IV Produkt Envistar Top Series Operation And Maintenance

Operation and Maintenance

Envistar Top

Order number:

Project:

Translation of the original instructions

Unit specifications

Unit type

TEM

TXM

TER

TXR

TEC 1V 2V

TTC

Home Concept model

Unit parts and accessories

Rotary heat exchanger TXRR

Counter-flow exchanger TXMM

Air heater water ETAB-VV Output var

1 2 3

ETAB-TV

Output var 1 2

Size

04 06 09 10

12 16 21

Control equipment

MX

UC

MK

US

HS

Filter, supply air

ePM10-60% / M5

ePM1-50% / F7

Excl. filter

Air heater electric ETAB-EV

Output var. 1 2 3

Air heater electric ETKB-EV Output var.

1 2 3 4

Air cooler water ETKB-VK

Damper ETSP-UM,

ETSP-TR, ETRL

Sound attenuator ETLD

Filter, extract air

ePM10-60% / M5

ePM1-50% / F7

Excl. filter

Table of Contents

1 Safety precautions

1.1 Lockable safety switch ..................................................................................................................6

1.2 Inspection doors ................................................................................................................................ 6

1.3 Electrical connection ....................................................................................................................... 6

1.4 Cooling unit/Revresible heat pump ......................................................................................6

2 General

2.1 Intended use

......................................................................................................................................... 7

2.2 Manufacturer .........................................................................................................................................7

2.3 Designations ......................................................................................................................................... 7

2.4 CE marking and EU Declaration of Conformity ...........................................................8

2.5 Maintenance .......................................................................................................................................... 8

2.6 Handling of refrigerant ...................................................................................................................9

2.7 Extended warranty .........................................................................................................................10

2.8 Spare parts .......................................................................................................................................... 10

2.9 Dismantling and decommissioning ................................................................................... 10

3 Technical description

3.1 Envistar Top air handling unit

................................................................................................. 11

3.2 Home Concept model ................................................................................................................. 11

3.3 EcoCooler cooling unit (code TEC) ................................................................................... 12

3.4 Reversible heat pump ThermoCooler HP (code TTC) .........................................15

4 Wiring instructions and fuse protection

4.1 MX – Complete control equipment and

UC – Complete electrical connection to terminal without controller unit

18

4.2 MK – Fans and heat exchangers electrically connected to terminal .......19

4.3 HS, US - Without control and without electrical connection .......................... 19

Table of Contents, cntd

5 Operation

5.1 Hygiene inspection ........................................................................................................................ 21

5.2 Actions in case of standstill .................................................................................................... 21

5.3 Commissioning ................................................................................................................................ 22

5.4 Cooling Status – Cooling unit (code TEC), size 04 .................................................23

5.5 Cooling Status – Cooling unit (code TEC), size 06-12 .........................................26

5.6 Cooling Status – Cooling unit, size (code TEC) 16-21 .........................................28

5.7 Cooling Status - reversible heat pump (code TTC) ................................................30

6 Maintenance instructions

6.1 Service schedule

6.2 Filters (code ELEF) ......................................................................................................................... 34

6.3 Rotary heat exchanger (code TXRR) ................................................................................37

6.4 Counter-flow exchanger (code TXMM) ......................................................................... 42

6.5 Air heater water (code ETAB-VV) and Thermoguard (ETAB-TV) .................... 44

6.6 Air Heater electric (Code ETAB-EV, ETKB-EV, ETAB-SV) ..................................46

6.7 Air cooler water (code ETKB-VK) ........................................................................................47

6.8 Fan unit (code ELFF) ....................................................................................................................48

6.9 Damper (code ETSP-UM, ETSP-TR, ETRL) ...............................................................51

6.10 Sound attenuator (code ETLD) ............................................................................................ 52

6.11 Cooling unit (code TEC) and reversible heat pump (code TTC) .................. 53

7 Alarm management and troubleshooting

7.1 Cooling unit (code TEC) - size 04 and 16-21

7.2 Cooling unit (code TEC) - size 06-12 ...............................................................................56

7.3 Reversible heat pump (code TTC) ......................................................................................60

............................................................................................................................. 32

............................................................. 54

Page 6

1 Safety precautions

Observe warning labels on the unit as well as the following safety precautions:

1.1 Lockable safety switch

NB:

The safety switch is not designed for starting/stopping the unit. Always

use the control equipment to start and shut down the unit.

Operation and Maintenance

Envistar Top 04-21

DSET.190501.01.EN

WARNING!

High voltage, risk of personal injury.

Working on/servicing the unit – Shut down the unit via the service switch in the control equipment, then turn the safety switch

to the 0 position and lock it.

1.2 Inspection doors

NB:

The doors in front of moving parts should normally be locked; there are

no safety guards. Before carrying out work, unlock the doors with the

key provided.

1.3 Electrical connection

WARNING!

Positive pressure inside the unit, risk of personal injury.

Allow the pressure to drop before you open the inspection

doors.

WARNING!

Rotating fan impeller, risk of personal injury. Shut down the unit

via the service switch in the control equipment, then turn the

safety switch to the 0 position and lock it. Wait at least 3 minutes before opening inspection doors.

WARNING!

Rotating fan impeller, risk of personal injury. The unit must not

be energised until all ducts have been connected.

NB:

Wiring of connections and other electrical work may only be carried out

by a qualified electrician or by service personnel recommended by IV

Produkt.

1.4 Cooling unit/Revresible heat pump

WARNING!

Hot surfaces, risk of personal injury. Shut down the unit via the

service switch in the control equipment, then turn the safety

switch to the 0 position and lock it. Wait at least 30 minutes

before opening the compressor inspection doors.

Continuous product development may give rise to specification changes without notice.

2 General

Kodnyckel

Code key

Beteckning

Project name

Ordernummer

Order number

Max. varv

Max. rev.

Tillv. ort

Made in

Tillv. månad

Manuf. month

YYMM

TER-04-AA-00-C1-H-00

Modell

Model

Envistar Top

TA1 FA1 POS 1

1234-567

– –

VÄXJÖ, SWEDEN

Max. temp. °Cr/m

1904

2.1 Intended use

2.2 Manufacturer

Operation and Maintenance

Envistar Top 04-21

DSET.190501.01.EN

Page 7

The air handling units in the Envistar Top series are intended for comfort ventilation in buildings.

The air handling unit, in its standard design, must be installed in an area that

maintains a temperature between +7 to +30°C and during the winter a moisture

content <3.5 g/kg in the fan room. The unit can also be equipped for outdoor

installation.

Any other use and installation in other environments is prohibited unless specifically permitted by IV Produkt AB.

The Envistar air handling units (AHUs) are manufactured by:

2.3 Designations

IV Produkt AB

Sjöuddevägen 7

SE-350 43 VÄXJÖ

The unit and cooling unit/reversible heat pump (if selected) have a model type

plate affixed to the front.

The model type plate shows the series number and the requisite designations to

identify the unit.

Typical model identification label

Continuous product development may give rise to specification changes without notice.

