En

Operating instructions and spare parts list

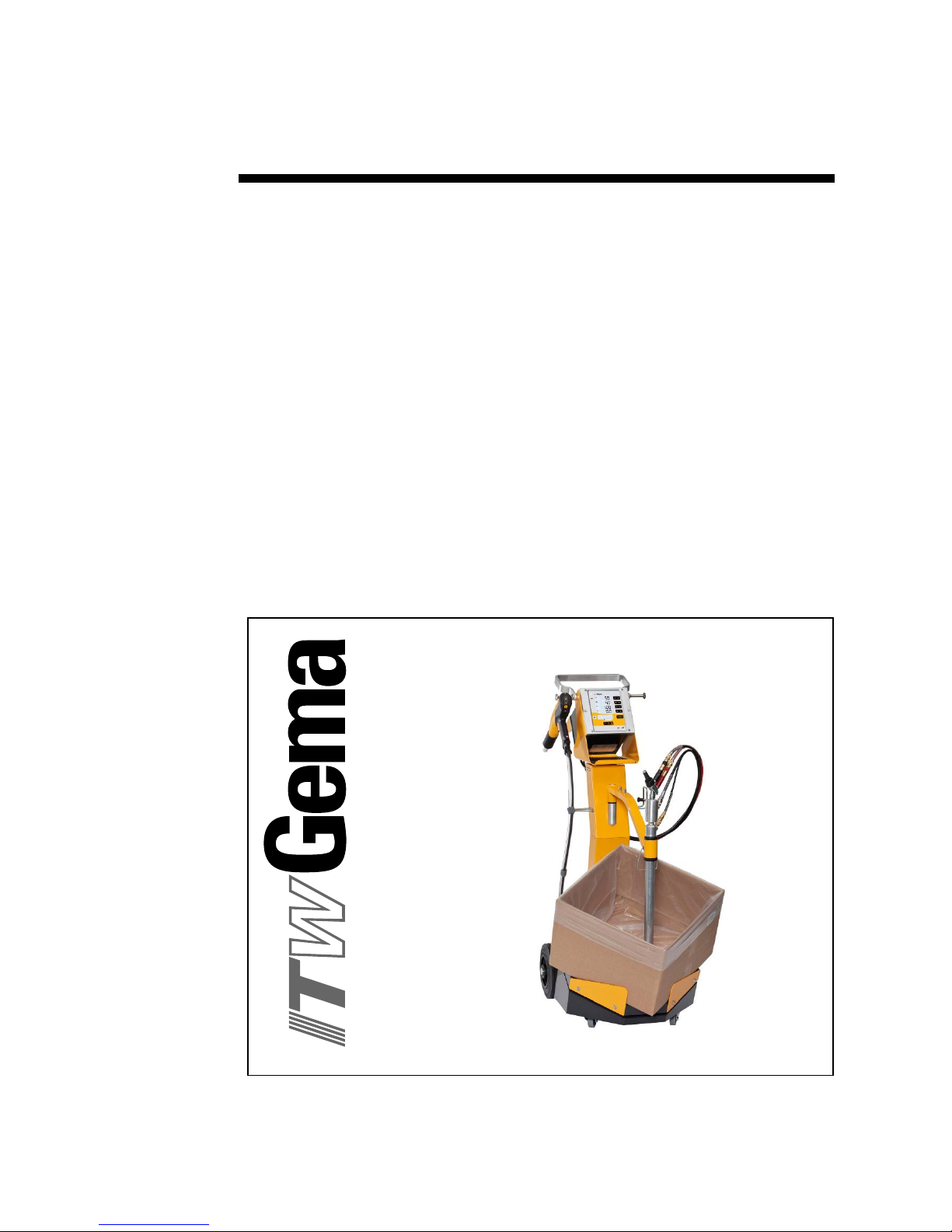

Manual coating equipment

OptiFlex 2 B

Translation of the original operating instructions

V 05/11

Documentation OptiFlex 2 B

© Copyright 2010 ITW Gema GmbH

All rights reserved.

This publication is protected by copyright. Unauthorized copying is

prohibited by law. No part of this publication may be reproduced,

photocopied, translated, stored on a retrieval system or transmitted in

any form or by any means for any purpose, neither as a whole nor

partially, without the express written consent of ITW Gema GmbH.

OptiTronic, OptiGun, EasyTronic, EasySelect, OptiFlow and

SuperCorona are registered trademarks of ITW Gema GmbH

OptiMatic, OptiMove, OptiMaster, OptiPlus, PowerClean, Precise Charge

Control (PCC), OptiSpray, MultiTronic and Gematic are trademarks of

ITW Gema GmbH.

All other product names are trademarks or registered trademarks of their

respective holders.

Reference is made in this manual to different trademarks or registered

trademarks. Such references do not mean that the manufacturers

concerned approve of or are bound in any form by this manual. We have

endeavored to retain the preferred spelling of the trademarks, and

registered trademarks of the copyright holders.

To the best of our knowledge and belief, the information contained in this

publication was correct and valid on the date of publication. ITW Gema

GmbH makes no representations or warranties with respect to the

contents or use of this publication, and reserves the right to revise this

publication and make changes to its content without prior notice.

