Page 1

ITW Dynatec

An Illinois Tool Works Company

31 V olunteer Drive

Hendersonville, TN 37075 USA

Telephone 615.824.3634

FAX 615.264.5222

Adhesive Application Solutions · ISO 9001 Certified

ITW Dynatec GmbH

Industiestrasse 28

D-40822 Mettmann, Germany

Telephone 49.2104.915.0

FAX 49.210.2104.915.1 11

ITW Dynatec K.K.

Daiwashinagawa Bldg., 7-15 Konan, 3-Chome

Minata-Ku, Tokoyo 108 Japan

Telephone 81.3.3450.5901

FAX 81.3.3450.8405

OPERATIONS & SERVICE MANUAL

Manual 20 -25

Revised 1/05

DYNAMINI

ä

ADHESIVE SUPPLY UNIT

OPERATIONS AND SERVICE MANUAL

with Software Version 2.00

For an online copy of this manual, go to www.itwdynatec.com/manuals.htm

IMPORT ANT! -READ ALL INSTRUCTIONS BEFORE OPERATING THIS EQUIPMENT

It is the customer’s responsibility to have all operators and service personnel read and understand

this information. Contact your ITW Dynatec customer service representative for additional copies.

NOTICE! Please be sure to include the serial number of your application system

each time you order replacement parts and/or supplies. This will enable us to

send you the correct items that you need.

ITW Dynatec Service Parts Direct Dial: 1- 800-538-9540

ITW Dynatec Technical Service Direct Dial: 1- 800-654-6711

Page 2

Page ii

Revised 1/05

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20 -25

The Dynamini ASU is manufactured under one or more of the following PA TENTS:

United States:

D388,800 5,613,451

5,632,918 5,645,743

5,683,578 5,719,378

5,806,720

Europe:

97309164.8-2206

ITW Dynatec

An Illinois Tool Works Company

Adhesive Application Solutions

Page 3

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20 -25

TABLE OF CONTENTS

Chapter 1 Safety Precautions Chapter -Page #

Chapter 2 Specifications & Dimensions

Model Description Matrix 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 Installation & Start Up

Mounting the ASU/ Lifting the ASU 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

W attageAvailabilityChart 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adding to or Changing the Adhesive Formula 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Control Filter Unit/ Rear Cover: Head & Hose Connections 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical Start Up and Shut Down Procedures 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage and Disposal of the Application System 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Dynamini Temperature Controller Set- Up

Page iii

Revised 1/05

Temperature Control Functions in General 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining Dynamini Temperature Control Terms 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Indication Messages 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Chip (EPROM) and Checksum 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Settings for a Typical Operation 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System V alues 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Default Settings of the Controller 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helpful Tips for the User 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 Programming of the Dynamini Controller

Controller Keypad 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turn On 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature Setpoints 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning Zones On/ Off 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Indication Messages 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Locking 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Functions 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram of the Service Functions Loop 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standby 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tolerance 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sequential Startup 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature Scale 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ready Delay 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change Access Code 5-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 Preventive Maintenence

General Cleaning 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenanace 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Filter 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hose Fittings and Fasteners 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Page iv

Revised 1/05

DYNAMINI ASU Manual #20 -25

Hopper Filter Inspection and Cleaning 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purging the Filter Manifold of Adhesive and Pressure 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flushing the System 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7 Troubleshooting

Handling Printed Circuit Boards 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printed Circuit Board & Layout Illustration 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overtemp Thermostat 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location of PCB & Overtemp Thermostat Re-set 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resistance Tables 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Guide 7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Operation & Adjustable Pressure Relief 7-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piston Pump Troubleshooting Guide 7-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Pump Troubleshooting Guide 7-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8 Disassembly & Re- assembly Procedures

To Remove the Pump & Electronics Cover 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Remove the Hopper Cover 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Remove the Hopper Lid 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermostat Replacement 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RTD Sensor Replacement 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Access & Replace the Electrical Components 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Access & Replace the Pumps or Motors 8-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Note on Cast-in Heaters 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Re-assembly Procedures & Cautions 8-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ITW Dynatec c. 2004

Chapter 9 Available Options & Accessories

Pressure Gauge Kit 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filter Option 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Options & Accessories 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Job Aide 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Service Parts List 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 10 Component Illustrations & Bills of Material

Electrical Panel Assembly 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piston Pump Assembly 10-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabinet Assembly 10-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Section 10-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filter & Melt Assembly 10-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Assemblies 10-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 1 1 System Schematics & Engineering Drawings

Hose Schematic: all models 11-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head Schematic: all models 11-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

W iringDiagrams 11-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Page 1-1

Revised 9/98

Chapter 1

SAFETY PRECAUTIONS

All operators and service personnel must read

and understand this manual before operating

or servicing equipment.

Electrical

DANGER

HIGH VOLTAGE

Dangerous voltages exist at several points in this

equipment. Toavoid personal injury, do not touch

exposed connections and components while input

High Temperatures

WARNING

HOT

SURFACE

All maintenance and service on this equipment must be performed by trained technicians.

power is on. Disconnect, lockout and tag external

electrical power before removing protective panels.

A secure connection to a reliable earth ground is

essential for safe operation.

A disconnect switch with lockout capability must be

provided in the line ahead of the unit. Wiringused to

supply electrical power should be installed by a

qualified electrician.

Severe burns can occur if unprotected skin comes in

contact with molten adhesive or hot application system

parts.

Safety glasses, gloves and long- sleeved clothing must

be worn whenever working with or around adhesive

application systems.

High Pressure

WARNING

HIGH PRESSURE

PRESENT

To avoid personal injury, do not operate the equipment

Protective Covers

WARNING

DO NOT OPERATE

WITHOUT GUARDS

IN PLACE

without all covers, panels and safety guards properly

installed.

To prevent serious injury from molten adhesive under

pressure when servicing the equipment, disengage the

pumps and relieve the adhesive system’s hydraulic

pressure (e.g., trigger the heads, hand-held applicators,

and/or other application devices into a waste container)

before opening any hydraulic fittings or connections.

Keep all guards in place!

To avoid personal injury, do not operate the application

system without all covers, panels and safety guards

properly installed.

Page 6

Page 1-2

Revised 3/97

Eye Protection & Protective Clothing

WARNING

ITW Dynatec c. 2004

DYNAMINI ASU Manual 20-25

Wear safety glasses with side shields which conform to

ANSI Z87.1 or EN166.

EYE PROTECTION

REQUIRED

PROTECTIVE

CLOTHING

REQUIRED

It is very important that you PROTECT YOUR EYES

when working around hot melt adhesive equipment!

Safe Installation and Operation

To avoid possible failure of hoses, make sure all hoses

are routed to avoid kinking, tight radius turns (8” or

less) and abrasive contact. Hot-melt hoses should not

have prolonged contact with heat-absorbing surfaces

such as cold floors or metal troughs. These

heat-absorbing surfaces can alter adhesive flow and

cause incorrect calibration. Hoses should never be

covered with materials that p revent heat dissipation,

such as insulation or sheathing.

Read this manual before applying electrical power to

the equipment. Equipment may be damaged by

incorrect electrical connections.

Do not use adhesive that is dirty or that may be

chemically contaminated. Doing so can cause system

Failure to wear safety glasses could result in severe eye

injury.

It is important to protect yourself from potential burns

when working around hot melt adhesive equipment.

Wear protective gloves and long-sleeved, protective

clothing to prevent burns that could result from contact

with hot material or hot components.

Always wear steel-reinforced safety shoes.

clogging and pump damage.

When adhesive hand-held applicators or other movable

applicators are used, never point them at yourself or at

any other person. Never leave a hand-held applicator’s

trigger unlocked when not actually in use.

Do not operate the hopper or other system components

without adhesive for more than 15 minutes if the

temperature is 150 degrees C (300 degrees F) or more.

To do so will cause charring of the residual adhesive.

Never activate the heads, hand-held applicators and/ or

other application devices until the adhesive’s

temperature is within the operating range. Severe

damage could result to internal parts and seals.

Treatment for Burns From Hot Melt Adhesives

Burns caused by hot melt adhesive must be treated at a

burn center.

Care should be used when working with hot melt

adhesives in the molten state. Because they rapidly

solidify,they present a unique hazard.

Even when first solidified, they are still hot and can

cause severe burns. When working near a hot melt

application system, always wear safety gloves, safety

glasses and long-sleeved, protective clothing.

Always have first-aid information and supplies

available.

Call a physician and/or an emergency medical

technician immediately.

Page 7

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Service

Refer all servicing to qualified personnel only.

Explosion/ Fire Hazard

Page 1-3

Revised 9/98

Never operate this unit in an explosive environment.

Use cleaning compounds recommended by ITW

Dynatec or your adhesive supplier only.Flash points

Lockout/ Tagout

Follow OSHA 1910.147 (Lockout/ Tagout Regulation)

for equipment’slockout procedures and other important lockout/ tagout guidelines.

Be familiar with all lockout sources on the equipment.

In This Manual

WARNINGS and CAUTIONS are found throughout

this manual.

WARNINGS mean that failure to observe the specific

of cleaning compounds vary according to their composition, so consult with your supplier to determine the

maximum heating temperatures and safety precautions.

Even after the equipment has been locked out, there

may be stored energy in the application system, particularly in the capacitors within the panel box. Toensure

that all stored energy is relieved, wait at least one minute before servicing electrical capacitors.

instructions may cause injury to personnel.

CAUTIONS mean that failure to observe the specific

instructions may damage the equipment.

Page 8

Page 1-4

Revised 3/97

ITW Dynatec c. 2004

DYNAMINI ASU Manual 20-25

ITW Dynatec

An Illinois Tool Works Company

Page 9

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20 -25

SPECIFICATIONS AND DIMENSIONS

DYNAMINI

5 = 5 kg/ 10 lb.

1 = 10 kg/ 20 lb.