Operation and Maintenance

Envistar Top 04-21

Page 8

DSET.190501.01.EN

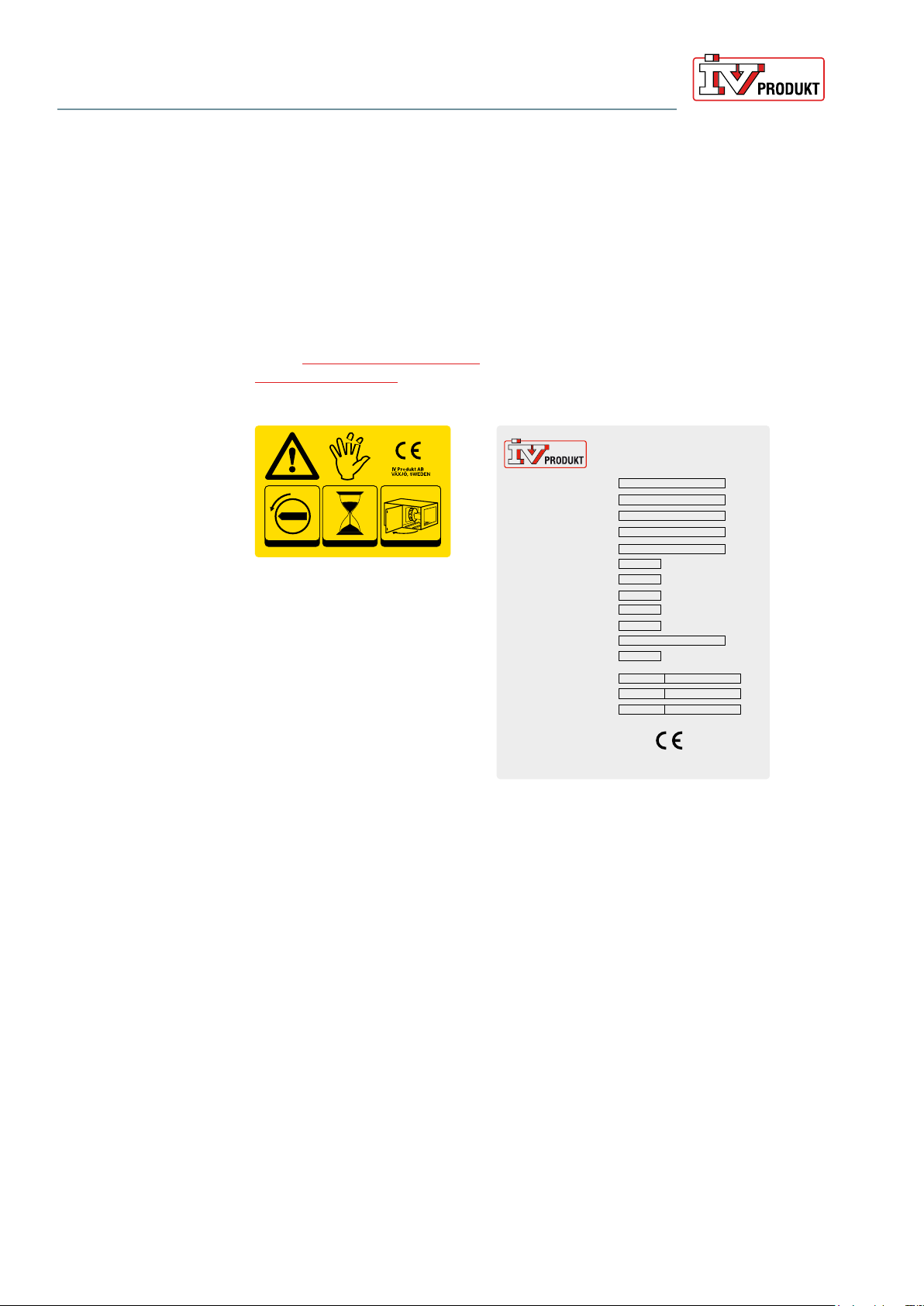

2.4 CE marking and EU Declaration of Conformity

The air handling units and cooling unit or reversible heat pump (if selected) are

CE marked, which means that upon delivery they conform to applicable provisions in EU Machinery Directive 2006/42/EC as well as to other EU Directives

applicable to the types of air handling units, e.g. Pressure Equipment Directive

PED 2014/68/EU.

As certification confirming that the requirements have been met, we provide an EU Declaration of Conformity, which is available under Documentation at ivprodukt.docfactory.com, or under Order Unique Documentation at

docs.ivprodukt.com.

1

s

0

12 3

180

Art. Nr. 19194-0001_01

Typical CE label for air handling units

Order number

Code Key

Model

Name of project

Date of manufacture

PS Max allowable pressure

PT Test pressure

TS Temperature range

Protection level - low

Protection level - high

Refrigerant / Fluid group

GWP

Refrigerant charge Circuit 1

Refrigerant charge Circuit 2

Refrigerant charge Circuit 3

Cooling unit

bar (e)

bar (e)

°C

bar (e)

bar (e)

kg

kg

kg

ton CO

ton CO

ton CO

2e

2

e

2e

Typical CE label for cooling units

For units without integrated control equipment

The EC declaration applies only to units in the condition in which they have been

delivered and installed at the facility in accordance with the enclosed installation

instructions. The declaration does not include components that were subsequently added or measures subsequently taken on the unit.

2.5 Maintenance

The ongoing maintenance of this unit can be carried out either by the person

normally in charge of maintaining the building or through a contract with a wellreputed service company.

Contains fluorinated greenhouse gases

covered by the Kyotot protocol.

0409

IV Produkt AB

VÄXJÖ, SWEDEN

Continuous product development may give rise to specification changes without notice.

2.6 Handling of refrigerant

The following information summarises the requirements and guidelines for handling the refrigerant used in cooling units. For further information, see the F-gas

Regulation (EU/517/2014 on fluorinated greenhouse gases) and the Swedish

Refrigerant Regulation (SFS 2016:1128). The purpose of the regulations is to

contribute to achieving EU goals for reduced climate impact in accordance with

the Kyoto Protocol.

Operator responsibilities

Generally speaking, the unit operator must:

• Minimise and prevent leakage

• Take corrective action to remedy any leakage that arises

• Ensure that leak inspection, service and repair of the refrigerant circuit are

carried out by a certified refrigeration technician

Operation and Maintenance

Envistar Top 04-21

DSET.190501.01.EN

Page 9

• Ensure that refrigerant is handled in an environmentally secure manner and in

accordance with national regulations.

By operator, we refer to the European Parliament’s definition: “...the natural or

legal person exercising actual power over the technical functioning of the equipment and systems...”.

The levels for the various actions to be taken for a system are calculated using

carbon dioxide equivalents, CO2e (tonnes). This figure is calculated by multiplying the refrigerant’s GWP value (Global Warming Potential) by the filling amount

in kilos. GWP for R410a is 2088. A filling amount of 1.1 kg R410a therefore corresponds to (1.1×2088)/1000 = 2.30 CO2e(tonnes).

The unit is marked with refrigerant quantity and carbon dioxide equivalent.

