IVT AirX Series, AirModule E 9 Series, Airbox E Series, AirModule E15 Series, Airbox S Series Operating Instructions Manual

Page 1

Operating Instructions

AirX, AirModule E 9/15, Airbox E/S

6 720 809 065-00.1I

230V 1N~ / 400V 3N~

6 720 810 266 (2014/10)

Page 2

Table of Contents

AirX, AirModule E 9/15, Airbox E/S – 6 720 810 266 (2014/10)

2

Table of Contents

1 Key to symbols and safety instructions . . . . . . . . . . . . . . . . . . . 2

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . 3

2 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 Description of the functions . . . . . . . . . . . . . . . . . . . . . . . 4

4 Overview of the most common functions . . . . . . . . . . . . . . . . . 6

4.1 Changing the room temperature . . . . . . . . . . . . . . . . . . . 7

4.2 Setting the operating mode . . . . . . . . . . . . . . . . . . . . . . . 7

4.3 Selecting a heating circuit for the standard display . . . . 8

4.4 Favourite functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1 Remove dirt and leaves . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 Protective covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.3 Evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.4 Snow and ice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.5 Moisture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.6 Checking the safety valves . . . . . . . . . . . . . . . . . . . . . . . . 9

5.7 Particle filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.8 Pressure Switch and Overheat protection . . . . . . . . . . 10

5.9 Cleaning the condensate pan . . . . . . . . . . . . . . . . . . . . 12

6 Connection for IP-module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 Environment / disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1 Key to symbols and safety instructions

1.1 Key to symbols

Warnings

The following keywords are defined and can be used in this document:

• NOTICE indicates a situation that could result in damage to property

or equipment.

• CAUTION indicates a situation that could result in minor to medium

injury.

• WARNING indicates a situation that could result in severe injury or

death.

• DANGER indicates a situation that will result in severe injury or death.

Important information

Additional symbols

Warnings in this document are identified by a warning

triangle printed against a grey background.

Keywords at the start of a warning indicate the type and

seriousness of the ensuing risk if measures to prevent

the risk are not taken.

This symbol indicates important information where

there is no risk to people or property.

Symbol Explanation

▶ Step in an action sequence

Cross-reference to another part of the document

• List entry

– List entry (second level)

Table 1

Page 3

General

AirX, AirModule E 9/15, Airbox E/S – 6 720 810 266 (2014/10)

3

1.2 General safety instructions

These operating instructions are intended for the user of the heating

system.

▶ Read any operating instructions (heat pump, heating controls, etc.)

carefully before operation and keep them.

▶ Observe the safety instructions and warnings.

Intended use

This heat pump must only be used as a heat appliance in a sealed hot

water heating system for domestic purposes.

Any other use is considered inappropriate. Any damage that results from

such use is excluded from liability.

Safety of electrical appliances for domestic use and similar

purposes

The following requirements apply in accordance with EN 60335-1 in

order to prevent hazards from occurring when using electrical

appliances:

“This device can be used by children of 8 years and up as well and by

people with reduced physical, sensory or mental capabilities or lacking

in experience and knowledge, if they are supervised and have been given

instruction in the safe use of the device and understand the resulting

dangers. Children must not play with the device. Cleaning and user

maintenance may not be performed by children without supervision”

“If the power supply cable is damaged, in order to avoid risks it must be

replaced by the manufacturer or its customer service department or a

similarly qualified person.”

Inspection and servicing

Regular inspection and maintenance are prerequisites for safe and

environmentally compatible operation of the heating system.

We recommend you enter into a contract for the annual inspection and

demand-dependent servicing with an authorised contractor.

▶ Have any work carried out only by an authorised contractor.

▶ If any faults are discovered, have them remedied immediately.

Modifications and repairs

Unprofessional modifications to the heat pump or other parts of the

heating system can result in injury and/or damage to property or

equipment.

▶ Have any work carried out only by an authorised contractor.

▶ Do not remove the casing of the heat pump.

▶ Do not modify the heat pump or other parts of the heating system in

any way.

Room air

The air in the installation room must be free of combustible or chemically

aggressive substances.

▶ Do not use or store combustible or explosive materials (paper,

propellants, thinners, paints, etc.) within the vicinity of the appliance.

▶ Do not use or store corrosive substances (solvents, adhesives,

chlorinated cleaning agents, etc.) within the vicinity of the appliance.

2 General

Cooling is disabled in the UK model to comply with

the regulations for RHI.

Heat pum p AirX is together with h eat pump module AirModule or Air box

part of a series of heating systems that use outside air to provide energy

for water transferred heat and hot water.

By reversing the process and extract heat from the water and release it

into the outdoor air, the heat pump can if needed produce cooling. This

however requires the heating system to be intended for cooling.

The heat pump outdoors is connected to a heat pump module indoors

and possibly also an external heat source, which constitutes a complete

heating system. The heat pump module with an integrated immersion

heater, or the external source, acts as a supplement when additional

heat is needed, for example if the outside temperature is too low for

effective heat pump operation.

The heating system is operated via a user interface, which is fo und in the

heat pump module. The user interface manages and supervises the

system with different settings for heat, cold, hot water and other

operations. The monitoring function will e.g. turn off the heat pump in

case of disturbances to avoid damage to vital components.