HOSE: 2- hose capable

PUMP TYPE:

P12 = Piston Pump 12:1

GAS = Gear Pump 1.5cc

GBS = Gear Pump 3.2cc

GCS = Gear Pump 4.5cc

GDS = Gear Pump 0.55cc

GES = Gear Pump 10cc

Page 2 -1

Revised 1/05

Chapter 2

N X 2 X X X X - X X X X

VOL TAGE:

1 = 100 - 120VAC, 1 phase

2 = 200 - 240VAC, 1 phase

OPTIONS:

ACCESSORIES:

F = 100 mesh/ 149 micron outlet filter (40 mesh/ 420 micron is standard)

G = Analog pressure gauge

V = Swirl kit, 1 hose

W = Swirl kit, 2 hose

CONFIGURED SYSTEM OPTIONS:

C24 = 2.4m/ 8 ft. Abrasion resistant hose

C36 = 3.6m/ 12 ft. Abrasion resistant hose

CHB = Hand Bead Applicator

CHS = Hand Swirl Applicator

STACKTITE SYSTEM OPTIONS:

SB = Bead applicator

SS = Swirl applicator

EXAMPLE:

N52GAS2- F = Dynamini 10 lb. hopper w/ 1.5cc gear pump, 240 VAC/ 1 phase and 100 mesh outlet

filter .

DYNAMINI Model Designation Matrix

Page 10

Page 2 -2

Revised 1/05

DYNAMINI ASU Manual #20 -25

ITW Dynatec c. 2004

Specifications

Environmental:

Storage/ shipping temperature -40° C to 70°C (-40° F to 158°F). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ambient service temperature -7° C to 50°C (20° F to 122°F). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Noise emission TBD < db(A). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical:

Dimensions see dimensional layouts on following pages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Number of heads/ hoses 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Number of hopper temperature zones 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Number of pumps 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piston pump ratio 12:1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear pump see options on page 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enclosure styled, durable metal and high temp plastic, dust and splatter resistant. . . . . . . . . . . . . . . . .

Hose connections Electrical: universal 15-pin Amphenol connectors at asu,. . . . . . . . . . . . . . . . . . . . .

Mechanical: wrench-secured fluid fittings (#6 JIC)

Hopper (tank) capacity Model 05: 5 kg/ 11 lb. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model 10: 10 kg/ 20 lb

Hopper construction cast-in heaters, TFE Teflon impregnated. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filtration hopper bottom screen, manifold basket filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weight, empty tbd kg/ tbd lb. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adhesive form standard grades (non-water based only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical:

Power Supply Required 100-120 VAC/ 1p/ 50-60 Hz/ 15 Ampere. . . . . . . . . . . . . . . . . . . . . . . . . . .

or 200-240 VAC/ 1p/ 50-60 Hz/ 30 Ampere

Hopper heater type cast-in tubular. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power consumption, system maximum 100-120 VAC system: 1800 watts. . . . . . . . . . . . . . . . . . . . . .

200-240 VAC system: 6800 watts (w. piston pump)

200-240 VAC system: 7200 watts (w. gear pump)

Hopper Power 100-120 VAC system: 600 watts at 120 VAC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

200-240 VAC system: 1200 watts at 240 VAC

Temperature control microcontroller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature sensors 100 Ohm Platinum RTD standard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear pump Motor 1/4 hp, constant speed, AC, direct drive, horizontal orientation. . . . . . . . . . . . . . . .

Page 11

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20 -25

Pressurized Air:

Air pressure supply 1.4 to 6.8 bar (20 to 100 psig). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air consumption at 60 pump cycles per minute 90 normal liters/ minute. . . . . . . . . . . . . . . . . . . . . . .

(3.2 SCFM at 100 psig)

Performance:

Adhesive temperature control range 40°C to 218°C (100°F to 425°F). . . . . . . . . . . . . . . . . . . . . . . . .

Adhesive temperature control accuracy ± 1°C (± 1°F). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Over-temperature cutoff for hopper 232°C (450°F). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adhesive viscosity 500 to 50,000 centipoise. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warm-up time, full hopper approximately .5 hour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adhesive delivery rate, open line .91 kg/min (2 lb/min)(12:1 piston pump). . . . . . . . . . . . . . . . . . . . .

Adhesive melt rate (depends on adhesive used) 8 kg/hr (17.3 lb/hr). . . . . . . . . . . . . . . . . . . . . . . . . . .

Adhesive pressure up to 68 bar (1000 psi) maximum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum pump speed, piston pump 60 pump cycles per minute. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum pump speed, gear pump 87 revolutions per minute, 60 Hz, constant speed. . . . . . . . . . . . . .

73 revolutions per minute, 50 Hz, constant speed

Page 2 -3

Revised 1/05

Dynamini Temperature Control:

Controller board 1 printed circuit board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display type long-life, light-emitting diode (LED). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature control zones 5 triac-output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Other:

Operator interface digital display with simplified, all-icon keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature offset no. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sensor open error message yes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 12

Page 2 -4

Revised 1/05

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20 -25

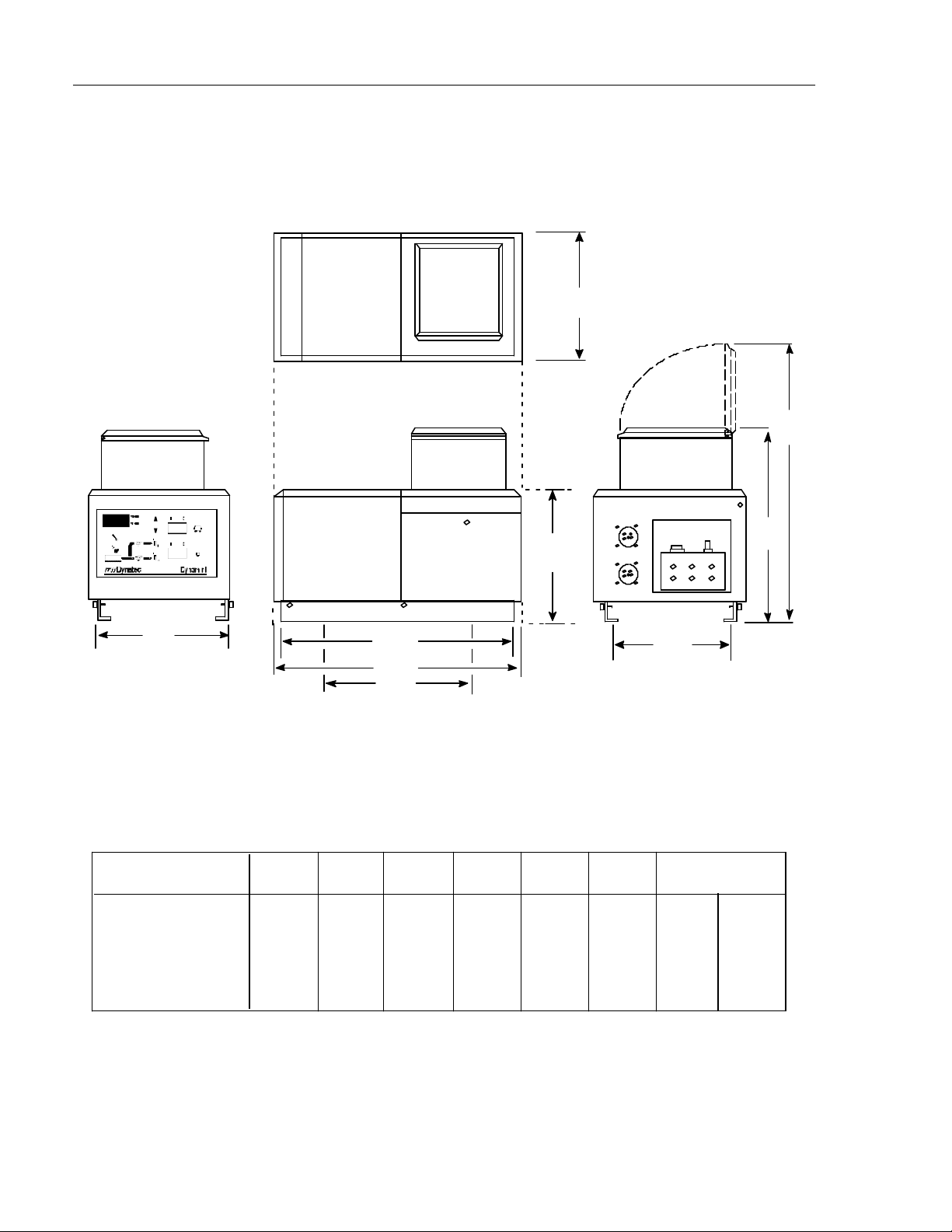

A

F

A

DIMENSION A B C D E F G H

MODEL 05 (mm)

MODEL 05 (inches)

MODEL 10 (mm)

MODEL 10 (inches)

D

B

C

H

G

mounting holes*

289 527 540 238 451 635 249 381

11.38 20.75 21.25 9.37 17.75 25.0 9.8 15.0

289 527 540 238 654 838 249 381

11.38 20.75 21.25 9.37 25.75 33.0 9.8 15.0

E

* All Mounting holes are 10mm diameter .

DYNAMINI Installation Dimensions

Page 13

ITW Dynatec c. 2004

DYNAMINI ASU Manual 20-25

Page 3-1

Revised 1/05

Chapter 3

INSTALLATION & START-UP

Mounting the DYNAMINI ASU

The DYNAMINI ASU can be mounted on most flat surfaces, on either an open or a solid frame (as

shown below). The main electrical power and the serial communication connections come in from

below the unit and connect under the keypad. Access to the underside of the ASU is not a necessary

consideration in mounting the unit.

The Dynamini’s hinged hopper lid may be rotated 90 degrees in any direction.

For installation dimensions, see illustration on page 2-4.

Lifting the ASU

Hopper Cover

WARNING

The unit must be lifted by two persons, using proper lifting technique, one

person at either end. Securely hold it under its base plate. No belts or hooks

should be used. Never allow anyone to stand on the ASU.

Hopper Lid

Access Cover

Pump & Electronics Cover

Pump ON/OFF

Switch

Main ON/OFF

Power Switch

Controller

Keypad

Captive Cover Screws

Base

Plate

Page 14

Page 3-2

Revised 1/05

DYNAMINI ASU Manual #20-25

ITW Dynatec c. 2004

Installation

NOTE: Re-read Chapter 1 “Safety Precautions” before performing any installation procedures. All

installation procedures must be performed by qualified, trained technicians.

