ITW Gema EasySelect-Cup Operating Instructions Manual

27EasySelect-Cup

Issued 05/00

Operating Instructions and Spare parts list

EasySelect-Cup Manual Powder Gun

E

28

EasySelect-Cup

Issued 05/00

29EasySelect-Cup

Issued 05/00

Table of Contents

Safety rules

EasySelect-Cup Manual Powder gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Scope of delivery: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Technical Data for EasySelect-Cup Manual Powder gun . . . . . . . . . . . . . . . . . . . . 1

EasySelect-Cup Manual Powder gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1. High-voltage Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3. Powder flow and Rinsing air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4. Flat jet nozzle with vented central electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5. Round jet nozzle with vented deflector plate and vented central electrode . . . . 6

Preparation for Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

a) Connecting the EasySelect-Cup Powder gun . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

b) Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Start up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

a) Setting the Powder output and Powder cloud . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Setting the Total air volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Select the Powder output volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Select Electrode rinsing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

b) Start up - Powder coating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

c) Remote control through the gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

d) Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

a) Daily maintenance: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

b) Weekly maintenance: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cleaning and Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

a) Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

b) Dismantling the Gun: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

c) Assembling the powder gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

d) Repairs on the powder gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

e) Cleaning the Spray Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Spare parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Ordering Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

EasySelect-Cup Manual gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Nozzle combinations for EasySelect-Cup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

30

EasySelect-Cup

Issued 05/00

31EasySelect-Cup

Issued 05/00

SAFETY RULES

SAFETY RULES FOR ELECTROSTATIC POWDER COATING OPERATIONS

1. This equipment is dangerous when not operated according to the

following standards: EN 50 050 (or VDE 0745, Part 100), EN 50

053, Part 2 (or VDE 0745, Part 102), and specification sheet, ZH

1/443 Electrostatic Powder Coating.

2. All electrostatically conductive parts located within 5 m of the

coating area and especially the workpieces

must

be properly

grounded.

3. The floor in the coating area

must

be electrostatically conductive.

Normal concrete is generally conductive

4. The operating personnel

must

wear electrostatically conductive

footwear (e.g. leather soles).

5. The operating personnel should hold the gun in the bare hand.

If gloves are worn, they

must

be electrostatically conductive.

6. Connect the grounding cable (yellow/green) supplied to the

grounding terminal on the control module. The grounding cable

must

have a good metal to metal connection with the coating

booth, recovery unit, and the workpiece conveyor system,

especially with the workpiece suspension.

7. The electrical and the powder feed lines to the guns must be laid

out so that they are protected from possible mechanical damage.

8. The powder coating equipment should only be switched on after

the booth is in operation. If the booth breaks down then the

powder coating equipment

must

also switch off.

9. Check the grounding of all electrostatic conductive parts at least

once a week.

10. When cleaning the gun or changing nozzles the control module

must

be switched off

32

EasySelect-Cup

Issued 05/00

1EasySelect-Cup

Issued 05/00

EASYSELECT-CUP MANUAL POWDER GUN

The very light EasySelect-Cup Manual Powder gun with an integrated

High-voltage cascade has very good penetration and because of the

patented, vented electrode a high, and constant transfer efficiency. The

gun can be easily dismantled, making it maintenance and repairfriendly. It is particularly suitable for manually coating of small series

especially for trails with coating powders

SCOPE OF DELIVERY:

- EasySelect-Cup Manual Powder gun with a 6 m gun cable

- Type D100 Cup

- Pneumatic connection (Conveying air) - 6 m

- Rinsing air hose - 6 m

- 40 mm Nozzle holder

- ø 16, ø 24, and ø␣ 32 mm vented deflector plates

- Deflector plate holder with electrode, and nozzle

- Flat jet nozzle with electrode, and holder

- Cable binding with Velcro straps

- Gun cleaning brush

- Spare parts set

Available options:

- Gun cable - 12 m

- Type D 125 Cup

- Fluidized Cup

- Pneumatic connection (Conveying air) - 12 m

TECHNICAL DATA FOR EASYSELECT-CUP MANUAL POWDER GUN

Nominal input voltage: 0–12 V DC

(depending on mode and opera-

tion)

Nominal output voltage: 80 kV

Polarity: Negative

(Option - Positive)

Max. Output current: 150 µA

High-voltage display: 2 Light emitting diodes - LEDs

(for displaying 3 modes, and gun

triggering

Flash protection:

Approval:

Connection: The EasySelect-Cup must only be connected to the

EasyTronic Control unit.