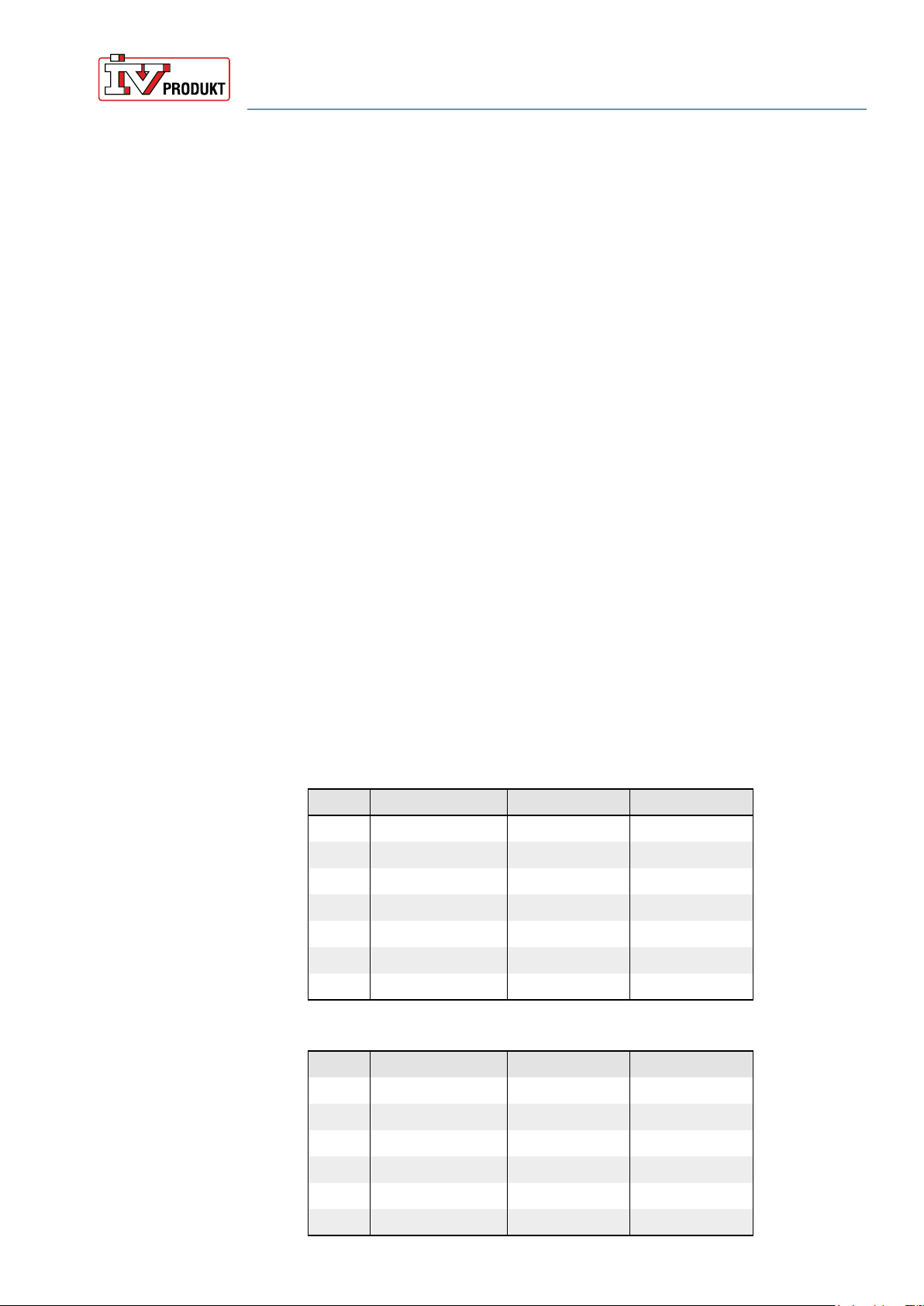

Envistar Top with cooling unit (TEC)

Size Refrigerant Refrigerant volume CO2e (tonnes)

04 R410a 1.1 kg 2.30

06 R410a 1.7 kg 3.55

09 R410a 1.9 kg 3.97

10 R410a 2.1 kg 4.38

12 R410a 2.38 kg 4.97

16 R134a 5.0 kg 7.15

21 R134a 5.2 kg 7.44

Envistar Top with reversible heat pump (TTC)

Size Refrigerant Refrigerant volume CO2e (tonnes)

06 R410a 1.75 kg 3.65

09 R410a 2.8 kg 5.85

10 R410a 2.7 kg 5.64

12 R410a 4.1 kg 8.56

16 R410a 4.9 kg 10.23

21 R410a 6.68 kg 13.95

Continuous product development may give rise to specification changes without notice.

Operation and Maintenance

Envistar Top 04-21

Page 10

DSET.190501.01.EN

Leakage inspection and registration

For Envistar Top with cooling unit (TEC) size 16-21 and reversible heat pump

(code TTC) size 16-21 the following applies:

• Leakage inspection must be carried out by a certified refrigeration technician:

– When installing/commissioning the unit

– Periodically at least once per 12 months,

i.e. no more than 12 months between inspections

– within one month of any work being performed (e.g. sealing a leak, replacing a

component).

• The operator must record events, such as the volume and type of refrigerant

topped up, refrigerant taken into possession, results of inspections and work

done, person and company who carried out service and maintenance.

Envistar Top with cooling unit (code TEC) size 04-12 and reversible heat pump

(code TTC) size 06 is not subject to registering or leakage inspection requirements.

2.7 Extended warranty

In cases in which the equipment delivered falls under a 5-year warranty, in accordance with ABM 07 with supplement ABM-V 07 or in accordance with NL 09

with supplement VU13, the IV Produkt Service and Warranty Manual is supplied

with the product.

In order to lay claim to an extended warranty, a complete, documented and

signed IV Produkt Service and Warranty Manual must be presented.

2.8 Spare parts

Spare parts and accessories for this unit are ordered from your nearest IV

Produkt sales representative. When ordering, state the order number and

designation. These are stated on a model type plate, affixed to each component.

There is a separate spare parts list for the unit, refer to Order Unique

Documentation at docs.ivprodukt.com.

2.9 Dismantling and decommissioning

When an air handling unit is to be dismantled, separate instructions must be followed, see Dismantling and decommissioning the AHU under Documentation at

ivprodukt.docfactory.com.

Continuous product development may give rise to specification changes without notice.

