q19

2.4K

R55

GND for

5V LINE

KRC102S

KRC108S

KRC102S

4.7K

RN

4

TEMP THERMO

SIGNAL

5V

OFSERIAL

SERIALSIGNALS

REMOTECONTROLLER

ERRORSIGNAL

Q3

Q1

5V

C39

C36

16V

0.01μ

R58

R59

10K

10.0KF

R60

16V10μ

C30

3

2

TH1

TH2

PIPE THERMO

2 – 3

Page 8

AYXP12FRN

1.2. Display circuit diagram

IC105

TOP

5432112345

LOUVER MOTOR

12V

12V LINE

GND for

KID65004AF

IC106

1234567

CN101

12V

12345

CN102

GND for

12V LINE

8

SIGNALS

4.7K

KRC106S

SERIAL SIGNALS

ERROR SIGNAL

REMOTE CONTROLLER

OF SERIAL

M5V

POWER SUPPLY OF

SUB MICRO COMPUTER

9

5V

R108

5V LINE

GND for

12V LINE

GND for

1K5VR119

Q105

CIRCUIT DAIGRAM

LOUVER MOTOR

987654321

10

CN103

12V

KID65004AF

BOTTOM

8

7

4.7K

R115

R116

100K

6

5

M5V

R118

10K

IC101

Q104

KRC106S

R114

KRA106S

Q102Q101

12V

KRA106S

Q103

KRC106S

R110

R113

R109

JP2

1/4W

1.2K*4

KID65783AF

12V

1W180*7

P11 36

M37542

P12

123

R101

P01 28

P02 29

P03 30

P04 31

P05 32

P06 33

P07 34

P10 35

P13

P14

P20

P21

P22

P23

P24

P25

4

98765

IC103

R102

R103

R104

R105

P30 19

P31 20

P32 21

P33 22

P34 23

P35 24

P36 25

P37 26

P00 27

12V

IC104

GND for

KID65004AF

Vss18

Xout17

P26

P27

Vref

RESET

CNVss

Vcc

Xin

16

1514131211

10

R106

R107

13

8MHz

2

OSC101

25V

C101

0.1μ

50V

C105

0.22μ

C102

25V

4.7μ

IC102

RESET

25V

C103

C104

0.1μ

16V

47μ

12V LINE

GND for

M5V

12V LINE

5V LINE

GND for

JP1

4

3

2

1

M5V

FLASH

SUB MICRO COMPUTER PWB

cdefg

123456789

7

6

5

4

3

2

1

LED LED LED LED LED LED LED LED

LEDLED

101 102 103 104 105 106 107 108 109 110

LED

PC

111B

CN105B

BLU

()

10

123

E

12V LINE

GND for

11

CN105A

CN105C

abcdefg

6

5

4

3

2

1

8

7

123456789

SIGNALS

5V LINE

GND for

5V

REMOTE CONTROLLER

9

12

11

1010

11

12

CN104B CN104A

2 (H2)

9(G2)

g

8(F2)

f

3 (E2)

e

1 (D2)

d

4 (C2)

c

6 (B2)

b

7 (A2)

a

2 (H1)

9(G1)

g

8(F1)

f

3 (E1)

e

1 (D1)

d

4 (C1)

c

6 (B1)

b

7 (A1)

a

R201

47

C201

+

16V

47μ

C202

25V

0.1μ

IC201

GP1U261RK

RECEIVER CIRCUIT

DISPLAY PWB

7 - SEG LED & RECEIVER PWB

SG201

B2B1

A2

(COM) 5

F2

A1

(COM) 10

F1

H2

C2

G2G1

D2

E2

H1

C1

D1

E1

2 – 4

Page 9

1.3. Printed wiring board

AYXP12FRN

2 – 5

Page 10

AYXP12FRN

2. Outdoor unit

2.1. Electronic control circuit diagram

PS21563 or 21564

IPM

15A

FU5

250V

j

PTC

1μF

275V

275V

1μF

275V

FC1

TERMINAL

BOARD

WP

VP

UP

VPI

EARTH

YELLOW

GREEN/

C

(R)

S

(THERMISTOR)

5V

(C)

R100

R

FC3 FC4

(THERMISTOR CIRCUIT)

T9

T7

T8

V33

U32

W34

N

35

R50

26

CIN

R128

R7

MRY1

2.7kF

R88

13KF

R127

R6

23.7KF

510K

4

2

4

2

T1

0V

1/4W

BROWN

1

13KF

23.7KF

T11

T10

T13

25

CF0

Q7

5V

R107

2

0V

8

6

150

R110

-P

V

Q5

18

FU6

15A

250V

WH

WH

e

d

D12

D13

FU2

3.15A

250V

4700pF

250V

C6A

C6

C7A

C7

4700pF

250V

4700pF

250V

C5A

C5

C4

C4A

4700pF

250V

PC1

SA1

NR1

C13

20A

FU1

250V

T4

YELLOW

GREEN/

31

P

M

C14

630V

0.33μ

R126

1/2W

R125

1/2W

270KD

270KD

R5

R2

1/2W

300KF

255KF

1/2W

C10

750μ

+

C9

420V 420V

750μ

+

DB1

T5

GR

GR

OUT

IN

GR

T6

CT1

R89

C3

1/4W

510K

R43

3

L4

1

C2

3

L3

1

1μF

C1

R1

1M

T12

1/2W

T2

BLUE

N

1

330K

10K x 5 R63 ~ 67

5W

R49

0.02

1.8KF

C59

C58

c

KRC105S

330

PC4

3

R101, 102

1/2W 47K x 2

5V

4

1

PC817XP3

0.1μ

D1

FC2

R51 ~ 53

R111

ZD3

1000P

0.022μ

TLP351

5

2.2K

R103, 104

R74

TH4

TH5

TH3

TH2

65432

798

10

CN8

R68 ~ 72

6.8KF x 5

D11

0V

C70 ~ 74

16V 10μ x 5

0V

0.01μ x 5 C65 ~ 69

1/2W

470KF x 3

R99 100

15K

R112

R57 100

R59 100

R58 100

0V

D24

D23

D22

V

D21

5

11

4

15

3

2

14

13

R114

1M

1.8K

0V - P

R115

5V

1.8K

R60

1.8K

R61

1.8K

DB2

R62

μ

7

9

.01

C

0

6

K

5V

.3

C83

3

R10

220μ

1000P

1

4

1000P

6

Q

0V

2S

μ

2

0V

0V

R41 R42

01

C8

KRC10

0.

