IV Produkt Envicooler Operation And Maintenance Instructions

Air handling with the focus on LCC

Cooling Unit for Producing Chilled Water

Envicooler

®

Operation and Maintenance Instructions

Address and telephone list for calling for service

Supplier:

IV Produkt

Box 3103

SE-350 43 VÄXJÖ, Sweden

Street address: Sjöuddevägen 7

Phone: +46 (0)470-75 88 00

Telefax: +46 (0)470-75 88 77

Seller: .......................................................................... Service: ........................................................................

Post address: .............................................................. Post address: ...............................................................

Telephone: ................................................................... Telephone: ...................................................................

Other: ...................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

..............................................................................................................................................................................

System Data

Type of unit: .................................................................

Order number: .............................................................

Year manufactured: .....................................................

Supply voltage: ............................................................

Refrigerant: .................................................................

SAQ approved HP: ......................................................

Hydrostatic test: ..........................................................

Operation and Maintenance Instructions

Envicooler

2001-03-09 Pa

g

e 3

Air handling with the focus on LCC

Contents

1. The Cooling and Heat Pump System _______________________________________ 4

1.1 General ____________________________________________________________ 4

1.2 How the Cooling Circuit Works ________________________________________ 4

1.3 How the Controller Works _____________________________________________ 4

2. Summary of Specific Rules in the Refrigerant Act____________________________ 6

2.1 One-piece Units containing less than 3 kg of Refrigerant ___________________ 6

2.2 One-piece Units containing more than 3 kg of Refrigerant __________________ 6

2.3 One-piece Units containing a total of more than 10 kg of Refrigerant _________ 6

3. Operating Instructions for Components and Assembled Equipment ____________ 7

3.1 Regulations for Commissioning ________________________________________ 7

3.2 Checklist ___________________________________________________________ 8

4.Maintenance Instructions and Procedures __________________________________ 9

4.1 General ____________________________________________________________ 9

4.2 Requirements by Authorities according to the Refrigerant Act ______________ 9

4.3 Periodic Inspection __________________________________________________ 9

5. Fault Tracing and Searching for Leakage __________________________________ 10

5.1 Fault-tracing Schedule ______________________________________________ 10

5.2 Searching for Leakage_______________________________________________ 11

6. Flow Diagram for the Refrigerant System__________________________________ 12

7. Technical Specification_________________________________________________ 13

8. Appendices

8:1 Pressure and Tightness Tests - Refrigerant Circuit

8:2 Safety Equipment

8:3 Commissioning Report

8:4 Pressure and Tightness Tests - Liquid Circuits

Pa

g

e 4

Operation and Maintenance Instructions

Envicooler

2001-03-09

Air handling with the focus on LCC

1. The Cooling and Heat Pump System

1.1 General

All cooling and heat pump systems operate according to the same principle. The system moves the heat content in a medium, such as air, water, gas, etc. from one space

where the heat isn’t wanted or needed, to another place where it is possible to utilise

the heat, or

g

et rid of it.

Your system

has been designed and installed to meet given performance requirements. We’ve selected and combined special components to meet these requirements with optimum safety and at lowest possible total cost.

We’ve desi

g

ned the system according to specific fundamental prerequisites, which

must exist for it to operate. These prerequisites should not be altered without first

checking that the system can cope with this change.

1.2 How the Cooling Circuit Works

See the flow diagram.

The refri

g

erant in the cooling circuit absorbs heat from the component being chilled

while it passes through the evaporator. As its pressure drops, the refrigerant evaporates and transforms from liquid to gas.

The cold suction

g

as that now has absorbed heat from the cooled space/medium is

sucked back into the compressor where it is compressed and heats up.

In all fully hermetic compressors, the suction

g

as is also used to cool the electric motor that drives the compressor. The refrigerant now contains heat from the component

bein

g

chilled, heat from the compressor motor and heat generated by compression.

The refrigerant is in the form of hot gas when it leaves the compressor and circulates

to the condenser where it

g

ives off its heat.

The refrigerant then condenses as it cools, transforming from gas to liquid. This occurs repeatedly in a totally closed system, until the temperature in the chilled/heated

medium drops/rises to its set point.

1.3 How the Controller Works

1.3.1 Interlocking

EVC is interlocked across an external start si

g

nal.

1.3.2 Operation

The selector switch S1 is used for initiatin

g

start-up (yellow LED is lit). When the temperature at the heating medium sensor drops below the preset value, a signal is transmitted across the stepping switch to start the compressors in a preset starting order

so as to maintain the preset temperature. The in-operation condition of each compressor is indicated across the steppin

g

switch. Output terminal blocks are provided

for in-operation indication.

Operation and Maintenance Instructions

Envicooler

2001-03-09 Pa

g

e 5

Air handling with the focus on LCC

1.3.3 Compressor Protection

If the safety circuit alarm trips the compressor will stop and a red LED will li

g

ht up. A

flow monitor supervises the water flow in the cooling medium circuit. On insufficient

flow the monitor stops the compressors and initiates an alarm across a stepping

switch. The flow monitor alarm can be reset by settin

g

the selector switch S1 in the 0

position. The safety circuit alarm will trip if any of the following four conditions arises:

• Hi

g

h pressure in the system, HP

• Low pressure in the system, LP

• Tripped protective motor switch Q

• Tripped thermocouple in the compressor

The

g

roup alarm safety circuit has output terminal blocks. If the safety circuit alarm

trips repeatedly,

g

et in touch with an authorised refrigeration service company.

