IVC Displays NP-612S User Manual

NP-612S

RISC-based operator interface terminal with 12.1” flat panel display

User’s Manual

Copyright.................................................................................................................. 4

Safety Instructions..................................................................................................... 5

Chapter 1 Introduction............................................................................................... 6

1.1 Introduction................................................................................................... 6

Chapter 2 Installation Instructions............................................................................. 8

2.1 Mounting Instructions.................................................................................... 8

2.1.1 Location Considerations........................................................................ 8

2.1.2 Making a NEMA-4 Mounting............................................................... 8

2.1.3 Environmental Considerations............................................................... 8

2.2 Power Connections........................................................................................ 9

2.2.1 Power Requirements ........................................................................... 10

2.2.2 Grounding Requirements......................................................................11

2.2.3 CE Requirements.................................................................................11

2.2.4 Safety Guidelines.................................................................................11

2.3 Communications Connections...................................................................... 13

2.3.1 Connector COM 1 [RS232]................................................................. 13

2.3.2 Connector COM2[RS232], COM3[RS485] and COM3[RS232].......... 14

2.3.3 Serial Port Settings.............................................................................. 15

2.3.4 USB Master port................................................................................. 16

2.4 Dip Switch................................................................................................... 17

2.4 Dip Switch................................................................................................... 17

2.5 CE Requirements......................................................................................... 18

2.6 Dimensions of NP-612S............................................................................... 19

Chapter 3 Windows CE.NET................................................................................... 20

3.1 Introduction................................................................................................. 20

3.2 Utilities........................................................................................................ 20

3.2.1 Soft-Keyboard..................................................................................... 20

3.2.2 System Settings................................................................................... 21

3.2.3 NORFlash........................................................................................... 25

3.2.4 Startup ................................................................................................ 25

3.2.5 Remote Desktop Connection............................................................... 26

3.3 NP-612S Networking................................................................................... 28

3.3.1 Networking via Ethernet ..................................................................... 28

3.3.2 ActiveSync.......................................................................................... 29

3.3.3 Web browser....................................................................................... 30

3.4 Application program development ............................................................... 31

3.4.1 Microsoft eMbedded Visual C++ 4.0................................................... 31

2

3.4.2 NP-612S SDK..................................................................................... 32

3

Copyright

This document is copyrighted April, 2005, by IVC Displays, Inc. All rights are

reserved. IVC Displays, Inc. reserved the right to make improvements to the products

described in this manual at any time. Specifications are thus subject to change without

notice.

No part of this manual may be reproduced, copied, translated, or transmitted in any

form or by any means without the prior written permission of IVC Displays, Inc.

Information provided in this manual is intended to be accurate and reliable. However,

IVC Displays, Inc. assumes no responsibility for its use, nor for any infringements

upon the rights of third parties which may result from its use.

4

Safety Instructions

conditions that could cause personal injury or equipment damage if care is not

Warns of situations in which high voltage can

Overview

This section states the safety instructions, which must be followed when installing,

operating and servicing the NP-612S. If neglected, physical injury and death may

follow, or damage may occur to controller and related equipment. The material in this

chapter must be studied before attempting any work on, or with, the unit.

Warnings and Notes

This manual distinguishes safety instructions. Warnings are used to inform of

conditions, which can, if proper steps are not taken, lead to a serious fault condition,

physical injury or death. Notes are used when the reader is required to pay special

attention or when there is additional information available on the subject. Notes are

less crucial than warnings, but should not be disregarded.

Warnings Readers are informed of situations that can result in serious physical injury

and/or serious damage to equipment with the symbol shown to the left. A

Warning symbol indicates that the reader should pay special attention to the

accompanying text. Precautionary steps should be taken to insure that the

installation is in compliance with warnings. Warnings include hazardous

taken. The text next to this symbol describes ways to avoid the danger.

Warnings Dangerous Voltage Warnings:

cause physical injury and or damage equipment.

General warning: Warns of situations, which can cause physical injury and

or damage equipment by means other than electrical.

Electrostatic Discharge Warning: Warns of situations in which an

electrostatic discharge can damage equipment.

