Page 1

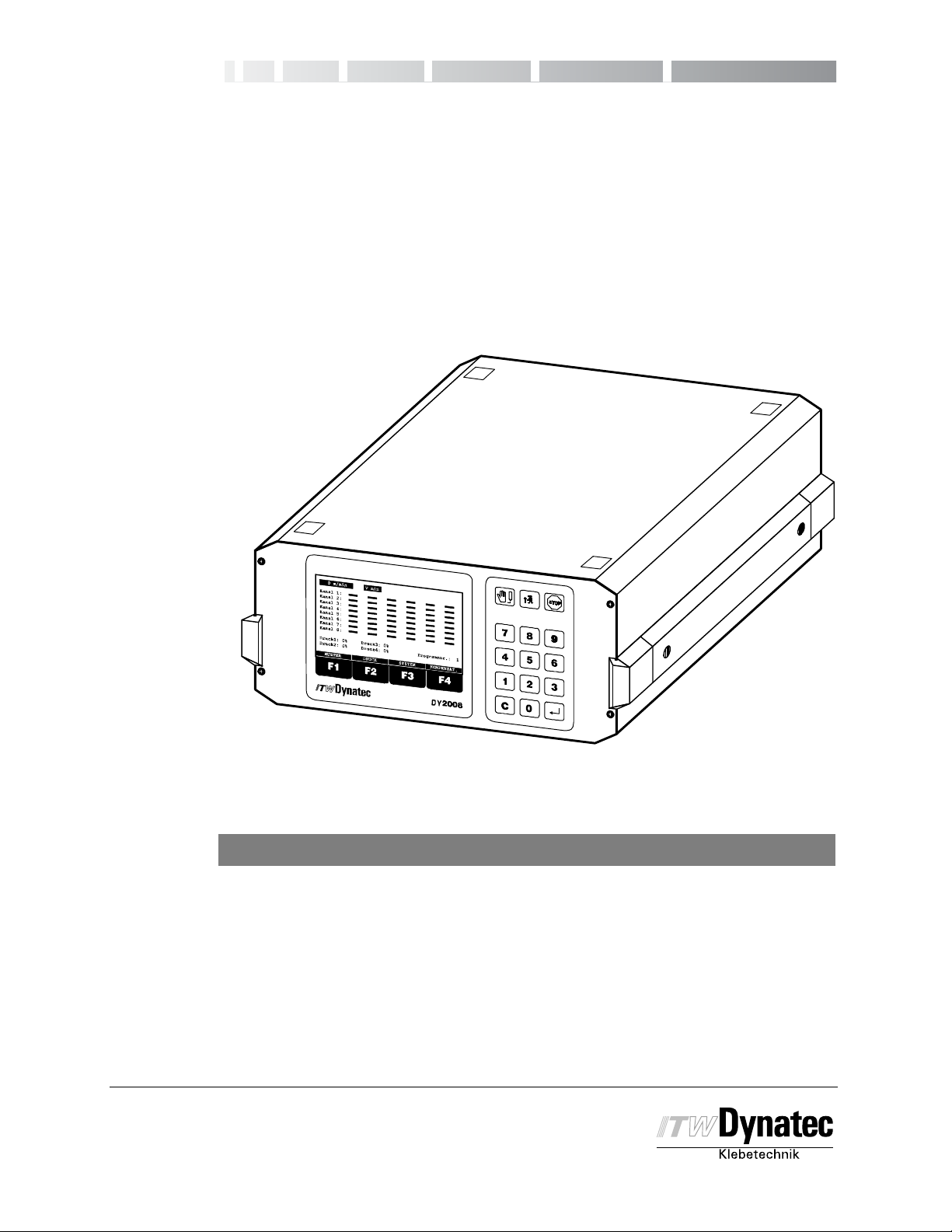

CONTROLLER

Manual #50-14

Rev.11/15

ITW Dynatec

Industriestraße 28

40822 Mettmann, Germany

Tel.: +49 (0)2104 915-0

FAX: +49 (0)2104 / 915 111

info@itwdynatec.de

Operating Manual

DY 2008

Pattern Controller

2008 D.BOO 11/02

For an online copy of this manual, go to www.itwdynatec.com/manuals.htm

ITW Dynatec

An Illinois Tool Works Company

31 Volunteer Drive

Hendersonville, TN 37075 USA

Telephone +1 615 824 3634

FAX +1 615 264 5222

dynatec@itwdynatec.com

www.itwdynatec.com

ITW Dynatec K.K.

Daiwashinagawa Bldg., 7-15 Konan, 3-Chome

Minata-Ku, Tokyo 108 Japan

Telephone 81 3 3450 5901

FAX 81 3 3450 8405

info@itwdynatec.co.jp

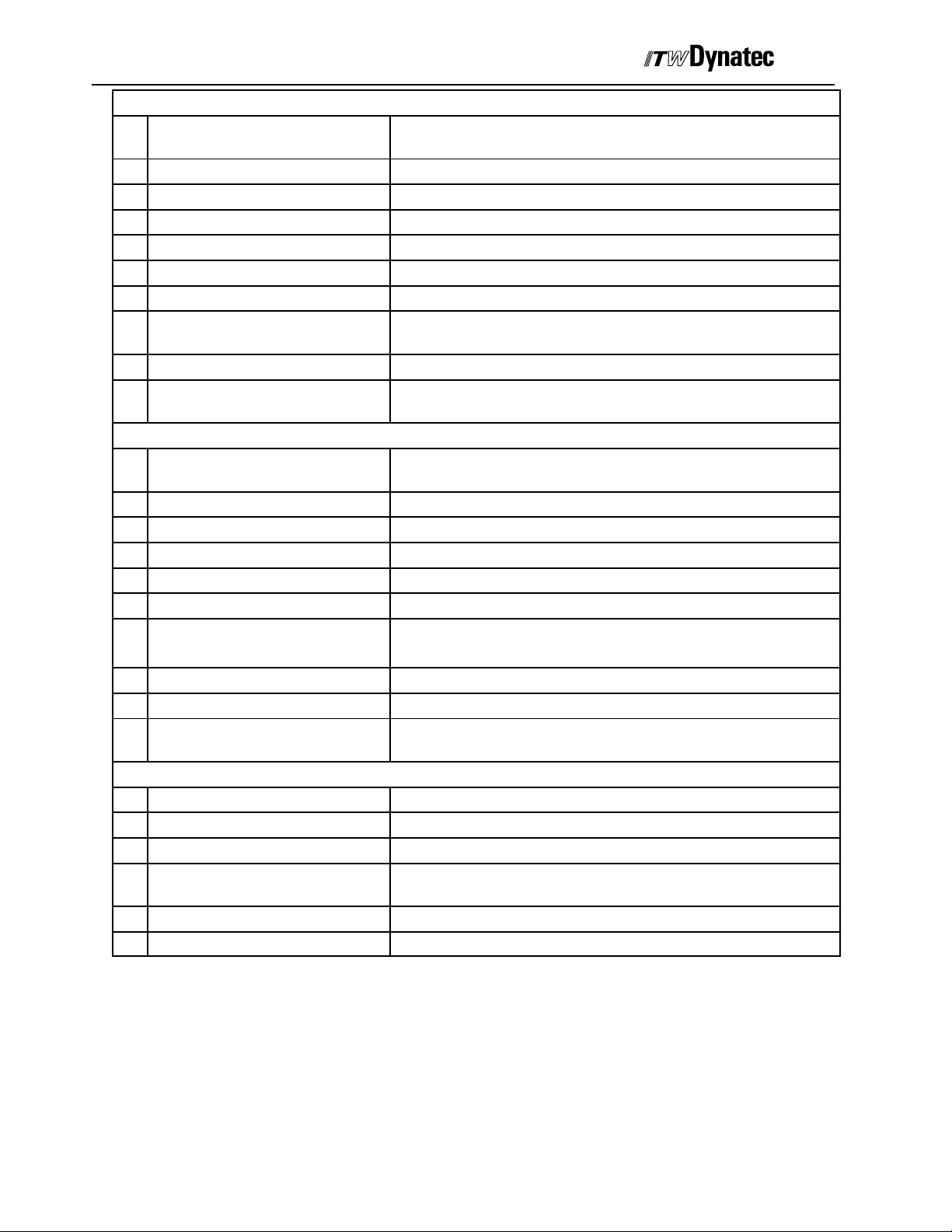

Page 2

Page 3

Page 4

Page 5

C. 2002

Manual #50-14 Revised 3/05

1: Safety Instructions 1 - 1...........................................

About this Manual 1 - 1...........................................................

Proper Use of System 1 - 1........................................................

Manual Symbols 1 - 1............................................................

Authorized Use of System 1 - 1....................................................

Installation, Maintenance, Repair or Disposal of the System 1 - 1.......................

Modification to the System 1 - 2....................................................

Working with Cover Open 1 - 2....................................................

2: Product Description 2 - 1..........................................

General 2-1....................................................................

Technical Data 2-2..............................................................

Dimensions (Basic version) 2 - 4...................................................

Operating and Connecting Elements (Basic version) 2 - 4.............................

3: Installation 3 - 1..................................................

Connectors and Pin Definitions 3 - 1................................................

Connecting the System 3 - 2......................................................

Locating an Optical Trigger (Sensor) 3 - 2...........................................

Connecting Optional Accessories 3 - 3..............................................

I

4: Operating 4 - 1...................................................

Operator’s Panel 4 - 1............................................................

Remote Purge Control 4 - 2.......................................................

Service Settings Menus 4 - 3......................................................

Production Setup Menu 4 - 4......................................................

Power On and Software Version 4 - 5...............................................

Service Settings 4-6.............................................................

Service Settings Menu 1 of 3 Overview 4 - 6..............................................

Service Settings Menu 2 of 3 Overview 4 - 8..............................................

Service Settings Menu 3 of 3 Overview 4 - 9..............................................

Factory Defaults 4-9..................................................................

Service Setting Programming Conventions 4 - 11.....................................

Display Contrast Adjustments 4 - 11.................................................

Service Settings Menu 1 4 - 12.....................................................

Select Language 4-12..................................................................

Load Program 4-13....................................................................

Trigger Assignment 4-14................................................................

Trigger Lock 4-15......................................................................

Encoder--Channel Assignment 4 - 15......................................................

Encoder Scaling (Encoder Type and Unit) 4 - 17............................................

Min/Max Speed Configuration 4 - 18.......................................................

Channel Mode Adjustment 4 - 19.........................................................

Change Security Lock 4 - 22.............................................................

Change Access Code 4 - 22.............................................................

Service Settings Menu 2 4 - 23.....................................................

Trigger Setup 4-23.....................................................................

Pressure Signaling 4-24................................................................

Pressure Assignment 4-25..............................................................

Pressure Curve Configuration 4 - 25.......................................................

Page 6

II

Manual #50-14 Revised 1/09

Spike Voltage Adjustment 4 - 27..........................................................

Spike Duration Adjustment 4 - 28.........................................................

Shutter Assignment 4-29...............................................................

Shutter Dwell Timing Adjustment 4 - 30....................................................

Change Security Lock 4 - 31.............................................................

Change Access Code 4 - 31.............................................................

Service Settings Menu 3 4 - 32.....................................................

STOP Configuration 4-32...............................................................

PC--Communication (Option) 4 - 33.......................................................

Change Profibus Address (Option) 4 - 33..................................................

Shutter Trigger Setup 4-34..............................................................

Digital Configuration 4-35...............................................................

Load Factory Defaults 4 - 37.............................................................

Change Security Lock 4 - 39.............................................................

Change Access Code 4 - 39.............................................................

Production Setup 4 - 40............................................................

Stop Function 4-41....................................................................

Glue Pattern Setup 4-42................................................................

Copy/ Paste Function 4-44..............................................................

Pressure Adjustment 4 - 45.........................................................

Adjust Minimum Pressure (2--Point Curve) 4 - 45............................................

Adjust Maximum Pressure (2--Point Curve) 4 - 45...........................................

Adjust Purge Pressure (2--Point Curve) 4 - 46..............................................

Assigning the Pressure Points to the Machine Speed (12--Point Curve) 4 - 46...................

Adjust Purge Pressure (12--Point Curve) 4 - 47.............................................

System Menus: Dot Function, Stitching and Head Position 4 - 48........................

Dot Configuration 4-48.................................................................

Stitching Configuration 4 - 50.............................................................

Offset (Head Position) 4 - 52.............................................................

Speed Compensation Adjustment 4 - 54.............................................

Manual Gluing (Purge) 4 - 55......................................................

C. 2002

5: Troubleshooting 5 - 1.............................................

Error Messages of the DY 2008 5 - 1...............................................

Communication Error 5-1..............................................................

Over Current Failure 5-1...............................................................

Compensation Error 5-1...............................................................

Appendix A

Common Accessories App. A 1........................................................

Appendix B

Printed Circuit Boards and Wiring Information App. B 1...................................

Appendix C

Programming Log App. C 1...........................................................

Page 7

C. 1998

Manual #50-14 Revised 1/03

1-1

Safety Instructions

Authorized Use of System

Only authorized persons who have read and understood the instruction manual or who

have been trained by ITW Dynatec may install, operate or dispose off this system.

Appropriate electrical safety procedures must be observed.

A copy of this manual should be kept with the installed system as reference material.

Proper Use of the System

This controller is designed for use only with ITW Dynatec hot melt or cold glue systems.

Other applications should be attempted only after consulting with ITW Dynatec.

Manual Symbols

Caution

This symbol means that failure to observe the specific instructions could

cause damage to the equipment.

Danger! High Voltage!

This symbol means there is a danger of electrical hazard.

Note! Provides useful information regarding the use of the system.

Page 8

1-2

C. 1998

Safety Instructions

Manual #50-14 Revised 1/03

Modifications to the System

No modification can be made to the system without consulting ITW Dynatec. Use only

factory--recommended parts and fittings. ITW Dynatec does not assume any resonsibility

for damage which occurs as a result of using parts that are not factory recommended.