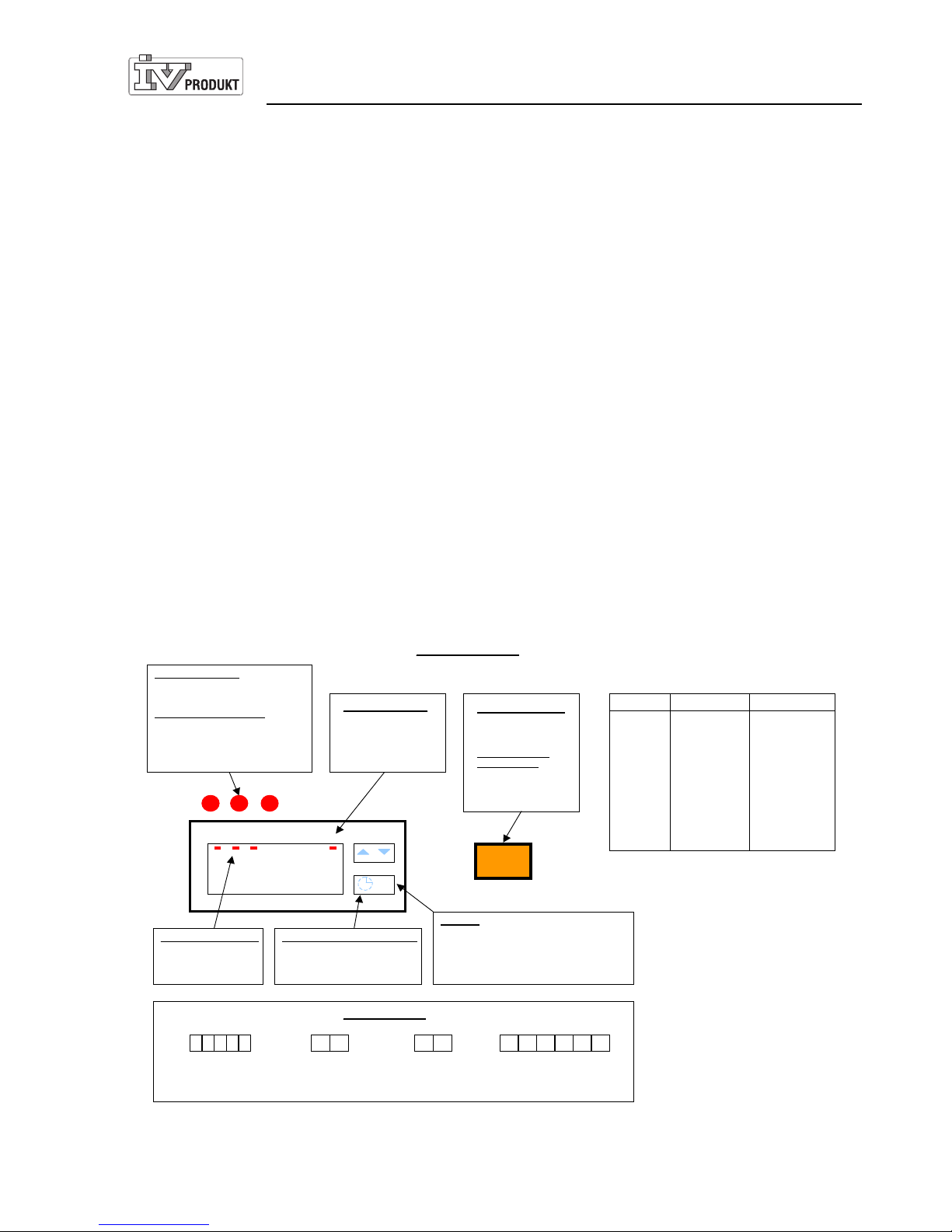

1.3.4 Technical Description

The compressor power cubicle of the EVC unit contains the followin

g

:

• Main switch

• Protective motor switch

• Contactors

• Auxiliary relays

• Controller

• Selector switch

• Flow monitor

The cubicle is mounted inside the EVC unit and has been internally prewired and

tested at the factory.

L1 L2 L3 N PE

Power supply

3*x 400 V + N 50 Hz

Size Rec. fuse Rec. cable section

EVC-1610

EVC-2410

EVC-3110

EVC-4020

EVC-4820

EVC-6220

EVC-7830

EVC-9330

20 AT

25 AT

35 AT

50 AT

50 AT

63 AT

80 AT

100 AT

4 mm

2

6 mm

2

10 mm

2

16 mm

2

16 mm

2

25 mm

2

35 mm

2

50 mm

2

Envicooler

251 252

External start signal

Potential-free, NO

253 254

Group alarm

Potential-free, NO

C1 C2 C3 C4

((!))

SET

AL

prg

o

C

XC440C

Dixell

1

2

Set point

To show the set point

: press the SET key.

To change the set point

: press the SET key for

at least 2 sec. Alter the setting by pressing the

arrow up or arrow down key. Then press the

SET k ey to save your setting.

Running period – compressors

Press and hold the clock button

for at least 3 sec. Shows the running period of each compressor.

Flow monitor alarm

If a buzzer sounds and a

red LED is lit, the flow

monitor alarm has

tripped.

In-ope ratio n indica tion

A red LED indicates that

the compressors are

running.

Input cables

EVC Selector switch

O

= EV C sw itched o ff

I

= EVC start mode

To re set the flow

monitor alarm

Press the switch to O;

then pres s it to Iagain.

Safety circuit alarm

If a red LED is lit, the safet y circu it of

the relevant compressor has tripped.

To re set the sa fety c ircuit

Press the reset button on the high

pressure switch or low pressure

switch. Reset the protective motor

switch

.

I O

255 256

In-operatio n indication

C1, C2, C3

Potential-free, NO

257 258 259 260

LJ 990520

*) If the order of phases is wrong, the machine will run unusually loud.

Loading...

Loading...