ITW Gema OptiFlex B, OptiFlex Operating Instructions And Spare Parts List

En

Operating instructions and spare parts list

OptiFlex B

Manual coating equipment

Translation of the original operating instructions

V 05/10

Documentation OptiFlex B manual coating equipment

© Copyright 2006 ITW Gema GmbH

All rights reserved.

This publication is protected by copyright. Unauthorized copying is prohibited by law. No part of this publication may be reproduced, photocopied,

translated, stored on a retrieval system or transmitted in any form or by

any means for any purpose, neither as a whole nor partially, without the

express written consent of ITW Gema GmbH.

OptiTronic, OptiGun, EasyTronic, EasySelect, OptiFlow and SuperCorona are registered trademarks of ITW Gema GmbH.

OptiMatic, OptiMove, OptiMaster, OptiPlus, MultiTronic and Gematic are

trademarks of ITW Gema GmbH.

All other product names are trademarks or registered trademarks of their

respective holders.

Reference is made in this manual to different trademarks or registered

trademarks. Such references do not mean that the manufacturers concerned approve of or are bound in any form by this manual. We have endeavored to retain the preferred spelling of the trademarks, and registered trademarks of the copyright holders.

To the best of our knowledge and belief, the information contained in this

publication was correct and valid on the date of issue. ITW Gema GmbH

makes no representations or warranties with respect to the contents or

use of this publication, and reserves the right to revise this publication

and make changes to its content without prior notice.

Printed in Switzerland

ITW Gema GmbH

Mövenstrasse 17

9015 St. Gallen

Switzerland

Phone: +41-71-313 83 00

Fax.: +41-71-313 83 83

E-Mail: info@itwgema.ch

Homepage: www.itwgema.ch

V 05/10

OptiFlex B manual coating equipment Table of contents 1

Table of contents

General safety regulations 3

Safety symbols (pictograms) ................................................................................... 3

Conformity of use .................................................................................................... 3

Technical safety regulations for stationary electrostatic powder spraying

equipment ............................................................................................................... 4

General information ................................................................................... 4

Safety conscious working .......................................................................... 5

Individual safety regulations for the operating firm and/or operating

personnel ................................................................................................... 5

Notes on special types of hazard ............................................................... 6

Safety requirements for electrostatic powder coating ................................ 7

A summary of the rules and regulations .................................................... 8

Product specific security measures ...................................................................... 10

About this manual 11

General information .............................................................................................. 11

Function description 13

Field of application ................................................................................................ 13

Typical characteristics ........................................................................................... 13

OptiFlex B manual coating equipment .................................................................. 14

Structure ................................................................................................... 14

OptiStar control unit ................................................................................. 14

OptiFlow injector ...................................................................................... 15

Scope of delivery .................................................................................................. 15

OptiFlex B-1 ............................................................................................. 15

Additional supply for OptiFlex B-2 ........................................................... 15

Technical data 17

OptiFlex B manual coating equipment .................................................................. 17

Electrical data .......................................................................................... 17

Pneumatical data ..................................................................................... 17

Connectable guns .................................................................................... 17

Dimensions .............................................................................................. 18

Start-up and operation 19

Connecting guide .................................................................................................. 19

Preparation for start-up ......................................................................................... 20

Preparing the powder container ............................................................... 20

Switching on the booth ............................................................................. 20

Start-up ................................................................................................................. 20

Switch on the control unit ......................................................................... 20

Color change 21

General information .............................................................................................. 21

V 05/10

2 Table of contents OptiFlex B manual coating equipment

Maintenance and cleaning 23

Daily maintenance ................................................................................................ 23

Weekly maintenance ............................................................................................ 23

If in disuse for several days .................................................................................. 23

Powder hose rinsing ................................................................................ 23

Cleaning ................................................................................................................ 24

Cleaning the fluidizing/suction unit .......................................................... 24

Cleaning the OptiSelect manual powder gun .......................................... 24

Maintenance and cleaning of the filter unit ........................................................... 25

Replacing the filter element ..................................................................... 25

Troubleshooting guide 27

General information .............................................................................................. 27

Schematic diagrams 29

Block diagram - OptiFlex B ................................................................................... 29

Pneumatic diagram - OptiFlex B ........................................................................... 30

Spare parts list 31

Ordering spare parts ............................................................................................. 31

OptiFlex B manual coating equipment - spare parts list ....................................... 32

OptiFlex B manual coating equipment - spare parts list ....................................... 33

OptiFlex B - fluidizing/suction unit ........................................................................ 34

OptiFlex B - filter unit ............................................................................................ 35

V 05/10

OptiFlex B manual coating equipment General safety regulations 3

General safety regulations

This chapter sets out the fundamental safety regulations that must be followed by the user and third parties using the OptiFlex B manual coating

equipment.

