ITW Tapcon 24193 User Manual

DESCRIPTION/SUGGESTED SPECIFICATIONS

ADHESIVE ANCHORING SPECIALISTS

CONCRETE ANCHORING SPECIALISTS

ADHESIVE ANCHORING SPECIALISTS

CONCRETE ANCHORING SPECIALISTS

TM

Large

Diameter

Tapcon

(

LDT

Removable Anchor

)

Anchors

Finished head,

Self-threading Anchors—

SPECIFIED FOR ANCHORAGE INTO CONCRETE

The LDT anchor is a high performance anchor that cuts its own threads

into concrete.

LDT

Self-threading

Anchor

ADVANTAGES

SAVE TIME

EASILY INSTALLED

n Installs in less than half the time of wedge anchors

or adhesive anchors

n Simply drill a pilot hole and drive the LDT anchor by

hand or impact

EASILY REMOVED

n No torching or grinding required to remove anchors

Anchor bodies are made of hardened carbon steel and zinc plated, Grade 5.

The anchors shall have a nished hex washer head with anti-rotation

serrations to prevent anchor back-out. The head of the anchor is stamped

with a length identication code for easy inspection.

The hole shall be drilled with carbide tipped hammer drill bits made

in accordance to ANSI B212.15-1994.

SAVE MONEY

LOWER DRILL BIT COSTS

n Use standard ANSI bits instead of proprietary bits

n Single piece design, no nut and washer to assemble

USE STANDARD ANSI BITS

n No special proprietary bits to purchase or lose

n Reduce chances for anchor failure due to incorrect

bit usage

LDT

(3/8” & 1/2”) (5/8” & 3/4”)

Sawtooth™

3/8” and 1/2” are available

with coating

Uses standard drill bits—

no special drill bits to

purchase or lose!

Sawtooth Threads™ diameters available on

5/8” and 3/4”

