ITW Gema EasyTronic Operating Instructions And Spare Parts List

23

EasyTronic

Issued 07/02

Operating Instructions and Spare Parts List

EasyTronic

Control Unit

E

24

EasyTronic

Issued 07/02

Mains connectionAux

Gun

1.1 IN

5 ... 10 bar

73...145 PSI

1.4 2.2 2.3

2.1

1.3

1.2 1.5

Input voltage:

Input power:

Degree of protection:

Output:

Corresponding guns:

85 – 264 V

47 – 440 Hz

65 VA

IP 54

10 V 1,2 A

EasySelect

POWDER GUN CONTROL

TYPE EASYTRONIC

CONNECTIONS ON THE REAR OF THE EASYTRONIC CONTROL UNIT

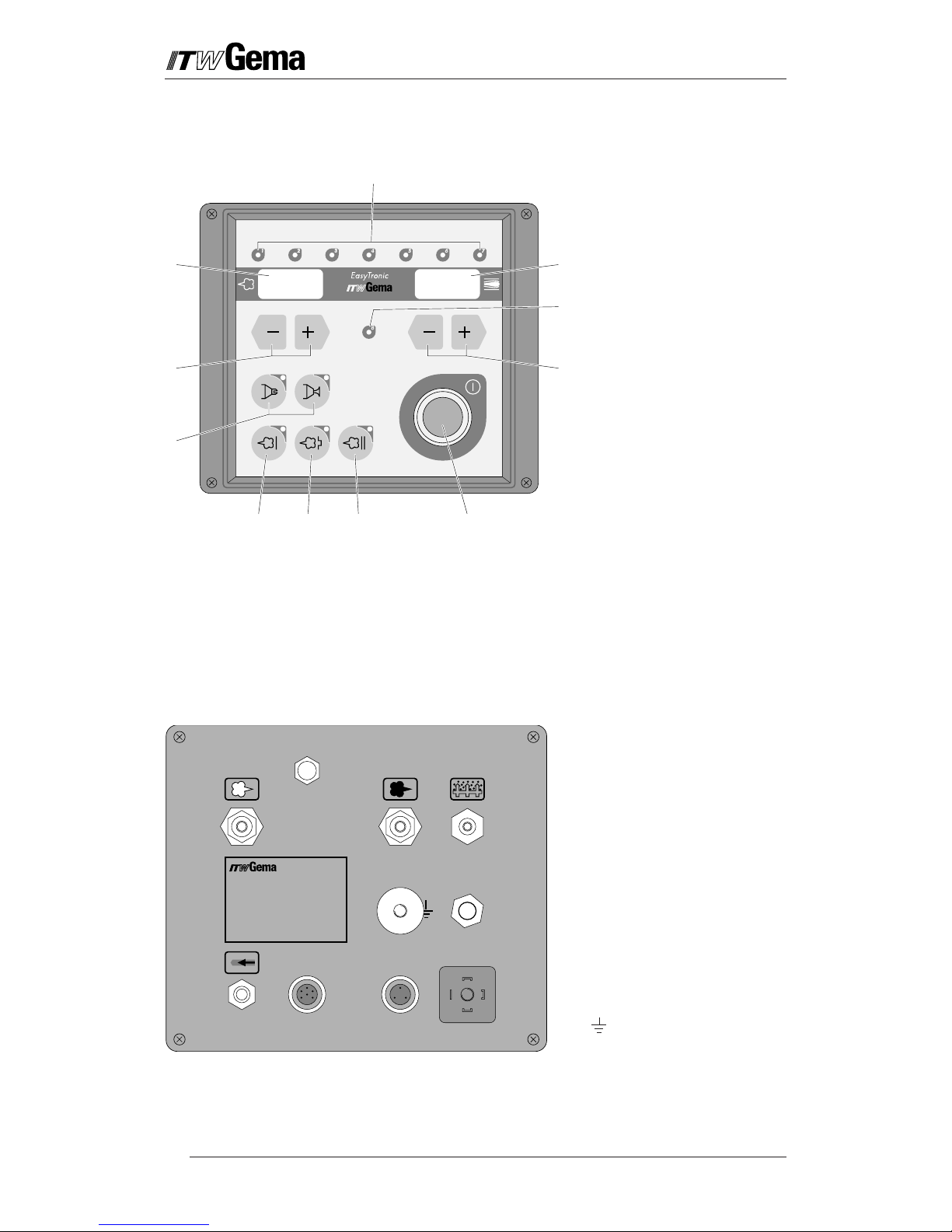

1 Diagnostic LEDs

2 Powder output display

