IVT AirModule E 15, AirModule E 9, Airbox E 50- 90, Airbox E 130-170, Airbox S 50- 90 Installer's Manual

...Page 1

AirModule E 9/15

230V 1N~ / 400V 3N~

Installer Guide

6 720 813 268(2014/10)

6 720 809 156-00.1I

Page 2

Table of Contents

Table of Contents

1 Key to symbols and safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

8.12 Connection option EMS bus . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9 User interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.1 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.2 Important notices on usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.3 Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2 Standard delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 Information about the heat pump . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 Application area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.3 Heating system minimum volume and operation . . . . . . . . . . . . 4

3.4 Type plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.5 Transport and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.6 Heat pump module positioning . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.7 Checks before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.8 Connection principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Technical information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1 Technical information - heat pump module . . . . . . . . . . . . . . . . 6

4.2 System configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

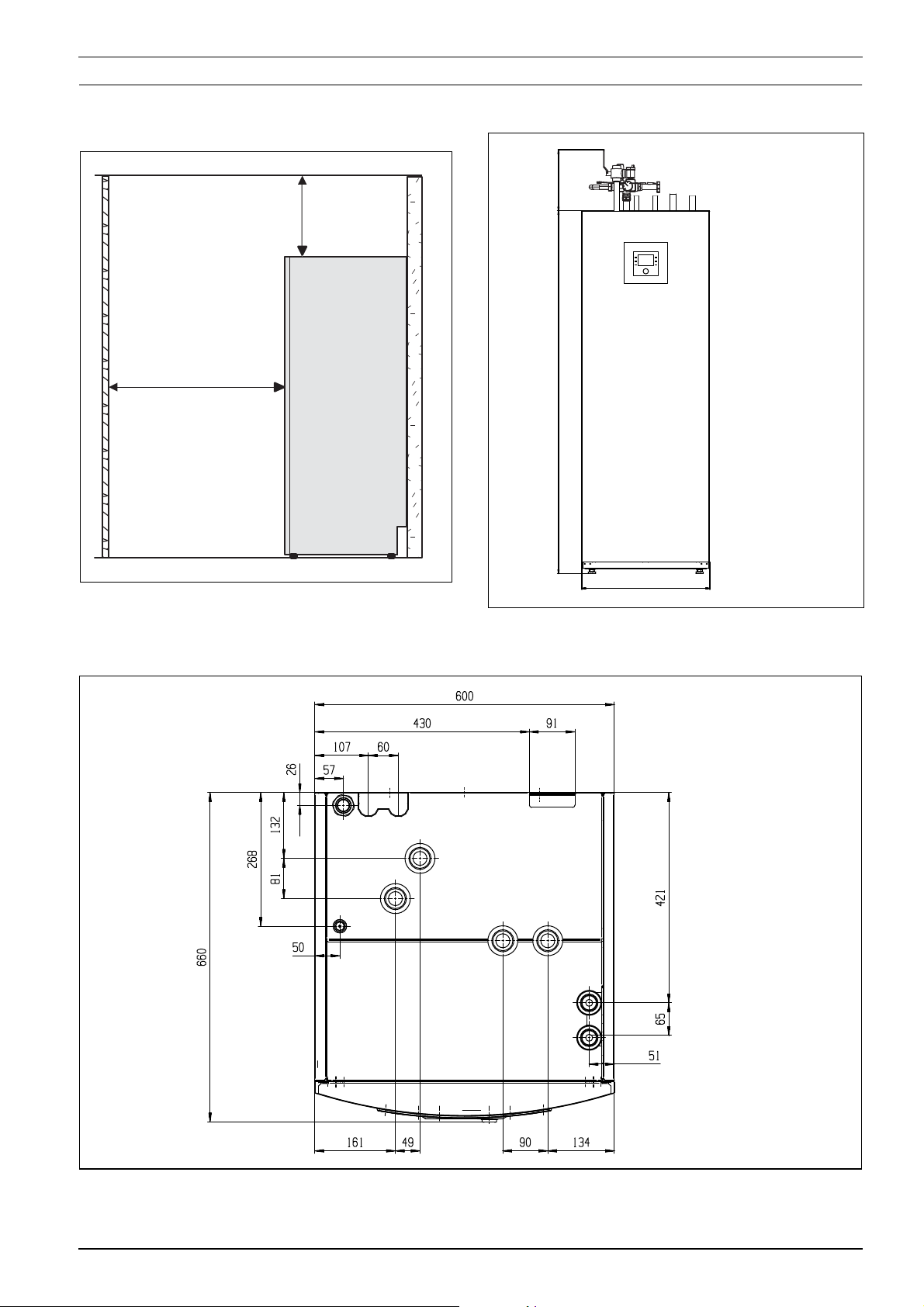

5 Measurements, positioning distance, and pipe connections . . . . . . 11

5.1 Heat pump module dimensions and connections . . . . . . . . . . 11

5.2 Pipework . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.1 Detailed discharge pipe installation requirements (Combi model)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.2 Preparatory pipework . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.3 Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.4 Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.5 Water quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.6 Heating system flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.7 Operation without heat pump (stand-alone) . . . . . . . . . . . . . . 15

7.8 Installation with cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.9 Installation with solar heater (only solar model) . . . . . . . . . . . 16

7.10 Installation with pool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.11 Connecting the heat pump module to the heat pump . . . . . . . 17

7.12 Connecting the heat pump module to the heating system and tap

water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.13 Low energy pump for heat transfer medium (PC0) . . . . . . . . . 19

7.14 Circulation pump for the heating system (PC1) . . . . . . . . . . . . 19

7.15 DHW circulation pump PW2 (accessory) . . . . . . . . . . . . . . . . . 19

7.16 Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.17 Several heating circuits (mixing valve module accessory, see

separate instructions) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.18 Installation of condensation sensor (accessories) . . . . . . . . . . 19

7.19 Temperature sensor installation . . . . . . . . . . . . . . . . . . . . . . . . 20

7.20 Heat pump and heat pump module filling . . . . . . . . . . . . . . . . . 22

10 Basic principles of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 Key and symbol overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.2 Display symbols overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.3 Using the service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

10.4 Service menu overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11.1 General user interface commissioning . . . . . . . . . . . . . . . . . . . 38

11.2 System commissioning via configuration wizard . . . . . . . . . . . 39

11.3 Commissioning other settings . . . . . . . . . . . . . . . . . . . . . . . . . 40

11.4 Performing the function test . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11.5 Check monitored values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11.6 System handover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

12 Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

12.1 Heat pump settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

12.2 Booster heater settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

12.3 Settings for heating/cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

12.4 DHW settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

12.5 Pool settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

12.6 Solar system settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

12.7 Hybrid system settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

12.8 Anti-seizing protection settings . . . . . . . . . . . . . . . . . . . . . . . . 53

12.9 Diagnostics menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

13 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

14 Heat pump and heat pump module venting . . . . . . . . . . . . . . . . . . . . . 57

15 Heat pump module components replacement . . . . . . . . . . . . . . . . . . 58

16 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

16.1 Set heating system operating pressure . . . . . . . . . . . . . . . . . . 58

16.2 Pressure switch and overheating protection . . . . . . . . . . . . . . 58

16.3 Operating temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

17 Environmental protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

18 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

19 Connection for IP module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

20 Commissioning protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8 Electric installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.1 CAN-BUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.2 EMS-BUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.3 Printed circuit board handling . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.4 External connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.5 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.6 Connecting the heat pump module . . . . . . . . . . . . . . . . . . . . . . 24

8.7 Electric box layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.8 Power supply heat pump and heat pump module 9 kW 3N~ . 29

8.9 Power supply heat pump and heat pump module 15 kW . . . . 30

8.10 Installer module circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . 31

8.11 Heat pump/heat pump module circuit diagram . . . . . . . . . . . . 32

2

AirModule 6 720 813 268(2014/10)

Page 3

Key to symbols and safety instructions

1 Key to symbols and safety instructions

1.1 Key to symbols

Warnings

Warnings in this document are identified by a warning

triangle printed against a grey background.

Keywords at the start of a warning indicate the type and

seriousness of the ensuing risk if measures to prevent

the risk are not taken.

The following keywords are defined and can be used in this document:

• NOTICE indicates a situation that could result in damage to property

or equipment.

• CAUTION indicates a situation that could result in minor to medium

injury.

• WARNING indicates a situation that could result in severe injury or

death.

• DANGER indicates a situation that will result in severe injury or

death.

Important information

This symbol indicates important information where

there is no risk to people or property.

Additional symbols

Symbol Explanation

▶ Step in an action sequence

Cross-reference to another part of the document

• List entry

– List entry (second level)

Table 1

1.2 General safety instructions

These installation instructions are intended for plumbers, heating

engineers and electricians.

▶ Read any installation instructions (heat pump, heating controls, etc.)

carefully before starting the installation.

▶ Observe the safety instructions and warnings.

▶ Observe national and regional regulations, technical rules and

guidelines.

▶ Record all work carried out.

Intended use

This heat pump must only be used as a heat appliance in a sealed hot

water heating system for domestic purposes.

Any other use is considered inappropriate. Any damage that results from

such use is excluded from liability.

Installation, commissioning and servicing

Installation, commissioning and servicing must only be carried out by an

authorised contractor.

▶ Only use original spares.

Electrical work

Electrical work must only be carried out by a qualified electrician.

▶ Before starting electrical work:

– Isolate the mains electrical supply and secure against

unintentional reconnection.

– Check for zero potential.

▶ Also observe connection diagrams of other system components.

Handover to the user

When handing over, instruct the user how to operate the heating system

and inform him about its operating conditions.

▶ Explain how to operate the heating system and draw the user's

attention to any safety-relevant action.

▶ Explain that modifications and repairs must only be carried out by an

authorised contractor.

▶ Point out the necessity of inspection and servicing for safe and

environmentally compatible operation.

▶ Leave the installation instructions and the operating instructions

with the user.

AirModule –6 720 813 268(2014/10)

3

Page 4

Standard delivery

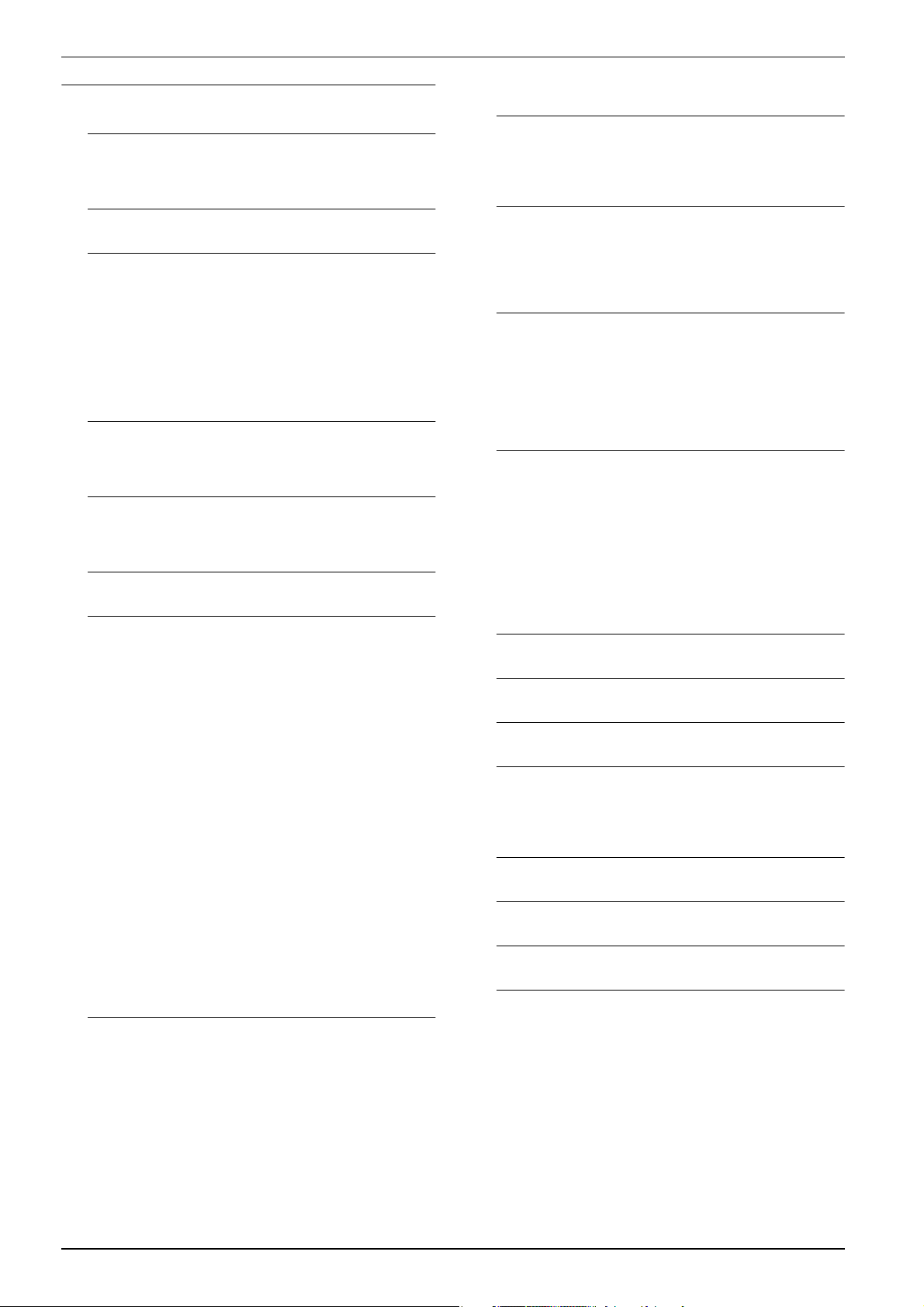

2 Standard delivery

1

2

TL1

4

Fig. 1 Standard delivery

[1] Heat pump module

[2] Legs

[3] Operating Instructions

[4] Installation instructions

[5] Safety assembly in loose parts

[T1] Outside temperature sensor

3 General

The language of the original manual is Swedish, other languages are a

translation of the original manual.

