IVM Vent-Tech SWG C Series, Vent-Tech SWG B Series, Vent-Tech SWG N Series, Vent-Tech SWG V Series Operation And Maintenance Manual

Manufacturer:

International Valve Marketing, LLC

2571 Kaneville Court

Geneva, IL 60134

P: 630-232-4207

F: 630-232-8005

engineering@internationalvalve.com

Operation and Maintenance

Manual

MODEL SWG – SERIES C, B, V, AND N

WASTE WATER AIR RELEASE AND VACUUM RELIEF

VALVES

Revised: 09-13-13

Vent-Tech

Sewage Air Relief Valve

Model SWG

Local Representative:

Southwest Valve

402 Bedford #111, Fresno, CA 93711

P: 559-261-2703

F: 559-261-2711

www.internationalvalve.com

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

MODEL SWG, SERIES C, B, V, N

International Valve Marketing, LLC

Page | 2

Last Revision Date: 09/13/2013

OPERATION AND MAINTENANCE MANUAL FOR VENT-TECH MODEL SWG, SERIES C, B,

V, AND N, WASTE WATER AIR RELEASE AND VACUUM RELIEF VALVES

SECT: 1.01 TABLE OF CONTENTS

SECT: 1.01 TABLE OF CONTENTS ......................................................................................................................2

SECT: 1.02 INTRODUCTION ..............................................................................................................................2

SECT: 1.03 SAFETY MESSAGES ..........................................................................................................................3

SECT: 1.04 RECEIVING, INSPECTION AND STORAGE ........................................................................................3

SECT: 1.05 DESCRIPTION ..................................................................................................................................3

SECT: 1.06 PARTS ..............................................................................................................................................5

SECT: 1.07 IVM SERVICE ...................................................................................................................................7

SECT: 1.08 HANDLING AND STORAGE ..............................................................................................................7

SECT: 1.09 INSTALLATION .................................................................................................................................7

SECT: 1.10 MAINTENACE ..................................................................................................................................8

SECT: 1.11 OPERATION .................................................................................................................................. 11

SECT: 1.12 WARRANTY .................................................................................................................................. 12

SECT: 1.13 ADDENDUM ................................................................................................................................. 14

SECT: 1.02 INTRODUCTION

Thank you for purchasing the Vent-Tech Model SWG “Anti-Surge” air release/vacuum relief

valve for sewage duty. Vent-Tech, manufactured by International Valve Marketing (IVM, LLC)

was incorporated in 2009 for the express purpose of expanding and improving the technological

advances of the flat float combination air release valve. IVM, LLC has gained success quickly and

is a recognized air valve leader. This success is the result of incorporating thirteen years of

manufacturing experience with the flat float design and the cutting edge Patent Pending

advanced flow configurations. The result is the SWG line of Sewage Valves.

The Vent-Tech Model SWG, Series C, B, V and N waste water air release and vacuum relief valves

are ruggedly constructed to provide years of trouble-free, low maintenance operation. These

instructions provide the proper Operation and Maintenance information for use by personnel

who are responsible for the operation and maintenance of Vent-Tech Model SWG, Series C, B, V

and N waste water air release and vacuum relief valves.

www.internationalvalve.com

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

MODEL SWG, SERIES C, B, V, N

International Valve Marketing, LLC

Page | 3

Last Revision Date: 09/13/2013

WARNING!

Personnel involved in the installation or maintenance of valves should be constantly alert to potential

emissions of pipeline material and take appropriate safety precautions. Always wear suitable protection

when dealing with hazardous pipeline materials. Handle valves, which have been removed from service

with suitable protection for any potential pipeline material in the valve.