2

EasySelect-Cup

Issued 05/00

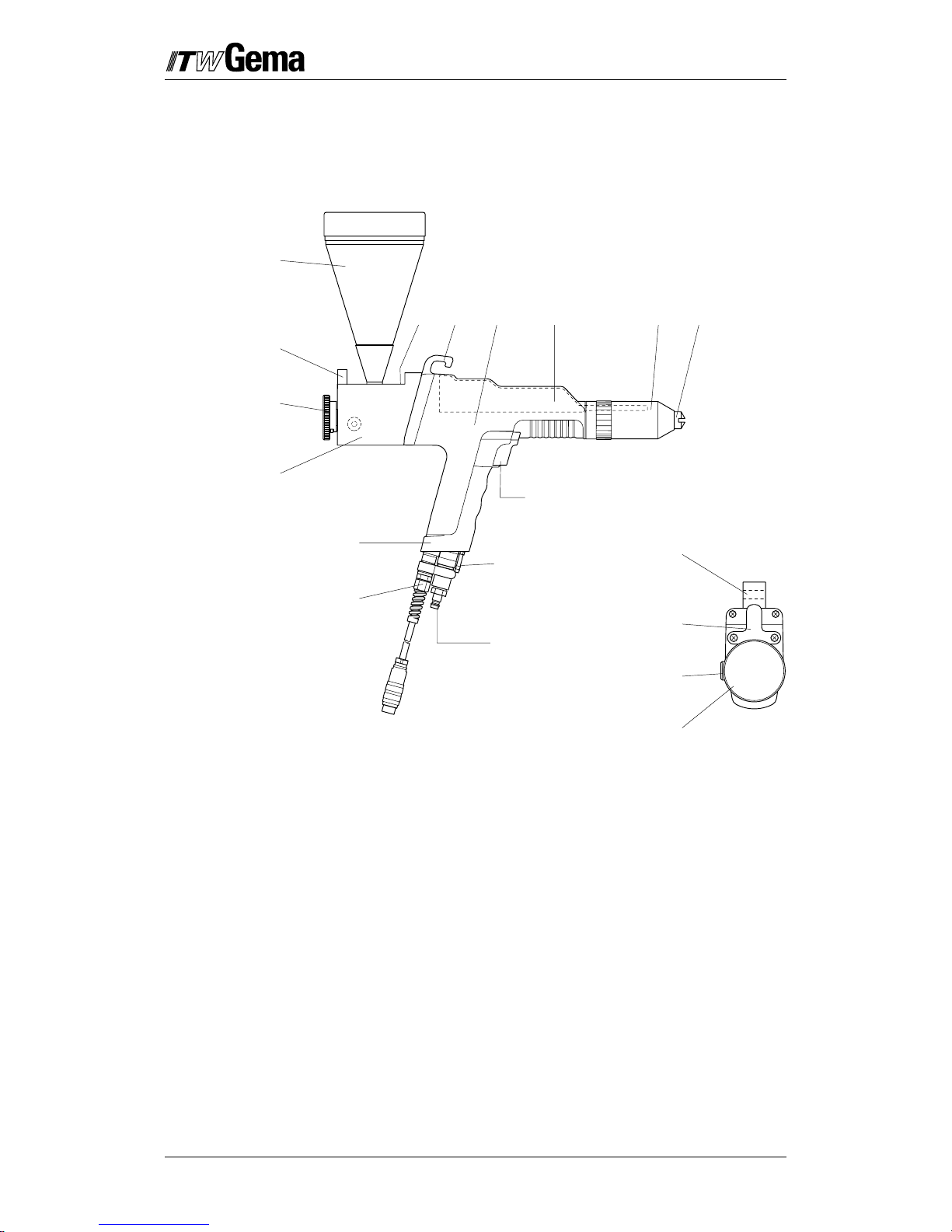

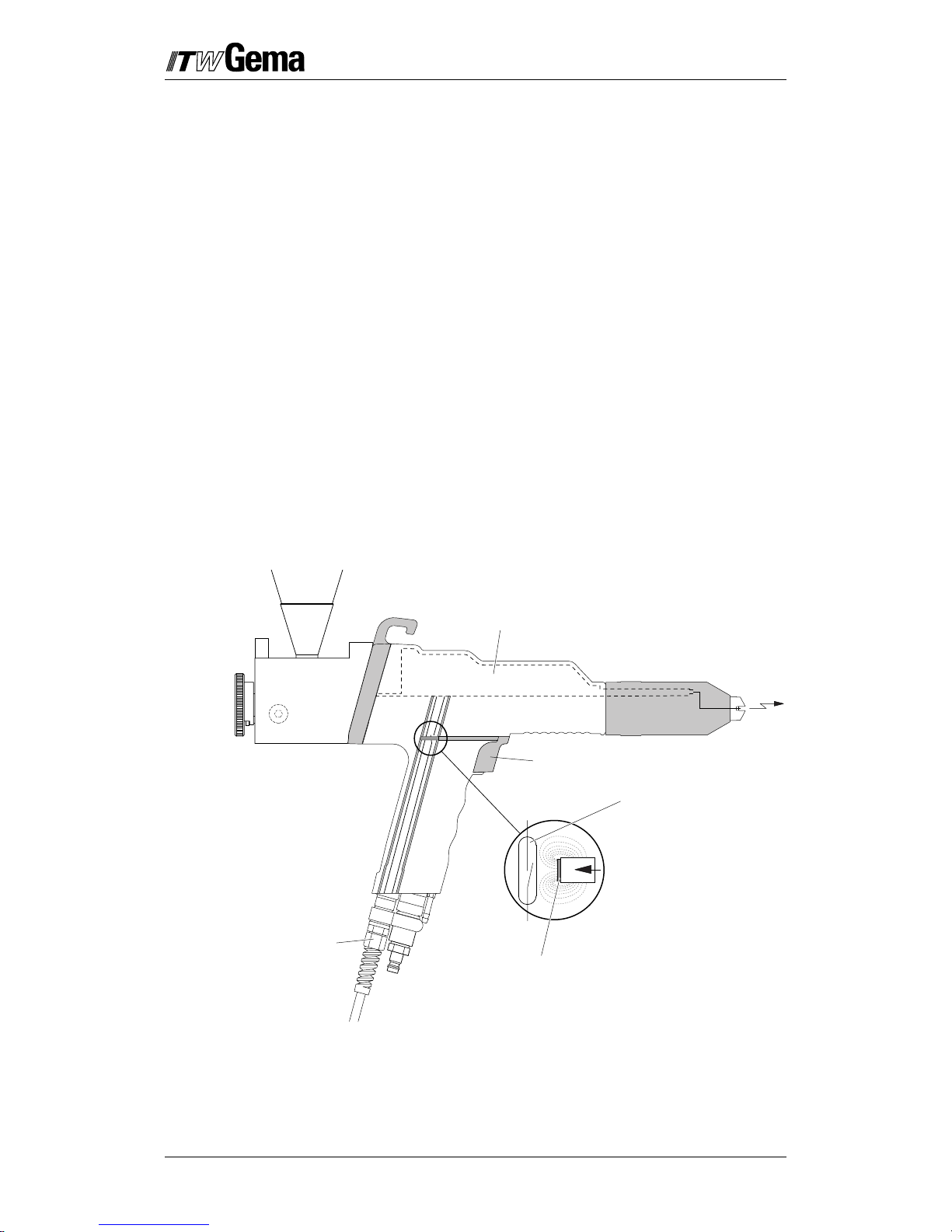

EASYSELECT-CUP MANUAL POWDER GUN

15 Conveying air hose connection

16 Rinsing air hose connection

17 Trigger

21 Setting knob

24 Venting plug

(connection for fluidized cup)