After the DYNAMINI ASU has been properly mounted, the following general sequence should be

followed for installation:

1. Make sure that incoming line power to the ASU is turned OFF at a customer-providedcircuit

breaker. Incoming line power must be overcurrent-protected.

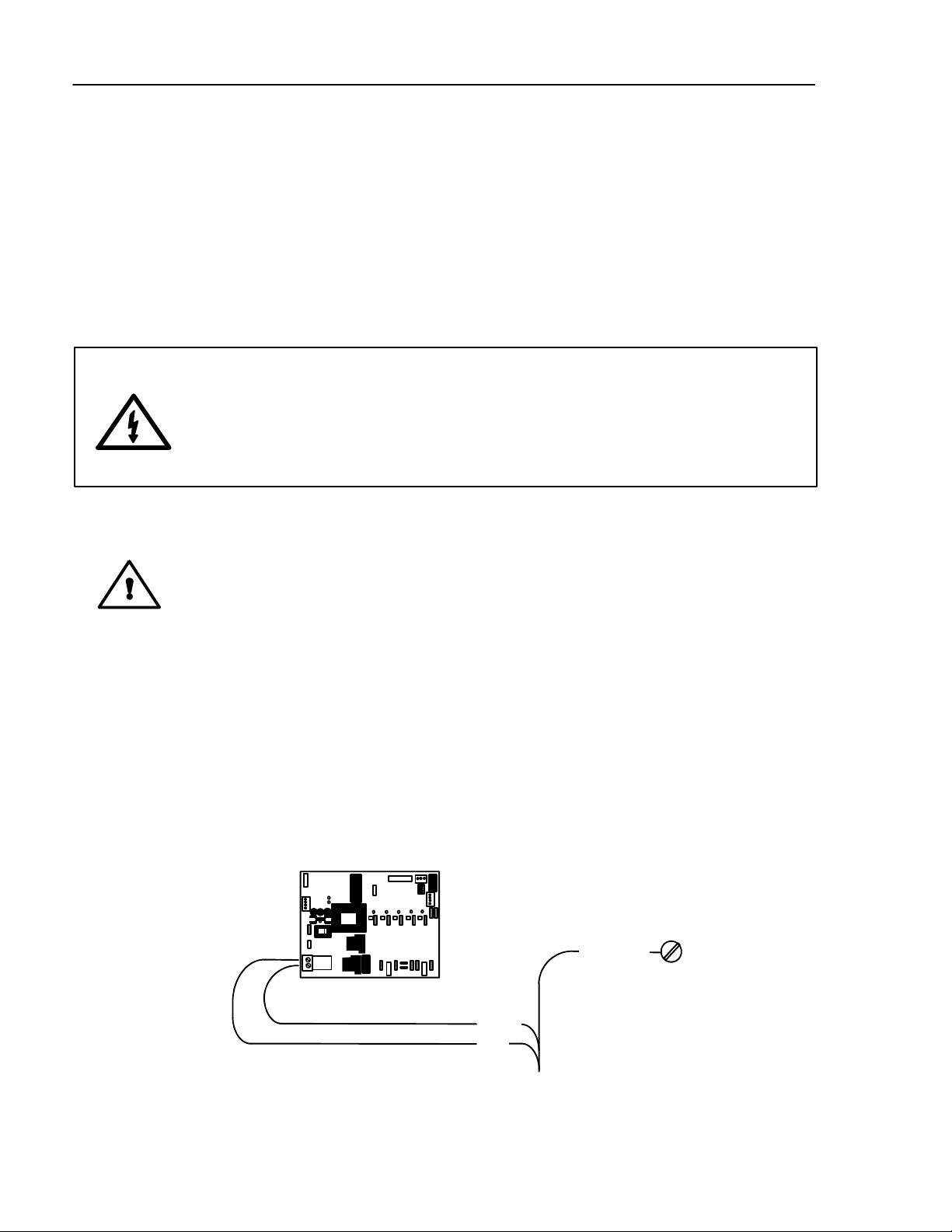

DANGER HIGH VOLTAGE

Disconnect and lockout input power to the application system before starting any installation procedures. Make sure there is no electrical power on the

leads you will be connecting. THE UNIT’S MAIN SWITCH DOES NOT SHUT OFF

ALL POWER WITHIN UNIT!! Make sure incoming line power is turned off at the

customer-provided circuit breaker before opening unit.

2. For 200-240 VAC units, power supply wires should be rated for 30 Amperes service and

should include an earth ground conductor.

CAUTION: Grounding conductors never carry electrical current. The use of a

neutral conducting wire as earth ground is incorrect and may cause damage to

the equipment.

3. 100-120 VAC units are supplied with a line cord and a plug suitable for use in North America

on 15 AMP power supplies. For other types of 100-120 VAC power wiring, supply wires should

be rated for 1.5 Amp service and include an earth ground conductor.

4. Acceptable power supplies are either 100-120 VAC 1-Ph 50/60 Hz with a neutral wire, or

200-240 VAC 1-Ph 50/60 Hz with or without a neutral wire. The information plate on the ASU

(adhesive supply unit) will indicate the required power supply.

5. Power supply wires are to be connected to the removable plug at header X1 on the printed

circuit board,, as shown below.

Printed

Circuit

Board

X1

GROUND

L2/ N

L1

POWER IN

Supply Power Installation Diagram

Page 15

ITW Dynatec c. 2004

DYNAMINI ASU Manual 20-25

6. Choose ASU Voltage:

Using the selection switch on the printed circuit board, set the controller for the appropriate

supply voltage.

Voltage Selection Switch:

“230” for 200-240VAC

or

“115” for 100-120VAC

Printed Circuit Board

7. Reassemble the pump and electronics cover to the ASU.

8. Gear Pump models: omit this step.

Piston Pump models: Install t he Air Control/ Filter Unit (containing the air regulator,the

coalescing filter and pre-filter). See illustration on page 3-5. The air control/ filter unit is

mounted directly to the ASU via a threaded hole on the rear cover. WrapTeflon tape around

the nipple fitting before installing in the ASU. The unit requires clean, dry air. NEVER use

lubricated oil.

Page 3-3

Revised 1/05

For operator convenience, the air pressure gauge can be mounted to either side of the air

control regulator.

Withthe air pressure regulator, a clockwise turn increases pressure. A counter-clockwise

turn decreases pressure. The recommended pressure is 1.4 to 6.8 bar (20 to 100 psi).

9. Refer to the WattageAvailability Chart on the next page to determine the hose and head

power available for the various configurations of the Dynamini ASU.

10. The adhesive hoses are connected at the rear cover (see illustration on page 3-5). Make

your electrical hose connections at the two numbered connects on the left side of the cover.

Route hoses so that there is at least an eight-inch radius at any bend. Do not hang hoses

without proper support. Do not crimp, clamp, squeeze or tie hoses.

The hose adhesive ports are located at the bottom of the filter block, to the right of the

electrical connections. There are three ports for the use of up to two hoses and for the

(optional) adhesive pressure gauge.When making hose connections, use the numbered

guides shown on the illustration to coordinate; ie. when using one hose make your hookup

to electrical connection #1 and adhesive port #1. When using two heads/ hoses, hookup

hose/ head #1 to electrical connection #1 and adhesive port #1, then hookup hose/ head #2

to electrical connection #2 and adhesive port #2.

Refer to the hose and applicator manuals for further details on these items.

11.Install the hose manifold outlet cover by sliding it into place and attaching with the two M4

screws provided.

Page 16

Page 3-4

Revised 1/05

DYNAMINI ASU Manual #20-25

ITW Dynatec c. 2004

Wattage Availability Chart

Wattage Available for

All Hoses and Heads

ASU Voltage Max. System Hopper Gear Pump Piston Pump Gear Pump

Wattage Wattage Motor Wattage

100-120 VAC 1800 @ 120VAC 600 @ 120VAC 370 @120VAC 1200 @ 120VAC 830 @ 120VAC

200-240 VAC 7200 @ 240VAC 1200 @ 240VAC 370 @ 240VAC 6000 @ 240VAC 5630 @ 240VAC

Notes:

1. Assume 33 Watts per foot of hose, #6 hose at 120VAC or 240VAC.

2. Assume 100 Watts per inch of head width, at 120VAC or 240VAC.

3. The power available for any one hose or head is 720 Watts at 120VAC or 1440 Watts at 240VAC.

4. At reduced voltage, less wattage is available. For example: 120 volt equipment operated on 100

volts or 240 volt equipment on 200 volts, will develop wattage 31% lower than the wattage available

at 120 or 240 volts.

Adding Adhesive

WARNING HOT ADHESIVE

Do not overfill the hopper (melt tank) since adhesive generally expands as it

melts and a full hopper will overflow.

CAUTION: Using adhesive with viscosity over 50,000 centipoise could cause

motor stall and/ or pump failure.

The adhesive level should be maintained at 13mm to 100mm (1/2” to 4”) from the top of the hopper. Where applications demand a high output volume of adhesive, add small amounts of adhesive

frequently. Adding large amounts of adhesive to an almost empty hopper will lower the temperature

of the adhesive in the hopper and may cause the ASU to fall below its READY setpoint.

Changing the Adhesive Formula

If a different adhesive formulation from the one being currently used is needed, the system will

have to be flushed if the two formulations are incompatible. See page 6-3 of this manual for the

proper flushing procedure. When in doubt about adhesive compatibility, flush your system.

Page 17

ITW Dynatec c. 2004

DYNAMINI ASU Manual 20-25

Pressurized Air In

1/4 NPT female

Air pressure gauge

Page 3-5

Revised 1/05

Air Pressure Regulator (clockwise increases)

Air Flow

Coalescing filter

Air Control/ Filter Unit

Maintain adhesive level 13mm-100mm (1/2”4”) from top of hopper.