Operation and Maintenance

Envistar Top 04-21

DSET.190501.01.EN

3 Technical description

3.1 Envistar Top air handling unit

Page 11

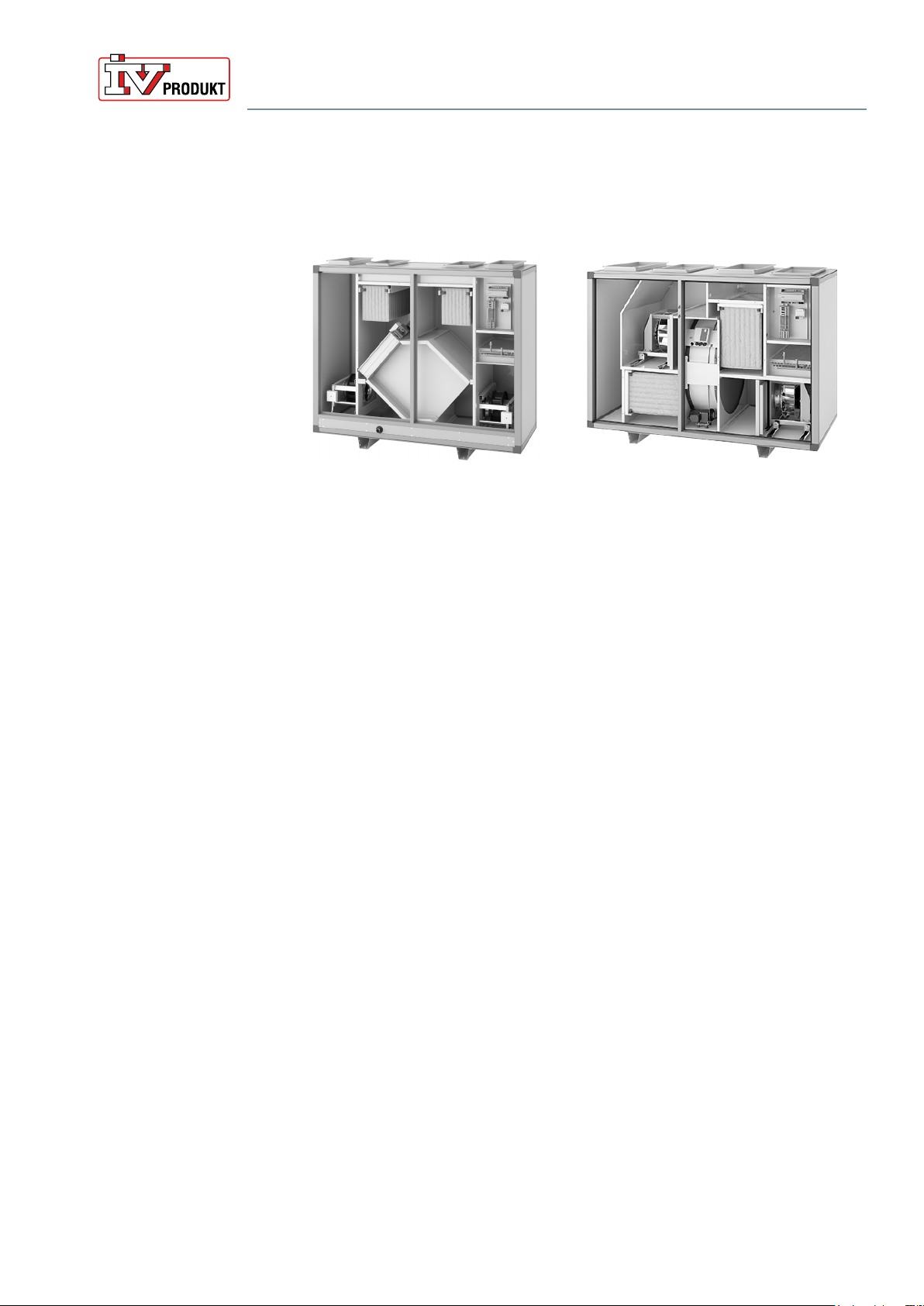

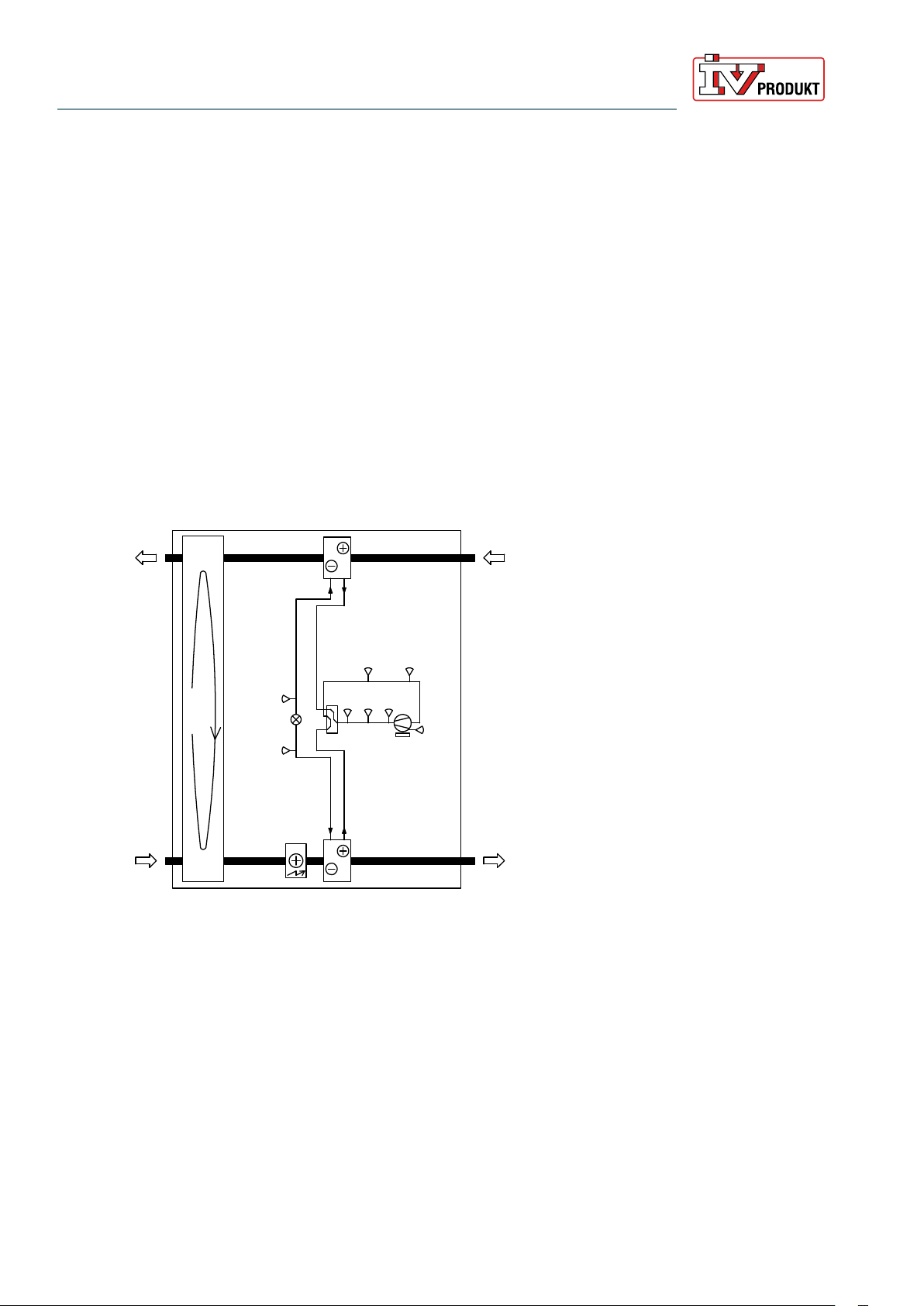

Envistar Top with counter-flow exchanger (code

TEM)

Envistar Top is manufactured as a compact unit or modularly, depending on the

size and version selected.

The compact unit is supplied complete preassembled from the factory. Modular

units are supplied in parts to facilitate transport and entry and are assembled on

site

The unit is available in different sizes and in right-hand or left-hand versions. All

units have duct connections in the top (up). The units are equipped with either a

counter-flow exchanger (code TEM/TXM) or rotary heat exchanger (code TER/

TXR).

The units are usually supplied with integrated control equipment, but can also be

obtained without control equipment.

3.2 Home Concept model

Units with a rotary heat exchanger or counter-flow exchanger in the

Home Concept versions have, among other things, specialised control

equipment such as automatic defrosting. Units with rotary heat exchangers are

also equipped with a pressure balance function for optimal rotor operation.

Envistar Top with rotary heat exchanger (code TER)

Continuous product development may give rise to specification changes without notice.

