ITW Gema OptiFlex 2 C Operating Instructions And Spare Parts List

En

Operating instructions and spare parts list

Manual coating equipment

OptiFlex 2 C

Translation of the original operating instructions

V 06/11

Documentation OptiFlex 2 C

© Copyright 2010 ITW Gema GmbH

All rights reserved.

This publication is protected by copyright. Unauthorized copying is

prohibited by law. No part of this publication may be reproduced,

photocopied, translated, stored on a retrieval system or transmitted in

any form or by any means for any purpose, neither as a whole nor

partially, without the express written consent of ITW Gema GmbH.

OptiFlex, OptiTronic, OptiGun, EasyTronic, OptiSelect, OptiFlow and

SuperCorona are registered trademarks of ITW Gema GmbH.

OptiMatic, OptiMove, OptiMaster, OptiPlus, PowerClean, Precise Charge

Control (PCC), OptiSpray, MultiTronic and Gematic are trademarks of

ITW Gema GmbH.

All other product names are trademarks or registered trademarks of their

respective holders.

Reference is made in this manual to different trademarks or registered

trademarks. Such references do not mean that the manufacturers

concerned approve of or are bound in any form by this manual. We have

endeavored to retain the preferred spelling of the trademarks, and

registered trademarks of the copyright holders.

To the best of our knowledge and belief, the information contained in this

publication was correct and valid on the date of publication. ITW Gema

GmbH makes no representations or warranties with respect to the

contents or use of this publication, and reserves the right to revise this

publication and make changes to its content without prior notice.

Printed in Switzerland

ITW Gema GmbH

Mövenstrasse 17

9015 St.Gallen

Switzerland

Phone: +41-71-313 83 00

Fax.: +41-71-313 83 83

E-Mail: info@itwgema.ch

Homepage: www.itwgema.ch

V 06/11

Table of contents

General safety regulations 3

Safety symbols (pictograms) ................................................................................... 3

Conformity of use .................................................................................................... 8

Product-specific safety measures ........................................................................... 8

OptiFlex 2 C Manual coating equipment .................................................... 8

About this manual 9

General information ................................................................................................ 9

Product description 11

Field of application ................................................................................................ 11

Utilization .................................................................................................. 11

Reasonably foreseeable misuse .............................................................. 12

Technical data ....................................................................................................... 12

Connectable guns .................................................................................... 12

Air flow rates ............................................................................................ 12

Electrical data .......................................................................................... 13

Pneumatic data ........................................................................................ 13

Dimensions .............................................................................................. 13

Processible powders ................................................................................ 13

Design and function .............................................................................................. 14

General view ............................................................................................ 14

Scope of delivery .................................................................................................. 15

OptiFlex 2 C ............................................................................................. 15

Typical properties - Characteristics of the functions ............................................. 15

Processing the powder from the application cup ..................................... 15

Start-up 17

Preparation for start-up ......................................................................................... 17

Basic conditions ....................................................................................... 17

Set-up .................................................................................................................... 17

Mounting instructions ............................................................................................ 18

Connection instructions ......................................................................................... 18

Initial start-up 21

Setting the device type .......................................................................................... 22

Operation .............................................................................................................. 23

Coating ..................................................................................................... 23

Setting the background illumination ......................................................... 26

Color change ......................................................................................................... 26

General information ................................................................................. 26

Shutdown .............................................................................................................. 27

Cleaning and maintenance 29

Daily maintenance ................................................................................................ 29

OptiFlex 2 C Table of contents 1

V 06/11

Weekly maintenance ............................................................................................ 29

If in disuse for several days .................................................................................. 29

Cleaning ................................................................................................................ 30

Cleaning the application cup ................................................................... 30

Cleaning the OptiFlex 2 GM03 manual powder gun ............................... 30

Maintenance and cleaning of the filter unit ........................................................... 31

Replacing the filter element ..................................................................... 31

Troubleshooting 33

General information .............................................................................................. 33

Spare parts list 35

Ordering spare parts ............................................................................................. 35

OptiFlex 2 C manual coating equipment - Spare Parts List ................................. 36

OptiFlex 2 C manual coating equipment - Spare Parts ........................................ 37

OptiFlex 2 C - Pneumatic group ........................................................................... 38

2 Table of contents OptiFlex 2 C

V 06/11

General safety regulations

This chapter sets out the fundamental safety regulations that must be

followed by the user and third parties using OptiFlex 2 C manual coating

equipment.