These safety regulations must be read and understood before the OptiFlex B manual coating equipment is used.

Safety symbols (pictograms)

The following warnings with their meanings can be found in the ITW Gema operating instructions. The general safety precautions must also be

followed as well as the regulations in the operating instructions.

DANGER!

Danger due to live electricity or moving parts. Possible consequences:

Death or serious injury

WARNING!

Improper use of the equipment could damage the machine or cause it to

malfunction. Possible consequences: minor injuries or damage to equipment

INFORMATION!

Useful tips and other information

Conformity of use

1. The OptiFlex B manual coating equipment is built to the latest

specification and conforms to the recognized technical safety

regulations. It is designed for the normal application of powder

coating.

2. Any other use is considered as non-conform. The manufacturer

is not responsible for damage resulting from improper use of this

equipment; the end-user alone is responsible. If the OptiFlex B

manual coating equipment is to be used for other purposes or

other substances outside of our guidelines then ITW Gema

GmbH should be consulted.

3. Observance of the operating, service and maintenance instructions specified by the manufacturer is also part of conformity of

V 05/10

4 General safety regulations OptiFlex B manual coating equipment

use. The OptiFlex B manual coating equipment should only be

used, maintained and started up by trained personnel, who are

informed about and are familiar with the possible hazards involved.

4. Start-up (i.e. the execution of a particular operation) is forbidden

until it has been established that the OptiFlex B manual coating

equipment has been set up and wired according to the guidelines

for machinery (98/37 EG). EN 60204-1 (machine safety) must also be observed.

5. Unauthorized modifications to OptiFlex B manual coating equipment exempts the manufacturer from any liability from resulting

damage.

6. The relevant accident prevention regulations, as well as other

generally recognized safety regulations, occupational health and

structural regulations are to be observed.