Operation and Maintenance

Envistar Top 04-21

Page 12

DSET.190501.01.EN

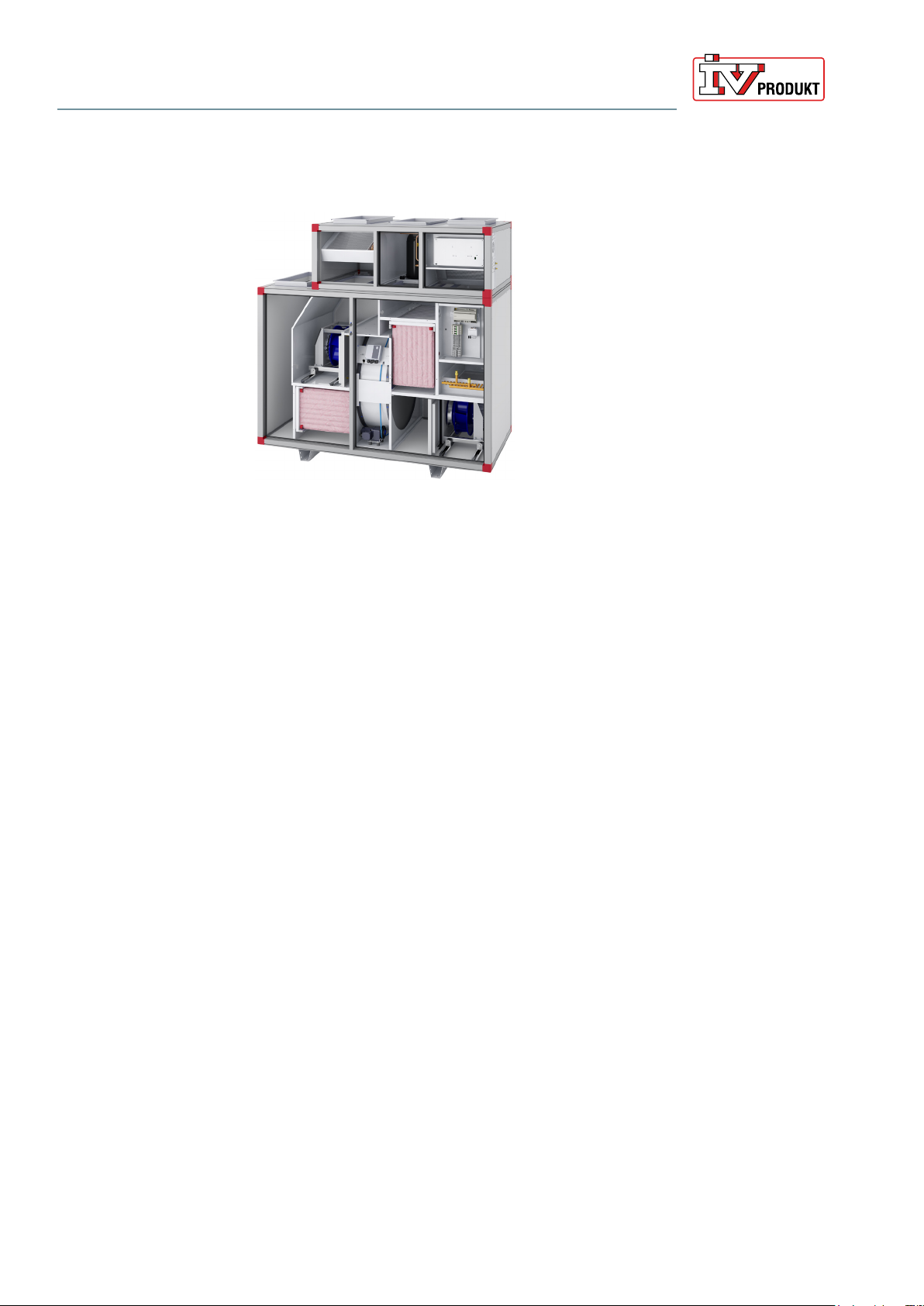

3.3 EcoCooler cooling unit (code TEC)

Envistar Top with EcoCooler (code TEC) size 10

The integrated cooling unit with EcoCooler (code TEC) cooling recovery

is available as an optional extra to an Envistar Top unit with a rotary heat

exchanger. Cooling recovery means that the heat exchanger starts up when the

extract air/room temperature drops below the outdoor temperature and cooling

is required.

The unit has an electronic expansion valve, rotary compressor size 04, scroll

compressor size 06-12 and reciprocating compressor size 16-21.

Compressor

Power control takes place with a speed-controlled compressor. When

increased cooling is required, the frequency inverter increases the speed of the

compressor.

Compressor protection

In the event of an alarm initiated by the frequency inverter or the safety circuit,

the compressor stops and an alarm indication is given. If the unit is equipped

with control equipment, the alarm can be read on the Climatix display.

In the event of an alarm, correct the fault and then reset the alarm. If the safety

circuit alarm trips repeatedly, an authorised refrigeration service company must

be called in.

For size 04-12

The safety circuit consists of a high pressure switch (HP), which protects by tripping when there is high pressure in the system. Use the manual reset button on

the pressure switch to perform a reset.

For size 16-21

The safety circuit consists of a low pressure control and a high pressure switch

with a manual reset button. The safety circuit can trip for two different faults:

• High pressure in the system, HP (manual reset on the pressure switch)

• Low pressure in the system, LP (resets itself automatically)

Continuous product development may give rise to specification changes without notice.

Cooling function

Circuit board

Operation and Maintenance

Envistar Top 04-21

DSET.190501.01.EN

For integrated control equipment (MX), the cooling unit is interlocked across

the ventilation unit. If any of the fans stop, the cooling unit will also stop. The

interlock and demand signal is sent via Modbus.

For external control equipment (US, UC, MK), the interlock signal must be sent

via a potential-free relay. The demand signal must be sent via 0–10 V.

The cooling unit has internal communication between the frequency inverter and

the expansion valve’s control equipment. Communication takes place through

the Modbus protocol.

The circuit board in the cooling unit is internally prewired and tested at the factory.

The circuit board contains:

Page 13

Size 04:

Control centre with integrated expansion valve controller

Size 0 6 -12 :

• Compressor inverter

• Expansion valve controller

• Contactor

Size 16-21:

• Main switch

• Fuse

• Control unit

• Control unit for expansion valve

Continuous product development may give rise to specification changes without notice.

Operation and Maintenance

Envistar Top 04-21

Page 14

DSET.190501.01.EN

Cooling circuit function

From the compressor, the refrigerant is compressed as hot gas to the condenser, where heat is emitted. The refrigerant condenses from gas to liquid when it is cooled by the extract air.

The refrigerant passes the pressure reducing expansion valve and undergoes a phase transformation

in the evaporator from liquid to gas (the refrigerant evaporates).

Inside the evaporator, the refrigerant absorbs the heat required for phase transformation. The heat is

taken from the supply air which is thus cooled.

The cold refrigerant in gaseous form is drawn back into the compressor, where it is compressed and

thus heated. The gas is also used for cooling the compressor’s electric motor. The refrigerant now contains the heat from the supply air, the compressor’s motor heat and the compression heat.

12

15

1

14

13

10

6

7

9

8

Flow chart for refrigerant system size 04-12

10

14

13

8

11

12

1

4

5

1 Compressor

2 Hot gas sensor

2

3

5

3 Condenser

4 Extract air fan

5 High pressure switch

6 Pressure sensor - high pressure

7 Measurement outlet – high pressure

8 Drying filter

9 Expansion valve

411

10 Evaporator

11 Supply air fan

12 Measurement outlets – low pressure

13 Control unit

14 Suction gas sensor (temp after evaporator)

15 Pressure sensor – low pressure

1 Compressor

2 Condenser

3 Extract air fan

4 High pressure switch

5 Measurement outlet – high pressure

6 Drying filter

7 Expansion valve

8 Evaporator

9 Supply air fan

39

2

10 Measurement outlets – low pressure

11 Low pressure control

12 Control unit

13 Suction gas sensor (temp after evaporator)

14 Pressure sensor – low pressure

7

6

Flow chart for refrigerant system size 16-21

Continuous product development may give rise to specification changes without notice.