3 Key for setting the

powder output

4 Electrode rinsing air key

5 Application key for flat

parts

6 Application key for

complicated parts

7 Application key for

overspraying

8 On / Off Push button

9 Key for setting the total

air volume

10 Diagnostic LED for High-

voltage

11 Total air volume display

EASYTRONIC CONTROL UNIT - FRONT VIEW

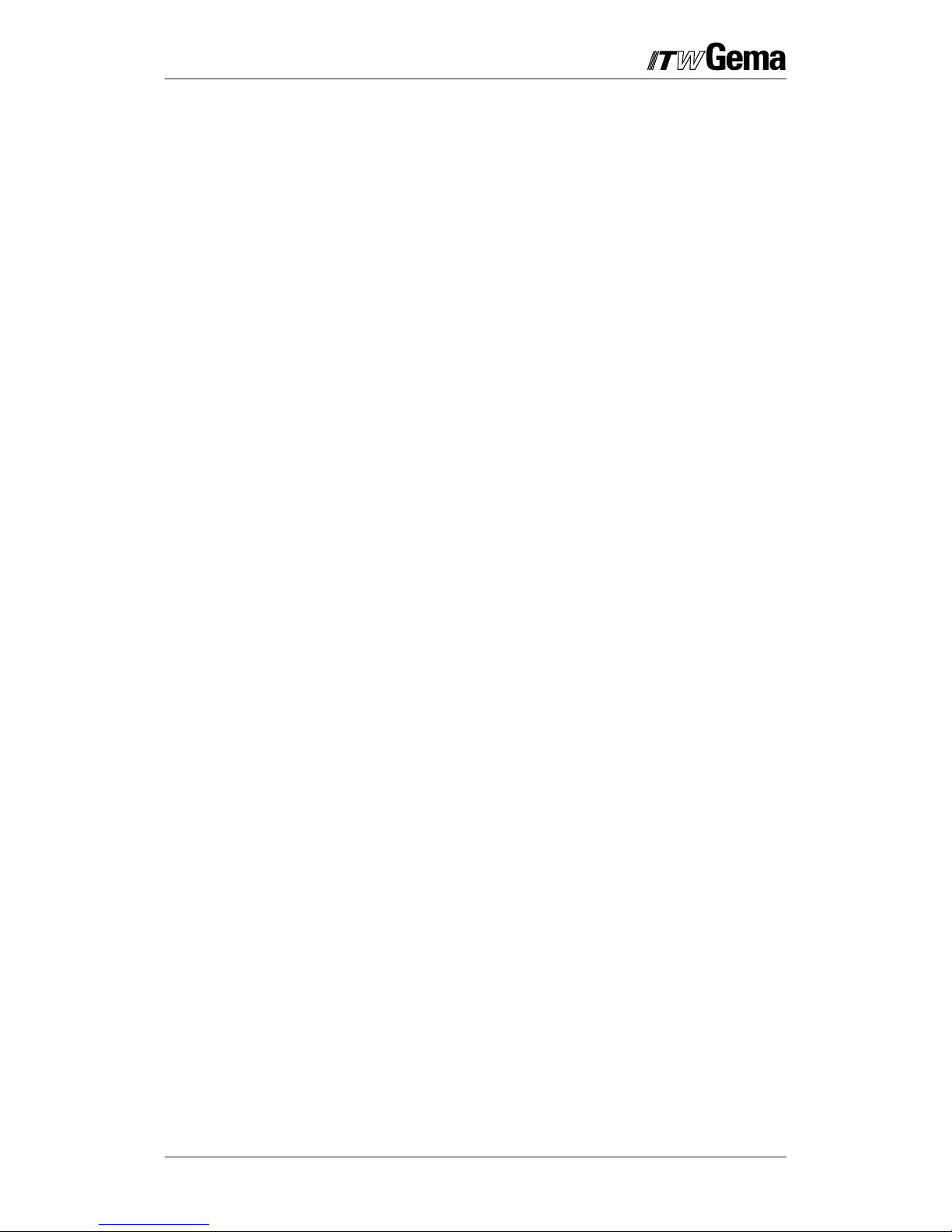

1.1 IN Compressed air input

1.2 Conveying air connection

1.3 Supplementary air connection

1.4 Rinsing air connection

1.5 Fluidizing air connection

2.1 Mains input (85-264 V)

2.2 Gun connection for the

EasySelect Manual Powder

Gun.