7. Furthermore the country-specific safety regulations must be observed.

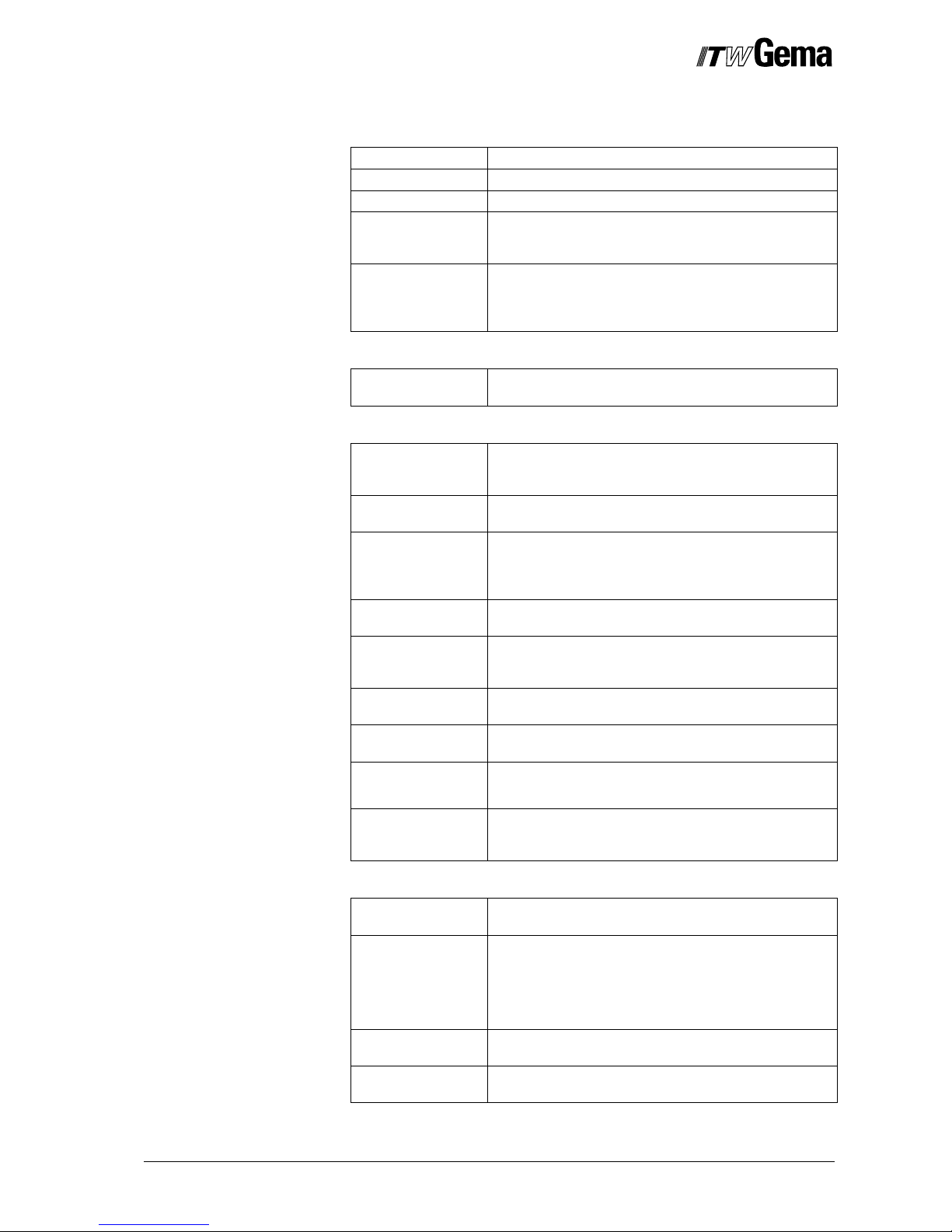

Explosion protection Protection type Temperature class

0102 II (2) D

IP54

T6 (zone 21)

T4 (zone 22)

Technical safety regulations for stationary electrostatic powder spraying equipment

General information

The powder spraying equipment from ITW Gema is designed with safety

in mind and is built according to the latest technological specifications.

This equipment can be dangerous if it is not used for its specified purpose. Consequently it should be noted that there exists a danger to life

and limb of the user or third party, a danger of damage to the equipment

and other machinery belonging to the user and a hazard to the efficient

operation of the equipment.

1. The powder spraying equipment should only be started up and

used once the operating instructions have been carefully studied.

Improper use of the controlling device can lead to accidents, malfunction or damage to the control itself.

2. Before every start-up check the equipment for operational safety

(regular servicing is essential)!

3. Safety regulations BGI 764 and VDE regulations DIN VDE 0147,

Part 1, must be observed for safe operation.

4. Safety precautions specified by local legislation must be observed.

5. The plug must be disconnected before the machine is opened for

repair.

6. The plug and socket connection between the powder spraying

equipment and the mains network should only be taken out when

the power is switched off.

V 05/10

OptiFlex B manual coating equipment General safety regulations 5

7. The connecting cable between the controlling device and the

spray gun must be set up so that it cannot be damaged during

operation. Safety precautions specified by local legislation must

be observed!

8. Only original ITW-Gema spare parts should be used, because

the explosion protection will also be preserved that way. Damage

caused by other parts is not covered by guarantee.

9. If ITW-Gema powder spraying equipment is used in conjunction

with machinery from other manufacturers then their safety regulations must also be taken into account.

10. Before starting work familiarize yourself with all installations and

operating elements, as well as with their functions! Familiarization during operation is too late!

11. Caution must be exercised when working with a powder/air mix-

ture! A powder/air mixture in the right concentration is flammable!

Smoking is forbidden in the entire plant area!

12. As a general rule for all powder spraying installations, persons

with pacemakers should never enter high voltage areas or areas

with electromagnetic fields. Persons with pacemakers should not

enter areas with powder spraying installations!

WARNING!

We emphasize that the customer himself is responsible for the safe

operation of equipment. ITW-Gema is in no way responsible for any

resulting damages!

Safety conscious working

Each person responsible for the assembly, start-up, operation, service

and repair of powder spraying equipment must have read and understood the operating instructions and the “Safety regulations”-chapter. The

operator must ensure that the user has had the appropriate training for

powder spraying equipment and is aware of the possible sources of danger.

The control devices for the spray guns must only be set up and used in

zone 22. Only the spray gun should be used in zone 21.

The powder spraying equipment should only be used by trained and authorized personnel. This applies to modifications to the electrical equipment, which should only be carried out by a specialist.

The operating instructions and the necessary closing down procedures

must be followed before any work is carried out concerning the set-up,

start-up, operation, modification, operating conditions, mode of operation,

servicing, inspection or repairs.

The powder spray equipment can be turned off by using the main switch

or failing that, the emergency shut-down. Individual components can be

turned off during operation by using the appropriate switches.

Individual safety regulations for the operating

firm and/or operating personnel

1. Any operating method which will negatively influence the tech-

nical safety of the powder spraying equipment is to be avoided.

