CNH America S8000, 8035.05.716, 8035.25C.313T, 8035.25D.313T, 8045.05.260 User Manual

...

SERVICE MANUAL

8035.05.716 / 8035.25C.313T /

8035.25D.313T / 8045.05.260 /

8045.05.716 / 8045.05R.939T /

8045.25.260 / 8045.25.261 /

8045.25.262 / 8045.25L.939T

S8000

Engine

Part number 47454136

1st edition English

November 2013

Copyright © 2013 CNH America LLC. All Rights Reserved.

Contents

INTRODUCTION

Engine.......................................................................................10

[10.001]Engineandcrankcase.............................................................10.1

[10.101]Cylinderheads.....................................................................10.2

[10.102]Panandcovers....................................................................10.3

[10.103]Crankshaftandywheel............................................................10.4

[10.105]Connectingrodsandpistons.......................................................10.5

[10.106]Valvedriveandgears..............................................................10.6

[10.114]Pumpdrives........................................................................10.7

[10.206]Fuellters..........................................................................10.8

[10.210]Liftpumpandlines.................................................................10.9

[10.218]Fuelinjectionsystem.............................................................10.10

[10.254]Intakeandexhaustmanifoldsandmufer.......................................10.11

[10.304]Enginelubricationsystem........................................................10.12

[10.400]Enginecoolingsystem...........................................................10.13

[10.414]Fananddrive....................................................................10.14

Electricalsystems.......................................................................55

[55.013]Engineoilsystem..................................................................55.1

[55.201]Enginestartingsystem.............................................................55.2

[55.301]Alternator...........................................................................55.3

4745413625/11/2013

INTRODUCTION

4745413625/11/2013

1

Contents

INTRODUCTION

Foreword-Ecologyandtheenvironment......................................................3

Safetyrules.....................................................................................4

Basicinstructions-Importantnoticeregardingequipmentservicing...........................5

Basicinstructions-Shopandassembly........................................................6

Torque-Minimumtighteningtorquesfornormalassembly.....................................8

4745413625/11/2013

2

INTRODUCTION

Foreword-Ecologyandtheenvironment

Soil,air,andwaterarevitalfactorsofagricultureandlifeingeneral.Whenlegislationdoesnotyetrulethetreatment

ofsomeofthesubstancesrequiredbyadvancedtechnology,soundjudgmentshouldgoverntheuseanddisposalof

productsofachemicalandpetrochemicalnature.

NOTE:Thefollowingarerecommendationsthatmaybeofassistance:

Becomeacquaintedwithandensurethatyouunderstandtherelativelegislationapplicabletoyourcountry.

•

Wherenolegislationexists,obtaininformationfromsuppliersofoils,lters,batteries,fuels,antifreeze,cleaning

•

agents,etc.,withregardtotheireffectonmanandnatureandhowtosafelystore,use,anddisposeofthese

substances.

Agriculturalconsultantswill,inmanycases,beabletohelpyouaswell.

•

Helpfulhints

Avoidllingtanksusingcansorinappropriatepressurizedfueldeliverysystemsthatmaycauseconsiderable

•

spillage.

Ingeneral,avoidskincontactwithallfuels,oils,acids,solvents,etc.Mostofthemcontainsubstancesthatmaybe

•

harmfultoyourhealth.

Modernoilscontainadditives.Donotburncontaminatedfuelsandorwasteoilsinordinaryheatingsystems.

•

Avoidspillagewhendrainingoffusedenginecoolantmixtures,engine,gearboxandhydraulicoils,brakeuids,etc.

•

Donotmixdrainedbrakeuidsorfuelswithlubricants.Storethemsafelyuntiltheycanbedisposedofinaproper

waytocomplywithlocallegislationandavailableresources.

Moderncoolantmixtures,i.e.antifreezeandotheradditives,shouldbereplacedeverytwoyears.Theyshouldnot

•

beallowedtogetintothesoil,butshouldbecollectedanddisposedofproperly.

Donotopentheair-conditioningsystemyourself.Itcontainsgasesthatshouldnotbereleasedintotheatmosphere.

•

YourCNHdealerorairconditioningspecialisthasaspecialextractorforthispurposeandwillhavetorechargethe

systemproperly.

Repairanyleaksordefectsintheenginecoolingorhydraulicsystemimmediately.

•

Donotincreasethepressureinapressurizedcircuitasthismayleadtoacomponentfailure.

•

Protecthosesduringweldingaspenetratingweldsplattermayburnaholeorweakenthem,allowingthelossof

•

oils,coolant,etc.

4745413625/11/2013

3

INTRODUCTION

Safetyrules

Personalsafety

Thisisthesafetyalertsymbol.Itisusedtoalertyoutopotentialpersonalinjuryhazards.Obeyall

safetymessagesthatfollowthissymboltoavoidpossibledeathorinjury.

Throughoutthismanualandonmachinedecals,youwillndthesignalwordsDANGER,WARNING,andCAUTION

followedbyspecialinstructions.Theseprecautionsareintendedforthepersonalsafetyofyouandthoseworking

withyou.

Readandunderstandallthesafetymessagesinthismanualbeforeyouoperateorservicethemachine.

DANGERindicatesahazardoussituationwhich,ifnotavoided,willresultindeathorseriousinjury.The

colorassociatedwithDANGERisRED.

WARNINGindicatesahazardoussituationwhich,ifnotavoided,couldresultindeathorseriousinjury.

ThecolorassociatedwithWARNINGisORANGE.

CAUTION,usedwiththesafetyalertsymbol,indicatesahazardoussituationwhich,ifnotavoided,couldresult

inminorormoderateinjury.ThecolorassociatedwithCAUTIONisYELLOW.

FAILURETOFOLLOWDANGER,WARNING,ANDCAUTIONMESSAGESCOULDRESULT

INDEATHORSERIOUSINJURY .

Machinesafety

NOTICE:Noticeindicatesasituationwhich,ifnotavoided,couldresultinmachineorpropertydamage.Thecolor

associatedwithNoticeisBLUE.

ThroughoutthismanualyouwillndthesignalwordNoticefollowedbyspecialinstructionstopreventmachineor

propertydamage.ThewordNoticeisusedtoaddresspracticesnotrelatedtopersonalsafety.

Information

NOTE:Noteindicatesadditionalinformationwhichclariessteps,procedures,orotherinformationinthismanual.

ThroughoutthismanualyouwillndthewordNotefollowedbyadditionalinformationaboutastep,procedure,or

otherinformationinthemanual.ThewordNoteisnotintendedtoaddresspersonalsafetyorpropertydamage.

4745413625/11/2013

4

INTRODUCTION

Basicinstructions-Importantnoticeregardingequipmentservicing

Allrepairandmaintenanceworklistedinthismanualmustbecarriedoutonlybyqualieddealershippersonnel,

strictlycomplyingwiththeinstructionsgiven,andusing,wheneverpossible,thespecialtools.

Anyonewhoperformsrepairandmaintenanceoperationswithoutcomplyingwiththeproceduresprovidedherein

shallberesponsibleforanysubsequentdamages.

Themanufacturerandalltheorganizationsofitsdistributionchain,including-withoutlimitation-national,regional,or

localdealers,rejectanyresponsibilityfordamagescausedbypartsand/orcomponentsnotapprovedbythemanufacturer,includingthoseusedfortheservicingorrepairoftheproductmanufacturedormarketedbythemanufacturer.

Inanycase,nowarrantyisgivenorattributedontheproductmanufacturedormarketedbythemanufacturerincase

ofdamagescausedbypartsand/orcomponentsnotapprovedbythemanufacturer.

Theinformationinthismanualisup-to-dateatthedateofthepublication.Itisthepolicyofthemanufacturerfor

continuousimprovement.Someinformationcouldnotbeupdatedduetomodicationsofatechnicalorcommercial

type,orchangestothelawsandregulationsofdifferentcountries.

Incaseofquestions,refertoyourCNHSalesandServiceNetworks.

4745413625/11/2013

5

INTRODUCTION

Basicinstructions-Shopandassembly

Shimming

Foreachadjustmentoperation,selectadjustingshimsandmeasureindividuallyusingamicrometer,thenaddup

therecordedvalues.Donotrelyonmeasuringtheentireshimmingset,whichmaybeincorrect,ortheratedvalue

indicatedoneachshim.

Rotatingshaftseals

Forcorrectrotatingshaftsealinstallation,proceedasfollows:

Beforeassembly,allowthesealtosoakintheoilitwillbesealingforatleastthirtyminutes.

•

Thoroughlycleantheshaftandcheckthattheworkingsurfaceontheshaftisnotdamaged.

•

Positionthesealinglipfacingtheuid;withhydrodynamiclips,takeintoconsiderationtheshaftrotationdirection

•

andpositionthegroovessothattheywilldeviatetheuidtowardstheinnersideoftheseal.

Coatthesealinglipwithathinlayeroflubricant(useoilratherthangrease)andllthegapbetweenthesealinglip

•

andthedustlipondoublelipsealswithgreaseunlessinstructedotherwise.

Insertthesealinitsseatandpressdownusingaatpunchorsealinstallationtool.Donottapthesealwitha

•

hammerormallet.

Whileinsertingtheseal,checkthatitisperpendiculartotheseat;oncesettled,makesurethatitmakescontact

•

withthethrustelement,ifrequired.

Topreventdamagingtheseallipontheshaft,positionaprotectiveguardduringinstallationoperations.

•

O-ringseals

LubricatetheO-ringsealsbeforeinsertingthemintheseats,thiswillpreventthemfromoverturningandtwisting,

whichwouldjeopardizesealingefciency .

Sealingcompounds

Applyoneofthefollowingsealingcompoundsonthematingsurfaceswhenspecied:SILMATE®RTV1473,or

LOCTITE®RTV598orLOCTITE®INSTANTGASKET587BLUE.Beforeapplyingthesealingcompound,preparethe

surfacesasdirectedonproductcontainerorasfollows:

Removeanyincrustationsusingametalbrush.