Working with the Cover Open

Never operate this controller with open cover. There are no servicable components inside.

All settings are done via Software.

Inside the controller are electric current--carrying components. To avoid personal injury, do

not touch them while input power is ON. Disconnect and lockout main power before opening

the cover. Then wait a few seconds until all electrical components have discharged.

Page 9

C. 2002

Manual #50-14 Revised 1/03

2-1

Product Description

General

The DY 2008 Pattern Controller is one component of an adhesive application system

consisting of a hot-melt unit, cold glue pressure vessel or cold glue pump, adhesive hoses

and applicator heads. The controller can be used for hot--melt or cold glue application.

The pattern controller activates solenoids for four (Basic Version) up to 128 (Option)

applicator heads in order to create individual adhesive patterns. It is possible to program

up to 16 independent glue events (16 glue + 16 delay) per channel.

Each channel can operate in one of the possible modes: glue beads, dots, continuous

gluing, random product length and stitching.

Gluing can be triggered with a photo eye, proximity switch or by exceeding a certain

machine speed.

Every channel may be assigned to its own trigger input, if desired, to increase the accuracy

of multiple parallel running products.

In order to accelerate the timing of solenoids it is possible to apply initially a higher voltage

(Over--excitation). The voltage level and the duration time of this over--excitation is

programmable via software on a channel-by-channel basis. This enables applications for

hot--melt and cold glue.

The speed of the production machine will be registered with up to four encoders and

indicated on the display. It can be used to control the speed of one or more gear pumps of

adhesive supply units or to control the glue pressure on a cold glue system via I/P or U/P

transducers. Every time the machine speed varies the glue pressure will follow.

Working with four encoders enables application on machines with different speeds e.g.

Right--Angle machine.

The pressure vs. speed ramp can be linear or for better adaptation to production conditions

a 12--point curve is programmable.

A machine contact is available to enable or disable the controller. With this contact it is

possible to start and stop the gluing together with the parent machine.

The user can select whether the gluing stops immediately or continues.

The controller can provide an output signal to close a shutter devise (automatic tip sealer)

in order to prevent clogging of cold glue applicators from drying during production breaks.

If necessary this shutter output can be activated with a dedicated trigger input.

Alternatively the programming of the glue pattern can be done on a computer and

corresponding software. An optional RS232/485 or Profibus interface can be used to

communicate with the pattern controller from an external device.

Critical conditions can be signalled by means of two alarm outputs.

Page 10

2-2

C. 2002

Product Description

Manual 50-14 Revised 11/15

Technical Data

General

Operating Temperature

Storage Temperature

Power Supply 1/N/PE 230 V 50--60 Hz

Power Consumption 180w (8 channel version)

Operating Languages German, English, Finnish, French, Italian

Number of Programs 60 stored in permanent memory

Protection Class IP 40

CE Approval Granted yes

Trigger

Input connectors 24 V DC, max. 100 mA, NPN, PNP, Push--Pull

Max. Number 4 Master Triggers (Triggers #1 thru 4)

Assignment (every channel can be assigned to a Master

Trigger or its Channel Trigger and any trigger may be “Anded”

to a Master Trigger)

Trigger Lock 0--8000 mm (0.01 to 80.00 in)

0 °Cto+50°C(32°F to122 °F)

-- 1 0 °Cto50°C(32°F to122 °F)

1/N/PE 115 V 50--60 Hz

1/N/PE 200 V 50--60 Hz

(Option IP 54)

1 additional per channel (Channel #5 and above)

Every Trigger can be assigned to each of the channel

Via AND--Function multiple Triggers can be combined.

Encoder

Max. Number 4

Input connectors X17 and X18 24 V DC, max. 100 mA, NPN (scalable)

Assignment Any encoder can be assigned to any channel.

Configuration Metric or inch

Scaling

Indication of Production Machine Speed max. 1200 m/min (2000 pulses/m)

Speed Configuration

Start Gluing above (Vmin START) 0--999 m/min

Stop Gluing below (V min STOP) 0--999 m/min

Maximum Machine Speed (V max) 0--1200 m/min

Output (Valve Output)

Channel X1 to X4 (Basic Version) for Controlling of Solenoids Valves (Short circuit proof)

Max. Number 4 (Option max. 128)

Output Voltage Nominal: 24 V DC

Overexcitation Timing 0.5--2.5 ms adjustable per software in steps of 0.5 ms

Wattage Capacity per Channel max. 20 W

Total Wattage Capacity for Channels 1--8 max. 160 W

Speed Compensation 0--999 mm

1--4000 pulse/m

0.01--99.99 pulse/inch

4000 ft/min (50 pulses/inch)

0--999 ft/min

0--999 ft/min

0--4000 ft/min

Overexcitation:

55 V (Factory Default) or 170 V

all Channels are individually adjustable

9.99 inch

Page 11

C. 2002

2-3

Manual #50-14 Revised 11/14

Valve M od e

Standard Mode Glue pattern, with or without stitching, is initiated by a trigger

signal. Gluing at speeds between Vmin and Vmax

Standard with Dot-Mode Glue pattern, with or without stitching, is initiated by a trigger

signal. Gluing at speeds between V-min START and V-min STOP

is Dot Mode. Gluing at speeds above V-min STOP is Standard

Mode.

Dot Mode Dot- Mode between Vmin and Vmax

Random Product Length Automatic adjustment of the pattern length to different product

length. Start and Stop of the pattern is controlled with a trigger

signal. Pattern can be stitched or continuous.

Continuous Gluing with Trigger Continuous gluing controlled with a trigger signal (i.e. glue active

when trigger active). Gluing starts above 1 m/min or 1 ft/min

Continuous with Trigger and Low Speed Cut Off Continuous gluing controlled with a trigger signal (i.e. glue active

when trigger active).Gluing starts when machine speed between

Vmin and Vmax

Continuous Gluing with Low Speed Continuous gluing starts at machine speed between Vmin and

Vmax, no trigger input is required

Glue Pattern

Maximum selectable Pattern and Delay Length 0- 8000 mm in steps of 1 mm

0- 80.00 inch in steps of 0.01 inch

Stitching: Glue Bead and Break Length 1- 200 mm in steps of 1 mm

0.01- 2.00 inch in steps of 0.01 inch

Dot Mode Breaks:

1- 8000 mm in steps of 1 mm

0.01- 9.99 inch in steps of 0.01 inch

Dot Length:

0.10- 9.90 ms

Product Description

Pressure Control Output

Max. Number 4

Connectors X24 to X27 4- 20 mA or 0- 20 mA and 0- 10 V scalable

Assignment Each Pressure Control Output can be assigned to any Encoder

Pressure Range min/max-Limits 0 to 100 %

Pressure Control Mode 2- or 12- Point Curve

Shutter Control

Output Connector X23 24V DC, max. 2 A

Trigger Input X20 Controlled by dedicated input or one of the Master Triggers

Machine contact, Alarm outputs and Interfaces

Machine contact X19 NPN, normally open contact required

Ready- /Alarm output connector X21 Normally open / normally closed, potential- free 24V DC, max. 500

RS232/485 Interface Connector X30 Option

Profibus Connector X28, X29 Option

mA or 230V AC, max. 500 mA,

Page 12

2-4

C. 2002

Product Description

Dimensions (Basic Version, 4 or 8 Channels)

0 m/min

Kanal 1:

Kanal 2:

Kanal 3:

Kanal 4:

Kanal 5:

Kanal 6:

Kanal 7:

Kanal 8:

Druck1: 0%

Druck3: 0%

Druck2: 0%

MUSTER DRUCK SYSTEM KOMPENSAT.

F1 F2 F3 F4

Programm.: 1

Druck4: 0%

DY 2008

241.3mm (9.5”)

279.4mm (11”)

326mm (13”) 345 mm (14”)

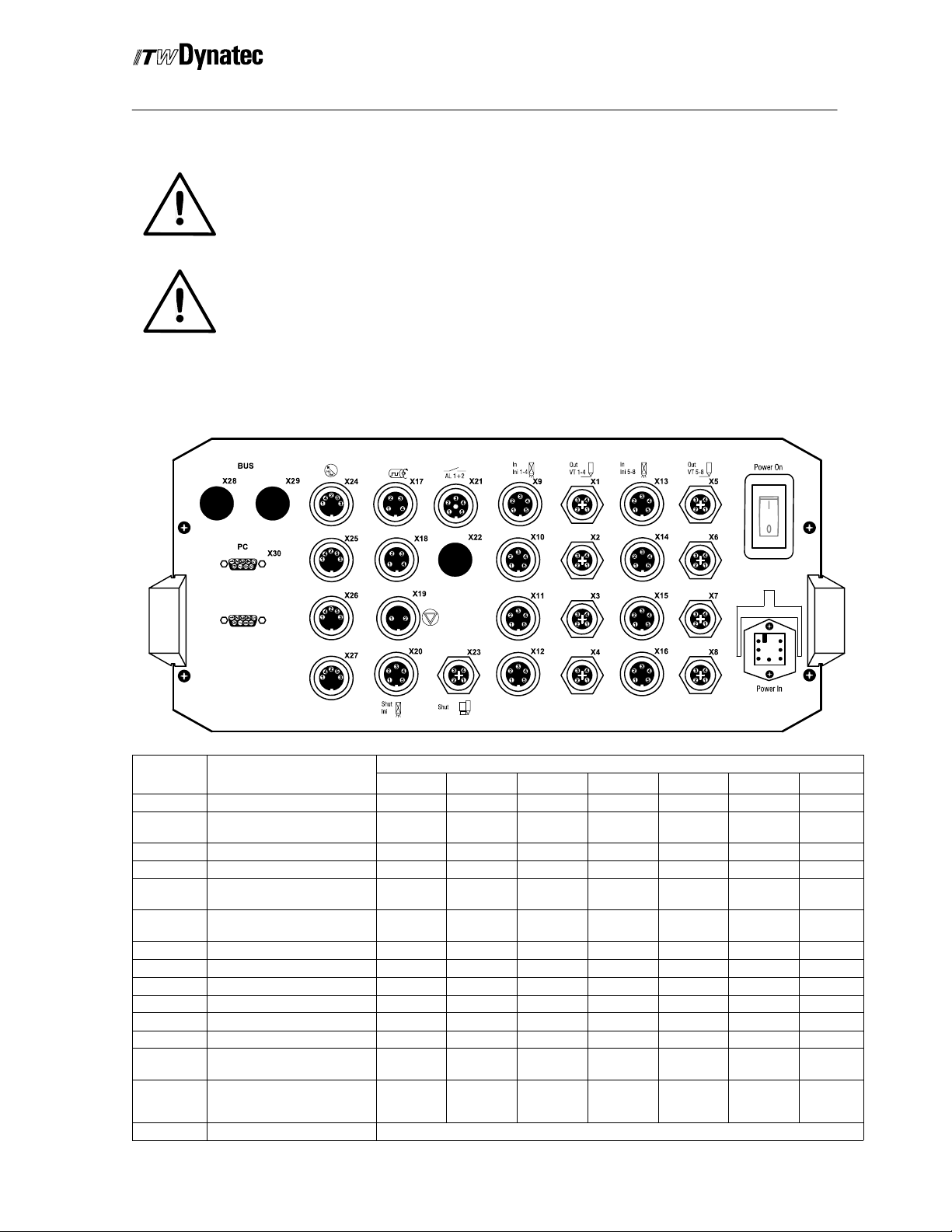

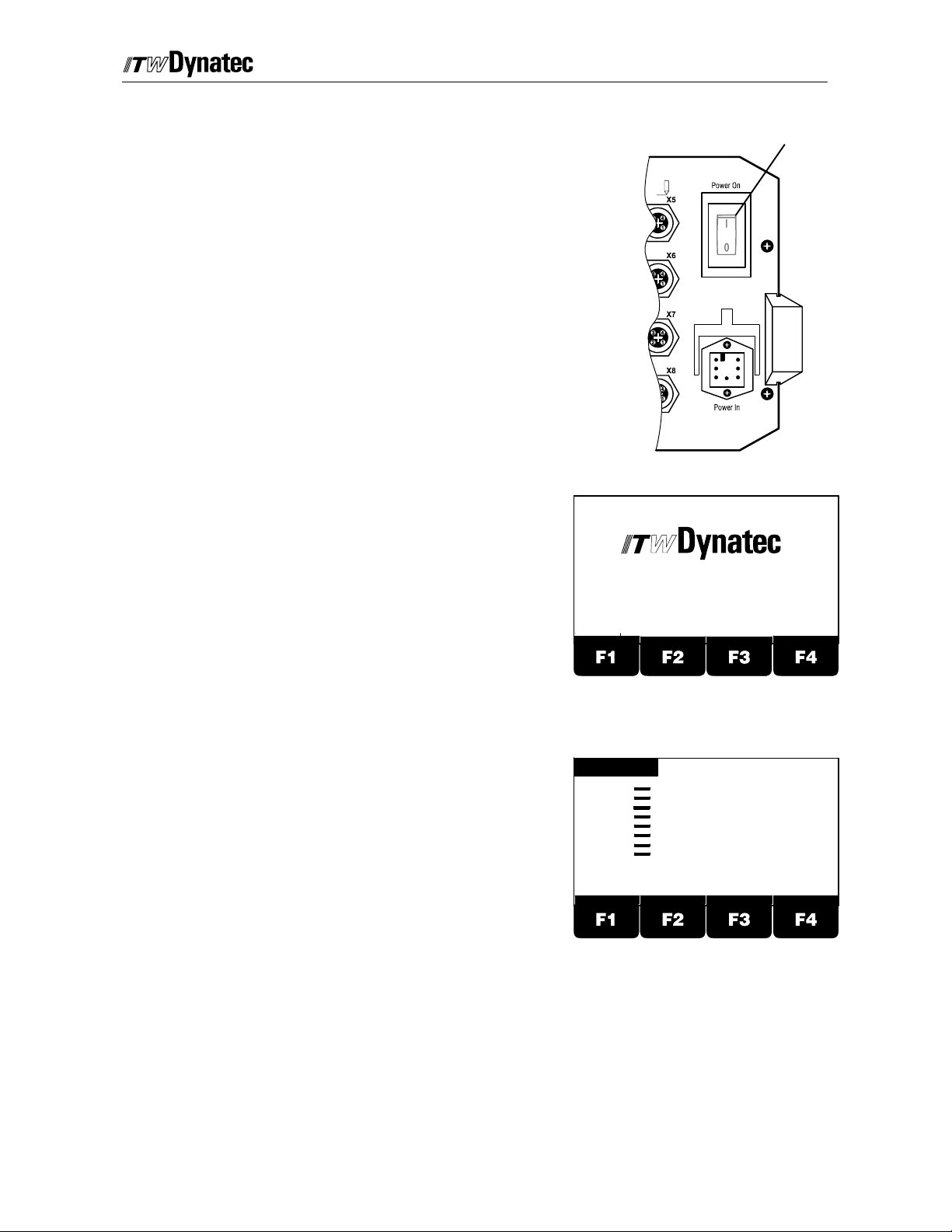

Operating and Connecting Elements (Basic Version)

Manual 50-14 Revised 7/03

150mm (6”)

Operating Panel

Connectors

Main Switch

Power Inlet

Page 13

C. 1998

Manual #50-14 Revised 1/03

Installation

Caution!