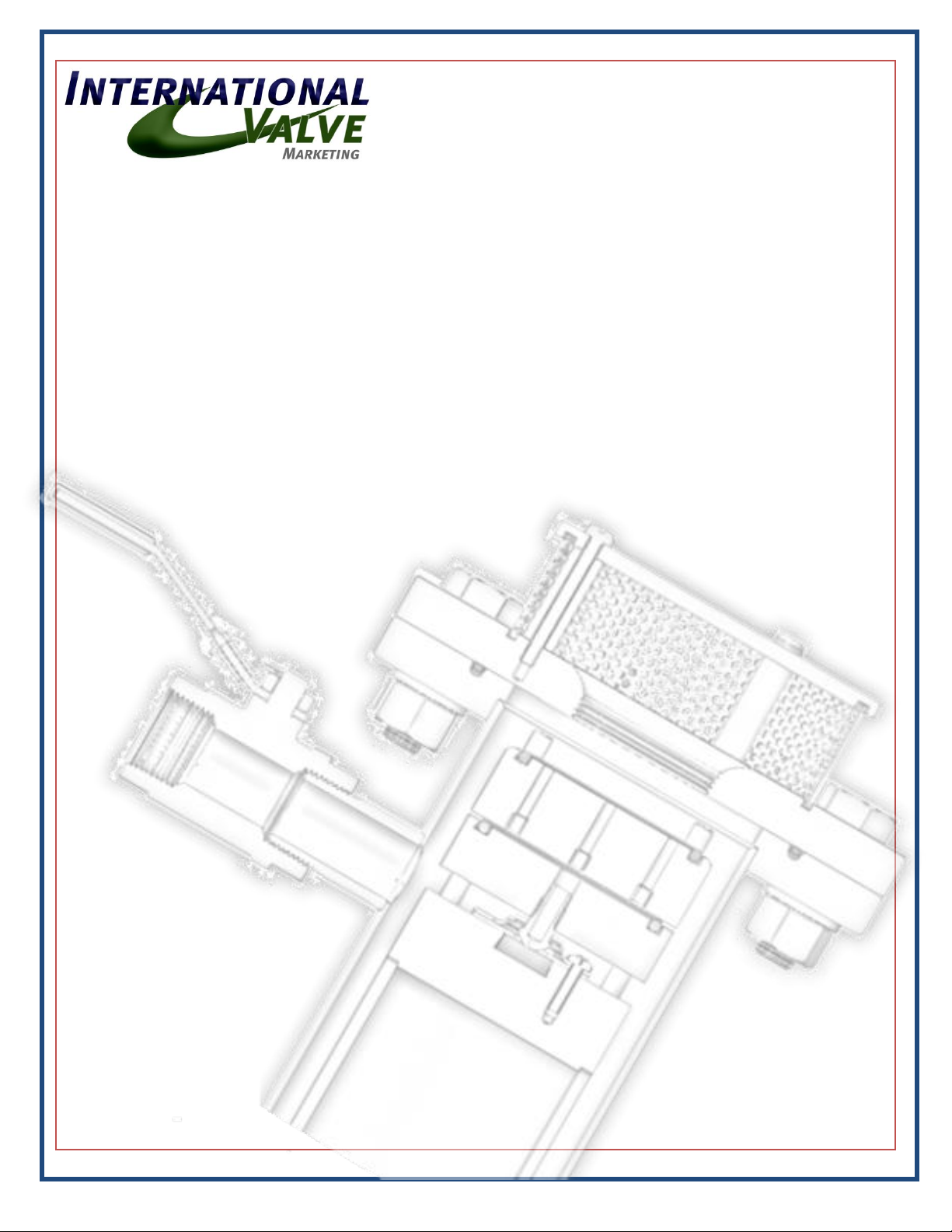

Series - C

Series - B

Series - V

Series - N

SECT: 1.03 SAFETY MESSAGES

All safety messages in the instructions are flagged with an exclamation symbol and the word

“Caution,” “Warning,” or “Danger.” These messages indicate procedures that must be followed

exactly to avoid equipment damage, personal injury or death. Safety label(s) on the product

indicate hazards that can cause equipment damage, personal injury or death.

If a safety label becomes difficult to see or read, or if a label has been removed, please contact

International Valve Marketing for replacement labels(s).

SECT: 1.04 RECEIVING, INSPECTION AND STORAGE

Your Vent-Tech Model SWG, Series C, B, V and N waste water air release and vacuum relief valve

has been packaged to provide protection during shipment; however, it can be damaged in

transport. Upon receipt, inspect the unit for damage and file a claim with the carrier if damage

is apparent. Carefully, unload all valves to the ground without dropping. The valve should be

lifted by the body, the sealing flange fasteners or where applicable, the factory supplied lifting

lugs included with your shipment.

If installation will be delayed, the valves should remain in a clean, dry and weather protected

area until installed. All threaded connections should be protected from damage.

SECT: 1.05 DESCRIPTION

The Vent-Tech Air Relief Valves work in many different types of environments, protecting

pipeline infrastructure against the effects of water hammering and vacuum. High quality

stainless steel parts, HDPE floats, anti-wear inserts and air flow design enhancements are

components of each Vent-Tech sewage air relief valve. When combined with Vent-Tech’s

superior design elements, these materials ensure that the valve operates in highly corrosive

environments within a wide range of pressures and temperatures. Each valve body contains air

flow enhancements to maximize flow under vacuum conditions.