•

Thoroughlyde-greasethesurfacesusingalocallyapprovedcleaningagentsuchassafetysolventorbrakeparts

•

cleaner.

Spareparts

Onlyuse"CNHOriginalParts"or"CNHParts".

Onlygenuinesparepartsguaranteethesamequality ,durationandsafetyasoriginalparts,astheyarethesame

partsthatareassembledduringstandardproduction.Only"CNHOriginalParts"or"CNHParts"canofferthis

guarantee.

Whenorderingspareparts,alwaysprovidethefollowinginformation:

Machinemodel(commercialname)andserialnumber

•

Partnumberoftheorderedpart,whichcanbefoundinthe"ServicePartsCatalogue",usedfororderprocessing

•

4745413625/11/2013

6

INTRODUCTION

Protectingtheelectrical/electronicsystemsduringchargingorwelding

WARNING

Batteryacidcausesburns.Batteriescontainsulfuricacid.

Avoidcontactwithskin,eyesorclothing.Antidote(external):Flushwithwater.Antidote(eyes):ush

withwaterfor15minutesandseekmedicalattentionimmediately.Antidote(internal):Drinklargequantitiesofwaterormilk.Donotinducevomiting.Seekmedicalattentionimmediately.

Failuretocomplycouldresultindeathorseriousinjury.

Toavoiddamagetotheelectronic/electricalsystems,alwaysobservethefollowing:

1.Nevermakeorbreakanyofthechargingcircuitconnections,includingthebatteryconnections,whentheengine

isrunning.

2.Nevershortanyofthechargingcomponentstoground.

3.Alwaysdisconnectthegroundcablefromthebatterybeforearcweldingonthemachineoronanyattachments

onthemachine.

Positiontheweldergroundclampasclosetotheweldingareaaspossible

•

Ifweldingincloseproximitytoacomputermodule,thenthemoduleshouldberemovedfromthemachine

•

Neverallowweldingcablestolayon,nearoracrossanyelectricalwiringorelectroniccomponentwhilewelding

•

isinprogress

4.Alwaysdisconnectthenegativecablefromthebatterywhenchargingthebatteryinthemachinewithabattery

charger.

W0111A

NOTICE:Ifweldingmustbeperformedontheunit,thebatterygroundcablemustbedisconnectedfromthemachine

battery.Theelectronicmonitoringsystemandchargingsystemwillbedamagedifthisisnotdone.

Removethebatterygroundcable.Reconnectthecablewhenweldingiscompleted.

Tools

ThetoolsthatCNHsuggestsandillustratedinthismanualhavebeen:

SpecicallyresearchedanddesignedforusewithCNHmachines

•

Essentialforreliablerepairoperations

•

Accuratelybuiltandrigorouslytestedsoastoofferefcientandlong-lastingoperation

•

Byusingthesetools,repairpersonnelwillbenetfrom:

Operatinginoptimaltechnicalconditions

•

Obtainingthebestresults

•

Savingtimeandeffort

•

Workinginsafeconditions

•

NOTE:Theterms"front","rear","right-hand"and"left-hand"(whenreferredtodifferentparts)aredeterminedfrom

therear,facinginthedirectionoftravelofthemachineduringoperation.

4745413625/11/2013

7

INTRODUCTION

Torque-Minimumtighteningtorquesfornormalassembly

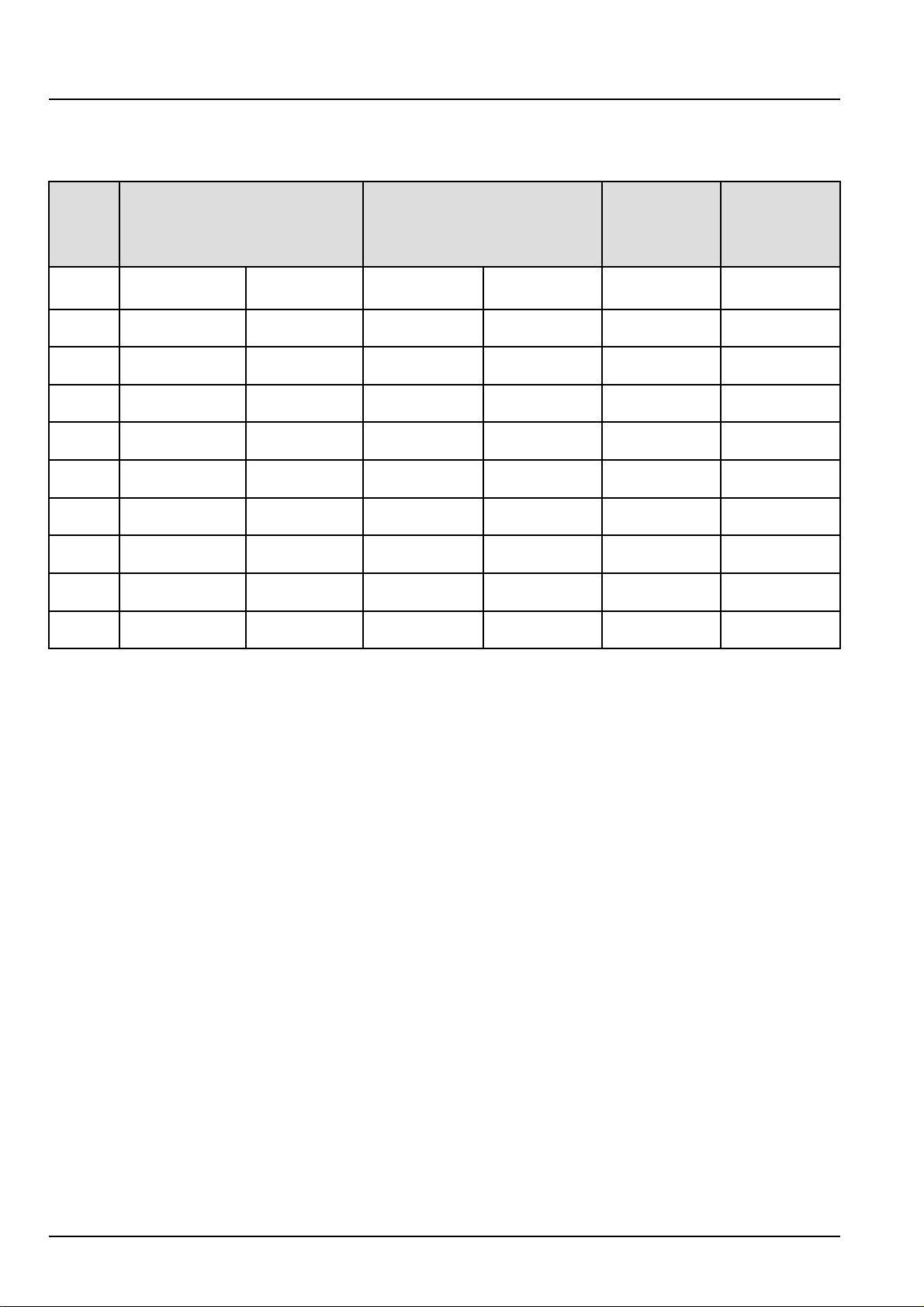

METRICNON-FLANGEDHARDWARE

NOM.

SIZE

CLASS8.8BOLTand

CLASS8NUT

UNPLATED

M4

M5

M6

M8

M10

M12

M16

M20

M24

2.2N·m(19lb

in)

4.5N·m(40lb

in)

7.5N·m(66lb

in)

18N·m(163lb

in)

37N·m(27lbft)

64N·m(47lbft)

158N·m(116lb

ft)

319N·m(235lb

ft)

551N·m(410lb

ft)

PLATED

W/ZnCr

2.9N·m(26lb

in)

5.9N·m(52lb

in)

10N·m(89lb

in)

25N·m(217lb

in)

49N·m(36lb

ft)

85N·m(63lb

ft)

210N·m

(155lbft)

425N·m

(313lbft)

735N·m

(500lbft)

CLASS10.9BOLTand

CLASS10NUT

UNPLATED

3.2N·m(28lb

in)

6.4N·m(57lb

in)

11N·m(96lb

in)

26N·m(234lb

in)

52N·m(38lbft)

91N·m(67lbft)

225N·m(166lb

ft)

440N·m(325lb

ft)

762N·m(560lb

ft)

PLATED

W/ZnCr

4.2N·m(37lb

in)

8.5N·m(75lb

in)

15N·m(128lb

in)

35N·m(311lb

in)

70N·m(51lb

ft)

121N·m(90lb

ft)

301N·m(222lb

ft)

587N·m(433lb

ft)

1016N·m

(750lbft)

LOCKNUT

CL.8

W/CL8.8

BOLT

2N·m(18lbin)

4N·m(36lbin)

6.8N·m(60lb

in)

17N·m(151lb

in)

33N·m(25lb

ft)

58N·m(43lb

ft)

143N·m(106lb

ft)

290N·m(214lb

ft)

501N·m(370lb

ft)

LOCKNUT

CL.10

W/CL10.9

BOLT

2.9N·m(26lb

in)

5.8N·m(51lb

in)

10N·m(89lb

in)

24N·m(212lb

in)

48N·m(35lb

ft)

83N·m(61lb

ft)

205N·m(151lb

ft)

400N·m(295lb

ft)

693N·m(510lb

ft)

NOTE:M4throughM8hardwaretorquespecicationsareshowninpound-inches.M10throughM24hardwaretorque

specicationsareshowninpound-feet.

4745413625/11/2013

8

METRICFLANGEDHARDWARE

INTRODUCTION

NOM.