Pre-filter

Adjustable Pressure

Relief Valve

Air Control/ Filter Unit

Hose/ Head

Electrical Connections

120v 240v

Electrical #1

Electrical #2

Electrical #1

Electrical #2

Rear Cover: Hose and Head Electrical and Adhesive Connections

Output Filter Manifold

Adhesive Supply

Hose

Pressure Gauge (optional)

Hose/ Head Adhesive Ports

Adhesive Port Connections

#1

Gauge

#2

Page 18

Page 3-6

Revised 1/05

DYNAMINI ASU Manual #20-25

ITW Dynatec c. 2004

Typical Start-Up and Shut Down of the DYNAMINI Application System

Start Up Procedures

1. Fill the ASU’shopper with clean hot-melt adhesive as described on page 3-4. Close the

hopper lid immediately to prevent contaminants from falling in. (Cover your bulk supply of

adhesive to prevent contaminants also.)

2. At the control panel, turn ON the Main Power Switch. The controller will perform its initial

calibration cycle. The display will read “CAL”. Each of the five temperature zone’s LEDs will

flash as a lamp test.

3. Program your adhesive setpoints (see instructions on page 5-2) or use the factory settings listed

below. Allow adequate time (approximately 20-30 min.) for the adhesive to melt and the

temperatures of the temperature zones to stabilize.

Note: When the ASU leaves the ITW Dynatec factory, it is programmed with the following

factory settings (unless special factory settings were requested):

Hopper: 150°C (300°F)

Hose: 177°C (350°F)

Applicator: 177°C (350°F)

Sequential Startup: ON

4. Once the ASU has reached temperature, turn ON the Pump ON/ OFF Switch. The ASU will

begin to pump adhesive.

5. a. On piston pump units: use the air pressure regulator, located at the rear of the ASU, to

regulate adhesive output.

b. On gear pump units: use the pressure relief valve, located on the filter outlet manifold, to

regulate adhesive output.

Shut Down Procedures

1. Turn OFF the Pump Switch.

2. Turn OFF the Main Power Switch.

Page 19

ITW Dynatec c. 2004

DYNAMINI ASU Manual 20-25

Revised 1/05

Storage and Disposal of the DYNAMINI Application System

Temporary Storage of the Unit

1. Flush the adhesive application system with flushing fluid (PN L15653), following the

instructions detailed in chapter 6 of this manual.

2. Clean or replace both the output filter and the primary filter, following instructions detailed

in chapter 6.

3. Shut OFF all pressure and power sources.

4. Release residual air pressure.

5. Remove all residual adhesive and wipe components clean.

6. Remove all air lines and all power supply cables.

Page 3-7

7. Pack the unit in a corrosion-proof manner.

8. Store the unit in such a way that it is protected from damage.

Disposal of the Unit

1. Shut OFF all pressure and power sources.

2. Release residual air pressure.

3. Remove all residual adhesive.

4. Remove all air and adhesive supply hoses and all power supply cables.

5. Dismantle all components and sort into mechanical and electrical components.

6. Arrange for all components to be recycled.

Page 20

Page 3-8

Revised 1/05

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

ITW Dynatec

An Illinois Tool Works Company

Adhesive Application Solutions

Page 21

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Page 4-1

Revised 11/04

Chapter 4

DYNAMINI TEMPERATURE CONTROLLER SET-UP

Temperature Control Functions in General

The Dynamini temperature controller provides accurate temperature control for the hopper, hoses

and applicators. Setpoints are programmed at the user-friendly,all-icon keypad. The controller will

display an error message any time an open or shorted sensor condition occurs.

Defining Dynamini Temperature Control Terms

Adhesive Temperature Control Range

The temperature limits within which the ASU, hoses and applicators may be programmed and maintained.

Printed Circuit Board (PCB)

The Dynamini contains one pcb. It contains the central processing unit (CPU) of the microprocessor

temperature control as well as providing control signals to, and monitoring signals from, the hopper,

hoses and applicators. It features lighted LEDs to indicate that heater power is ON. The ASU’s fuses

are located on this board.

Dynamini Temperature Controller

The built-in control system that controls, monitors and displays all system temperature values of the

Dynamini adhesive application system.

Mechanical High-Temperature Protection

A mechanical, redundant thermostat located on the hopper that will turn off t he system above 232°C

(450°F).

RTD Sensors

The Dynamini system uses 100-ohm platinum resistance temperature detector sensors for all temperature controls.

Sequential Startup

This feature allows the temperature zones to come on in sequence (hopper,followed by hose, followed by head). When activated, and the ASU is turned ON from a cold start, the hopper heats first.

When the hopper is within the programmable tolerance of setpoint, the Head(s) and hose(s) begin to

heat. No other features of the ASU are affected by sequential startup.

Note: sequential startup is rarelyused. In most cases, it should be de-activated to ensure rapid warm

up.

Page 22

Page 4-2

Revised 1/05

Setpoint

DYNAMINI ASU Manual #20-25

ITW Dynatec c. 2004

A programmable temperature that has been selected for hopper, hoses and applicators.

Setpoint Limitation

This is a universal maximum temperature for all zones (218°C [425°F]). The programmer cannot

program a temperature setpoint higher than the setpoint limitation.

Stepped Function

(Future feature, not on V2.0)

Used on systems with electric applicators only. After programming the temperature (to the softening

point of your adhesive, see your adhesive manufacturer), the controller holds all electric heads at

the operator-selected temperature for ten minutes before releasing them to operating setpoint. This

feature allows for the stabilization of the electric valves.

Error Indication Messages

A controller display of “EO1” indiates that the selected zone (ie, a hose, applicator or the hopper)

has an open sensor. A display of “EO2” indicates a shorted sensor.

If either alarm occurs, first verify that the following three connections are made correctly:

1. The ASU-to-hose connection(s) located at the back of the ASU,

2. The hose-to-applicator connection(s),

3. The RTD Input connections (X4) located on the Control Printed Circuit Board.

If the problem is not with a connection, check the sensor and replace if necessary.

Software Chip (EPROM) and Checksum

The software EPROM is on the Control Printed Circuit Board (see Ch. 7). Inscribed on the controller’s software chip is information that is required if your controller needs service, including the controller’schecksum.

Software chip example:

Part Number of

Control PCB

The date this Software EPROM was manufactured

102434 OEF8

Date: 12-7-04

Software chip (EPROM)

Checksum example

Page 23

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Settings for a Typical Operation

Note: The values given here are approximate settings for a typical packaging operation. The values

you choose will be based on the type of equipment and adhesive you are using and the nature of

your particular operation.

If Application Temperature is 163°C (325°F):

·

Hose and head temperature: 177°C (350°F).

·

Hopper setpoint temperature: 150°C (300°F).

·

ASU operating range: 135°C to 177°C (275°F to 350°F).

·

Mechanical thermostat (for the hopper) over-temperature: 232°C (450°F)

Page 4-3

Revised 11/04

System Values That Are Permanently Programmed

·

Minimum setpoint value: 40°C (100°F).

·

Maximum setpoint value: 218°C (425°F).

System Values as Programmed by the Factory

ITW Dynatec can set the controller’s system values to customer’s specs, if provided.

If customer’s specs are not provided, the following values will be entered into the Dynamini tem-

perture controller at the factory. They may be changed by reprogramming through the keypad.

(These are not the “default” settings, see following section).

·

Temperature scale: displayed in degrees Farenheit.

·

Applicator (head) and hose setpoints: 177°C (350°F).

·

Hopper setpoint: 150°C (300°F).

·

All zones are switched off, except for the hopper.

Page 24

Page 4-4

Revised 1/05

Default Settings of the Controller

Default settings are the manufacturer’s preset values to which the system will return if the Dynamini tempearture control is subjected to an internal memory reset. While you can change your programmed values to anything within the system’s limits, the default settings cannot be changed.

To cause an internal memory reset (ie, to restore the defaults) of a temperature zone, turn that temperature zone ON and then OFF.

Defaults

·

Temperature setpoint for each zone: 93°C (200°F).

·

Sequential Startup: SSO (OFF)

Helpful Tips for the User

DYNAMINI ASU Manual #20-25

ITW Dynatec c. 2004

·

When the ASU is turned on, all temperature setpoints and other operating parameters will

be exactly where they were when the ASU was turned off.

·

When the ASU is turned on, all system heaters go on unless they have previously been set

below 40°C (100°F).