Only authorized person should execute the following procedures. Observe

all applicable safety rules.

Danger!

Place this controller in a dry and dust-free environment and not in the

danger zone of other machines. The operating elements must be accesable

without hazards.

Connectors and Contact Definitions

6

3--1

REMOTE

X31

Connector Function

X1--X8 Output for Solenoids 1 to 8 + -- Shield

X9--X16 Trigger 1 to 8 GND +24 V

X17 Encoder 1 and 3 GND +24 V Encoder 1 Encoder 3

X18 Encoder 2 and 4 GND +24 V Encoder 2 Encoder 4

X19 Machine contact GND

X20 Trigger for Shutter Control GND +24 V

X21 Alarm/ Zero Speed N.O. Common N.C.

X21 Stop/ System Ready N.O. Common N.C.

X22 Not Used

X23 Shutter Output + -- Shield

X24--X27 Pressure Control Output GND 0(4)-20mA 0-10 V +24 V

X28 Profi--Bus Connector Male Bus A Bus B Shield

X29

X30

X31 Remote Control RS 485 only for ITW Dynatec Remote Control

Profi--Bus Connector

Female

PC--Interface RS 232

or RS 485

1

5VDC Bus A GND Bus B Shield

2 3 4 5 6 7

Signal

NPN

TXD (232)

B (485)

Contact Definition

Signal

NPN/PNP

Signal

NPN/PNP

RXD

(232)

GND

A (485)

Page 14

3--2

C. 2002

Installation

Manual #50-14 Revised 8/2008

Connecting the System

Caution!

The over-excitation (spike) voltage for the outputs is shut off as a factory

default. Make sure this voltage is set appropriately for the applicator heads

being used. If necessary change the over-excitation as per instructions

provided in Chapter 4 of this manual.

Note! ITW Dynatec DynaCold and DynaCold Mini applicators always require an

over-excitation voltage of 170V.

(1)

1. Plug all connectors in the corresponding

receptacles.

2. Engage the locking ring (1) of the connector plugs

to the receptacles.

3. Connect the controller to the power supply.

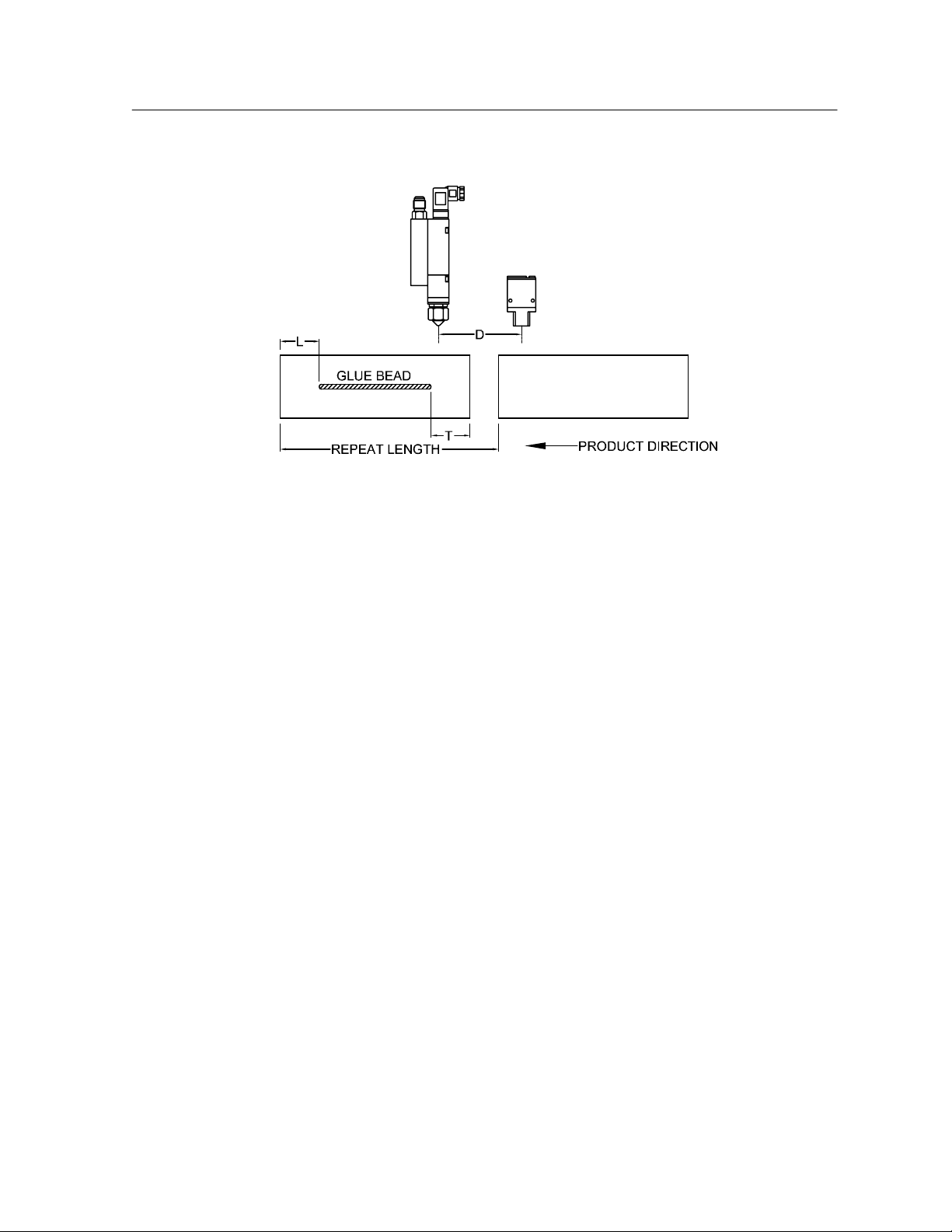

Locating an Optical Trigger (Sensor)

Use the information below to assist in the proper location of an optical triggering device.

TRIGGER LOCATION GUIDELINES (All Conditions Must Be Met)

All Intermittent Modes Except RANDOM

D + L > On Compensation

D < Repeat Length

RANDOM Mode

D + L > On Compensation

D > T + Off Compensation

D < Repeat Length

D = Distance from Optical Sensor to Glue Applicator (i.e. OFFSET)

L = Leading gap on product prior to first glue bead application.

T = Trailing gap on product after last glue bead application.

See the following diagram for additional clarification on this subject.

Page 15

C. 1998

3--3

2008 D 12/98

Manual #50-14 Revised 3/2005

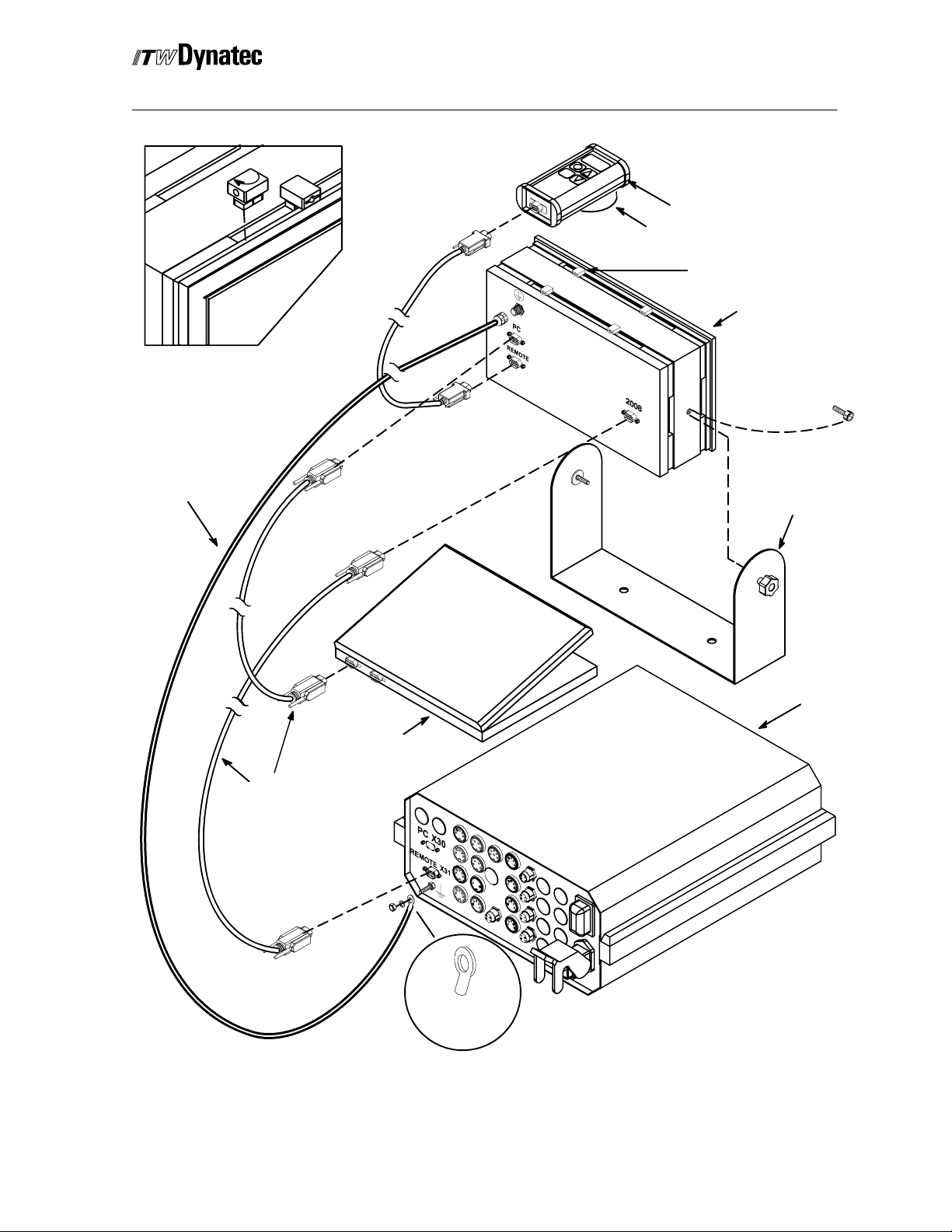

Connecting Optional Accessories

Installation

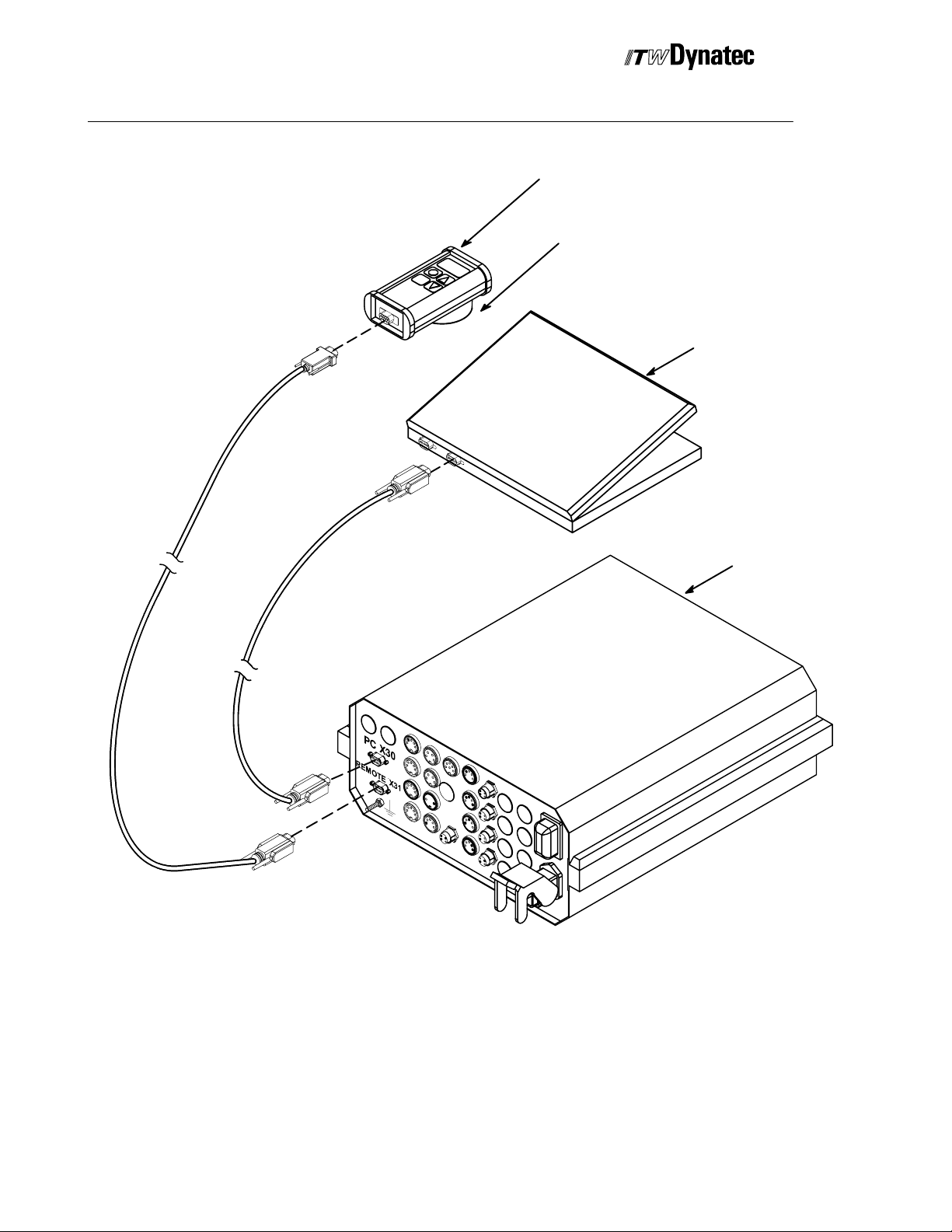

The DY2008 may be supplied with optional accessories as follows:

1. Remote Front Panel (28.11101.601): this allows the DY2008 operator interface to be

installed up to 10 meters (33 feet) away from the main control box. This is provided as an

option for the four and eight channel units and is standard for 12 or more channel units.