These safety regulations must be read and understood in full before the

OptiFlex 2 C is put into operation.

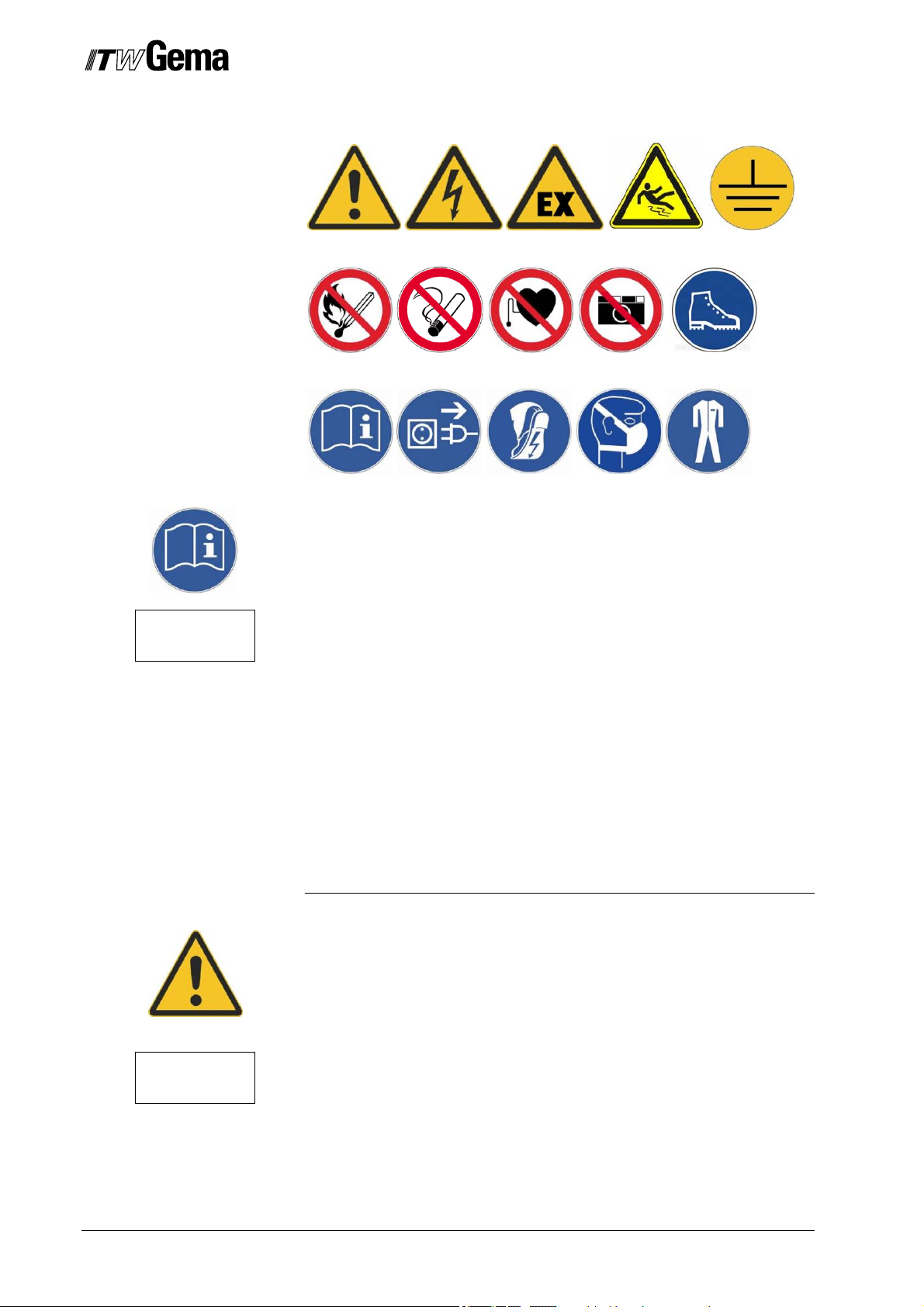

Safety symbols (pictograms)

The following warnings with their meanings can be found in the ITW

Gema operating instructions. The general safety precautions must also

be followed as well as the regulations in the operating instructions.

DANGER!

danger due to live electricity or moving parts. Possible consequences:

death or serious injury

WARNING!

improper use of the equipment could damage the machine or cause it to

malfunction. Possible consequences: minor injuries or damage to

equipment

INFORMATION!