SIZE

M4

M5

M6

M8

M10

M12

M16

M20

M24

CLASS8.8BOLTand

CLASS8NUT

UNPLATED

2.4N·m(21lb

in)

4.9N·m(43lb

in)

8.3N·m(73lb

in)

20N·m(179lb

in)

40N·m(30lbft)

70N·m(52lbft)

174N·m(128lb

ft)

350N·m(259lb

ft)

607N·m(447lb

ft)

PLATED

W/ZnCr

3.2N·m(28lb

in)

6.5N·m(58lb

in)

11N·m(96lb

in)

27N·m(240lb

in)

54N·m(40lb

ft)

93N·m(69lb

ft)

231N·m(171lb

ft)

467N·m(345lb

ft)

809N·m(597lb

ft)

CLASS10.9BOLTand

CLASS10NUT

UNPLATED

3.5N·m(31lb

in)

7.0N·m(62lb

in)

12N·m(105lb

in)

29N·m(257lb

in)

57N·m(42lbft)

100N·m(74lb

ft)

248N·m(183lb

ft)

484N·m(357lb

ft)

838N·m(618lb

ft)

PLATED

W/ZnCr

4.6N·m(41lb

in)

9.4N·m(83lb

in)

16N·m(141lb

in)

39N·m(343lb

in)

77N·m(56lb

ft)

134N·m(98lb

ft)

331N·m(244lb

ft)

645N·m(476lb

ft)

1118N·m

(824lbft)

LOCKNUT

CL.8

W/CL8.8

BOLT

2.2N·m(19lb

in)

4.4N·m(39lb

in)

7.5N·m(66lb

in)

18N·m(163lb

in)

37N·m(27lbft)53N·m(39lbft)

63N·m(47lbft)91N·m(67lbft)

158N·m(116lb

ft)

318N·m(235lb

ft)

552N·m(407lb

ft)

LOCKNUT

CL.10

W/CL10.9

BOLT

3.1N·m(27lb

in)

6.4N·m(57lb

in)

11N·m(96lb

in)

27N·m(240lb

in)

226N·m(167lb

ft)

440N·m(325lb

ft)

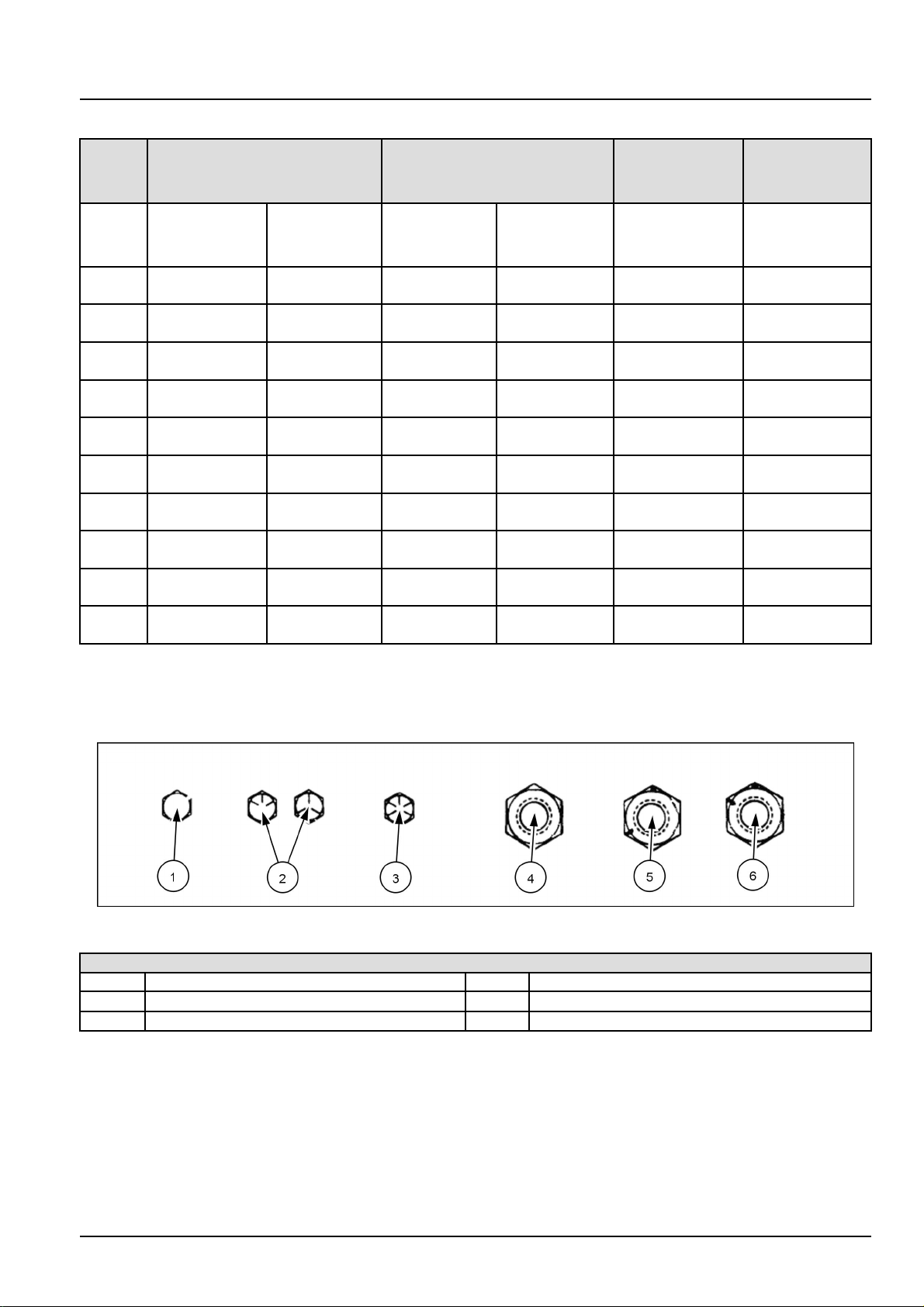

IDENTIFICATION

MetricHexheadandcarriagebolts,classes5.6andup

200836801

1.Manufacturer'sIdentication

2.PropertyClass

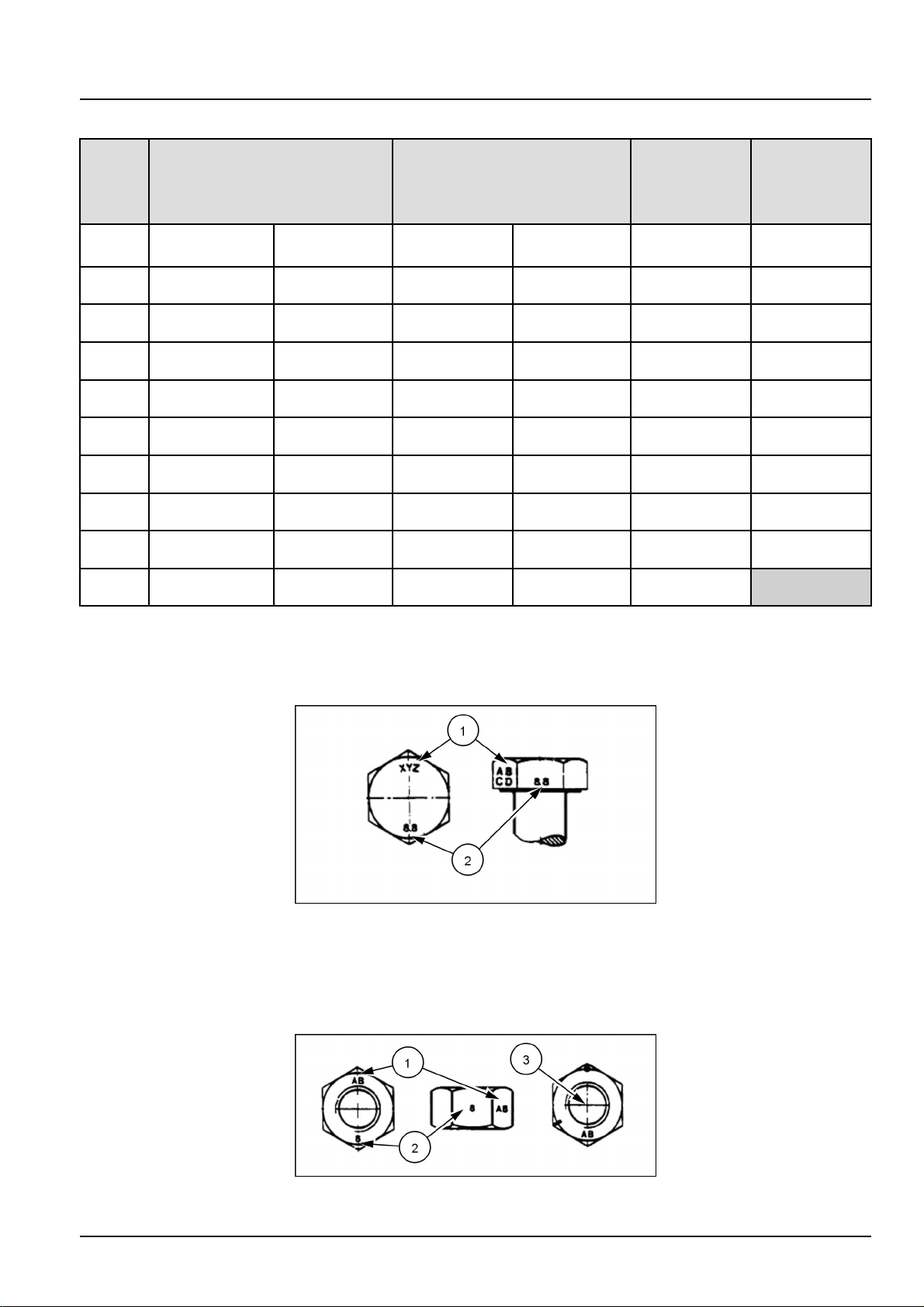

MetricHexnutsandlocknuts,classes05andup

4745413625/11/2013

200836812

9

INTRODUCTION

1.Manufacturer'sIdentication

2.PropertyClass

3.ClockMarkingofPropertyClassandManufacturer'sIdentication(Optional),i.e.marks60°apartindicateClass

10properties,andmarks120°apartindicateClass8.