2.1 Control unit

The user interface in the heat pump module manages heat production

based on outside temperature sensors and possibly in combination with

a room controller (accessories). House heating is automatically adjusted

depending on the outside temperature.

The user determines the heating system temperature by setting the

desired room temperature in the user interface or on the room

controller.

A number of accessories can be connected to the heat pump module

(e.g. pool, sun, and room controllers), providing extra functions and

setting possibilities controlled via the user interface. You will find more

information on the accessories in their user guides.

2.2 Use

After the heat pump and the heat pump module have been installed and

taken into operation, some regular maintenance is required. This might

include checking on an alarm, or other simple maintenance. The user is

usually able to solve the problem, however if it remains, the retailer

should be contacted.

Page 4

System overview

AirX, AirModule E 9/15, Airbox E/S – 6 720 810 266 (2014/10)

4

3 System overview

The heating system consists of two parts: the heat pump, which is

installed outdoors, and the heat pump module with or without integrated

hot water cylinder, which is installed indoors (AirModule and Airbox E).

Installation may be done using an external heat source, and the

supplemental heat source will then consist of an existing electric/gas/oil

boiler (Airbox S).

The most common heating systems are consistent with one of these

alternatives, however the system flexibility makes other combinations

possible.

3.1 Description of the functions

In a house with water based heating a difference is made between

heating water and domestic hot water (DHW). The heating water is for

radiators and floor coils and hot water is for showers and taps.

If there is a DHW cylinder in the system, the user interface will make sure

the heating of DHW is prioritised before heating of heating water for

optimised comfort.

3.1.1 Heat pump (outdoor unit)

The task of the heat pump is to retrieve energy from the outside air and

transfer it to the heat pump module.

The heat pump is inverter operated, which means that it will

automatically change the compressor speed to deliver the exact amount

of energy required at the moment. The fan is also RPM controlled and will

change its speed as needed. This provides the lowest possible energy

consumption.

Defrosting

Ice might form on the evaporator during lower outside temperatures. In

case there is enough ice to inhibit the air flow through the evaporator, an

automatic defrosting will start. As soon as the ice is gone, the heat pump

returns to its normal operation.

If the outside temperature is above +5°C the defrosting will be

performed alongside continued heat production, however if the

temperature is lower, the defrosting is done by ways of a 4-way valve

turning the heat medium direction in the circuit so that the hot gas from

the compressor melts away the ice.

Function principle

The heat production principle:

• The fan sucks up air through the evaporator.

• The energy in the air makes the refrigerant boil. The resulting gas is

drawn into the compressor.

• In the compressor, the pressure of the refrigerant is increased, and

the temperature rises. The hot gas is pushed into the condenser.

• In the condenser, the energy is transferred from the gas to water in the

heat transfer circuit. The gas is cooled down and turns into liquid.

• The pressure on the refrigerant is decreased and transferred back to

the evaporator. When the refrigerant passes the evaporator, it turns

back into gas.

• In the heat pump module, the energy is transferred from the heat

transfer circuit to the house heating system and hot water cylinder.

3.1.2 Heat pump module (indoor unit)

The heat pump module task is to distribute t he heat from the heat pump

to the heating system and the hot water cylinder. The circulation pump

in the heat pump module is RPM controlled, and will automatically

decrease in speed when demand is low. This decreases energy

consumption.

When the heating demand is higher during cold outdoor temperatures,

an additional heat source - a booster - may be required. This booster

heater is either integrated or external, an its on/off is controlled by the

user interface in the heat pump module. Please note that when the heat

pump is running, the booster heater will only provide the heating output

that the heat pump cannot produce itself. When the he at pu mp is able t o

provide all the heating needed, the booster is automatically turned off.

The heat pump stops around – 20 °C; heating and DHW

production is then taken over by the heat pump module

or a external heat source.

Page 5

System overview

AirX, AirModule E 9/15, Airbox E/S – 6 720 810 266 (2014/10)