5

2K

0

2

1

R

5V5V

3

4

PC3

2

1

PC81716NIP

C81

0.01μ

R146

100K

5

2

R

b

R75

2.7K

R76

56K

D6

2

TR1

3

(SERIAL I/O CIRCUIT)

1K

2W

1K

1K

2W 2W

FB

R11

1/2W 1M

V

0

5

2

U4

F

A

1

j

R8R9R10

1/2W 1M

R147

10K

C79

10V

R91

6.8KF

R90

1.0KF

D2

R104

R103

R102

R101

1W 47K x 2

a

C75

4.7K

3

PC2

PC853HXP

2

R4

3.3K

250V

C12

4700P

T3

RED

2

VUFS

VUFB

IPM

3

4

1

C49

0.1μ

33 x 2

33 x 2

D8

C50

R47A, 48A

25V

R47, 48

1/4W

1/4W

100μ

C37

25V

ZD4

330μ

C38

0.1μ

15V

0V

R56

20.5KF

R55

20.5KF

R54

20.5KF

25V

C60

0.1μ

C86

0.1μ

R113

19.1KF

C61

330P

50V

DETECT CIRCUIT)

(ROTOR POSITION

50V

C62

330P

C63

50V

330P

C64

25V

0.1μ

678910

12

1

IC8

KIA339

5V

N

W

C93

0.1μ

V

C30

10V

U

5V

V

5V

15

13V

5

0

C4

I

8

7

7

W

8

1

6

R2

4

K

2

2

R

2

μ

3

1

KF

C2

.03

.65

0

1

3

K

IC3

2

8

R

6

1

2

.5K

R

1

2

K

0

R2

1

μ

0

V

0

2

5

8

C

2

6

9

V

μ

5

0

C1

3

5

1

7

D

8

7

3

1

7

0

W

1

D3

2

R1

D5

5

μ

V

0

0

C1

1

5

K

8

5

1

.

1

R

PF

7

0

KV

2

C2

1

2

rain

1~4

R12

1/2W 1M

1/2W 1M

D

R13

1/2W 1M

cc

8

V

C2

2

I

7

STR -L4

1/2W 1M

6

D20

100μ

3

C2

6

R2

2

K

0

R8

1

9

R1

G

6

8

5

SA1

2

VVFB

9

D9

C39

1000P

M

0V

a

b

R92

10K

μ

1

.

0

KF

4

.6

4

9

K

2

1

Q

ZD1

ce

r

6

ou

S

B

9

/F

P

OC

10

D

N

7

G

VVFS

10

7

C51

0.1μ

C52

25V

100μ

C40

1000P

1234567

CONNECTOR)

(FRASH WRITER

JP7

JP8

JP9

0V

S

T

Q

0V

-P

0V - P

V

18

μ

5

8

.1

C

0

7

K

0

R8

1

μ

V

0

5

5

C84

3

1

4

1

D

5

6

D4

P

0

5

6

0

3

3

D1

C1

K

0

3

.

R2

3

4

1

R

VPI

12

CND

1

2

34

5

6

7

89

10111213141516171819

11

0

8

6

VWFB

VWFS

15

13

C53

D10

25V

C54

100μ

C41

1000P

9

8

S

T

R

1

JP10

R154

10K

5V

(FOR DEBUG)

10K

R155

P42

P43

P44

P45

P46

P50

P51

P52

P53

P54

P55

P56

P57

AVCC

AVR

AVSS

P60

P61

P62

P63

MD0

RST

MD1

10K

10K

R94

R93

0V

5V

10

P

8

0

8

C1

6

6

.6

1

R1

5

.6

R1

1

P

7

0

7

C1

4

0V

VPI

18

16

0.1μ

C42

1000P

5V

Q

2

3

P40

P41

MD2X1X0

OSC1 4MHz

K

.7

R29

4

(SWITCHING POWER

(RESET CIRCUIT)

VNI

28

LED1

R73

2.2K

4

MONITOR

P37

VSS

0V

5V

13V

SUPPLY CIRCUIT)

IC5

5V

UN

22

21

C55

0.1μ

C56

0.1μ

C57

0.1μ

C44

C43

1000P

R134 100

R135 100

R136 100

R137 100

(LED CIRCUIT)

(CN)

5V

P33

P34

P35

VCCCP36

(Y)

(W)

(Z)

IC1

(B)

(O)

(Y)

P00

P01

P02

P03

P04

10K

10K

R35

R34

JP16

9

MRY1

RY1

13V

6

5

VALV COIL

EXPANSION

+

C33

R79

0.1μ

C32

100

3

2

1

PST993D

270

R78

C31

0.1μ

C

VN

1000P

P32

(V)

(W)

P05

4

50V

1μ

0V

VNO

F0

WN

23

N

VNC

24

27

20

35

JP17

0V

C47

10V

100μ

C48

0.1μ

10K

R45

5V

C45

0.1μ

1K

R46

0V

1000P

C46

(DC OVERCURRENT CHECK CIRCUIT)

R133 100

R132 100

0.1μ

C95

C94

100μ

10V

0.1μ

C98

V

W

JPF

KID65004AP

U

R38 1K

R37 1K

R36 1K

0V

C36

C35

C34

1000P x 3

c

0V

1K

10K

R129

4.7K

R30

5V

(PAM OVER CURRENT CIRCUIT)

RY1

e

CNE

IC6

10K

R31

R32

431

VALV

4-WAY

3

R28

1/2W

275V

C26

3

120

0.033μ

COIL

1

d

R144

2.2K

R33

2

8

756

0V

124

(EEPROM CIRCUIT)

CN4

NR2

(4 - WAY VALVECIRCUIT)

C76

1000P

0V

6.8K

JP2

0V

JP1

5V

C88

1000P

0V

1K

R116

N

52535455565758596061626364

(U)

P30

51504948474645444342414039383736353433

(X)

VSS

P27

(W)

(V)

P26

P25

(U)

P24

P23

P22

P21

P20

P17

P16

P15

P14

P13

P12

P11

P10

P07

P06 P31

32313029282726252423222120

8

IC7

0V

3

2

1

CN12

5V

Q9

R81

KRC105S

Q4

KRA106S

10K

KRC105S

0V

Q10

KRA106S

R84

9.53KF

10V

47μ

C78

0V

R86

6.8KJ

(FAN MOTOR CIRCUIT)

Q3

0V

C77

15V

0.01μ

6.8K

R85

5V

R83

10K

0V

C29

400V

0.1μ

1

7

3

2

4

CN3

5

R

270

R77

j

2A

FU3

250V

(FAN MOTOR)

2 – 6

Page 11

2.2. Printed wiring board

AYXP12FRN

2 – 7

Page 12

AYXP12FRN

[3] FUNCTION

1. Function

1.1. Startup control

The main relay remains off during the first 45 seconds (first safety

time) immediately after the power cord is plugged into an AC outlet in

order to disable outdoor unit operation and protect outdoor unit electric

components.

1.2. Restart control

Once the compressor stops operating, it will not restart for 180 seconds to protect the compressor.

Therefore, if the operating compressor is shut down from the remote

control and then turned back on immediately after, the compressor will

restart after a preset delay time.

(The indoor unit will restart operation immediately after the ON switch

is operated on the remote control.)

Compressor operation

Compressor ON Compressor can

Compressor remains OFF

turn ON

for 180 seconds

OFF operation on

remote control

ON operation on

remote control

Compressor ON

1.3. Cold air prevention control

When the air conditioner starts up in heating mode, the indoor unit fan

will not operate until the temperature of the indoor unit heat exchanger

reaches about 23°C in order to prevent cold air from blowing into the

room.

Also, the indoor unit fan operates at low speed until the temperature of

the indoor unit heat exchanger reaches about 38°C so that people in

the room will not feel chilly air flow.

Indoor unit heat exchanger temperature

38

23

Set fan speed

35

Indoor unit fan at low speed

21

Indoor unit fan in non-operation

1.6. Outdoor unit 2-way valve freeze prevention control

If the temperature of the outdoor unit 2-way valve remains below 0°C

for 10 consecutive minutes during cooling or dehumidifying operation,

the compressor operation stops temporarily in order to prevent freezing.

When the temperature of the 2-way valve rises to 10°C or higher after

about 180 seconds, the compressor restarts and resumes normal

operation.