Page 25

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

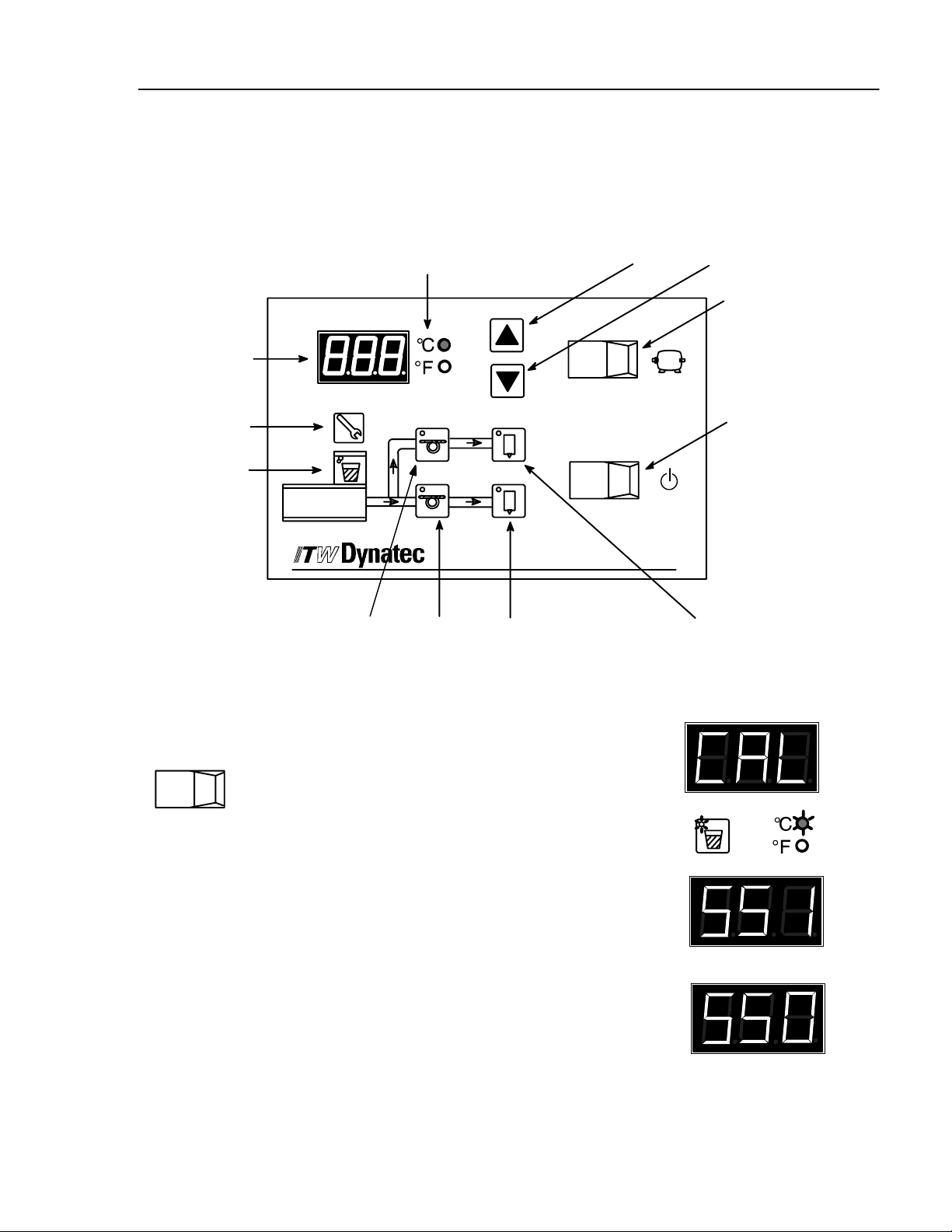

PROGRAMMING INSTRUCTIONS FOR DYNAMINI CONTROLLER

Dynamini Keypad

Page 5-1

Revised 1/05

Chapter 5

Scroll Keys:

Pump Switch

O

Main Power Switch

O

Temperature

Display

Service Key

Hopper

Temperature

Zone

Temperature

Scale

1

1

22

to increase value to reduce value

I

I

Dynamini

Temperature Zones: Hose #1 Hose #2 Application Head #2 Application Head #1

Programming

Turn controller ON

O

I

Turn ON the main power switch.

System will go through its self-diagnostics (CAL).

Temperature zone LEDs will flash.

Controller will display “SS 1” (On) or “SS 0” (Off) to

indicate status of the Sequential Statup feature

(see info on “Sequential Startup” later in this chapter).

Controller will display it’s software version, ie.

V.2.XX

or

Page 26

Page 5-2

Revised 1/05

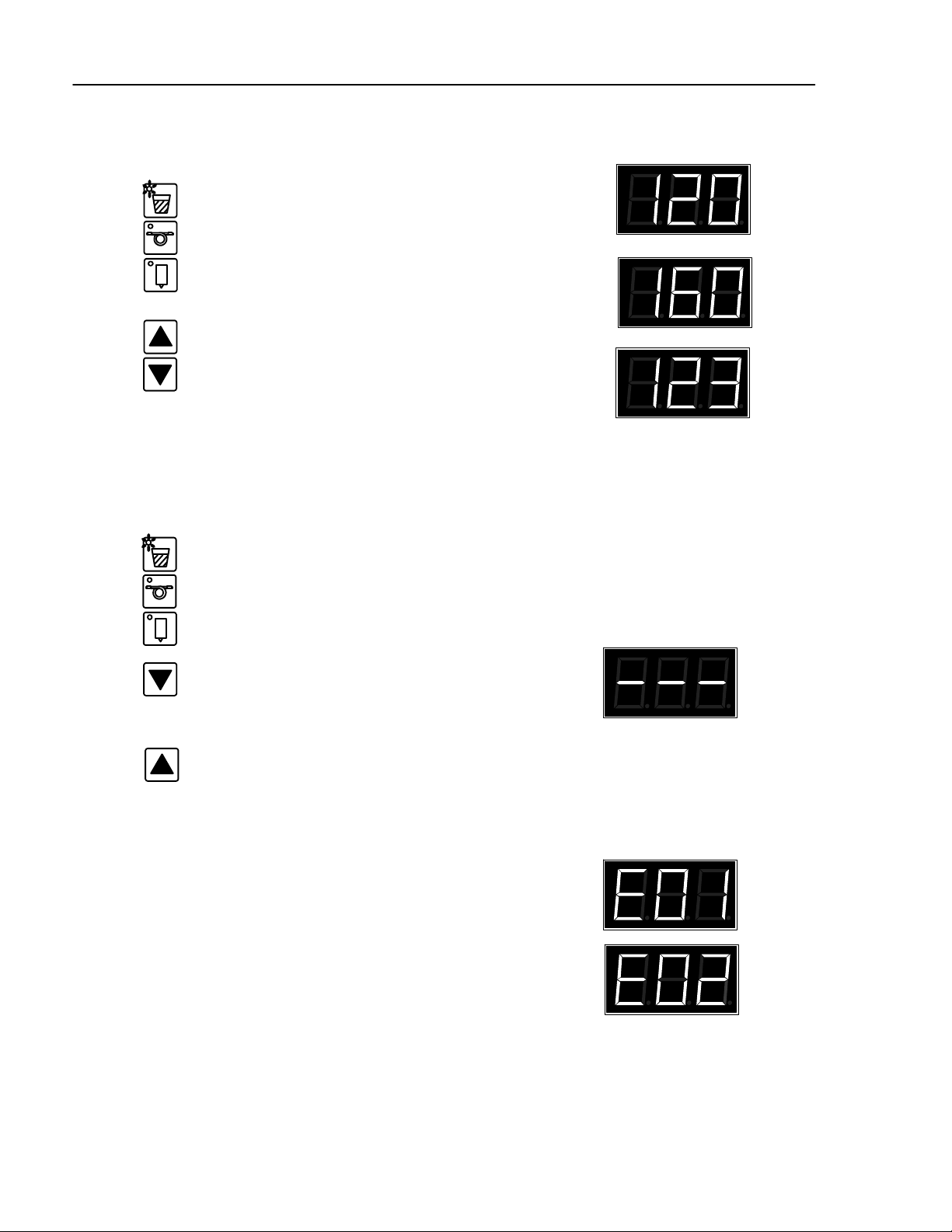

Programming temperature setpoints

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

or

Choose a temperature zone.

or

Scroll to “increase value” or ”reduce value”,

or

in order to adjust the setpoint temperature.

After two seconds the display will read the

actual temperature. The setpoint is stored.

Turning temperature zones ON/OFF

or

Choose a temperature zone.

or

Scroll to “reduce value” until temperature

setpoint is 0. The temperature zone is now

turned OFF.

To turn ON the temperature zone, increase

the setpoint.

Error indication messages

The temperature sensor is open or has high resistance.

The temperature sensor is shorted or has low resistance.

Page 27

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Keypad Locking

Page 5-3

Revised 1/05

Itis possible to lockorunlock the controller inorderto restrict programming changes.Tochange the

code which is necessary to over-ride or unlock the keypad lock, see Service Functions.

Note: the ASU is shipped with de-activated keypad lock. If the keypad lock must be used, an access

code must be programmedprior to locking the keypad.

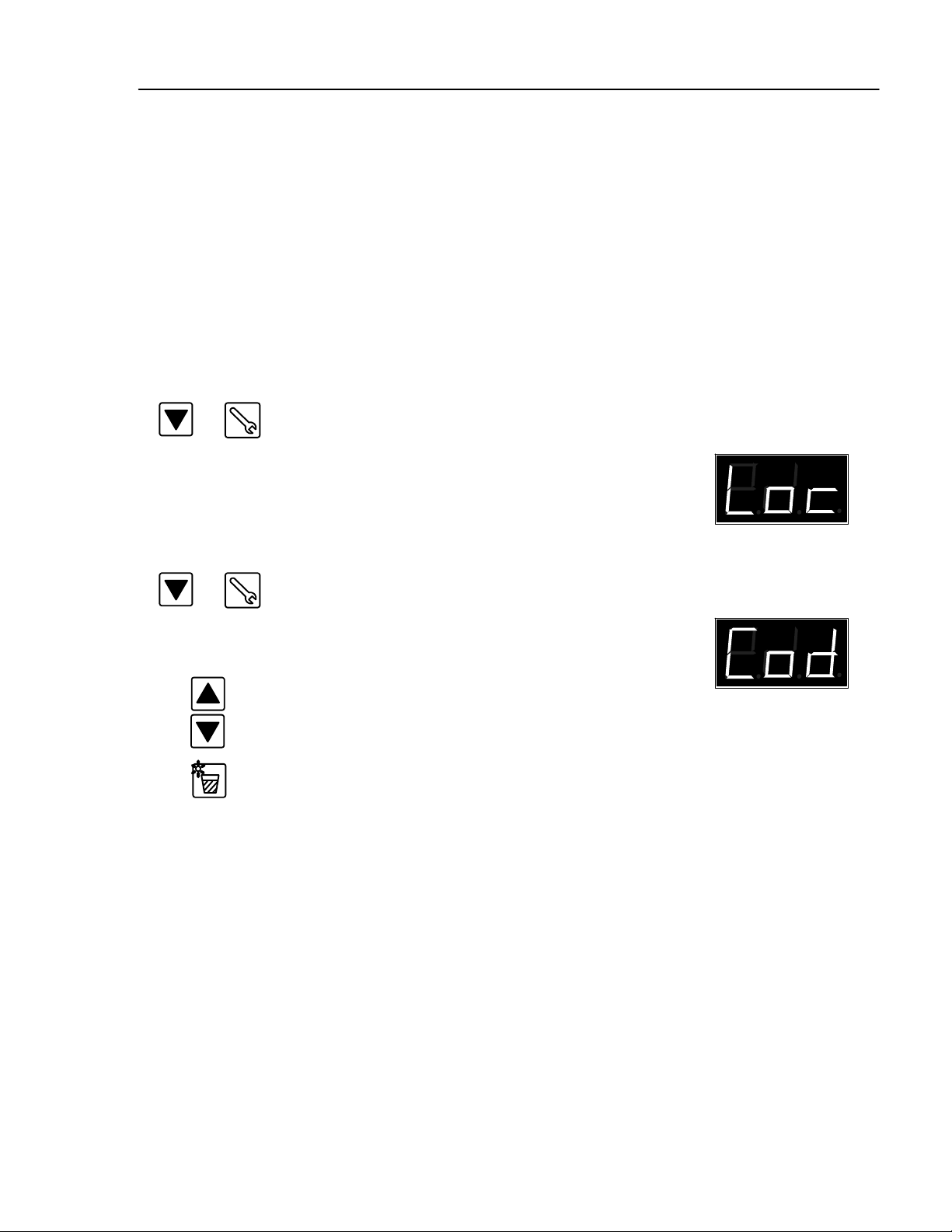

Locking or Unlocking the Keypad

Important Note: the controller must be in the Temperature Display mode in order to allow

locking or unlocking of the keypad.