5

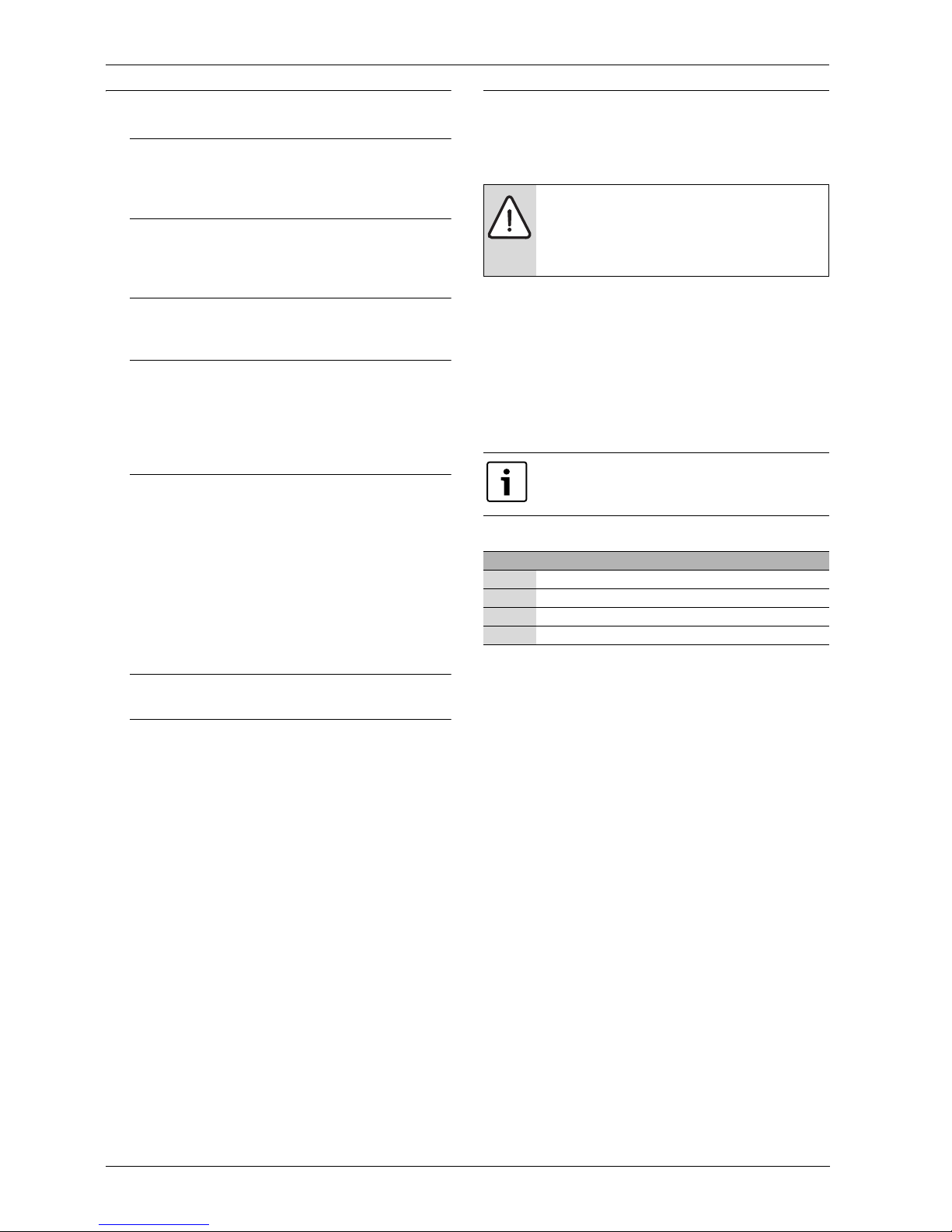

AirModule

Heat pump AirX connected to heat pump module AirModule provides a

complete installation for both heating and domestic hot water, since the

heat pump module contains a hot water cylinder. Switching between

heating and DHW is managed by an internal 3-way valve. The integrated

booster in the heat pump module will turn on if needed.

Fig. 1 Heat pump AirX, heat pump module AirModule with integrated hot water cylinder and immersion heater