1.7. Indoor unit overheat prevention control

During heating operation, if the temperature of the indoor unit heat

exchanger exceeds the indoor unit heat exchanger overheat prevention temperature (about 45 to 54°C) which is determined by the operating frequency and operating status, the operating frequency is

decreased by about 4 to 15 Hz. Then, this operation is repeated every

60 seconds until the temperature of the indoor unit heat exchanger

drops below the overheat protection temperature.

Once the temperature of the indoor unit heat exchanger drops below

the overheat protection temperature, the operating frequency is

increased by about 4 to 10 Hz every 60 seconds until the normal operation condition resumes.

If the temperature of the indoor unit heat exchanger exceeds the overheat protection temperature for 60 seconds at minimum operating frequency, the compressor stops operating and then restarts after about

180 seconds, and the abovementioned control is repeated.

1.8. Outdoor unit overheat prevention control

During cooling operation, if the temperature of the outdoor unit heat

exchanger exceeds the outdoor unit heat exchanger overheat prevention temperature (about 55°C), the operating frequency is decreased

by about 4 to 15 Hz. Then, this operation is repeated every 60 seconds until the temperature of the outdoor unit heat exchanger drops to

about 54°C or lower.

Once the temperature of the outdoor unit heat exchanger drops to

about 54°C or lower, the operating frequency is increased by about 4

to 10 Hz every 60 seconds until the normal operation condition

resumes.

If the temperature of the outdoor unit heat exchanger exceeds the outdoor unit heat exchanger overheat protection temperature for (120 sec

: outdoor temperature ≥ 40°C • 60 sec : outdoor temperature < 40°C)

at minimum operating frequency, the compressor stops operating and

then restarts after about 180 seconds, and the abovementioned control is repeated.

1.4. Odor prevention control

When the air conditioner starts up in cooling mode, the discharged air

temperature is lowered slightly, and for the reduction of unpleasant

odors the operation of the indoor unit fan is delayed 60 seconds if the

automatic fan speed mode in cooling mode is set.

1.5. Indoor unit heat exchanger freeze prevention control

If the temperature of the indoor unit heat exchanger remains below

0°C for 4 consecutive minutes during cooling or dehumidifying operation, the compressor operation stops temporarily in order to prevent

freezing.

When the temperature of the indoor unit heat exchanger rises to 2°C

or higher after about 180 seconds, the compressor restarts and

resumes normal operation.

1.9. Compressor overheat prevention control

If the temperature of the compressor exceeds the compressor overheat prevention temperature (110°C), the operation frequency is

decreased by about 4 to 10 Hz. Then, this operation is repeated every

60 seconds until the temperature of the compressor drops below the

overheat protection temperature (100°C).

Once the temperature of the compressor drops below the overheat

protection temperature, the operating frequency is increased by about

4 to 10 Hz every 60 seconds until the normal operation condition

resumes.

If the temperature of the compressor exceeds the overheat protection

temperature (for 120 seconds in cooling operation or 60 seconds in

heating operation) at minimum operating frequency, the compressor

stops operating and then restarts after about 180 seconds, and the

abovementioned control is repeated.

2 – 8

Page 13

1.10. Startup control

Heating operation

Set temperature

Activation of

OFF timer

1hour

later

Max.

1.5 hours

later

Max.

2 hours

later

Timer setting

reached

1hour

later

Max.

1.5 hours

later

Max.

2 hours

later

Timer setting

reached

Activation of

OFF timer

Set temperature

-1

O

C

-1

O

C

-1

O

C

0.3

O

C

0.3

O

C

0.3

O

C

Cooling/dehumidifying operation

When the air conditioner starts in the cooling or heating mode, if the

room temperature is 2°C higher than the set temperature (in cooling

operation) or 3.5°C lower (in heating operation), the air conditioner

operates with the operating frequency at maximum. Then, when the

set temperature is reached, the air conditioner operates at the operating frequency determined by fuzzy logic calculation, then enters the

normal control mode after a while.

1.11. Peak control

If the current flowing in the air conditioner exceeds the peak control

current (see the table below), the operation frequency is decreased

until the current value drops below the peak control current regardless

of the frequency control demand issued from the indoor unit based on

the room temperature.

AY-XP12FR-N Approx. 6.4 A Approx. 7.5 A

1.12. Outdoor unit fan delay control

The compressor stops immediately after cooling, dehumidifying or

heating operation is shut down, but the outdoor unit fan continues

operation for 50 seconds before it stops.

1.13. Defrosting

1.13.1 Reverse defrosting

The defrost operation starts when the compressor operating time

exceeds 20 minutes during heating operation, as shown below, and

the outside air temperature and the outdoor unit heat exchanger temperature meet certain conditions. When the defrost operation starts,

the indoor unit fan stops. The defrost operation stops when the outdoor unit heat exchanger temperature rises to about 13C or higher or

the defrosting time exceeds 10 minutes.

Start of

heating

operation

1.14. ON timer

The ON timer can be activated by pressing the ON timer button. When

the ON timer is activated, the operation start time is adjusted based on

fuzzy logic calculations 1 hour before the set time so that the room

temperature reaches the set temperature at the set time.

1.15. OFF timer

The OFF timer can be activated by pressing the OFF timer button.

When the OFF timer is set, the operation stops after the set time.

When this timer is set, the compressor operating frequency lowers for

quieter operation, and the room temperature is gradually varied after

one hour (reduced 1°C three times (max. 3°C) in heating, or increased

0.3°C three times (max. 1°C) in cooling or dehumidifying operation) so

that the room temperature remains suitable for comfortable sleeping.

Model Peak control current

Cooling operation Heating operation

20 min or more 20 min or more 20 min or more

Defrosting

Max. 10 min

Defrosting

Max. 10 min

AYXP12FRN

1.16. Power ON start

If a jumper cable is inserted in the location marked with HAJP on the

indoor unit control printed circuit board (control PCB), connecting the

power cord to an AC outlet starts the air conditioner in either cooling or

heating mode, which is determined automatically by the room temperature sensor.

When a circuit breaker is used to control the ON/OFF operation,

please insert a jumper as described above.

1.17. Self-diagnostic malfunction code display

1.17.1 Indoor unit

1) When a malfunction is confirmed, all relays turn off and a flashing

malfunction code number is displayed to indicate the type of malfunction.

When the air conditioner is in non-operating condition, holding

down AUX button for more than 5 seconds activates the malfunction code display function.

The operation continues only in the case of a serial open-circuit,

and the main relay turns off after 30 seconds if the open-circuit condition remains.

In the case of a serial short-circuit, the air conditioner continues

operating without a malfunction code display, and the main relay

turns off after 30 seconds if the short-circuit condition remains.

The malfunction information is stored in memory, and can be

recalled later and shown on display.

2) The self-diagnostic memory can be recalled and shown on the display by stopping the operation and holding down AUX button for

more than 5 seconds.

3) The content of self-diagnosis (malfunction mode) is indicated by a

flashing number.

(For details, refer to the troubleshooting section.)

1.17.2 Outdoor unit

If a malfunction occurs, LED1 on the outdoor unit flashes in 0.2-second intervals as shown below.

(Example) Compressor high temperature abnormality

ON

OFF

1 sec 1 sec 0.6 sec

2 – 9

Page 14

AYXP12FRN

1.18. Information about auto mode

In the AUTO mode, the temperature setting and mode are automatically selected according to the room temperature and outdoor temperature when the unit is turned on.