Useful tips and other information

OptiFlex 2 C General safety regulations 3

V 06/11

General

information

The OptiFlex 2 C manual coating equipment is state of the art equipment

that conforms to the recognized technical safety regulations and is

designed for normal powder coating applications.

Any other use is considered non-compliant. The manufacturer shall not

be liable for damage resulting from such use; the user bears sole

responsibility for such actions. ITW Gema GmbH must be consulted

before OptiFlex 2 C manual coating equipment is used for any other

purposes or substances beyond those indicated here.

Observance of the operating, service and maintenance instructions

specified by the manufacturer is also part of conformity of use.

The relevant accident prevention regulations, as well as other generally

recognized safety regulations, occupational health and structural

regulations are to be observed.

Furthermore, the country-specific safety regulations also must be

observed.

Additional safety and operation notices can be found on the

accompanying CD or on the homepage www.itwgema.ch.

Start-up is forbidden until it has been established that the OptiFlex 2 C

manual coating equipment has been set up and wired according to the

EU guidelines for machinery.

Unauthorized modifications to the OptiFlex 2 C Manual coating

equipment exempt the manufacturer from any liability from resulting

damages or accidents.

General

dangers

The operator must ensure that all users have received appropriate

training for powder spraying equipment and are aware of the possible

sources of danger.

Any operating method, which will negatively influence the technical safety

of the powder spraying equipment, is to be avoided.

4 General safety regulations OptiFlex 2 C

V 06/11

For your own safety, only use accessories and attachments listed in the

operating instructions. The use of other parts can lead to risk of injury.

Only original ITW Gema spare parts should be used!

Repairs must only be carried out by specialists or by authorized ITW

Gema service centers. Unauthorized conversions and modifications can

lead to injuries and damage to the equipment and invalidate the ITW

Gema GmbH guarantee.

The connecting cables between the control unit and the spray gun must

be installed so as to eliminate the possibility of damage during the

operation. Please observe the local safety regulations!

The plug connections between the powder spraying equipment and the

mains should only be removed when the power supply is switched off.

Electrical

danger

Explosion hazard

All maintenance activities must take place when the powder spraying

equipment is switched off.

The powder coating equipment may not be switched on until the booth is

in operation. If the booth stops, the powder coating device must switch off

too.

The control units for the spray guns must be installed and used in zone

22. Spray guns are allowed in zone 21.

Only original ITW Gema OEM parts are guaranteed to maintain the

explosion protection rating. If damages occur related to the use of spare

parts from other manufacturers, all relevant warranty or compensation

claims are void!

Conditions leading to dangerous levels of dust concentration in the

powder spraying booths or in the powder spraying areas must be

avoided. There must be sufficient technical ventilation available, to

prevent a dust concentration of greater than 50% of the lower explosion

limit (UEG = max. permissible powder/air concentration). If the UEG is

not known, then a value of 10 g/m³ should be considered (see EN

50177).

All unauthorized conversions and modifications to the electrostatic

spraying equipment are forbidden for safety reasons.

The safety devices may not be dismantled or put out of operation.

Mandatory operational and workplace notices from the operating

company must be written in a comprehensible manner in the language of

equipment operators and posted in a suitable place.

OptiFlex 2 C General safety regulations 5

Slip hazard

V 06/11

Powder lying on the floor around the powder spraying equipment is a

potentially dangerous source of slipping. Booths may be entered only in

the places designed for this purpose.

Static charges

Static charges can have the following consequences: Charges to people,

electric shocks, sparking. Proper grounding must be in place to prevent

objects from becoming charged.

Grounding

All electrically conductive parts found within 5 meters around each booth

opening, and in particularly the objects to be coated, must be grounded.

The grounding resistance of each object must amount to maximally 1

MOhm. This resistance must be checked/tested regularly when starting

work.

Observe the

grounding

regulations

Fire and smoke

prohibition

The condition of the work piece attachments, as well as the hangers,

must guarantee that the work pieces remain grounded. The appropriate

measuring devices must be kept ready in the workplace, in order to

check the grounding.

The floor of the coating area must conduct electricity (normal concrete is

generally conductive).

The supplied grounding cable (green/yellow) must be connected to the

grounding screw of the electrostatic manual powder coating equipment.