Only trained personnel may perform this installation.

The installer must comply with local rules and

regulations as well as the information in the installation

and operating instructions.

Cooling is disabled in the UK model to comply with

the regulations for RHI.

3.1 Information about the heat pump

AirModule are heat pump modules that are intended for indoor use and

for connection with outdoor AirX heat pumps.

The following combinations are possible:

AirModule AirX

E9 50

E9 70

E9 90

E15 130

E15 170

Table 2

The AirModule heat pump module has a built-in immersion heater.

3

5

6 720 810 350-01.1I

3.2 Application area

The heat pump module may only be used in closed heating systems in

accordance with EN 12828.

Other usage is prohibited. Any damage resulting from prohibited usage

is excluded from liability.

3.3 Heating system minimum volume and operation

To avoid multiple start/stop cycles, incomplete

defrosting or unnecessary alarms, a sufficient amount of

energy stored in the system is required. Energy is stored

in the heating system water volume, as well as in the

system components (radiators) and in the concrete

foundation (underfloor heating system).

Since the requirements vary for different heat pump installations and

heating systems, no general minimum volume is stated. Please refer to

the following prerequisites for all heat pump sizes instead:

Under floor heating system without a buffer cylinder

To ensure that a sufficient amount of energy is available for defrosting,

the largest room should not contain room thermostats but room

controllers should be used instead. At least 30 m

be regulated by a room controller, since the heat pump then will adjust

flow temperature automatically.

Radiator system without a buffer cylinder

To ensure that a sufficient amount of energy is available for defrosting,

there should be at least 4 water radiators of 500 W/unit in one system

without mixing valve. A room controller is recommended, since the heat

pump then will automatically adjust flow temperature.

Radiator and under floor heating systems on different circuits without a buffer cylinder

To ensure that a sufficient amount of energy is available for defrosting,

there should be at least 4 water radiators of 500 W/unit in the circuit

without mixing valve. No minimum floor surface is required for the

2

floor surface should

4

AirModule 6 720 813 268(2014/10)

Page 5

underfloor heating system circuit with mixing valve. A room controller is

recommended, since the heat pump then will automatically adjust flow

temperature.

Only circuits with mixing valve

To ensure that a sufficient amount of energy is available for defrosting, a

buffer cylinder of at least 50L is required for heat pump sizes 5-9 and of

at least 100L for heat pump sizes 13-17.

Fan convector

To ensure that a sufficient amount of energy is available for defrosting, a

buffer cylinder of at least 10L is required.

3.4 Type plate

The data plate is found on the module roof plate.

3.5 Transport and storage

The heat pump module must always be transported and stored upright.

If needed, it may be leaned temporarily.

The heat pump module may not be stored or transported in

temperatures below – 10 °C.

3.6 Heat pump module positioning

• The heat pump module is placed indoors. Pipework between the heat

pump and the heat pump module should be as short as possible. The

pipes must be insulated ( Chapter 7.16).

• Leakage drain water from the pressure relief valve should be drained

from the heat pump module to a frost protected outlet.

• The space where the heat pump module is placed must have a floor

drain.

General

3.7 Checks before installation

▶ Check that all pipe connections are intact and have not shaken loose

during transportation.

▶ Before operation of the heat pump module, the heating system and

the water heater, including the heat pump module, must be filled and

depressurized.

▶ Wiring should be kept as short as possible to protect the system from

downtime, for example during a thunderstorm.

▶ Low voltage wiring must be separated from high voltage wiring by at

least 100 mm.

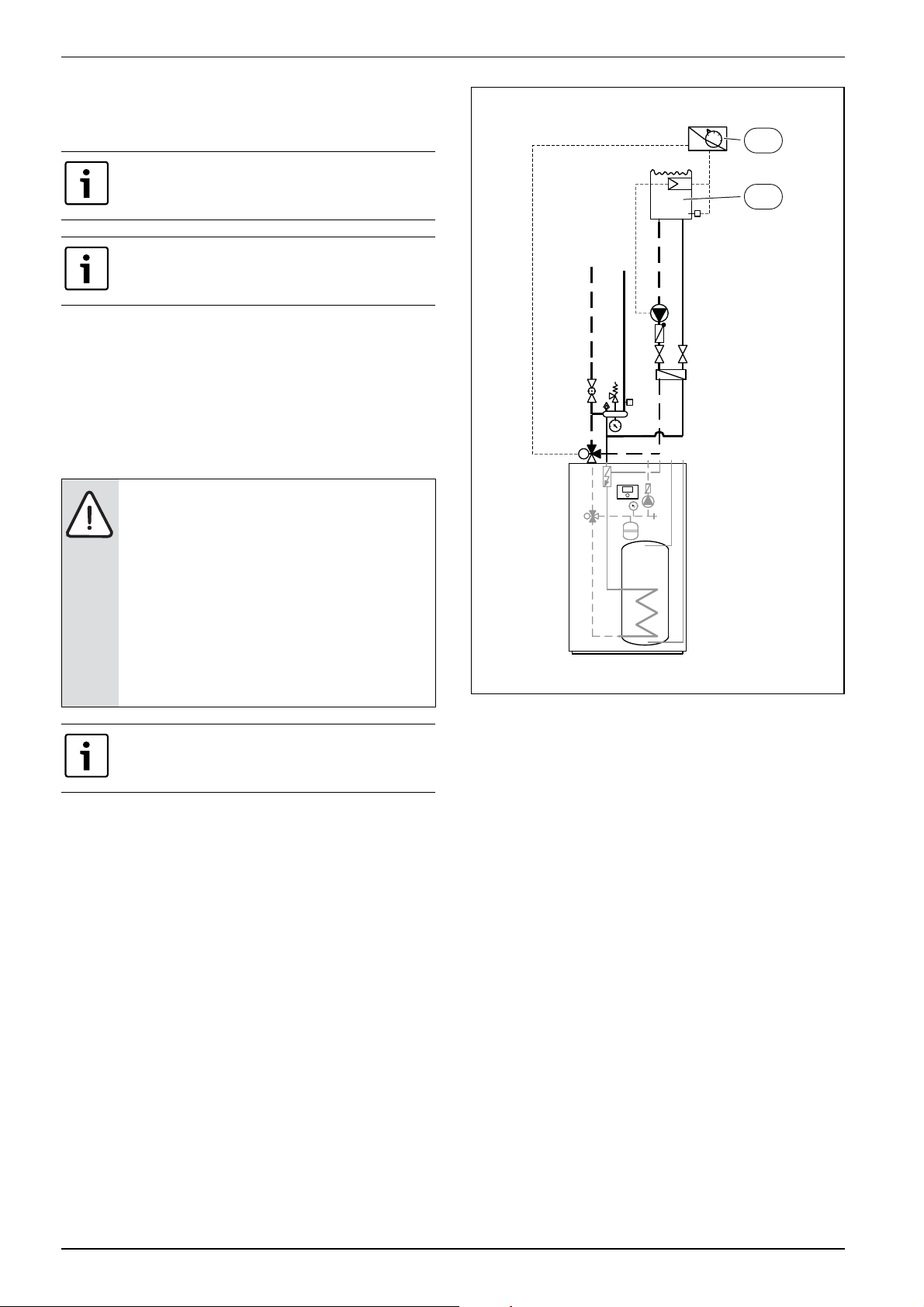

3.8 Connection principle

The principle is based on floating condensation and a immersion heater

in the heat pump module. The user interface manages the heat pump

and the heat pump module according to a set heating curve.

When the heat pump is not able to heat the house on its own, the heat

pump module automatically starts the booster heater and produces

together with the heat pump the desired temperature in the house.

DHW is prioritized and is managed by a sensor TW1 in the hot water

cylinder. While the heater is heated, the heating system heating mode is

temporarily disconnected by a 3-way valve. When the hot water cylinder

is heated, the heat pump heating mode continues.

Heating and DHW mode when heat pump is inactive:

At outside temperatures below app. –20 °C (adjustable value) the heat

pump stops automatically and cannot produce hot water. The booster

heater in the heat pump module will in this case take over both the

heating mode and the DHW production. The heat pump will restart when

the temperature gets above –17 °C.

AirModule –6 720 813 268(2014/10)

5

Page 6

Technical information

4 Technical information

4.1 Technical information - heat pump module

Unit E9 E15

Electrical information

Power supply V 4001) /230

Recommended fuse size A 161) / 50

Immersion heater in steps kW 3/6/9 3/6/9/12/15

Heating installation

Connection

3)

Maximum operating pressure kPa 250 250

Minimum operating pressure kPa 50 50

Expansion vessel L 14 14

External available pressure kPa

Minimum flow L/s 0.36 0.59

Circulation pump model Grundfos UPM2 25-75 PWM Wilo Stratos Para 25/1-11 PWM

Flow max. temperature, booster

°C 85 85

only

General

Hot water cylinder volume L 190 190

Maximum operating pressure on

MPa 1

tap DHW circuit

Material Stainless steel 1.4521

IP rating IP X1

Dimensions (WxDxH) mm 600x660x1800

Weight kg 135

Table 3 heat pump module with immersion heater

1) 3N AC 50 Hz

2) 1N AC 50 Hz

3) See Connections in safety assembly

4) This depends on the type of heat pump, see tab. 11

2)

2)

400

25

1)

Cu 28 Cu 28

4)

4)

1)

6

AirModule 6 720 813 268(2014/10)

Page 7

Technical information

4.2 System configurations

The heat pump and heat pump module may be installed

only in accordance with the official system solutions

provided by the manufacturer.

Other system solutions are not allowed. Any damage and

problems resulting from prohibited installation are

excluded from liability.

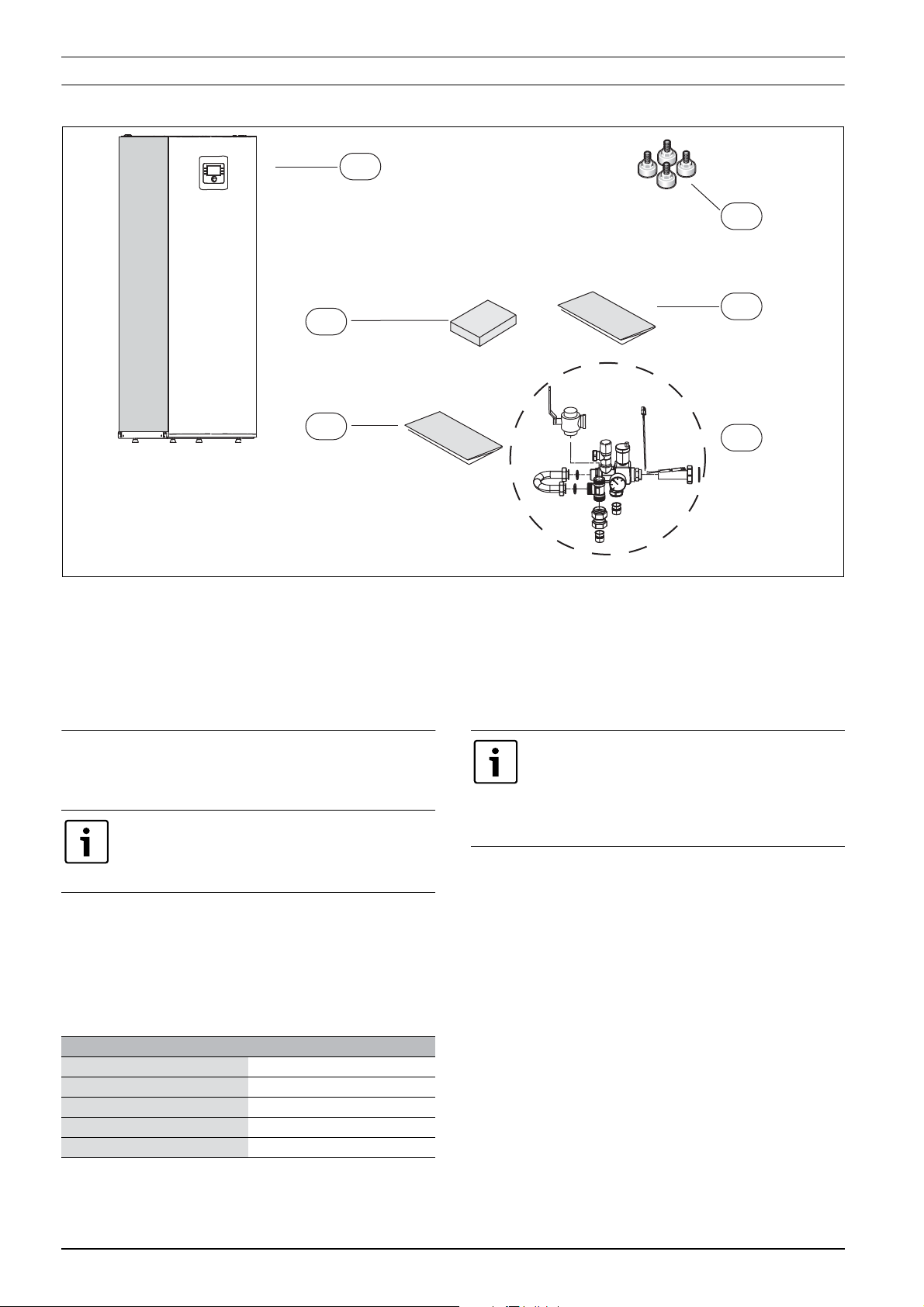

4.2.1 System configuration explanations

General

Installer

module

ProControl 600 User interface

CR10H Room controller (accessories)