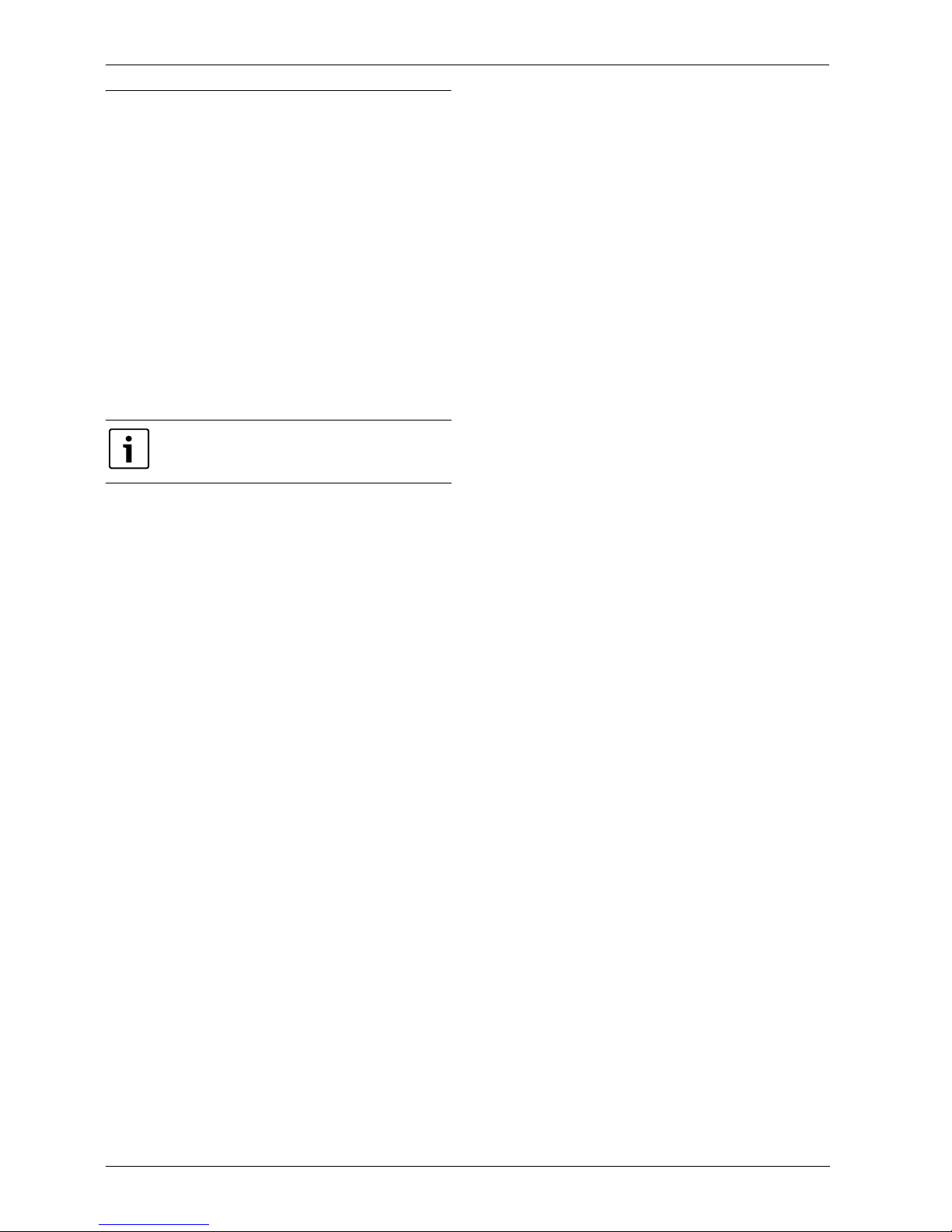

Airbox E

When heat pump AirX is connected to heat pump module AirBox E, an

external hot water cylinder is required if the purpose of the heat pump is

also to produce hot water. In this case, switching between heating and

DHW is managed by an external 3-way valve. The integrated booster in

the heat pump module will turn on if needed.

Fig. 2 Heat pump AirX, heat pump module Airbox with immersion heater, external hot water cylinder

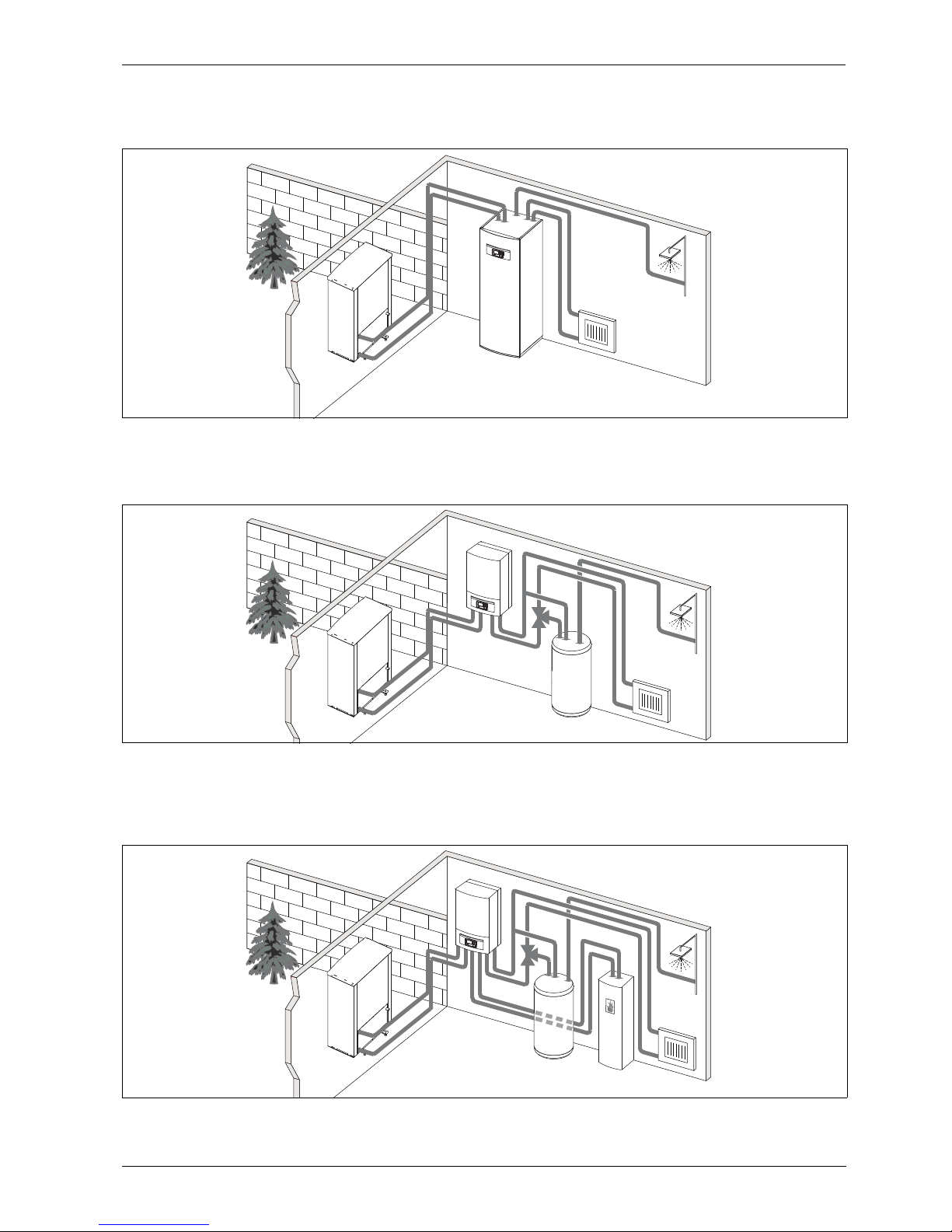

Airbox S

When heat pump AirX is connected to heat pump module AirBox S, an

external hot water cylinder is required if the purpose of the heat pump is

also to produce hot water. In this case, switching between heating and

DHW is managed by an external 3-way valve. The module contains a

mixing valve that regulates the heat from the external booster, which is

turned on when needed.

