Page 1

www.itwdynatec.com

Adhesive Applic at i on S olut i on s | ISO 9001 certified

DynaFiber UFD

Spray Applicator, 1-6 Port

Technical Documentation

ITW Dynatec

An Illinois Tool Works Company

Page 2

ITW Dynatec

Information about this manual

Read all instructions before operating this equipment!

NOTICE:

Information about this manual

It is the customer’s responsibility to have all operators and service

personnel read and understand this information. Contact your ITW

Dynatec customer service representative for additional copies.

Please be sure to include the serial number of your application

system each time you order replacement parts and/or supplies. This

will enable us to send you the correct items that you need.

ITW Dynatec Service Parts Direct Dial: 1-800-538-9540

ITW Dynatec Technical Service Direct Dial: 1-800-654-6711

Page 2 UFD Applicator, Manual 40-43, Rev. 6.16

Page 3

Index

ITW Dynatec

Index

Information about this ma nua l ................................................ 2

Index .......................................................................................... 3

Chapter 1 Declaration of Incorporation .................................. 7

Chapter 2 Safety Instructions ................................................. 9

General Considerations ............................................................................................................ 9

Warning Labels ......................................................................................................................... 9

Safety Symbols in this Manual ................................................................................................ 10

Safe Installation and Operation ............................................................................................... 10

Explosion/ Fire Hazard ............................................................................................................ 11

Use of PUR (Polyurethane) Adhesives ................................................................................... 11

Eye Protection & Protective Clothing ...................................................................................... 11

Electrical .................................................................................................................................. 12

Lockout/ Tagout ...................................................................................................................... 12

High Temperatures ................................................................................................................. 12

High Pressure ......................................................................................................................... 13

Protective Covers .................................................................................................................... 13

Servicing, maintenance ........................................................................................................... 14

Secure transport ...................................................................................................................... 14

Treatment for Burns from Hot Melt Adhesives ........................................................................ 15

Measures in case of fire .......................................................................................................... 15

Keep attention to environmental protection standards ........................................................... 16

Chapter 3 Description and Technical Specs ....................... 17

3.1 Applicable Safety Regulations ...................................................................... 17

Intended Use ........................................................................................................................... 17

Unintended Use, Examples..................................................................................................... 17

Residual Risks ........................................................................................................................ 17

Technical changes .................................................................................................................. 18

Using foreign components ...................................................................................................... 18

Setting-up operation ................................................................................................................ 18

3.2 Description of UFD Spray Applicator ............................................................ 19

Description .............................................................................................................................. 19

Technical Data ........................................................................................................................ 21

Model Designation Guide ........................................................................................................ 22

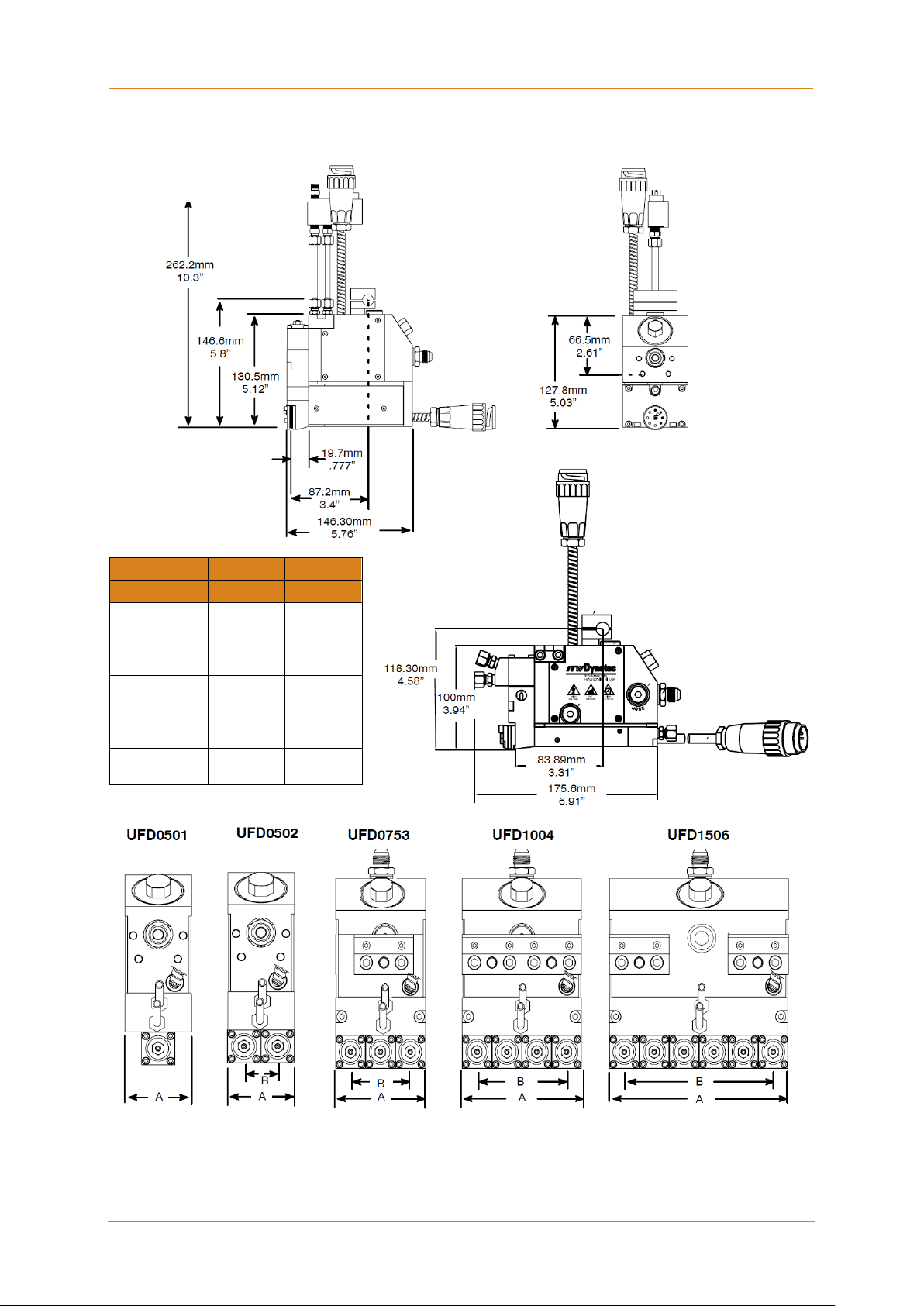

Dimensions.............................................................................................................................. 23

Chapter 4 Installation & Startup ............................................ 25

4.1 Conditions for set-up and mounting .............................................................. 25

4.2 Installation & Startup ..................................................................................... 26

Special Installation Notes on HiSpeed, Vertical Snuffback, Direct-Air Module ....................... 29

Operation of Optional Drain Valve .......................................................................................... 29

Purging Adhesive Through the App licat or .............................................................................. 30

4.3 Quality of compressed Air ............................................................................. 30

Chapter 5 Maintenance and Repair Notes ........................... 31

5.1 Security advices for maintenance and repair ................................................ 31

5.2 Re-Assembly Procedures and General Cautions ......................................... 32

UFD Applicator, Manual 40-43, Rev. 6.16 Page 3

Page 4

ITW Dynatec

Index

5.3 Stroke Limit Adjustmen t ................................................................................ 32

5.4 Relieving Adhesive Pressure ........................................................................ 33

5.5 Replacement of the Built-in Filter .................................................................. 34

5.6 Replacement of the Module .......................................................................... 36

Modules Which Are Not Serviceable ...................................................................................... 36

Replacement of the Standard Module .................................................................................... 36

Module Assembly Instructions for the PN 104993 UFD Module ............................................. 37

Module Assembly Instructions for the PN 106224 UFD or 106226 HiTemp UFD Module ..... 38

Module Assembly Instructions for the PN 110840 Horizontal SB and PN 111074 Vertical SB

UFD Modules .......................................................................................................................... 39

5.7 Replacement of the UFD Nozzle .................................................................. 40

5.8 Cleaning of the UFD Nozzle ......................................................................... 41

5.9 Testing of Resistance ................................................................................... 43

Testing Resistance of Heater Cartridges ................................................................................ 43

Testing Resistance of the RTD Temperature Sensor ............................................................. 44

Testing the J-type Thermocouple Temperature Sensor ......................................................... 44

Resistance Tables, Temperature sensors .............................................................................. 45

5.10 Replacement of Heater Cartridge or Temperature Sensor ......................... 46

5.11 Maintenance plan ....................................................................................... 49

Chapter 6 Troubleshooting ................................................... 51

Troubleshooting In General..................................................................................................... 51

Troubleshooting Guide UFD Applicator .................................................................................. 51

Chapter 7 Component Illustrations & Bills of Materials ..... 53

1-Port UFD Vertical & Horizontal Apply Applicator Assemblies .......................... 54

Air Preheater Assembly for 1-Port UFD Vertical & Horizontal Apply ...................................... 56

Air Preheater Assembl y for 1- or 2-Port UFD Slim Design ..................................................... 58

2-Port UFD Vertical & Horizontal Apply, 1 or 2 Program, Applicator Assemblies 60

Air Preheater Assembly for 2-Port UFD Vertical & Horizontal Apply, 1 or 2 Program ............ 62

3-Port UFD Vertical & Horizontal Apply, 1, 2 or 3 Program, Applicator Assemblies

............................................................................................................................ 64

Air Preheater Assembly for 3-Port UFD Vertical & Horizontal Apply, 1 or 3 Program ............ 66

Air Preheater Assembly for 3-Port UFD Slim Design ............................................................. 68

4-Port UFD Vertical & Horizontal Apply, 1 or 4 Program, Applicator Assemblies 70

Air Preheater Assembly for 4-Port UFD Vertical & Horizontal Apply, 1 or 4 Program ............ 72

Air Preheater Assembly PN 112793 for 4-Port UFD Slim Design .......................................... 74

6-Port UFD Vertical & Horizontal Apply, 1 or 6 Program, Applicator Assemblies 76

Air Preheater Assembly for 6-Port UFD Vertical & Horizontal Apply, 1 or 6 Program ............ 78

Air Preheater Assembly PN 112794 for 6-Port UFD Slim Design .......................................... 80