1.19. Airflow control

The airflow control holds the two upper and lower louvers at special

positions during operation to prevent discharged air from directly blowing onto people in the room.

Modes and Temperature Settings

1.19.1 Cooling/dehumidifying operation

When the airflow button is pressed the upper louver is set at an

upward angle to send the air along the ceiling.

1.19.2 Heating

When the airflow button is pressed the lower louver is set at a down-

the figures in ( ) are temperature settings

During operation, if the outdoor temperature changes, the temperature

settings will automatically slide as shown in the chart.

ward angle to send the air directly toward the floor.

1.20. Difference of operation in Auto and Manual modes

In the Auto mode, the temperature setting is automatically determined based on the outside air temperature. In addition, the air conditioner operation

differs from the operation in the Manual mode as explained below.

1.20.1 Difference relating to set temperature

Auto mode Manual mode

Cooling Heating Dehumidifying Cooling Heating Dehumidifying

Temperature

setting

method

Automatic temperature setting based on outside air temperature. Can be changed within ±2°C using remote control.

1.21. Dehumidifying operation control

If the room temperature is 26°C or higher when dehumidifying operation starts, the dehumidifying operation provides a low cooling effect in

accordance with the room temperature setting automatically determined based on the outside air operation. (The setting value is the

same as the set temperature for cooling operation in the auto mode.)

If the room temperature is lower than 26°C when dehumidifying operation starts, the dehumidifying operation minimizes the lowering of the

room temperature.

1.22. Self Clean operation

Heating or Fan operation and Cluster operation are performed simultaneously.

The judgment of whether Heating or Fan operation is used is based on

the outside air temperature at 3 minutes after the start of internal

cleaning.

The operation stops after 40 minutes. (The air conditioner shows the

remaining minutes: 40 → 39 → 38 ... 3 → 2 → 1)

Heating operation Fan operation

Outside air temperature

24OC

1.23. Plasmacluster Ion function

Operating the Plasmacluster Ion button while the air conditioner is in

operation or in non-operation allows the switching of the operation

mode in the following sequence: “Air Clean operation” → “Stop”.

• “Self Clean operation” generates about equal amounts of (+)ions

and (-)ions from the cluster unit to provide clean air.

If the Plasmacluster Ion generation function is operated together with

the air conditioner operation, the indoor unit fan speed and louver

direction are in accordance with the air conditioner settings.

If the Plasmacluster Ion generation function is used without operating

the air conditioning function, the indoor unit fan operates at a very low

speed and the upper louver is angled upward and the lower louver

remains horizontal. (The airflow volume and direction can be changed

by using the remote control.)

Can be changed

between 18 and 32°C

using remote control.

Can be changed

between 18 and 32°C

using remote control.

1.24. Hot keep

When the room temperature rises above the set temperature by 0.6°C

or more, the ON/OFF operation of the compressor and indoor unit fan

is controlled in order to lower the room temperature.

(The values indicated below, such as "0.6°C" and "1.3°C," vary

depending on the outside air temperature.)

1.3OC

O

0.6

C

Set temperature

1.24.1 Hot keep zone 1

With the compressor frequency at the lowest, if the room temperature

is higher than the set temperature by 0.6°C but no more than 1.3°C,

the following processes will be activated.

1) The compressor stops temporarily, and restarts after 2 minutes.

2) If the room temperature remains in the hot keep zone, the compressor is turned OFF and ON in 3-minute intervals.

3) The indoor unit fan turns OFF and ON with a delay of 30 seconds

from the compressor OFF/ON.

4) After the above operation in 3-minute intervals is repeated four

times, the interval extends to 6 minutes.

1.24.2 Hot keep zone 2

If the compressor ON/OFF in hot keep zone 1 fails to bring the room

temperature within 1.3°C above the set temperature, the following processes will be activated.

1) The compressor repeats a cycle of 8-minute OFF and 6-minute

ON.

2) After the second time, the compressor remains completely OFF

and only the indoor unit fan repeats OFF-ON in set intervals.

3) While the compressor is completely OFF in 2), the louvers are set

horizontally to prevent cold air from blowing.

The zone transition and the end of hot keep operation (room temperature lower than the set temperature) are judged when the compressor

ON period ends.

* This function cannot be repealed.

Automatic setting.

Can be changed

within ±2°C.

2 – 10

Page 15

AYXP12FRN

1.25. Winter cool

Cooling operation is available during the winter season by the built in

winter cool function.

Lower limit of outdoor temperature range is -10°C DB.

When the outside air temperature is low, the outdoor unit fan operates

at slower speed.

NOTE: Built-in protect device may work when outdoor temperature

falls below 21°C DB., depending on conditions.

1.26. Auto restart

When power failure occures, after power is recovered, the unit will

automatically restart in the same setting which were active before the

power failure.

1.26.1 Operating mode (Cool, Heat, Dry)

• Temperature adjustment (within 2°C range) automatic operation

• Temperature setting

2. Explanation of cluster circuit

The cluster unit generates cluster ions, which are circulated throughout the room by the air flow created by the blower fan (indoor unit fan motor) in

the air conditioner unit.

1) When microcomputer output turns "H," the IC6 output changes to "Lo," turning ON the SSR and applying 230 V to the cluster unit for the generation of cluster ions (positive and negative ions).

• Fan setting

• Air flow direction

• Power ON/OFF

• Automatic operation mode setting

• Swing louvre

• Plasmacluster mode

1.26.2 Setting not memorized

• Timer setting

• Full power setting

• Internal cleaning

1.26.3 Disabling auto restart function

By removing (cutting) jumper J (JPJ) on the printed circuit board

(PCB), the auto restart function can be disabled.