Fig. 3 Heat pump AirX, heat pump module Airbox without immersion heater, external hot water cylinder and external booster

Page 6

Overview of the most common functions

AirX, AirModule E 9/15, Airbox E/S – 6 720 810 266 (2014/10)

6

4 Overview of the most common functions

Fig. 4 Keys

In the user interface operating instructions you will find a

complete description of all functions and settings.

Pos. Key Designation Explanation

1 Favourites key ▶ Press this key to show favourite functions for heating circuit 1.

▶ Keep this key pressed down to change Favourites menu settings.

2 Extra DHW key ▶ Press this key to activate the extra DHW function.

3 DHW key ▶ Press this key to select DHW mode.

4 Menu key ▶ Press this key to enter the mai n menu.

5 Info key When a menu is shown:

▶ Press this key for more information about the selected menu option.

When standard display is active:

▶ Press this key to enter the information menu.

6 Return key ▶ Press this key to return to the previous menu or to cancel changes.

For maintenance or when an error has been detected:

▶ Press this key to switch between standard display and error message.

▶ Keep this key pressed down to switch between a menu and the standard display.

7 Selector ▶ Turn the selector to change a set value (e.g. the temperature) or to select a menu or menu option.

When the display is off:

▶ Press the selector to turn on the display.

When the display is on:

▶ Press the selector to open a selected menu or menu option, o r confirm a set value (e.g. temperature) or a message, or

to close a pop-up window.

When standard display is active:

▶ Press the selector to a ctivate the input window for heating circuit options in the standard display (only valid for

installations with at least two heating circuits).

Table 2 Keys

menu

fav

info

6 720 808 471-01.1O

5

6

7

4

2

3

1

fav

menu

info

Page 7

Overview of the most common functions

AirX, AirModule E 9/15, Airbox E/S – 6 720 810 266 (2014/10)

7

4.1 Changing the room temperature

4.2 Setting the operating mode

Optimised operation is active with the standard settings, since this operating mode ensures the most effective heat pump operation.

Operation Results

If some day you are cold or feel it is too hot: temporarily change the room temperature

Automatic mode

Change the room temperature until the next switching time

▶ Turn the selector to set desired room temperature.

The corresponding time slot is displayed in grey in the time program bar chart.

▶ Wait a few seconds or press the selector.

The user interface operates with the modified setting. The change applies until the next switching time in your heating time

program is reached. After this, the time program settings are restored.

Undoing a temperature change

▶ Turn the select or until the corresponding time slot tu rns back to bl ack in the ti me program bar chart and press the selector.

The change is undone.

If you are always cold or feel it is too hot: set desired room temperature (e.g. for heating and setback operating mode)

Optimised operation

▶ Activate optimized operation ( chapter 4.2).

▶ Wait a few seconds or press the selector to close the pop-up window.

▶ Turn the selector to set desired room temperature.

▶ Wait a few seconds or press the selector. Confirm the change in the pop-up window by pressing the selector (or undo the

change by pressing the Return key).

Current room temperature is shown in a pop-up window in the lower part of the display.

The user interface operates with the modified settings.

Automatic mode

▶ Press the menu k ey to enter the main menu.

▶ Press th e selector to open the Heating/Cooling menu.

▶ Turn the selec tor to highlight the Temperature settings menu.

▶ Press th e selector to open the menu.

▶ If two or more heating circuits are installed: turn the selector to highlight Heating circuit 1, 2, 3 or 4 and press the

selector.

▶ Turn the selector to h ighlight Heating or Setback.

▶ Press the selector.

▶ Turn the selector to h ighlight desired setback operation setting.

▶ Press the selector t o activate selected setting.

When temperature control is activated:

▶ turn the selector and press it to set the temperature. The temperature setting value limits are determined by the settings

for the other operating mode.

The user interface operates with the modified settings. The settings apply to all heating time programs (when two or more

heating circuits are set it only applies to the selected heating circuit).

Table 3 Room temperature

Operation Results

If you want to activate optimised operation (without time program)

▶ Press the m enu key to enter the main menu.

▶ Press the select or to open the Heating/Cooling menu.

▶ Press the select or to open the Operating mode menu.

▶ If two or more heating circuits are installed: turn the selector to highlight Heating circuit 1, 2, 3 or 4 and press the selector.

▶ Turn the selector to highlight Optimised and press the selector.

▶ Return to the standard display by pressing the Return key and keeping it pressed down.

Desired room temperature is shown in the lower part of the display, in a pop-up window. The user interface will change the

permanent room temperature to the desired room temperature.

If you want to activate automatic mode (and use the time program)

▶ Press the m enu key to enter the main menu.

▶ Press the select or to open the Heating/Cooling menu.

▶ Press the select or to open the Operating mode menu.

▶ If two or more heating circuits are installed: turn the selector to highlight Heating circuit 1, 2, 3 or 4 and press the selector.

▶ Turn the selector to highlight Auto and press the selector.

▶ Return to the standard display by pressing the Return key and keeping it pressed down.

All temperatures set in the current time program for heating are shown in the lower part of the display, in a pop-up window.

Current temperature flashes.The user interface regulates the room temperature according to the active heating time program.