Locking the Keypad

&

Unlocking the Keypad

&

or

Press the Down Scroll key, then hold and press the

Serviceiconkey.

You will see “Loc” to indicate that the Keypad Lock is

active.

Press the Down Scroll key, then hold and press the

Serviceiconkey.

You will see “Cod” to indicate that the access code is

required.

Enter your access code by scrolling up or down. Default

co de = “ -- -- -- ”.

Confirm your code input by pressing Tank key.

Notes:

1. Once the keypad lock is active, unauthorized programming is not possible, even after turning the

ASU OFF, then back ON again.

2.Once the keypad lockisunlocked,programming is possibleuntiltheASUis turnedOFF,then back

ON or the keypad is locked again.

3.Ifthekeypadmust be unlocked permanently,theaccesscodemust must be de-activatedin the Service Functions.

Page 28

Page 5-4

Revised 1/05

DYNAMINI ASU Manual #20-25

ITW Dynatec c. 2004

Service Functions

After the basic programming of TemperatureSetpoints is complete, the programmer proceeds to

programming of the Service Functions, if desired.

The Service Functions are a continuous loop of programming steps (”functions”) which the programmer moves through by pressing the “Service” key. These steps are described in this section

of the chapter. The Service Functions loop and b asic programming is diagrammed below.

There are three ways to exit the Service Functions loop:

1. Just wait (approx. 10 seconds) and the controller will automatically return to the actual temperatures display,

2. Press the Service key until you are back to the actual temperatures display, or

3. Press any Hose or Head key and you will return to the actual temperatures screen.

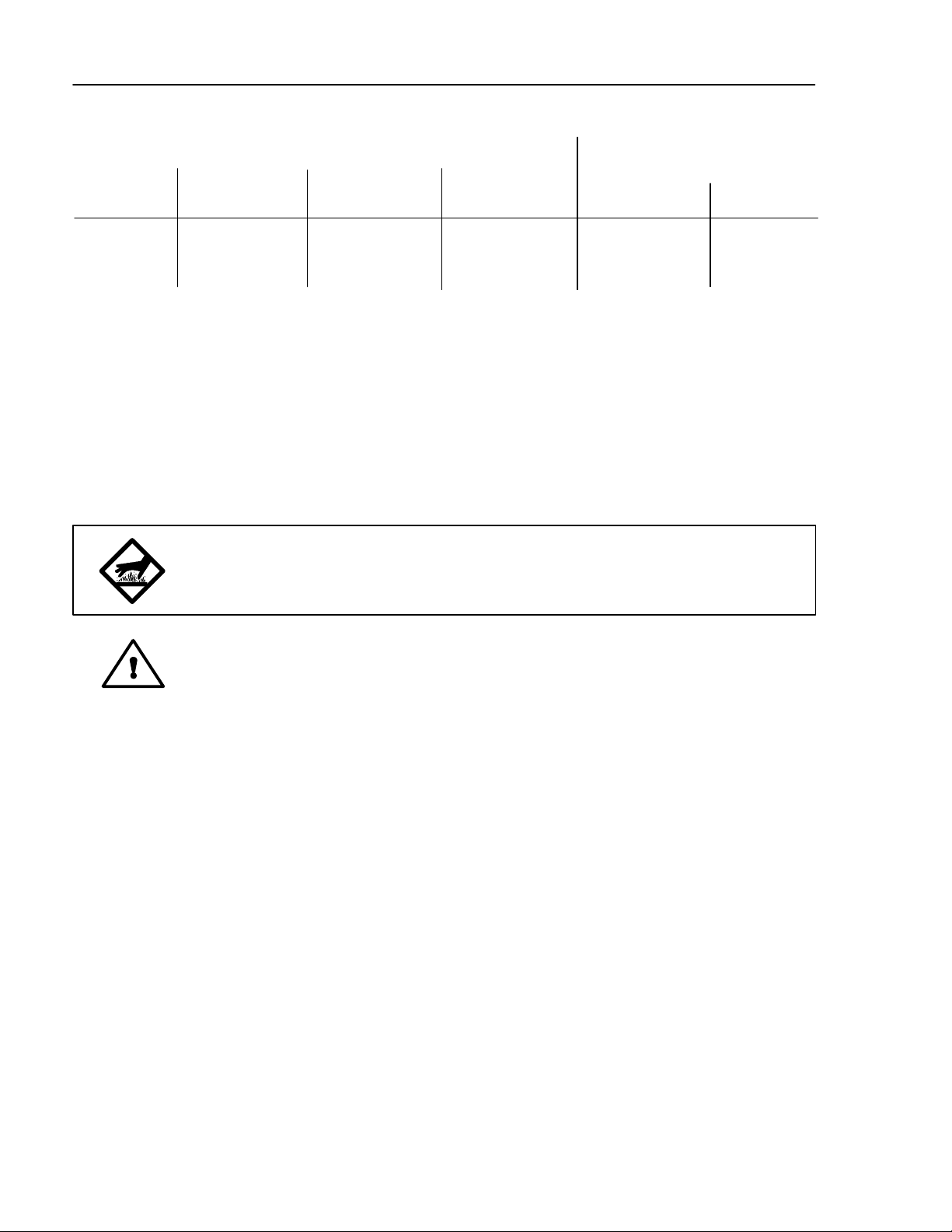

Diagram of the

Service Functions Loop

C

F

Actual Temperature Display

Activate De-activate Temperature Setback

Change Setback Temperature Value

Change Hi/ Lo Tolerance Value

Activate/ De-activate Sequential Startup

Select Temperature Scale

Change Ready Delay

Change Access Code

C

F

Actual Temperature Display

Page 29

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Page 5-5

Revised 1/05

Service Functions

Standby Programming

, cont.

“Standby” is a temperature value by which all temperature zones will lower when Standby mode

is activated. For example, if your temperature setpoints are all 300 degrees, and you program a

100 degree Standby, then the Standby temperature of all zones will be 200 degrees. Similarly, if

your temperature zones setpoints vary, and you program a 100 degrees Standby,each zone’s

Standby temperature will be 100 degrees lower than its setpoint.

Press Service icon to enter Service Functions.

You will see either “S--1” (standby is On) or “S--0”

(standby is Off).

Press the Tank icon to activate/ de-activate Standby.

If desired, you may set the Standby temperature by

scrolling up or down to desired temperature.

When programming is complete, wait a few seconds

and the controller will return to the ASU’s actual

temperature.

or

Note: When Standby is active, the display will alternate between the ASU’sactual temperature

and S--1.

Page 30

Page 5-6

Revised 1/05

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Service Functions,

T o Set Tolerance (Hi & Low Temperature Limits)

cont.

The Tolerance (high/ low alarm) setpoint is a range (+ and -- the zone’s temperature setpoint) between which your ASU can safely operate. It’s lower temperature represents the ASU’sready

temperature. It’s upper value represents the over-temperature point.

Setting the Tolerancerange, for example: if the temperature setpoint is 200 degrees, and the Tolerance setpoint is 10 degrees, then the high alarm (overtemp) equals 210 degrees and the low alarm

(ready temp) equals 190 degrees.

x2

or

Press the Service icon twice to select the Tolerances of your

temperature zones. An display of “t--1” indicates the Tolerance

function has been selected.

Press the Tank button to display the Tolerance.

Use the scroll buttons to change the Tolerance range for all zones.

Note: your Tolerance range must be a value between ± 50 degrees

for Fahrenheit (± 27 degrees for Celsius).

When Tolerance programming is complete, wait a few seconds and

the controller will return to the ASU’s actual temperature.

Turning Sequential Startup ON/OFF

The Sequential Startup feature programs the order in which the temperature zones will come on at

startup. A Sequential Startup” of “SS1” (On) means the tank will begin heating first, then, when the

tank is ready, the other zones will begin heating. A Sequential Startup of “SSO” means Sequential

Startup is Off and all zones will begin heating immediately.

x3

or

Press the Service icon three times to set Sequential Startup.

The display will flash either “SS1” (sequential startup is ON) or

“SS0” (sequential startup is OFF).

Scroll to choose between ON and OFF. When programming is

complete, wait a few seconds and the controller will return to

the ASU’s actual temperature.

Note: Any time the ASU is switched ON, you will briefly see

“SS1” or “SS0” displayed.

or

Page 31

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Page 5-7

Revised 1/05

Service Functions,

To Set Temperature Scale

cont.

The Temperature Scale may be set to display temperature either in degrees Celsius or Fahrenheit.

x4

or

To Set Ready Delay

Press the Service icon four times to set the Temperature

Scale.

Scroll to choose between Celsius (”C”) or Fahrenheit

(”F”) as indicated by the Temperature Scale LED. When

programming is complete, wait a few seconds and the

controller will return to the ASU’s actual temperature.

When the system is ready (all temperature zones are within tolerance), a ready delay may be programmed to delay the system’s ready output signal.

x5

Press the Service icon five times to set a Ready Delay.

You will see “d--1” to indicate you are in Ready Delay

programming mode.

or

Press the Tank icon to display the Ready Delay.

To change a Ready Delay, scroll up or down to the

desired length (in minutes) of delay.

0 = Default, no delay

99 minutes = maximum length of delay

When programming is complete, wait a few seconds and

the controller will return to the ASU’s actual temperature.

Page 32

Page 5-8

Revised 1/05

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Service Functions,

cont.