Operation and Maintenance

Envistar Top 04-21

DSET.190501.01.EN

3.4 Reversible heat pump ThermoCooler HP (code TTC)

Page 15

Envistar Top with ThermoCooler HP (code TTC) size 10

Envistar Top with ThermoCooler HP (code TTC) Size 12

The integrated reversible heat pump ThermoCooler HP (code TTC) is available

as an optional extra to an Envistar Top unit with a rotary heat exchanger. The

units are intended to be used to cool or heat supply air in properties.

The heating pump function takes the heat content of the extract air and reuses

it, supplying the same heat to the ventilation unit’s supply air.

The cooling function moves the heat content in the supply air to the exhaust air,

where it can be emitted.

The unit has an electronic expansion valve and scroll compressor.

Continuous product development may give rise to specification changes without notice.

Page 16

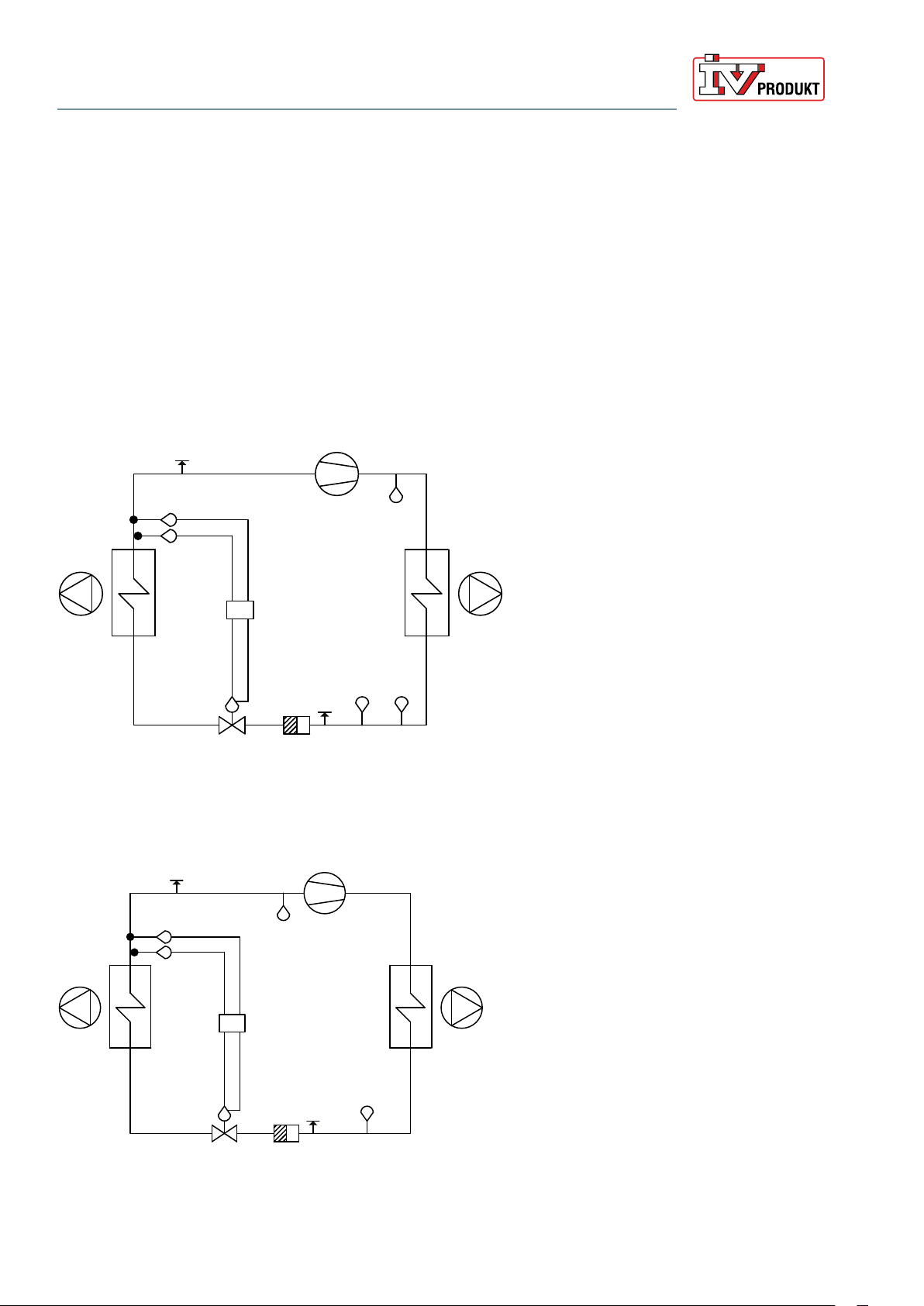

Cooling circuit function

Cooling mode

From the compressor (1), the refrigerant is pushed as hot gas to the condenser

(the extract air coil) where the heat is emitted. The refrigerant condenses from

gas to liquid when it is cooled by the extract air.

The refrigerant passes the pressure reducing expansion valve (4) and undergoes

a phase transformation in the evaporator from liquid to gas (the refrigerant

evaporates).

Inside the evaporator (the supply air coil), the refrigerant absorbs the heat

required for phase transformation. The heat is taken from the supply air which is

thus cooled.

The cold refrigerant in gaseous form is drawn back into the compressor (1),

where it is compressed and thus heated. The gas is also used for cooling the

compressor’s electric motor. The refrigerant now contains the heat from the

supply air, the compressor’s motor heat and the compression heat.

Operation and Maintenance

Envistar Top 04-21

DSET.190501.01.EN

15

13

2

3

10

4

11

17 18

Flow chart for refrigerant system

9

8

7

1

6

5

14

Heating mode

16

12

1 Compressor

2 Suction gas sensor (temp after evaporator)

3 Pressure sensor, low pressure

4 Expansion valve

5 Frequency inverter

6 4-way valve

7 High pressure switch

8 Pressure sensor, high pressure

9 Temperature sensor, hot gas

10 Temperature sensor liquid line cooling

11 Temperature sensor liquid line heating

12 Temperature sensor sump

13 Extract air coil (condenser/evaporator)

14 Supply air coil (condenser/evaporator)

15 Exhaust air

16 Extract air

17 Outdoor air

18 Supply air

The function of heating mode is similar to that of cooling mode. The difference

between the cooling and heating modes is that the 4-way valve is in the

heating position. This means that the extract air coil, which was a condenser in

cooling mode, is now an evaporator. Conversely, the supply air coil becomes a

condenser.

Continuous product development may give rise to specification changes without notice.

Compressor

Operation and Maintenance

Envistar Top 04-21

DSET.190501.01.EN

The extract air is the heat pump’s energy source. When the extract air meets the

extract air coil, it is cooled since the coil functions as an evaporator. From the

evaporator, the refrigerant moves to the compressor, where it is compressed.

The refrigerant then moves to the supply air coil, where the energy from the

extract air and the compressor is released. The energy remaining downstream of

the heat pump is then recovered in the rotor.

These two recovery systems combined give a very high degree of efficiency.

Since the rotor requires less energy to run than the compressor system, this will

be in the first instance. The compressor will only start when the rotor’s energy

recovery is insufficient to heat the supply air.

Power control takes place with a speed-controlled PM scroll compressor. In the

event of an increased power requirement, the frequency inverter will increase the

speed of the compressor.

Page 17

Compressor protection

In the event of an alarm initiated by the control equipment or the safety circuit,

the compressor stops and an alarm indication is given. The alarm can be read

on the Climatix display or the Carel unit on the unit’s circuit board.

In the event of an alarm, correct the fault and then reset the alarm. If alarm trips

repeatedly, an authorised refrigeration service company must be called in.

