ITW Red Head 13367 User Manual

Trubolt

ADHESIVE ANCHORING SPECIALISTS

CONCRETE ANCHORING SPECIALISTS

ADHESIVE ANCHORING SPECIALISTS

CONCRETE ANCHORING SPECIALISTS

Compliant

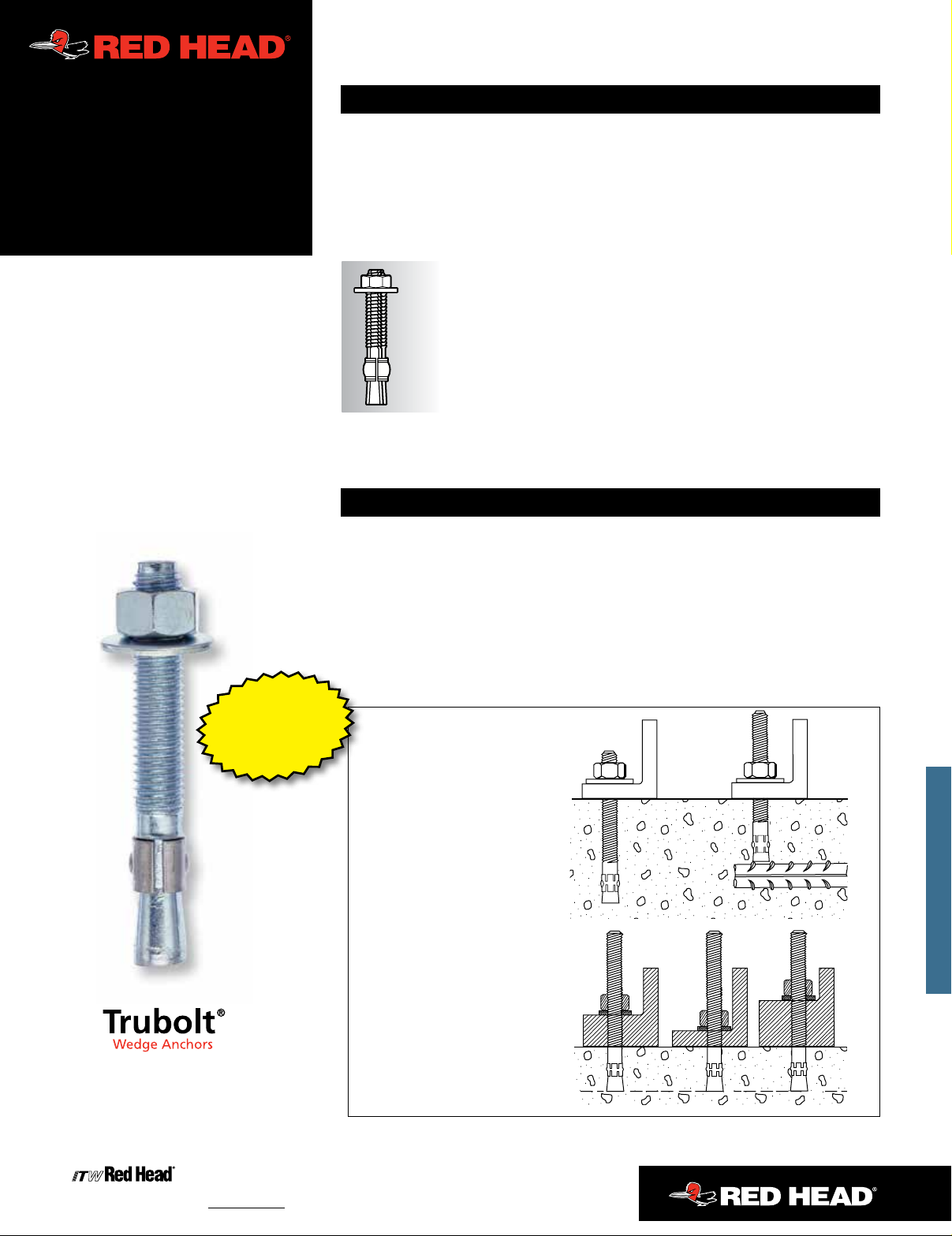

Wedge Anchors

Dependable,

Heavy-Duty,

Inspectable,

DESCRIPTION/SUGGESTED SPECIFICATIONS

Wedge Type Anchors—

SPECIFIED FOR ANCHORAGE INTO CONCRETE

®

Trubolt Wedge anchors feature a stainless steel expansion clip, threaded stud body, nut and washer. Anchor

bodies are made of plated carbon steel, hot-dipped galvanized carbon steel, type 304 stainless steel or type

316 stainless steel as identied in the drawings or other notations.