T1 Outside temperature sensor

CC1 Buffer cylinder (accessories)

MK2 Condensation sensor (accessories)

VC0 3-way valve (accessories)

PW2 DHW circulation pump hot water (accessories)

Table 4 General

Z1 Heating circuit without mixing valve

PC1 Circulation pump, heating circuit

T0 Flow temperature sensor (placed in the safety assembly or

Table 5 Z1

Installer module integrated into the heat pump

module

in the buffer cylinder)

Circulation pump PC1 is controlled by the control unit in the heat pump

module.

If a fresh water station is installed, it must have its own control unit.

If a buffer cylinder is used, a 3-way valve VC0 must be installed in

accordance with the system solution. The 3-way valve replaces the Tunit in the safety assembly ( Chapter 5.1.1) and is connected

electrically to terminal VC0 on the installer module.

Z2/Z3 Heating circuit with mixing valve (accessories)

MM100 Mixing valve module (controller for circuit)

PC1 Circulation pump, heating circuit 2

VC1 Mixing valve

TC1 Flow temperature sensor, heating circuit 2,3..

MC1 Thermal shut-off valve, heating circuit 2,3...

Table 6 Z2

4.2.2 Non-return valve in heating circuit

T

T

1

6 720 809 064-09.1I

Fig. 2 Heating circuit

[1] Non-return valve

One non-return valve in each heating circuit is required for preventing

natural circulation in the heating system in summer mode. Natural

circulation may arise as the domestic hot water 3-way valve is open to

the heating system when the heat pump prepares DHW heating.

AirModule –6 720 813 268(2014/10)

7

Page 8

Technical information

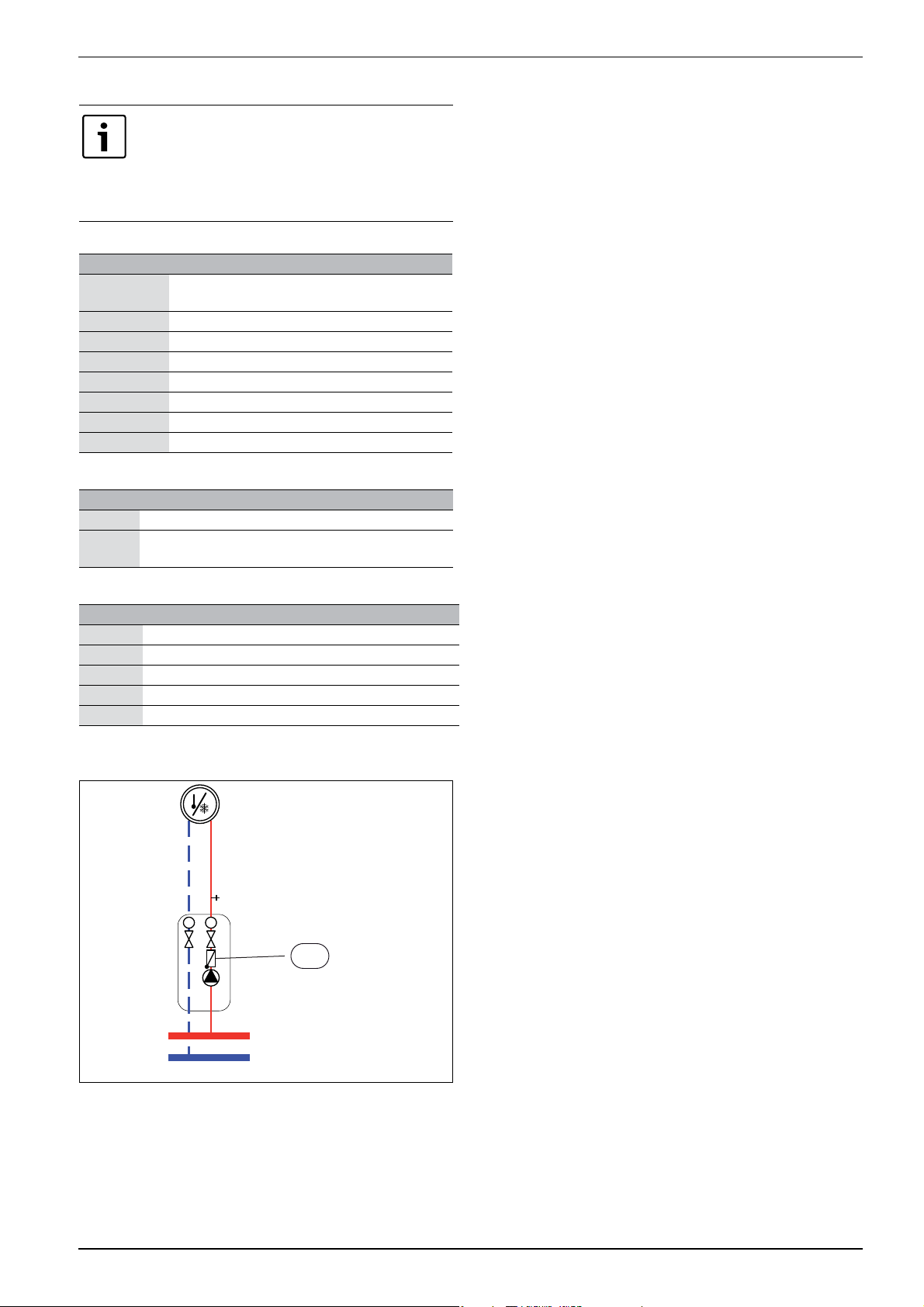

4.2.3 Heat pump with heat pump module system configuration

1

Rego 2000

4

3

HCM2000RTH2000 RTH2000Installermodul

T T

5

MC1

TC1

PC1

M

VC1

3

MK2

5

T T

PC1

T1

T0

400V AC

PW2

Airmodule E..

Fig. 3 Heat pump with heat pump module

[3] Installed in the heat pump module.

[4] Installed either in the heat pump module or mounted to the wall.

[5] Installed on the wall

400 /230 V AC

AirX ..

6 720 809 156-22.2I

8

AirModule 6 720 813 268(2014/10)

Page 9

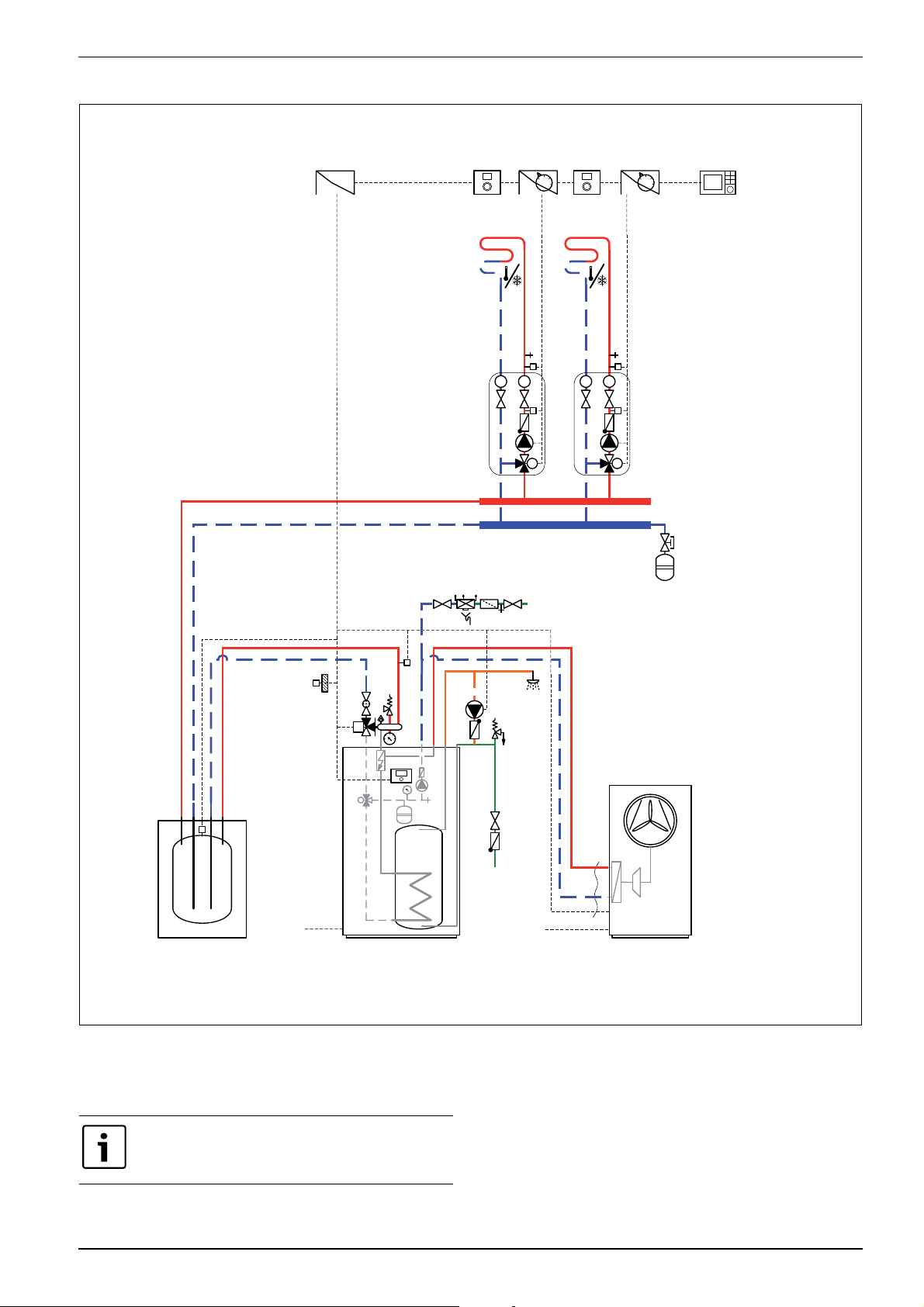

4.2.4 Heat pump, heat pump module and buffer cylinder system configuration

Technical information

Installermodul

3

RTH2000

T

HCM2000

5

T

M

1

MC1

TC1

PC1

VC1

RTH2000

4

T

HCM2000

5

T

TC1

PC1

M

VC1

2

MC1

4

Rego 2000

3

MK2

B

T1

T0

BC 100/120

VC0

400V AC

M

AB

Airmodule E..

A

Fig. 4 Heat pump with heat pump module and buffer cylinder

[3] Installed in the heat pump module.

[4] Installed either in the heat pump module or mounted to the wall.

[5] Installed on the wall

PW2

400 /230 V AC

AirX ..

6 720 809 156-22.3I

The extra expansion vessel for the heating system is

designed primarily for the volume of the buffer cylinder.