UFD Modules ...................................................................................................... 82

UFD Spray Module Assembly, Horizontal, PN 104993 .......................................................... 82

UFD Spray Module Assembly, Vertical, Extended, PN 106224 ............................................. 84

UFD Spray Module Assembly, Horizontal, Snuffback, PN 110840 ........................................ 86

UFD Spray Module Assembly, High Speed, Vertical, PN 113778 .......................................... 86

UFD Spray Module Assembly, Snuffback, Vertical, PN 111074 ............................................. 87

UPD Spray Module Assembly, High Speed, Vertical, PN 113346 .......................................... 88

UFD Spray Module Assembly, High Speed, Horizontal, PN 113550...................................... 89

UFD Spray Module Assembly, High Speed, Horizontal, PN 115160...................................... 90

Blank Module, Horizontal & Vertica .................................................................... 91

Page 4 UFD Applicator, Manual 40-43, Rev. 6.16

Page 5

Index

ITW Dynatec

Blank Module, Vertical Air Only, PN 111053 .......................................................................... 91

Blank Module, Horizontal Air Only, PN 111052 ...................................................................... 91

UFD Nozzle Seals .............................................................................................. 92

Festo Solenoid Assemblies, PN 115055 & 115056 ............................................ 93

Chapter 8 Options & Accessories ........................................ 95

Applicator Heater Cartridges ................................................................................................... 95

Applicator RTD Sensors .......................................................................................................... 95

Filters ....................................................................................................................................... 95

Filter Kits ................................................................................................................................. 96

Service Kits ............................................................................................................................. 96

High-Temp Splice Kit, PN1 0264 5 ........................................................................................... 96

UFD Nozzle Cleaning Oven .................................................................................................... 96

Pressure Transducer Tap ....................................................................................................... 97

Drain Valve PN 107820 ........................................................................................................... 97

Balanced Solenoid Manifold.................................................................................................... 97

Low-Profile (Slim line) Models (codes A, J, M, P) ................................................................... 97

Elastic Guide Bracket Assembly, PN 107622 ......................................................................... 98

Extension Cable Assemblies................................................................................................... 99

Strand Coating System (SCS) .............................................................................................. 100

Recommended Service Parts List ......................................................................................... 102

Chapter 9 Engineering Drawings & Schematics ............... 103

Pin Connectors & Electrical Schematics ............................................................................... 103

Chapter 10 Appendix............................................................ 105

Solenoid Valve Configurations, Schematics & Setup ........................................................... 105

Air Filter/ Regulator Installation Notes .................................................................................. 105

Section 1, 24 VDC MAC solenoid valve, 4 way, 02, 1/8 NPT, PN 100054 ........................... 106

Section 2, MAC solenoid valve, 4 way, 1/4 NPT................................................................... 107

Section 3, 24 VDC MAC solenoid valve, 5 way, 1/8 NPT, PN 106937 ................................. 108

Section 4, 24 VDC MAC solenoid valve, 4 way, 1/4 NPT, PN 112496 ................................. 109

Section 5, 24 VDC MAC solenoid valve, 4 way, 1/4 NPT, PN 112496 ................................. 110

Section 6, Air Control Kit PN 100055, Component Illustration.............................................. 111

Process (Preheater) Air Control Filter/ Regulator, PN 107404 ............................................. 112

UFD Applicator, Manual 40-43, Rev. 6.16 Page 5

Page 6

ITW Dynatec

Index

This page intentionally left blank.

Page 6 UFD Applicator, Manual 40-43, Rev. 6.16

Page 7

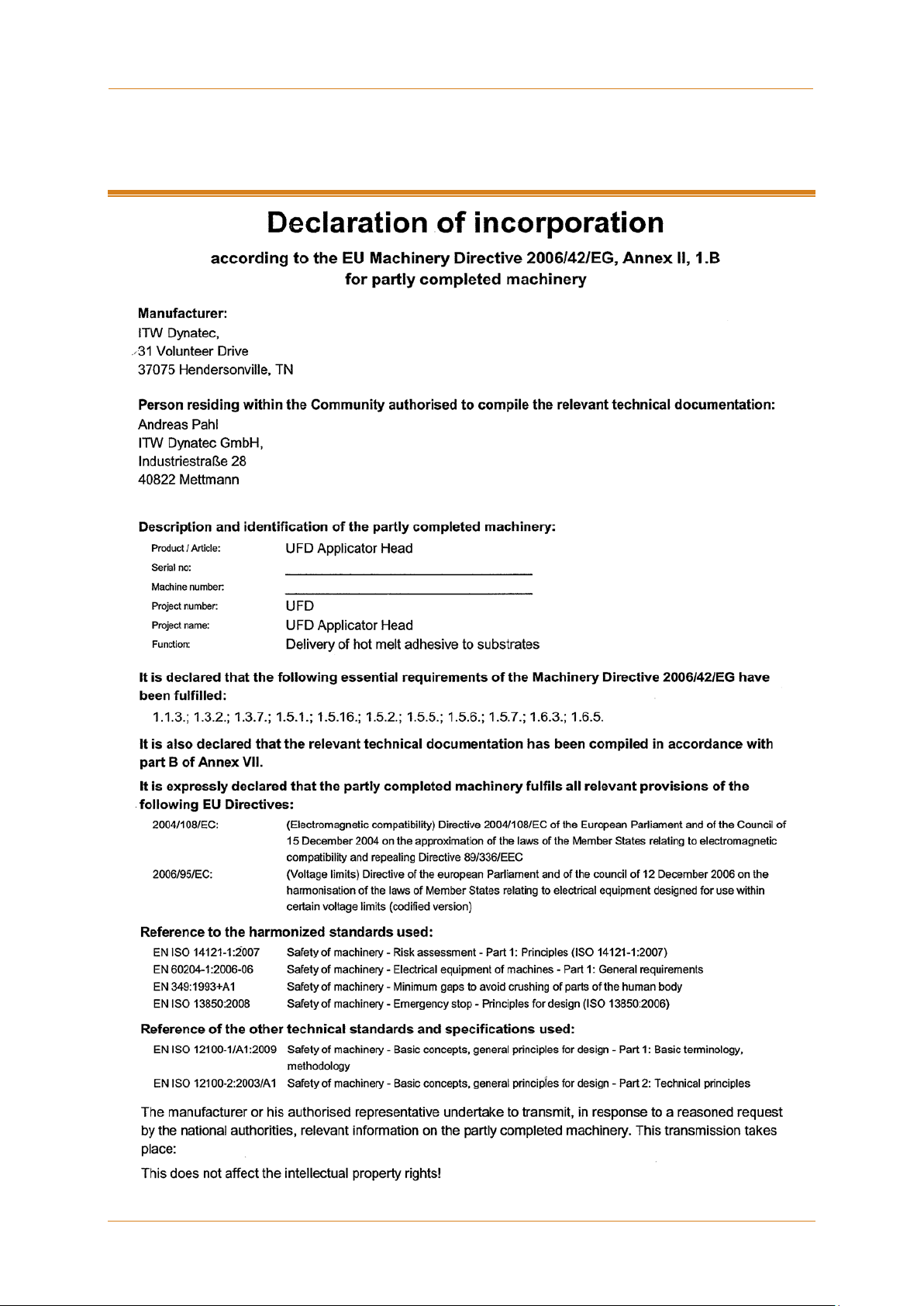

Chapter 1 Declaration of Incorporation

ITW Dynatec

Chapter 1

Declaration of Incorporation

UFD Applicator, Manual 40-43, Rev. 6.16 Page 7

Page 8

ITW Dynatec

Chapter 1

Declaration of Incorporation

Page 8 UFD Applicator, Manual 40-43, Rev. 6.16

Page 9

Chapter 2 Safety Instructions

ITW Dynatec

General Considerations

All operators and service personnel must read and understand this manual

before operating or servicing equipmen t.

All maintenance and service on this equipment must be performed by trained

technicians.

Read and adhere to the manual!

1. Read and follow these instructions.

Failure to do this could result in severe personal injury or death.

2. Keep the binding rules for accident prevention valid for your country and the place of

installation. Also keep the approved qualified technical rules for safety-conscious and

professional work.

3. Additional safety instructions and/ or symbols are located throughout this manual.

They serve to warn maintenance personnel and operators about potentially hazardous

situations.

4. Inspect the machine for unsafe conditions daily and replace all worn or defective parts.

5. Keep work area uncluttered and well lit. Remove all material or things not needed for

the production from the workspace of the equipment!

6. All covers and guards must be in place before operating this equipment.

7. Subject to technical modifications without notice!

8. To ensure proper operation of the equipment, use specified electrical and/ or air

supply sources.

9. Do not attempt to alter the design of the equipment unless written approval is received

from ITW Dynatec.

10. Keep all manuals readily accessible at all times and refer to it often for the best

performance from your equipment.

Warning Labels

Chapter 2

Safety Instructions

1. Read and obey all of the warning labels, signs and caution statements on the

equipment.

2. Do not remove or deface any of the warning labels, signs and caution statements on

the equipment.

3. Replace any warning labels, signs and caution statements which have been removed

or defaced. Replacements are available from ITW Dynatec.

UFD Applicator, Manual 40-43, Rev. 6.16 Page 9

Page 10

ITW Dynatec

Chapter 2

Safety Instructions

Safety Symbols in this Manual

1. WARNINGS and CAUTIONS are found throughout this manual.

WARNINGS mean that failure to observe the specific instructions may cause injury to

personnel.

2. CAUTIONS mean that failure to observe the specific instructions may damage the

equipment.

Safe Installation and O per at ion

Read and adhere to the manual!

1. Read this manual before applying electrical power to the equipment. Equipment may

be damaged by incorrect electrical connections.

2. To avoid possible failure of hoses, make sure all hoses are routed to avoid kinking,

tight radius turns (8” or less) and abrasive contact. Hot‐melt hoses should not have

prolonged contact with heat‐absorbing surfaces such as cold floors or metal troughs.

These heat‐absorbing surfaces can alter adhesive flow and cause incorrect

calibration. Hoses should never be covered with materials that prevent heat

dissipation, such as insulation or sheathing. Hoses should be spaced apart from each

other, not making direct contact.

3. Do not use adhesive that is dirty or that may be chemically contaminated. Doing so

can cause system clogging and pump damage.