2. Remote Purge Control (28.11101.602): this allows one-person operation of the manual

gluing (purge) function at distances up to 10 meters (33 feet) from the Main Control Unit or

Remote Front Panel (if installed).

3. Data Interface Option (28.00005.107): this provides the ability to control the

programming of the DY2008 from another CPU via a RS232 or RS485 data interface.

Use the diagrams that follow as a guide in connecting the above accessories to the DY2008

Control Unit.

Page 16

3--4

C. 2002

Installation

Manual #50-14 Revised 8/2008

Purge Control

Magnet mount

PC

DY 2008

ConnectingOptions Directlyto Control Unit

Page 17

C. 1998

3--5

2008 D 12/98

Turn mounting

clip clockwise in

slot.

Ground Wire

Manual #50-14 Revised 3/2005

Installation

Purge Control

Magnet mount

Mounting Clip (used

for panel mounting)

Remote Panel

Remove screw

to attach Mounting

Bracket.

Remote Panel

Mounting Bracket.

Data Cable

DY 2008

PC

Attach terminal

to ground wire

Connecting Options Through Remote Front Panel

Page 18

3--6

C. 2002

Installation

Manual #50-14 Revised 8/2008

ITW Dynatec

An Illinois Tool Works Company

Page 19

Operation

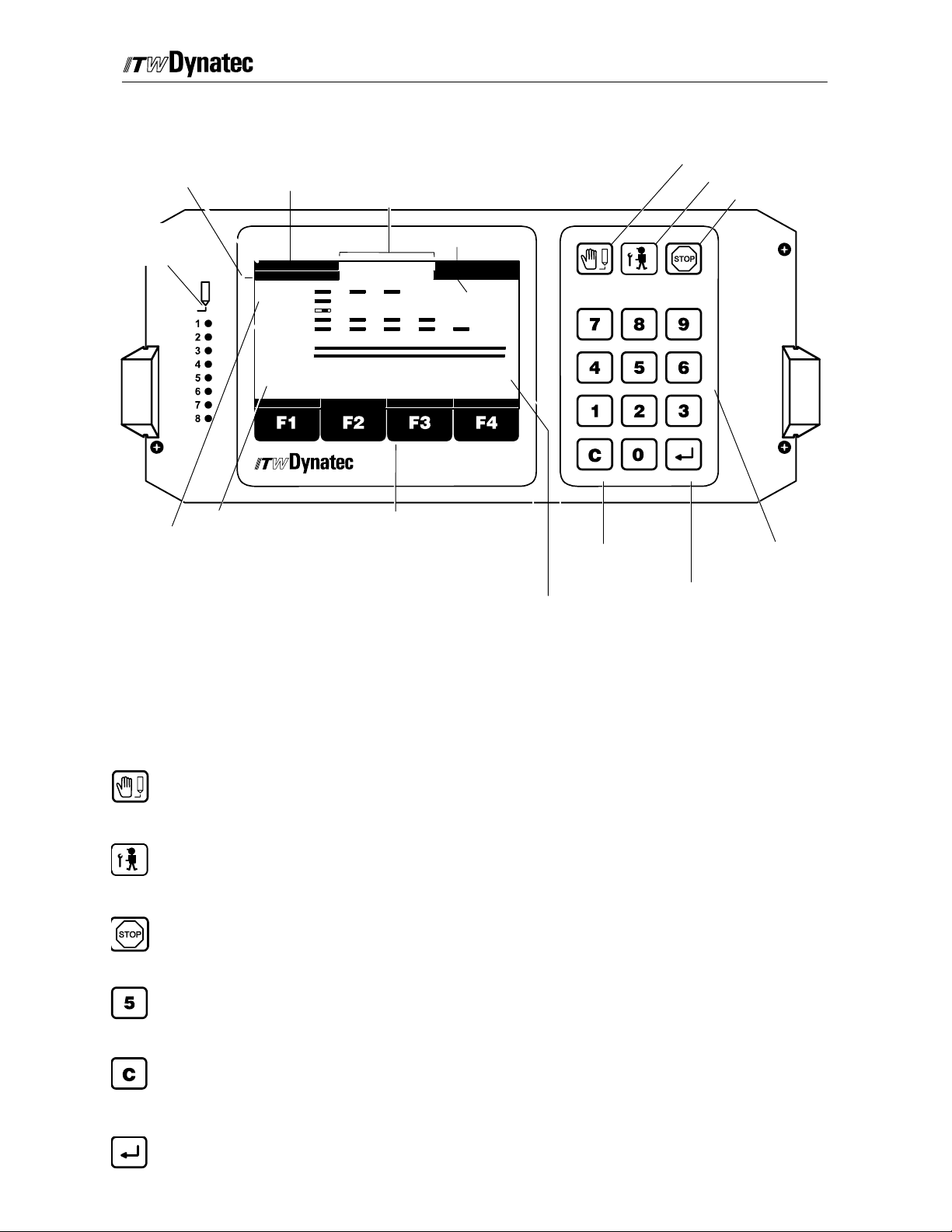

Operator’s Panel

Machine Speed

Encoder 2 Encoder 1

C. 1998

Manual #50-14 Revised 8/08

COM-STOP

COM 2-STOP

BUS-STOP

STOP

EXTER.STOP

All Channels stopped via serial interface

All Channels stopped via Purge Control

All Channels stopped via Profi--Bus

All Channels manually stopped

Stop cause by external contact

Page 4-- 1

Manual Gluing (Purge)

Service Menu

Manual Stop

LEDs Signal

Activation of the

Valve Outputs

Pressure Indication

1: 0 m/min

2: 0 m/min

C1:S

C2:S

C3:D

C4:S

C5:S

C7:C

C8:R

PRESS1: 0%

PRESS2: 0%

PATTERN SYSTEM COMP.

PRESS3: 0%

PRESS4: 0%

PRESSURE

Function Keys

Glue Pattern:

Channel 1: 3 Glue Events

Channel 2: 1 Glue Event

Channel 3: Dot Mode, 1 Event

Channel 4: 4 Glue Events

Channel 5: 5 Glue Events

Channel 6: Turned Off

Channel 7: Continuous Gluing

Channel 8: Random Length Gluing

S: Trigger Indication for Standard Mode Gluing

C: Trigger Indication for Continuous Mode Gluing

D: Trigger Indicator for Dot Mode Gluing

R: Trigger Indication for Random Mode Gluing

Function Keys F1, F2, F3, F4

STOP

EXTER.STOP

Encoder 3

3: 0 m/min

4: 0 m/min

Encoder 4

PROGRAM:

DY2008

1

Clear Button

Program Number

Numeric Keys

Enter Button

These keys can have changing functions. The lower line of the display above

the keys will indicate the current function.

Manual Gluing (Purge) Button

This button is used to activate the valve outputs manually. It is possible to select individual

channels. The button operates only when manual stop (see below) mode is activated.

Service Button

Use this button to open the configurationmenu. The button operates only when manual stop (see

below) mode is activated.

Stop Button

Pressing this button will stop gluing. “STOP” will flash at the top, center of the display when this

mode is active.

Numeric Keys

Use these keys to enter parameter values.

Clear Button

Pressing this button will reset a parameter to the previously programmed value or to “0” (zero),

depending upon the specific parameter.

Enter Button

This button is used to confirm a new entry.

Page 20

Page 4-- 2

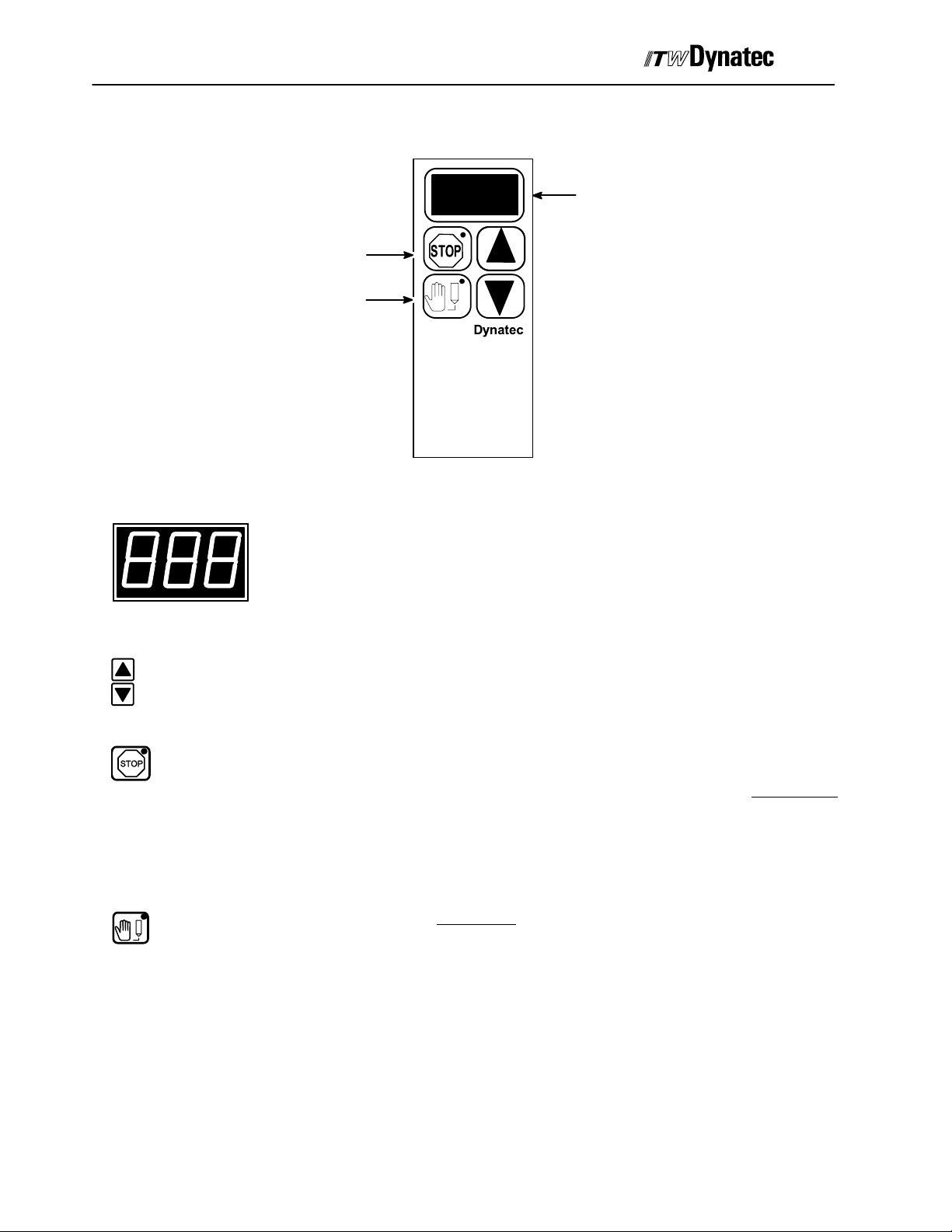

Remote Purge Control

Manual #50-14 Revised 8/08

Channel

Indicator

C. 1998

Stop Button

Manual Gluing

Button

Channel Indicator

Channel Select Buttons

Use the “increment” or “decrement” button to change the current channel displayed in the

Channel Indicator.

Channel

Select

}

Purge Control

Displays the current channel selected from the Remote Purge Control Unit.

Stop Button

Used to place the control into a STOP condition for manual gluing activation. Also causes the

pressure output circuitry (X24 through X27) to output programmed PURGE PRESSURE when

STOP is activated. STOP activation is indicated by an amber LED that is continuously

illuminated. See the section of this chapter on Stop Conditions for more detail. Deactivating

STOP will also automatically cease manual gluing operations on any channels that are still

active.

Manual Gluing (Purge) Button

Used to activate (amber LED on continuously) or deactivate (amber LED is either OFF or

flashing) the current channel displayed in the Channel Indicator LED’s.

Mounting Note

A magnet is attached to the back side of the Remote Purge Control unit for convenient mounting to any ferrous

metal object.