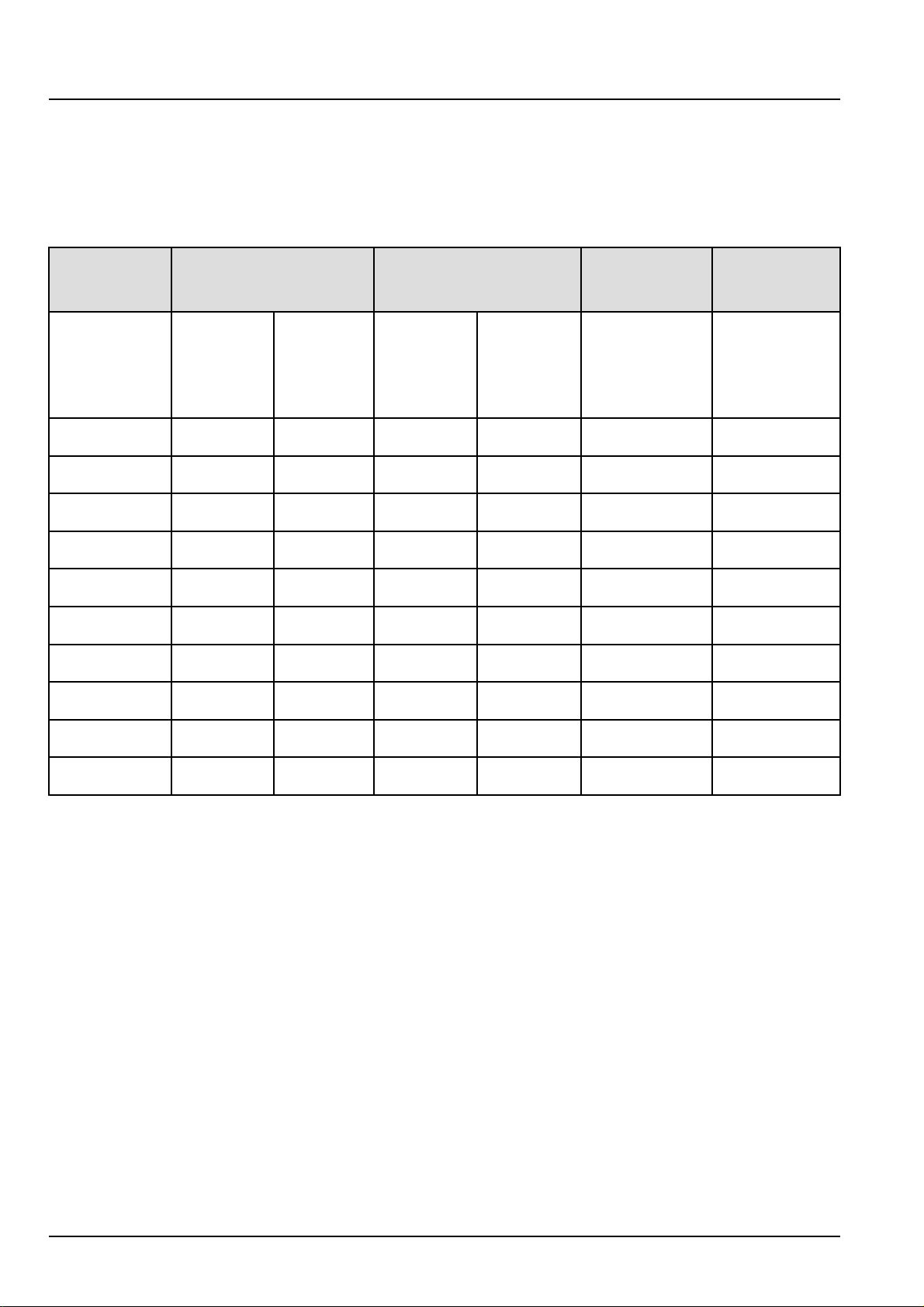

INCHNON-FLANGEDHARDWARE

NOMINAL

SIZE

1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

1

SAEGRADE5BOLT

andNUT

UN-

PLATED

or

PLATED

PLATED

W/ZnCr

GOLD

SILVER

8N·m(71lb

in)

17N·m

(150lbin)

30N·m(22lb

ft)

48N·m(36lb

ft)

74N·m(54lb

ft)

107N·m

(79lbft)

147N·m

(108lbft)

261N·m

(193lbft)

420N·m

(310lbft)

630N·m

(465lbft)

11N·m(97lb

in)

23N·m

(204lbin)

40N·m

(30lbft)

65N·m

(48lbft)

98N·m

(73lbft)

142N·m

(105lbft)

196N·m

(145lbft)

348N·m

(257lbft)

561N·m

(413lbft)

841N·m

(620lbft)

SAEGRADE8BOLT

andNUT

UN-

PLATED

orPLATED

SILVER

12N·m

(106lbin)

24N·m

(212lbin)

43N·m(31lb

ft)

68N·m(50lb

ft)

104N·m

(77lbft)

150N·m

(111lbft)

208N·m

(153lbft)

369N·m

(272lbft)

594N·m

(438lbft)

890N·m

(656lbft)

PLATED

W/ZnCr

GOLD

16N·m

(142lbin)

32N·m

(283lbin)

57N·m(42lb

91N·m(67lb

139N·m

(103lbft)

201N·m

(148lbft)

277N·m

(204lbft)

491N·m

(362lbft)

791N·m

(584lbft)

1187N·m

(875lbft)

ft)

ft)

LOCKNUT

GrBW/Gr5

BOLT

8.5N·m(75lbin)

17.5N·m(155lb

in)

31N·m(23lbft)44N·m(33lbft)

50N·m(37lbft)71N·m(53lbft)

76N·m(56lbft)

111N·m(82lbft)

153N·m(113lb

ft)

271N·m(200lb

ft)

437N·m(323lb

ft)

654N·m(483lb

ft)

LOCKNUT

GrCW/Gr8

BOLT

12.2N·m(109lb

in)

25N·m(220lb

in)

108N·m(80lb

ft)

156N·m(115lb

ft)

215N·m(159lb

ft)

383N·m(282lb

ft)

617N·m(455lb

ft)

924N·m(681lb

ft)

NOTE:ForImperialUnits,1/4inand5/16inhardwaretorquespecicationsareshowninpound-inches.3/8in

through1inhardwaretorquespecicationsareshowninpound-feet.

4745413625/11/2013

10

INCHFLANGEDHARDWARE

INTRODUCTION

NOM-

INAL

SIZE

1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

SAEGRADE5BOL Tand

UNPLATED

orPLATED

SILVER

9N·m(80lbin)

19N·m(168lb

in)

33N·m(25lb

ft)

53N·m(39lb

ft)

81N·m(60lb

ft)

117N·m(86lb

ft)

162N·m(119lb

ft)

287N·m(212lb

ft)

462N·m(341lb

ft)

693N·m(512lb

1

ft)

NUT

12N·m(106lb

25N·m(221lb

44N·m(33lb

71N·m(52lb

108N·m(80lb

PLATED

W/ZnCr

GOLD

in)

in)

ft)

ft)

ft)

156N·m

(115lbft)

216N·m

(159lbft)

383N·m

(282lbft)

617N·m

(455lbft)

925N·m

(682lbft)

SAEGRADE8BOLTand

NUT

UNPLATED

orPLA TED

SILVER

13N·m(115lb

in)

26N·m(230lb

in)

47N·m(35lb

ft)

75N·m(55lb

ft)

115N·m(85lb

ft)

165N·m

(122lbft)

228N·m

(168lbft)

405N·m

(299lbft)

653N·m

(482lbft)

979N·m

(722lbft)

PLATED

W/ZnCr

GOLD

17N·m(150lb

35N·m(310lb

63N·m(46lb

100N·m(74lb

153N·m

(113lbft)

221N·m

(163lbft)

304N·m

(225lbft)

541N·m

(399lbft)

871N·m

(642lbft)

1305N·m

(963lbft)

in)

in)

ft)

ft)

LOCKNUT

GrFW/Gr5

BOLT

8N·m(71lbin)

17N·m(150lb

in)

30N·m(22lbft)43N·m(32lbft)

48N·m(35lbft)68N·m(50lbft)

74N·m(55lbft)

106N·m(78lbft)

147N·m(108lb

ft)

261N·m(193lb

ft)

421N·m(311lb

ft)

631N·m(465lb

ft)

LOCKNUT

GrGW/Gr8

BOLT

12N·m(106lb

in)

24N·m(212lb

in)

104N·m(77lb

ft)

157N·m(116lb

ft)

207N·m(153lb

ft)

369N·m(272lb

ft)

594N·m(438lb

ft)

890N·m(656lb

ft)