4. When adhesive hand‐ held applicators or other movable applicators are used, never

point them at yourself or at any other person. Never leave a hand‐held applicator's

trigger unlocked when not actually in use.

5. Do not operate the hopper or other system components without adhesive for more

than 15 minutes if the temperature is 150 degrees C (300 degrees F) or more. To do

so will cause charring of the residual adhesive.

6. Never activate the heads, hand‐held applicators and/ or other application devices until

the adhesive's temperature is within the operating range. Severe damage could result

to internal parts and seals.

7. Never attempt to lift or move the unit when there is molten adhesive in the system.

8. In case of an emergency or exceptional incident, press the emergency stop button in

order to stop the unit quickly.

9. Use the unit only as it is intended to.

10. Never let the unit run unattended.

11. Operate the unit only in a faultless and fully functional condition. Check and make

sure that all safety devices work in proper form!

Page 10 UFD Applicator, Manual 40-43, Rev. 6.16

Page 11

Chapter 2

Safety Instructions

ITW Dynatec

DYNATEC'S WARRANTY.

Explosion/ Fire Hazard

1. Never operate this unit in an explosive environment.

2. Use cleaning compounds recommended by ITW Dynatec or your adhesive supplier

only.

3. Flash points of cleaning compounds vary according to their composition, so consult

with your supplier to determine the maximum heating temperatures and safety

precautions.

Use of PUR (Polyurethane) Adhesives

1. PUR adhesives emit fumes (MDI and TDI) that can be dangerous to anyone exposed

to them. These fumes cannot be detected by the sense of smell. ITW Dynatec strongly

recommends that a power‐vented exhaust hood or system be installed over any PUR

system.

2. Consult with your adhesive manufacturer for specifics about required ventilation.

CAUTION

Because of the nature of PUR adhesives to strongly bond in the presence of moisture,

care must be taken to prevent them from curing inside ITW Dynatec equipment.

If PUR adhesive solidifies in a unit, the unit must be replaced. Always purge old PUR

adhesive from the system per your adhesive manufacturer's instructions and time table.

ALLOWING PUR ADHESIVE TO CURE IN A UNIT OR ITS COMPONENTS VOIDS ITW

Eye Protection & Protective Clothing

WARNING

EYE PROTECTION & PROTECTIVE CLOTHING REQUIRED

1. It is very important that you PROTECT YOUR EYES when working around

hot melt adhesive equipment!

2. Wear a face shield conforming to ANSI Z87.1 or safety glasses with side

shields which conform to ANSI Z87.1 or EN166.

3. Failure to wear a face shield or safety glasses could result in severe eye injury.

4. It is important to protect yourself from potential burns when working around hot melt

adhesive equipment.

5. Wear heat-resistant protective gloves and long‐sleeved, protective clothing to prevent

burns that could result from contact with hot material or hot components.

6. Always wear steel‐reinforced safety shoes.

UFD Applicator, Manual 40-43, Rev. 6.16 Page 11

Page 12

ITW Dynatec

Chapter 2

Safety Instructions

WARNING HOT SURFACE

Electrical

DANGER HIGH VOLTAGE

1. Dangerous voltages exist at several points in this equipment. To avoid personal injury,

do not touch exposed connections and components while input power is on.

2. Disconnect, lockout and tag external electrical power before removing protective

panels.

3. A secure connection to a reliable earth ground is essential for safe operation.

4. An electrical disconnect switch with lockout capability must be provided in the line

ahead of the unit. Wiring used to supply electrical power should be installed by a

qualified electrician.

5. Notify the maintenance personnel immediately, if cables are damaged. Provide for

exchanging the defective components immediately.

Lockout/ Tagout

Switch the unit voltage-free before working!

Main switch OFF!

1. Follow OSHA 1910.147 (Lockout/ Tagout Regulation) for equipment's lockout

procedures and other important lockout/tagout guidelines.

2. Be familiar with all lockout sources on the equipment.

3. Even after the equipment has been locked out, there may be stored energy in the

application system, particularly in the capacitors within the panel box. To ensure that

all stored energy is relieved, wait at least one minute after removing power before

servicing electrical capacitors.

High Temperatures

1. Severe burns can occur if unprotected skin comes in contact with molten adhesive or

hot application system parts.

2. Face shields (preferred) or safety glasses (for minimum protection), heat-resistant

protective gloves and long-sleeved clothing m us t be worn whene ver wor k ing with or

around adhesive application systems.

Page 12 UFD Applicator, Manual 40-43, Rev. 6.16

Page 13

Chapter 2

Safety Instructions

ITW Dynatec

WARNING HIGH PRESSURE PRESENT

WARNING

High Pressure

1. To avoid personal injury, do not operate the equipment without all covers, panels and

safety guards properly installed.

2. To prevent serious injury from molten adhesive under pressure when servicing the

equipment, disengage the pumps and relieve the adhesive system's hydraulic

pressure (i.e. trigger the heads, hand‐held applicators, and/or other application

devices into a waste container) before opening any hydraulic fittings or connections.

3. IMPORTANT NOTE: Even when a system's pressure gauge reads “0” psi, residual

pressure and trapped air can remain within it causing hot adhesive and pressure to

escape without warning when a filter cap or a hose or hydraulic connection is

loosened or removed. For this reason, always wear eye protection and protective

clothing.

4. Either of the two High Pressure symbols shown may be used on ITW Dynatec

equipment.

5. Keep the given operating pressure.

6. Notify the maintenance personnel immediately, if hoses or components are damaged.

Provide for exchanging the defective components immediately.

Protective Covers

DO NOT OPERATE WITHOUT GUARDS IN PL ACE

1. Keep all guards in place!

2. To avoid personal injury, do not operate the application system without all covers,

panels and safety guards properly installed.

3. Never get your extremities and/or objects into the danger area of the unit. Keep your

hands away from running parts of the unit (pumps, motors, rolls or others).

UFD Applicator, Manual 40-43, Rev. 6.16 Page 13

Page 14

ITW Dynatec

Chapter 2

Safety Instructions

Servicing, maintenance

1. Only trained an d qualified personnel are to operate and service this equipment.

2. Before any service work disconnect the external power supply and the pressure air

supply!

3. Never service or clean equipment while it is in motion. Shut off the equipment and lock

out all input power at the source before attempting any maintenance.

4. Follow the maintenance and service instructions in the manual.

5. Keep the maintenance rates given in this documentation!

6. Any defects in the equipment that impact safe operation have to be repaired

immediately.

7. Check screws that have been loosened during the repair or maintenance, if they are

tight again.

8. Replace the air hoses in preventive maintenance regularly, even if they have got no

viewable damages! Adhere to the manufacturers` instructions!

9. Never clean control cabinets or other houses of electrical equipment with a jet of

water!

10. Adhere to the current safety data sheet of the manufacturer when using hazardous

materials (cleaning agents, etc.)!

Secure transport

1. Examine the entire unit immediately after receipt, if it has been delivered in perf ec t

condition.

2. Let damages in transit certify by the carrier and announce them immediately to ITW

Dynatec.

3. Use only lifting devices that are suitable for the weight and the dimensions of the

equipment (see drawing of the equipment).

4. The unit has to be transported upright and horizontally!

5. The unit has to cool down to room temperature before packaged and transported.

Page 14 UFD Applicator, Manual 40-43, Rev. 6.16

Page 15

Chapter 2

Safety Instructions

ITW Dynatec

EXTINGUISH FIRE

For safety reasons not appropriate extinguishing agents: None.

Treatment for Burns from Hot Melt Adhesives

Measures after being burned:

1. Burns caused by hot melt adhesive must be treated at a burn center. Provide the burn

center's staff a copy of the adhesive's M.S.D.S. to expedite treatment.

2. Cool burnt parts immediately!

3. Do not remove adhesive forcibly from the skin!

4. Care should be used when work ing with hot melt adhesives in the molten state.

Because they rapidly solidify, they present a unique hazard. Even when first solidified,

they are still hot and can cause severe burns.

5. When working near a hot melt application system, always wear safety shoes, heatresistant protective gloves, safety goggles and protective clothes that cover all

vulnerable parts of the body.

6. Always have first-aid information and supplies available.

7. Call a physician and/or an emergency medical technician immediately. Let the burns

medicate by a medic immediately.

Measures in case of fire

UFD Applicator, Manual 40-43, Rev. 6.16 Page 15

1. Please heed that not covered hot parts of the engine and molten hot melt may cause

heavy burns. Risk of burns!

2. Work very carefully with molten hot melt. Keep in mind, that already jelled hot melt can

be very hot, too.

3. When working near a hot melt application system, always wear safety shoes, heatresistant protective gloves, safety goggles and protective clothes that cover all

vulnerable parts of the body!

Measures in case of fire:

Wear safety shoes, heat-resistant protective gloves, safety goggles and protective

clothes that cover all vulnerable parts of the body.

Firefighting - burning hot melt:

Please keep attention to the safety data sheet given by the adhesive manufacturer.

Appropriate extinguishing agents:

Foam extinguisher, Dry powder, Spray, Carbon dioxide (CO2), Dry sand.

Firefighting - burning electrical equipment:

Appropriate extinguishing agents:

Carbon dioxide (CO2), Dry powder.

Page 16

ITW Dynatec

Chapter 2

Safety Instructions

1. When working on or with the unit, the legal obligations for waste avoidance and the

Keep attention to environmental protection standards

duly recycling / disposals have to be fulfilled.

2. Keep attention, that during installations, repairs or maintenance matters hazardous

to water, like adhesive / adhesive scrap, lubricating grease or oil, hydraulic oil,

coolant and cleaner containing solvent not pollute the ground or get into the

canalization!

3. These matters have to be caught, kept, transported and disposed in appropriate

reservoirs!

4. Dispose these matters according to the international, national and regional

regulations.

Page 16 UFD Applicator, Manual 40-43, Rev. 6.16

Page 17

Chapter 3 Description and Technical Specs

ITW Dynatec

If the unit is not used in accordance with this regulation, a safe operation cannot be

resulting from unintended use!

Intended use includes, that you

• do all maintenance within the given maintenance rates.

• Risk of burns from hot material.

• The safety valves may malfunction due to hardened or charred material.