The cooling/heating pump will primarily trip alarms for the following errors:

• High pressure in the system, manual reset on pressure control HP1

• Low pressure in the system

• Alarm from frequency inverter

Function

The reversible heat pump is interlocked across the ventilation unit. If any of the

fans stop, the cooling/heating pump will also stop. The unit will not start unless

the minimum flow is achieved. If a trim heater is installed, the minimum flow

must also be reached before start up is permitted.

Heating mode is blocked if the return air temperature does not reach the permitted minimum temperature.

The interlock and demand signal is sent via Modbus.

Circuit board

The circuit board for the unit contains:

• Main switch

• Fuses

• Control unit

The circuit board is installed inside the unit and is internally prewired and tested

at the factory.

Continuous product development may give rise to specification changes without notice.

Operation and Maintenance

Envistar Top 04-21

Page 18

DSET.190501.01.EN

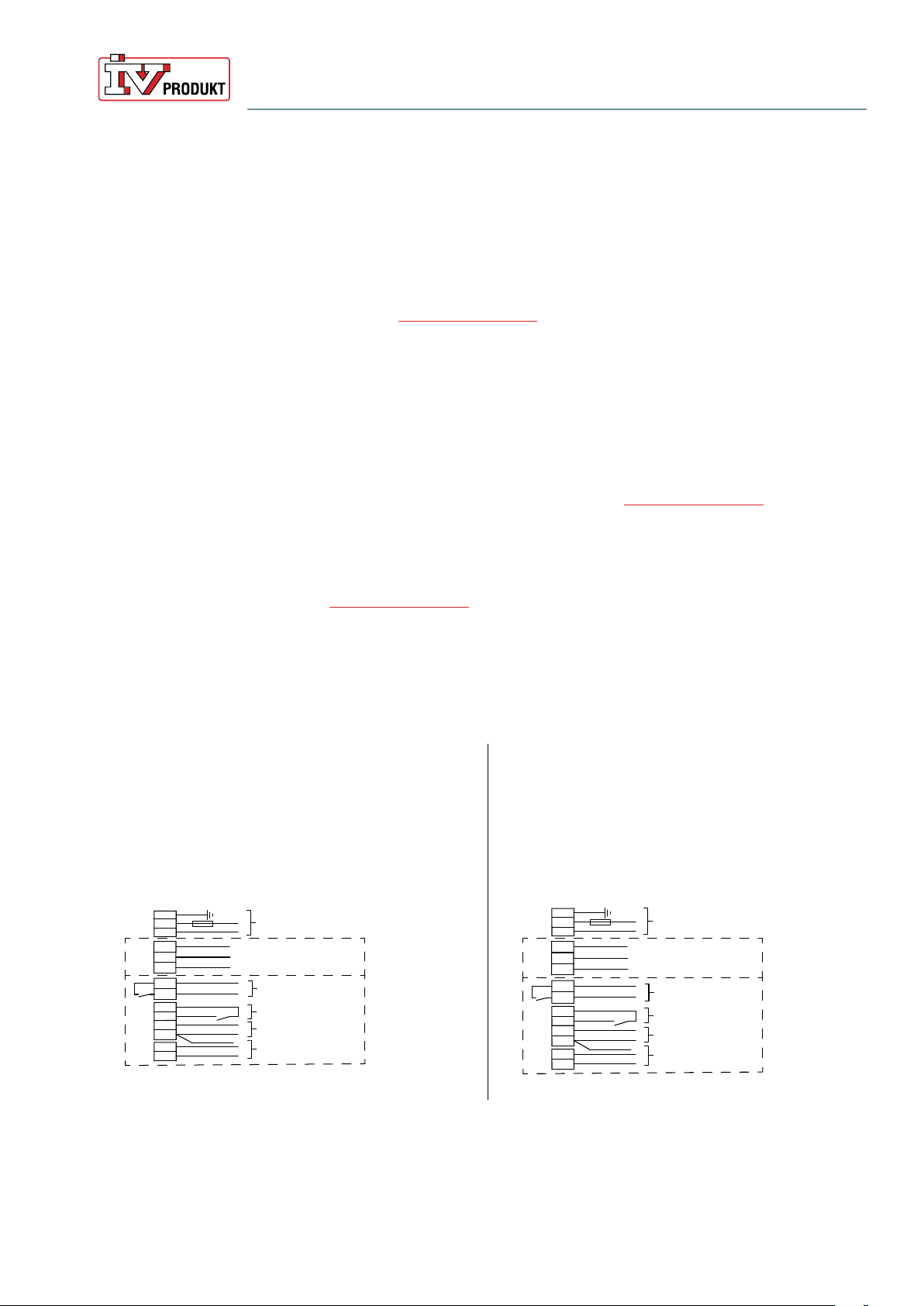

4 Wiring instructions and fuse protection

4.1 MX – Complete control equipment and UC – Complete electrical connection to terminal without controller unit

Applies to:

• Code MX - units supplied prewired with complete, integrated Siemens Climatix control equipment.

• Code UC - units supplied without controller unit but with sensor and damper

actuator connected electrically to the terminal. Fans and heat exchangers

are fused and connected electrically to the terminal. The terminal connections are positioned at a shared place in the unit. For further connection to

an external process unit, we recommend using a multi-conductor cable.

Safety switch

A safety switch must be fitted and wired on each power supply.

Wiring diagrams

For wiring diagrams for units with control equipment, see the order-unique wiring

diagram supplied with the unit at docs.ivprodukt.com (Control Diagram).

Unit functions, power supply and fuse protection

For recommended fuses, refer to Order Unique Documentation at

docs.ivprodukt.com (Technical Data and Control Diagram), or the product

program IV Produkt Designer.

• The unit has a shared power supply for all unit functions as standard, but

can be ordered with separate power supplies on special order.

• Electric heaters (air heater electric) have a power supply 3x400 V as standard.

A special coil or a transformer is required for a 230 V power supply.

• Fuses with type C characteristics are recommended.

Continuous product development may give rise to specification changes without notice.

Operation and Maintenance

INKOPPLING / WIRING

Ziehl 1×230 V - DC

PE

L1

N

Kraft matning 1×230 V ~ 50 Hz

Power suppl y 1×230 V ~ 50 Hz

Art. Nr. 19151-04 31_00

MX

IVP-styr

IVP Contr ols

MK

UC

US

Exter n styr

External

controls

A (D+)

B (D-)

Brun/Brown

GND

Vit/White

Blå/Blue

E1 +

+

-

GND

-

A (D+)

B (D-)

11

14

Styrn ing 0-10 V =

Control 0-10 V =

RS-4 85 Modbus

D1

24 V

Brandfunktion

Fire mode

LARM

(Bry ter vid larm)

ALARM

(Opens whe n triggered)

Ref.

Vit/White

Brun/Brown

Grå/Grey

Rosa/Pink

Gu l/Ye llow

Grön/Green

A (D+)

B (D-)

Brun/Brown

GND

Vit/White / Gul/Yellow

Blå/Blue / Grön/Green

E1 +

+

-

GND

-

A (D+)

B (D-)

11

14

Styrn ing 0-10 V =

Control 0-10 V =

RS-4 85 Modbus

D1

10 V

Brandfunktion

Fire mode

LARM (Br yter vid larm)

ALARM (Op ens when trigge red)

Ref.