AirModule –6 720 813 268(2014/10)

9

Page 10

Technical information

4.2.5 General symbol explanation

Symbol Designation Symbol Designation Symbol Designation

Pipework/Wiring

Flow - heating/solar circuit DHW Electric wire

Return - heating/solar circuit Potable water Electric wire disconnected

DHW circulation

Actuators/Valves/Temperature sensors/Pumps

Valve Differential pressure regulator DHW circulation pump

Revision bypass Pressure relief valve Non-return valve

Adjustment valve Safety assembly Temperature sensor/switch

Other

Overcurrent valve 3-way mixing valve

M

(mixing/distributing)

Overheating protection

(temperature)

Filter valve (particle filter) Thermal DHW mixing valve Outside temperature sensor

T

Shut-off valve with unintentional

closure control

Valve, motorized 3-way valve (changing, normally

M

M

M

I

II

3-way valve

(change)

closed to II)

Wireless outside temperature

sensor

...Radio (wireless)...

III

Valve, thermal 3-way valve (changing, normally

T

M

AB

A

closed to A)

B

Shut-off valve, magnetic 4-way valve

Thermometer Funnel with siphon Low loss header with sensor

T

Pressure gauge Return flow safety module in

M

Heat exchanger

accordance with EN1717

Fill / drain valve Expansion vessel with shut-off valve

Flow meter

with closure

Water filter Collector Heat meter

Air separator Heating circuit DHW outlet

Automatic air vent valve Underfloor heating circuit Relay

Compensator (devibration) Low loss header Immersion heater

Table 7 Symbols key

10

000

∏

R

J

AirModule 6 720 813 268(2014/10)

Page 11

5 Measurements, positioning distance, and pipe connections

5.1 Heat pump module dimensions and connections

>

_

400

>

_

800

Measurements, positioning distance, and pipe connections

1800 304

6 720 809 156-06.1I

Fig. 5 Heat pump module minimum distance

There should be at least 50 mm between the heat pump module sides

and other fixed installations (walls, sinks, etc.). Ideal positioning is by an

outer wall or a middle wall.

304

Fig. 6 Heat pump module dimensions (mm)

6 720 810 350-09.1I

Fig. 7 Roof view dimensions

AirModule –6 720 813 268(2014/10)

6 720 809 156-11.2I

11

Page 12

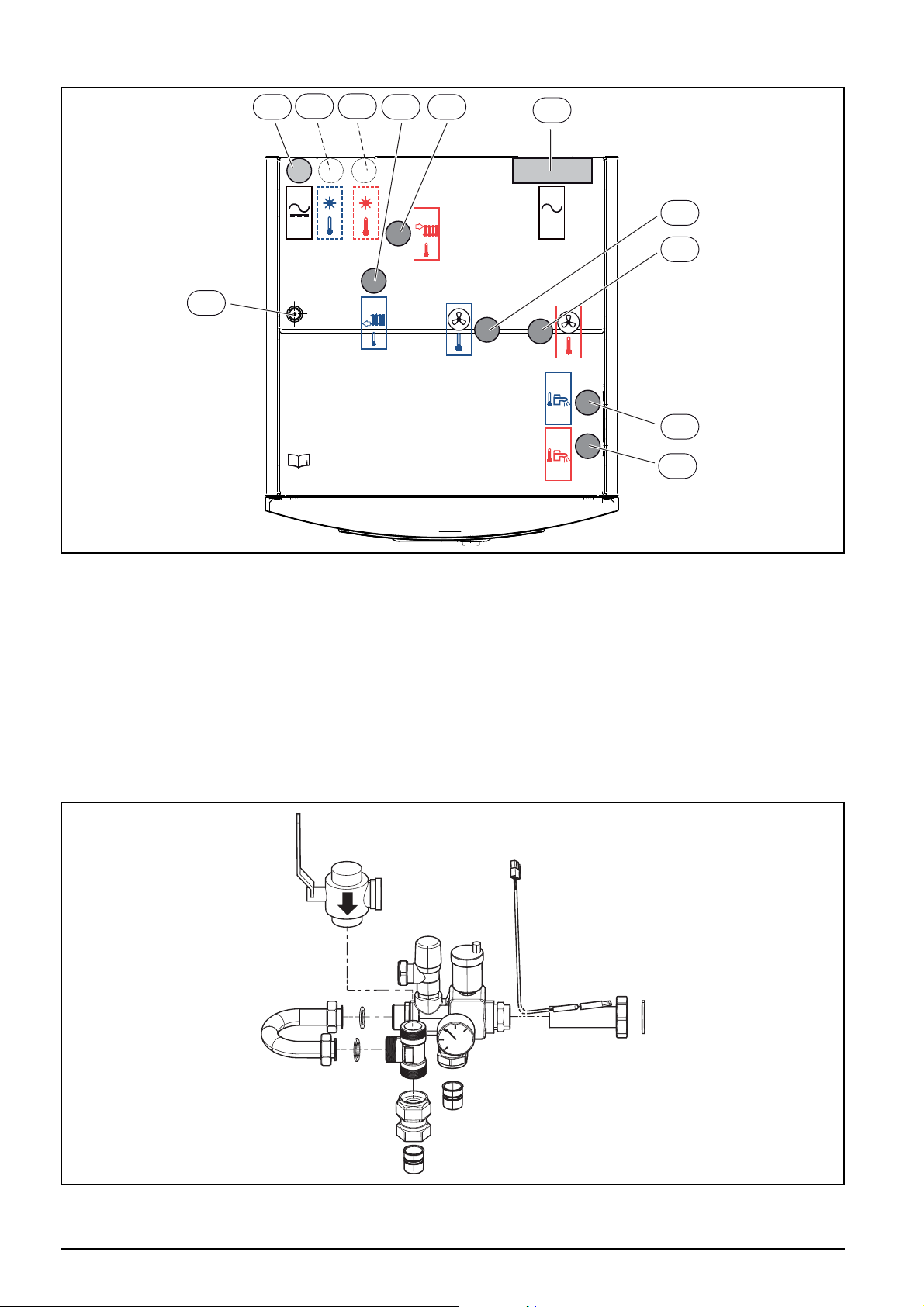

Measurements, positioning distance, and pipe connections

7 8

<50V

5

Fig. 8 Heat pump module connections

[1] Heat transfer medium out (to the heat pump)

[2] Heat transfer medium in (from the heat pump)

[3] Cold water inlet connection

[4] DHW outlet connection

[5] Cable feed to IP module

[6] Cable bus CAN-BUS and sensor

[7] Return to solar thermal system (only on the solar models)

[8] Flow from solar thermal system (only on the solar models)

[9] Return from safety group

[10] Flow to safety group

[11] Cable bus electrical connection

9 106

11

230V

400V

/

1

2

3

4

6 720 809 156-08.2I

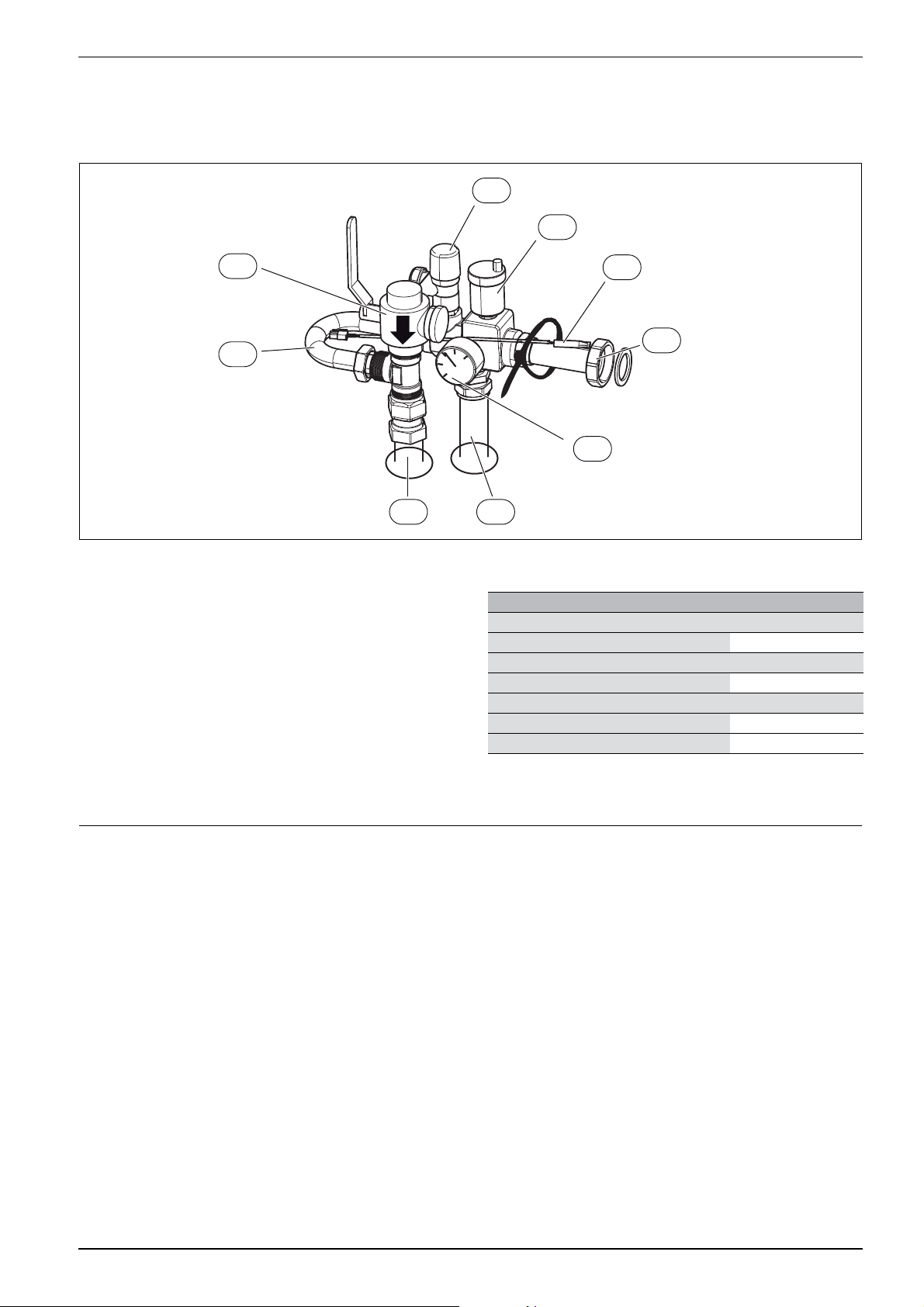

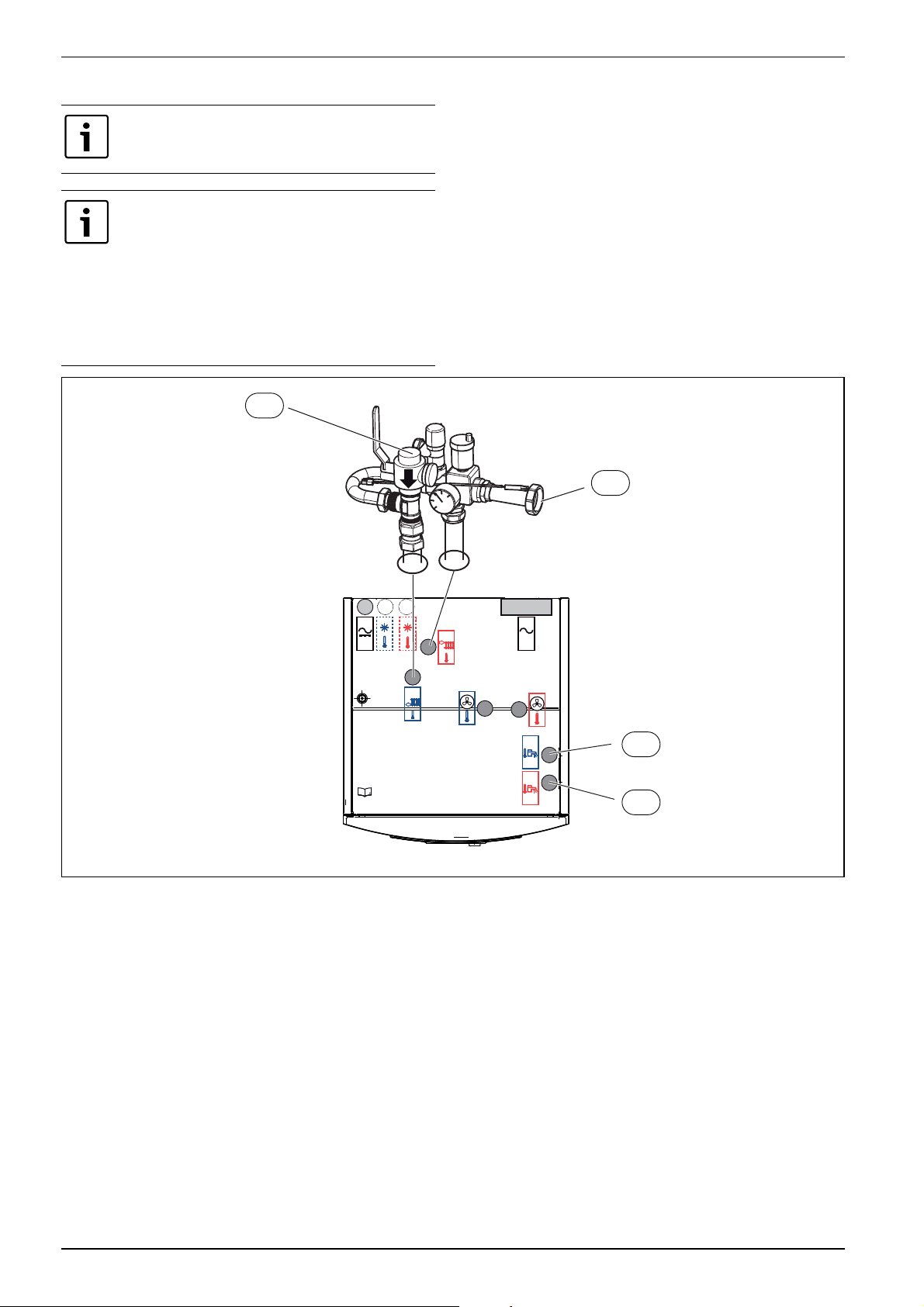

5.1.1 Safety assembly

Fig. 9 Safety assembly delivery

6 720 809 156-12.2I

12

AirModule 6 720 813 268(2014/10)

Page 13

Regulations

Assemble the safety assembly:

▶ First install the particle filter ([SC1], figure 10) on the T-unit.