12V

R76

C23

RE RH

Cluster unit

1

1

3

3

5

6

AC230V

Microcomputer output

IC6

R75

R23

SSR

R20

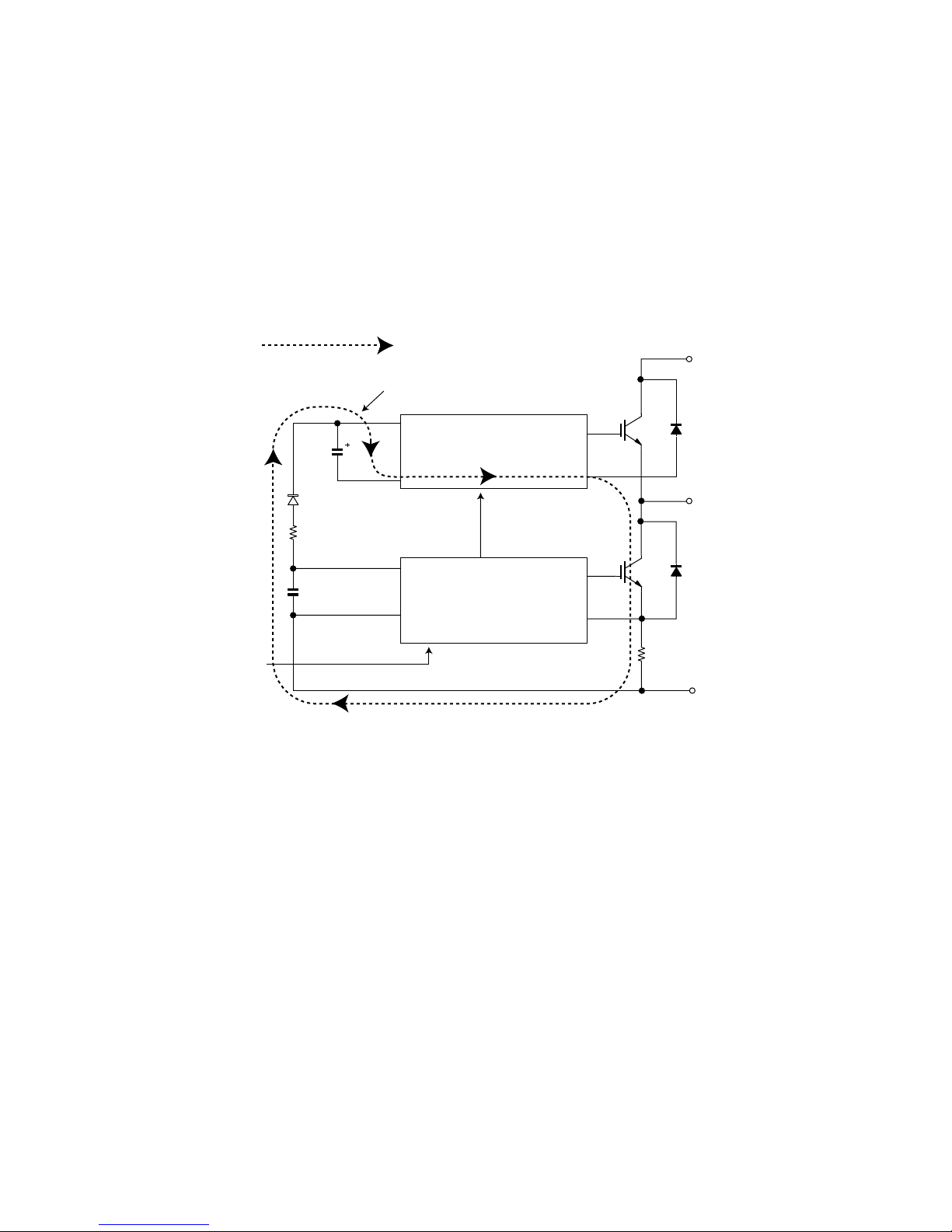

3. Outline of PAM circuit

3.1. PAM (Pulse Amplitude Modulation)

The PAM circuit varies the compressor drive voltage and controls the rotation speed of the compressor.

The IGBT shown in the block diagram charges the energy (electromotive force) generated by the reactor to the electrolytic capacitor for the inverter

by turning ON and OFF.

Reactor L5

DB1

AC

230V

Noise

filter

Reactor L6

+

IPM

Compressor

AC clock

detection

circuit

DB2

IGBT

[PAM drive circuit]

Microcomputer (IC1)

PAM drive circuit block diagram

2 – 11

IGBT

drive

circuit

Overvoltage

detection

circuit

Compressor

position

detector

Page 16

AYXP12FRN

When the IGBT is ON, an electric current flows to the IGBT via the reactor (L5), (L6) and diode bridge (DB2).

When the IGBT turns OFF, the energy stored while the IGBT was ON is charged to the voltage doubler capacitor via the diode bridge (DB1).

As such, by varying the ON/OFF duty of the IGBT, the output voltage is varied.

DB1

Stored energy

IGBT ON

IGBT OFF

Reactor

L6

L5

DB2

IGBT

3.2. High power factor control circuit

This circuit brings the operating current waveform closer to the waveform of commercial power supply voltage to maintain a high power factor.

Because of the capacitor input, when the PAM circuit is OFF, the phase of the current waveform deviates from the voltage waveform as shown below.

To prevent this deviation, a current is supplied during the periods indicated by "O" in the diagram.

To determine the length of period to supply a current, the zero-cross timing of the AC input voltage is input to the microcomputer via the clock circuit.

The power source frequency is also determined at the same time.

The IGBT turns ON after the time length determined by the zero-cross point to supply a current to the IGBT via the reactor.

This brings the current waveform closer to the voltage waveform in phase.

As described above, the ON/OFF operation of the IGBT controls the increase/decrease of the compressor power supply voltage (DC voltage) to

improve the compressor efficiency and maintain a high power factor by keeping the current phase closer to that of the supply voltage.

AC voltage waveform

AC voltage waveform

AC current waveform

AC voltage and current waveforms when PAM is OFF

AC current waveform

Zero-cross detection

IGBT ON period

AC voltage and current waveform when PAM is ON

3.2.1 Detailed explanation of PAM drive circuit sequence

AC voltage waveform

Clock

IGBT ON

A

BC

50Hz

A

1.2mS

B

1.2mS

C

0.25 2.3mS

3.2.2 AC clock (zero-cross) judgment

• The clock circuit determines the time from one rising point of the clock waveform to the next rising point.

The detected clock waveform is used to judge the power source frequency (50Hz).

• The zero-cross of the AC voltage is judged as the rising of the clock waveform, as shown in the diagram above.

3.2.3 IGBT ON start time (delay time B)

• Based on the zero-cross of the AC voltage, the IGBT turns ON after a delay time set according to the power source frequency.

3.2.4 IGBT ON time (C)

• After the above delay time, the IGBT turns ON to supply a current to the reactor.

• The ON time of the IGBT determines the amount of energy (level of DC voltage rise) supplied to the reactor.

DC voltage level in each operation mode (varies depending on external load conditions)

– Cooling operation --- 220 to 240 V

– Heating operation --- 220 to 280 V

2 – 12

Page 17

3.3. PAM protection circuit

R2

255K

C10C9

420V

750uF

R5

300K

R7

23.7KR823.7K

0V

0V

0V

IC8

15V

R113

19.1KF

R112

15K

5V

R114

1M

R115

1.8K

R116

1K

5

4

2

(Overvoltage detection)

During abnormal voltage output

IC1

38

To prevent excessive voltage of PAM output from

damaging the IPM and electrolytic capacitor as well

as the control printed circuit board (PCB), this circuit

monitors the PAM output voltage and turns off the

PAM control signal and PAM drive immediately

when an abnormal voltage output is generated. At

the same time, it shuts off the compressor operation.

The PAM output voltage is distributed to pin (4) of

the comparator (IC8). If this voltage exceeds the reference voltage at pin (5) of the IC8, the output of the

comparator (IC8) reverses (from H to L) and it is

input to pin (38) of the microcomputer (IC1) to halt

the PAM drive.

The protection voltage level is as follows.

3.3.1 Details of troubleshooting procedure for PAM

1) PAM shutdown due to error

1) When the DC voltage detection circuit sends a signal exceeding the specified voltage to the microcomputer

DC voltage of 350 V or higher (detection circuit input voltage of about 9.2 V or higher) [IC8 pin (4)]

– When an error is detected

• PAM IGBT turns OFF.

• Compressor turns OFF.

• All units shut down completely when the error occurs four times.

2) When the outdoor unit clock waveform differs from the specified value immediately before the PAM IGBT turns ON

When there is no clock waveform input

When a clock signal of other than specified power source frequency (50/60 Hz) is input

– When an error is detected

• PAM IGBT does not turn ON.

• Compressor operates normally.

• Complete shutdown does not occur.

2) PAM error indication

In case of error “1)”

– An error signal is sent to the indoor unit as soon as an error is generated.