Readers are notified of the need for special attention or additional in formation

available on the subject with the following symbols:

CAUTION! Aims to draw special attention to it.

Note: Note: gives additional information or points out more information available

on the subject.

5

Chapter 1 Introduction

1.1 Introduction

The MT612S is a miniature and compact platform that has no redundant functions. It is

designed for small-sized operator interface market. Its RISC kernel, the CIRRUS

LOGIC EP9135 200MHz processor design with a memory management unit (MMU),

that supports Windows CE. The ARM920T's 32-bit microcontroller architecture, with a

five-stage pipeline, delivers impressive performance at very low power.

The EP9315 includes a hardware graphics acceleration engine that improves graphic

performance by handling block copy, block fill and hardware line draw operations.

The graphics accelerator is used in the system to off load graphics operations from the

processor.

Features

• Built-in flash memory and Windows CE OS inside

• All in one platform: the CPU, DRAM and Windows CE are integrated

• Low power consumption and Fan-less

• NEMA 4 / IP65 compliant front panel

• One CompactFlash™ slot

• Audio

• Ethernet port(10/100Base-T)

1.2 Specifications

• Construction: plastic molding housing

• Display: 12.1" SVGA Color TFT LCD

• CPU and core logic: CIRRUS LOGIC EP9315 200MHz ARM920T core processor

• DRAM: 64 MB on board

• Storage: 32 MB flash memory on board

• 1 CompactFlash™ card slot

• 44-pin IDE Interface (DOM)

• I/O: 3 serial ports

Com1: RS-232/RS-485 2w/4w,

Com2: RS-232,

Com3: RS-232/RS-485 2w

• 1 Ethernet port (10/100Base-T)

6

• 3 USB 2.0 full-speed host (12Mbps)

• Sound output: 20-bits Stereo output

• RTC: Built-in

• Power input: 24 VDC, 0.5A maximum

• Dimensions: (W x H x D): 303 x 240 x 55mm (11.93” X 9.2” X 1.99”)

• Weight: 6 kg

FUSE

• BUSSMANN Fast Acting, Glass Tube

• Rating: 250VAC, 1A

• Size: 5x20mm

LCD Display

• Display type TFT color LCD

• Display size (diagonal) 12.1"

• Max colors 65536

• Resolution 800 x 600

• Pixel pitch (HxV, mm) 0.246 x 0.246

• Viewing angle (°) 100 (Upper+Lower), 120 (Left+Right)

• Luminance (cd/m2) 250

• Storage temperature (°C) -20~60

• Operating temperature (°C) 0~45

• Backlight CCFLx1

• Contrast ratio 200:1

Touch screen

• Type: 4-wire, analog resistive

• Resolution: continuous

• Light transmission: above 80%

• Life: 1 million activation minimal

Environmental Specifications

• Operating temperature: 0° ~ 45°C (32° ~ 113°F)

• Relative humidity: 10% ~ 90% @ 40°C, non-condensing

• Shock (operation): 10 to 25Hz(X,Y,Z direction 2G 30minutes)

• EMI: Complies FCC class A

• CE: Complies with EN50081-2 and EN50082-2 standards

• Front panel meets NEMA4 / IP65

7

Chapter 2 Installation Instructions

mm).

depth

2.1 Mounting Instructions

2.1.1 Location Considerations

Care should be taken when locating equipment behind the unit to ensure that AC power wiring,

PLC output modules, contactors, starters and relays, and any other source of electrical

interference are located away from the back of the unit.

Particular note should be taken to the position of variable speed drives and switching power

supplies. Their input and load cables should be screened to a central star earth point.