The exposed end of the anchor is stamped to identify anchor length. Stampings

should be preserved during installation for any subsequent embedment verication.

Trubolt

Wedge

Anchor

Use carbide tipped hammer drill bits made in accordance with ANSI B212.15-1994

to install anchors.

Anchors are tested to ACI 355.2 and ICC-ES AC193. Anchors are listed by the following

agencies as required by the local building code: ICC-ES, UL, FM, and Caltrans.

Wedge Type

Expansion

Anchor

2015 IBC

See Appendix B (pages 106-107) for performance values in accordance to

2015 IBC.

ADVANTAGES

n 2015 International Building Code (IBC) Compliant

for 1/4” through 1/2” diameters-carbon steel

n Versatile fully threaded design is standard

on sizes up to 1” diameter and 10” length

n Anchor diameter equals hole diameter

n Standard carbon and stainless steel anchors

Fully Threaded

Advantage

Trubolt’s fully threaded

feature eliminates subsurface

obstruction problems.

n Non bottom-bearing, may be used in hole

depth exceeding anchor length

n Can be installed through the work fixture,

eliminating hole spotting

n Inspectable torque values, indicating

proper installation

Call our toll free number 800-848-5611 or visit our web site for the most

current product and technical information at www.itwredhead.com

Fully threaded design

accommodates various

material thicknesses at

the same embedment.

One anchor length saves

time and money.