The grounding cable must have a good metallic connection with the

coating booth, the recovery unit and the conveyor chain, respectively with

the suspension arrangement of the objects.

Smoking and igniting fire are forbidden in the entire vicinity of the system!

No work that could potentially produce sparks is allowed!

6 General safety regulations OptiFlex 2 C

V 06/11

As a general rule for all powder spraying installations, persons with

pacemakers should never enter high voltage areas or areas with

electromagnetic fields. Persons with pacemakers should not enter areas

The stay for persons

with cardiac

pacemakers is

forbidden

Photographing with

flashlight is

forbidden

with powder spraying installations!

Photographing with flashlight can lead to unnecessary releases and/or

disconnections by safety devices.

Disconnect from

mains before

maintenance works

take place

Disconnect the plugs before the machines are opened for maintenance

or repair.

The plug connections between the powder spraying equipment and the

mains should only be removed when the power supply is switched off.

As far as it is necessary, the operating firm must ensure that the

operating personnel wear protective clothing (e.g. facemasks).

A dust mask corresponding to filter class FFP2 at minimum must be worn

during any cleaning work.

The operating personnel must wear electrically conductive, steel-toe

footwear (e.g. leather soles).

The operating personnel should hold the gun with bare hands. If gloves

are worn, these must also conduct electricity.

These general safety regulations must

be read and understood in all cases

prior to start-up!

OptiFlex 2 C General safety regulations 7

V 06/11

Conformity of use

1. The OptiFlex 2 C manual coating equipment is state of the art

equipment that conforms to the recognized technical safety

regulations and is designed for normal powder coating

applications.

2. Any other use is considered non-compliant. The manufacturer

shall not be liable for damage resulting from such use; the user

bears sole responsibility for such actions. ITW Gema GmbH

must be consulted before OptiFlex 2 C manual coating

equipment is used for any other purposes or substances beyond

those indicated here.

3. Observance of the operating, service and maintenance

instructions specified by the manufacturer is also part of

conformity of use. The OptiFlex 2 C manual coating equipment

should only be used, maintained and started up by trained

personnel informed and familiar with the possible hazards

involved.

4. Start-up (i.e. operation of its intended use) is not allowed until it

has been established that the OptiFlex 2 C manual coating

equipment has been installed and wired according to the EU

Machinery Directive (2006/42/EC). EN 60204-1 (machine safety)

must also be observed.

5. Unauthorized modifications to the OptiFlex 2 C manual coating

equipment exempt the manufacturer from any liability from

resulting damage.

6. The relevant accident prevention regulations, as well as other

generally recognized safety regulations, occupational health and

structural regulations are to be observed.

7. Furthermore, the country-specific safety regulations also must be

observed.

Product-specific safety measures

- Installation work performed by the customer must be carried

out according to local regulations.

- All components must be grounded according to the local

regulations before start-up.

OptiFlex 2 C Manual coating equipment

The OptiFlex 2 C manual coating equipment is a constituent part of the

equipment and is therefore integrated in the system's safety concept.

If it is to be used in a manner outside the scope of the safety concept,

then corresponding measures must be taken.

Note:

For further security information, see the more detailed ITW Gema

safety regulations!

8 General safety regulations OptiFlex 2 C

V 06/11

About this manual

General information

This operating manual contains all important information required to work

with the OptiFlex 2 COptiFlex 2 C-en.doc manual coating equipment. It

will safely guide you through the start-up process and give you

references and tips for the optimal use of your new powder coating

system.

Information about the functionality of the individual system components booth, gun control unit, manual gun or powder injector - should be

referenced to their enclosed corresponding documents.

OptiFlex 2 C About this manual 9

V 06/11

Product description

Field of application

The OptiFlex 2 C (with application cup) manual coating equipment is

exclusively intended for electrostatic coating using organic powders (For

more on this please also review chapter "Technical Data").

Any other use is considered non-compliant. The manufacturer is not

responsible for any incorrect use and the risks associated with such

actions are assumed by the user alone!

For a better understanding of the interrelationships in powder coating, it

is recommended that the operating instructions for all other components

be read as well, so as to be familiar with their functions too!

OptiFlex 2 C Manual coating equipment

Utilization

The electrostatic OptiFlex 2 C manual coating equipment with the

OptiFlex 2 GM03 manual powder gun is ideally suited for manual coating

of objects.

OptiFlex 2 C Product description 11

Loading...

Loading...