Printed in Switzerland

ITW Gema GmbH

Mövenstrasse 17

9015 St. Gallen

Switzerland

Phone: +41-71-313 83 00

Fax.: +41-71-313 83 83

E-Mail: info@itwgema.ch

Homepage: www.itwgema.ch

V 05/11

OptiFlex 2 B Table of contents 1

Table of contents

General safety regulations 3

Safety symbols (pictograms) ................................................................................... 3

Conformity of use .................................................................................................... 8

Product-specific safety measures ........................................................................... 8

OptiFlex 2 B manual coating equipment .................................................... 8

About this manual 9

General information ................................................................................................ 9

Product description 11

Field of application ................................................................................................ 11

Utilization .................................................................................................. 11

Reasonably foreseeable misuse .............................................................. 12

Technical data ....................................................................................................... 12

Connectable guns .................................................................................... 12

Powder output (guide values) .................................................................. 12

Guide values for OptiFlex 2 CG09 with the OptiFlow IG06 injector ......... 13

Air flow rates ............................................................................................ 13

Electrical data .......................................................................................... 13

Pneumatic data ........................................................................................ 14

Dimensions .............................................................................................. 14

Processible powders ................................................................................ 14

Design and function .............................................................................................. 15

General view ............................................................................................ 15

Scope of delivery .................................................................................................. 16

OptiFlex 2 B ............................................................................................. 16

Typical properties - Characteristics of the functions ............................................. 16

Processing the powder directly from the original powder manufacturer's

container .................................................................................................. 16

Freely rotating head piece ....................................................................... 16

Start-up 17

Preparation for start-up ......................................................................................... 17

Basic conditions ....................................................................................... 17

Set-up .................................................................................................................... 17

Mounting instructions ............................................................................................ 18

Connection instructions ......................................................................................... 19

Initial start-up 21

Set head piece ...................................................................................................... 22

Setting the device type .......................................................................................... 22

Operation .............................................................................................................. 23

Coating ..................................................................................................... 23

Setting the background illumination ......................................................... 26

Color change ......................................................................................................... 27

General information ................................................................................. 27

V 05/11

2 Table of contents OptiFlex 2 B

Shutdown .............................................................................................................. 30

Cleaning and maintenance 31

Daily maintenance ................................................................................................ 31

Weekly maintenance ............................................................................................ 31

If in disuse for several days .................................................................................. 31

Powder hose rinsing ................................................................................ 32

Cleaning ................................................................................................................ 32

Cleaning the fluidizing/suction unit .......................................................... 32

Cleaning the OptiFlex 2 GM03 manual powder gun ............................... 32

Maintenance and cleaning of the filter unit ........................................................... 33

Replacing the filter element ..................................................................... 33

Troubleshooting 35

General information .............................................................................................. 35

Spare parts list 37

Ordering spare parts ............................................................................................. 37

OptiFlex 2 B manual coating equipment – Spare parts ........................................ 38

OptiFlex 2 B manual coating equipment – Spare parts ........................................ 39

OptiFlex 2 B – Pneumatic group........................................................................... 40

V 05/11

OptiFlex 2 B General safety regulations 3

General safety regulations

This chapter sets out the fundamental safety regulations that must be

followed by the user and any third parties using OptiFlex 2 B manual

coating equipment.

These safety regulations must be read and understood in full before the

OptiFlex 2 B is put into operation.

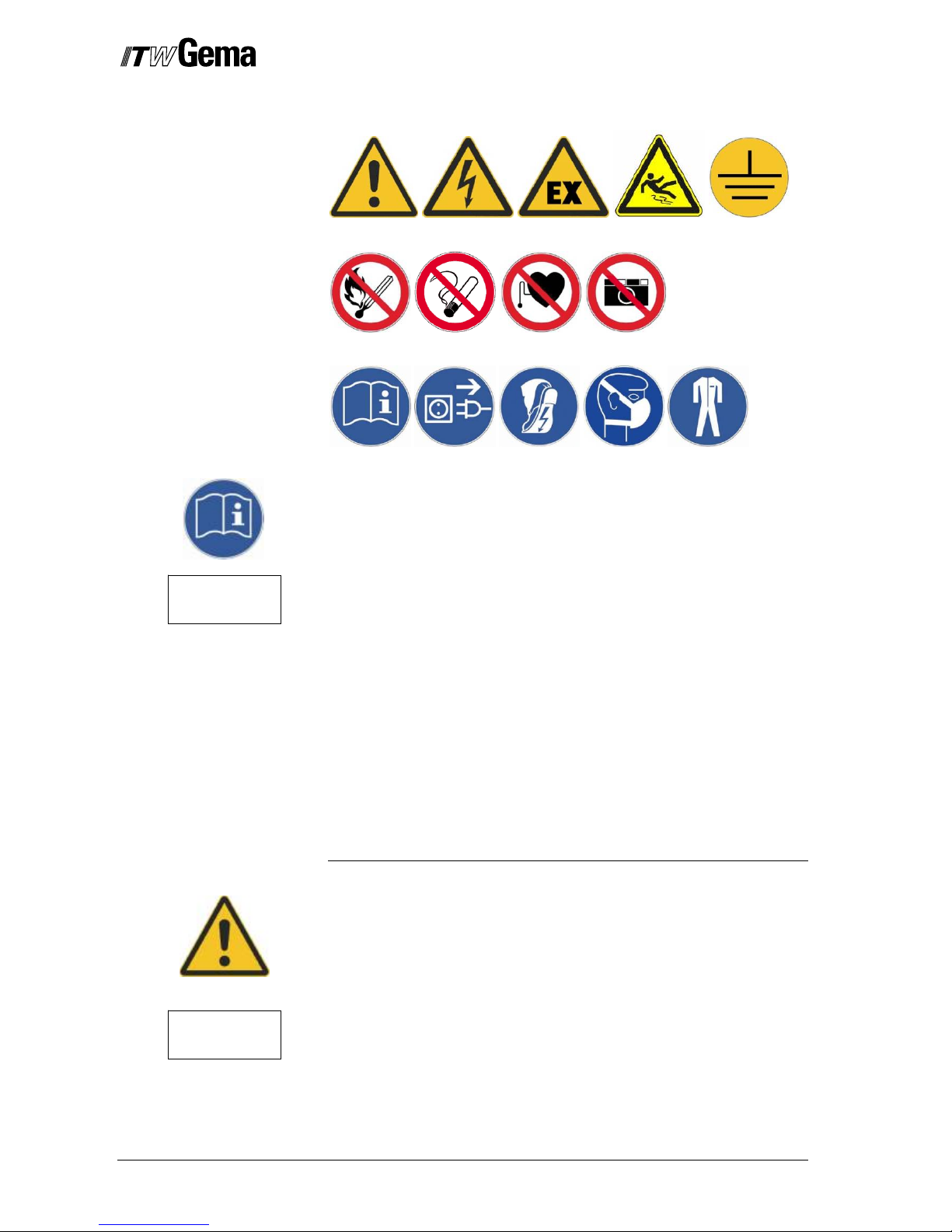

Safety symbols (pictograms)

The following warnings with their meanings can be found in the ITW

Gema operating instructions. The general safety precautions must also

be followed as well as the regulations in the operating instructions.