▶ Install the other parts, but do not tighten the nuts completely on the

bypass ([4], figure 10).

SC1

4

▶ Place the flow temperature sensor in the sensor pocket ([T0],

figure 10), and secure the sensor with a cable tie.

▶ Fit the safety assembly on the heat pump module.

▶ Tighten the nuts completely on the bypass ([4], figure 10).

FC1

VL1

T0

1

GC1

23

6 720 809 156-13.3I

Fig. 10 Safety assembly fitted

[1] Circulation pump heating system connection (PC1), G1

½ (40R) adapter to heating system flow

[2] Flow to safety group

[3] Return from safety group

[4] Bypass

[SC1] Particle filter, connection G1internal thread from heating

system return

[FC1] Pressure relief valve

[VL1] Automatic air vent valve

[T0] Flow temperature sensor

[GC1] Pressure gauge

6 Regulations

The following regulations and requirements must be observed:

• Local rules and regulations, including special rules, of the

responsible power supply company

• National building regulations

• EN 50160 (Voltage properties in power grids for public distribution)

• EN 12828 (Heating systems in buildings - Design and installation of

water-based heating systems)

• EN 1717 (Water supply - Protection against pollution of potable

water)

5.2 Pipework

Pipe dimensions (mm) Heat pump module

Heating installation

Spring clip connection Cu Ø 28

Cold and hot water

Stainless spring clip connection Ø 22

Heat transfer medium

Spring clip connection Cu Ø 28

Leakage drain water/drain in both Ø 32

Table 8 Pipe dimensions

1) See Connections in safety assembly

1)

AirModule –6 720 813 268(2014/10)

13

Page 14

Installation

7 Installation

NOTICE: Risk of operating problems due to pipe

contamination!

Particulates, metal/plastic filings, flax and thread tape

residue and similar material can get stuck in pumps,

valves and heat exchangers.

▶ Avoid particulates in the pipework.

▶ Do not leave pipe parts and connections directly on

the ground.

▶ Ensure that no filings remain in the pipes following

deburring.

Only qualified installers may carry out the installation.

The installer must follow applicable rules and regulations

and recommendations from the supplier.

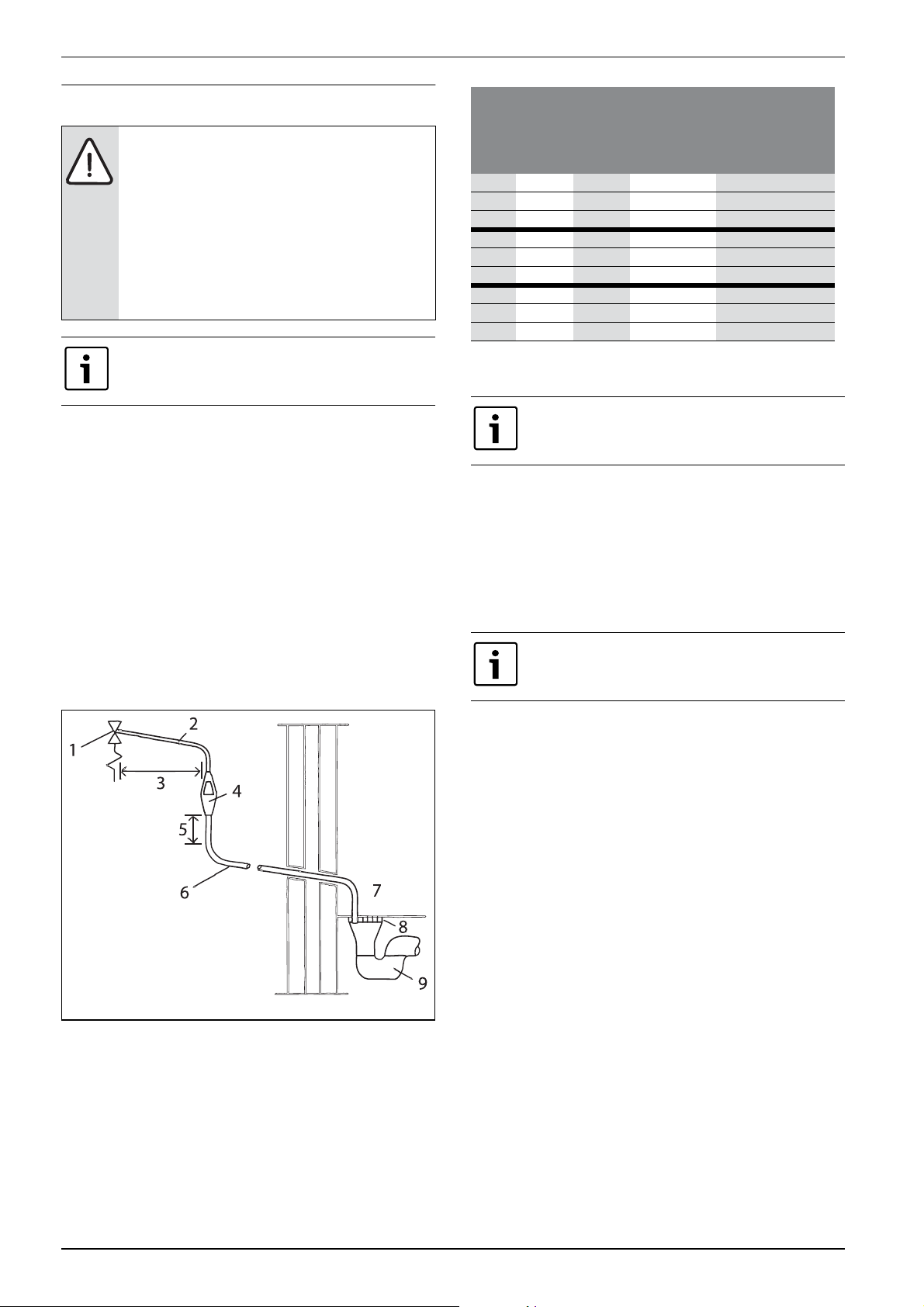

7.1 Detailed discharge pipe installation requirements (Combi model)

The discharge pipework must be routed in accordance with part G3 of

schedule 1 of the building Regulations.

The tundish should be vertical, located in the same space as the

unvented hot water cylinder and be as close as possible and within

600mm of the safety device e.g. the temperature relief valve. The discharge pipe from the tundish should be:

• made of metal

• at least one pipe size larger than the nominal outlet size of the safety

device (larger sizes may be required if the equivalent hydraulic

resistance exceeds that of a straight pipe 9m long - refer to BS6700)

• terminate in a safe place where there is no risk to persons in the

vicinity of the discharge, and position safely from electrical devices

• have a vertical section of pipe at least 300mm long below the tundish

before any elbows or bends in the pipework.

Maximum

Size of

Valve

discharge

outlet

size

G1/2 15 mm 28 mm Up to 18 m 1.0 m

G3/4 22 mm 35 mm Up to 18 m 1.4 m

G1 28 mm 42 mm Up to 18 m 1.7 m

pipework

D1

Size of

discharge

pipework

D2

22 mm Up to 9 m 0.8 m

35 mm Up to 27 m 1.4 m

28 mm Up to 9 m 1.0 m

42 mm Up to 27 m 1.7 m

35 mm Up to 9 m 1.4 m

54 mm Up to 27 m 2.3 m

length of

straight pipe

(no bends or

elbows)

Deduct the figure

below from the

maximum length for

each bend or elbow in

the discharge pipe

Table 9

7.2 Preparatory pipework

The safety valve drain in the heat pump module should

be secured against frost and the drain pipe should lead

to a drain.

▶ Fit heating system and cold/hot water connector pipes in the space

up to the heat pump module position.

7.3 Positioning

▶ Remove the packaging according to the instructions on the

packaging.

▶ Remove the supplied accessories.

7.4 Checklist

Each installation is different. The following check list will

provide a general description of the installation process.

6 720 806 768-05.1I

Fig. 11 Typical discharge pipe arrangement

[1] Safety device (e.g. temperature relief valve)

[2] Metal discharge pipe (D1) from temperature relief valve to tunish

[3] 600mm maximum

[4] Tundish

[5] 300mm minimum

[6] Metal discharge pipe (D2) from tundish, with continous fall

[7] Discharge below fixed grating

[8] Fixed grating

[9] Trapped gulley

1. Install the heat pump module safety assembly (Chapter 5.1.1)

and fill valve.

2. Fit the heat pump module leakage water hose(s).

3. Connect the heat pump and the heat pump module

(Chapter 7.11).

4. Connect the heat pump module to the heating system

(Chapter 7.12).

5. Install the outside temperature sensor (Chapter 7.19.3) and room

controller (optional).

6. Connect the CAN-BUS wire between the heat pump and the heat

pump module (Chapter 8.1).

7. Install any accessory (mixing module, solar module, pool module,

etc).

8. Connect EMS-BUS wire (optional) to accessories (Chapter 8.2).

9. Fill up and bleed the hot water cylinder.

10. Fill up and vent the heating system before commissioning

(Chapter 7.20).

11.Connect the heating system to the electrical system (Chapter 8).

12.Commission the heating system by managing necessary settings in

the user interface (Chapter 11).

13.Vent the heating system (Chapter 14).

14.Check that all sensors show reasonable values (Chapter 12.9.2).

15.Check and clean out the particle filter (Chapter 18).

16. Check the heating system function following commissioning

(Chapter 12.9).

14

AirModule 6 720 813 268(2014/10)

Page 15

Installation

7.5 Water quality

Heat pumps operate with lower temperatures than other heating

systems, which means that the thermal degassing is not as effective and

the oxygen content will never be as low as in an electric/oil/gas system.

This means that the heating system will be more sensitive to rust with

aggressive water.

Do not use any water additives except for pH-enhancer and keep the

water clean.

Recommended pH level is 7.5 – 9.

Water quality

Hardness < 3°dH

Oxygen content < 1 mg/L

Carbon dioxide, Co

Chloride ions, Cl- < 250 mg/L

Sulphate, So42- < 100 mg/L

Conductivity < 350 μs/cm

Table 10 Water quality

1) Electric anode (accessory) in the water heater is recommended for higher

chloride content. If electric anode is used, it has to be purchased in

connection with commissioning.

2

< 1 mg/L

1)

7.6 Heating system flushing

NOTICE: System damage due to objects in the pipes!

Objects in the pipes will decrease the flow and cause

operational problems.

▶ Flush out the system to remove all dirt residues

before connecting the heat pump and heat pump

module.

The heat pump module is a part of a heating system. Problems in the heat

pump module can be caused by poor water quality in the radiators/floor

loops or by constant system oxygenation.

Oxygen causes corrosion products in the form of magnetite and

sediment.

Magnetite has a grinding effect on the heating system's pumps, valves

and components with turbulent flows such as the condenser.

Heating systems which require regular filling or where the heating water

does not produce clear water during water sampling require measures

prior to the installation of the heat pump, e.g. supplementing the heating

system with magnetite filters and air vent valves.

7.7 Operation without heat pump (stand-alone)

The heat pump module can be put into operation without a connected

heat pump, for example, if the heat pump is installed at a later date. This

is called "stand-alone" operation.

In stand-alone mode, the heat pump module uses only the integrated

immersion heater for heating and DHW production.

If the heat pump module and the heating system are

filled before the heat pump is connected, then the heat

transfer medium in and out to / from the heat pump must

be connected to secure circulation ( [1] and [2],

Fig. 13).