To Change Access Code (De-activate Keypad Locking)

x6

To change the Access Code, press the Service icon six

times.

You will see “C--1” to indicate you are in Access Code

programming mode.

Press the Tank icon to see the programmed Access

Code. For example, “999”.

To change the Access Code, scroll up or down to the desired

or

numeric value.

“-- -- --” = no Access Code (Access code is de-activated),

“-- -- --” = no Keypad Locking

1 - 999 = possible Access Code values

When programming is complete, wait a few seconds and the controller will return to

the ASU’s actual temperature.

Page 33

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Page 5-9

Revised 1/05

Controller Features

System Ready Indicator Light

When not in programming mode, a flashing temperature scale light

(LED) indicates that the ASU is not “Ready” forproduction. This LED

will cease to flash when all temperature zones are within the programmed temperature tolerance window.

Error Indication Messages

“EO1” = the temperature sensor is open (no sensor attached) or has

high resistance.

“EO2” = the temperature sensor is shorted or has low resistance.

To Copy and Paste Setpoints

The Copy/ Paste feature of the controller copies the tank setpoint and pastes it as the setpoint of

other temperature zones. The paste will apply to only temperature zones that are switched ON.

then

Set your Tank setpoint as described earlier in this chapter.

&

&

Push and hold the Tank icon. While holding, press the #1 Hose icon. Release.

Push and hold the Tank icon again. While holding, press the #1 Head icon. Release.

The manually programmed setpoint has now been pasted in to all turned on hose and

head zones. When programming is complete, wait a few seconds and the controller

will return to the ASU’s actual temperature.

Page 34

Page 5-10

Revised 1/05

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

ITW Dynatec

An Illinois Tool Works Company

Adhesive Application Solutions

Page 35

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Page 6-1

Revised 1/05

Chapter 6

PREVENTIVE MAINTENANCE

Note: Re-read Chapter 1 “Safety Precautions” before performing any maintenance procedures. All

maintenance procedures must be performed by qualified, trained technicians.

General Cleaning

Follow the manufacturer’s directions when using industrial cleaners on the enclosure.

Preventive Maintenence

Output Filter

During the first weeks of operation, the output filter must be replaced monthly.

To replace the output filter:

1. Follow instructions “Purging the Filter

Filter Nut

Manifold of Adhesive and Pressure”, page 6-2.

2. Unscrew and remove the filter nut

(15.8 mm or 5/8” nut).

3. With pliers, pull the filter basket out.

4. Replace the o-ring on the filter nut. Apply

o-ring lubricant (PN N07588) to the new

o-ring.

5. Replace the filter basket.

6. Apply anti-seize to the threads of the filter

nut and re-install. Tighten the filter nut until

it is seated firmly, taking care not to cut the

o-ring.

Hose Fittings & Fasteners

Periodically check all hose fittings and screws for tightness.

O-ring

Filter Basket

Output Filter

Manifold

Purge Screw

Purge Drain (on underside)

Page 36

Page 6-2

Revised 1/05

Hopper FIlter Inspection & Cleaning

DYNAMINI ASU Manual #20-25

ITW Dynatec c. 2004

The hopper filter is a coarse screen located in the bottom of the hopper. It fits over the hopper’s

drain hole and prevents any large debris from leaving the hopper.

1. Pump all adhesive out of the ASU.

2. Open the hopper lid and inspect the hopper filter.

3. If cleaning the filter is necessary,lower the temperature of the hopper 20-30°C (35-50°F)

from operating temperature.

WARNING HOT SURFACE

The ASU will still be hot during this procedure. Use insulated gloves and

protective clothing when handling the hopper filter.

4. Use a hook to pull the hopper filter out.

Hopper

Filter

5. Emerse the clogged filter in flushing fluid (PN L15653),

then use a hot air gun and rags to clean it.

6. Re-insert the filter into the hopper.

7. Refill the hopper and resume production.

Purging the Filter Manifold of Adhesive and P ressure

As a safety precaution, purge the filter manifold before changing the output filter or before removing any of the hoses or applicators from their manifold port.

Refer to the illustration on page 6-1 while following these instructions.

WARNING

HIGH PRESSURE

During the purging procedure, hot adhesive can come out of the manifold under

high pressure. Wear safety glasses, gloves and protective clothing. Stand clear

of the ASU until all pressure is relieved.

HOT ADHESIVE

Avoid splashing hot adhesive. Position a heat -resistant container under the

manifold’s purge drain before proceeding.

1. The system should be at operating temperature. Turn the pump/ motor OFF.

2. With a hex key screwdriver (allen wrench), slowly loosen the purge screw (do not remove

it). Allow the adhesive and pressure to escape. All the adhesive will flow into the heatresistant container.

3. Re-tighten the purge screw.

Page 37

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Page 6-3

Revised 1/05

Flushing the System

Contaminated adhesive, accumulation of residue, or changing the adhesive formulation may require

the system to be flushed. At least 6 liters (1.5 gallons) of flushing fluid is required (PN L15653).

WARNING

The flushing fluid will splash easily. Wear protective clothing, gloves and

goggles to prevent severe burns.

1. Pump out as much of the molten adhesive as possible.

2. Reduce the pump pressure to zero by first turning the pump switch to OFF. Then open the

purge screw,following the instructions given in “Purging the Filter Manifold of Adhesive

and Pressure” on page 6-2.

3. Disconnect one of the supply hoses’ adhesive feed from its applicator head. Do not

disconnect electrical power to the head. Put the hose in a secured position within a container

to catch the used flushing fluid.

4. Add flushing fluid to the hopper and allow approximately fifteen minutes for it to reach

hopper temperature. Carefully stir the flushing fluid to mix with any remaining adhesive.

5. For Piston Pumps: Slowly turn the air pressure regulator clockwise.

ForGearPumps:Slowly turn the pressure relief control valve clockwise.

6. Pump about half of the fluid into the container.

7. For Piston Pumps: Turn the regulator counter-clockwise.

ForGearPumps:Turn the motor OFF.

Pressure

Regulator

Pressure

Relief Valve

8. Remove the output filter and replace the basket. Install a new o-ring on the filter nut

(lubricate the new o-ring with o-ring lubricant prior to installation) and tighten the brass nut.

9. Add new adhesive to the hopper and heat to application temperature.

10. For Piston Pumps: Slowly turn the air pressure regulator clockwise.

ForGearPumps:Turn the motor ON.

11. Actuate each applicator until all flushing fluid is removed and a steady stream of new

adhesive flows.

12. For Piston Pumps: Re-adjust the pump air pressure for desired flow.

ForGearPumps:Re-adjust the pressure relief for desired flow.

13. Re-fill the hopper and resume production.

Page 38

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Page 7-1

Revised 1/05

Chapter 7

TROUBLESHOOTING

General Troubleshooting Notes

Note: Re-read Chapter 1 “Safety Precautions” before performing any troubleshooting or repair procedures. All troubleshooting or repair must be performed by qualified, trained technicians.

DANGER

HIGH VOLTAGE

Dynamini systems use electrical power that can be life threatening and hot-melt adhesives that

can cause serious burns. Only qualified persons should perform service on the Dynamini system.

Handling Printed Circuit Boards (PCBs)

WARNING

HOT SURFACE

DANGER HIGH VOLTAGE

Before unplugging connectors from the I/O PCBs, ground yourself to the

ASU by touching any available unpainted cool metal surface, mounting

screws, etc. This will avoid electrical discharge to the PCB assembly when you are removing and replacing connectors.

CAUTION: Printed circuit boards (PCBs) should b e handled using the following

procedures:

1. Wear a wrist grounding strap. If a grounding strap is not available, frequently touch a

bare metal part of the ASU (unpainted frame, mounting screw, etc.) to safely discharge

any electrostatic buildup on your body.

2. Handle a PCB by its edges only. Don’t grip a PCB across its surface.

3. When removed from the ASU, each PCB must be individually packaged inside a

metallized, static drain envelope. Do not place the removed PCB on a table, counter,

etc. until it has first been placed in or on a static drain envelope.

4. When handing a PCB to another person, touch the hand or wrist of that person to

eliminate any electrostatic charge before you hand the PCB to him.

5. When unwrapping a PCB from its static drain envelope, place the envelope on a

grounded, nonmetallic surface.

6. To cushion PCBs for shipment, use only static-drain bubble pack. Do not use foam

peanuts or bubble pack not known to be static draining.

Page 39

Page 7-2

Revised 1/05

DYNAMINI ASU Manual #20-25

ITW Dynatec c. 2004

Printed Circuit Board

Notes:

The PC board contains the controller’s software/ CPU chip and non-volatile memory.

The green, temperature zone LEDs cycle on and off as each heater outputs.

The PCB is mounted under the ASU’s cover.

The fuses are designated F1 thru F13 below. See diagram for sizes. The fuses are the only replace-

able parts on the pc board. Each temperature zone is fused with two fuses.

Connect to RTDs:

1&2 = Hopper

3&4 = Hose 1

5&6 = Head 1

7&8 = Hose 2

9&10 = Head 2

Over Temp

{

Thermostat

PCB fuse

(1A slow)

Connect to

Main Switch

Customer’s

Power Input

Software/

CPU chip

10

1

X4

LED1 (5v OK)

LED2 (12v OK)

X3

230v

F1

Transformer

for Dynatec

use

J1

54321

LED3 LED4

F2 F3 F4 F5

HOSE1 HEAD1 HOPPER HOSE2 hEAD2

Relay

1

X2

HOSE1 HEAD1 HOSE2 HEAD2

X1

N

Relay

L

F9

Connect to

Keypad at J1

X5

Hopper

LED5

F10

HOPPER

X9

X10

Ready

No Com NC

X6

S4

S3

S2

S1

ON

LED6 LED7

F12F11

Dip switches:

not used

Pump

X7

N

L

2 pump fuses

(2A slow)

F7 F8

F6

Temperature

zone fuses,

2 per zone

(6.3A fast)

F13

X8X11

11

Voltage Selector:

“230” = 200-240v

“115” = 100/120v

Ground

Terminal (2)

Layout of Components on PC Board

Mounting

Holes (2)

Heater RTD for

Hose/ Head 1

Mounting

Bracket/

Heat Sink

Heater rtd for

Hose/ Head 2

Connect to

Hopper Heater

Page 40

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Page 7-3

Revised 1/05

Overtemp Thermostat

The overtemp thermostat is a safety back-up. If the hopper temperature exceeds 232°C (450°F), the

thermostat causes a circuit breaker to open and power to the hopper and all hoses and heads will be

cut off. The overtemp thermostat re-sets when the hopper temperature falls below 204°C (400°F).