DANGER!

Danger due to live electricity or moving parts. Possible consequences:

death or serious injury

WARNING!

Improper use of the equipment could damage the machine or cause it to

malfunction. Possible consequences: light injuries or damage to the

equipment

INFORMATION!

Useful tips and other information

V 05/11

4 General safety regulations OptiFlex 2 B

The OptiFlex 2 B Manual coating equipment is built to the latest

specification and conforms to the recognized technical safety regulations.

It is designed for the normal application of powder coating.

Any other use is considered non-compliant. The manufacturer shall not

be liable for damage resulting from any such non-compliant use and the

user shall bear sole responsibility for such actions. ITW Gema GmbH

must be consulted prior to any use of the OptiFlex 2 B Manual coating

equipment for purposes or substances beyond those stipulated in our

guidelines.

Observance of the operating, service and maintenance instructions

specified by the manufacturer is also part of the conformity of use.

The relevant accident prevention regulations, as well as other generally

recognized safety regulations, occupational health and structural

regulations are to be observed.

Furthermore, the country-specific safety regulations also must be

observed.

Additional safety and operation notices can be found on the

accompanying CD or on the homepage www.itwgema.ch.

Start-up is forbidden until it has been established that the OptiFlex 2 B

manual coating equipment has been set up and wired according to the

EU guidelines for machinery.

Unauthorized modifications to the OptiFlex 2 B Manual coating

equipment exempts the manufacturer from any liability from resulting

damages or accidents.

The operator must ensure that all users have received appropriate

training for powder spraying equipment and are aware of the possible

sources of danger.

Any operating method, which will negatively influence the technical safety

of the powder spraying equipment, is to be avoided.

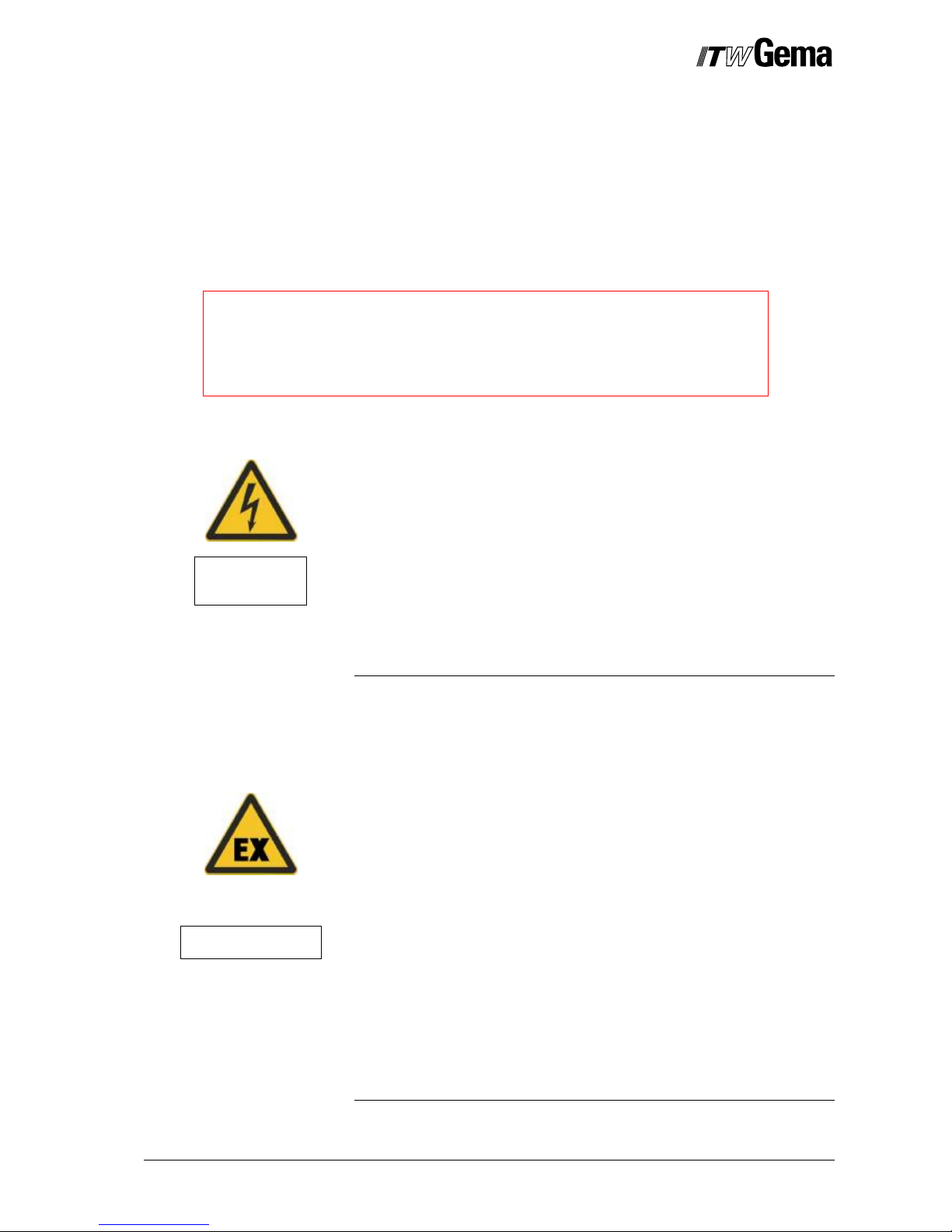

General

dangers

General

Information

V 05/11

OptiFlex 2 B General safety regulations 5

For your own safety, only use accessories and attachments listed in the

operating instructions. The use of other parts can lead to risk of injury.