• Malfunction No. 14-0 is indicated when the error code is called out by the indoor unit's self-diagnosis function.

– The LED on the outdoor unit flashes 14 times when an error is generated.

• The LED continues flashing in the 14-time cycle even after the compressor stops operating.

• The LED turns off (data is deleted from the memory) when the outdoor unit power is turned off.

In case of error “2)”

– An error signal is sent to the indoor unit as soon as an error is judged.

• Malfunction No. 14-1 is indicated when the error code is called out by the indoor unit's self-diagnosis function.

– The LED on the outdoor unit flashes 14 times when an error is judged.

• The LED on the outdoor unit flashes in normal pattern when the compressor stops operating.

(Compressor OFF or Thermostat OFF from remote control)

* When a user complains that the air conditioner does not provide sufficient cool air or warm air

In addition to conventional error-generating reasons, there is a possibility that the PAM IGBT does not turn ON even if the compressor is operating.

In that case, the DC voltage does not rise even though the compressor is operating, and lowers to the 180-VDC level.

– Check items

• Clock circuit check

• PAM IGBT check

• Fuse (Fu6) open-circuit check

AYXP12FRN

2 – 13

Page 18

AYXP12FRN

D

4. Explanation of IPM drive circuit

The IPM for compressor drive is made by Mitsubishi Electric.

The power supply for the IPM drive, the shunt resistance for overcurrent detection, etc., are provided outside the IPM (control PCB).

4.1. IPM drive power supply circuit

The power supply for the upper-phase IGBT (HU, HV, HW) drive employs a bootstrap system, and provides power to the upper-phase IC.

The 15-V power supply for the lower-phase IC is provided by the control printed circuit board (PCB).

4.1.1 Brief explanation of bootstrap system (single power drive system)

To supply power to the upper-phase IC, the microcomputer (IC1) turns ON the lower-phase IGBT (LU, LV, LW).

This results in a charging current that flows to the electrolytic capacitor of each upper-phase IC input and charges the bootstrap capacitor with a 15-V

current.

The power supply for the subsequent stages is charged while the lower-phase IGBT is ON in ordinary compressor drive control.

Initial charge period

VDB

Charging current group

Bootstrap capacitor

(HU,HV,HW)

HVIC

High-voltage-withstanding,

high-speed recovery diode

P(Vcc)

U,V,W,

V

D

VCIN(n)

(LU,LV,LW)

Bootstrapcircuit

LVIC

N-side

IGBT

N(GN

2 – 14

Page 19

AYXP12FRN

4.1.2 DC overcurrent detection circuit

When a current of about 25 A or higher flows through the shunt resistance (R49) on the control printed circuit board (PCB), the voltage at this resistance is input to IPM CIN pin (26). Then, the gate voltage of the lower-phase IGBT (LU, LV, LW) inside the IPM turns OFF to cut off the overcurrent. At

the same time, an L output of about 1.8 ms is generated from IPM Fo pin (24), and this results in an L input to overcurrent detection input pin (34) of

the microcomputer (IC1) and turns OFF the PWM signal output (IC1 pins (51) through (56)) to the IGBT gate.

Protection circuit status

(Lower phase)

Internal IGBT gate

Output current Ic (A)

Sense voltage relative

to shunt resistance

Error output Fo

SET

RESET

(About 22 A)

SC

a1

SC reference voltage

Delay by CR time constant circuit

About 1.8 ms

IPM overcurrent

detection circuit

CiN

26

FO

24

P

Shunt resistance

R49

N

Overcurrent

5V

IC1

34

0V

2 – 15

Page 20

AYXP12FRN

5. 120° energizing control (digital position detection control)

This control system detects the digital position detection signal and adjusts the rate of acceleration/deceleration accordingly.

The motor's induced voltage waveform is input to the comparator in the form of PWM-switched pulse waveform, and a position detection signal is

generated as a reference voltage equaling 1/2 of 280 VDC. However, since there is no induced voltage waveform when the PWM waveform is OFF,

the microcomputer performs internal processing so that detection is enabled only when it is ON. Based on the detected position signal, actual PWM

waveform output timing is determined. Since it does not use a filter circuit, the detection accuracy is high.

The microcomputer performs internal processing to cancel spike voltage during the regenerative process.

Furthermore, even if the induced voltage is low, position detection is still possible, thus allowing sensor-less operation at low rotation speed in the initial stage of operation. This reduces the starting current and improves the IPM reliability.

Terminal voltage waveform

Reference voltage

(1/2 of DC voltage)

Spike voltage

(cancelled)

Comparator output waveform

(Position signal waveform)