IDENTIFICATION

InchBoltsandfree-spinningnuts

1

2

3

Grade2-NoMarks

Grade5-ThreeMarks

Grade8-FiveMarks

GradeMarkingExamples

SAEGradeIdentication

200836823

4

5

6

Grade2Nut-NoMarks

Grade5Nut-Marks120°Apart

Grade8Nut-Marks60°Apart

4745413625/11/2013

11

INTRODUCTION

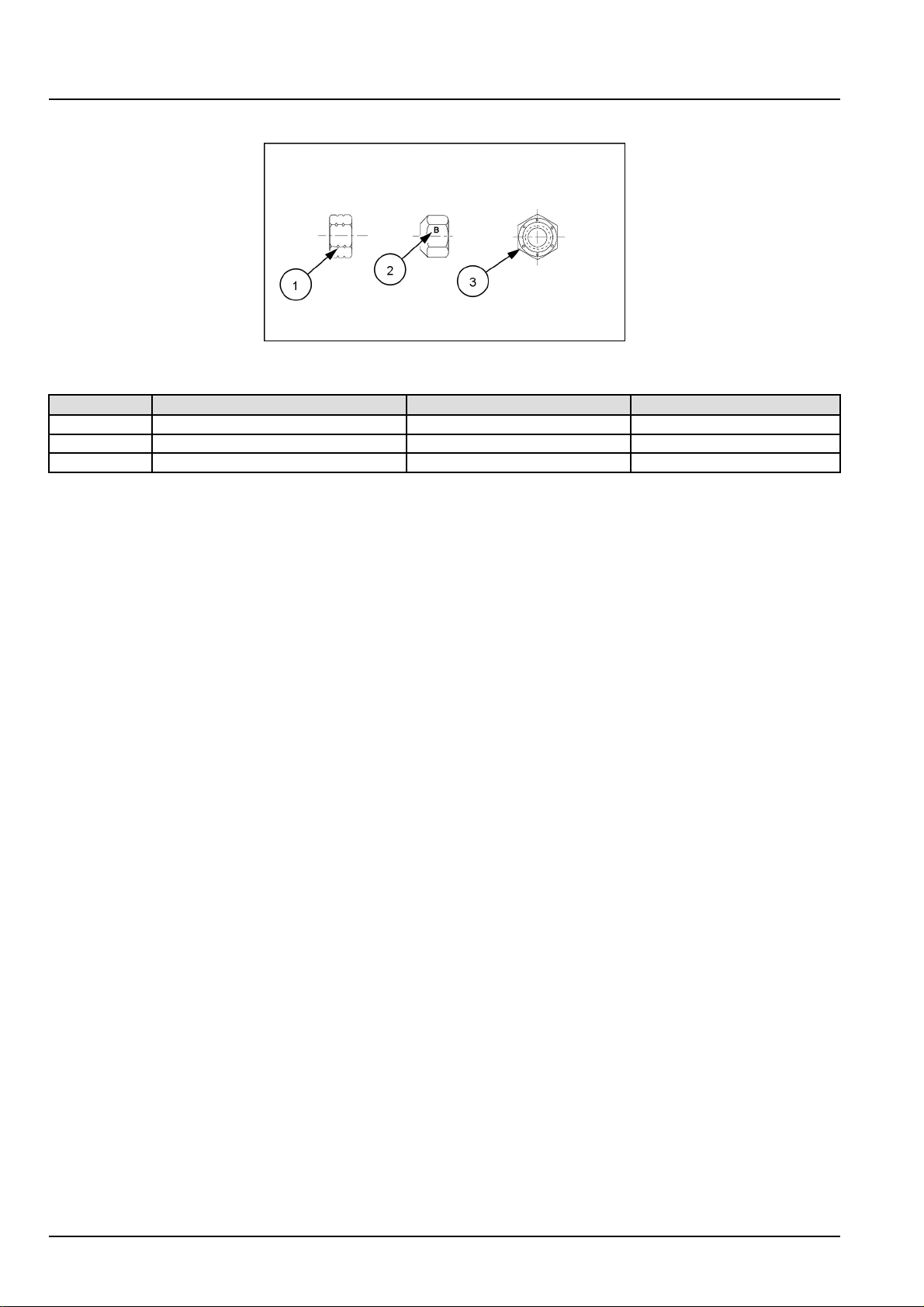

InchLockNuts,AllMetal(Threeoptionalmethods)

200902684

GradeIdentication

GradeCornerMarkingMethod(1)FlatsMarkingMethod(2)ClockMarkingMethod(3)

GradeA

GradeBOneCircumferentialNotch

GradeCTwoCircumferentialNotchesLetterCSixMarks

NoNotchesNoMarkNoMarks

LetterBThreeMarks

4745413625/11/2013

12

SERVICEMANUAL

Engine

8035.05.716,8035.25C.313T,8035.25D.313T,8045.05.260,8045.05.716,

8045.05R.939T,8045.25.260,8045.25.261,8045.25.262,8045.25L.939T

4745413625/11/2013

10

Contents

Engine-10

[10.001]Engineandcrankcase...............................................................10.1

[10.101]Cylinderheads.......................................................................10.2

[10.102]Panandcovers......................................................................10.3

[10.103]Crankshaftandywheel..............................................................10.4

[10.105]Connectingrodsandpistons.........................................................10.5

[10.106]Valvedriveandgears................................................................10.6

[10.114]Pumpdrives..........................................................................10.7

[10.206]Fuellters............................................................................10.8

[10.210]Liftpumpandlines...................................................................10.9

[10.218]Fuelinjectionsystem...............................................................10.10

[10.254]Intakeandexhaustmanifoldsandmufer.........................................10.11

[10.304]Enginelubricationsystem..........................................................10.12

[10.400]Enginecoolingsystem.............................................................10.13

[10.414]Fananddrive......................................................................10.14

4745413625/11/2013

10

Engine-10

Engineandcrankcase-001

8035.05.716,8035.25C.313T,8035.25D.313T,8045.05.260,8045.05.716,

8045.05R.939T,8045.25.260,8045.25.261,8045.25.262,8045.25L.939T

4745413625/11/2013

10.1[10.001]/1

TECHNICALDA TA

Engine

Generalspecication(*).....................................................................3

Generalspecication(*).....................................................................3

Servicelimits..............................................................................3

FUNCTIONALDA TA

Engine

Sectionalview.............................................................................4

Contents

Engine-10

Engineandcrankcase-001

SERVICE

Crankcase

Liner-Measure............................................................................6

Liner-Rebore.............................................................................7

Liner-Replace............................................................................8

(*)Seecontentforspecicmodels

4745413625/11/2013

10.1[10.001]/2

Engine-Engineandcrankcase

Engine-Generalspecication

8035.25C.313T

Specications

Enginetype4–strokediesel

FuelinjectionDirect

Numberofcylinders

Orientationofcylinders

Bore

Stroke115mm(4.528in)

Displacement

Compressionratio

Maximumpowerat2300RPM

Maximumtorqueat1400RPM

Numberofmainbearings

OilpanconstructionStructural,Castiron

3

In-line

104mm(4.094in)

2931cm³(178.9in³)

18:1

48kW(65Hp)

261N·m(192.5lbft)

4

Engine-Generalspecication

8035.25D.313T

Specications

Enginetype4–strokediesel

FuelinjectionDirect

Numberofcylinders

Orientationofcylinders

Bore

Stroke115mm(4.528in)

Displacement

Compressionratio

Maximumpowerat2300RPM

Maximumtorqueat1400RPM

Numberofmainbearings

OilpanconstructionStructural,Castiron

3

In-line

104mm(4.094in)

2931cm³(178.9in³)

18:1

53kW(72Hp)

295N·m(217.6lbft)

4

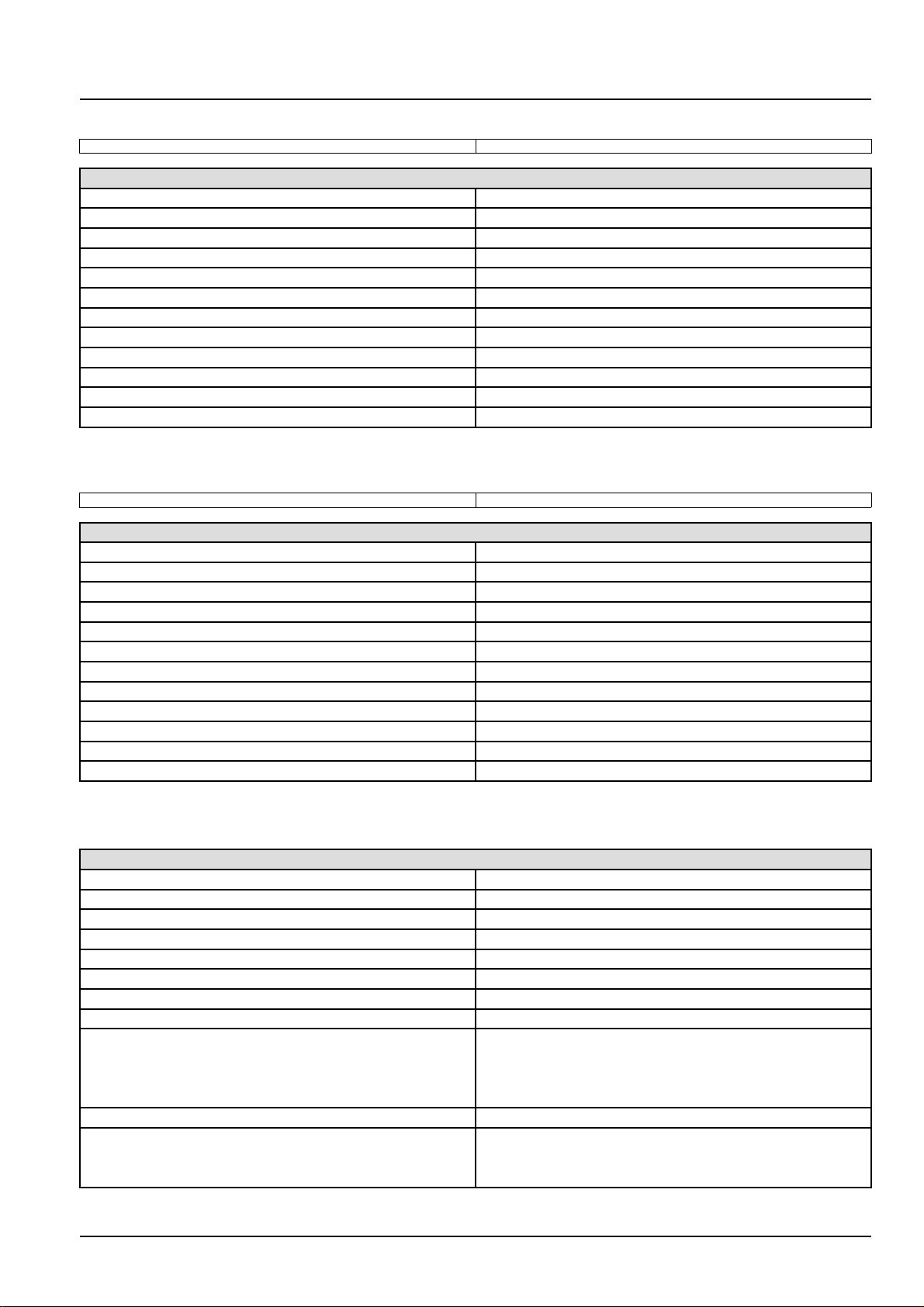

Engine-Servicelimits

Specications

Insidediameterofcylinderliners104.000-104.024mm(4.094-4.095in)