IMPROVED PERFORMANCE IN LARGE

DIAMETER HOLES

n Superior performance to wedge anchor

n Higher loads in shallow embedments

n Closer edge/spacing distance than

mechanical anchors

n More threads for better thread engagement

and higher pullout resistance

n Durable induction-hardened tip

EASY INSTALLATION

n Easy 2-step installation, simply drill

a pilot hole and drive

Patented Sawtooth™

thread design drives

easily into concrete

to optimize pullout

performance and

installation speed

n Installs in less than half the time of a

wedge anchor

n Efficient thread cutting

n Use standard drill bit sizes

n Single piece design—no nut and

washer assembly

n Easily removed

Call our toll free number 800-848-5611 or visit our web site for the most

current product and technical information at www.itwredhead.com

71

LDT Anchors

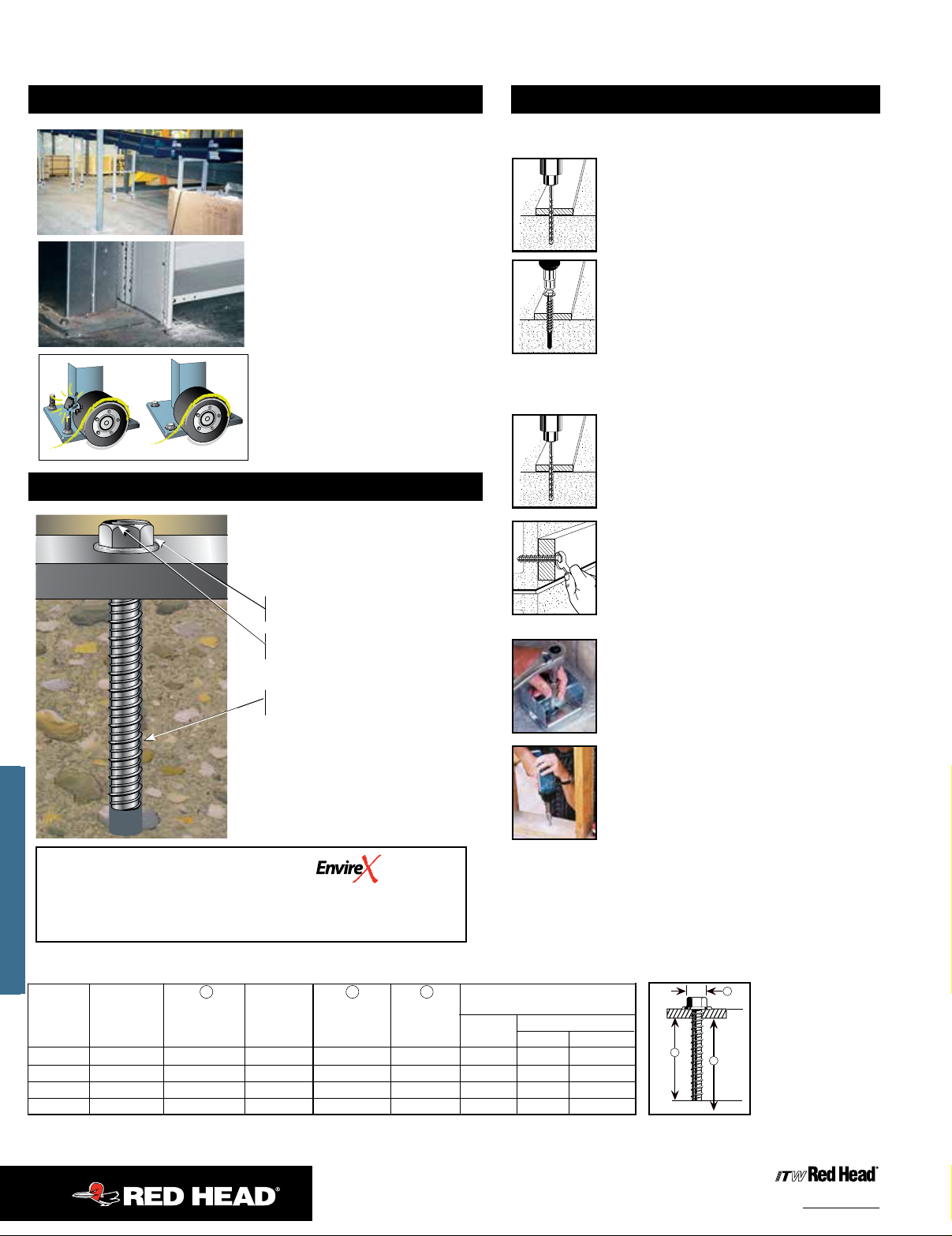

APPLICATIONS

Racking, shelving and conveyors are just

a few high volume applications ideal for

Large Diameter Tapcon (L DT ™). The ease

and speed of installation of the LDT can

reduce installation time to less than half

the time of typical systems used today.

For installation speed, high performance

and easy removability, LDT is the anchor

of choice.

The LDT’s nished head and lack of exposed

threads virtually eliminates tire damage on

fork lift trucks.

FEATURES

Easy Installation

Installs into concrete by hand or impact wrench

Anti-rotation Serrated Washer

— Prevents anchor back-out

Extra Large Hex Washer Head

— With increased bearing surface

Length Identication Head Stamp

— For embedment inspection after

installation

Hi-Lo Threads

— Cuts its own threads into concrete for

greater pull-out resistance

LDT 3/8” and 1/2” are available with coating

INSTALLATION STEPS

Installation Steps for Concrete, Lightweight Concrete and Metal Deck

1. Using the proper size carbide bit (see chart)

drill “a pilot hole at least 1” deeper than anchor

embedment. “ ”

2. Using an electric impact wrench, or socket wrench

(hand install) insert anchor into hole and tighten

anchor until fully seated. (see chart for socket size)

(do not over tighten).

Installation Steps for Hollow or Grout-Filled CMU

(3/8” and 1/2” diameter)

1. Using a 5/16” (for 3/8” LDT) or 7/16” (for 1/2”

LDT) carbide tipped bit, drill a pilot hole at least

1” deeper than anchor embedment.

2. Using a socket wrench insert anchor into hole

and hand tighten anchor until fully seated.

(9/16” socket for 3/8” and 3/4” socket for 1/2”)

(do not over tighten).

LDT’s can be installed by hand or

with an impact wrench

Installation by hand—is easy, simply using

a socket wrench

Installation by impact wrench—is

recommended for faster installations

or for high volume projects. Installation

with impact wrench—is not recommended

for hollow block.

TM

C

C

“ ”

1,000 hours salt spray ASTM B117. Approved for use in ACQ and MCQ lumber*

*Excessive content of copper in the ACQ and MCQ lumber may affect the anchor finish.

Selection Chart

ANSI Washer

LDT Size Standard Anchor Head Diameter Minimum Hole

Drill Bit (Socket S ize) Embedment Depth CMU

Diameter Diameter Concrete Hollow Grout-lled

LDT 3/8” 5/16” 9/16” 13/16” 1-1/2” 2-1/2” YES YES YES

LDT 1/2” 7/16” 3/4” 1” 2-1/2” 3-1/2” YES NO YES

LDT 5/8” 1/2” 13/16” 1-3/16” 2-3/4” 3-3/4” YES NO YES

LDT 3/4” 5/8” 15/16” 1-5/16” 3-1/4” 4-1/4” YES NO YES

See page 75 for effective lengths and length indication code.

A

B

C

USE IN

72

A

B

C

Call our toll free number 800-848-5611 or visit our web site for the most

current product and technical information at www.itwredhead.com

Loading...

Loading...