Page 21

C. 1998

Manual #50-14 Revised 8/08

Page 4-- 3

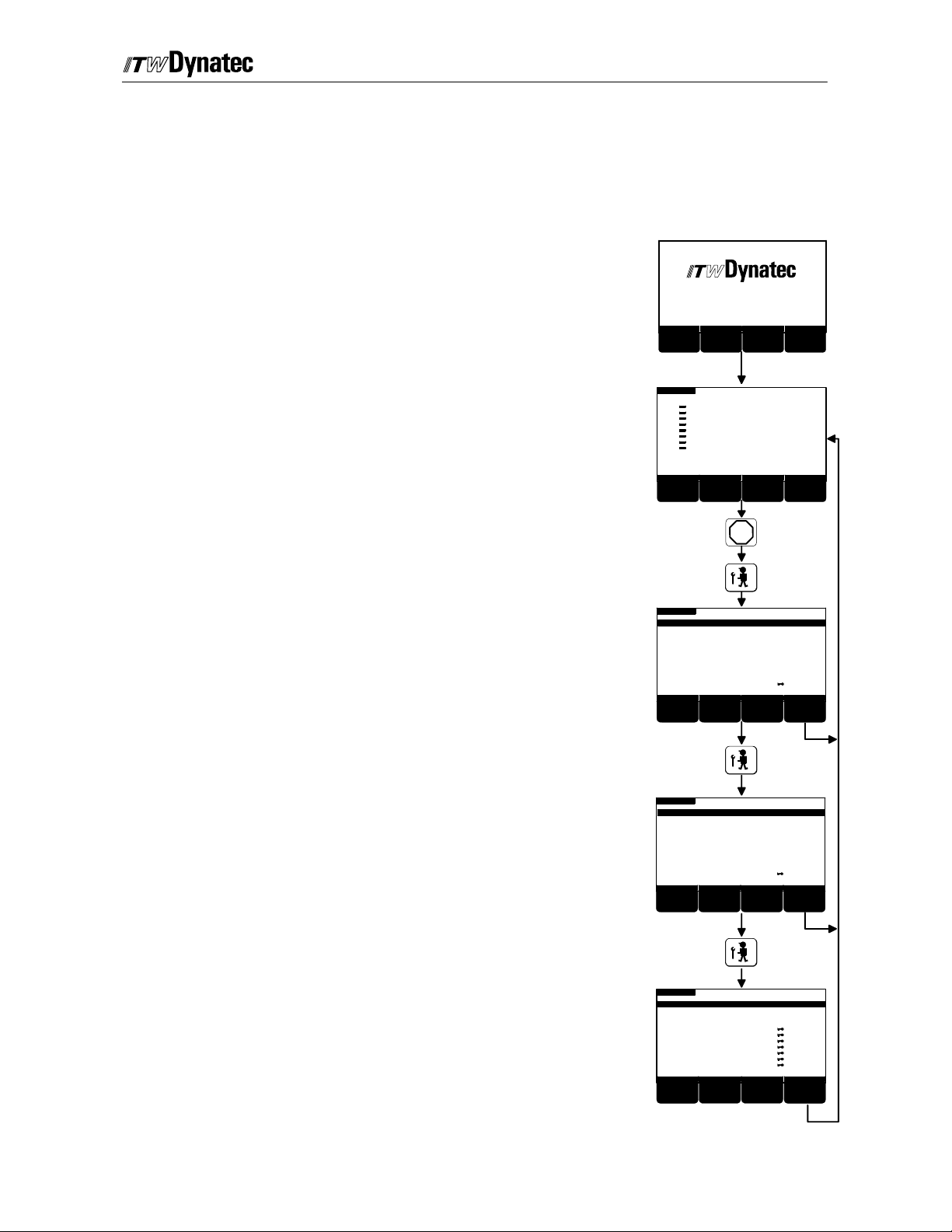

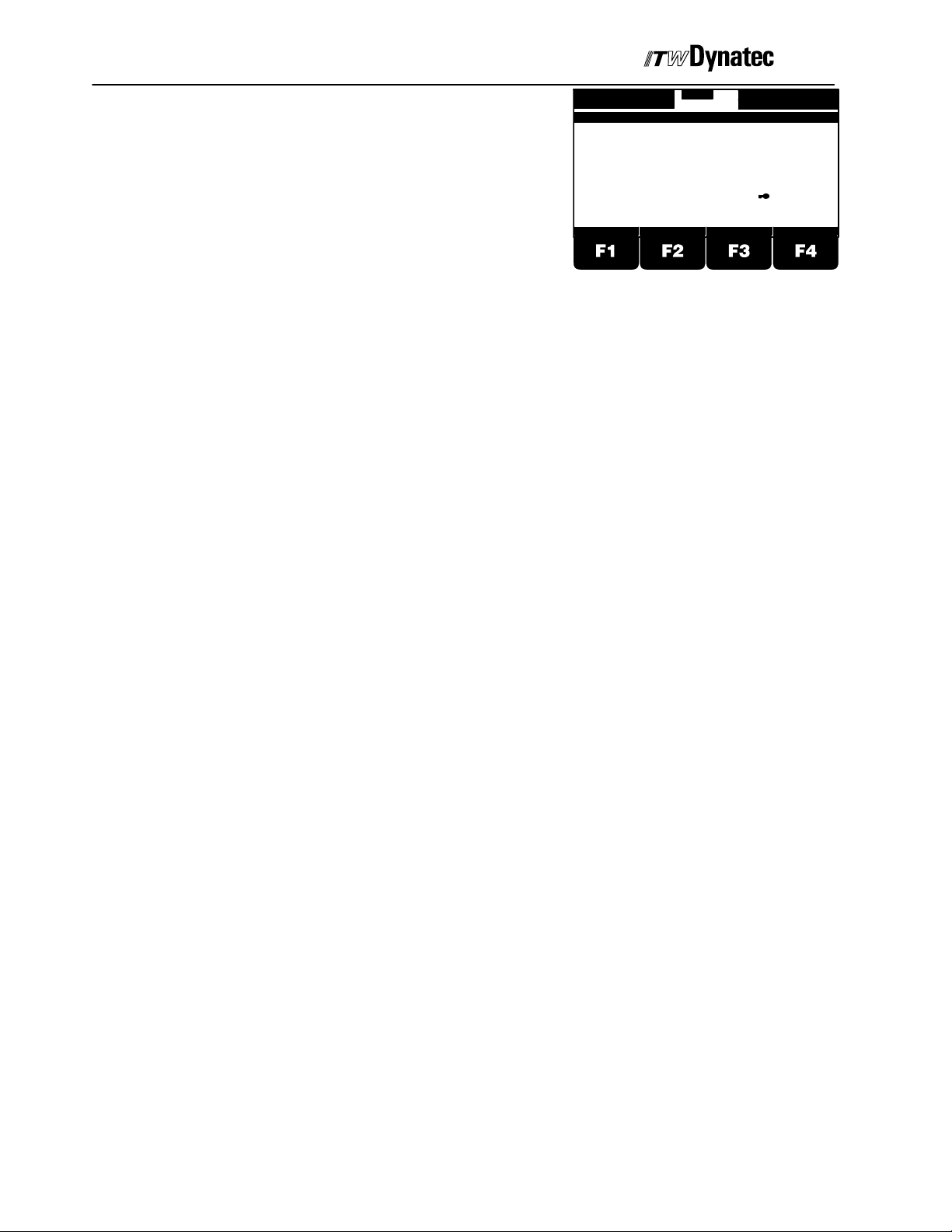

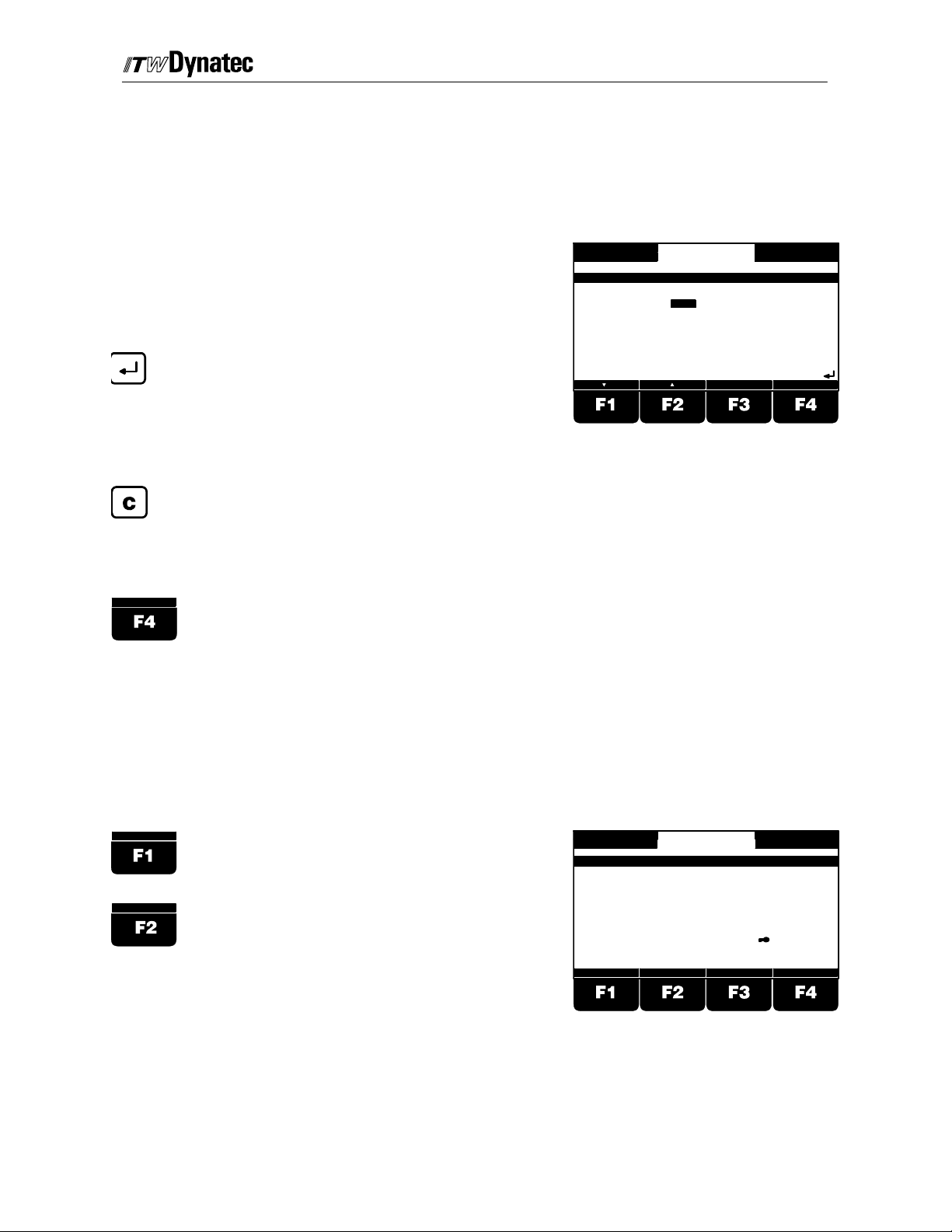

Service Setting Menus

Changing these settings may be neccesary during initial installation or after modification

to the system. After pressing the Stop button, these menus are selectable with the Service

button. The following settings are some of the available selections:

Turn power on to the control unit.

Adhesive Applic ation S ystems

Version: V2.xx

INITIALIZING CHANNEL

F1 F2 F3 F4

0 m/min

The Main Menu will come up after a few seconds

K 1:C

K2:

K3:

c4:

K5:

KC6:

K7:

K8:

PRESS1: 20%

PRESS2: 10%

Pattern

PRESS3: 10%

PRESS4: 10%

Pressure

Programm: 1

System

F1 F2 F3 F4

Compensat.

Press the Stop button,

and then the Service Settings Button.

Service Settings Menu 1 appears.

Select the desired parameter menu with the numeric

keys and procede with programming.

Press the Service Settings key again

Service Settings Menu 2 appears.

Select the desired parameter menu with the numeric

keys and procede with programming.

Press the Service Settings button again

Service Settings Menu 3 appears.

Select the desired parameter menu with the numeric

keys and procede with programming.

STOP

0 m/min

LANGUAGE

LOAD PROGRAM

CHANNEL : TRIGGER

TRIGGER LOCK

CHANNEL : ENCODER

ENCODER SCALING

MIN/MAX SPEED SET.

CHANNEL MODE

CHANGE SECURITY LOCK

CONTRAST+

STOP

SERVICE SETTINGS 1 OF 3

CONTRAST-

--

1

--

2

--

3

--

4

--

5

--

6

--

7

--

8

--

9

F1 F2 F3 F4

0 m/min

SERVICE SETTINGS 2 OF 3

TRIGGER SETUP

PRESSURE SIGNALING

PRESSURE ASSIGNMENT

PRESSURE CURVE

SPIKE VOLTAGE

SPIKE DURATION

SHUTTER ASSIGNMENT

SHUTTER DWELL TIME

CHANGE SECURITY LOCK

CONTRAST +

CONTRAST-

STOP

--

1

--

2

--

3

--

4

--

5

--

6

--

7

--

8

--

9

F1 F2 F3 F4

0 m/min

STOP-CONFIGURATION

PC-COMMUNICATION

PROFIBUS ADDRESS

RESERVE

RESERVE

RESERVE

RESERVE

LOAD FACTORY SETUP

CHANGE SECURITY LOCK

CONTRAST+

STOP

SERVICE SETTINGS 3 OF 3

CONTRAST-

--

1

--

2

--

3

--

4

--

5

--

6

--

7

--

8

--

9

F1 F2 F3 F4

RETURN

RETURN

RETURN

123

123

123

Use button F4 to return to the Main menu at any time.

Page 22

Page 4-- 4

Production Setup Menu

Switch Power on

Manual #50-14 Revised 8/08

C. 1998

Main Menu appears after a few seconds

Glue Pattern Set --up

or

0%

100%

0%

ZURUECK

SYSTEM

F3 F4

Pressure Configuration (Linear)

Pressure Configuration(12--Point Curve)

Display shows machine speed and glue pattern

Pressure and program number

System Configuration

Valve--Compensation

Dot Configuration

Menu Structure of the Production Settings

Stitching Configuration

0 m/min

LADE

Head Position

ZURUECK

SYSTEM

Page 23

C. 1998

Manual #50-14 Revised 8/08

Power (Switch) On and Software--Version Indication

Page 4-- 5

The main power switch is located at the back side of the

controller.