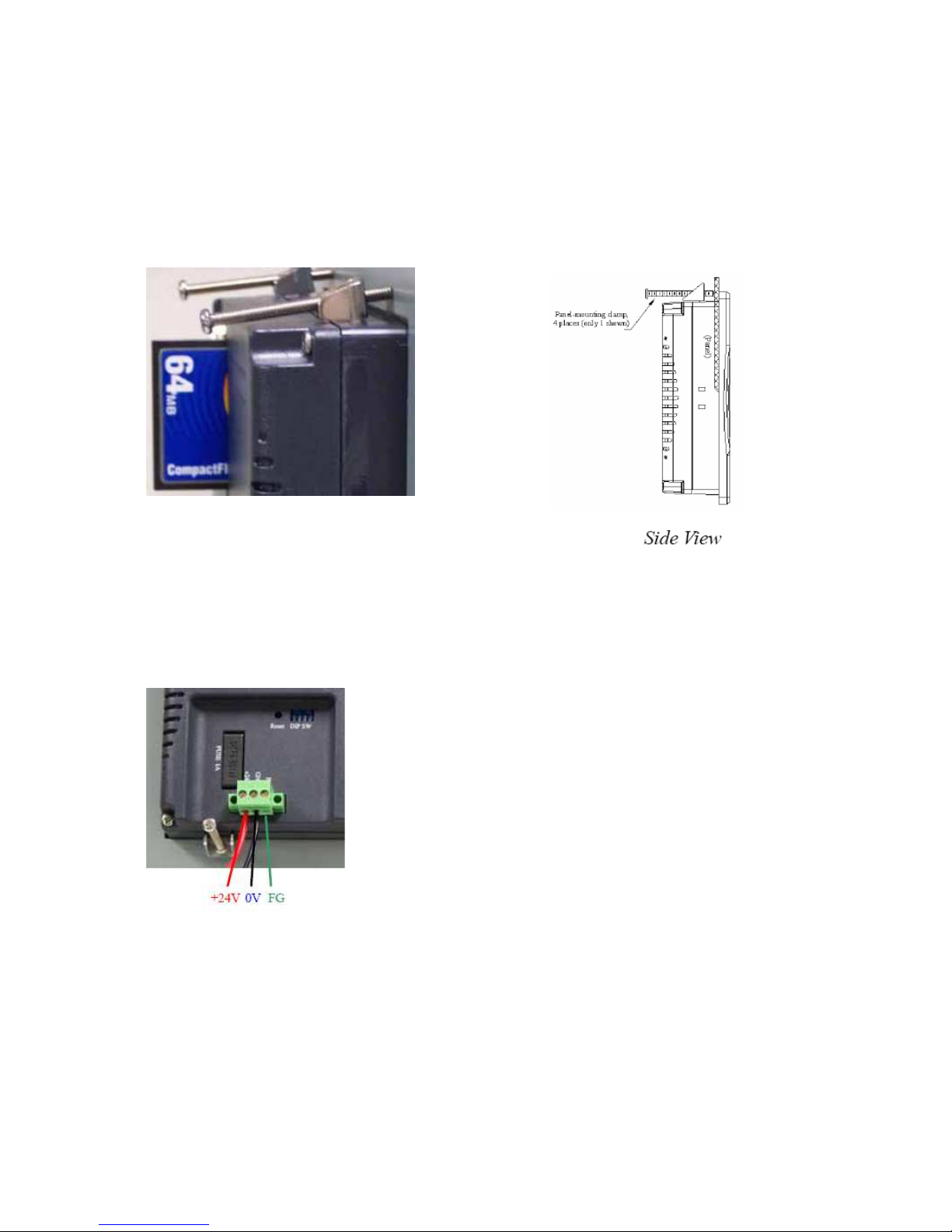

2.1.2 Making a NEMA-4 Mounting

Panel Details The unit can be mounted into panels with a depth of 1.72”(51

It is recommended that the unit be mounted on the front panel of a

steel enclosure, through an appropriate opening*. Allow a clearance

of 1”(25mm) around the sides of the unit for mounting hardware.

Allow clearance for cable connections to the back of the unit. Unit

depth may vary according to cable type used. Typically, plan a

to accommodate at least 1.72”(51mm) behind the panel.

NEMA-4

Mounting

Caution! Do not over tighten mounting clamps!

Note: Specifications Note:

Put the unit through the panel cut out. Slide the clamps into the 6

holes provided around the case. Tighten the clamping screws in an

even pattern until the unit is secured in the panel.