All Vent-Tech Model SWG Sewage valves consist of 4 primary assemblies. These are:

(a) Inlet Connection

There are 4 series of valve configurations available in the Model SWG line of Vent-Tech Sewage

valves. Inlet configurations can be adapted to many configurations to pipe discharge effluent

gasses for treatment using elbows, vertical tees, horizontal tees and/or swivel flanges. Your

particular configuration may not match exactly the following depictions.

www.internationalvalve.com

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

MODEL SWG, SERIES C, B, V, N

International Valve Marketing, LLC

Page | 4

Last Revision Date: 09/13/2013

SWG10

10 Bar

Standard Body

SWG16 / SWG25

16-25 Bar

Expanded Body

SWG10 / SWG16 / SWG25

10-25 Bar

Reduced Height Body

Male NPT Thread

-T

Threaded Connection

ANSI Studded Flange

-S

Studded Connection

Trophy Connection

-R

Bolted Connection

The functions of a model SWG Sewage valve are:

(i) Series C:

Allow large air release at start-up

Discharge of air/gas from pressurized pipeline

Surge control to prevent the development of hydraulic transients during start-up and

pressure surges

Full port, high volume air intake for vacuum relief

(ii) Series B:

Controlled air/gas discharge at pump start up

Discharge of air/gas from pressurized pipeline

Surge control to prevent the development of hydraulic transients during start-up and

pressure surges

Full port, high volume air intake for vacuum relief

(iii) Series V:

Allow large air release at start-up

Discharge of air/gas from pressurized pipeline

Surge control to prevent the development of hydraulic transients during start-up and

pressure surges

(iv) Series N:

Full port, high volume air intake for vacuum relief

(b) Valve Body

(c) Base Flange

www.internationalvalve.com

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

MODEL SWG, SERIES C, B, V, N

International Valve Marketing, LLC

Page | 5

Last Revision Date: 09/13/2013

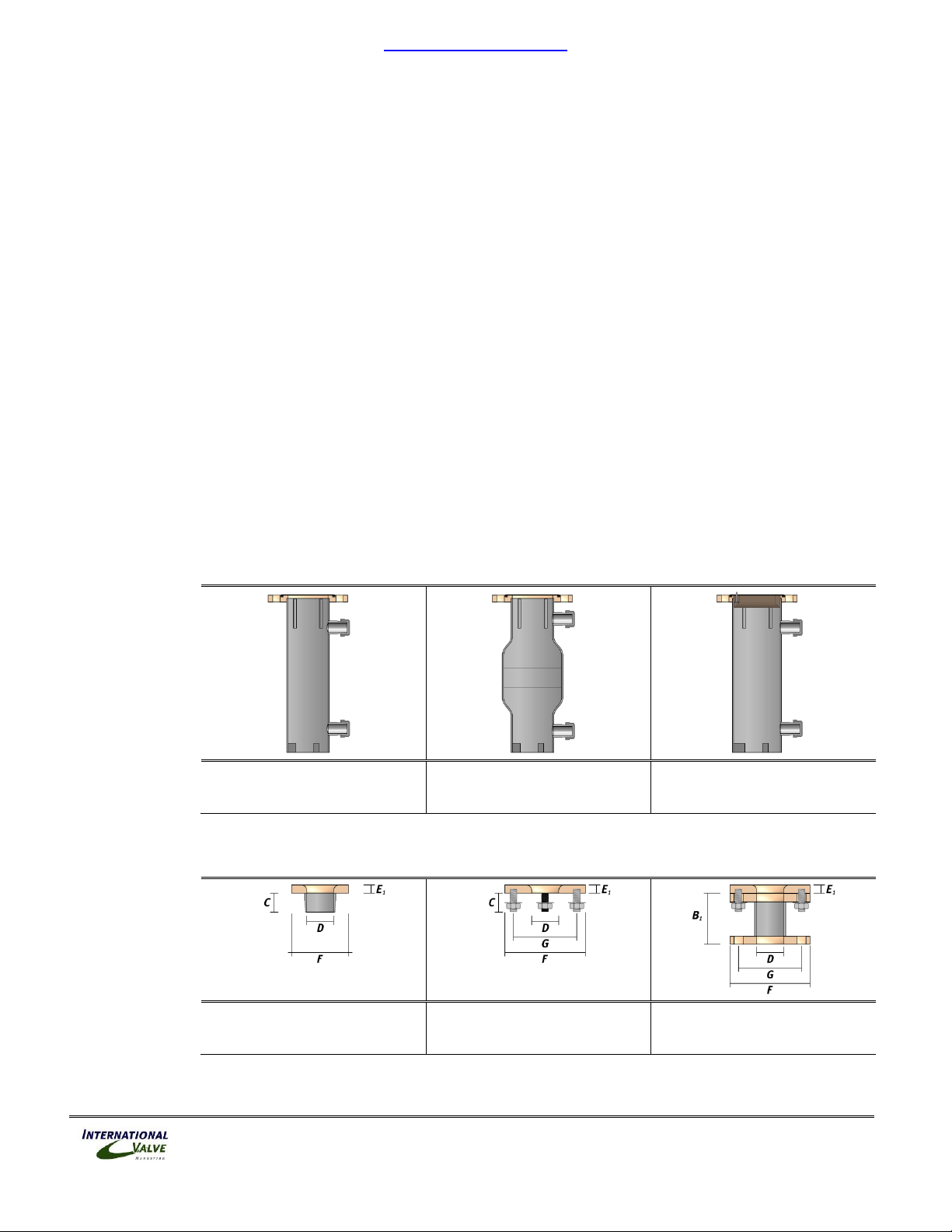

Type 1

Series – C, V

Series - B

Series - N

Type 2

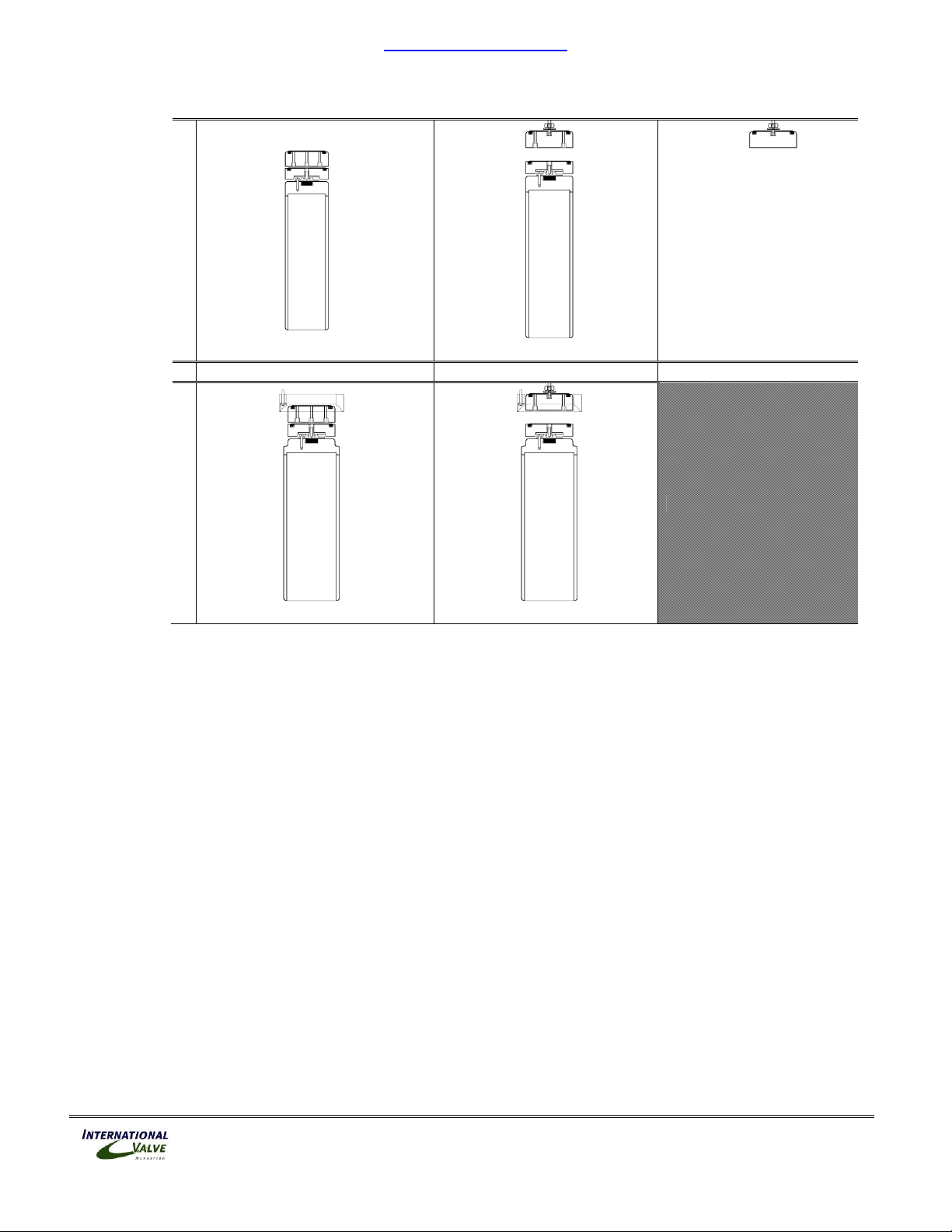

(d) Float Stack Configurations

There are three primary float configurations contained within the valve bodies listed above.

SECT: 1.06 PARTS

Recommended spare parts are listed on the assembly drawing. These parts should be stocked to

minimize downtime. Order parts from your local Vent-Tech sales representative, or directly

from International Valve Marketing. When ordering parts, please refer to the following:

If the valve has a Vent-Tech name-plate, please include the model number, date of

manufacture, serial number, small orifice and nozzle size and any station information that may

be included.

If there isn’t any nameplate visible on the valve, please include valve model number, the part

name, and item number from the assembly drawing. You may contact your local Vent-Tech

Representative to help you identify your valve.

Spare and replacement parts are available in the following configurations:

Loading...

Loading...