ITW Gema PG 1-R1 Operating Instructions And Spare Parts List

17PG 1-R1

Issued 05/01

Operating Instructions and Spare Parts List

PG 1-R1 Robot Powder Gun

E

18 PG 1-R1

Issued 05/01

19PG 1-R1

Issued 05/01

Table of Content

PG 1-R1 Robot Powder Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Technical data of the PG 1-R1 Robot Powder Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1. High-Voltage generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Powder flow and supplementary air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. Flat jet nozzle with vented centre electrode . . . . . . . . . . . . . . . . . . . . . . . . 3

Preparatory steps for initial start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

a) Connecting the PG 1-R1 Powder gun . . . . . . . . . . . . . . . . . . . . . . . . 4

b) Functional check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

a) Adjusting the powder output and powder cloud . . . . . . . . . . . . . . . . 6

b) Powder coating - Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

c) Shut-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

d) Rinsing the powder hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

a) Daily maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

b) Weekly maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cleaning and repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

PG 1-R1 Powder Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

a) Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

b) Gun dismantling: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

c) Gun assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

e) Cleaning the Spray nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Trouble shooting guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Spare Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Ordering Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

PG 1-R1 Robot Powder Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

20 PG 1-R1

Issued 05/01

1PG 1-R1

Issued 05/01

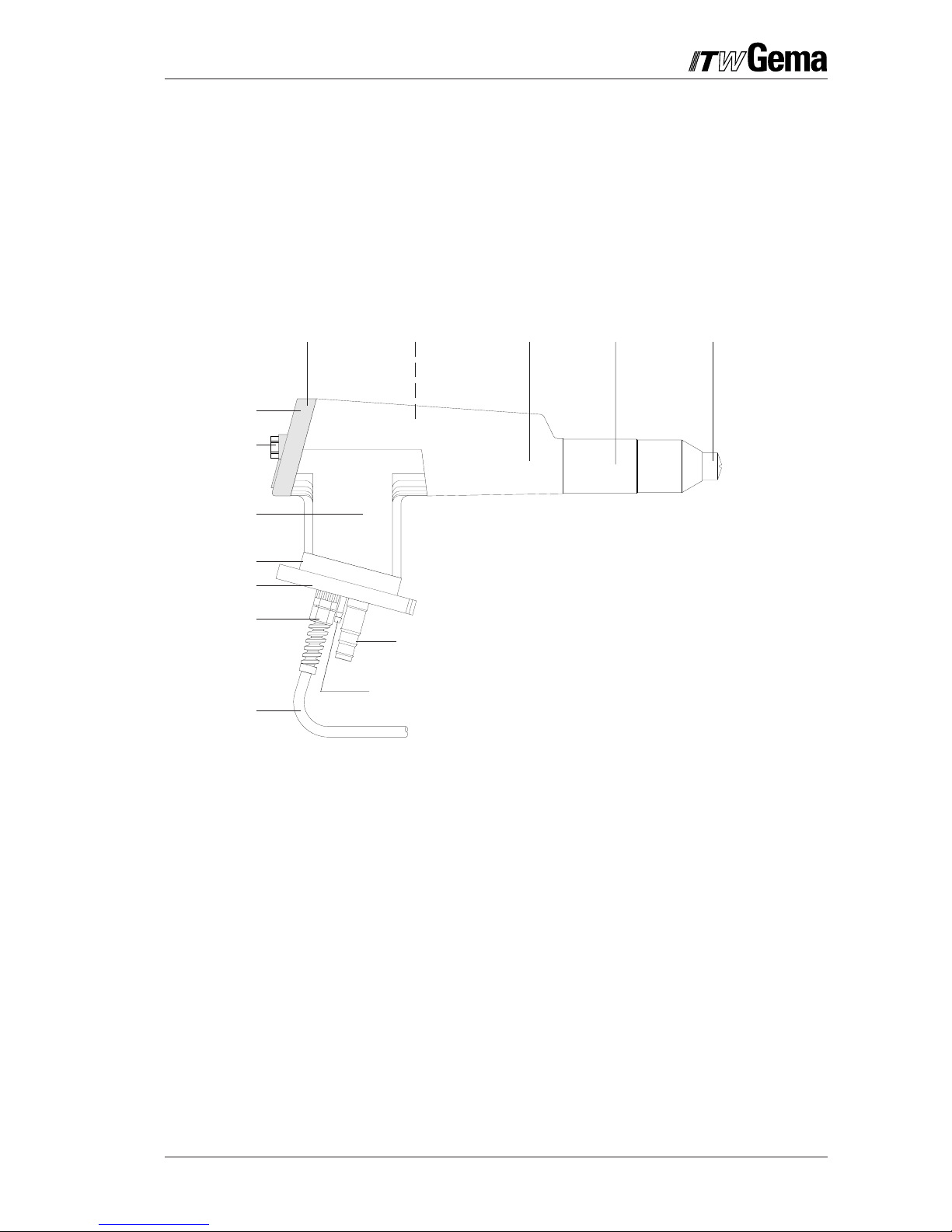

PG 1-R1 Robot Powder Gun

The PG 1-R1 Robot Powder Gun with integrated High-voltage generation is especially suited

for operation on a freely programmable Robot (up to 7 axes) for coating complex contours

and difficult to reach workpiece positions. The gun has very good penetration capability, and

a high, constant Transfer efficiency. The gun is easily dismantled, making it maintenance and

repair-friendly.

For fitting the gun on the Robot, the customer must supply the necessary Adapter for the

corresponding Robot type, by means of a pin for the exact positioning of the gun and also a

carrier for the gun cable and hoses.