Vit/White

Brun/Brown

Grå/Grey

Rosa/Pink

Gul/Yel low

Grön/Green

PE

L1

N

Kraft matning 1×230 V ~ 50 Hz

Power supp ly 1×230 V ~ 50 Hz

INKOPPLING / WIRING

Ziehl 1×230 V - BD

MX

IVP-styr

IVP Controls

MK

UC

US

Exter n styr

External

Controls

Art. Nr. 19151-04 30_01

Envistar Top 04-21

DSET.190501.01.EN

Page 19

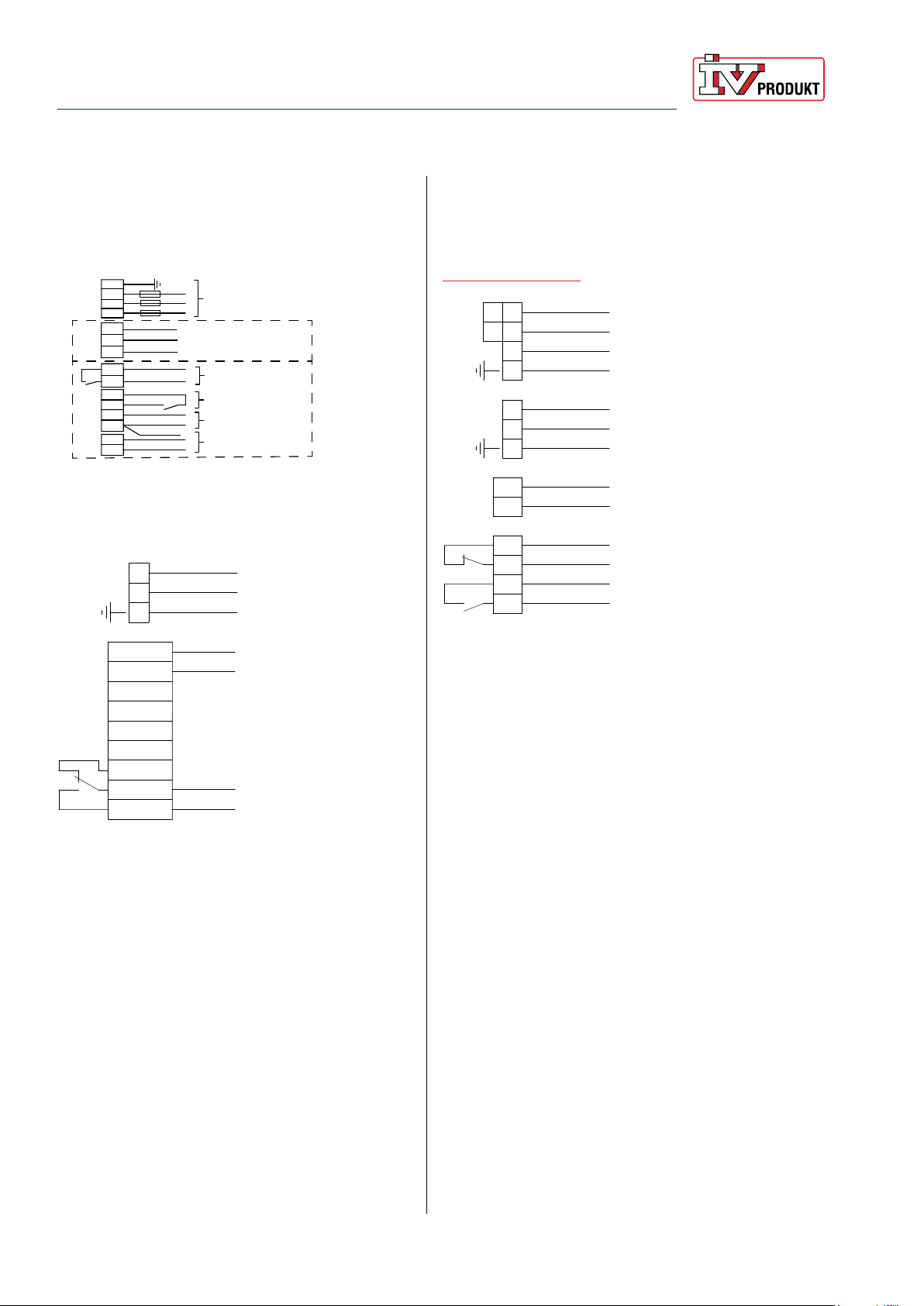

4.2 MK – Fans and heat exchangers electrically connected to terminal

Code MK - units supplied without control equipment but with fans and heat exchangers connected electrically to terminals.

Connections to terminal blocks are located on each unit section.

For wiring instructions and recommended fuses, refer to Order Unique Documentation at docs.ivprodukt.com (Terminal Connection and Technical Data).

Safety switch

A safety switch must be fitted and wired on each power supply.

4.3 HS, US - Without control and without electrical connection

• Code HS - for units without control equipment and without electrical connection, control diagrams are available for the heat exchanger and cooling

unit under order unique documentation at docs.ivprodukt.com, for other

connection instructions, see below.

• Code HS - for units without control equipment and without electrical connection, control diagrams are available for the cooling unit under order

unique documentation at

docs.ivprodukt.com, for other connection instructions, see below.

Recommended fuse protection refers to fuses with type C characteristics.

Safety switch

A safety switch must be fitted and wired on each power supply.

Fans (code ELFF)

Ziehl EC 1×230 V 0.50 / 0.78 kW

fan impeller 025 / 028 / 031

Sizes 04, 06, 09 and 10

Ziehl EC 1×230 V 1.35 kW

fan impeller 031 / 035

Size 10 and 12

Continuous product development may give rise to specification changes without notice.

Page 20

INKOPPLING / WIRING

Ziehl 3×400 V - DC, DG

PE

L1

L2

Kraftmatning 3×400 V ~ 50 Hz

Power suppl y 3×400 V ~ 50 Hz

Art. Nr. 19151-04 32_01

MX

IVP-styr

IVP Contr ols

MK

UC

US

Exter n styr

External

controls

L3

A (D+)

B (D-)

Brun/Brown

GND

Vit/ White / Gul/Yellow

Blå/ Blue / Grön/G reen

E1 +

+

-

GND

-

A (D+)

B (D-)

11

14

Styrning 0-10 V =

Control 0-10 V =

RS-4 85 Modbus

D1

24 V

Brandfunktion

Fire mode

LARM

(Bry ter vid larm)

ALARM

(Opens wh en triggered)

Ref.

Vit/White

Brun/Brown

Grå/Grey

Rosa/Pink

Gu l/Ye llow

Grön/Green

Operation and Maintenance

Envistar Top 04-21

DSET.190501.01.EN

Ziehl EC 3×400 V 2.40 / 2.90 kW fan

impeller 040 / 045

Sizes 16 and 21

Rotor (Code TXRD)

L

N

PE

POWER SUPPLY

1×230 V AC

Air Heater electric (Code ETAB-EV*, ETKBEV**)

For power supply, output variant and recommended

fuse, refer to Order Unique Documentation at

docs.ivprodukt.com (Technical Data).

L1 L1

L2

L2

L3

PE

7

8

PE

Y

G0

1

2

3

4

POWER SUPPLY

OPERATION

1×230V~

+

CONTROL

0-10V=

–

NC

ALARM (CLOSES

BETWEEN 3-4 IN

EVENT OF ALARM)

NO

1: GND

2: 0-10V

8: NC

9: C

10: NO

–

CONTROL

+

ALARM (CLOSES IN

EVENT OF ALARM)

*For unit mounting, selectable for counter-flow exchanger and

rotary heat exchanger.

**For duct mounting, selectable for counter-flow exchanger

Continuous product development may give rise to specification changes without notice.

Loading...

Loading...