Table 4 Getting started – Activating operating modes

6 720 811 136-05.1O

6 720 811 136-06.1O

6 720 811 136-07.1O

6 720 811 136-08.1O

6 720 811 136-04.1O

6 720 811 136-05.1O

Page 8

Overview of the most common functions

AirX, AirModule E 9/15, Airbox E/S – 6 720 810 266 (2014/10)

8

4.3 Selecting a heating circuit for the standard display

The standard display only ever shows data for a single heating circuit. If

two or more heating circuits are installed, a setting can be made to

determine which heating circuit the data in the standard display relates

to.

4.4 Favourite functions

The Favourites key provides direct access to the functions that you use

most often with heating circuit 1. When you press the Favourites key for

the first time, the menu Configuration of the Favourites menu appears.

Here, you are able to save your personal favourites and modify the

Favourites menu according to your needs on a later occasion.

The Favourites key function depends on the heating circuit shown in the

standard display. The settings that are modified in the Favourites menu

only apply to heating circuit 1.

Operation Results

▶ If the display is on, press the selector.

Current selected heating circuit number, operating mode and name (optional) is shown in the lower part of the display.

▶ Turn the selector to select a heating circuit.

Only heating circuits that exist in the system are displayed for selection.

▶ Wait a few seconds or press the selector.

The standard display displays the selected heating circuit.

Table 5 General – Heating circuit in standard display

6 720 811 136-02.1O

Operation Results

When you want to use a Favourites function: open the Favourites menu

▶ Press the F avourites key to open the Favourites menu.

▶ Turn the selector and press to select a favourite function.

▶ Modify settings (this is done in the same way as in the main menu).

If you want to modify the favourite functions list according to your own needs: Modify Favourites menu

▶ Press the Favourites key and keep it pressed down until the menu Configuration of the Favourites menu is shown.

▶ Turn and press the selector to select a function (Yes) or to cancel your selection (No).

The changes are effective immediately.

▶ Press the Return key t o close the menu.

Table 6 Favourite functions

6 720 811 136-15.1O

Page 9

Maintenance

AirX, AirModule E 9/15, Airbox E/S – 6 720 810 266 (2014/10)

9

5 Maintenance

The heat pump requires a minimum of maintenance, however, some

servicing is still required to get optimal performance from your heat

pump. Check the following items a few times per year:

• Remove dirt and leaves

•Cover

• Evaporator

5.1 Remove dirt and leaves

▶ Use a brush to remove the dirt and leaves from the heat pump.

5.2 Protective covers

Over time dust and other dirt will collect on the heat pump.

▶ If required, wipe the cover with a damp cloth.

▶ Scratches and damage to the outer cover should be treated with rust

protection.

▶ The lacquer can be protected with car wax.

5.3 Evaporator

If a film has formed (e.g. dust or dirt) on the evaporator surface, it must

be removed.

To clean the evaporator:

▶ Spray the evaporator fins with the cleaning product on the back of the

heat pump.

▶ Rinse off dirt and the cleaning product with water.

5.4 Snow and ice

In some geographical regions or during periods of heavy snow, snow can

get stuck on the back of the heat pump.

▶ Carefully brush the snow off the fins.

5.5 Moisture

Moisture might develop under the heat pump (outdoors) due to

condensation not collected by the condensate pan. This is normal and

does not require any action.

5.6 Checking the safety valves

▶ Check the DHW safety valve by pressing the valve lever.

▶ Check that the safety valve leakage drain hose is not plugged.

5.7 Particle filter

Check the heating system and collector system particle filters

The filters will prevent dirt from entering the heat pump. Operating

problems might occur if these are blocked.

Cleaning the strainer

▶ Close the valve (1).

▶ Screw off the hood (by hand), (2).

▶ Take out the strainer and clean it by running water over it.

▶ Put the strainer back; it has rails that fit into the groove in the valve to

avoid incorrect installation (3).

Fig. 5 Filter version without circlip

▶ Screw back the hood (by hand).

▶ Open the valve (4).

DANGER: The heat pump is connected to high current.

▶ Break the power supply before rectifying.

Using the wrong cleaning product may damage the

installation!

▶ Do not use acid or chlorine based products since they

contain abrasives.

WARNING: The thin aluminium fins are fragile and can

be damaged if careless. Never wipe the delicate fins with

a cloth.

▶ Use protective gloves to protect your hands from

cuts.

▶ Do not use a too powerful water jet.

NOTICE: If you often find moisture near the heat pump

module or the fan convector, this might indicate gaps in

the condensation insulation.

▶ Turn off the heat pump and contact your retailer of

you find moisture surrounding one of the heat system

components.

The safety valve should be checked by a qualified

engineer - usually as part of an annual service visit.

Water is expelled from the safety valve during heat-up.

Never close the safety valve.

It is not necessary to empty the installation in order to

clean the filters. Filter and shut-off valve are integrated.

1.

2.

2.

1.

1

2

3

4

6 720 805 915-01.1I

Page 10

Maintenance

AirX, AirModule E 9/15, Airbox E/S – 6 720 810 266 (2014/10)

10

5.8 Pressure Switch and Overheat protection

If the pressure switch has tripped resets itself when the pressure is

sufficient in the system.

▶ Check the pressure gauge.

▶ If the pressure is below 0.5 bar, slowly increase the pressure in the

heating system by adding water to the filling valve to a maximum of 2

bar.