2 – 16

Page 21

AYXP12FRN

AYXP12FRN

CHAPTER 3. FUNCTION AND OPERATION OF PROTECTIVE PROCEDURES

Service Manual

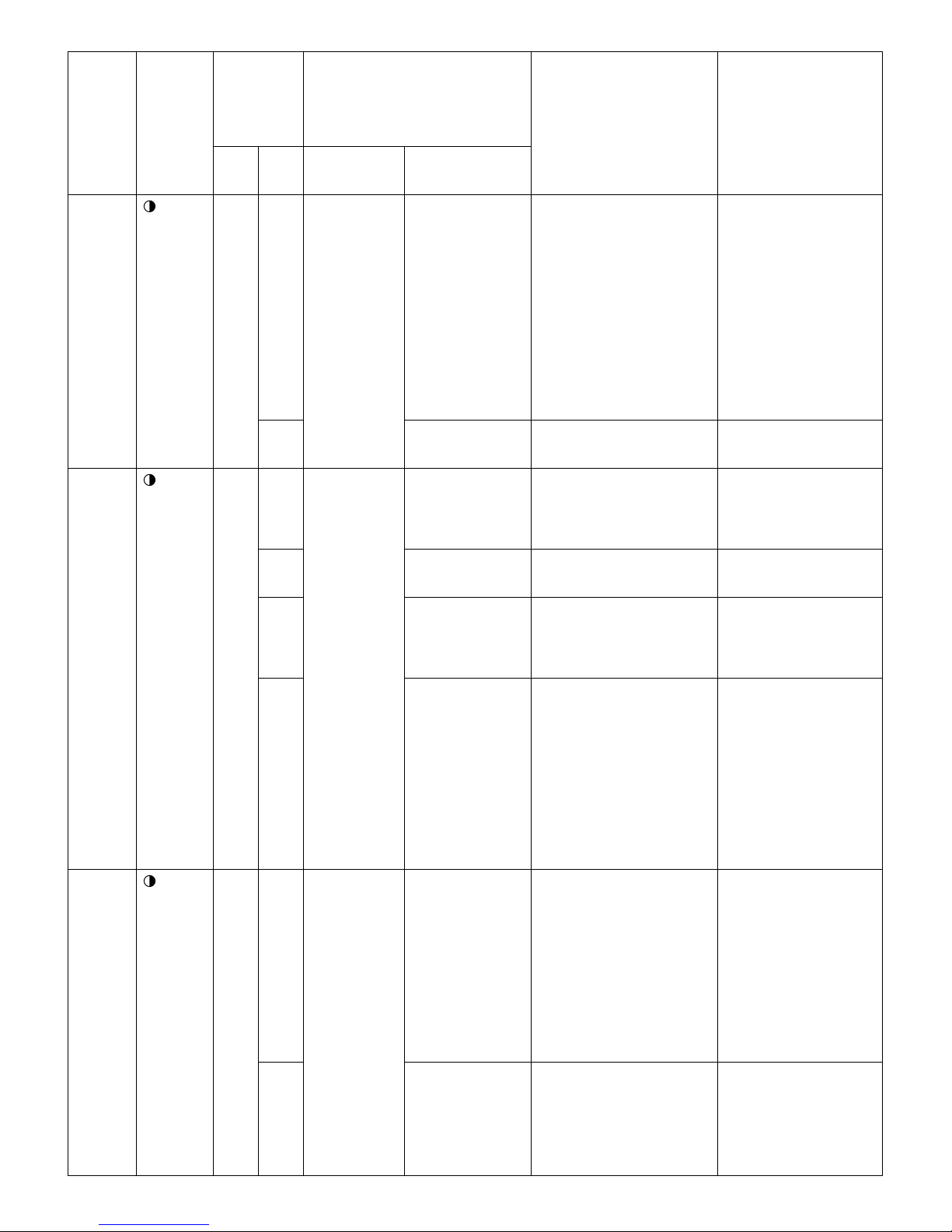

[1] PROTECTION DEVICE FUNCTIONS AND OPERATIONS

Function Operation Self-diagnosis

result display

Description Detection period Reset condition Indoor

1 Indoor unit fan lock Operation stops if there is no

Indoor unit fan rotation speed error

2 Indoor unit freeze

prevention

3 2-way valve freeze

prevention

4 Indoor unit heat

exchanger overheat shutdown

5 Outdoor unit heat

exchanger overheat shutdown

6 Compressor dis-

charge overheat

shutdown

7 Dehumidifying oper-

ation temporary

stop

8 DC overcurrent

error

input of rotation pulse signal from

indoor unit fan motor for 1 minute.

Operation stops if rotation pulse

signal from indoor unit fan indicates abnormally low speed

(about 300 rpm or slower).

Compressor stops if temperature

remains below 0°C for 4 minutes.

Compressor stops if temperature

of outdoor unit 2-way valve

remains below 0°C for 10 continuous minutes during cooling or

dehumidifying operation.

Operating frequency lowers if

indoor unit heat exchanger temperature exceeds overheat temperature during heating

operation.

Compressor stops if indoor unit

heat exchanger temperature

exceeds overheat temperature for

60 seconds at minimum frequency.

Overheat temperature setting

value indoor unit heat exchanger

thermistor temperature: about 45

to 54°C

Operation frequency lowers if outdoor unit heat exchanger temperature exceeds about 55°C during

cooling operation.

Compressor stops if outdoor unit

heat exchanger temperature

exceeds about 55°C for 120 seconds at minimum frequency.

Operating frequency lowers if

temperature of compressor

chamber thermistor (TH1) falls

below about 110°C.

Compressor stops if temperature

of compressor chamber thermistor (TH1) remains at about

110 °C (for 120 seconds in cooling

operation, or 60 seconds in heating operation) at minimum frequency.

Compressor stops if outside air

temperature thermistor is lower

than about 16°C during dehumidifying operation.

Compressor stops if electric current of about 25 A or higher flows

in IPM.

When indoor unit fan

is in operation

When indoor unit fan

is in operation

When in cooling or

dehumidifying operation

When in cooling or

dehumidifying operation

When in heating

operation

When in cooling or

dehumidifying operation

When compressor is

in operation

When in dehumidifying operation

When compressor is

in operation

Indoor

unit

error

display

Operation OFF or ON ✩2 Yes None

Operation OFF or ON ✩2 Yes None

Automatic reset when

heat exchanger temperature rises above

freeze prevention

temperature (2°C or

higher)

Automatic reset when

temperature of 2-way

valve rises above

10°C.

Automatic reset after

safety period (180

sec).

Automatic reset after

safety period (180

sec).

Automatic reset after

safety period (180

sec).

Automatic reset when

outside air temperature rises above

16°C.

Operation OFF or ON Yes ✩1Yes Yes

— None None

None Yes Yes

None Yes Yes

None Yes Yes

None Yes Yes

None Yes Yes

unit

Outdoor

unit

3 – 1

Page 22

AYXP12FRN

Function Operation Self-diagnosis

Description Detection period Reset condition Indoor

9 AC overcurrent

error

10 AC overcurrent

error in compressor

OFF status

11 AC maximum cur-

rent error

12 AC current defi-

ciency error

13 Thermistor installa-

tion error or 4-way

valve error

14 Compressor high

temperature error

15 Outdoor unit heat

exchanger thermistor short-circuit

error

16 Outdoor unit outside

air temperature

thermistor short-circuit error

17 Outdoor unit suction

thermistor short-circuit error

18 Outdoor unit 2-way

valve thermistor

short-circuit error

19 Outdoor unit heat

exchanger thermistor open-circuit

error

20 Outdoor unit outside

air temperature

thermistor open-circuit error

21 Outdoor unit suction

thermistor open-circuit error

22 Outdoor unit 2-way

valve thermistor

open-circuit error

23 Outdoor unit dis-

charge thermistor

open-circuit error

24 Serial signal error Power relay turns OFF if indoor

Operating frequency lowers if

compressor AC current exceeds

peak control current value. Compressor stops if compressor AC

current exceeds peak control current value at minimum frequency.

Indoor and outdoor units stop if

AC current exceeds about 3 A

while compressor is in non-operation status.

Compressor stops if compressor

AC current exceeds 17 A.

Compressor stops if operating

frequency is 50 Hz or higher and

compressor AC current is about

2.0 A or lower.

Compressor stops if high and low

values of temperatures detected

by outdoor unit heat exchanger

thermistor (TH2) and 2-way valve

thermistor (TH5) do not match

operating cycle.

Compressor stops if compressor

chamber thermistor (TH1)

exceeds about 114°C, or if there

is short-circuit in TH1.

Compressor stops if there is

short-circuit in outdoor unit heat

exchanger thermistor (TH2).

Compressor stops if there is

short-circuit in outdoor unit outside air temperature thermistor

(TH3).

Compressor stops if there is

short-circuit in outdoor unit suction thermistor (TH4).

Compressor stops if there is

short-circuit in outdoor unit 2-way

valve thermistor (TH5).

Compressor stops if there is

open-circuit in outdoor unit heat

exchanger thermistor (TH2).

Compressor stops if there is

open-circuit in outdoor unit outside air temperature thermistor

(TH3).

Compressor stops if there is

open-circuit in outdoor unit suction thermistor (TH4).

Compressor stops if there is

open-circuit in outdoor unit 2-way

valve thermistor (TH5).

Compressor stops if there is

open-circuit in outdoor unit discharge thermistor (TH1).

unit cannot receive serial signal

from outdoor unit for 8 minutes.