Chapter 3

Description and Technical Specs

3.1 Applicable Safety Regulations

Intended Use

The UFD Applicator may be used only to apply suitable materials, e.g. adhesives. When

in doubt, seek permission from ITW Dynatec.

guaranteed.

The operator - and not ITW D ynatec - is liable for all personal injury or property damages

• read this documentation,

• heed all given warnings and safety instructions, and

Any other use is considered to be unintended.

Unintended Use, Examples

The UFD Applicator may not be used under the following conditions:

• In defective condition.

• In a potentially explosive atmosphere.

• With unsuitable operating/processing materials.

• When the values stated under Specifications are not complied with.

The UFD Applicator may not be used to process the following materials:

• Toxic, explosive and easily flammable materials.

• Erosive and corrosive materials.

• Food products.

Residual Risks

In the design of the UFD Applicator, every measure was taken to protect personnel from

potential danger. However, some residual risks cannot be avoided.

Personnel should be aware of the following:

• Risk of burns from hot Applicator components.

• Risk of burns when conducting maintenance and repair work for which the system

must be heated up.

• Risk of burns when attaching and removing heated hoses.

• Material fumes can be hazardous. Avoid inhalation. If necessary, exhaust material

vapors and/or provide sufficient ventilation of the location of the system.

• Risk of pinching parts of the body at running parts of the unit (pumps, motors, rolls or

others).

UFD Applicator, Manual 40-43, Rev. 6.16 Page 17

Page 18

ITW Dynatec

Chapter 3

Description and Technical Specs

Technical changes

Any kind of technical changes having impact to the security or the operational liability of

the system should only be done by written agreement of ITW Dynatec. Suchlike changes

made without given a corresponding written agreement will lead to immediate exclusion

of liability granted by ITW Dynatec for all direct and indirect subsequent damages.

Using foreign components

ITW Dynatec takes no responsibility for consequential damages caused by using foreign

components or controllers that have not been provided or installed by ITW Dynatec.

ITW Dynatec does not guarantee that foreign components or controllers used by the

operating company are compatible to the ITW Dynatec-system.

Setting-up operation

We recommend asking for an ITW Dynatec-service technician for the setting-up

operation, to ensure a functioning system. Let yourself and the people working with or

working on the system be introduced to the system on this occasion.

ITW Dynatec takes no responsibility for damages or faults caused by any untrained

personal.

Page 18 UFD Applicator, Manual 40-43, Rev. 6.16

Page 19

Chapter 3

Description and Technical Specs

ITW Dynatec

UFD Omega:

UFD Random:

3.2 Description of UFD Spray Applicator

Description

ITW Dynatec’s UFD Spray Applicators are air-operated, single or multi-module hot melt

adhesive applicator assemblies with integrated basket filters, which prevent particulate

matter from obstructing flow through the heads.

The Applicator is heated by replaceable cartridge heating elements which are controlled

by an integrated sensor and electronic control. Each model can be configured for ITW

Dynatec’s DynaControl, MCV or Upgrade control schemes or for Allen-Bradley PLC

controls. Pressure transducer ports are standard features for all Applicators. A choice of

adhesive inlets and an angled filter nut allows either vertical or horizontal spray.

Four standard UFD models supporting up to six modules, are available, ranging in width

from 50mm to 150mm (2” to 6”). Their design is metric.

Theory of Operation

Each Applicator features one or more modules (adhesive valve) mounted to a single

service block. Each module is opened and closed by air pressure (solenoid valve).

Springs are used to keep the stem closed when no air pressure is supplied to the head.

The rate of adhesive flow from the applicator is determined by the adhesive pressure

applied by the Adhesive Supply Unit’s (ASU’s) pump, the nozzle type and the stem stroke

adjustment.

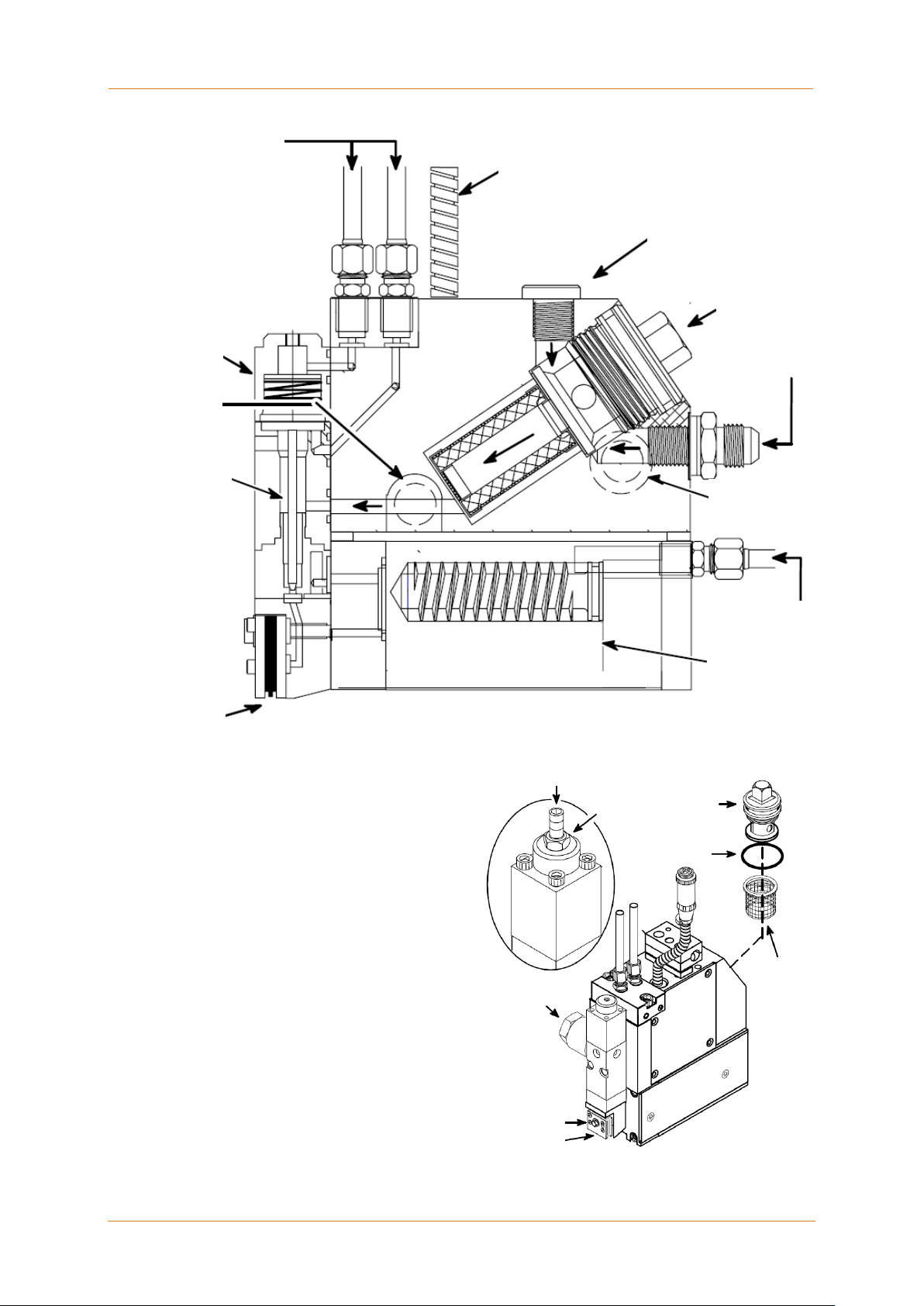

As shown in the illustration below, the heated adhesive supply hose may be connected at

the rear of the applicator or at the top. Adhesive flows from the hose into the service

block, through the filter and then to the module. Air pressure (Control Air) opens the

module, allowing adhesive to flow through the module’s nozzle.

Adapters are available to allow indus try-standard pressure transducers (1/2-20 thread) to

be connected to monitor adhesive pressure within the service block.

On the UFD spray models, an air preheater is located below the service block. The

preheater supplies heated air (Process Air), used to fiberize the adhesive streams, to the

UFD modules. The air preheater is thermally isolated from the service block and its

temperature is controlled independently.

The adhesive pressure in the system is influenced by the following parameters:

• Temperature and viscosity of the adhesive

• Size and speed of the Adhesive Application Unit’s (ASU’s) pump

• Cross-section and length of the adhesive hoses

• Adjusted adhesive pressure at Applicator (if adjustable pressure relief valve)

• Nozzle type

See illustration typical parts of UFD Applicator on next page.

Nozzles compatible with UFD Applicator:

Two different UFD nozzles (Omega and Random) are available to fiberize the

adhesive streams:

UFD Applicator, Manual 40-43, Rev. 6.16 Page 19

Page 20

ITW Dynatec

Chapter 3

Description and Technical Specs

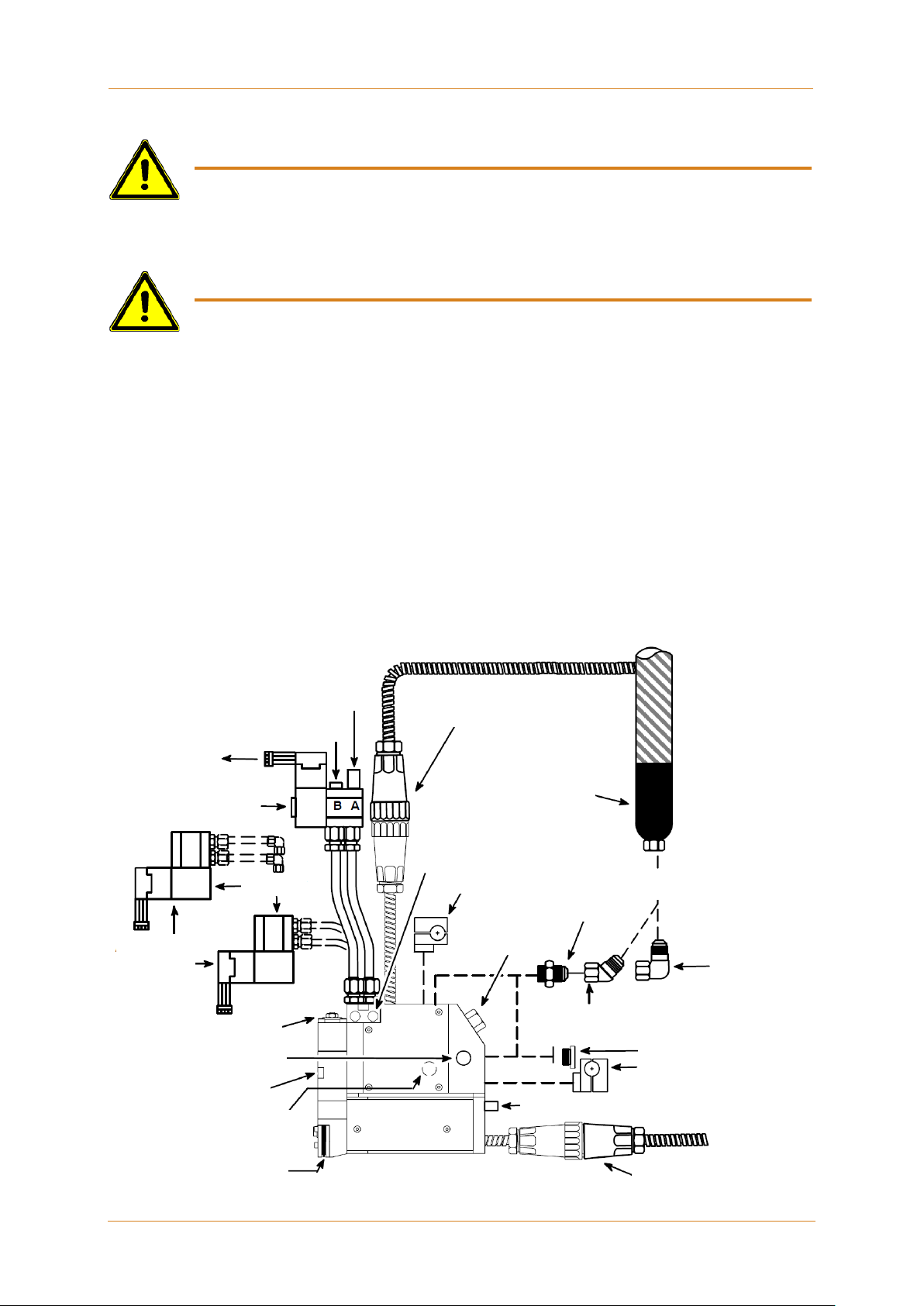

Alternate Hose

Inlet

Process Air Inlet

Air Preheater

Piston

Accessory Port

UFD Module

Control Air Inlet

Electrical

Inlet

Mounting screw

Nozzle

Filter

O-ring

Filter Nut

Lock

Nut

Optional Drain

(Purge) Valve

Stroke Adjustment Screw

Connection

Alternate Glue

Fiberizing Nozzle

Filter Cap

Glue Inlet

Page 20 UFD Applicator, Manual 40-43, Rev. 6.16

Illustration: Standard UFD Spray Applicator

Basket

Page 21

Chapter 3

Description and Technical Specs

ITW Dynatec

Technical Data

Model UFD 0501 0502 0753 1004 1506

Number of Modules

Spacing between nozzle centers

Wattage Adhesive Manifold

Wattage Standard Air Perheater

Wattage Slim Line Preheater

Supply voltage

Dimensions

Weight (including module and

solenoid valve)

Mounting

Temperature range

Warm-up time

1 2 3 4 6

- 25.2 mm 25.2 mm 25.2 mm 25.2 mm

450 450 525 600 900

600 600 900 1200 1200

400 400 600 800 1200

200-240 VAC/ 1p/ 50-60 Hz

See dimensional layout on follo wing pag e.

Model UFD0501: 3.52 kg (7.75 lb.)

M6 x 1 screws with insulators or 1/2” rod mount,

insulated clamps, 12 to 13 mm rod

38°C to 218°C (100°F to 425°F)

15 minutes for cold start/

5 minutes for module change only

Adhesive viscosity

Adhesive pressure range

Noise emission

Air pressure range

Air pressure range for high

speed snuffback modules (only)

Storage/ shipping temperature

Ambient service temperature

CE approval granted

100 to 30.000 mPa. sec. (100 to 30.000 centipoise)

68 bar maximum (1000 psi maximum)

70 dB(A)

4.1 to 6.9 bar (60 to 100 psi)

4.8 to 6.2 bar (70 to 90 psi)

-40°C to 70°C (-40°F to 158°F)

-7°C to 50°C (20°F to 122°F)

Yes

UFD Applicator, Manual 40-43, Rev. 6.16 Page 21

Page 22

ITW Dynatec

Chapter 3

Description and Technical Specs

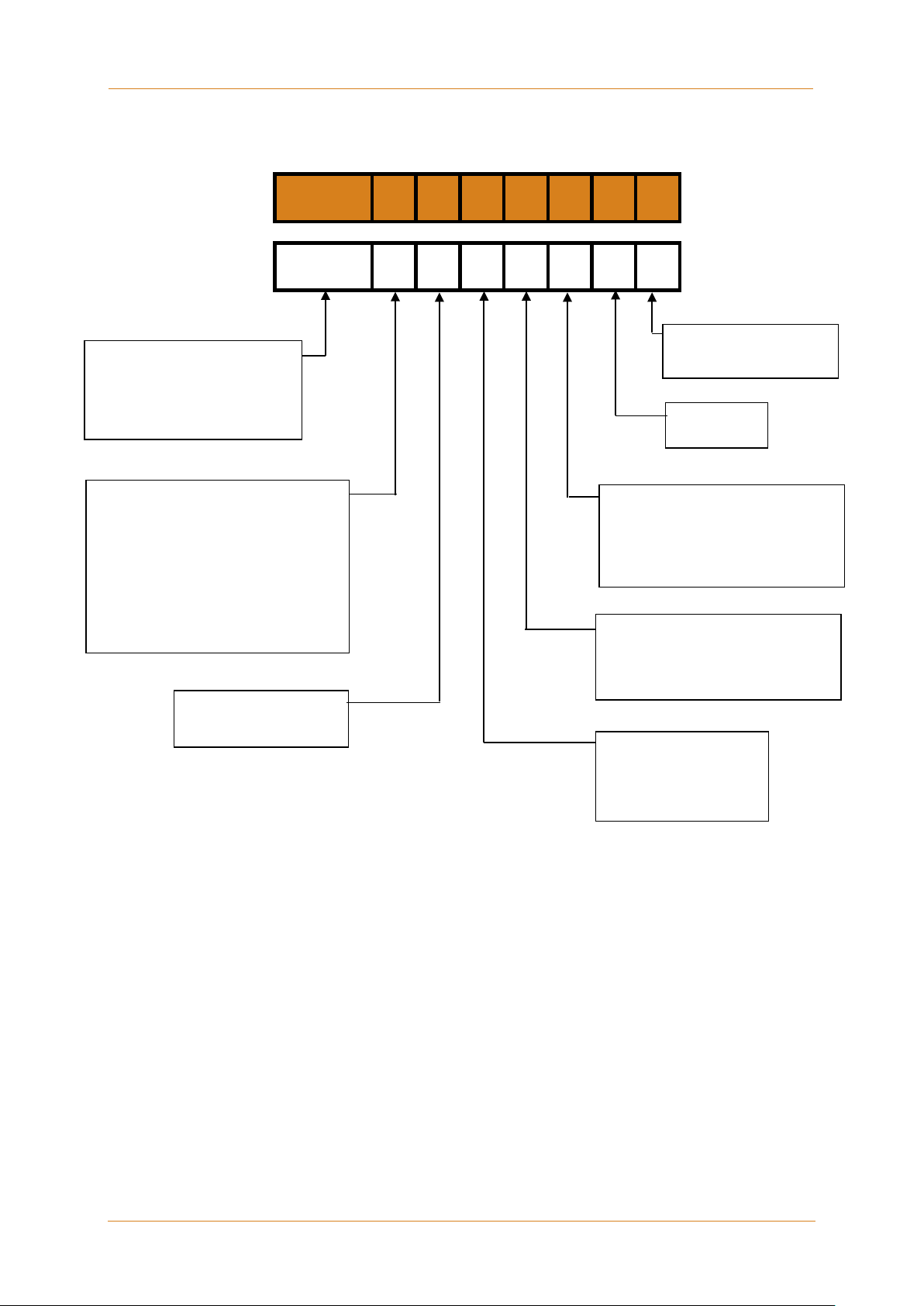

Service Block Length:

150 6 = 150mm (6 port/ 1 solenoid)

Module Type:

No. of Modules installed:

Z (no modules)

Voltage:

Control:

Filter Options:

Number of Solenoids:

(not available for J, M)

Applicator Options:

A = Adds Purge Valve

Model Designation Guide

UFD XXX X X X X X X X X

Example: UFD 100 4 V 4 A 1 D 2 S

050 1 = (1 port/1 solenoid)

050 2 = 50mm (2 port/1 solenoid)

075 3 = 75mm (3 port/1 solenoid)

100 4 = 100mm (4 port/ 1 solenoid)

S = Standard (No Options)

2 = 240VAC

A = Vertic al Hi-Speed SB (manifold air)

H = Horizontal UFD* (continuous)

V = Vertical UFD* (continuous)

K = Horizontal UFD SB (intermittent)

F = Vertical UFD SB (intermittent)

J = Verti cal, Hi-Speed SB, (intermittent)

Festo

M = Horizontal, Hi-Speed SB, (intermittent)

Festo

P = Horizontal Hi-Speed SB (manifold air)

D = DynaControl / PLC

M = MCV

N = Upgrade, Nor (Nickel RTD)

L = Upgrade, Mel (J -type t herm ocouple)

P = Upgrade, Mel (Platinum RTD)

1, 2, 3, 4, 5 or 6

0 = Only for options J, M

E = Adds Balanced Solenoid Manifold

1, 2, 3, 4, 5, 6 or

A = 100 mesh, basket

B = 150 mesh, basket

C = 150 mesh, spin-on

D = 200 mesh, spin-on

Notes: When specifying an Applicator with no modules, (see “Z” above), the Module Type (H, V, etc.)

must still be specified for the application.