▶ Contact the installer or retailer if you are unsure of how to proceed.

To reset the overheat protection on AirModule:

▶ Pull out the front cover by the bottom and lift it off upwards.

▶ Press the button hard on the overheating protection.

▶ Put the front cover back.

To reset the overheat protection on AirBox E:

▶ Contact the installer or retailer

Fig. 6 AirBox E

[1] Pressure gauge

Pressure switch and overheat protection are only in heat

pump module with integrated electrical supplement.

Overheat protection must be manually reset if it trips.

The pressure switch and overheat protection are

connected in series, triggered alarm or information in

the controll unit means either low pressure in the system

or to high temperature in the additional heater.

1 6 720 810 156-11.1I

Page 11

Maintenance

AirX, AirModule E 9/15, Airbox E/S – 6 720 810 266 (2014/10)

11

Fig. 7 AirModule

[1] Reset overheating protection

[2] Particle filter

[3] Pressure gauge

1

6 720 810 156-10.1I

3

2

Page 12

Maintenance

AirX, AirModule E 9/15, Airbox E/S – 6 720 810 266 (2014/10)

12

5.9 Cleaning the condensate pan

If the user interface shows an alarm indicating that the heat pump cover

requires cleaning, the condensate pan should be cleared of dirt and

leaves, which inhibit defrosting.

▶ Screw off the protective cover.

▶ Clean the condensate pan with a cloth or soft brush.

▶ Put the protective cover back.

Fig. 8 Heat pump condensate pan

[1] Condensate pan

Warning: The thin aluminum fins of the evaporator are

sharp and delicate and can be damaged by negligence.

▶ Wear gloves to protect hands from cuts

▶ Be careful not to damage the fins

6 720 809 065-11.1I

1

Page 13

Connection for IP-module

AirX, AirModule E 9/15, Airbox E/S – 6 720 810 266 (2014/10)

13

6 Connection for IP-module

The heat pump module AirModule has a built in IP-module, which is

available as an accessory to the AirBox. The IP-module may be used to

manage and monitor the heat pump module and the heat pump from a

mobile unit. It is used as an interface between the heating system and a

network (LAN) and enables the SmartGrid function.

Commissioning

The router must be configured as follows:

• DHCP enabled

• Ports 5222 and 5223 may not be blocked from outgoing traffic.

• Free IP address available

• The address filter (MAC filter) must not filter out the module.

During commissioning of the IP-module, the following is possible:

• Internet

The module automatically obtains an IP address from the router. The

name and address of the target server are stored in the standard

settings of the module. As soon as an internet connection is

established, the module automatically logs on to the server.

• Local network

The module must not be connected to the internet. It can also be used

in a local network. In this case, however, the module cannot be

reached via the internet, and the module software cannot

automatically update.

• The app IVT AnyWare

When the app is opened for the first time, the predefined login name

and password must be entered. The login information can be found on

the IP-module data plate.

•SmartGrid

The heat pump module can communicate with the electricity market

and will in this case adjust operation so that the heat pump operates

at its maximum when the cost of electricity is lower. See the website

for further information.

Login data for IP-module

Manufact.no.:__ __ __ __ - __ __ __ __ __ __ __ __ __ - __ __ __ __ __ __ __ __ __ __

Login name: ___ ___ ___ ___ ___ ___ ___ ___ ___

Password: __ __ __ __ - __ __ __ __ - __ __ __ __ - __ __ __ __

Mac: ___ ___ - ___ ___ - ___ ___ - ___ ___ - ___ ___ - ___ ___

7 Environment / disposal

Environmental protection is a fundamental corporate strategy of the

Bosch Group.

The quality of our products, their economy and environmental safety are

all of equal importance to us and all environmental protection legislation

and regulations are strictly observed.

We use the best possible technology and materials for protecting the

environment taking account of economic considerations.

Packaging

We participate in the recycling programmes of the countries in which our

products are sold to ensure optimum recycling.

All of our packaging materials are environmentally compatible and can

be recycled.

Used appliances

Used appliances contain valuable materials that should be recycled.

The various assemblies can be easily dismantled and synthetic materials

are marked accordingly. Assemblies can therefore be sorted by

composition and passed on for recycling or disposal.

Use of all the functions requires an internet connection

and a router with an available RJ45 output. This may

incur additional costs. Managing the installation from a

cell phone requires the free app IVT Anywhere.

Please refer to the router documentation during

commissioning.

NOTICE: You will lose your login information when you

change IP-module!

Each IP-module has its own unique login information.

▶ Enter your login information after commissioning in

the appropriate field.

▶ Change the information according to the new IP-

module if it has been changed.

You can also change the password in the

user interface.

Page 14

Technical glossary

AirX, AirModule E 9/15, Airbox E/S – 6 720 810 266 (2014/10)

14

Technical glossary

Heat pump

The central heat source. Placed outdoors, also referred to as an outside

unit. Contains the cooling circuit. Waterborne heating or cooling is

transferred from the heat pump to the heat pump module.

Heat pump module

Placed indoors and distributes the heat from the heat pump to the

heating system or the water heater. Contains the user interface and the

circulation pump for the water to the heat pump.

Heating installation

Includes the entire installation, with heat pump, heat pump module,

water heater, heating system and accessories.

Heating system

Comprises the heat source, cylinders, radiators, underfloor heating

system or fan convector or a combination of these if the heating system

has several heating circuits.