PG 1 manual powder guns

cannot

be connected here!

2.3 Output for Vibrator (EASY 1-B

only) and Stirrer control unit

(EASY 1-S only)

Ground connection

11

1

0

9

4

3

2

1

25

EasyTronic

Issued 07/02

Table of Contents

Directions for use

Safety rules for electrostatic Powder coating

Technical Data - EasyTronic Control unit

EasyTronic Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Field of Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Operating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Description of the EasyTronic Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation of the Powder coating equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Preparation for Start up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

a) Setting the Operating mode on the Electronic board . . . . . . . . . . . . . . . . . . . . . 4

b) Preparation of the Powder hopper / container . . . . . . . . . . . . . . . . . . . . . . . . . . 5

c) Switching on the Booth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

d) Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Daily Start up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

a) Setting the Powder output, and Powder cloud . . . . . . . . . . . . . . . . . . . . . . . . . 6

Set the Total air volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Select the Powder output volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Select the electrode rinsing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

b) Powder coating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

c) Remote control through the Powder gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

d) Switching off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

When the Powder coating equipment is not used for a number of days . . 7

Repairs to Electrical parts of the Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

a) Replacing fuse(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

b) Replacing the CG 01 Printed Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

c) Replacing the Front plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Dismantle Main switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Repairs to Pneumatic parts in the Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

a) Replacing a Pneumatic Part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Removing the pneumatic tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Replacing the pneumatic tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pneumatic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Display of the Operating Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Spare parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Ordering Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

EasyTronic Control Unit - Pneumatic Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

EasyTronic Control Unit - electrical Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

EasyTronic Control Unit - Accessory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

26

EasyTronic

Issued 07/02

27

EasyTronic

Issued 07/02

DIRECTIONS FOR USE

Safety rules for electrostatic Powder coating

1. This equipment can be dangerous when not operated according

to the following standards:

EN 50 050 (or VDE 0745 Part 100),

EN 50 053 Part 2 (or VDE 0745 Part 102),

and specification sheet, ZH 1/443 Electrostatic Powder Coating.

2. All electrically conductive parts within 5 m of the coating area,

especially the workpieces, must be grounded.

3. The floor in the coating area must be electrically conductive

(normal concrete is generally conductive).

4. The operating personnel must wear electrically conductive footwear (i.e. leather soles).

5. The operating personnel should hold the powder gun in the bare

hand. If gloves are worn they must be electrically conductive.

6. Connect the grounding cable (green/yellow) supplied to the

grounding screw of the electrostatic manual powder coating

equipment. The grounding cable must have a good metal to metal

connection with the powder coating booth, the powder recovery

equipment and the chain conveyor or the hangers of the objects.

7. The electric cables and powder hose to the guns must be laid out

so that they are protected from possible mechanical damage.

8. The powder coating equipment must switch on only after the

powder booth is in operation. If the booth breaks down, then the

powder coating equipment must switch off.

9. The grounding of all conductive parts is to be checked at least

once a week.

10. When cleaning the powder gun and when replacing nozzles the

control unit must be switched off.

28

EasyTronic

Issued 07/02

TECHNICAL DATA - EASYTRONIC CONTROL UNIT

Mains connection:

Input voltage: 90 - 264 V

Frequency: 47 - 440 Hz

Nominal output voltage (to gun): max. 12 V

S

Nominal output current (to gun): max. 1 A

Type of protection: IP 54

Temperature range: 0 °C to +40 °C

(+32 °F to +104 °F)

Approval:

Pneumatic Data

Main compressed air input: B.S.P.1/4" (Female)

Max. Input pressure: 10 bar

Min. Input pressure: 6 bar

Max. water content of the compressed air: 1.3 g/m

3

Max. oil vapour content of the compressed air: 0.1 mg/kg

Dimensions:

Width: 248 mm

Depth: 250 mm

Height: 174 mm

Weight: 5.2 kg

The EasyTronic Control Unit can only be used with the EasySelect

manual gun.