Page 22 UFD Applicator, Manual 40-43, Rev. 6.16

Page 23

Chapter 3

Description and Technical Specs

ITW Dynatec

Dynafiber UFD Applicator,

side view:

Dynafiber UFD Applicator,

front view:

Dynafiber UFD

Width

Centers

Model No.

A

B

50mm

2“

50mm

2“

25.2mm

1“

75mm

3“

50.4mm

2“

100mm

4“

75.6mm

3“

150mm

6“

126mm

5“

Dimensions

UFD0501

UFD0502

UFD0753

UFD1004

UFD1506

SlimLine Applicator

-

UFD Applicator, Manual 40-43, Rev. 6.16 Page 23

Page 24

ITW Dynatec

Chapter 3

Description and Technical Specs

This page intentionally left blank.

Page 24 UFD Applicator, Manual 40-43, Rev. 6.16

Page 25

Chapter 4 Installation & Startup

ITW Dynatec

CAUTION

• Heed all safety instructions mentioned in Chapter 2.

• In any case the air has to be clean and dry! See advice in Chapter 4.3 “Quality of

applicator, 3/8” O.D. airline is recommended.

Advices:

occurs.

Chapter 4

Installation & Startup

• Before setting up, please read this documentation carefully.

• Pay attention to all the installation and connecting advices.

4.1 Conditions for set-up and mounting

Place requirement

Install the Applicator in the machine so that the operator is able to work on it from all

sides, for e.g. for adjusting, preparing, maintaining, repairing, cleaning, etc. See drawing

of the unit for admeasurements.

Mounting and alignment

• The complete unit has to be set up on solid, stable and flat ground.

• The alignment in height of the complete system has to be considered.

• The alignment of the machine has to be considered.

Electrical connection

• Necessary electrical connection has to be provided. See electrical schematics.

• Never connect or disconnect plug-and-socket connections under load!

• The service block’s incoming electrical power and temperature control is supplied

through the flexible cable exiting the adhesive supply hose cuff or through an

extension cable from the ASU. The Applicator has a circular, plastic connector which

mates with the connector attached to this cable.

• Incoming power and temperature control for the air preheater, if applicable, is supplied

by a cable extension from the ASU.

Pneumatic connection

compressed air”.

• Please heed that units with high air demand may not be used at the same time with

the same air supply.

• Incoming module-activation air is supplied through a solenoid valve. It must be clean

and unlubricated.

For conventional modules (module option H, V, HQ or VQ in the model number (see

previous pages), the module activation air is controlled by a four-way solenoid valve

and should be separately regulated and maintained at a pressure between 4.1 to 6.9

bar (60 to 100 psi). Air lines from the solenoid valve should be 6.4mm (1/4 inch).

Head air inlet ports are G 1/8 threads (1/8 NPT).

For snuffback modules (all other module options), the module activation air is

UFD Applicator, Manual 40-43, Rev. 6.16 Page 25

controlled by a either a four-way or a five-way solenoid valve. See Appendix A and B

for details on the solenoid setup.

• Incoming process (preheater) air must be supplied through a pressure regulator. The

air must be clean and unlubricated. Operating pressure depends on the choice of

nozzle. The Applicator’s air supply line must be at least 1/4” O.D. For the UFD 150

• Check all screw connections at the unit and retighten if necessary.

• Lay the cables and heated hoses so that no risk or least possible risk of stumbling

Page 26

ITW Dynatec

Chapter 4

Installation & Startup

CAUTION

valid regulations.

WARNING

• Risk of burns and risk of injury!

Air Inlet

Fitting

Muffler

To Timer or

Limit Switch

Purge Button

Solenoid

Mounting of

assemblies

Stroke Limit Adjustment

Alternate Hose Inlet

(one on each side)

Weep Hole

Nozzle

Accessory Port (for a drain

(one on each side)

Hose/ Head Electrical

Connection

Alternative

Control Air

Inlet Port

Rod Mount Bracket

Filter Nut

Adhesive Inlet

or

90° Hose Fitting

45° Hose Fitting

Rod Mount Bracket & Plug

position.

Process Air Inlet for Air Preheater

Electrical Connection

For Air Preheater

4.2 Installation & Startup

• All work on or with this unit is only permitted for sk illed personnel!

• Pay attention to the electrical schematics!

• Clean and dry air and air pressure of 6 bar to the applicator solenoids is required.

• All heating elements have to be mounted and operated secured and according to the

• While installing the Applicator, use an appropriate protection device to avoid

unintended contact with heated parts and with spilling out Hotmelt. The protection

device has to prevent also the operator against not reaching into the adhesive

application and against injuring.

Typical installation for an ULTRA Applicator:

1. Install the Applicator on the machine at the foreseen place.

The Applicator should be supported from brackets that permit lateral and vertical

adjustments. Mount the Applicator on a 12mm to 13mm rod or bracketry using the 6

mm screws and insulators provided. Allow access to the filter. Be sure that the stroke

limit adjustment screws are accessible and that the “weep” holes are visible for

periodic inspection. Leave s uff ic ient clearance to install a pressure transducer, if

applicable, and allow access to a drain valve, if installed.

Installation Diagram: See the diagram for location of the components referred to in the following

section.

optional

solenoid

valve and/ or transducer tap)

Page 26 UFD Applicator, Manual 40-43, Rev. 6.16

Adhesive Supply Hose

used in alternate glue inlet

Page 27

Chapter 4

Installation & Startup

ITW Dynatec

6 bar air pressure are required. Reason:

be installed between the standard air regulator/ filter and the UFD Applicator.

Heed the following for the installation of the heated hoses:

they cannot be repaired the hose would have to be changed completely.

2. Connect the compressed-air supply to Applicator. Connect all solenoids with air hoses

as required.

• Lower air pressure causes uneven adhesive application.

• The modules do not switch or switch with delay, resp. open and close again, if the air

supply is uneven.

• Only permanent pressure and sufficient volume flow leads to reproducible application

accuracy regarding position and amount.

CAUTION: Do not use lubricating oil with the air supply as Applicators are

lubricated at the factory and do not require lubrication when used in production.

Where oil is present in the air supply, a coalescing filter (Dynatec PN 100055) must

UFD Applicators require at least one solenoid valve for each applicator. If your head was

ordered without a solenoid valve, a 4-way valve (or a 5-way valve for snuffback modules)

should be mounted so that the air lines to each Applicator are as close to the same length

as practical.

Note: Air lines and fittings must be capable of withstanding temperatures up to 218°C

(425°F). ITW Dynatec supplies Air Control Filter Coalescing Kits (PN 100055) to be used

with air-operated Applicators (see the Air Control Filter Coalescing Kit Manual in

Appendix A of this manual).

For process (preheater) air control, the filter/ regulator kit PN 107404 is recommended. It

contains a 0-50 psi air filter/ regulator combination and a liquid-filled gauge for accurate

process air control.

See the Process (Preheater) Air Control Filter/ Regulator information in Appendix B.

When connecting the air lines to the applicator, the air line which has air pressure to the

module when the solenoid is OFF is the closing air line. See Appendix A and B for details

and diagrams of solenoid setup.

3. If a pre- or post- filter pressure transducer is to be utilized: install the supplied adapter

into the desired accessory port. Thread the transducer into the adapter (transducer

adapter has 1/2-20 thread). Follow the transducer manufacturer’s recommendations

for torque specifications. Note: the alternate hose inlets on either side of the Applicator

can also be used for the transducer adapter.

4. Before making the adhesive connection to the Applicator, align the adhesive supply

hose with its electrical connector oriented in relation to the electrical connector on the

top of the Applicator.

Connect the swivel fitting of the hot melt hose to the adapter on the service block,

using either the inlet port located below the filter nut or the port located on the top of

the Applicator (beside the electrical connection in the diagram). When tightening the

hose fitting, hold the hose cuff to prevent the hose core from rotating.

• Heated hoses may be damaged by overheating, if they are laid faulty.

• The heated hoses may not be stacked one on the other!

• The heated hoses may not be pressed together and / or bound.

• Put the hoses separated next to each other!

• The connections for supply resp. return hoses may not be mixed up.

• It is essential that the hoses will be laid without twisting!

• Heated hoses may not be fastened with binders or similar.

• Heated hoses may not be laid on a sharp edge.

• When using a balancer, a hose support with a radius of 400mm has to be mounted.

Reason: The sensor cables and heating cables within the hoses can be damaged. As

UFD Applicator, Manual 40-43, Rev. 6.16 Page 27

Page 28

ITW Dynatec

Chapter 4

Installation & Startup

WARNING! HIGH PRESSURE! HOT ADHESIVE!

Use a stable, deep container to collect hot-melt adhesive and/ or oil.

Purge the Applicator before every start of production respectively of a shift by allowing

Bring the Applicator in work position and continue production.

5. Make the electrical connection from the hose to the applicator by connecting the

6. Connect the spray air line to the preheater using the adapter provided. Do not

7. Make the electrical connection from the extension cable to the preheater by

8. It is advisable to check the temperature of the applicator. This can be done through

9. Purge the Applicator of air and oil. Turn the Applicator O N electric a l ly and

10. Replace the nozzle, orienting the nozzle tip so it points toward the substrate.

11. Interconnect the components with the foreseen Profibus (or EtherNet, etc.) interface

Daily operation

female connector of the hose to the male connector of the applicator.

overtighten the compression fitting, or the air line could collapse, reducing air flow.

connecting the female connector of the cable to the male connector of the preheater

the temperature readout of the adhesive supply unit. Surface temperature may be

checked with a separate pyrometer and surface probe or with a dial thermometer.

Turn the system power switch ON. Permit the applicator to warm up at least 15

minutes (5 minutes for module change) before reading temper ature.

pneumatically.

During the purging procedure, hot adhe sive and oil can come out of

the Applicator under high pressure. Wear safety glasses, gloves and

protective clothing.

Remove the nozzle from the module. Place a heat resistant container under the

module to collect the material that drains from the Applicator. Manually open the

solenoid by pushing (with a small screwdriver or other tool) the purge button located

on the solenoid coil. Continue to hold in the purge button until all air and oil have

drained and only adhesive flows from the module.

cables (if applicable).

the adhesive flows out until it is satisfactory.

Then switch off the adhesive and clean the nozzle from adhesive.

Page 28 UFD Applicator, Manual 40-43, Rev. 6.16

Page 29

Chapter 4

Installation & Startup

ITW Dynatec

WARNING! HOT SURFACE & ADHESIVE!