To re-set, turn the main power switch OFF, then ON again.

Heater

PCB Board

Control PC Board

Sensor

Overtemp Thermostat

Overtemp Thermostat

Location of Printed Circuit Boards and Overtemp Thermostat

Page 41

Page 7-4

Revised 1/05

Resistance Tables

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Temperature Resistance

°

F

°

CinOhms

32 0 100

50 10 104

68 20 108

86 30 112

104 40 116

122 50 119

140 60 123

158 70 127

176 80 131

194 90 135

212 100 139

230 110 142

248 120 146

268 130 150

284 140 154

302 150 157

320 160 161

338 170 164

356 180 168

374 190 172

392 200 176

410 210 180

428 220 183

Hose Length Resistance in Ohms

Meters Feet 120V 240V

1.2 4 102-125 400-490

1.8 6 63-77 291-355

2.4 8 50-61 204-249

3 10 39-48 155-189

3.7 12 31-37 125-153

4.9 16 23.6-29 98-120

7.3 24 N.A. 61-75

Nominal Hose Heater Resistance

for DynaFlex Hoses

Watts Resistance in Ohms

120V 240V

200 72 288

270 53 213

350 41 165

500 29 115

700 N.A. 82

Temperature Sensor Resistance

Note: Resistance is measured at ambient temperature (20

Nominal Head Heater Resistance

Qty. Heaters

Resistance in Ohms

for each heater

2

25

Nominal Hopper Heater Resistance

°

C/ 68°F).

Page 42

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Troubleshooting Guide

Preliminary Checks: Verify the following before proceeding

1. The ASU is switched on.

2. The ASU is supplied with power.

3. The ASU is supplied with pneumatic air.

4. Pneumatic and electrical connections are correct.

5. Adhesive is in the hopper.

Error Messages (see also Chapter 4)

EO1 = temperature zone has an open sensor

EO2 = temperature zone has a shorted sensor

Hose/ Applicator Troubleshooting Tip

Hose or applicator problems can be isolated by electrically connecting the

applicator and hose to an alternate socket on the ASU. If the malfunction

goes with the applicator and hose, the problem will usually be in the applicator

or hose that was moved. If the malfunction does not move with the applicator

and hose, the problem is probably in the ASU.

Page 7-5

Revised 1/05

Problem Possible Cause Solution

Controllersetpointsare

1.Main Power switch OFF.

1.Switch ON.

not adjustable.

All channels display

2.PCB inoperative.

3.Keypad locked.

1.PCB inoperative.

2.Replace PCB.

3.Unlock.

1.Replace PCB.

errormessage orwrong

actual temperatures.

System is not working,

display is OFF.

1.Power supply plug at X1

is not plugged in.

1.Check power supply plug

connection.

2.Ribbon connector J1 is

disconnected from back

2 Check connection.

of PCB or display panel.

Display

Panel

3.F1 fuse on the PCB is

inoperative.

J1 ribbon connector to display panel

3.Insert new fuse, if it blows, the

PCB is inoperative.

F1

X2

Incoming AC power

X1

ON

Page 43

Page 7-6

Revised 1/05

Problem Possible Cause Solution

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Hopper temperature is

higher than setpoint

(overtemp).

X4

Display for Hopper =

EO1.

Display for Hopper =

EO2.

1.Hopper sensor not fully

inserted.

2.Hopper sensor (X4)

inoperative.

ON

3.Inoperative PCB.

1.Plug connection X4 on

PCB is loose.

2.Temperature sensor inoperative.

1.Hopper sensor short circuit.

1.Check hopper sensor.

2.Replace hopper sensor if resistance does not comply with resistance table.

3.Replace PCB.

1.Restore connection.

2.Replace sensor if resistance does

not comply with resistance table.

1.Replace sensor if resistance does

not comply with resistance table.

Hopper does not heat,

but LED is ON.

Heater

25 Ohms

25 Ohms

2.Shortcircuitat plugconnectionX4onPCB.

3.Inoperative PCB.

1.Hopperfuses(F4&F11)

inoperative on PCB.

2.Hopper heater element

is inoperative.

3.Disconnectioninhopper

heater circuit.

4.Inoperative PCB.

2.Check and eliminate short circuit.

3.Replace PCB.

1.Insert new fuse(s) and observe

ASU. If fuse(s) blows again, check

for a short circuit in heater.

2.Replace hopper if element’sresistance does not comply with resistance table. Note: remove wires

fromboth heater elements when

measuring.

3.Check and repair (see wiring diagram).

4.Replace PCB.

Page 44

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Problem Possible Cause Solution

Page 7-7

Revised 1/05

Hopper does not heat,

and LED is OFF.

Hose (or Head) is not

heating. Hose (or

Head) LED on the

PCB is ON.

Fuses:

F2 & F9 = Hose 1

F3 & F10 = Head 1

F5 & F12 = Hose 2

F6 & F13 = Head 2

1.Inoperative Control PCB.

1.Disconnection between

ASU and Hose (or

between Hose and Head).

2.Hose (or Head) fuse(s) on

the PCB is inoperative.

3.Loose plug connection on

PCB.

4.Heating element inoperative.

1.Replace PCB.

1.Check plug connections.

2.Insert new fuse(s). If fuse blows

again, check for a short circuit in

heater.

3.Check connectors X8 and X11

and restore connection.

4.Check resistance and compare to

resistance table.

a. For head: if heater cartridge

is inoperative, replace heater.

b. For hose: if heating element

is inoperative, replace hose.

Hose (or Head) is not

heating. Hose (or

Head)LED on thePCB

is OFF.

Hose (or Head) actual

temperature is much

higher than setpoint.

1.Inoperative PCB.

2.Sequential Startup is

active.

1.Inoperative Hose (or

Head) triac on PCB

(corresponding PCB LED

is OFF).

2.Inoperative Hose (or

Head) temperature sensor

(corresponding PCB LED

is ON).

1.Replace PCB.

2.Wait until hopper has reached

setpoint or re-program the heat-up

mode (see pg. 5-6).

1.Replace PCB.

2.Check resistance and compare to

resistance table.

a. For head: if sensor is

inoperative, replace sensor.

b. For hose: if sensor is

inoperative, replace hose.

Page 45

Page 7-8

Revised 1/05

Problem Possible Cause Solution

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Display for Hose (or

Head) = EO1

ASU Socket

&

Hose Plug

Sensor

Heater

Plug

Sensor &

Heater

1.No Hose (or Head) is

connected.

2.Disconnection between

ASU and Hose (or between Head and Hose).

3.Disconnection at X4 on

PCB.

4.Hose(orHead)sensoris

inoperative.

1.Connect Hose (or Head) if needed. If not needed, ignore display.

2.Check plug connection.

3.Make proper connection.

4.Check resistance and compare to

resistance table.

a. For head: if sensor is

inoperative, replace sensor.

b. For hose: if sensor is

inoperative, replace hose.

Display for Hose (or

Head) = EO2

1.Hose (or Head) sensor

short circuit.

2.Shortcircuitinplugconnection between ASU

and Hose (or between

Hose and Head).

3.Inoperative PCB.

1.Check resistance and compare to

resistance table.

a. For head: if sensor is

inoperative, replace sensor.

b. For hose: if sensor is

inoperative, replace hose.

2.Make proper connection.

3.Replace PCB.

Page 46

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

Page 7-9

Revised 1/05

Pump Operation & Adjustable Pressure Relief

When the ASU’s hopper reaches setpoint, the controller places the hopper in “Ready” condition and

power is supplied to the pump.

An adjustable pressure relief valve is located on the output filter manifold.

When adhesive pressure exceeds the set limit, adhesive flows back to the hopper .Therefore, the

greater the setting on the pressure relief valve, the greater the adhesive output.

To change the setting of this valve, loosen the lock nut and turn the adjustment screw clockwise to

increase pressure or counterclockwise to decrease pressure. The relief valve is factory set at 27 bar

(400 psi) for gear pumps and 68 bar (1000 psi) for piston pumps.

Normally Closed (Unrelieved):

In the drawing below, the valve

is closed.

Open (Relieved):

In this drawing, pressure has

exceeded the setting of the valve,

causing the valve to open and

discharge adhesive to the hopper.

Adjustment screw

Lock nut

Mounting nut

return to

hopper

from

pump

to

hose

Adhesive flow through

filter block to hose

from

pump

Adhesive flow through

filter block to hose

Operation of the Adjustable Adhesive Pressure Relief Valve

to

hose

Page 47

Page 7-10

Revised 1/05

Piston Pump Troubleshooting Guide

ITW Dynatec c. 2004

DYNAMINI ASU Manual #20-25

WARNING

Some of the p rocedures in the following Troubleshooting G uide require working

near hot adhesive. Be sure to wear protective gloves, safety glasses and clothing

and use proper tools for handling hot melt components.

Problem Possible Cause

Pump WillNot Stroke 1.No air pressure.

Relief

Valve

Regulator

2.3-way solenoid valve is

closed.

HOT SURFACE & ADHESIVE

Solution

1.Verify system has been provided

with at least 0.5 SCFM of air at

20-100 PSIG (.014 std. cubic meters/

minute at 6.8 bar).

2.Verify that valve is properly connected (electrically) inside ASU.

Verify that valve is properly connected to Air Control/ Filter Unit.

Disconnect valve electrical leads

and verify that air is passed through

when 240 VAC is applied to the

valve terminals. Replace valve if

defective.

Solenoid

Air fittings

Air Tubes

Air

valve

3.Fault in compressed air

fitting on ASU.

4.Hopper temperature

not ready.

5.Inoperative air valve (on

back end of pump air

cylinder).

6.Inoperative air cylinder

4-way solenoid valve.

7.System is not ready.