Outsidediameterofcylinderliners107.020-107.050mm(4.213-4.215in)

Diameterofcylinderbores106.850-106.900mm(4.207-4.209in)

Interferencetbetweencylinderlinersandbores0.120-0.200mm(0.005-0.008in)

Linerinternaldiameteroversizes

Linerexternaldiameteroversizes

Maximumpermissiblelinerovalityortaperduetowear

Diameterofcrankshaftbore84.200-84.230mm(3.315-3.316in)

Diameterofcamshaftbore

-Front

-Middle

-Rear

Diameteroftappetbore15.000-15.018mm(0.591-0.591in)

Sparetappetoversizes0.1mm(0.004in)

0.4-0.8mm(0.016-0.031in)

0.2mm(0.008in)

0.12mm(0.005in)

54.780-54.805mm(2.157-2.158in)

54.280-54.305mm(2.137-2.138in)

53.780-53.805mm(2.117-2.118in)

0.2mm(0.008in)

0.3mm(0.012in)

4745413625/11/2013

10.1[10.001]/3

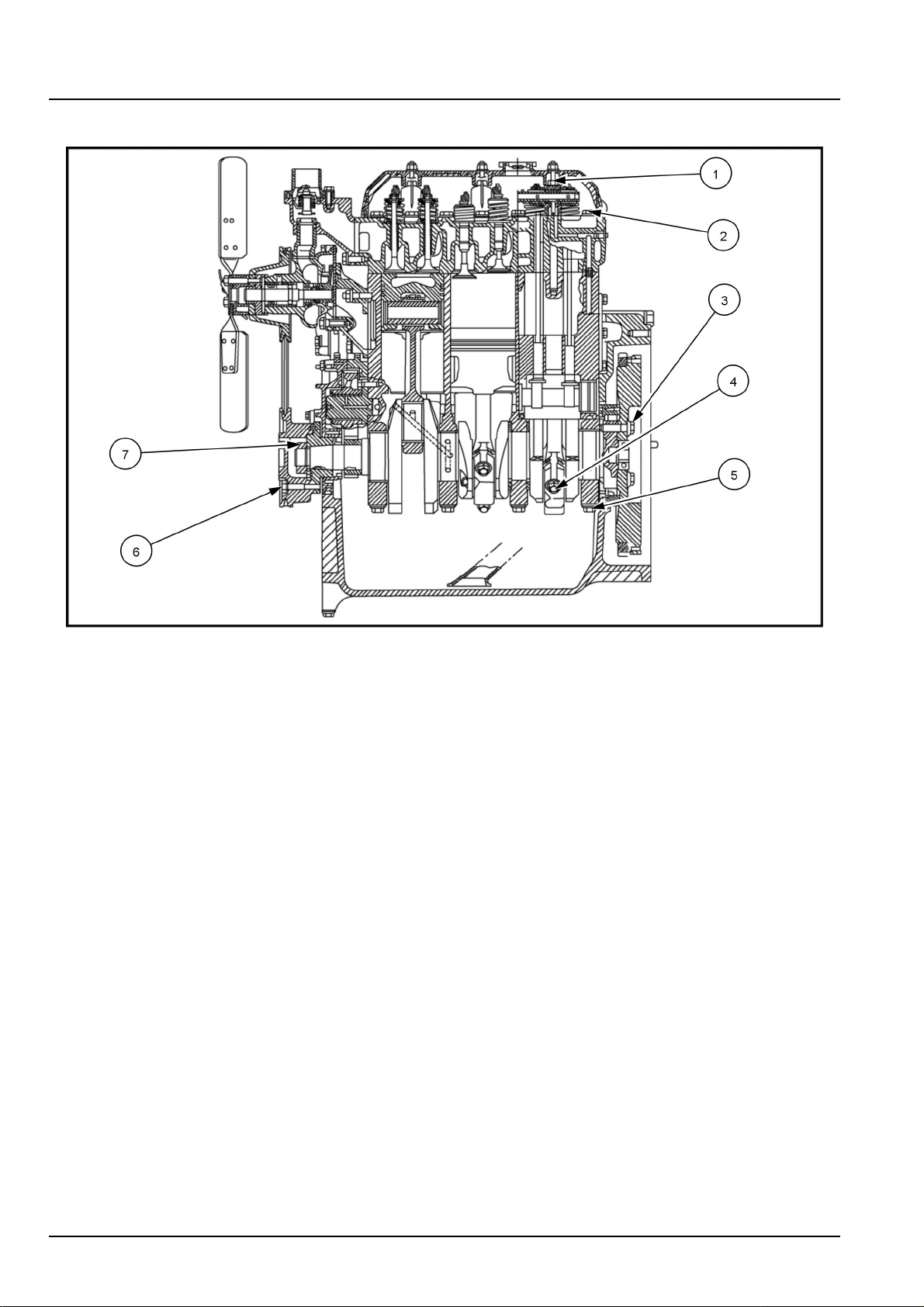

Engine-Sectionalview

Engine-Engineandcrankcase

NHIL12ENG0237AA1

(1)Rockershaftpedestalbolts(5)Mainbearingcapbolts

(2)Cylinderheadbolts(6)Fanandalternatorpulleybolts

(3)Flywheelbolts(7)Crankshafthubbolts

(4)Big-endcapbolts

4745413625/11/2013

10.1[10.001]/4

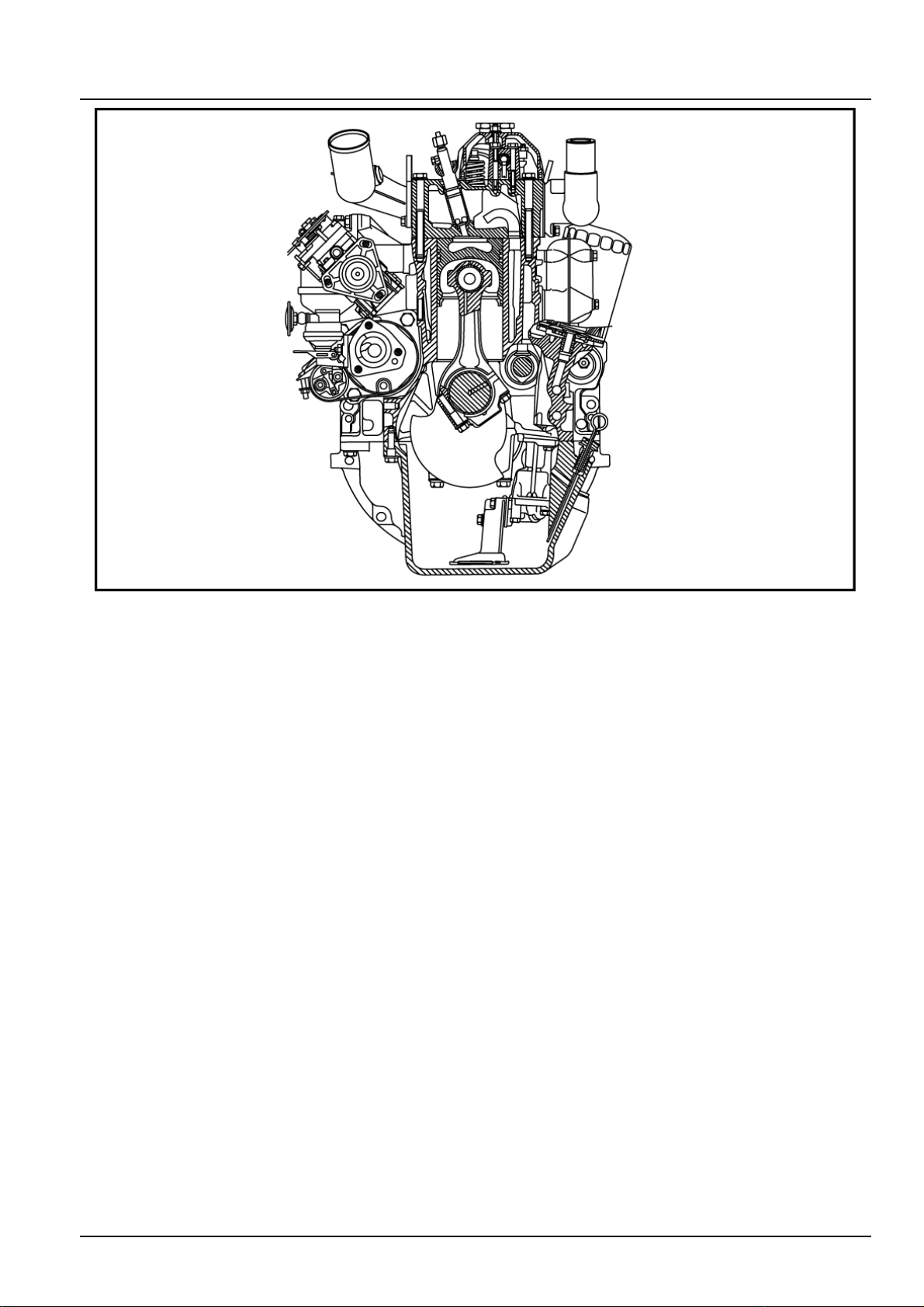

Engine-Engineandcrankcase

NHIL12ENG0238AA2

4745413625/11/2013

10.1[10.001]/5

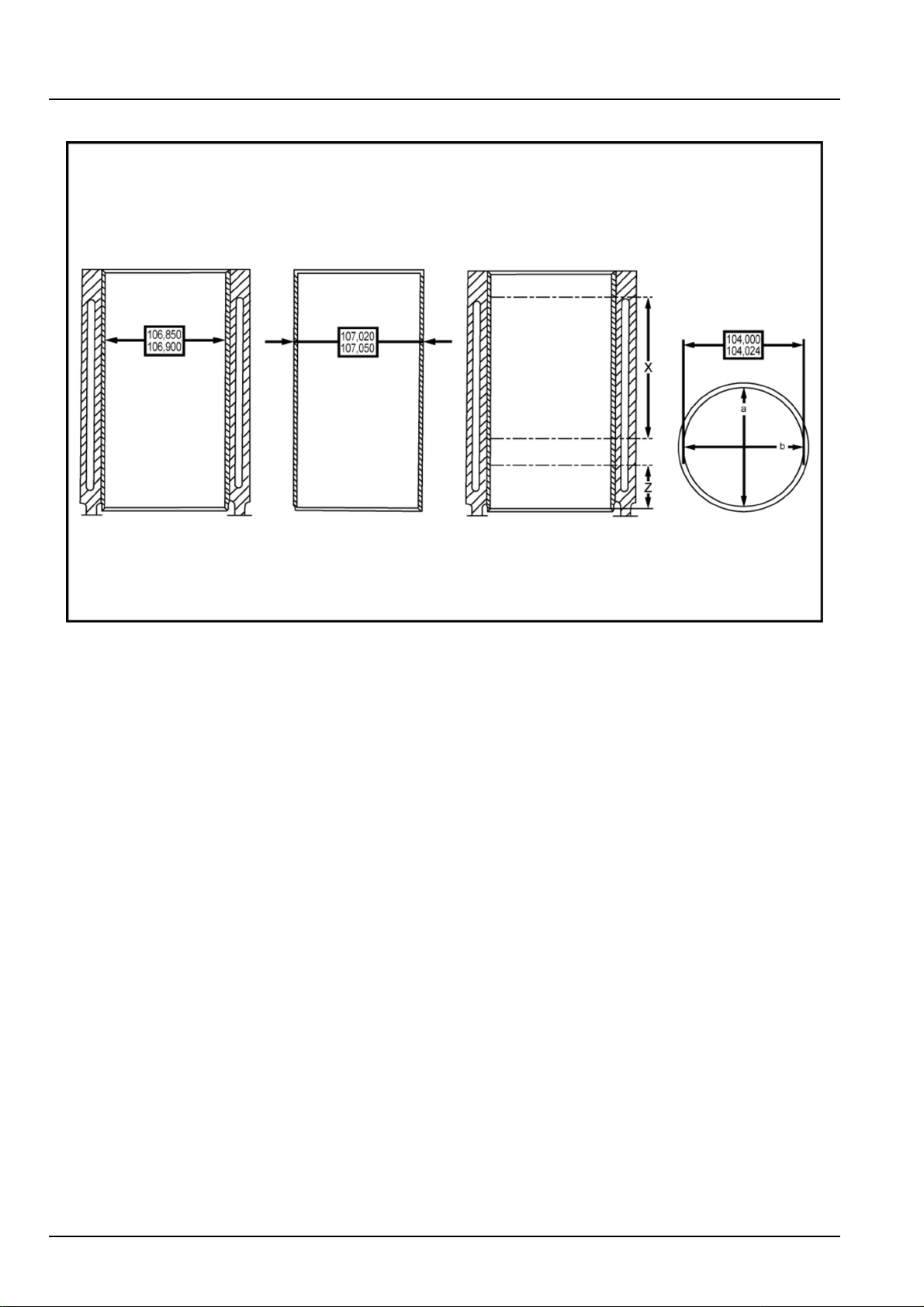

CrankcaseLiner-Measure

Engine-Engineandcrankcase

NHIL12ENG0321AA1

1.Usegure1tomeasurethecylinderliners.

2.Measuretheupperandlowerendsofarea(X)parallel

tothecrankshaft(a)andperpendiculartothecrank-

shaft(b).

3.Comparethemeasuredvaluestodeterminelinerovalityandtaper.Thevaluesshouldnotexceed0.12mm

(0.005in).

4.Measurearea(Z)paralleltothecrankshaft(a)andper-

pendiculartothecrankshaft(b).

5.Comparethemeasuredvaluewiththediameterof

thepiston.Thecalculatedvalueshouldnotexceed

0.3mm(0.012in).

6.Borethecylindersorreplacethelinersifanyofthe

valuesaboveareexceeded.