8

3

4

7

9

6

1

2

16

10

11

12

15

8 Support

9 Flange plate

10 Locking screw

11 Gun cable connection

12 Gun cable

15 Powder hose connection

16 Rinsing air connection

1 Atomizing system

2 Threaded sleeve

3 Shaft

4 HV cascade

5 End plate

6 LED window

7 Plastic bolt

Technical data of the PG 1-R1 Robot Powder Gun

Rated input voltage: 10 V eff.

Frequency: 17 kHz

Rated output voltage: 98 kV

Polarity: negative

Maximum output current: 140 µA

HV indication: LED

Polarity: Negative

Approval: EN 50050

PTB test No. Ex-91.C.9102

Date PTB tested Oct. 1991

Figure 1

5

2 PG 1-R1

Issued 05/01

Functional description

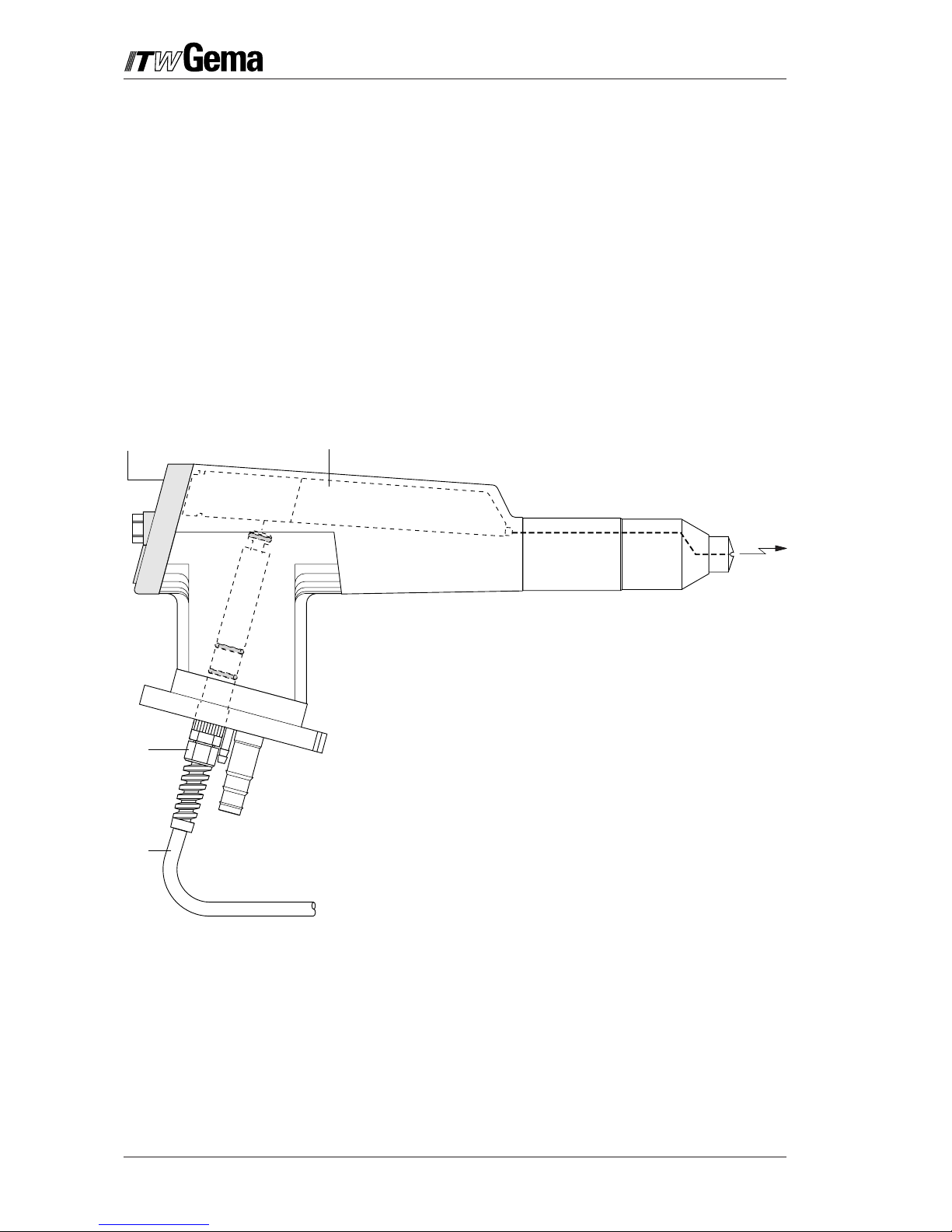

1. High-Voltage generation

The voltage generation module (Control module) supplies high-frequency low-voltage.

This voltage is conducted by the gun cable (12) and the gun connector (11) in the Support to

the high-voltage cascade (4).

This low voltage is stepped up (c) in the cascade (4). This primary high-voltage is subsequently rectified and multiplied in several stages in the cascade (d) until the required highvoltage is attained.

The high-voltage is then fed from the spray nozzle to the electrode (e). See Figure 3.

When the high-voltage is adjusted on the control module, the intensity of the LED (6) also

changes. The user has the assurance that high-voltage is present and has control over this

function.

Figure 2

2. Powder flow and supplementary air

The supplementary air, serving as rinsing air, is connected to the gun, shown in Figure 4,

when air-cleaned nozzles are used.

The function of the nozzles are described in the applicable sections (see page 3).

4

11

12

c

d

6

e

Loading...

Loading...