Special Installation Notes on HiSpeed, Vertical Snuffback, Direct-Air Module

Special Installation Notes on Optional PN 112690, 112440 & 112934 HiSpeed, Vertical

Snuffback, Direct-Air Module (Option Code C,D, G see Chapter Model Designation Guide)

The PN 112690, 112440 & 112934 modules are designed for the solenoid valve to be

connected directly to the module air cylinder. Fittings and tubing are included with the

module assembly.

If alternative fittings or tubing are desired, the recommended tubing is aluminum or

stainless steel, 1/4” OD x 3/16” ID. For best performance, the tubing length should be as

short as practical (recommended length is 2.5” min. to 6” max.). The port threads in the

module are 1/8-27 NPT.

If necessary for clearance, the air cylinder can be rotated to re-position the tube fittings.

Remove the four cap screws securing the air cylinder, and without removing the air

cylinder, rotate to the desired position. Replace the cap screws and torque crosswise,

first to 5 in-lb., then to 20 in-lbs.

Recommended operating air pressure is 70-90 psi.

Operation of Optional Drain Valve

(Option Code A, see Chapter Model Designation Guide)

UFD Applicators with the “A” option are equipped with a drain valve located on the right

side of the Applicator. This drain valve allows residual adhesive pressure to be relieved

prior to maintenance or repair of the Ap pl icator . Dur ing Applicator installation, the drain

valve can be relocated to the left side of the Applicator for access, if necessary.

The drain valve consists of a valve body with a rotatable outlet collar that directs the flow

of adhesive. A plug is located inside the body, retained by a snap ring to prevent the plug

from being fully removed.

Operation

1. Ensure that all pumps in the ASU (Adhesive Supply Unit) are turned off. Power down

the ASU or disable the Applicator and preheater zones at the control panel.

Disconnect all electrical cables from the Applicator.

The equipmet will still be hot when this procedure is being done.

Use insulated gloves and protective c lothing.

2. Place a suitable container under the Applicator to catch adhesive. Using pliers, rotate

the knurled outlet collar of the drain valve so that the exit hole points toward the

container, and away from any personnel. Stand away from the valve while the

adhesive pressure is being relieved.

3. Using a 19mm (3/4”) wrench on the valve body to prevent rotation, insert a 5mm hex

wrench into the plug. Rotate the plug counter-clockwise to allow adhesive to flow

through the valve.

4. If no adhesive flows from the drain valve, do not assume that there is no adhesive

pressure in the system. Always verify that adhesive pressure has been completely

relieved before proceeding with maintenance or repairs. Never remove the snap ring

in the end of the valve, as this would allow the plug to be removed, possibly resulting

in personal injury.

5. After maintenance or repairs are complete, tighten the plug securely. Wipe any

adhesive from the outer surface of the drain valve.

UFD Applicator, Manual 40-43, Rev. 6.16 Page 29

Page 30

ITW Dynatec

Chapter 4

Installation & Startup

WARNING! HOT SURFACE & ADHESIVE!

max. oil

(mg/m3)

1

0,1

0,1

-70

0,01 2 1 1 -40

0,1

3

5 5 -20

1 4 15

8

+3

5

5

40

10

+7

25 6 +10

7 not defined

Purging Adhesive Through the Applicator

This procedure may be used anytime the operator wishes to purge old adhesive from the

Applicator and replace it with fresh adhesive. For example, this procedure could be used

in instances where the adhesive system has been held at temperature for an extended

time without running, such as during a produc tio n line s tar t-up.

The equipment will still be hot when this procedure is being do ne.

Use insulated gloves and protective c lothing.

Procedure

1. Remove all nozzles. Place a suitable container under the Applicator to catch adhesive.

2. Activate the modules and manually run the adhesive pump to purge the hoses and

Applicators of old adhesive. Purge until the adhesive exiting the modules is fresh.

3. Check system pressure to see if filters are clogged and need to be changed.

4. Replace the nozzles and check the adhesive flow through them. Compare to target

flow.

5. Check the nozzle spray pattern.

6. Clean any nozzles that do not spray properly and check the spray pattern again.

4.3 Quality of compressed Air

Compressed air quality class according to ISO 8573-1

• We recommend to use a maintenance-unit for compressed-air conditioning with a filter

40µm.

• Keep the quality class 5.4.2 according to ISO 8573-1.

Classification of Quality Classes According to ISO 8573-1:

Class 1. Particulate Material 2. Water Content 3. Oil Content

max. particle size

(μm)

max. particle density

Page 30 UFD Applicator, Manual 40-43, Rev. 6.16

(mg/m3)

max. pressure dew point

(°C)

concentration

Page 31

Chapter 5 Maintenance and Repair Notes

ITW Dynatec

Heed all security advices given in Chapter 2.

3. Open the pressure purge valve manually until the pressure is relieved.

Maintenance and Repair Notes

5.1 Security advices for maintenance and repair

Use only original parts from ITW Dynatec, otherwise ITW Dynatec’s

warranty is void!

Maintenance and repair work is only permitted for skilled personnel!

Always wear safety shoes, heat-resistant protective gloves, safety goggles

and protective clothing that cover all vuln er ab le parts of the bod y while

working on the heated unit! Risk of injury or heavy burns!

High Voltage! Risk of injury and mortal danger!

• All electrical connections must be made by qualified electrical personnel.

• Care must be taken to assure proper grounding prior to any disassembly.

• Lockout and tag the electrical sources as required.

• Make sure there is no electrical power on the leads you will be

connecting.

• When covers are removed, high voltage sources create an electrocution

hazard.

• Wear appropriate safet y equipm ent when wor k ing with high vol tag e

sources.

Parts and surfaces of the unit get very hot. High temperatures! Risk of

heavy burns!

High adhesive temperature and adhesive pressure! Risk of injury or

heavy burns!

Always assume that the system is under pressure, proceed with caution.

Keep a cool-pack, or bucket of clean water near the work area.

Place a heat-resistant catchment container/underlay under the components.

Hot adhesive may come out.

CAUTION: At working temperature, molten adhesive could cause heavy

burns. Let spilled out adhesive cool down first, before removing it!

CAUTION: Use only lint-free cleaning cloth and suitable cleaner for cleaning!

Do not damage surfaces! Do not scratch above them with sharp-edged

tools, otherwise the components will get leaky and inoperable!

All maintenance and repair work has to be done at working

temperature, except as noted otherwise. Else there is a risk of

damaging the unit components!

Before any service work disconnect the external power supply and

switch the unit voltage-free:

1. Switch off the main switch and the controller.

2. Disconnect the power supply respectively remove the plug / cable.

3. Guard the unit against unauthorized restarting!

Before any service work the adhesive pressure must be relieved

throughout the system. Switch the unit pressureless:

1. Disconnect the pressure air supply.

2. Turn the pressure regulator to zero bar, if necessary. Wait approximately

1 minute until the pressure is relieved.

Chapter 5

UFD Applicator, Manual 40-43, Rev. 6.16 Page 31

Page 32

ITW Dynatec

Chapter 5

Maintenance and Repair Notes

CAUTION

temperature.

CAUTION

Applicator.

5.2 Re-Assembly Procedures and General Cautions

Unless noted, component re-assembly is simply the reverse sequence of the disassembly

procedures. However, the following “cautions” should be followed (whenever they apply)

for proper re-assembly:

In general, all O-RINGS AND SEALS must be replaced whenever hot-melt equipment is

re-assembled. All new O-rings must be lubricated with O-ring lube (PN N07588).

TAPERED PIPE THREADS are found on air pipe fittings used with the pump air supply

and on the outlet filter manifold. Apply thread sealant (PN N02892) whenever tapered

pipe threaded parts are re-assembled.

SOME FITTINGS used for adhesive on hot melt equipment have straight threads and Oring seals. Use of thread sealant is not necessary with these parts, but the O-ring seals

should be clean and lubricated. Tighten straight-threaded parts and fittings until their

shoulders are firmly seated. Excessive torque may damage straight-threaded parts and

the use of power wrenches is not recommended.

HOT-MELT RESIDUE must be cleaned from parts before they are re-assembled,

particularly from threaded parts. As a precaution against adhesive residue preventing

proper re-assembly, threaded parts must always be re-tightened at operating

5.3 Stroke Limit Adjustment

All conventional MR1300 applicators are equipped with a stroke limit adjustment.

For snuffback valves, the stroke is factory pre-set and no field adjustment is necessary.

Whenever the conventional module is disassembled, the stroke limit must be adjusted

using the following procedure:

1. Bring applicator up to operating temperature.

2. Loosen the lock nut (see illustration on next pages, under Chapter 5.5 Replacement of

the Built-in Filter) located on the top of the module.

3. Bottom the stroke adjustment screw lightly.

Tightening the stroke adjustment to shut OFF the nozzl e will cause damage to the

4. Back off the screw one-half to one turn.

5. While holding the screw in position, tighten the lock nut.

Page 32 UFD Applicator, Manual 40-43, Rev. 6.16

Page 33

Chapter 5

Maintenance and Repair Notes

ITW Dynatec

WARNING

Maintenance and repair work is only permitted for skilled personnel!

protective clothing.

5.4 Relieving Adhesive Pressure

Heed all security advices given in Chapter 5.1.

Always wear safety shoes, heat-resistant protective gloves, safety goggles

and protective clothing that cover all vulnerable parts of the body while

working on the heated unit! Risk of injury or severe burns!

Components and adhesive are hot. Take every precaution to prevent the

material and hot surfaces from contacting the skin.

During the purging procedure, hot adhe sive can come out of the

Applicator under high pressure. Wear safety glasses, gloves and

Many maintenance and troubleshooting procedures potentially expose the maintenance

technician to dangerous hot adhesive, which is under pressure. Follow this procedure to

release the adhesive pressure in the Applicator before performing such maintenance.

1. The Applicator should be at operating temperature.

2. Turn the ASU’s pump/ motor OFF.

3. Place a heat-resistant catchment container/underlay under the Applicator.

Relieving Adhesive Pressure Manually:

1. Push the purge button located on the side of the air solenoid coil.

Or, if the ASU filter block is equipped with a drain, adhesive pressure may be relieved

at the ASU.