27 Injector

28 Cup

1 Spray Nozzle system

2 Threaded sleeve

3 Shaft

4 H-V cascade

5 End plate with hook

6 LEDs

7 Remote control keys

9 Grip

11 Powder gun cable connection

Figure 1

17

1234

7

7

9

11

24

16

15

5

21

6 5

21

27

28

3EasySelect-Cup

Issued 05/00

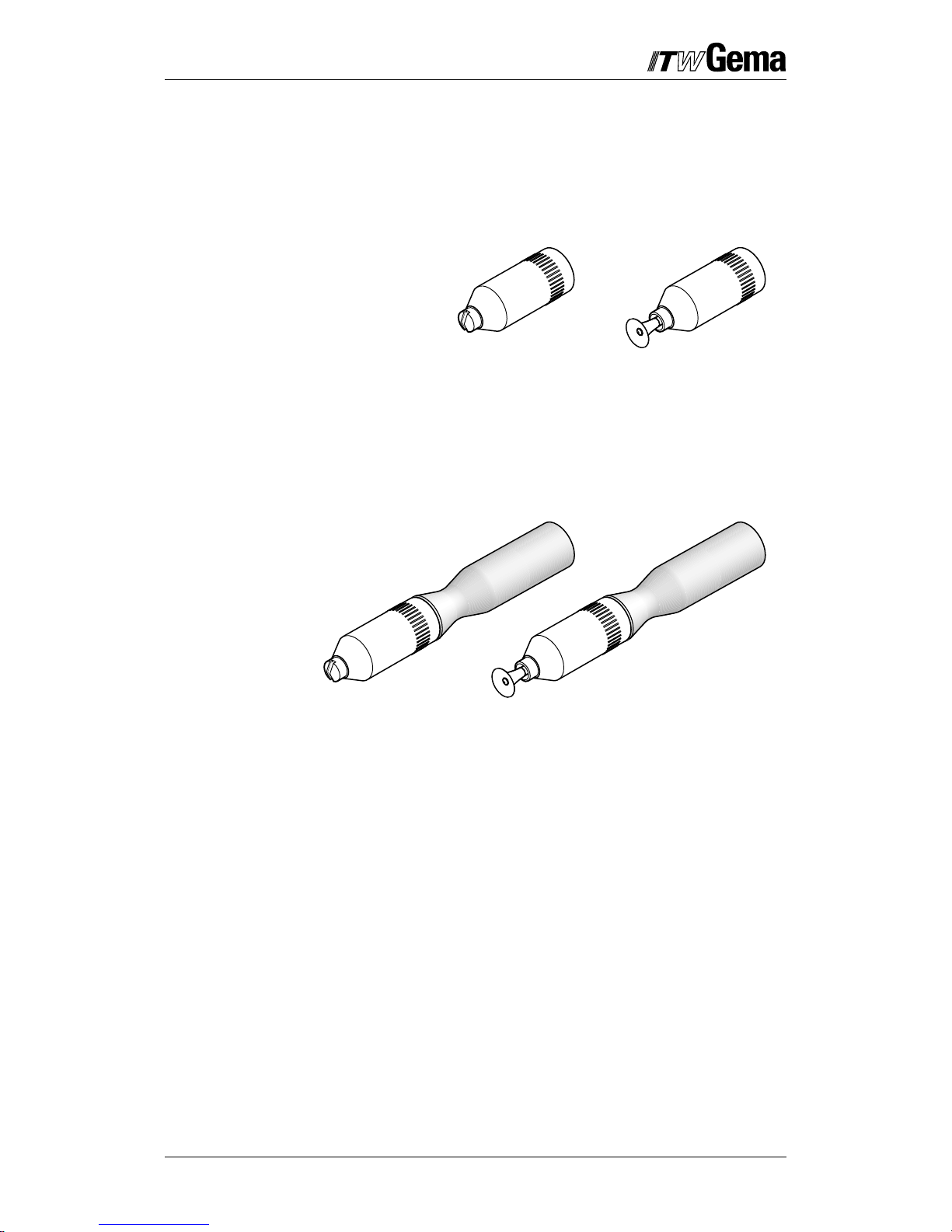

40 mm Nozzle

300 mm Nozzle

(not shown - does not belong to the standard set, available separately – see Spare parts

list )

Flat jet nozzle with vented

central electrode

Extended Flat jet nozzle

with vented central

electrode

150 mm Nozzle

(does not belong to the standard set, available separately – see Spare parts list )

Extended Round jet nozzle

with vented deflector plate

and vented central electrode

Round jet nozzle with

vented deflector plate and

vented central electrode

The EasySelect-Cup Manual gun can be fitted with following Spray nozzles:

Figure 2

4

EasySelect-Cup

Issued 05/00

1. HIGH-VOLTAGE GENERATION

Reed switch (closing)

Figure 3

The control unit supplies DC voltage to the gun. This is fed through the

powder gun cable (11) to the high-voltage generation section (4).

The integrated electronics (c) in the gun generates an alternating

current from the direct current. This alternating current is stepped up

in the multiplier (d) to the rectified high-voltage required for the application. The High-voltage is now fed to the electrode (e) in the spray

nozzle (compare Figs 5 and 6).

The coating mode chosen - Flat parts, Complicated parts, Over-spraying - is indicated through a red, and a green LED (Light emitting diode).

2. SWITCHING

In addition to the low voltage a switching current is fed into the gun

through the gun cable.

If the gun trigger (17) is pulled, a reed switch closes the current circuit.

The control unit switches the modulated low voltage, powder conveying, and the rinsing air on.

The reed switch complies with the safety regulations of all recognized

standards.

Magnet

4

c

d

e

11

17

Loading...

Loading...