Heating circuit

The part of the heating system that distributes heat to different rooms.

Consists of pipework, circulation pump and either radiators, underfloor

heating system loops or fan convectors. Only one of these alternatives is

possible in one circuit, but if there are e.g. two circuits in the heating

system, then one may comprise radiators and the other underfloor

heating system loops. A heating circuit can be installed with or without a

mixing valve.

Heating circuit without mixing valve

A heating circuit without mixing valve does not contain a mixer; the

temperature on the circuit is maintained completely b y th e he at f rom th e

heat source.

Heating circuit with mixing valve

A heating circuit with mixing valve contains a mixer, which mixes in the

closed circuit water with the water from the heat pump. This means that

the heating circuit with mixing valve can maintain a lower temperature

than the rest of the heating system, which may be used to separate

underfloor heating system loops that use a lower temperature from

radiators that operate at a higher temperature.

Mixing valve

The mixing valve is a valve that seamlessly mixes cooler closed circuit

water with water from the heat source to reach the desired temperature.

The mixing valve may be placed in a heating circuit or in a heat pump

module as an external booster mixer.

3-way valve

The 3-way valve distributes heat either to the heating circuits or to the

water heater. The valve has two fixed modes, hence the heating and

DHW production cannot occur simultaneously. This provides for the

most effective operation, since DHW is always heated to a specific

temperature, while the heating water temperature is adjusted

continuously according to current outdoor temperature.

External booster heater

The external booster is a separate heat source, which is connected to the

heat pump module with pipework. The heating from the booster is

regulated via a mixing valve, and is therefore also called a mixing valve

booster. The user interface manages the booster on/off based on the

current heating requirements. The heat source is either an electric, oil or

gas boiler.

Heat transfer circuit

The part of the heating system that transfers heat from the heat pump to

the heat pump module.

Cooling circuit

Cooling is disabled in the UK model to comply with

the regulations for RHI.

The main part of the heat pump, which retrieve energy from outside air

and transfers it as heat to the heat transfer circuit. Consists of

evaporator, compressor, condenser and expansion valve. The

refrigerant circulates in the cooling circuit.

Evaporator

A heat exchanger between air and refrigerant. The energy in the air,

which is sucked up through the evaporator makes the refrigerant boil

and turn into gas.

Compressor

Makes the refrigerant circulate in the coolant circuit, from the

evaporator to the condenser and back. Increases the gaseous

refrigerant pressure. When the pressure increases, the temperature

increases too.

Condenser

Is a heat exchanger between the refrigerant in the cooling circuit and the

water in the heat transfer circuit. When heat is transferred, the

refrigerant temperature decreases as it is condensed into a liquid.

Expansion valve

Decreases the refrigerant pressure when it comes from the condenser.

The refrigerant is then transferred back to the evaporator, where the

process starts over.

Inverter

Is found in the heat pump and enables RPM control of the compressor

according to current heating requirements.

Setback phase

A time slot during automatic mode, with Setback operating mode.

Automatic mode

The heating system is heating in accordance with the time program and

an automatic changeover takes place between operating modes.

Operating mode

The operating modes for heating are: Heating and Setback. These are

indicated by the symbols and .

The operating modes for water heating are: DHW, DHW reduced and

Off.

It is possible to set a temperature for each operating mode (except Off).

Frost protection

Depending on the selected frost protection, the heat pump will turn on

when the outside and/or room temperature reaches below a certain set

threshold. Frost protection prevents the heating system from freezing

up.

Required room temperature (also desired or set temperature/set

room temp.)

The room temperature to be achieved by the heating system. It can be

set individually.

Default setting

Values permanently saved in the programming unit (e.g. complete time

programs) that are available at any time and that can be reinstated

according to demand.

Heating phase

A time slot during automatic mode, with Heating operating mode.

Page 15

Technical glossary

AirX, AirModule E 9/15, Airbox E/S – 6 720 810 266 (2014/10)

15

Child lock

The standard display settings and in the menu can only be modified if the

child lock (key lock) has been disabled ( page 8).

Mixing device

Assembly that automatically ensures that hot water can be drawn from

the taps at a temperature no higher than the temperature set on the

mixer.

Optimised operation

Automatic mode (the heating time program) is not active during

optimized operation, instead the system is continuously heating

according to the temperature set for optimized operation.

Reference room

The reference room is the room in the home where a room unit has been

installed. The room temperature in this room acts as the control variable

for the assigned heating circuit.

Switching time

A certain time at which the heating system starts to heat or hot water is

produced, for example. A switching time is a component of a time

program.

Temperature of an operating mode

A temperature that is assigned to an operating mode. The temperature is

adjustable. See the explanations on operating mode.

Flow temperature

Temperature at which the heated water flows in the central heating

system from the heat source to the heating surfaces in the rooms.

Hot water cylinder

A hot water cylinder stores large volumes of heated tap DHW. Thereby,

sufficient DHW is available at the draw-off points (e.g. taps). This is a

prerequisite for longer hot showers.

Time program for the heating system

This time program ensures automatic changeover between operating

modes at defined switching times.

Page 16

Alto Energy Limited

Unit 17 Glenmore Business Centre

Witney, Oxfordshire OX29 0AA

United Kingdom

www.altoenergy.co.uk | support@altoenergy.co.uk

Loading...

Loading...