Only original ITW Gema spare parts should be used!

Repairs must only be carried out by specialists or by authorized ITW

Gema service centers. Unauthorized conversions and modifications can

lead to injuries and damage to the equipment and invalidate the ITW

Gema GmbH guarantee.

These general safety regulations must

be read and understood in all cases

prior to start-up!

The connecting cables between the control unit and the spray gun must

be installed so as to eliminate the possibility of damage during the

operation. Safety precautions specified by local legislation must be

observed!

The plug connections between the powder spraying equipment and the

mains should only be removed when the power supply is switched off.

All maintenance activities must take place when the powder spraying

equipment is switched off.

The powder coating equipment may not be switched on until the booth is

in operation. If the booth stops, the powder coating device must switch off

too.

The control units for the spray guns must be installed and used in

zone 22. Spray guns are allowed in zone 21.

Only original ITW Gema OEM parts are guaranteed to maintain the

explosion protection rating. If damages occur related to the use of spare

parts from other manufacturers, all relevant warranty or compensation

claims are void!

Conditions leading to dangerous levels of dust concentration in the

powder spraying booths or in the powder spraying areas must be

avoided. There must be sufficient technical ventilation available, to

prevent a dust concentration of greater than 50% of the lower explosion

limit (UEG = max. permissible powder/air concentration). If the UEG is

not known, then a value of 10 g/m³ should be considered (see

EN 50177).

All unauthorized conversions and modifications to the electrostatic

spraying equipment are forbidden for safety reasons.

The safety devices may not be dismantled or put out of operation.

Mandatory operational and workplace notices from the operating

company must be written in a comprehensible manner in the language of

equipment operators and posted in a suitable location.

Electrical

dangers

Explosive danger

V 05/11

6 General safety regulations OptiFlex 2 B

Powder lying on the floor around the powder spraying equipment is a

potentially dangerous source of slipping. Booths may be entered only in

the places designed for this purpose.

Static charges

Static charges can have the following consequences: Charges to people,

electric shocks, sparking. Proper grounding must be in place to prevent

objects from becoming charged.

Grounding

All electrically conductive parts found within 5 meters around each booth

opening, and in particularly the objects to be coated, must be grounded.

The grounding resistance of each object must amount to maximally

1 MOhm. This resistance must be checked/tested regularly when starting

work.

The condition of the work piece attachments, as well as the hangers,

must guarantee that the work pieces remain grounded. The appropriate

measuring devices must be kept ready in the workplace, in order to

check the grounding.

The floor of the coating area must conduct electricity (normal concrete is

generally conductive).

The supplied grounding cable (green/yellow) must be connected to the

grounding screw of the electrostatic manual powder coating equipment.

The grounding cable must have a good metallic connection with the

coating booth, the recovery unit and the conveyor chain, respectively with

the suspension arrangement of the objects.

Smoking and open flames are forbidden in the entire plant area! No work

that could potentially produce sparks is allowed!

Slipping

danger

No smoking or open

flames

Strict compliance

with grounding

requirements

V 05/11

OptiFlex 2 B General safety regulations 7

As a general rule for all powder spraying installations, persons with

pacemakers should never enter high voltage areas or areas with

electromagnetic fields. Persons with pacemakers should not enter areas

with powder spraying installations!

Photographing with flashlight can lead to unnecessary releases and/or

disconnections by safety devices.

Disconnect the plugs before the machines are opened for maintenance

or repair.

The plug connections between the powder spraying equipment and the

mains should only be removed when the power supply is switched off.

As far as it is necessary, the operating firm must ensure that the

operating personnel wear protective clothing (e.g. facemasks).

The operating personnel must wear electrically conductive footwear (e.g.

leather soles).

The operating personnel should hold the gun with bare hands. If gloves

are worn, these must also conduct electricity.

These general safety regulations must

be read and understood in all cases

prior to start-up!

No flash

photography

Not safe for persons

with pacemakers

Separate from

power mains before

maintenance or

repairs

V 05/11

8 General safety regulations OptiFlex 2 B

Conformity of use

1. The OptiFlex 2 B manual coating equipment is state of the art

equipment that conforms to the recognized technical safety

regulations and is designed for normal powder coating

applications.

2. Any other use is considered non-compliant. The manufacturer

shall not be liable for damages resulting from such use; the user

bears sole responsibility for such actions. ITW Gema GmbH

must be consulted before OptiFlex 2 B manual coating

equipment is used for any other purposes or substances beyond

those indicated here.

3. Observance of the operating, service and maintenance

instructions specified by the manufacturer is also part of

conformity of use. The OptiFlex 2 B manual coating equipment

should only be used, maintained and started up by trained

personnel informed and familiar with the possible hazards

involved.

4. Start-up (i.e. operation of its intended use) is not allowed

until it has been established that the OptiFlex 2 B manual coating

equipment has been installed and wired according to the EU

Machinery Directive (2006/42/EC). EN 60204-1 (machine safety)

must also be observed.

5. Unauthorized modifications to the OptiFlex 2 B manual coating

equipment exempts the manufacturer from any liability from

resulting damage.

6. The relevant accident prevention regulations, as well as other

generally recognized safety regulations, occupational health and

structural regulations are to be observed.

7. Furthermore, the country-specific safety regulations also must be

observed.

Product-specific safety measures

- Installation work performed by the customer must be carried

out according to local regulations.