Relieving Adhesive Pressure by using the Optional Drain Valve (if applicable):

1. Place a heat-resistant container under the drain valve. If necessary, rotate the drain

valve’s opening by turning its knurled collar so that the opening is aiming downward

into the container.

2. With a 5mm hex key screwdriver (Allen-wrench), slowly loosen the drain valve’s purge

screw (do not try to remove it) and allow the adhesive and residues to flow out of

Applicator. Be sure to stand clear since there may be residual adhesive pressure in

the Applicator.

3. Turn ON the ASU’s pump/ motor. When all the contaminants have run out and the

adhesive is clean, retighten the screw.

UFD Applicator, Manual 40-43, Rev. 6.16 Page 33

Page 34

ITW Dynatec

Chapter 5

Maintenance and Repair Notes

WARNING

Maintenance and repair work is only permitted for skilled personnel!

protective clothing.

1. Stop all motors.

care not to cut the O-ring.

Mounting screw

Filter

Basket

O-ring

Filter Nut

Lock Nut

Stroke Adjustment Screw

Optional Drain

(Purge) Valve

5.5 Replacement of the Built-in Filter

Heed all security advices given in Chapter 5.1.

Always wear safety shoes, heat-resistant protective gloves, safety goggles

and protective clothing that cover all vulnerable parts of the body while

working on the heated unit! Risk of injury or severe burns!

Components and adhesive are hot. Take every precaution to prevent the

material and hot surfaces from contacting the skin.

During the purging procedure, hot adhe sive can come out of the

Applicator under high pressure. Wear safety glasses, gloves and

Refer to the drawing in Chapter 7 for more information.

The applicator must be at operating temperature.

Procedure for Basket-type Filter (Filter Codes A & B):

2. Switch the unit voltage-free and

pressureless.

3. Guard the unit against

unauthorized restarting.

4. Place a heat-resistant catchment

container/underlay under the

Applicator. Hot adhesive may

come out!

5. Relieve the adhesive pressure by

following the instructions under

Chapter 5.4 “Relieving Ad h esiv e

Pressure”.

6. Unscrew and remove the filter

nut.

7. With needle nose pliers, pull the

filter basket out of the manifold.

8. Replace the O-ring on the filter

nut. Apply O-ring lubricant (PN

N07588) to the new O-ring.

9. Apply a coat of anti-seize to the

threads of the filter nut.

10. Re-install the filter basket and

the filter nut. Tighten the filter

nut until it is seated firmly, taking

Nozzle

Page 34 UFD Applicator, Manual 40-43, Rev. 6.16

Page 35

Chapter 5

Maintenance and Repair Notes

ITW Dynatec

1. Stop all motors.

O-ring

Filter Cap

O-ring groove

Sealing washer

Spin-on Filter

Procedure for Spin-on Filter (Filter Code C)

2. Switch the unit voltage-free and

pressureless.

3. Guard the unit against unauthorized

restarting.

4. Place a heat-resistant catchment

container/underlay under the Applicator. Hot

adhesive may come out!

5. Relieve the adhesive pressure by following

the instructions under Chapter 5.4 “Relieving

Adhesive Pressure”.

6. Unscrew and remove the filter cap.

7. Unscrew the filter from the filter cap.

8. Remove and discard the old sealing washer

and O-ring.

9. Make sure the mating surface of the filter cap

is clean.

10. Install a new sealing washer, filter and O-

ring. Torque the filter to 40-50 in-lbs

(4.5 – 5.5 Nm) on the cap.

11. Apply a coat of anti-seize to the threads of

the filter cap.

12. Re-install the filter and the filter cap. Tighten

the filter cap until it is seated firmly, taking

care not to

13. Close the pressure bleed (purge) valve,

return the equipment to service and check

for leaks.

14. If leaking, it might be necessary to replace

the filter cap’s O-ring.

cut the O-ring.

(upper groove)

UFD Applicator, Manual 40-43, Rev. 6.16 Page 35

After finishing the maintenance or repair works:

Remove all materials and tools used during the repair or maintenance from the

workspace of the unit.

Connect the voltage supply and the compressed air supply. Heat the unit up. Wait until

all temperatures are within the tolerances and the adhesive in the tank is molten

completely.

Continue production.

Page 36

ITW Dynatec

Chapter 5

Maintenance and Repair Notes

WARNING

Maintenance and repair work is only permitted for skilled personnel!

protective clothing.

1. Stop all motors.

2.8 Nm).

Module’s two

5.6 Replacement of the Module

Modules Which Are Not Serviceable

The following modules cannot be customer-serviced:

• PN 112440 Module, High-Speed SB, Hor, Dir Air

• PN 112444 Module, High-Speed SB, Hor, Bck Air

Replacement of the Standard Module

Heed all security advices given in Chapter 5.1.

Always wear safety shoes, heat-resistant protective gloves, safety goggles

and protective clothing that cover all vuln er ab le parts of the bod y while

working on the heated unit! Risk of injury or severe burns!

Components and adhesive are hot. Take every precaution to prevent the

material and hot surfaces from contacting the skin.

During the purging procedure, hot adhe sive can come out of the

Applicator under high pressure. Wear safety glasses, gloves and

Refer to the drawing in Chapter 7 for more information.

2. Switch the unit to stand-by and pressureless.

3. Place a heat-resistant catchment

container/underlay under the Applicator. Hot

adhesive may come out!

4. Relieve the adhesive pressure by following the

instructions under Ch apt er 5.4 “Relieving Adhesive

Pressure”.

5. Remove the module from the service block by

removing the two mounting screws on the front of

the module with a hex key screwdriver (Allen

wrench). Make sure that the old O-rings located on

the back of the module are also removed (the new

module will include new O-rings).

6. Mount the new module in reverse order and att ach

it to the manifold with a torque of 20-25 in./lbs (2.3-

After finishing the maintenance or repair works:

Remove all materials and tools used during the repair or maintenance from the

workspace of the unit.

Connect the voltage supply and the compressed air supply. Heat the unit up. Wait until

all temperatures are within the tolerances and the adhesive in the tank is molten

completely.

Continue production.

Page 36 UFD Applicator, Manual 40-43, Rev. 6.16

mounting screws

Page 37

Chapter 5

Maintenance and Repair Notes

ITW Dynatec

CAUTION

premature seal breakdown and leakage of glue from the Applicator!

Module Assembly Instructions for the PN 104993 UFD Module

Demount the module from the service block, refer to the instructions in Chapter 5.6

Replacement of Standard Module on previous page.

Use the component illustration and parts list in Chapter 7 as a reference with the

following instructions for the PN 104993 UFD module.

ITW Dynatec has a Module Seal Kit available (PN 105150) which contains the

components necessary to rebuild one module, including the seal cartridge assembly, all

O-rings, spring and seal lubricant.

1. During re-assembly, coat all O-rings with a liberal amount of High Temp Lube (PN

N07588).

DO NOT SUBSTITUTE! Failure to use High Temp Lube (N07588) may result in

2. Insert the new seal cartridge assembly into the module body. (Note that there are two

holes in the seal cartridge cavity in the module body. One hole accepts the roll pin in

the seal cartridge. The other is an air hole which must line up with the air hole in the

seal cartridge.) Align the roll pin in the seal cartridge with the corresponding hole in the

top of the module body. Press the seal cartridge into position. The air hole in the seal

cartridge must align with the air ho le in the module body for the valve to

function properly.

3. Place a new piston O-ring onto the stem assembly and slowly insert the stem

assembly into the seal cartridge.

4. Place the new spring on top of the piston.

5. Loosen and back out the adjusting screw in the air cylinder. Place the air cylinder over

the spring and piston and press down into place. Take care not to dislodge the spring

or damage may result. Secure the air cylinder with the four mounting screws.

6. Place new O-rings on the seat assembly and insert the seat assembly into the bottom

of the module body. Secure with the four mounting screws. Spring resistance will be

felt as the screws are tightened. Tighten the screws evenly to avoid binding.

7. Place new O-rings into the grooves on the rear face of the module and mount the

module onto the service block.

8. Allow five minutes for the module to heat. Adjust the stem stroke to the desired

setting.

To disassemble, reverse above order.

UFD Applicator, Manual 40-43, Rev. 6.16 Page 37

Page 38

ITW Dynatec

Chapter 5

Maintenance and Repair Notes

CAUTION

premature seal breakdown and leakage of glue from the Applicator!

Module Assembly Instructions for the PN 106224 UFD or 106226 HiTemp UFD Module

Demount the module from the service block, refer to the instructions in Chapter 5.6

Replacement of Standard Module on previous pages.

Use the component illustration and parts list in Chapter 7 as a reference with the

following instructions for the PN 106224 or 106226 module. ITW Dynatec has a Module

Seal Kit available (PN 105150/ 803012 for Hi Temp) which contains the components

necessary to rebuild one module, including the seal cartridge assembly, all O-rings,

spring and seal lubricant.

1. During re-assembly, coat all O-rings with a liberal amount of High Temp Lube (PN

N07588).

DO NOT SUBSTITUTE! Failure to use High Temp Lube (N07588) may result in

2. Insert the new seal cartridge assembly into the module body. (Note that there are two

holes in the seal cartridge cavity in the module body. One hole accepts the roll pin in

the seal cartridge. The other is an air hole which must line up with the air hole in the

seal cartridge.) Align the roll pin in the seal cartridge with the corresponding hole in the

top of the module body. Press the seal cartridge into position. The air hole in the seal

cartridge must align with the air ho le in the module body for the valve to

function properly.

3. Place a new piston O-ring onto the stem assembly and slowly insert the stem

assembly into the seal cartridge.

4. Place the new spring on top of the piston.

5. Loosen and back out the adjusting screw in the air cylinder. Place the air cylinder over

the spring and piston and press down into place. Take care not to dislodge the spring

or damage may result. Secure the air cylinder with the four mounting screws.

6. a. Follow this step for new-style modules (those built after 11/12/07): Place new O-

rings on the vertical adapter and insert the seat assembly into the bottom of the

module body. Spring resistance will be felt as the screws are tightened. Tighten the

screws evenly to avoid binding.

b. Follow this step for old-style modules (those built prior to 11/12/07): Place new Orings on the seat assembly and insert the seat assembly into the bottom of the module