IMPORTANT

1

EasyTronic

Issued 07/02

EASYTRONIC CONTROL UNIT

Field of Application

The electrostatic EasyTronic Control Unit is designed exclusively for the

controlling powder coating with the EasySelect manual powder gun.

This equipment is not to be used for any other purpose. Any damage

resulting from its misuse is not the responsibility of the manufacturer,

the entire risk is carried by the customer alone.

All settings for efficient powder coating have been made simple and

reproducible on the EasyTronic. The built-in electronics permit exact

setting of the optimum powder output, and the values set can be seen

on the digital display windows and can even be checked from a

distance. According to the selected application mode, the spray voltage

is set automatically and spray current is limited automatically.

The EasyTronic Control Unit can be connected to all usual mains

voltages.

For a better understanding of the relationships in powder coating it is

recommended to read the operating instructions of other components,

thoroughly, so as to be familiar with their functions also.

Operating mode

The EasyTronic Control Unit is foreseen as standard for operation with

all manual coating equipment in the EASY range. The desired

functionality must, however, be determined by means of a "jumper" on

the electronic board inside the control unit. If the control unit is supplied

as a component of an EASY unit, then the "jumper" will be

correspondingly set in the correct position at the factory.

In every other case, it is recommended to check the setting of the

"jumper" (see also the corresponding section "Setting the operating

mode on the electronic board ").

An incorrectly set "jumper" can lead to malfunctioning or to

reduced functioning of the Vibration, Fluidization or Stirrer!