- All components must be grounded according to the local

regulations before start-up.

OptiFlex 2 B manual coating equipment

The OptiFlex 2 B manual coating equipment is a constituent part of the

equipment and is therefore integrated in the system's safety concept.

If it is to be used in a manner outside the scope of the safety concept,

then corresponding measures must be taken.

Note:

For further security information, see the more detailed ITW Gema

safety regulations!

V 05/11

OptiFlex 2 B About this manual 9

About this manual

General information

This operating manual contains all important information required to work

with the OptiFlex 2 BOptiFlex 2 B-en.doc manual coating equipment. It

will safely guide you through the start-up process and give you

references and tips for the optimal use of your new powder coating

system.

Information about the functionality of the individual system components booth, gun control unit, manual gun or powder injector - should be

referenced to their enclosed corresponding documents.

V 05/11

OptiFlex 2 B Product description 11

Product description

Field of application

The OptiFlex 2 B (with powder box) manual coating equipment is

exclusively intended for electrostatic coating using organic powders (For

more on this please also review chapter "Technical Data").

Any other use is considered non-compliant. The manufacturer is not

responsible for any incorrect use, and any associated risks are assumed

by the user alone.

For a better understanding of the interrelationships in powder coating, it

is recommended that the operating instructions for all other components

be read as well, so as to be familiar with their functions too!

OptiFlex 2 B manual coating equipment

Utilization

The electrostatic OptiFlex 2 B manual coating equipment with the

OptiFlex 2 GM03 manual powder gun is ideally suited for manual coating

of objects.

V 05/11

12 Product description OptiFlex 2 B

Reasonably foreseeable misuse

- Operation without the proper training

- Use with insufficient compressed air quality and grounding

- Use in connection with unauthorized coating devices or

components

Technical data

Connectable guns

OptiFlex 2 B connectable

OptiFlex 2 GM03 yes

OptiSelect GM02 contact Gema

OptiGun GA02 contact Gema

PG3-E**

contact Gema

TriboJet*

yes

* The gun type must be configured (For more on this, please see the

operating instructions for the OptiFlex 2 CG09 manual gun control unit).

The Tribo gun the gun is not type approved (ATEX).

** Only for enamel powder, the gun is not type approved (ATEX).

Warning:

The OptiFlex 2 B manual coating equipment can only be used with

the specified gun types!

Powder output (guide values)

General conditions for the OptiFlow Injector

Powder type Epoxy/polyester

Powder hose length (m)

6

Powder hose Ø (mm)

10

Power hose type POE with guide strips

Input pressure (bar)

5,5

Conveying air nozzle Ø (mm)

1,6

Correction value C0 Powder output zeroing adjustment

V 05/11

OptiFlex 2 B Product description 13

Guide values for OptiFlex 2 CG09 with the

OptiFlow IG06 injector

All values in these tables are guide values. Differing environmental

conditions, wear and different powder types can affect the table values.

Total air

3 Nm³/h 4 Nm³/h 5 Nm³/h

Powder output (g/min)

Powder output (%)

20

85 100 120

40

150 185 210

60

210 255 280

80

270 320 350

100

300 360 395

Air flow rates

The total air consists of conveying air and supplementary air, in relation

to the selected powder quantity (in %). As a result the total air volume is

maintained constant.

OptiFlex 2 B Range

Factory

setting

Flow rate - fluidizing air

- OptiFlex B 0-1.0 Nm³/h 0.1 Nm³/h

Electrode rinsing air flow rate 0-3.0 Nm³/h 0.1 Nm³/h

Flow rate total air (at 5.5 bar) 1.8-6.5 Nm³/h

Note:

The total air consumption for the device is determined

based on the 3 configured air values.

These values apply for an internal control pressure of 5.5 bar!

Electrical data

OptiFlex 2 B

Nominal input voltage 100-240 VAC

Frequency 50 -60 Hz

Connected load (without vibrator) 140 VA

Nominal output voltage (to the gun) eff.10 V

Nominal output current (to the gun) max. 1.2 A

Connection and output for vibrator (on Aux

output)

110/230 VAC

max. 100 W

Connection for rinsing function (valve)

24 VDC

max. 3 W

Temperature range

0°C - +40°C

(+32°F - +104°F)

Max. operating temperature 85°C (+185°F)

Approvals pending

V 05/11

14 Product description OptiFlex 2 B

Pneumatic data

OptiFlex 2 B

Max. input pressure 10 bar

Min. input pressure 6 bar

Input pressure (Dynamic based on pressure

regulator setting)

5.5 bar / 80 psi

Max. water vapor content of the compressed

air

1.3 g/m³

Max. oil vapor content of the compressed air 0.1 mg/m³

Max. compressed air consumption 8 Nm³/h

Dimensions

OptiFlex 2 B

Width 460 mm

Depth 862 mm

Height 1105 mm

Weight 42 kg

Processible powders

OptiFlex 2 B

Plastic powder yes

Metallic powder yes

Enamel powder no

V 05/11

OptiFlex 2 B Product description 15

Design and function

General view

OptiFlex 2 B manual coating equipment - Structure

1 OptiFlex 2 CG09 control unit 10 Filter unit

2 OptiFlex 2 GM03 manual powder gun 11 Gun holder

3 OptiFlow injector 12 Hose holder

4 Mobile frame with hand rail 13 PowerClean module

5 Fluidizing/suction unit 14 Shelf

6 Vibrating table 15 Rubber wheel

7 Powder box 16 Swivel wheel

8 Swivel arm with guide sleeve

OptiFlex 2 GM03 manual powder gun

All information about the OptiFlex 2 CM03 manual powder gun can be

found in the documentation for that equipment (enclosed with this

manual)!

OptiFlex 2 CG09 control unit

All information about the OptiFlex 2 CG09 manual gun control unit can

found in the documentation for that equipment (enclosed with this

manual)!