Compressor stops if outdoor unit

cannot receive serial signal from

indoor unit for 30 seconds.

result display

Indoor

unit

error

display

When compressor is

in operation

When compressor is

in non-operation

When compressor is

in operation

When compressor is

in operation

3 minutes after compressor startup

When in operation Operation OFF or ON Yes ✩1Yes Yes

At compressor startup

At compressor startup

At compressor startup

At compressor startup

At compressor startup

At compressor startup

At compressor startup

At compressor startup

At compressor startup

When in operation Operation OFF or ON

When in operation Reset after reception

Operation OFF or ON Yes ✩1Yes Yes

Replacement of

defective parts such

as IPM

Operation OFF or ON Yes ✩1Yes Yes

Operation OFF or ON Yes ✩1Yes Yes

Operation OFF or ON Yes ✩1Yes Yes

Operation OFF or ON Yes ✩1Yes Yes

Operation OFF or ON Yes ✩1Yes Yes

Operation OFF or ON Yes ✩1Yes Yes

Operation OFF or ON Yes ✩1Yes Yes

Operation OFF or ON Yes ✩1Yes Yes

Operation OFF or ON Yes ✩1Yes Yes

Operation OFF or ON Yes ✩1Yes Yes

Operation OFF or ON Yes ✩1Yes Yes

Operation OFF or ON Yes ✩1Yes Yes

(Automatic reset

when less than 8 minutes)

of serial signal

Yes ✩ 2Yes Yes

None None None

unit

Yes None

Outdoor

unit

3 – 2

Page 23

Function Operation Self-diagnosis

Description Detection period Reset condition Indoor

25 Compressor star-

tup error

26 Compressor rota-

tion error (at 120°

energizing)

27 Outdoor unit DC fan

error

28 PAM overvoltage

error

29 PAM clock error When power source frequency

30 IPM pin level error When Outdoor unit starts to run,

✩1—The outdoor unit restarts four times before the indoor unit error is displayed (complete shutdown).

✩2—A single error judgment results in the display of the indoor unit error (complete shutdown).

✩3—The outdoor unit restarts eight times before the indoor unit error is displayed (complete shutdown).

Compressor stops if compressor

fails to start up.

Compressor stops if there is no

input of position detection signal

from compressor or input is

abnormal.

Operation stops if there is no

input of rotation pulse signal from

outdoor unit fan motor for 30 seconds.

Compressor stops if DC voltage is

350 V or higher.

cannot be determined (at startup),

or when power source clock cannot be detected for 1 continuous

second (at startup).

MCU checks 6 control pin levels

of IPM. If MCU detects some pin

levels isn’t different from another

pin level. MCU doesn’t run Compressor.

At compressor startup

Compressor operating at 120° energizing

When outdoor unit

fan is in operation

When in operation Operation OFF or ON Yes ✩1Yes Yes

At compressor startup, when in operation

At compressor startup

Operation OFF or ON Yes ✩3Yes Yes

Operation OFF or ON Yes ✩3Yes Yes

Operation OFF or ON Yes ✩1Yes Yes

Compressor continues operation without stopping.

Operation OFF or ON Yes ✩1Yes Yes

AYXP12FRN

result display

Indoor

unit

error

display

None Yes Yes

unit

Outdoor

unit

[2] AIR CONDITIONER OPERATION IN THERMISTOR ERROR

1. Indoor unit

Item Mode Control opera-

Room temperature thermistor

(TH1)

Auto Operation mode

judgment

Cooling Frequency control Room becomes

Dehumidifying Room tempera-

ture memory

Frequency control

Heating Frequency control Room does not

tion

When resistance is low

(temperature

judged higher

than actual)

Cooling mode is

activated even if

room temperature is low.

too cold.

Normal operation. Room tempera-

become warm.

Short-circuit When resis-

Cooling mode is

activated in most

cases.

Air conditioner

operates in full

power even when

set temperature is

reached.

ture is stored in

memory as

31.0°C, and compressor does not

stop.

Hot keep status

results immediately after operation starts.

Frequency does

not increase

above 30 Hz (40

Hz).

Open-circuit

tance is high

(temperature

judged lower

than actual)

Heating mode is

activated even if

room temperature is high.

Room does not

become cool.

Normal operation. Room tempera-

Room becomes

too warm.

Heating mode is

always activated.

Compressor does

not operate.

ture is stored in

memory as

18.5°C, and compressor does not

operate.

Air conditioner

operates in full

power even when

set temperature is

reached.

3 – 3

Page 24

AYXP12FRN

Item Mode Control opera-

Heat exchanger

thermistor (TH2)

Cooling

Dehumidifying

Heating Cold air preven-

2. Outdoor unit

Item Mode Control opera-

Compressor

chamber thermistor (TH1)

Heat exchanger

thermistor (TH2)

Outside air temperature thermistor (TH3)

Suction pipe thermistor (TH4)

Cooling

Dehumidifying

Heating

Cooling

Dehumidifying

Heating Expansion valve

Auto Operation mode

Cooling

Dehumidifying

Heating Rating control

Cooling

Dehumidifying

Heating Expansion valve

tion

Freeze prevention

tion

tion

Expansion valve

control and compressor protection

Outdoor unit heat

exchanger overheat prevention

control

Defrosting

judgment

Operation not

affected

Defrosting

Expansion valve

control

control

When resistance is low

(temperature

judged higher

than actual)

Indoor unit evaporator may

freeze.

Cold air prevention deactivates

too soon and cold

air discharges.

When resistance is low

(temperature

judged higher

than actual)

Compressor

operates, but

room does not

become cool or

warm (expansion

valve is open).

Compressor

operates at low

speed or stops.

Defrosting operation is not activated as needed,

and frost accumulates on outdoor

unit (expansion

valve is closed).

Cooling mode is

activated even if

room temperature is low.

Normal operation. Outdoor unit ther-

Defrosting operation is activated

unnecessarily.

Compressor

operates, but

room does not

become cool

(expansion valve

is open).

Compressor

operates, but

room does not

become warm

(expansion valve

is open).

Short-circuit When resis-

Indoor unit evaporator may

freeze.

Compressor

operates at low

speed or stops,

and frequency

does not

increase.

Short-circuit When resis-

Compressor high

temperature error

indication.

Outdoor unit thermistor short-circuit error

indication.

Outdoor unit thermistor short-circuit error

indication.

Outdoor unit thermistor short-circuit error

indication.

mistor short-circuit error

indication.

Outdoor unit thermistor short-circuit error

indication.

Outdoor unit thermistor short-circuit error

indication.

Outdoor unit thermistor short-circuit error

indication.

tance is high

(temperature

judged lower

than actual)

Compressor

stops occasionally.

Cold air prevention deactivates

too slow.

tance is high

(temperature

judged lower

than actual)

Layer short-circuit or open-circuit may result in

compressor in

normal operation.

Normal operation. Outdoor unit ther-

Defrosting operation is activated

unnecessarily,

and room does

not become warm

(expansion valve

is open).

Heating mode is

activated even if

room temperature is high.

Normal operation. Outdoor unit ther-

Defrosting operation is not activated, and frost

accumulates on

outdoor unit.

Frost accumulates on evaporator inlet section,

and room does

not become cool

(expansion valve

is closed).

Frost accumulates on expansion valve outlet

section, and room

does not become

warm (expansion

valve is closed).

Open-circuit

Compressor does

not operate.

Cold air prevention does not

deactivate, and

indoor unit fan

does not rotate.

Open-circuit

Outdoor unit thermistor open-circuit error

indication.

mistor open-circuit error

indication.

Outdoor unit thermistor open-circuit error

indication.

Outdoor unit thermistor open-circuit error

indication.

mistor open-circuit error

indication.

Outdoor unit thermistor open-circuit error

indication.

Outdoor unit thermistor open-circuit error

indication.

Outdoor unit thermistor open-circuit error

indication.

3 – 4

Page 25

AYXP12FRN

Item Mode Control opera-

tion

When resistance is low

Short-circuit When resis-

(temperature

judged higher

than actual)