NOTICE

2

EasyTronic

Issued 07/02

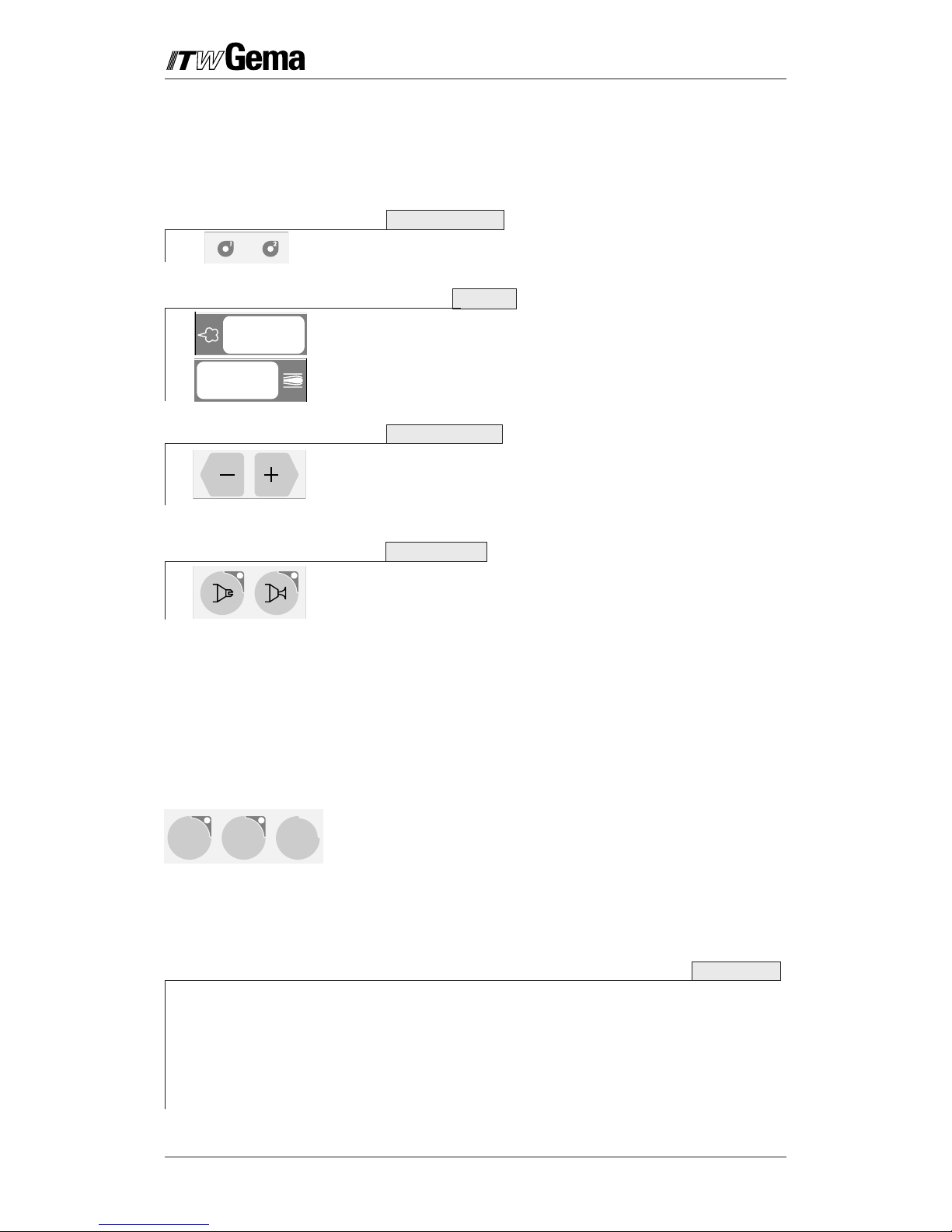

The operating panel of the EasyTronic control unit consists of 4 main

areas:

Diagnostic LEDs, Displays, "+/–" Keys, and Function keys.

1. The Diagnostic LEDs 1–8 serve to show the status of the equip-

ment, and equipment faults. Detailed information is found in the

"Troubleshooting Guide"

2. There are two Displays with whose help the following values are

displayed:

• Powder output (Setting range 0–100 %) Powder output in %

always refers to the max. possible output volume to the total

air volume setting.

• Total air volume (Setting range 1.6–6.0 Nm3/h)

3. The Keys "+" and "–" are for setting the powder output, and the

total air volume used.

If a key is pressed once, the value is increased or decreases,

respectively, by one step. If a key is pressed continuously, the

setting change rapidly.

4. The Function keys have the following functions:

• Electrode rinsing air for flat jet nozzles

• Electrode rinsing air for round jet nozzles

When a key is pressed once, the corresponding function is

activated, and the corresponding LED illuminates.

If a key with an illuminated LED is pressed for longer than 1

second, the function is deactivated.

ITW Gema recommends leaving the electrode rinsing air

switched on, but can, however, remain switched off for

applications with very small amounts of powder.

• Application keys: With these keys the electrostatic (High-

voltage, and current) are automatically set so that the setting

for the selected application is the optimum.

– Settings for flat parts

– Settings for complicated parts with depressions

– Settings for coating parts already coated

High-voltage and current can be deactivated, when the

corresponding key pad with the illuminated LED is pressed for

longer than 1 second.

The EasyTronic control unit is switched on and off with a Push button.

If the equipment is switched on, the yellow lamp is illuminated.

When the equipment is first switched on the preselected factory

settings displayed:

60% 4.0 Nm3/h

Flat jet rinsing Complicated parts

After switching the equipment off (also when the equipment is disconnected from the Mains) the actual settings are retained.