▶ Open shut-off valves on the heat transfer circuit, if

applicable.

In connection with commissioning of stand-alone operation:

▶ Set Stand-alone mode in the service menu Heat pump ( Chapter

12.1).

7.8 Installation with cooling

Cooling is disabled in the UK model to comply with

the regulations for RHI.

Using cooling mode requires the installation of a room

controller (accessory).

Installation of a room controller with integrated humidity

sensor (accessory) makes cooling mode more secure as

the user interface automatically adjusts the flow

temperature in relation to the current dew point.

▶ Insulate all connections and pipes from condensation.

▶ Install a room controller, with or without an integrated moisture

sensor ( manual for the respective room controller).

▶ Install condensation sensors ( Chapter 7.18).

▶ Select automatic mode heating/cooling ( Chapter 12.3.2,)

▶ Make the necessary cooling mode settings: start temperature, start

delay, room temperature and dew point differential (offset), as well

as lowest flow ( Chapter 12.3.2).

▶ Set the temperature differential (delta) over the heat pump (

Chapter 12.1.1)

AirModule –6 720 813 268(2014/10)

15

Page 16

Installation

▶ Turn off floor circuits in moist rooms (e.g. bathrooms and kitchens)

and use relay outputs PK2 in order to govern this ( Chapter 8.4).

7.9 Installation with solar heater (only solar model)

Using solar additional heating requires installation of a

solar module (accessory).

The solar energy coil in the cylinder is intended for

maximum added heating output of 4.5 kW. Only DHW

heating is possible with the integrated coil.

▶ Install solar panels ( panel manual).

▶ Insulate all connections and pipes.

▶ Install solar module ( solar module manual).

▶ Select Yes to the question Solar thermal sys installed during

commissioning ( Chapter 11.2).

▶ Make the necessary settings for the installed solar thermal system

( Chapter 12.6)

7.10 Installation with pool

NOTICE: Risk of malfunction!

Cooling mode is not possible if the mixing valve for the

pool is placed in a wrong position in the system. Even

other functional disturbances might arise. The mixing

valve for the pool must not be positioned so that it can

block the safety valve on the flow line.

▶ Install the mixing valve for pool on the return pipe to

the heat pump module ( [VC1] Bild 12).

▶ Install the T-pipe on the flow line from the heat pump

module, before the bypass in the safety assembly.

▶ The pool mixing valve may not be installed as a

heating circuit.

Installation of a pool module (accessory) is demanded to

use pool heating.

HS

VC1

M

Fig. 12 Pool installation example

[1] Pool module

[2] Pool

[VC1] Pool mixing valve

[HS] Heating system

1

1

2

6 720 810 931-10.3I

▶ Install the pool ( instructions for the pool).

▶ Install the mixing valve for pool.

▶ Isolate all pipes and connections.

▶ Install the pool module ( instruction for the pool module). Please

observe that the hydraulic solution that is presented in that can not

be used.

▶ Set the mixing valve running time at commissioning ( Chapter

11.2).

▶ Make necessary settings for the pool heating ( Kapitel 12.5).

16

AirModule 6 720 813 268(2014/10)

Page 17

7.11 Connecting the heat pump module to the heat pump

Insulate pipes and connections against condensation if cooling is to be

used.

▶ Select pipe size according to table 11.

<50V

230V

/

400V

Installation

▶ Connect the return to the heat pump [4] to the heat transfer medium

out [1] figure 13.

▶ Connect the flow from the heat pump [3] to the heat transfer medium

in [2] Figure 13.

1

2

3

<50V 230V

/

400V

4

6 720 809 156-14.1I

Fig. 13 Heat pump connections heat pump module

[1] Heat transfer medium out (to the heat pump)

[2] Heat transfer medium in (from the heat pump)

[3] Flow from heat pump

[4] Return to heat pump

Heat

transfer

Heat pump

output (kW)

fluid delta

(K)

Nominal flow

(L/s)

Maximum pressure

drop (kPa)

1)

550.32 68 28 60

750.33 55 14 33 60

950.43 40 82160

13 5 0.62 56 14 60 60

17 5 0.81 18 15 60

Table 11 Pipe dimensions and max. pipe length for connection of heat pump to heat pump module

1) For pipes and components between the heat pump module (indoor unit) and heat pump (outdoor unit).

AX20

inner-Ø 15 (mm)

AX25

inner-Ø 18 (mm)

Maximum pipe length PEX (m)

AX32

inner-Ø 26 (mm)

AX40

inner-Ø 33 (mm)

AirModule –6 720 813 268(2014/10)

17

Page 18

Installation

7.12 Connecting the heat pump module to the heating system and tap water

Pressure relief valve, non-return valve, and fill valve must

be installed on the tap DHW circuit (not included).

If there is not enough room to install the safety assembly

directly on the heat pump module connections:

▶ Extend the connections by max. 50 cm.

▶ Do not angle the connections downwards.

▶ Do not install any shut-off valves between the safety

assembly and the heat pump module.

▶ The particle filter can be installed at a bend to the left.

▶ Bends can be installed between the safety group and

the connection for the circulation pump.

Insulate the connections and pipes to the heating system from

condensation if cooling is used.

▶ Install the safety assembly ( Chapter 5.1.1).

▶ Install the pressure relief valve and non-return valve with a fill valve

for tap DHW.

▶ Drain leakage drain hoses from the pressure relief valves into a frost

protected drain.

▶ Connect the heating system circulation pump to [1] figure 14.

▶ Connect the heating system return to the particle filter [SC1]

figure 14.

▶ Connect cold water inlet to [2] figure 14.

▶ Connect DHW outlet to [3] figure 14.

▶ Connect the heating system flow to the circulation pump.

SC1

1

<50V

Fig. 14 Heating system and DHW connections heat pump module

[1] Connection for circulation pump PC1 (flow to heating system)

[2] Cold water inlet connection

[3] DHW outlet connection

[SC1] Particle filter (return from heating system connection)

230V

/

400V

2

3

6 720 809 156-05.1I

18

AirModule 6 720 813 268(2014/10)

Page 19

Installation

The heating system circulation pump is required and

selected based on the system pressure drop and flow

requirements.

PC1 must always be connected to the installer module in

the heat pump module according to the circuit diagram.

Relay output max. load for circulation pump PC1: 2 A,

cos>0.4. Higher load requires installation of an

intermediate relay.

7.15 DHW circulation pump PW2 (accessory)

Settings for the circulation pump PW2 is done in the control unit

(Chapter 12.4).

7.16 Insulation

NOTICE: Damage due to freezing!

In case of a power outage the water in the pipes may

freeze.

▶ Use at least 19 mm insulation for outside pipework.

▶ Use at least 12 mm insulation for inside pipework.

This is important for safe and efficient DHW heating.

1

6 720 809 156-10.1I

Fig. 15 Drain hose

[1] Drain hose

▶ Connect the drain hose with a leakage drain hose to a frost protected

drain.

7.13 Low energy pump for heat transfer medium (PC0)

PC0 heat transfer pump is PWM operated (RPM controlled). The pump

settings are managed on the heat pump module control panel.

Circulation pump speed is automatically adjusted for optimal operation.

7.14 Circulation pump for the heating system (PC1)

NOTICE: Damage due to deformation!

The circulation pump connecting pipe in the safety

assembly may bend if it is subject to heavy weight

pressure for an extended period of time.

▶ Use appropriate mounting installation for the heating

system pipes and DHW circulation pump to support

the safety assembly connection.

All heat conducting lines must have suitable heat insulation according to

applicable norms.

During cooling, all connections and lines must be condensation

insulated according to applicable norms.

7.17 Several heating circuits (mixing valve module accessory, see separate instructions)

The user interface can handle a heating circuit without a mixing valve in

standard configuration. A mixing valve module is required for each

circuit if additional circuits are installed.

▶ Install the mixing valve module, mixing valve, circulation pump and

other components in accordance with the selected system solution.

▶ Connect the mixing valve module to terminal EMS on the installer

module in the heat pump module electric box.

▶ Make settings for several heating circuits in accordance with Chapter

12.3.2.

If there is already a connection on the EMS terminal, the connection is

made parallel to the same terminal in accordance with Fig. 16. If several

EMS modules are installed in the system, these must be connected in

accordance with Fig. 33, Chapter 8.12.

7.18 Installation of condensation sensor (accessories)

NOTICE: Damage due to moisture!

Cooling below dew point will result in condensation on

the surrounding material (floor).

▶ Do not use the underfloor heating system for cooling

below dew point.

▶ Correctly adjust the flow temperature as described

in Chapter 12.3.2.

The condensation guard function will stop the cooling if condensation

develops on the heating system pipes. Condensation will develop during

cooling if the heating system temperature is lower than current dew

point temperature.

AirModule –6 720 813 268(2014/10)

19

Page 20

Installation

The dew point will vary depending on temperature and humidity. The

higher the humidity, the higher flow temperature is required to remain

above dew point and avoid condensation.

The condensation sensors will send a signal to the operating system

when they sense condensation and stop the cooling.

Instructions for installation and handling are included with the

condensation sensor.

7.18.1 Condensation monitoring, fan coils only

NOTICE: Damage due to moisture!

Moisture may be transferred to surrounding materials if

there are gaps in the condensation insulation.

▶ Apply condensation insulation to all pipes and

connections up to the fan element for cooling.

▶ Use condensation insulation material that is

intended for condensation cooling systems.

▶ Connect the drain to the drain outlet.

▶ Do not use condensation guard.

If only fan elements with drainage and condensation insulated pipes are

used, the flow temperature can be set to 7 °C. The lowest recommended

temperature is 10 °C for balanced cooling as the freeze guard is

activated at 5 °C.

7.19 Temperature sensor installation

The user interface in the delivery configuration automatically regulates

the flow temperature based on the outdoor temperature. A room

controller can be installed for greater comfort. If cooling mode is used, a

room controller is a must.

7.19.1 Room controller (accessories, see separate instructions)

If the room controller is installed after the system has

been put into operation, it must be selected as room

controller for heating circuit 1 in the start-up menu (

Chapter 11.2).

▶ Install the room controller in accordance with its instruction.

▶ Connect the room controller to a terminal EMS on the installer

module in the heat pump module electric box.

▶ Set room controller CR10 as remote control before the installation is

put into operation ( Room controller's instruction). CR10H does

not have this option.

▶ Make circuit settings on the room controller before the installation is

put into operation ( Room controller's instruction).

▶ Indicate when the installation is put into operation that room

controller (CR10 or CR10H) has been installed ( Chapter 11.2) as

a user interface for heating circuit 1.

▶ Make room temperature settings according to Chapter 12.3.2.

If there is already a connection on the EMS terminal, the connection is

made parallel to the same terminal in accordance with Fig. 16. If several

EMS modules are installed in the system, these must be connected in

accordance with Fig. 33, Chapter 8.12.

EMS NSC/IP

6 720 809 156-42.1I

Fig. 16 EMS connection on installer module

7.19.2 Flow temperature sensor T0

The sensor is delivered with the heat pump module.

▶ Fit the sensor in the pocket on the safety assembly ( figure 10) or

on the buffer cylinder if one is installed.

▶ Connect flow temperature sensor T0 to terminal T0 on the installer

module in the heat pump module electric box.

7.19.3 Outside temperature sensor T1

A screened cable must be used if the outside

temperature sensor cable is longer than 15 m. The

screened cable must be grounded in the inside unit. The

max. length of a screened cable is 50 m.

The outside temperature sensor cable must meet the following minimum

requirements:

Cable diameter: 0.5 mm

2

Resistance: max. 50 ohm/km

No. of conductors: 2

▶ Install the sensor on the cold side of the house, normally north facing.

It must be protected from direct sunlight, ventilation air or anything

that can affect the temperature measurement. The sensor must not

be installed directly beneath the roof.

▶ Connect outdoor temperature sensor T1 to terminal T1 on the

installer module in the heat pump module electric box.

20

AirModule 6 720 813 268(2014/10)

Page 21

Installation

N

NE

NW

W

SW

(min 2m)

H

H

2

/

1

E

SE

S

Fig. 17 Outside temperature sensor positioning

6 720 809 156-23.1I

AirModule –6 720 813 268(2014/10)

21

Page 22

Installation

7.20 Heat pump and heat pump module filling

When filled, the system has to be thoroughly vented.

▶ Fill the system according to these instructions.

▶ Connect the system to power as described in

Chapter 8.

▶ System commissioning as described in Chapter 11.

▶ Vent the system as described in Chapter 14.

PC1

SC1

VL1

VW2

VC1

T

VC2

T

Z1

GC1

VW1

PC0

VC0

VW3

Fig. 18 Heat pump module and heating system

1. Disconnect the heat pump and heat pump module power.

2. Activate automatic venting of VL1 by unscrewing the screw a couple

of turns without removing it.