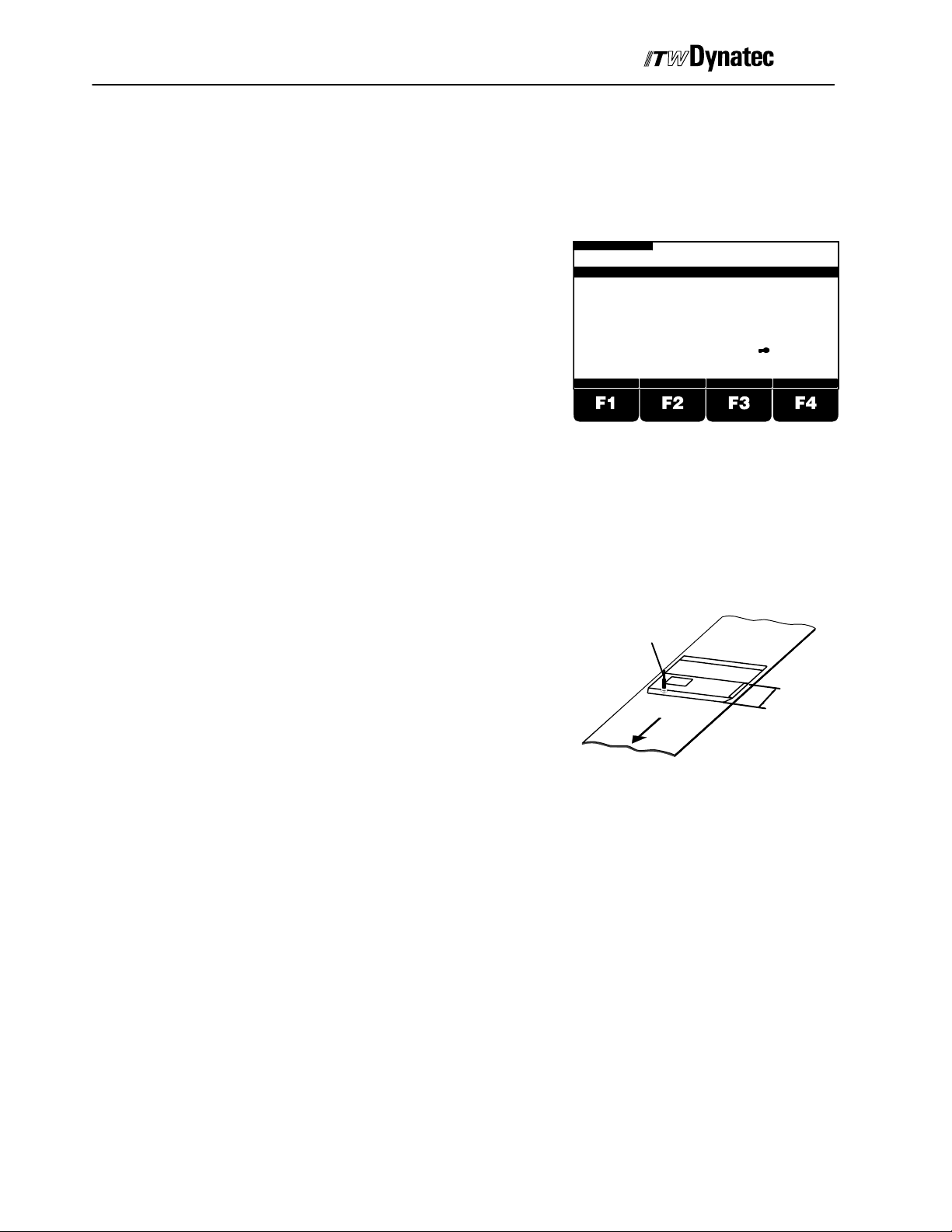

After the controller is switched on the display shortly

indicates the ITW Dynatec logo and the Software

revision.

Main Switch

Back Side

Adhesive Application Systems

After a few seconds the screen will display the Main

Menu.

Vers io n 2 .X X

INITIALIZING CHANNEL

PATTERN

1: 0 m/min

Channel 1:

Channel 2:

Channel 3:

Channel 4:

Channel 5:

Channel 6:

Channel 7:

Channel 8:

PRESS1: 0%

PRESS2: 0%

PATTERN PRESSURE SYSTEM

PRESS3: 0%

PRESS4: 0% PROGRAM: 1

COMP.

Page 24

Page 4-- 6

Manual #50-14 Revised 8/08

Service Settings

Modification of these settings will be necessary at initial

installation or after modifications to the system. After

pressing the Stop button the menus can be selected

with the Service button.

C. 1998

Service Settings Menu 1 (of 3) Overview

1 Language: Use this menu to select the

language. All display texts will appear in the

selected language.

2 Load Program: Use this menu to store all

settings within one of 60 available programs or

recall a previously saved program.

3 Channel: Trigger: Use this m enu to determine

which trigger should be assigned for the selected

channel or to deactivate this channel. It is also

possible to combine with an additional trigger via

AND--function. In this case that channel will be

triggered only when both trigger inputs are active.

4 Trigger Lock: This function determines for what

length of distance after a trigger signal additional

trigger signals will be ignored . This function can

be necessary gluing products with cut-outs (e.g.

envelopes with window).This will prevent the

detection of the window from triggering a new

glue cycle. It is possible to select values between

1 and 9999 mm (0.01 and 99.99 inch).

1: 0 m/min

CONTRAST +

STOP

SERVICE SETTINGS 1 OF 3

LANGUAGE

LOAD PROGRAM

CHANNEL : TRIGGER

TRIGGER LOCK

CHANNEL : ENCODER

ENCODER SCALING

MIN/MAX SPEED SET.

CHANNEL MODE

CHANGE SECURITY LOCK

CONTRAST-

Window

Envelope

Code

1

--

2

--

3

--

4

--

5

--

6

--

7

--

8

--

9

123

RETURN

Trigger Lock

5 Channel: Encoder: Use this menu to assign one of the encoder inputs to each

channel.

6 Encoder Scaling: Use this menu to configure the installed encoder. Program the

number of pulse per meter (inch). If metric unit is selected, all distances will be

shown in mm and all speed indications will be shown in m/min. If inch is selected, all

distances are shown in inch and all speed indications are shown in ft/min.

7 Min/Max Speed Set: This menu determines the speed conditions for start and stop

of gluing.The start is valid for increasing speed and stop for decreasing speed.

Additionally the maximum machine speed can be selected. This value is used to

determine the pressure output curve and valve compensation.

8 Channel Mode: Use this m enu to select the valve mode. The following modes are

available:

Standard, Standard with Dot, Dot, Random Product Length, Continuous with

Page 25

C. 1998

Manual #50-14 Revised 8/08

Page 4-- 7

Trigger, Continuous with Trigger and Speed, Continuous with Speed (Vmin).

9 Change Security Lock: This menu is used to lock individual functions to prevent

unauthorized modification. Additionally it is possible to change the access code. You

can lock/unlock every above mentioned function. After locking, these functions are

only available via access code. Locking/Unlocking is only possible if you know the

access code.

Page 26

Page 4-- 8

Manual #50-14 Revised 8/08

C. 1998

Service Settings Menu 2 (of 3) Overview

1 Trigger Setup: Use this menu to select the

properties of the trigger devices used.That

means the NPN--PNP selection.

1: 0 m/min

2: 0 m/min

TRIGGER SETUP

PRESSURE SIGNALING

PRESSURE ASSIGNMENT

PRESSURE CURVE

SPIKE VOLTAGE

SPIKE DURATION

SHUTTER ASSIGNMENT

SHUTTER DWELL TIME

CHANGE SECURITY LOCK

STOP

SERVICE SETTINGS 2 OF 3

3: 0 m/min

4: 0 m/min

1

2

3

4

5

6

7

8

9

Code

--

--

--

--

--

--

--

--

2 Pressure Signaling: Use this menu to configure

the pressure control outputs. You can select from

CONTRAST+

CONTRAST-

RETURN

0--10VDC/ 0--20 mA or 4--20 mA.

3 Pressure Assignment: Use this menu to assign each of the pressure control

outputs to one of the encoders.

4 Pressure Curve: Use this menu to select between 2 or 12 point pressure curve.

5 Spike Voltage: You can select the overexcitation voltage 55V or 170V for each

channel, or you can deactivate the overexcitation for this channel.

6 Spike Duration: The duration time of the overexcitation is programmable between

0.5ms and 2.5ms.

7 Shutter Assignment: Use this menu to assign the shutter output (X23) to one of

the triggers.

123

8 Shutter Dwell Time: Use this menu to adjust the duration of time the shutter circuit

remains active after the last trigger input. Values range from 1 to 99 seconds.

9 Change Security Lock: This menu is used to lock individual functions to prevent

unauthorized modification. Additionally it is possible to change the access code. You

can lock/unlock every above mentioned function. After locking, these functions are

only available via access code. Locking/Unlocking is only possible if you know the

access code.

Page 27

C. 1998

Manual #50-14 Revised 8/08

Page 4-- 9

Service Settings Menu 3 (of 3) Overview

1 STOP--Configuration: Use this menu to select

the Stop Mode for each channel: Complete or do

not complete an interrupted gluing pattern upon

machine restart.

2 PC--Communication: Use this menu to select

1: 0 m/min

2: 0 m/min

CONTRAST+

STOP-CONFIGURATION

PC-COMMUNICATION

RESERVE

SHUTTER

RESERVE

DIGITAL

RESERVE

LOAD FACTORY SETUP

CHANGE SECURITY LOCK

STOP

SERVICE SETTINGS 3 OF 3

CONTRAST-

3: 0 m/min

4: 0 m/min

1

2

3

4

5

6

7

8

9

Code

--

--

--

--

--

--

--

RETURN

RS232 or RS485 data protocol and to adjust the

baud rate.

3 Reserve: This menu is not used.

4 Shutter Trigger Setup: Use this menu to select a NPN or PNP shutter trigger

device.

5 Reserve: This menu is not used.

6 Digital Configuration: Use this menu to configure the Machine Contact (X19) and

Alarm Output (X21).

7 Reserve: This menu is not used.

8 Load Factory Setup: In this menu you can reload the factory default for the active

program. After entering the access code the active program will be reset to the

values listed below.

9 Change Security Lock: This menu is used to lock individual functions to prevent

unauthorized modification. Additionally it is possible to change the access code. You

can lock/unlock every above mentioned function. After locking, these functions are

only available via access code. Locking/Unlocking is only possible if you know the

access code.

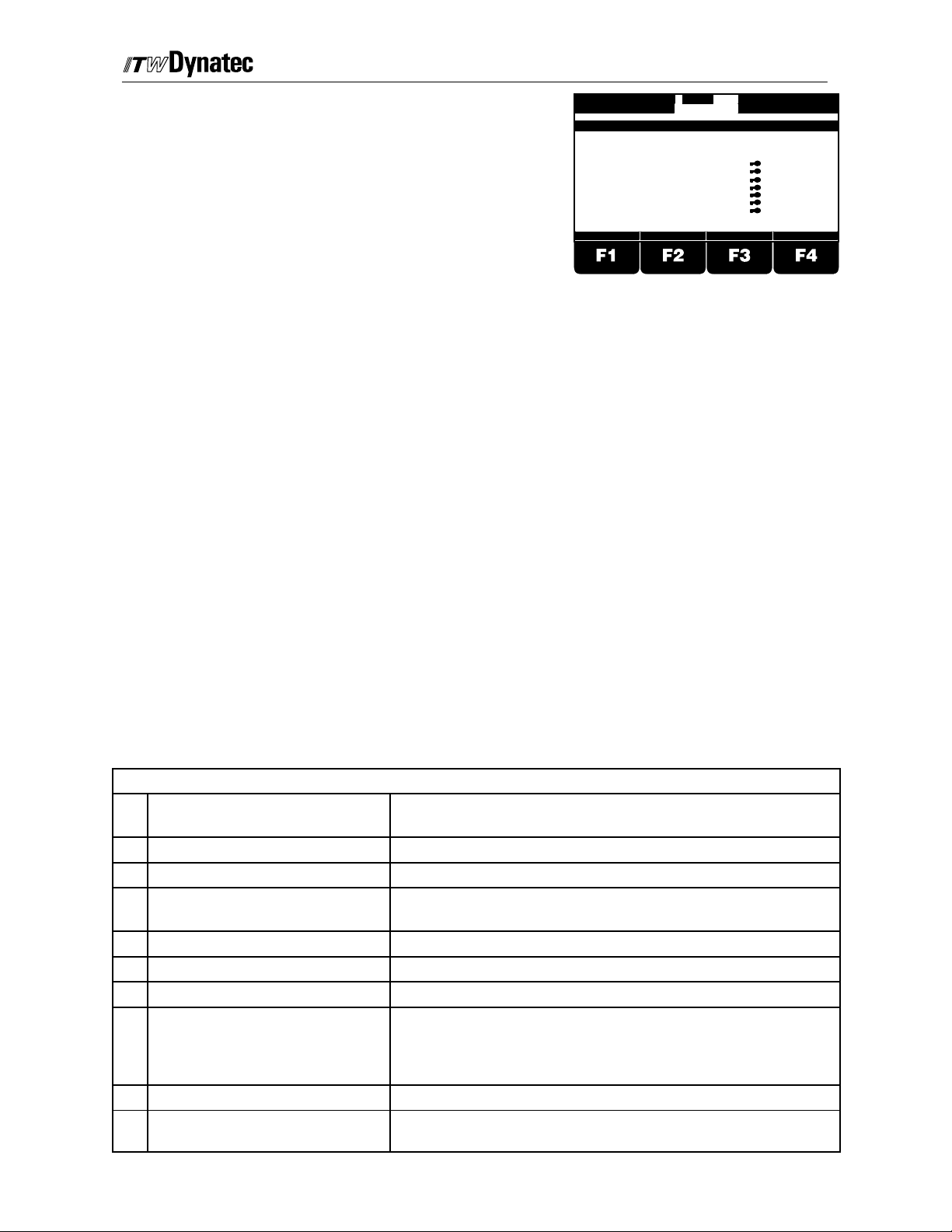

Factory Default Values

Service Settings Menu 1 of 3

No

Function Setting

.