DESCRIPTION OF THE EASYTRONIC CONTROL UNIT

Figure 1

3

EasyTronic

Issued 07/02

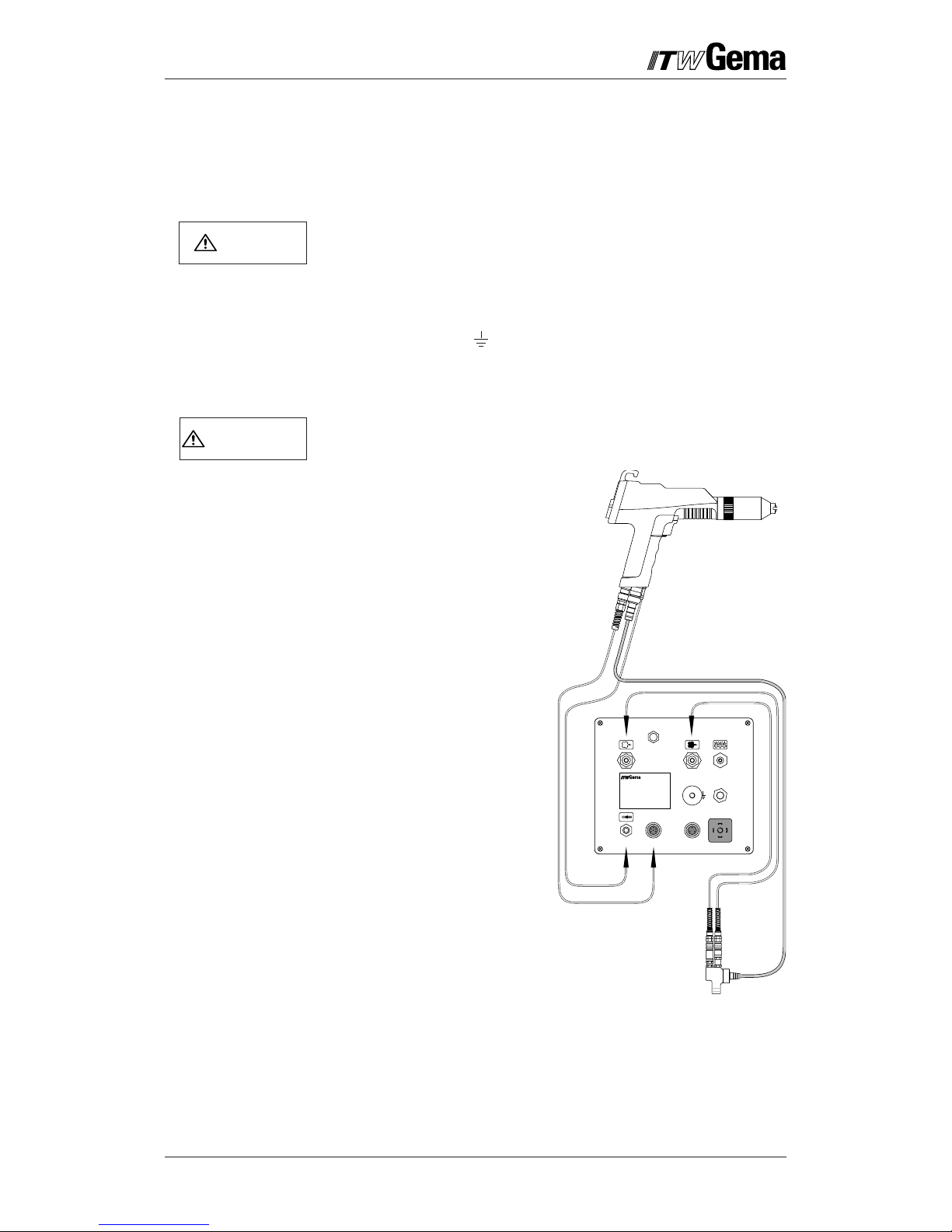

INSTALLATION OF THE POWDER COATING EQUIPMENT

1. Connect the hose for the compressed air supply from com-

pressed air circuit directly to the main air connection - 1.1 IN on

the rear of the control unit (female thread: 1/4" B.S.P.).

The compressed air must be free from oil and water.

2. Connect the black hose for the fluidizing air (if required) to the

corresponding output (1.5) on the rear of the control unit.

3. Fit the grounding connection cable on the control unit with the

grounding screw , and the 5 m long grounding cable with the

clamping clip to the booth or on the hanger device.

4. Connect the gun cable with the 7 pin plug on the rear of the

control unit on the socket - 2.2 (Gun).

PG 1 Manual powder guns cannot be connected!

5. Connect the hose for

rinsing air to the rinsing air

output - 1.4 and to the

powder gun.

6. Plug the injector in, and

connect the powder hose

to the injector and to the

powder gun.

7. Connect the red hose for

the conveying air to the

corresponding output - 1.2

on the rear of the control

unit and to the injector.

8. Connect the black hose for

the supplementary air to

the corresponding output -

1.3 on the rear of the

control unit and to the

injector.

9. Connect the Mains cable on

the socket - 2.1.

Figure 2

Mains connectionAux

Gun

1.1 IN

5 ... 10bar

73...145PSI

1.4 2.2 2.3

2.1

1.3

1.2 1.5

Input voltage:

Input power:

Degree of protection:

Output:

Corresponding guns:

85 – 264 V

47 – 440 Hz

65 VA

IP 54

10 V 1,2 A

EasySelect

POWDER GUN CONTROL

TYPE EASYTRONIC

NOTICE

IMPORTANT

Loading...

Loading...