V 05/10

6 General safety regulations OptiFlex B manual coating equipment

2. The operator should care about no non-authorized personnel

works on the powder spraying equipment (e.g. this also includes

using the equipment for non-conform work).

3. For dangerous materials, the employer has to provide an operating instructions manual for specifying the dangers arising for humans and environment by handling dangerous materials, as well

as the necessary preventive measures and behavior rules. The

operating instructions manual has to be written in an understandable form and in the language of the persons employed, and

has to be announced in a suitable place in the working area.

4. The operator is under obligation to check the powder spraying

equipment at least once every shift for signs of external damage,

defects or changes (including the operating chara cte ristics)

which could influence safety and to report them immediately.

5. The operator is obliged to check that the powder spraying

equipment is only operated when in satisfactory condition.

6. As far as it is necessary, the operating firm must ensure that the

operating personnel wear protective clothing (e.g. facemasks).

7. The operating firm must guarantee cleanliness and an overview

of the workplace with suitable instructions and checks in and

around the powder spraying equipment.

8. No safety devices should be dismantled or put out of operation. If

the dismantling of a safety device for set-up, repair or servicing is

necessary, reassembly of the safety devices must take place

immediately after the maintenance or repair work is finished. The

powder spraying device must be turned off while servicing is carried out. The operator must train and commit the responsible

personnel to this.

9. Activities such as checking powder fluidization or checking the

high-voltage spray gun etc. must be carried out with the powder

spraying equipment switched on.

Notes on special types of hazard

Power

It is necessary to refer once more to the danger of life from high-voltage

current if the shut-down procedures are not observed. High voltage

equipment must not be opened - the plug must first be taken out - otherwise there is danger of electric shock.

Powder

Powder/air mixtures can be ignited by sparks. There must be sufficient

ventilation in the powder coating booth. Powder lying on the floor around

the powder spraying device is a potentially dangerous source of slipping.

Static charges

Static charges can have the following consequences: Charges to people,

electric shocks, sparking. Charging of objects must be avoided - see

"Earthing".

Grounding/Earthing

All electricity conducting parts and machinery found in the workplace (according to DIN VDE 0745, part 102) must be earthed 1.5 meters either

V 05/10

OptiFlex B manual coating equipment General safety regulations 7

side and 2.5 meters around each booth opening. The earthing resistance

must amount to maximally 1 MOhm. The resistance must be tested on a

regular basis. The condition of the machinery surroundings as well as the

suspension gear must ensure that the machinery remains earthed. If the

earthing of the machinery includes the suspension arrangements, then

these must constantly be kept clean in order to guarantee the necessary

conductivity. The appropriate measuring devices must be kept ready in

the workplace in order to check the earthing.

Compressed air

When there are longer pauses or stand-still times between working, the

powder spraying equipment should be drained of compressed air. There

is a danger of injury when pneumatic hoses are damaged and from the

uncontrolled release and improper use of compressed air.

Crushing and cutting

During operation, moving parts may automatically start to move in the

operating area. It must be ensured that only instructed and trained personnel go near these parts. The operator should ensure that barriers

comply with the local security regulations.

Access under exceptional circumstances

The operating firm must ensure that local conditions are met when repairs are made to the electronic parts or when the equipment is restarted

so that there are additional measures such as barriers to prevent unauthorized access.

Prohibition of unauthorized conversions and modifications to machines

All unauthorized conversions and modifications to electrostatic spraying

equipment are forbidden for safety reasons.

The powder spraying equipment should not be used if damaged, the faulty part must be immediately replaced or repaired. Only original ITWGema replacement parts should be used. Damage caused by other parts

is not covered by guarantee.

Repairs must only be carried out by specialists or in ITW-Gema workshops. Unauthorized conversions and modifications may lead to injury or

damage to machinery. The ITW Gema GmbH guarantee would no longer

be valid.

Safety requirements for electrostatic powder

coating

1. This equipment is dangerous if the instructions in this operating

manual are not followed.

2. All electrostatic conductive parts, in particular the machinery

within 5 meters of the coating equipment, must be earthed.

3. The floor of the coating area must conduct electricity (normal

concrete is generally conductive).

4. The operating personnel must wear electricity conducting foot-

wear (e.g. leather soles).

5. The operating personnel should hold the gun with bare hands. If

gloves are worn, these must also conduct electricity.

V 05/10

8 General safety regulations OptiFlex B manual coating equipment

6. The supplied earthing cable (green/yellow) must be connected to

the earthing screw of the electrostatic powder spraying hand appliance. The earthing cable must have a good metallic connection with the coating booth, the recovery unit and the conveyor

chain and with the suspension arrangement of the objects.