OptiFlow injector

All information about the OptiFlow injector can be found in the

corresponding enclosed documentation!

2

1

3

13

5

7

16

4

8

6

15

11

12

14

10

V 05/11

16 Product description OptiFlex 2 B

Scope of delivery

OptiFlex 2 B

- OptiFlex 2 CG09 control unit in a metal case with power

supply cable

- mobile trolley with a gun/hose support

- vibrating base and a fluidizing/suction unit

- plug-in OptiFlow injector

- OptiFlex 2 CM03 manual powder gun with gun cable,

powder hose, rinsing air hose and standard nozzle set

(For more on this, see the operating manual for the

OptiFlex 2 CM03 manual powder gun)

- Pneumatic hoses for conveying air (red), supplementary

air (black), fluidizing air (black) and rinsing air (black)

- Operating manual

- Short instructions

Typical properties - Characteristics of the functions

Processing the powder directly from the original

powder manufacturer's container

The OptiFlex 2 B manual coating equipment allows for powder to be

processed directly out of the original powder manufacturer's container. A

titled vibrating floor has been included to ensure that the powder

container empties itself completely.

Freely rotating head piece

The OptiFlex 2 B manual coating equipment features a freely rotating and

lockable head piece for more ergonomic operation and configuration.

Freely rotating head piece

V 05/11

OptiFlex 2 B Start-up 17

Start-up

Preparation for start-up

Basic conditions

When starting up the OptiFlex 2 manual coating unit, the following

general conditions impacting the coating results must be taken into

consideration:

- Manual coating equipment is set up properly

- Gun control unit correctly connected

- Gun correctly connected

- Corresponding power and compressed air supply available

- Powder preparation and powder quality

Set-up

The OptiFlex 2 B manual coating equipment should always be set up

vertically on a flat surface.

WARNING

The manual coating equipment must not under any circumstances

be set up near a heat source (such as an enameling furnace) or an

electromagnetic source (such as a control cabinet).

V 05/11

18 Start-up OptiFlex 2 B

Mounting instructions

The OptiFlex 2 B manual coating equipment must be set up in

accordance with the setup and connecting instructions (included with

delivery).

V 05/11

OptiFlex 2 B Start-up 19

Connection instructions

Connection instructions - overview

The OptiFlex 2 B manual coating equipment must be connected in

accordance with the setup and connection instructions (Please also

review the operating instructions for the OptiFlex 2 CG09 manual gun

control unit).

1.

2.

Note:

Use clamp to connect grounding cable to the cabin or the

suspension arrangement. Check ground connections with Ohm

meter and ensure 1 MOhm or less!

Maintenance unit

Injector

Gun

PowerClean module

Fluidizing/suction unit

V 05/11

20 Start-up OptiFlex 2 B

3. 4.

5.

6.

7.

8.

9.

10.

Note:

The compressed air must be free of oil and water!

V 05/11

OptiFlex 2 B Initial start-up 21

Initial start-up

Note:

If a malfunction occurs, see the troubleshooting guide, as well as

the gun control unit operating manual!

Note:

The remainder of the start-up procedure for the OptiFlex 2 GM03

manual powder gun is explicitly described in the operating

instructions for the OptiFlex 2 CG09 manual powder gun control

unit (chapter "Initial start-up" and "Daily start-up")!

V 05/11

22 Initial start-up OptiFlex 2 B

Set head piece

1. 2.

3.

Setting the device type

Note:

If the control unit is delivered as a integral component of an

OptiFlex apparatus, then the system parameters will have been

factory preconfigured for optimal use (For more on this, please also

see the operating instructions for the OptiFlex 2 CG09 manual gun

control unit)!

NOTE!

The manual gun control unit always starts up to the last configured

settings.

V 05/11

OptiFlex 2 B Initial start-up 23

Operation

Coating

1. Turn on the gun control unit with the ON key

The displays illuminate and the control unit is ready for operation

2. Swivel aside the fluidizing/suction unit

3. Place the open powder container on the vibrating table

4. Place the fluidizing/suction unit onto the powder

5. Set coating parameters:

6. Press the application button for the appropriate preset mode:

flat parts

complicated parts

overcoat

The arrow above the desired button lights up

OR

7. Press

program key

a) Select desired program (01-20)

b) Change coati ng parameters as required

Note:

Programs 01-20 are preset at the factory but can be modified at any

time, after which they are automatically stored.

Description Presetting

Powder output

50%

Total air

4.0 Nm³/h

High voltage 80 kV

Spray current

80 µA

Electrode rinsing air

0.1 Nm³/h

Fluidizing air 0.1 Nm³/h (for OptiFlex-B and S)

V 05/11

24 Initial start-up OptiFlex 2 B

8. Setting the total air volume

correct powder cloud too little total air

Note:

A total air volume of 4 Nm³/h and a 50% powder share are

recommended as the base values.

9. Adjust the powder output volume (e.g. according to the desired

coating thickness)

or

much powder little powder

Note:

To achieve maximum efficiency, we recommend avoided an overly

high powder volume where possible! Für den Anfang empfiehlt sich

die Standardeinstellung von 50% und eine Gesamtluftmenge von 4

Nm³/h. Die Gesamtluftmenge wird dabei automatisch von der

Steuerung konstant gehalten

If values are entered that the equipment cannot implement, then the

operator is informed of this by a blinking in the relevant display and

a temporary error message!

V 05/11

OptiFlex 2 B Initial start-up 25

10. Setting the electrode rinsing air

a) Press the key

The second display level will be shown

b)

too much electrode rinsing air

11. Setting the fluidization

a) Press the key

The second display level will be shown

b)

c) Check the powder fluidization in the powder container

The powder fluidization in the powder containers depends on

the powder characteristics, the humidity and the ambient air

temperature. Fluidizing and vibration start by switching on

the control unit.