3. Close the heating system valves; particle filter SC1 and VC1.

4. Connect one end of a hose to VC0 and the other end to a drain. Open

the drain valve VC0.

5. Open the cold water valve VW3 and the fill valve VW2 to fill the heat

pump pipes.

6. Continue filling until only water comes out of the hose by the drain

and the outdoor unit does not form bubbles any more.

7. Close the drain valve VC0 and fill valve VW2.

8. Move the hose to the heating system drain valve VC2.

9. Open the particle filter SC1, the drain valve VC2 and the fill valve

VW2 to fill the heating system.

10.Continue filling until only water comes out of the hose by the drain

and the heating system does not form bubbles any more.

11.Close the drain valve VC2.

6 720 809 156-22.1I

12. Open the heating system fill valve VW2 and keep filling until the

pressure gauge GC1 shows 2 bar.

13.Close the fill valve VW2.

14.Remove the hose from VC2.

15.chapter 14.

22

AirModule 6 720 813 268(2014/10)

Page 23

Electric installation

8 Electric installation

DANGER: Risk of electric shock!

The heat pump module components conduct electricity.

▶ Turn off the main power before any electrical work.

NOTICE: The installation will get damaged if the power is

connected without water.

Components in the heating system can overheat if the

power is connected before it has been filled up with

water.

▶ Fill and pressurize the water heater and the heating

system before connecting the installation to power.

The heat pump module electrical connection must be

disconnected safely in accordance with the wiring rules.

▶ Install a separate safety switch that disconnects all

power to the heat pump module. In case of separate

power supplies you will need one safety switch for

each supply.

The compressor warms up before it starts. This can take

up to 2 hours, depending on the outside temperature.

The requirement is that the compressor temperature

(TR1) is 10 K above the air intake temperature (TL2).

The temperatures are visible in the Diagnostics menu (

Chapter 12.9).

For recommended fuse sizes, see Technical information

(Chapter 4.1).

The heat pump and the heat pump module are connected by a

communications wire, CAN-BUS.

A suitable cable for external cable installation is wire LIYCY (TP)

2x2x0.75, or equivalent. An alternative cable should have a cross

section area of at least 0.75 mm

2

, and be a duplex cable, screened and

approved for outside use. The screen should only be grounded in one

end (indoor unit) and to the chassis.

Maximum cable length is 30 m.

The connection between the circuit boards is by four wires, because the

12V-supply between the circuit boards must also be connected. The

circuit boards have markings for both the 12V and CAN-BUS

connections.

Switch Term is used to mark the start and end of a CAN-BUS loop.

Ensure that the correct circuit board is terminated and that all other

switches are in the opposite position.

6 720 809 156-24.1I

Fig. 19 Termination CAN-BUS

[On] Terminated CAN-BUS

[Off] Not terminated CAN-BUS

8.2 EMS-BUS

▶ Choose cable area and type that represent the fuse protection and

wire mode.

▶ Connect the heat pump according to the circuit diagram. Never

connect any other consumers.

▶ If the heat pump is connected through a circuit breaker, then a

separate circuit breaker for the heat pump must be used. Please

observe current regulations.

▶ Observe the colour coding when replacing circuit boards.

8.1 CAN-BUS

NOTICE: Malfunction due to electrical disturbances!

High voltage lines (230/400 V) close to a

communications line can cause the heat pump module

to malfunction.

▶ Install screened CAN-BUS wire away from a power

cord. Minimum distance 100 mm. Cabling together

with bus lines is allowed.

NOTICE: The system will be damaged if the 12 V- and

the CAN-BUS connections are confused!

The communication circuits are not designed for 12 V

constant voltage.

▶ Check that the four cables are connected to plugs

with corresponding rating on the printed circuit

board.

NOTICE: Malfunction due to electrical disturbances!

High voltage lines (230/400 V) close to a

communications line can cause the heat pump module

to malfunction.

▶ Install the EMS-BUS wire away from a power cord.

Minimum distance 100 mm. Cabling together with

bus lines is allowed.

EMS-BUS and CAN-BUS are not compatible.

▶ Do not connect EMS-BUS units with CAN-BUS units.

The user interface HPC400 and the installer module in the heat pump

module are connected by EMS-BUS.

The user interface is powered via the BUS cable. Polarity is not important

for the two cables in the EMS-BUS.

In case of EMS-BUS accessories it is important to note that (please also

refer to the installation instructions for each accessory):

▶ If several BUS units are installed, they must be separated by at least

100 mm.

▶ If several BUS units are installed, they must be connected in a series

or a star network.

▶ Use a cable with a cross section area of at least 0.5 mm

2

.

▶ In case of external inductive interferences (e.g. from PV systems),

use screened cables. The screen should only be grounded in one end

and to the chassis.

AirModule –6 720 813 268(2014/10)

23

Page 24

Electric installation

8.3 Printed circuit board handling

Circuit boards with control electronics are sensitive to discharges of

static electricity (ESD – ElectroStatic Discharge) when handled. To

prevent damaging the components, special care is therefore required

when handled.

CAUTION: Damage due to static electricity!

▶ Wear a grounded antistatic wrist strap when

handling unenclosed printed circuit boards.

6 720 614 366-24.1I

Fig. 20 Antistatic wrist strap

Damage is usually latent, and a circuit board can operate correctly

during commissioning but show signs of problems later. Charged

objects may only be problematic if they are in close proximity to the

electronics. Keep a distance of at least one metre from expanded

polystyrene, protective plastic and other packaging, synthetic material

(e.g. fleeces) and similar before starting work.

A method for good ESD protection is a ground-connected bracelet when

handling electronics. This bracelet must be put on before opening the

screened metal bag/packaging or before exposing an installed board.

The bracelet must be worn until the circuit board is enclosed in its screen

packaging or closed electric box. Replaced, returned circuit boards must

be handled in the same way.

8.4.1 External outputs

NOTICE: Damage due to incorrect connection!

Connections intended for a different voltage or current

can damage electrical components.

▶ Only add connections to the heat pump module

external outputs that are compatible with 5 V and 1

mA.

▶ If an intermediate relay is required, use only relays

with gold-plated plugs.

External inputs I1, I2, I3 and I4 can be used to remotely manage certain

functions in the user interface.

The functions that are activated by the external inputs are described in

chapter 12.1.2.

The external input is connected either to a power switch for manual

activation or to operating equipment with a relay output for 5 V.

8.5 Accessories

CAN-BUS connected accessories, e.g. power guard, are connected to

the installer card in the heat pump module parallel on the CAN-BUS

connection to the heat pump. They can also be connected in series with

other CAN-BUS connected units.

8.6 Connecting the heat pump module

▶ Remove the front panel.

▶ Remove the electric box cover.

▶ Feed the connecting cables through the cable feed in the ceiling and

to the electric box. Use an extension spring, if required.

▶ Feed the cables so that the electric box can be tilted forward.

▶ Connect the cables according to the circuit diagram.

▶ Put the electric box cover and the heat pump module front panel

back.

8.4 External connections

To avoid inductive interference, all low voltage conductors (measure

current) should be installed with a minimum distance of at least 100 mm

from the conducting 230V- and 400V cables.

If the temperature sensor conductor has to be extended, the following

conductor diameters should be used:

• Up to 20 m long cable: 0.75 to 1,50 mm

• Up to 30 m long cable: 1.0 to 1,50 mm

The relay output PK2 is active during cooling and can be used to manage

the exchange between cooling /heating of a fan convector or a

circulation pump or to regulate floor heating circuits in moist rooms.

Output VC0 is active during cooling and is used to manage a 3-way valve

to recirculation, to facilitate the exchange between DHW heating and

cooling.

Relay output max. load: 2A, cos>0.4. Higher load

requires installation of an intermediate relay.

2

2

2

Fig. 21 Cable feed

[1] Cable bus electrical connection

[2] Cable bus CAN-BUS and sensor

1

6 720 809 156-23.2I

24

AirModule 6 720 813 268(2014/10)

Page 25

8.7 Electric box layout

Electric installation

5

4 3

Fig. 22 Electric box layout

[1] Terminals

[2] Automatic fuses (only 15 kW model)

[3] Contactors K1, K2, K3

[4] Overheating protection reset

[5] Installer module

8.7.1 Terminal connections in electric box 9 kW immersion heater 3N~, standard setting

1

2

6 720 809 156-07.2I

Fig. 23 Terminal connections in electric box

[1] 400 V 3 N~ 16 A, input

[2] 230 V 1 N~, heat pump 5/7/9

[3] 230 V 1 N~, EMS Plus accessories

Immersion heater only on L1 and L2 during heat pump

mode. Otherwise the heat pump must have a separate

power supply from the distribution board.

1

2

3

6 720 809 156-16.3I

AirModule –6 720 813 268(2014/10)

25

Page 26

Electric installation

8.7.2 Terminal connections in electric box 9 kW immersion heater 1N~, see bridge placement

2 1

Fig. 24 Terminal connections in electric box

[1] 230 V 1 N~ 50 A, input

[2] 230 V 1 N~, EMS Plus accessories

The heat pump has a separate power supply from the

distribution board 230 V 1 N~16 A.

6 720 809 156-32.1I

8.7.3 Terminal connections in electric box 15 kW immersion heater 3N~, standard setting

1

2

3

Fig. 25 Terminal connections in electric box

[1] 400 V 3 N~ 25 A, input

[2] 230 V 1 N~, EMS Plus accessories

[3] 400 V 3 N~, heat pump 13/17

26

6 720 809 156-17.3I

Max. 9 kW immersion heater during heat pump mode.

Otherwise the heat pump must have a separate power

supply from the distribution board.

AirModule 6 720 813 268(2014/10)

Page 27

8.7.4 Circuit diagram 9 kW immersion heater 3N~, standard setting

1 2 3

Fig. 26 Circuit diagram 9 kW 3N~

[1] Distribution board

[2] Heat pump module 9 kW, 400 V 3 N~

[3] Heat pump 5/7/9, 230 V 1 N~

[PC1] Heating system circulation pump

[T0] Flow temperature sensor

[T1] Outside temperature sensor

Immersion heater L1-L2, heat pump L3. Immersion

heater L3 blocked during heat pump mode.

Electric installation

6 720 809 156-33.2I

8.7.5 Circuit diagram 9 kW immersion heater 1N~

1 2 3

Fig. 27 Circuit diagram 9 kW 1N~

[1] Distribution board

[2] Heat pump module 9 kW, 230 V 1 N~

[3] Heat pump 5/7/9/13, 230 V 1 N~

[PC1] Heating system circulation pump

[T0] Flow temperature sensor

[T1] Outside temperature sensor

6 720 809 156-35.2I

AirModule –6 720 813 268(2014/10)

27

Page 28

Electric installation

8.7.6 Circuit diagram 15 kW immersion heater 3N~, standard setting

1

Fig. 28 Circuit diagram 15 kW 3N~

[1] Distribution board

[2] Heat pump module 15 kW, 400 V 3 N~

[3] Heat pump 13/17, 400 V 3 N~

[PC1] Heating system circulation pump

[T0] Flow temperature sensor

[T1] Outside temperature sensor

2 3

6 720 809 156-34.2I

28

AirModule 6 720 813 268(2014/10)

Page 29

8.8 Power supply heat pump and heat pump module 9 kW 3N~

1

2

Electric installation

3

4

Fig. 29 Power supply heat pump and heat pump module 9 kW

[1] Input 400 V 3 N~

[2] User interface

[3] Immersion heater alarm output ([2] Fig. 31)

[4] Installer module operating voltage ([1] Fig. 31)

[EE] Immersion heater

[FE] Immersion heater overheating protection

[F1] Terminal fuse

[P] Pressure switch

[K1] Contactor step 1

[K2] Contactor step 2

[K3] Contactor step 3

AirModule –6 720 813 268(2014/10)

6 720 809 156-36.2I

Connection on: L1-L2-L3-1N-PE.

Feed heat pump: 2L3-2N-PE.