1 Language English

2 Program As per operator selection

3 Trigger Assignment All Channels are assigned to Trigger 1.

The ’AND’--function is deactivated

4 Trigger Lock All Channels set to 1 mm (0.01 in)

5 Encoder Assignment All Channels are assigned to Encoder 1.

6 Encoder Scaling All Encoders are scaled to 1000 pulses/meter (10.00 ppi)

7 Speed Configuration All Encoders:

Gluing starts above 20 m/min (20 ft.min)

Gluing stops below 30 m/min (30 ft/min)

Maximum Machine Speed: 600 m/min (600 ft/min)

8 Channel--Mode All Channels are set to “Standard”

9 Security Lock Acc e s s co d e 1111, this function l o c ked

All previous functions are unlocked

Page 28

Page 4-- 10

Manual #50-14 Revised 8/08

Service Settings Menu 2 of 3

No

Function Setting

.

1 Trigger Setup All Triggers set to NPN

2 Pressure Signaling All Pressure outputs set to 4--20 mA

3 Pressure Assignment All Pressure outputs assigned to Encoder 1

4 Pressure Curve All Outputs set to 2--Point curve

5 Spike Voltage All Channels set to 55 V

6 Spike Duration All Channels set to 1.6 ms

7 Shutter Assignment The Shutter output (X23) is assigned to the shutter trigger

(X20)

8 Shutter Dwell Time 2sec.

9 Security Lock Acc e s scode 1111, th i s fu n c t i o n lo c k ed

All previous functions are unlocked

Service Settings Menu 3 of 3

No

Function Setting

.

1 STOP--Configuration All Channels: “NOT FINISH GLUING UPON RESTART”

2 PC--Communication As previously programmed

3 Reserve not used, Function locked

4 Shutter Trigger Setting NPN

5 Reserve not used, Function locked

6 Digital Configuration Machine Contact: Normally Open

Relay 1: Stop Relay 2: Alarm

7 Reserve not used, Function locked

8 Load Factory Default Function Locked

9 Security Lock Acc e s s co d e 1111, this function l o c k ed

All previous functions are unlocked

Production Menus

Function Setting

Pattern All Channels: Del.1 = 10mm (0.10 in), Glue 1 = 20 mm (0.20 in)

Pressure All Outputs: Min: 0%, Max: 100%, Purge: 70%

Stitch All Channels: Glue 4mm (0.04 in), Gap 4 mm (0.04 in), no stitch

functions are active

Offset All Channels: 20mm (0.20 in)

Compensation All Channels: ON: 0, OFF: 0

C. 1998

Page 29

C. 1998

Manual #50-14 Revised 8/08

Page 4-- 11

Service Setting Programming Conventions

The following programming conventions are employed in the Service Settings Menus:

123

RETURN

The “numeral” icon is displayed in the lower

right corner of the screen to indicate that the

numeric keypad should be used to enter the

desired value.

The “enter” icon is displayed in the lower

right corner of the screen to indicate that the

ENTER button (see page 4-1) should be

pressed in order to accept the selected

value.

Press the CLEAR Button on the numeric

keypad to revert a modified parameter to its

original value provided the ENTER button

has not already been pressed.

Press the RETURN (F4) button to go to the

next higher level of programming menus or

to undo a programming change as long as

the ENTER button has not been pressed.

1: 0 m/min

2: 0 m/min

ENCODER 1:

ENCODER 2:

ENCODER 3:

ENCODER 4:

STOP

ENCODER SCALING MENU

500

1000

1000

1000

inch

3: 0 m/min

4: 0 m/min

PULSES / Meter

PULSES / Meter

PULSES / Meter

PULSES / Meter

RETURN

123

Display Contrast Adjustments

The display brightness (contrast) is adjusted from any of the three Service Settings Menus

via the following procedure. Take care not to adjust the display too bright as this will tend

to reduce the life of the display.

1

2

3

4

5

6

7

8

9

3: 0 m/min

4: 0 m/min

Code

--

--

--

--

--

--

--

--

RETURN

123

CONTRAST +

CONTRAST-

This button is used to make the display

background darker.

This button is used to make the display

background lighter. NOTE: do not set the

display too bright as this will tend to reduce

the life of the display.

1: 0 m/min

2: 0 m/min

LANGUAGE

LOAD PROGRAM

CHANNEL : TRIGGER

TRIGGER LOCK

CHANNEL : ENCODER

ENCODER SCALING

MIN/MAX SPEED SET.

CHANNEL MODE

CHANGE SECURITY LOCK

CONTRAST+

STOP

SERVICE SETTINGS 1 OF 3

CONTRAST-

Page 30

Page 4-- 12

Manual #50-14 Revised 8/08

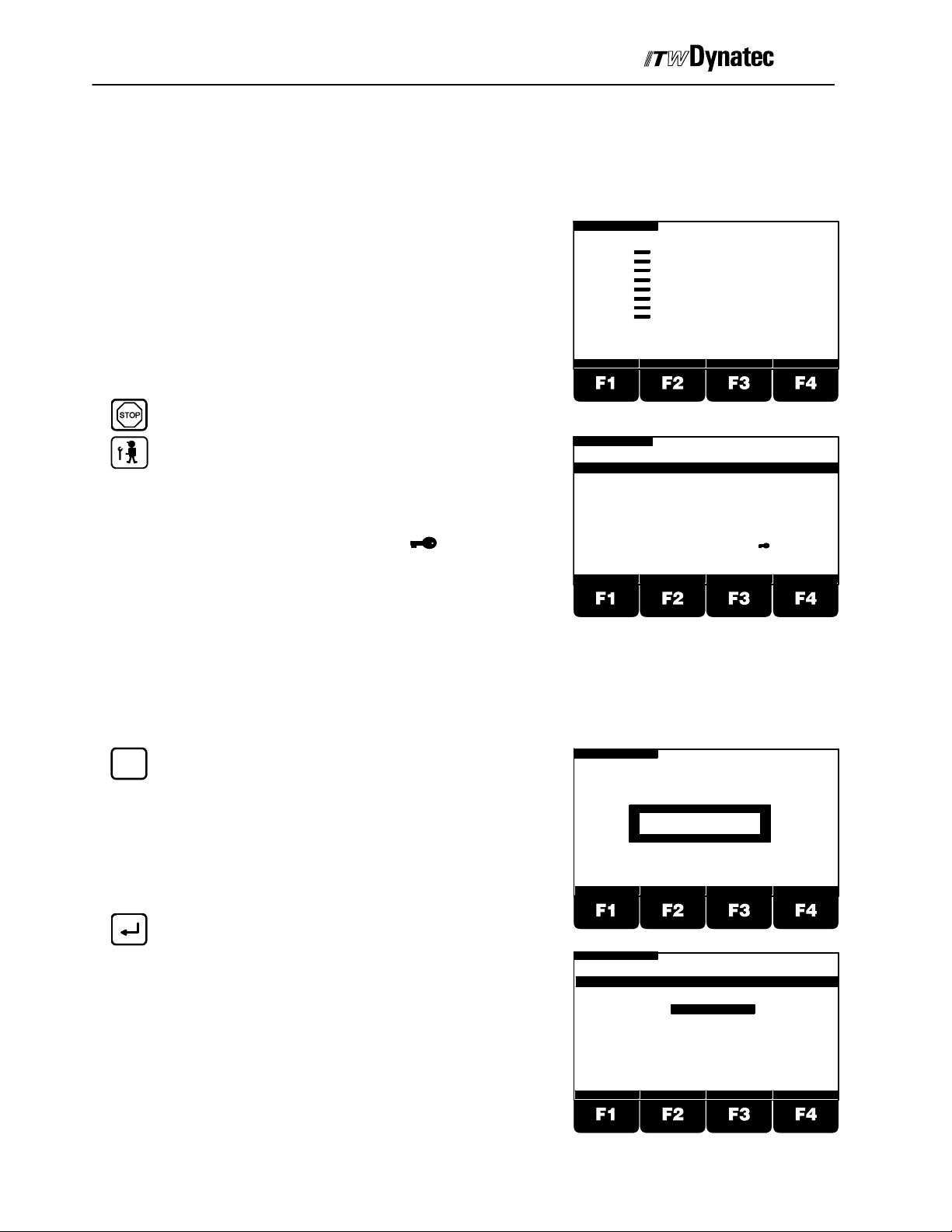

Service Settings Menu 1 (of 3) Programming

Note! The Service Settings Menu is only

accessible after activating the STOP

Button.

C. 1998

After the controller is switched on the

display shortly indicates the ITW Dynatec

logo and the Software revision.

After a few seconds the display changes

to the Main Menu. That means glue

pattern, pressure and program number will

be shown.

1: 0 m/min

C1:

C2:

C3:

C4:

C5:

C6:

C7:

C8:

PRESS1: 0%

PRESS2: 0%

PATTERN PRESSURE SYSTEM COMP.

PRESS3: 0%

PRESS4: 0%

PROGRAM:

1

Press the STOP Button.

Press the Service Button.

Select one of the listed functions by pressing the

corresponding numeric key.

Note! Functions labeled with a are

protected against modifying by an access

1: 0 m/min

CONTRAST +

LANGUAGE

LOAD PROGRAM

CHANNEL : TRIGGER

TRIGGER LOCK

CHANNEL : ENCODER

ENCODER SCALING

MIN/MAX SPEED SET.

CHANNEL MODE

CHANGE SECURITY LOCK

STOP

SERVICE SETTINGS 1 OF 3

1

2

3

4

5

6

7

8

9

CONTRAST-

Code

--

--

--

--

--

--

--

--

RETURN

123

code.

Select Language

Use this menu to select the operating language. All display texts will appear in the selected

language. Following languages are available: German, English, Finnish, French, Italian,

Swedish, Dutch, Spanish and Czech.

1

Press Button 1.

Enter Access Code if this function is

protected.

Press Enter Button.

Press a numeric key to select a language.

1: 0 m/min

1: 0m/min

0 m/min

STOP

ACCESS CODE: ----

STOP

LANGUAGE MENU

DEUTSCH

ENGLISH 2

ENGLISH

Suomi

Francais

Italiano

123

RETURN

1

2

3

4

5

123

RETURN

Page 31

Manual #50-14 Revised 8/08

RETURN

C. 1998

Press Button F4 to return to previous menu.

Load Program

Use this menu to load a new program or reload a

previously stored program.

1: 0 m/min

CONTRAST +

STOP

SERVICE SETTINGS 1 OF 3

LANGUAGE

LOAD PROGRAM

CHANNEL : TRIGGER

TRIGGER LOCK

CHANNEL : ENCODER

ENCODER SCALING

MIN/MAX SPEED SET.

CHANNEL MODE

CHANGE SECURITY LOCK

CONTRAST-

Page 4-- 13

Code

1

--

2

--

3

--

4

--

5

--

6

--

7

--

8

--

9

RETURN

123

2

Press Button 2.

Enter Access Code if this function is

protected.

Press Enter button.

2

Select one of the 60 possible programs

using the numeric keys.

Note! Loading a program the first time causes all

parameters from the previously loaded

program to be copied into the newly

loaded program with the exception of

Pattern, Mode, Stitch and Dot values.

Reloading a previously loaded program

will load all parameters as saved the last

time the program was loaded.

1: 0 m/min

ACCESS CODE: ----

1: 0 m/min

PLEASE SELECT A PROGRAM :

LOAD

STOP

STOP

PROGRAM MENU

RETURN

2

RETURN

123

123

LOAD

RETURN

Press Button F1 if you want to load a

previously saved program or if you want to

load a new program.

Press Button F4 to return to previous menu.

1: 0 m/min

CONTRAST +

STOP

SERVICE SETTINGS 1 OF 3

LANGUAGE

LOAD PROGRAM

CHANNEL : TRIGGER

TRIGGER LOCK

CHANNEL : ENCODER

ENCODER SCALING

MIN/MAX SPEED SET.

CHANNEL MODE

CHANGE SECURITY LOCK

CONTRAST-

Code

1

--

2

--

3

--

4

--

5

--

6

--

7

--

8

--

9

123

RETURN

Page 32

Page 4-- 14

Manual #50-14 Revised 8/08

Select Channel/Trigger Assignment

Use this menu to determine which trigger should be assigned for the selected channel

or to deactivate this channel. It is also possible to combine with an additional trigger via

AND--function. In this case that channel will be triggered only when both trigger inputs

are active.

NOTE! Master triggers 1 thru 4 (X9 thru X12) may be assigned to any channel.

Dedicated channel triggers are also available for each channel, #5 and greater.

C. 1998

TIME

Press Button 3.

Enter Access Code if this function is

protected.

Press Enter Button.

Select a channel with buttons F1 and F2.

With Button F3 you can select a trigger

(Master Triggers 1 to 4 or Channel Trigger

for channels 5 and greater) for the selected

channel or you can deactivate this channel.

Press F1 if you want to combine this

trigger with another trigger using the

’AND’--function. NOTE! Select “AND”

trigger value prior to “TRIGGER” value for

programming ease.

Use buttons F2 and F3 to select a trigger for

the ’AND’--function or to switch Off the

’AND’--function. NOTE! Only Master

Triggers 1 thru 4 are available as “AND”

triggers.