7. The electricity and powder supply to the hand guns must be set

up so that they are fully protected against heat and chemical

damage.

8. The powder coating device may only be switched on once the

booth has been started up. If the booth cuts out then the powder

coating device must be switched off.

9. The earthing of all electricity conducting devices (e.g. hooks,

conveyor chains) must be checked on a weekly basis. The earthing resistance must amount to maximally 1 MOhm.

10. The control device must be switched off if the hand gun is

cleaned or the nozzle is changed.

11. When working with cleaning agents there may be a risk of hazardous fumes. The manufacturers instructions must be observed when using such cleaning agents.

12. The manufacturers instructions and the applicable environmental

requirements must be observed when disposing of powder lacquer and cleaning agents.

13. If any part of the spray gun is damaged (broken parts, tears) or

missing then it should not be used.

14. For your own safety, only use accessories and attachments listed

in the operating instructions. The use of other parts can lead to

risk of injury. Only original ITW-Gema replacement parts should

be used.

15. Repairs must only be carried out by specialists and under no circumstances should they be carried out in the operating area. The

former protection must not be reduced.

16. Conditions leading to dangerous levels of dust concentration in

the powder spraying booths or in the powder spraying areas

must be avoided. There must be sufficient technical ventilation

available, to prevent a dust concentration of more than 50% of

the lower explosion limit (UEG) (UEG = max. permissible powder/air concentration). If the UEG is not known then a value of 10

g/m³ should be used.

A summary of the rules and regulations

The following is a list of relevant rules and regulations which are to be

observed:

V 05/10

OptiFlex B manual coating equipment General safety regulations 9

Guidelines and regulations, German professional association

BGV A1 General regulations

BGV A2 Electrical equipment and material

BGI 764 Electrostatic coating

BGR 132

Guidelines for the avoidance of the dangers of ignition

due to electrostatic charging (Guideline “Static Electricity”)

VDMA 24371

Guidelines for electrostatic coating with synthetic powder

1)

- Part 1 General requirements

- Part 2 Examples of use

Leaflets

ZH 1/310

Leaflet for the use of tools in locations where there is

danger of explosion

1)

EN European standards

RL94/9/EC

The approximation of the laws of the Member States

relating to apparatus and safety systems for their intended use in potentially explosive atmospheres

EN 292-1

EN 292-2

Machine safety

2)

EN 50 014 to EN

50 020, identical:

DIN VDE

0170/0171

Electrical equipment for locations where there is danger

of explosion

3)

EN 50 050

Electrical apparatus for potentially explosive atmospheres - Electrostatic hand-held spraying equipment

2)

EN 50 053, part 2

Requirements for the selection, installation and use of

electrostatic spraying equipment for flammable materials - Hand-held electrostatic powder spray guns

2)

EN 50 177

Stationary electrostatic spraying equipment for flammable coating powder

2)

PR EN 12981

Coating plants - Spray booths for application of organic

powder coating material - Safety requirements

EN 60 529, identical: DIN 40050

IP-Type protection: contact, foreign bodies and water

protection for electrical equipment

2)

EN 60 204 identical: DIN VDE 0113

VDE regulations for the setting up of high-voltage electrical machine tools and processing machines with

mains voltages up to 1000 V

3)

VDE (Association of German Engineers) Regulations

DIN VDE 0100

Regulations for setting-up high voltage equipment with

mains voltages up to 1000V

4)

DIN VDE 0105

part 1

part 4

VDE regulations for the operation of high voltage

equipment

4)

General regulations

Supplementary definitions for stationary electrical spray-

ing equipment

DIN VDE 0147

part 1

Setting up stationary electrostatic spraying equipment

4)

DIN VDE 0165

Setting up electrical equipment in locations in areas with

danger of explosion

4)

V 05/10

10 General safety regulations OptiFlex B manual coating equipment

*Sources:

1)

Carl Heymanns Verlag KG, Luxemburger Strasse 449, 5000 Köln 41,

or from the appropriate employers association

2)

Beuth Verlag GmbH, Burgrafenstrasse 4, 1000 Berlin 30

3)

General secretariat, Rue Bréderode 2, B-1000 Bruxelles, or the appro-

priate national committee

4)

VDE Verlag GmbH, Bismarckstrasse 33, 1000 Berlin 12

Product specific security measures

- The installation work, to be done by the customer, must be

carried out according to local regulations

- Before starting up the plant a check must be made that no

foreign objects are in the booth or in the ducting (input and

exhaust air)

- It must be observed, that all components are grounded ac-

cording to the local regulations, before start-up

Loading...

Loading...