63

Trubolt Anchors

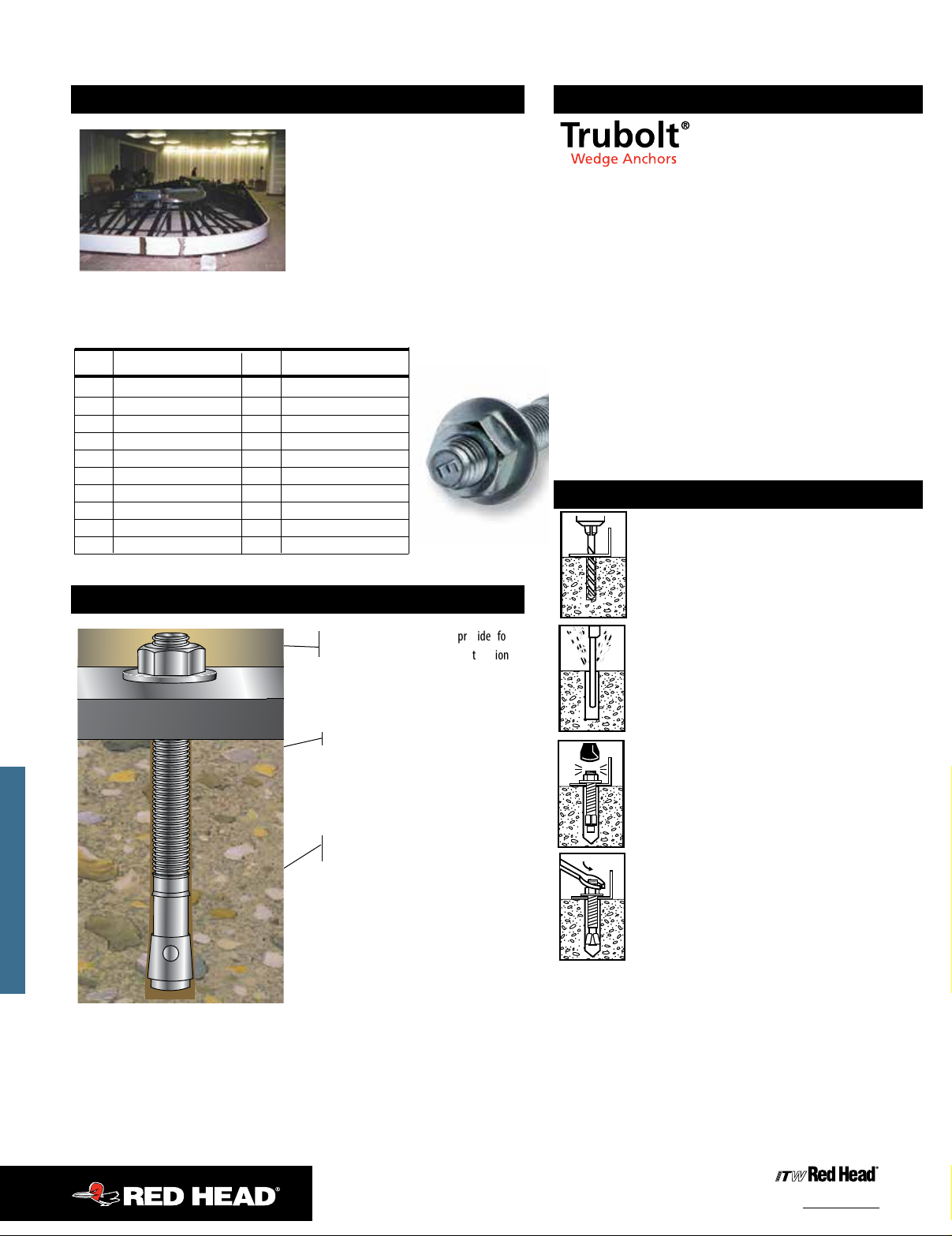

MANUFACTURER’S INSTALLATION STEPS

1 2 3 4

APPLICATIONS

Anchoring machinery and conveyors

is a common wedge anchor application.

The Trubolt is fully threaded to allow a

large range of embedment and

fixture thickness.

LENGTH INDICATION CODE*

CODE LENGTH OF ANCHOR CODE LENGTH OF ANCHOR

A 1-1/2 < 2 (38.1 < 50.8) K 6-1/2 < 7 (165.1 < 177.8)

B 2 < 2-1/2 (50.8 < 63.5) L 7 < 7-1/2 (177.8 < 190.5)

C 2-1/2 < 3 (63.5 < 76.2) M 7-1/2 < 8 (190.5 < 203.2)

D 3 < 3-1/2 (76.2 < 88.9) N 8 < 8-1/2 (203.2 < 215.9)

E 3-1/2 < 4 (88.9 < 101.6) O 8-1/2 < 9 (215.9 < 228.6)

F 4 < 4-1/2 (101.6 < 114.3) P 9 < 9-1/2 (228.6 < 241.3)

G 4-1/2 < 5 (114.3 < 127.0) Q

H 5 < 5-1/2 (127.0 < 139.7) R 10 < 11 (254.0 < 279.4)

I 5-1/2 < 6 (139.7 < 152.4) S 11 < 12 (279.4 < 304.8)

J 6 < 6-1/2 (152.4 < 165.1) T 12 < 13 (304.8 < 330.2)

* Located on top of anchor for easy inspection.

9-1/2 < 10

(241.3 < 254.0)

FEATURES

APPROVALS/LISTINGS

ICC Evaluation Service, Inc. ESR-2251

– Category 1 performance rating

– 2015 IBC compliant

– Meets ACI 318 ductility requirements

– Tested in accordance with ACI 355.2 and ICC-ES AC193

– For use in seismic zones A & B

– 1/4”, 3/8” & 1/2” diameter anchors listed in ESR-2251

Underwriters Laboratories

Factory Mutual

Caltrans

Meets or exceeds U.S. Government G.S.A. Specification A-A-1923A Type 4

(formerly GSA: FF-S-325 Group II, Type 4, Class 1)

Made in USA

INSTALLATION STEPS

1. Select a carbide drill bit with a diameter equal

to the anchor diameter. Drill hole to any depth

exceeding the desired embedment. See chart

for minimum recommended embedment.

TRUBOLT® WEDGE ANCHOR

Length ID Head Stamp—provides for

embedment inspection after installation

Fully Threaded Design

Cold-Formed—manufacturing process

adds strength

Stainless steel split expansion ring

Anchor Body—available in zinc-plated

steel, hot-dipped galvanized steel, 304

stainless steel and 316 stainless steel

2. Clean hole or continue drilling additional depth

to accommodate drill fines.

3. Assemble washer and nut, leaving top of stud

exposed through nut. Drive anchor through

material to be fastened until washer is flush to

surface of material.

4. Expand anchor by tightening nut 3-5 turns

past the hand tight position, or to the

specified torque requirement.

** ONLY FOR USE IN CONCRETE**

64

Call our toll free number 800-848-5611 or visit our web site for the most

current product and technical information at www.itwredhead.com

Loading...

Loading...