12. Point the gun into the booth (not at the object to be coated),

press the gun trigger and visually check the powder output

13. Check whether everything is functioning correctly

14. Coating

15. Adjust the coating parameters as necessary

16. Activate the rinsing function periodically

Note:

It prevents the bridging phenomena that can lead to short circuiting

when handling powders such as metallic powders.

In moist or tropical environments, any moisture is driven from the

injector, powder hose and powder gun.

a)

- The LCD segments begin to move on the CG09 display

approx.

0.1 Nm³/h

approx.

0.5 Nm³/h

V 05/11

26 Initial start-up OptiFlex 2 B

Note:

The PowerClean function can be stopped as required using the P

key.

b)

Procedure Effect

automatic

- The automatic rinsing process is started

- Injector, powder hose, gun and spray nozzle are purged

using compressed air

- The automated PowerClean function enables parallel

cleaning of other components, such as the fluid intake

unit, powder container, etc.

manual

- The operator controls the number and length of the

PowerClean impulse by pressing the pistol trigger a

second time

After completion of the PowerClean procedure, the controller switches

back to coating mode.

Setting the background illumination

1. Press key

The display switches to the following level:

2.

Select the desired brightness

= automatically

= manually

V 05/11

OptiFlex 2 B Initial start-up 27

Color change

General information

When a color change takes place, the individual components of the

manual coating equipment must be cleaned carefully. All powder

particles of the former color must be removed during this process!

The following describes an 'extreme' color change (light to dark).

1.

2.

3. 4.

5.

6.

7.

8.

9.

10.

V 05/11

28 Initial start-up OptiFlex 2 B

11. 12.

13.

14.

15.

16.

16.

17.

18.

19.

20.

21.

22.

23.

Remove and clean the nozzle

purge gun using air

V 05/11

OptiFlex 2 B Initial start-up 29

24. 25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

V 05/11

30 Initial start-up OptiFlex 2 B

Shutdown

1. Release gun trigger

2. Switch off the control unit

Note:

The adjustments for high voltage, powder output, electrode rinsing

air and fluidizing remain stored!

If in disuse for several days

1. Separate from power mains

2. Clean the coating equipment (see the corresponding

operating manual)

3. Turn off the compressed air main supply

V 05/11

OptiFlex 2 B Cleaning and maintenance 31

Cleaning and maintenance

Note:

Regular and conscientious maintenance increases the service life of

the OptiFlex 2 B manual coating equipment and provides for a

longer continuous coating quality!

The parts, which are to be replaced during maintenance work, are

available as spare parts. These parts will be found in the

corresponding spare parts list!

Daily maintenance

1. Clean the injector (see therefore the user manual of the OptiFlow

injector)

2. Clean the powder gun (For more on this, please also review the

user manual for the OptiFlex 2 GM03 manual powder gun)

3. Clean the powder hose; Please also review the section "Color

change"

Weekly maintenance

1. Clean fluidizing/suction unit, injector, rinsing module and powder

gun. The fluidizing/suction unit is placed back into the powder

shortly before restarting operation

2. Check the control unit grounding connections to the coating

booth, the suspension devices of the work pieces, or the

conveyor chain

If in disuse for several days

1. Separate from power mains

2. Clean the coating equipment

3. Turn off the compressed air main supply

V 05/11

32 Cleaning and maintenance OptiFlex 2 B

Powder hose rinsing

If longer downtimes take place, the powder hose has to be cleaned.

Procedure:

1. Disconnect the powder hose from the hose connection on the

injector

2. Point the gun into the booth

3. Blow through the hose manually with a compressed air gun

4. Connect the powder hose again to the hose connection on the

injector

Cleaning

Cleaning the fluidizing/suction unit

1. Remove the injector

2. Remove rinsing module

3. Remove the fluidizing/suction unit

4. Clean the fluidizing/suction unit with compressed air. Also blow

off the suction tube with compressed air

5. Clean the injector (see therefore the injector user manual)

6. Clean rinsing module

7. Reassemble the individual parts

Cleaning the OptiFlex 2 GM03 manual powder

gun

Frequent cleaning of the gun helps to guarantee the coating quality.

Note:

Before cleaning the powder gun, switch off the control unit. The

compressed air used for cleaning must be free of oil and water!

Daily:

1. Blow off the outside of the gun and wipe, clean etc.

Weekly:

2. Remove the powder hose from the connection

3. Remove the spray nozzle from the gun and clean it

4. Blow out the gun from the connection in flow direction with

compressed air

5. Clean the integrated gun tube with the provided gun brush

6. Blow through the gun with compressed air again

7. Clean the powder hose

8. Reassemble the gun and connect it

V 05/11

OptiFlex 2 B Cleaning and maintenance 33

Note:

Please also review the user manual for the OptiFlex 2 GM03 manual

powder gun!

Maintenance and cleaning of the filter unit

The filter unit on the OptiFlex B manual coating equipment measures and

cleans the compressed air. This is where the equipment's main

compressed air connection is located.

Replacing the filter element

Procedure:

1. Unscrew the filter glass on the filter unit

2. Loose the cap screw

3. Remove the complete filter element

4. Replace the filter element

5. Clean the filter glass on the inside and install it again

V 05/11

OptiFlex 2 B Troubleshooting 35

Troubleshooting

General information

Note:

Prior to any troubleshooting measures, always check whether the

equipment parameters (P0) as configured in the control unit are

correct (See operating instructions for the OptiFlex 2 CG09 manual

gun control unit, Chapter "Initial Start-up – Setting Equipment

Type")