4745413625/11/2013

10.1[10.001]/6

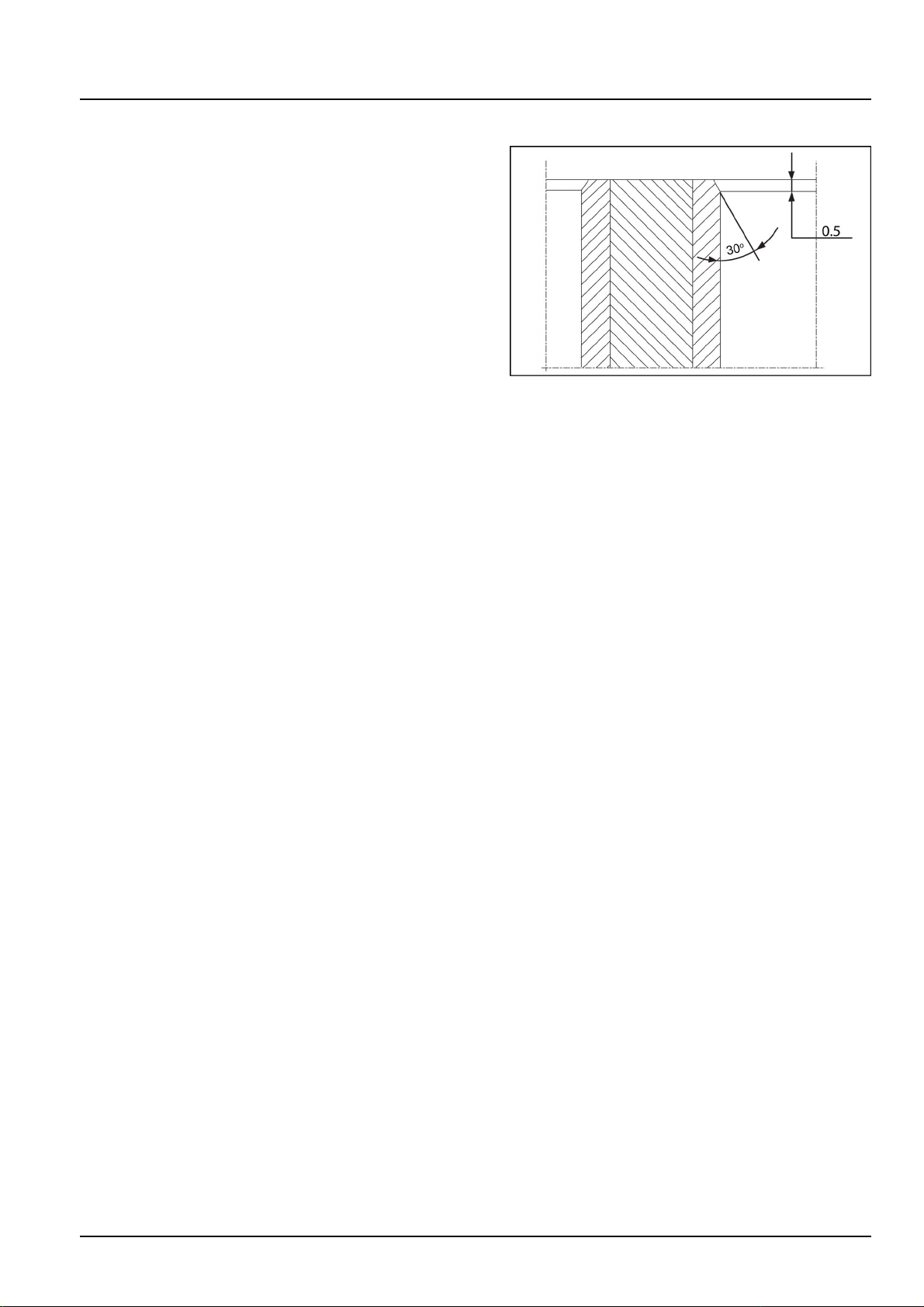

Engine-Engineandcrankcase

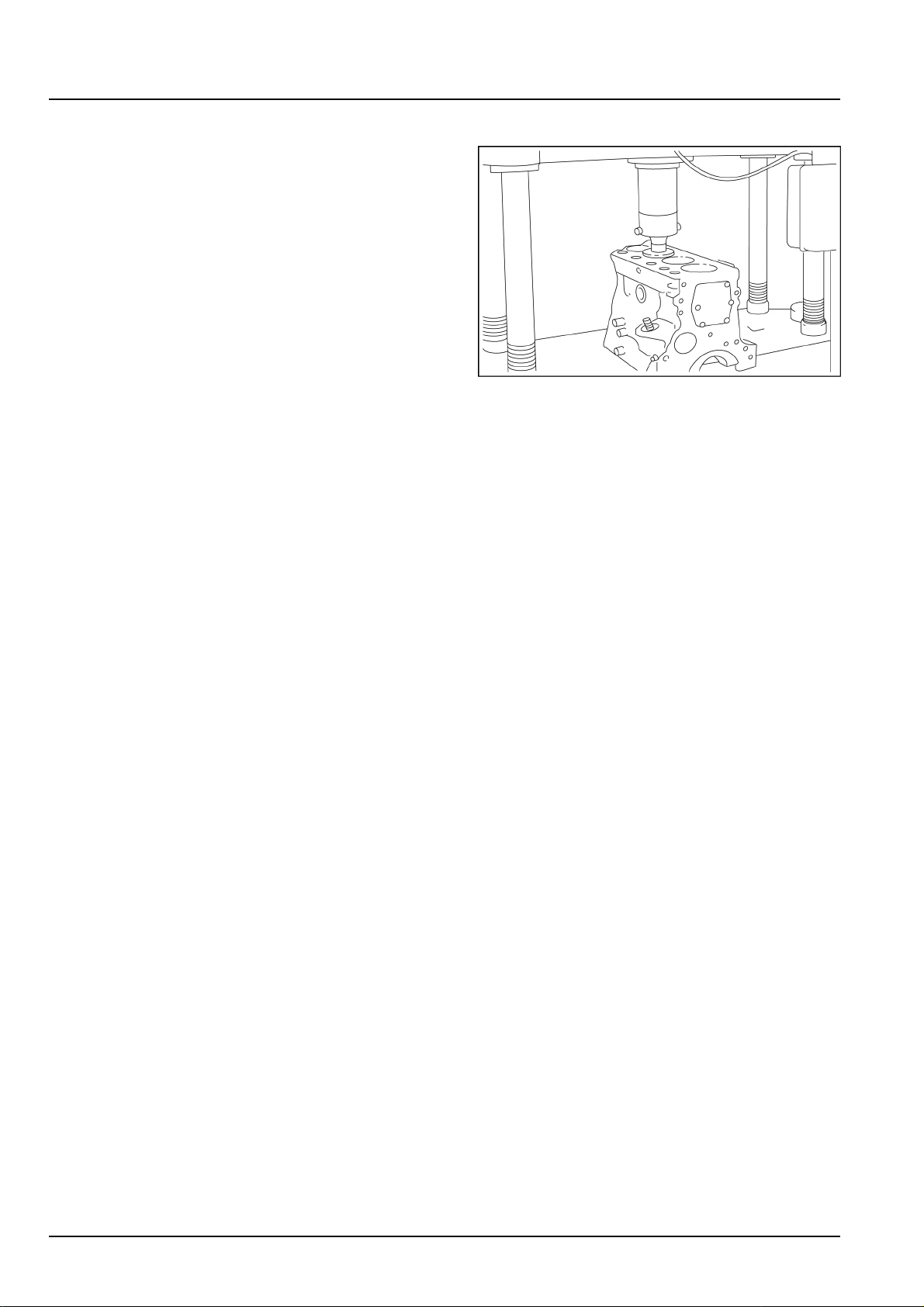

CrankcaseLiner-Rebore

1.Determineifboringthecylinderlinerisnecessary

byfollowingstepsinCrankcaseLiner-Measure

(10.001).

NOTICE:Ifonelinerrequiresboring,allofthelinersinthe

enginemustbeboredtothesameoversizeandmatched

withapistonofthesamesize.

2.Borethelinersto0.4-0.8mm(0.016-0.031in)over-

size.

3.Restorethe30°chamfer0.5mm(0.020in)intothe

linerasshowninthegure.

4.FollowthestepsinCrankcaseLiner-Measure

(10.001)toverifythatthelinersarewithinspecications.

5.Replacethelinersiftheyarestilloutsideoftheacceptableranges.

NHIL12ENG0319AA1

4745413625/11/2013

10.1[10.001]/7

Engine-Engineandcrankcase

CrankcaseLiner-Replace

1.Pressthelinerfromthebottomsideofthecrankcase.

2.Measuretheovalityoftheboreinthecrankcaseand

reboreifnecessaryto0.22mm(0.009in)oversize.

3.Pressthenewlinerintothetopofthecrankcase.

4.Borethenewlineraccordingtothespecicationsout-

linedinCrankcaseLiner-Rebore(10.001).

NHIL12ENG0320AA1

4745413625/11/2013

10.1[10.001]/8

Index

Engine-10

Engineandcrankcase-001

CrankcaseLiner-Measure..........................................................................6

CrankcaseLiner-Rebore...........................................................................7

CrankcaseLiner-Replace..........................................................................8

Engine-Generalspecication(*).....................................................................3

Engine-Generalspecication(*).....................................................................3

Engine-Sectionalview.............................................................................4

Engine-Servicelimits..............................................................................3

(*)Seecontentforspecicmodels

4745413625/11/2013

10.1[10.001]/9

4745413625/11/2013

10.1[10.001]/10

Engine-10

Cylinderheads-101

8035.05.716,8035.25C.313T,8035.25D.313T,8045.05.260,8045.05.716,

8045.05R.939T,8045.25.260,8045.25.261,8045.25.262,8045.25L.939T

4745413625/11/2013

10.2[10.101]/1

TECHNICALDA TA

Cylinderheads

Servicelimits..............................................................................3

SERVICE

Valvecover

Remove..................................................................................4