User interface: L-N-PE

• Immersion heater during compressor mode: 2-4-6 kW (K3 blocked)

• Only immersion heater, compressor off: 3-6-9 kW

29

Page 30

Electric installation

8.9 Power supply heat pump and heat pump module 15 kW

1

2

3

4

5

Fig. 30 Power supply heat pump and heat pump module 15 kW

[1] Input 400 V 3 N~

[2] User interface

[3] Heat pump

[4] Immersion heater/pressure switch alarm output ([2] Fig. 31)

[5] Installer module operating voltage ([1] Fig. 31)

[F1] Terminal fuse

[F2] Heat pump fuse

[EE] Immersion heater

[FE] Immersion heater overheating protection

[P] Pressure switch

30

6 720 809 156-38.2I

[K1] Contactor step 1

[K2] Contactor step 2

[K3] Contactor step 3

• Immersion heater: 3-6-9-12-15 kW

Delivered connected

Connected during installation/

accessories

AirModule 6 720 813 268(2014/10)

Page 31

8.10 Installer module circuit diagram

2

Electric installation

3

1

Fig. 31 Installer module circuit diagram

[I1] External input 1

[I2] External input 2

[I3] External input 3

[I4] External input 4

[MK2] Condensation sensor

[PC0] Circulation pump PWM signal

[T0] Flow temperature sensor

[T1] Outside temperature sensor

[TW1] DHW temperature sensor

[TC0] Return heat transfer medium temperature sensor

[TC1] Flow heat transfer medium temperature sensor

[EW1] Immersion heater start signal in hot water cylinder (external)

[FE] Overheating protection alarm

[FW0] Anode 230 V (accessories)

[K1] Immersion heater contactor EE1

[K2] Immersion heater contactor EE2

[K3] Immersion heater contactor EE3

[F50] Fuse 6.3 A

[PC0] Heat transfer medium circulation pump

AirModule –6 720 813 268(2014/10)

6 720 809 156-15.2I

[PC1] Heating system circulation pump

[PK2] Cooling season relay output 230 V

[PW2] Hot water DHW circulation pump

[VC0] Recirculation exchange valve

[VW1] Heating/DHW exchange valve

[1] 230 V~ operating voltage ([5] Fig. 30 or [4] Fig. 29)

[2] Immersion heater/pressure switch alarm output ([4] Fig. 30

or [3] Fig. 29)

[3] CAN BUS to heat pump (I/O module card)

Relay output max. load PK2: 2 A, cos>0.4. Higher load

requires installation of an intermediate relay.

Delivered connected

Connected during installation/

accessories

31

Page 32

Electric installation

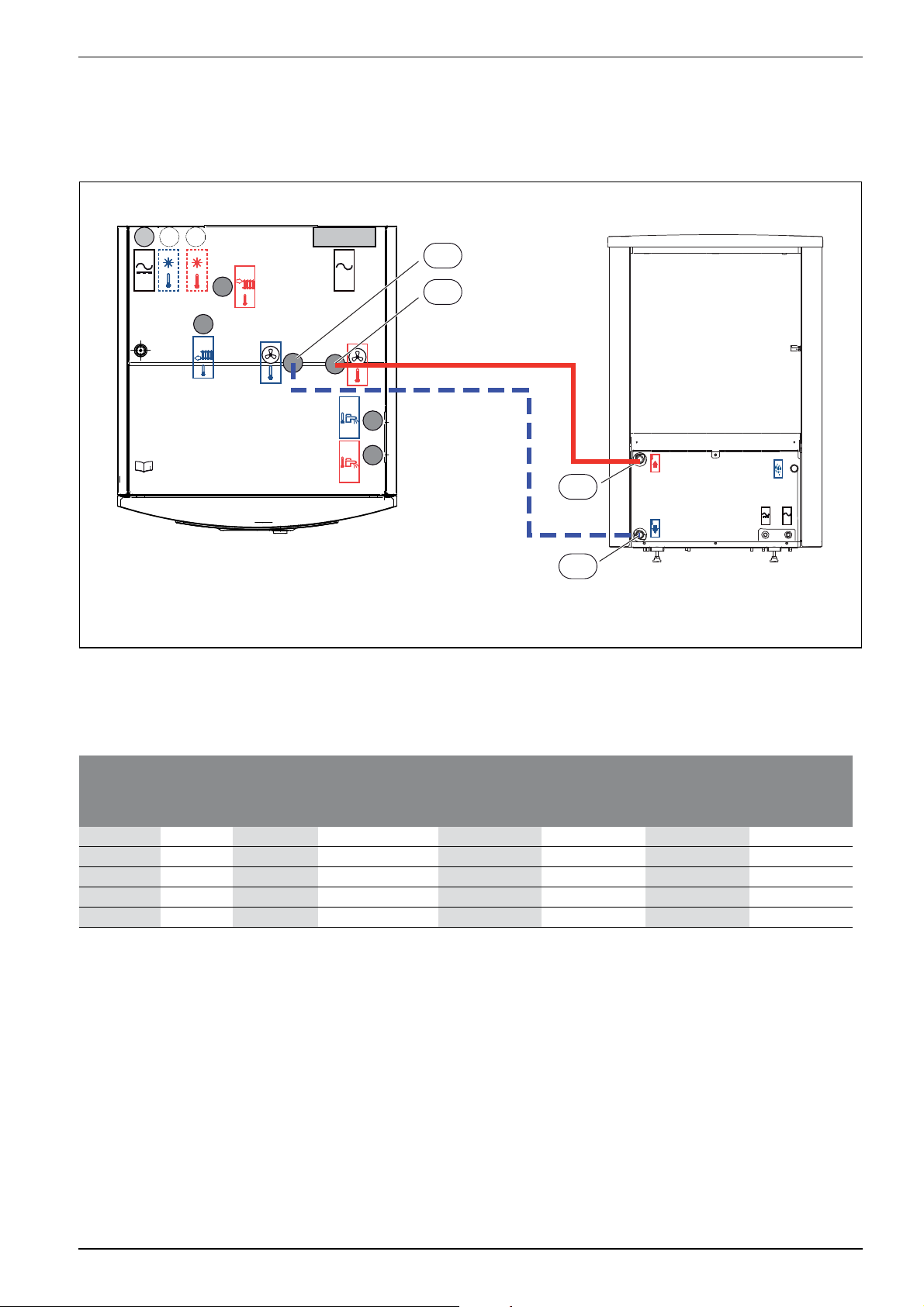

8.11 Heat pump/heat pump module circuit diagram

9kW

1

2

15kW

2

3

87

6

5

Fig. 32 Heat pump/heat pump module circuit diagram

[1] Heat pump module

[2] Heat pump

[3] IP module

[4] Accessories (extra heating circuit, pool, sun, etc.)

[5] Room controller (accessories)

[6] User interface

[7] Addressing with 9 kW immersion heater (standard setting)

[8] Addressing with 15 kW immersion heater (standard setting)

4

6 720 810 350-10.1I

32

Delivered connected

Connected during installation/

accessories

AirModule 6 720 813 268(2014/10)

Page 33

8.12 Connection option EMS bus

A B C

Electric installation

1

2

2

1

2

2

1

2

2

2

2

Fig. 33 Connection option EMS bus

[A] Star network or serial connection with external coupling box

[B] Star network

[C] Serial connection

[1] Installer module

[2] Accessory modules (for example: Room Controller, Mixing Valve

Module, Solar Module)

2

2

2

2

6 720 809 156-43.1I

AirModule –6 720 813 268(2014/10)

33

Page 34

User interface

9 User interface

9.1 Product description

• The user interface will manage a heating system with max. four

heating/cooling circuits, DHW heating with solar energy and heating

from solar power.

• In heat pump mode, optimized operation without time program will

provide the lowest energy consumption.

• The user interface can also operate according to a time program:

– Heating: 2 time programs for each heating circuit with two break

points per day. Heat circuits 2 to 4 can only change to heating

mode when heating circuit 1 is in heating mode if there is no

buffer cylinder installed.

– DHW: a time program for DHW heating.

• The user interface shows information from the heat pump module

and the heating system. It is also used to modify settings.

• After 1½ hour of operation the user interface has a battery life of at

least 8 hours. If a power outage lasts longer than the battery life, the

time and date settings will be erased. All other settings are saved.

• The functional scope and thus the menu structure of the user

interface are determined by the structure of the system. Reference to

the importance of the system structure to the functions will be made

in relevant places. Setting ranges and standard settings may not

correspond with the information in these instructions.

9.1.1 Control modes

The following main control modes are available for heating:

• Outside temperature compensated control: automatic flow

temperature control based on outside temperature.

• Outside temperature compensated control influenced by room

temperature: automatic flow temperature control based on outside

temperature and room temperature. A room controller must be

installed in the reference room.

If the cooling mode is active, it will be set to an adjustable constant

temperature.

Further information on control modes and settings that influence control

( chapter 12.3, page 44).

• Room controller CR10H as a separate room controller, which

measures relative humidity (for heating/cooling circuits)

• MM100: Module for heating and cooling circuits with mixing valve

• MP100: Module for heat pump heated pool

• MS100: Module for solar energy DHW heating

• MS200: Module for extended solar thermal systems

Instructions validity for modules supporting EMS plus

These instructions also apply to the user interface in combination with

heating/cooling circuit module MM100 (accessories).

Additional setting options may be found in some menus, if your heating

system is equipped with other modules (e.g. solar module, accessories).

These setting options are described in the module technical information.

9.2 Important notices on usage

WARNING: Risk of scalding!

If thermal disinfection has been activated to avoid

legionella, the hot water is heated once to in excess of

65 °C. The factory setting for the hot water temperature is

60 °C. There is a risk of scalding at the draw-off points if

the temperature is set higher than this.

▶ Make sure that a mixing device that prevents scalding

is installed. If in doubt, ask your contractor.

NOTICE: Floor damage!

▶ If using underfloor heating, ensure that the floor type

max. temperature is not exceeded.

▶ Optionally, install an extra temperature switch, and

connect it to one of the external inputs.

• Only products from the same distributor may be used within the EMS

BUS system.

9.3 Optional accessories

For details regarding suitable accessories, please refer to the catalogue/

price list.

Function modules and user interfaces in the control system EMS plus:

• Room controller CR10 as a separate room controller

34

AirModule 6 720 813 268(2014/10)

Page 35

10 Basic principles of operation

Basic principles of operation

10.1 Key and symbol overview

If the display is turned off, it will turn on when a key is

used and a function executed. Quickly press the selector

3

2

fav

menu

info

1

4

5

6

to turn on the display. If you don't use any keys, the

display will turn back off.

7

6 720 810 300-

Fig. 34 Keys

Pos. Section Designation Explanation

1 Favourites key ▶ Press this key to show favourite functions for heating/cooling circuit 1.

fav

2 Extra DHW key ▶ Press this key to activate the extra DHW function ( user interface operating instructions).

3 DHW key ▶ Press this key to activate the DHW operating mode ( user interface operating instructions).

4 Menu key ▶ Press this key to enter the main menu ( user interface operating instructions).

menu

▶ Keep this key pressed down to change Favourites menu settings ( User interface operating instructions).

5 Info key When a menu is shown:

info

▶ Press this key for more information about the selected item.

When standard display is active:

▶ Press this key to enter the information menu ( user interface operating instructions).

6 Return key ▶ Press this key to return to the previous menu or to cancel changes.

For maintenance or when an error has been detected:

▶ Press this key to switch between standard display and error message.

▶ Keep this key pressed down to switch between a menu and the standard display.

7 Selector ▶ Turn the selector to change a set value (e.g. the temperature) or to select a menu or item.

When the display is off:

▶ Press the selector to turn on the display.

When the display is on:

▶ Press the selector to open a selected menu or item, or confirm a set value (e.g. temperature) or a message, or to

close a pop-up window.

When standard display is active and the display is on:

▶ Press the selector to activate the input window for heating/cooling circuit options in the standard display (only

valid for systems with at least two heating/cooling circuits, User interface operating instructions).

Table 12 Keys

AirModule –6 720 813 268(2014/10)

35

Page 36

Basic principles of operation

10.2 Display symbols overview

2

1

7

3

4

5

6

6 720 811 136-01.1O

Fig. 35 An example of what the standard display might look like in a

system with several heating/cooling circuits

Pos. Symbol Designation Explanation

1 Temperature Shows current flow temperature (heat pump module temperature)

2 – Information line Displays time of day, day of the week and date.

3 Other temperature

indicator

4 – Text information E.g. the designation of the currently displayed temperature ( [1]). No designation is displayed for room

5 Key lock If key lock is enabled, the key symbol appears on the display.

6 Information graphic Displays information symbols, showing the user what functions are currently active in the system.

Displays an additional temperature, e.g. outside temperature, solar panel temperature, or the DHW system

temperature ( user interface operating instructions).

temperature. If an error occurs, corresponding information will be displayed here until the error has been

addressed.

DHW heating active

Thermal disinfection (DHW) active

Extra DHW function active

Basin/pool is being heated

Heating active

Cooling active

Power outage caused by energy supply company

Closed external input (remote control)

Holiday function active

Time program – heating program 1 or 2 active

Smart Grid (intelligent network) function activated

Screed drying active

Immersion heater active

Extra heat source (booster heater with mixing valve) active

Defrosting active

Heat pump active

Solar pump active

7 Optimised Operating mode Energy efficient operation with a constant set room temperature.

Program 1 The heating is controlled according to the time program active in the current heating circuit. At set times, the

Program 2

heating will switch between heating mode and setback mode.

Heating mode in displayed heating circuit active

Setback mode in displayed heating circuit active

Table 13 Symbols on the standard display

36

AirModule 6 720 813 268(2014/10)

Page 37

Basic principles of operation

menu

menu

menu

10.3 Using the service menu

If the display is turned off, it will turn on when a key is

used and a function executed. Quickly press the selector