Fault Causes Troubleshooting

Control unit displays

remain dark, although

the control unit is

switched on

Control unit is not

connected to the mains

Connect the equipment

with the mains cable

Power pack fuse

defective

Replace the fuse

Power pack defective

Contact local Gema

representative

The gun does not

spray powder,

although the control

unit is switched on and

the gun trigger is

pressed

Compressed air not

present

Connect the equipment

to the compressed air

Injector, throttle motor or

nozzle on injector,

powder hose or powder

gun are clogged

Clean the corresponding

part

Insert sleeve in the

injector is clogged

Replace

Insert sleeve is not

installed

Mount insert sleeve

Fluidization not running see below

Total air incorrectly

configured

Set total air correctly

(Default value 4 Nm³/h)

Main valve defective Replace main valve

Gun LED remains

dark, although the gun

is triggered

Gun not connected Connect the gun

Gun plug, gun cable or

gun cable connection

defective

Contact local Gema

representative

Remote control on

powder gun defective

Contact local Gema

representative

Powder does not

adhere to object,

The objects are

improperly or

Check grounding,

reground at better

V 05/11

36 Troubleshooting OptiFlex 2 B

Fault Causes Troubleshooting

although the gun is

triggered and sprays

powder

insufficiently grounded quality

High voltage and current

deactivated

Press the selection key

(application key)

High voltage cascade

defective

Contact local Gema

representative

The powder is not

fluidized

Compressed air not

present

Connect the equipment

to the compressed air

Fluidizing air is set too

low on the control unit

Set the fluidizing air

correctly

Throttle motor defective

Contact local Gema

representative

No electrode rinsing air

Rinsing air throttle motor

defective

Contact local Gema

representative

Vibrator not functioning

Vibrator/condenser

broken

Contact local Gema

representative

Vibrator not plugged in plug in

Incorrect equipment

type configured

Configure parameter P0

(See operating

instructions for the

OptiFlex 2 CG09

manual gun control unit,

Chapter "Initial Start-up

– Setting Equipment

Type")

V 05/11

OptiFlex 2 B Spare parts list 37

Spare parts list

Ordering spare parts

When ordering spare parts for powder coating equipment, please in dicate

the following specifications:

- Type and serial number of your powder coating

equipment

- Order number, quantity and description of each spare

part

Example:

- Type OptiFlex 2 B

Serial number 1234 5678

- Order no. 203 386, 1 piece, Clamp - Ø 18/15 mm

When ordering cable or hose material, the required length must also be

given. The spare part numbers for this kind of bulk stock is always

marked with an *.

Wearing parts are always marked with a #.

All dimensions of plastic hoses are specified with the external and

internal diameter:

Example:

Ø 8/6 mm, 8 mm outside diameter (o/d) / 6 mm inside diameter (i/d)

WARNING!

Only original ITW Gema spare parts should be used, because the

explosion protection will also be preserved that way. The use of

spare parts from other manufacturers will invalidate the ITW Gema

guarantee conditions!

V 05/11

38 Spare parts list OptiFlex 2 B

OptiFlex 2 B manual coating equipment – Spare parts

1 CH09 gun control unit - complete (see corresponding operating manual) 1007 018

2 GM03 manual powder gun - complete (see corresponding user manual) 1008 070

3 IG06 injector - complete (see corresponding user manual) 1007 780

4

Pneumatic connection for conveying air - complete (incl. Pos. 4.1, 4.2, 4.3) 1008 030

4.1 Quick release connection - NW5, Ø 8 mm, red 261 645

4.2 Nut with kink protection – M12x1 mm, Ø 8 mm 201 316

4.3 Plastic tube - Ø 8/6 mm, red 103 500*

5

Pneumatic connection for supplementary air - complete (incl. Pos. 5.1, 5.2 and 5.3) 1008 029

5.1 Quick release connection - NW5, Ø 8 mm, black 261 637

5.2 Nut with kink protection – M12x1 mm, Ø 8 mm 201 316

5.3 Plastic tube - Ø 8/6 mm, black 1008 038*

6 Rinsing module – complete (See operating instructions OptiFlex 2 GM03 manual

powder gun)

1007 362

7

Pneumatic connection for conveying air - complete (incl. Pos. 7.1 and 7.2) 1008 032

7.1 Quick release connection - NW5, Ø 8 mm 1008 027

7.2 Plastic tube - Ø 8/6 mm, black 103 152*

8 Fluidizing/suction unit - complete 1007 509

9

Pneumatic connection for conveying air - complete (incl. Pos. 9.1, 9.2 and 9.3) 1008 031

9.1 Quick release connection - NW5, Ø 6 mm 200 840

9.2 Nut with kink protection - M10x1 mm, Ø 6 mm 201 308

9.3 Plastic tube - Ø 6/4 mm, black 1001 973

10 Pneumatic group - complete (see corresponding spare parts list)

11 Quick release connection - NW7, 8-Ø 10- Ø 26 mm 239 267

12 Rubber damper - Ø 20x25 mm, M6/2a, 43sh 246 000

13 Hexagon shakeproof nut - M6 244 430

14 Powder hose – Ø 15/10 mm, 6m 1001 673

15 Spare parts kit – MB03, consisting of: 1007 147

Insert sleeve IG06 - complete 1006 485

O-ring - Ø 16x2 mm 1007 794

O-ring – Ø 20x3 mm 1007 121

Fuse - 0.1 AT 229 520

Fuse - 2 AT 221 872

Cable tie - L=100x2.5 mm 200 71 9

16 Brief instructions 1007 143

17 Operating manual 1007 141

* Please indicate length

V 05/11

OptiFlex 2 B Spare parts list 39

OptiFlex 2 B manual coating equipment – Spare parts

OptiFlex 2 B manual coating equipment – Spare parts

15

10

14

17

16

12, 13

2

1

3

11

6

8

5

4

9

7

V 05/11

40 Spare parts list OptiFlex 2 B

OptiFlex 2 B – Pneumatic group

Pneumatic group - complete 1007 120

1 Filter cartridge - 20 µm 1007 325

OptiFlex 2 B – Pneumatic group

1

V 05/11

OptiFlex 2 B Spare parts list 41

Loading...

Loading...