Install.....................................................................................5

Contents

Engine-10

Cylinderheads-101

Cylinderhead

Remove..................................................................................6

Install.....................................................................................7

Injectorcup-Replace......................................................................8

Valves

Remove.................................................................................10

Install....................................................................................1 1

Measure.................................................................................12

Valveguide

Replace..................................................................................13

Valveseat

Resurface................................................................................16

4745413625/11/2013

10.2[10.101]/2

Engine-Cylinderheads

Cylinderheads-Servicelimits

Specications

Originalheightofcylinderhead92mm(3.622in)

Maximumsurfaceregrindingdepth0.5mm(0.02in)

Diameterofvalveguidebores13.950-13.983mm(0.549-0.551in)

Outsidediameterofvalveguides13.993-14.016mm(0.551-0.552in)

Guideinterferencetinbores0.010-0.066mm(0.0004-0.003in)

Insidediameterofvalveguide(installedinhead)8.023-8.043mm(0.316-0.317in)

Valvestemdiameter

Assemblyclearancebetweenvalvestemandguide

Maximumpermissibleclearance

Maximumrun-outofvalvemeasuredfromthevalvehead0.03mm(0.001in)

Valveguideoversizes

Valveseatangle

-Intakevalve

-Exhaustvalve

Valvefaceangle

-Intakevalve

-Exhaustvalve

Valveheaddiameter

-Intakevalve

-Exhaustvalve

Valverecess

Maximumpermissiblevalverecess

Valvespringheight

-Freeheight

-Underaloadof256-284N(58-64lb)34mm(1.339in)

-Underaloadof502-544N(113-122lb)23.8mm(0.051in)

Injectorprotrusion

7.985-8.000mm(0.314-0.315in)

0.023-0.058mm(0.001-0.002in)

0.13mm(0.005in)

0.2mm(0.008in)

60°

45°

61°

46°

45.300-45.500mm(1.783-1.791in)

37.500-37.750mm(1.476-1.486in)

0.7-1.0mm(0.028-0.039in)

1.3mm(0.051in)

46mm(0.181in)

0.3-1.1mm(0.012-0.043in)

4745413625/11/2013

10.2[10.101]/3

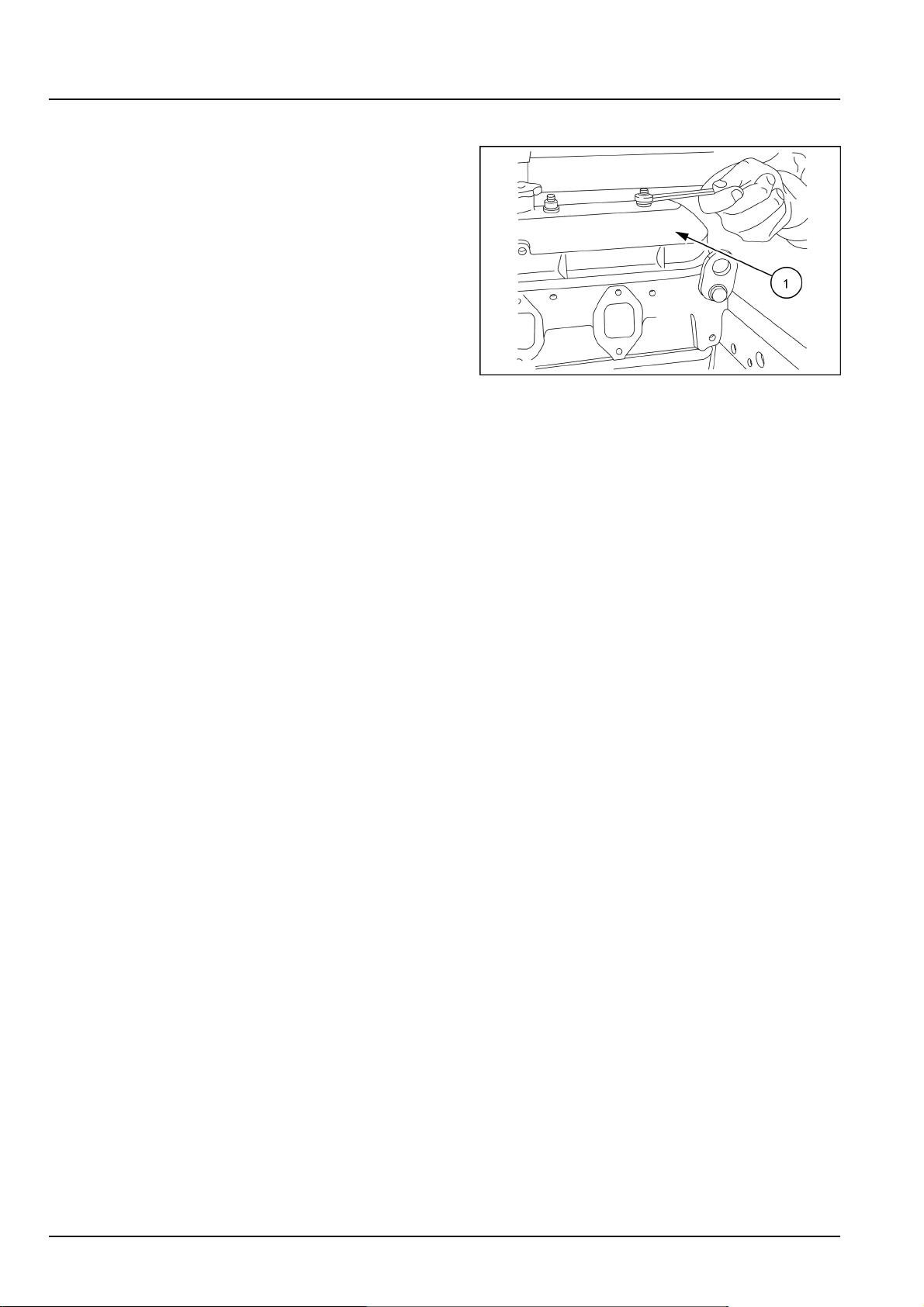

Valvecover-Remove

1.Removethenuts,washers,andseals.

2.Removethevalvecover(1).

Engine-Cylinderheads

NHIL12ENG0268AA1

4745413625/11/2013

10.2[10.101]/4

Loading...

Loading...