To seal to NEMA-4 specifications, all supplied mounting clamps

must be used and panel cannot flex more than 0.010”.

2.1.3 Environmental Considerations

The NP-612S are to be used indoors as built in displays. Make sure that the displays are

8

installed correctly and that the operating limits are followed (See Specifications).

Do not operate the unit in areas subject to explosion hazards due to flammable gases,

vapors or dusts.

The unit should not be installed where fast temperature variations and/or high humidity

are present. This will cause condensation of water in the device.

Do not install these terminals in environments where have inflammable gases.

2.2 Power Connections

Make sure that all local and national electrical standards are met when the installing the unit.

Contact your local authorities to determine which codes apply.

9

2.2.1 Power Requirements

circuitry to the controller, with the same power supply. Note: The 24

Wires should be run in pairs with a neutral or common paired with a

Power

Fusing

Requirements

Caution

High Voltage

Caution

Emergency

Stop

Caution

Supply Voltage

Condition

The NP-612S can be powered by DC power only. The specified

voltage range is +21 to 25 Volts DC. This insures compatibility

with most controller DC systems. The power conditioning circuitry

inside the unit is accomplished by a switching power supply. The

peak starting current can be as high as 700mA.

If the display does not come on within 2 seconds of power up,

remove power. An internal fuse will prevent damage if the polarity

of the DC power is incorrect. Check wiring to insure proper

connections and try to power up again.

An Internal fuse will prevent damage for over voltage condition

however it isn’t guaranteed.

DC voltage sources should provide proper isolation from main AC

power and similar hazards.

A Hard-wired EMERGENCY STOP should be fitted in any system

using an NP-612S to comply with ICS Safety Recommendations.

Do not power the NP-612S and inductive DC loads, or input

VDC output from some controllers may not have enough current to

power the NP-612S.

Caution

Wire Routing

Connection

Wire lengths should be minimized (Maximum 1600’ (500 m)

shielded, 1000’ (300 m) unshielded).

hot or signal line.

If wiring is to be exposed to lightning or surges, use appropriate

surge suppression devices.

Keep AC, high energy, and rapidly switching DC wiring separate

from signal wires.

Equip ungrounded DC supplies with a resistor and capacitor in

parallel to earth ground. This provides a path for static and high

frequency dissipation. Typical values to use are 1MOhm and

4700pF.

To make a connection, strip about 3/8” of insulation off the end of

the wire, turn the connector screw counterclockwise until the gap is

wide open, insert the wire all the way in, and turn the screw

clockwise until it’s tight.

Connect positive DC line to the ‘+24V’ terminal and the DC ground

to the ‘GND‘ terminal.

10

FUSE Replacement:

The fuse use on MT608 is:

BUSSMANN

Fast Acting, Glass Tube

Rating: 250VAC, 1A

Size: 5x20mm

Warning:

1. Make sure the power off before

replace the fuse.

2. Do not replace the fuse with a

different rating fuse.

2.2.2 Grounding Requirements

Chassis ground must be used. DC ground is not directly coupled to Earth ground

internally. It is preferable not to ground DC negative return to chassis ground as poor site

earths can introduce noise into a system, but if necessary an earth connection should be made,

from the power supply return point to the central star earth point. Ground conductors should be

as short and as large in size as possible. The conductors must always be large enough to carry

the maximum short circuit current of the path being considered. Ground conductors should be

connected to a tree from a central star earth ground point. This ensures that no ground

conductor carries current from any other branch.

2.2.3 CE Requirements

To make an NP-612S comply with EMC directives, and to reduce susceptibility to electrical

interference, a separate #14 AWG ground wire should be taken to the chassis ground terminal

of the power connector. This ground connection should be run directly to the central star earth

connection point (as recommended in most Installation Instructions).

2.2.4 Safety Guidelines

This section presents recommended installation practices, and procedures. Since no two

applications are identical, these recommendations should be considered as guidelines.

Hardware Considerations WARNING!

The system designer should be aware that devices in Controller systems could fail and thereby

create an unsafe condition. Furthermore, electrical interference in an operator interface, such

11

Loading...

Loading...