1: 0 m/min

ACCESS CODE: ----

1: 0 m/min

CHANNEL : TRIGGER ASSIGNMENT MENU

Channel

TRIGGER

1

In1

2

CHAN.OFF

3

In1

4

In1

AND

STOP

STOP

AND-TRIGGER

AND-OFF

AND-OFF

AND-OFF

AND-OFF

RETURN

ZURUECK

RETURN

123

RETURN

Press Enter button to accept the “AND”

trigger assignment. Press the Enter button

again to accept the basic trigger

assignment.

Repeat the procedure for the next channel.

Press button F4 to return t o previous menu.

1: 0 m/min

CONTRAST +

STOP

SERVICE SETTINGS 1 OF 3

LANGUAGE

LOAD PROGRAM

CHANNEL : TRIGGER

TRIGGER LOCK

CHANNEL : ENCODER

ENCODER SCALING

MIN/MAX SPEED SET.

CHANNEL MODE

CHANGE SECURITY LOCK

CONTRAST-

Code

1

--

2

--

3

--

4

--

5

--

6

--

7

--

8

--

9

123

RETURN

Page 33

C. 1998

Trigger Lock Adjustment

Manual #50-14 Revised 8/08

Page 4-- 15

This function determines for what distance after a

trigger signal additional trigger signals will be ignored.

This function can be necessary gluing products with

cut--outs (e.g. envelopes with window). T his will

prevent the detection of the window from triggering a

new glue cycle.

Press button 4.

Select a channel using buttons F1 or F2.

Press button F3 to highlight the Trigger Lock

value for the selected channel.

Use the numeric keys to enter the distance

you want to ignore trigger signals after a

valid trigger has been registered.

1: 0 m/min

CHAN.

1

2

3

4

1: 0 m/min

CHAN.

1

2

3

4

WINDOW

ENVELOPE

STOP

TRIGGER LOCK MENU

LOCK

1mm

1mm

1mm

1mm

STOP

TRIGGER LOCK MENU

LOCK

30 mm

1mm

1mm

1mm

TRIGGER LOCK

ZURUECK

RETURN

123

ZURUECK

RETURN

Press Enter button.

Use F 1 or F2 to select another channel.

Repeat previous steps for this channel.

RETURN

Press F4 to return to previous menu.

Channel / Encoder Assignment

Use this menu to assign one of the encoders to each

channel.

Press button 5.

Use F1 or F2 to select a channel.

1: 0 m/min

SERVICE SETTINGS 1 OF 3

LANGUAGE

LOAD PROGRAM

CHANNEL : TRIGGER

TRIGGER LOCK

CHANNEL : ENCODER

ENCODER SCALING

MIN/MAX SPEED SET.

CHANNEL MODE

CHANGE SECURITY LOCK

CONTRAST +

1: 0 m/min

CHAN.

1

2

3

4

CONTRAST-

CHANNEL : ENCODER ASSIGNMENT MENU

ENCODER

EN.1

EN.1

EN.1

EN.1

STOP

STOP

Code

1

--

2

--

3

--

4

--

5

--

6

--

7

--

8

--

9

123

RETURN

ZURUECK

RETURN

Page 34

Page 4-- 16

Manual #50-14 Revised 8/08

C. 1998

Press button F3.

Use F2 or F3 to select the encoder that you

want to assign to this channel (Encoder 1 to

4).

Press Enter button.

Note! For each of the selected encoders the

corresponding machine speed will appear

in the upper status lines of the display.

Use F 1 or F2 to select another channel.

Repeat previous steps for this channel.

1: 0 m/min

CHAN.

1

2

3

4

1: 0 m/min

CHAN.

1

2

3

4

1: 0 m/min

2: 0 m/min

CHAN.

1

2

3

4

STOP

ENCODER

EN.1

EN.1.1

EN.1

EN.1

EN.1

STOP

ENCODER

EN.1

EN.2

EN.1

EN.1

STOP

CHANNEL : ENCODER ASSIGNMENT MENU

ENCODER

EN.1

EN.2

EN.3

EN.4

ZURUECK

RETURN

RETURN

3: 0 m/min

4: 0 m/min

RETURN

RETURN

Press F4 to return to previous menu.

1: 0 m/min

2: 0 m/min

LANGUAGE

LOAD PROGRAM

CHANNEL : TRIGGER

TRIGGER LOCK

CHANNEL : ENCODER

ENCODER SCALING

MIN/MAX SPEED SET.

CHANNEL MODE

CHANGE SECURITY LOCK

CONTRAST+

STOP

SERVICE SETTINGS 1 OF 3

1

2

3

4

5

6

7

8

9

CONTRAST-

3: 0 m/min

4: 0 m/min

Code

--

--

--

--

--

--

--

--

RETURN

123

Page 35

C. 1998

Manual #50-14 Revised 8/08

Page 4-- 17

Encoder Scaling

Use this menu to configure the encoder that is installed by programming the number of

pulse per meter (inch). If the metric unit is selected all distances will be shown in “mm” and

all speed indications will be shown in “m/min”. If inch is selected all distances are shown

in “inch” and all s peed indications are shown in “ft/min”.

Press button 6.

Select an encoder using buttons F1 or F2

inch

Press button F3 if you want to change the

encoder type (i.e. metric or inch).

Note! F3 illustrates the units that would be

changed to if the button is pressed.

Use the numeric keys to enter the desired

pulses per inch (pulses per meter)

Note! Check the encoder specification to obtain

the proper setting.

1: 0 m/min

2: 0 m/min

ENCODER 1:

ENCODER 2:

ENCODER 3:

ENCODER 4:

1: 0 m/min

2: 0 m/min

ENCODER 1:

ENCODER 2:

ENCODER 3:

ENCODER 4:

1: 0 m/min

2: 0 m/min

ENCODER 1:

ENCODER 2:

ENCODER 3:

ENCODER 4:

STOP

ENCODER SCALING MENU

1000

1000

1000

1000

inch

STOP

ENCODER SCALING MENU

10.00

10.00

10.00

10.00

10.00

Meter

STOP

ENCODER SCALING MENU

500

1000

1000

1000

inch

3: 0 m/min

4: 0 m/min

PULSES / METER

PULSES / METER

PULSES / METER

PULSES / METER

RETURN

3: 0 m/min

4: 0 m/min

PULSES / inch

PULSES / inch

PULSES / inch

PULSES / inch

RETURN

3: 0 m/min

4: 0 m/min

PULSES / Meter

PULSES / Meter

PULSES / Meter

PULSES / Meter

RETURN

123

123

123

RETURN

Press Enter button.

Select another encoder using F1 or F2 and

repeat adjustment for all encoders in the

same way.

Press F4 to return to previous menu.

1: 0 m/min

2: 0 m/min

LANGUAGE

LOAD PROGRAM

CHANNEL : TRIGGER

TRIGGER LOCK

CHANNEL : ENCODER

ENCODER SCALING

MIN/MAX SPEED SET.

CHANNEL MODE

CHANGE SECURITY LOCK

CONTRAST+

STOP

SERVICE SETTINGS 1 OF 3

1

2

3

4

5

6

7

8

9

CONTRAST-

3: 0 m/min

4: 0 m/min

Code

--

--

--

--

--

--

--

--

RETURN

123

Page 36

Page 4-- 18

Manual #50-14 Revised 8/08

C. 1998

Min/Max Speed Configuration

This menu determines the speed conditions for start

and stop of gluing. The start is valid for increasing

speed and stop for decreasing speed. Additionally the

maximum machine speed can be selected. This value

is used to determine the pressure output curve and

valve compensation.

Press button 7.

Enter Access Code if this function is

protected.

Press Enter Button.

ENCODER

Select an encoder using the button F3.

1: 0 m/min

2: 0 m/min

SERVICE SETTINGS 1 OF 3

LANGUAGE

LOAD PROGRAM

CHANNEL : TRIGGER

TRIGGER LOCK

CHANNEL : ENCODER

ENCODER SCALING

MIN/MAX SPEED SET.

CHANNEL MODE

CHANGE SECURITY LOCK

CONTRAST+

1: 0 m/min

2: 0 m/min

1: 0 m/min

2: 0 m/min

GLUING STARTS ABOVE

GLUING STOPS BELOW

MAXIMUN MACHINE SPEED

CONTRAST-

ACCESS CODE: ----

MIN/MAX SPEED SETTING MENU

STOP

STOP

STOP

ENCODER 1

1

2

3

4

5

6

7

8

9

3: 0 m/min

4: 0 m/min

Code

--

--

--

--

--

--

--

--

3: 0 m/min

4: 0 m/min

3: 0 m/min

4: 0 m/min

600

RETURN

RETURN

20

30

123

m/min

m/min

m/min

1

Enter the speed at which the gluing should

start while the machine speed is ramping up

using the numeric keys.

Press Enter Button.

Press F1 or F2 to select next line.

Enter the speed at which the gluing should

stop while the machine speed is ramping

down using the numeric keys.

Press Enter Button.

1: 0 m/min

2: 0 m/min

MIN/MAX SPEED SETTING MENU

GLUING STARTED ABOVE

GLUING STOPS BELOW

MAXIMUM MACHINE SPEED

1: 0 m/min

2: 0 m/min

MIN/MAX SPEED SETTING MENU

GLUING STARTS ABOVE

GLUING STOPS BELOW

MAXIMUM MACHINE SPEED

STOP

ENCODER 1

STOP

ENCODER 1

ENCODER

ENCODER

ENCODER

RETURN

3: 0 m/min

4: 0 m/min

m/min

10

m/min

30

m/min

600

123

RETURN

3: 0 m/min

4: 0 m/min

m/min

10

m/min

35

m/min

600

123

RETURN

123

Page 37

C. 1998

Manual #50-14 Revised 8/08

Press F1 to select the next line.

Use the numeric keys to enter the maximum

machine speed e.g. 300 m/min.

Press Enter Button.

2: 0 m/min

Page 4-- 19

STOP1: 0 m/min

MIN/MAX SPEED SETTING MENU

GLUING STARTS ABOVE 10 m/min

GLUING STOPS BELOW 35 m/min

MAXIMUM MACHINE SPEED 300 m/min

ENCODER

3: 0 m/min

4: 0 m/min

RETURN

123

ENCODER

RETURN

Select another encoder with button F3 and

repeat previous steps for this encoder.

Press F4 to return to previous menu.

1: 0 m/min

2: 0 m/min

LANGUAGE

LOAD PROGRAM

CHANNEL : TRIGGER

TRIGGER LOCK

CHANNEL : ENCODER

ENCODER SCALING

MIN/MAX SPEED SET.

CHANNEL MODE

CHANGE SECURITY LOCK

CONTRAST+

STOP

SERVICE SETTINGS 1 OF 3

1

2

3

4

5

6

7

8

9

CONTRAST-

3: 0 m/min

4: 0 m/min

Code

--

--

--

--

--

--

--

--

RETURN

Channel Mode Adjustment

Use this menu to select the channel mode. Following modes are available:

Channel--Mode Description

Standard Up to 16 patterns per trigger input

Pattern can be stitched

Pattern is started with trigger signal and minimum

machine speed

Standard with Dot Up to 16 patterns per trigger input

Pattern can be stitched above “GLUE STOPS

BELOW” speed

Pattern is started with trigger signal

Dot mode is active between “GLUE STARTS

ABOVE” and “GLUE STOPS BELOW” speeds

Dot Up to 16 patterns per trigger input

All patterns are user programmable “dots”

Pattern is started with trigger signal and minimum

machine speed

Random Length Glue length depends on length of product Start

and stop delay is programmable Pattern length is

automatically adjusted. Uses trigger signal. Pattern

canalsobestitched

Continuous On Trigger Continuous gluing activated by trigger signal and is

active as long as trigger signal is present. Machine

speed has to be above 1m/min or 1ft/min. Stitching

is possible

Continuous On Trigger and Speed Continuous gluing activated by trigger signal and is

active as long as trigger signal is present. Machine

speed has to exceed programmed minimum

speed.

Continuous Above Low Speed Continuous Gluing activated by minimum machine

speed. No trigger signal is used.

123

Page 38

Page 4-- 20

Manual #50-14 Revised 8/08

C. 1998

8

Press button 8.

Enter Access Code if this function is

protected.

Press Enter Button.

Use button F1 or F2 to select a channel.

Press button F3 to change a selected

channel’s mode.

1: 0 m/min

2: 0 m/min

1: 0 m/min

2: 0 m/min

CHAN.

1

2

3

4

STOP

ACCESS CODE: ----

STOP

CHANNEL MODE MENU

MODE

STANDARD

STANDARD

STANDARD

STANDARD

3: 0 m/min

4: 0 m/min

RETURN

3: 0 m/min

4: 0 m/min

RETURN

RETURN

Press F2 or F3 to select the mode for this

channel.

Press Enter Button.

Repeat the procedure for additional

channels.

Press F4 to return to previous menu.

1: 0 m/min

2: 0 m/min

CHAN.

1

STANDARD WITH DOT

2

STANDARD

3

STANDARD

4

STANDARD

1: 0 m/min

2: 0 m/min

LANGUAGE

LOAD PROGRAM

CHANNEL : TRIGGER

TRIGGER LOCK

CHANNEL : ENCODER

ENCODER SCALING

MIN/MAX SPEED SET.

CHANNEL MODE

CHANGE SECURITY LOCK

CONTRAST+

STOP

CHANNEL MODE MENU

MODE

STOP

SERVICE SETTINGS 1 OF 3

1

2

3

4

5

6

7

8

9

CONTRAST-

3: 0 m/min

4: 0 m/min

3: 0 m/min

4: 0 m/min

Code

--

--

--

--

--

--

--

--

RETURN

RETURN

123

Page 39

C. 1998

Manual #50-14 Revised 8/08

Note! Random Length Mode incorporates a “time out”

function to prevent excessive, undesired glue flow in

the event of a product jam under the triggering device.

Set this value to be slightly greater than the longest

anticipated time by taking into account the longest

product and slowest production speeds.

TIME

Press F1 to enter the Time Out Menu.

Use the F3 button to select the existing time

value.

1: 0 m/min

2: 0 m/min

CHAN.

11

2

3

4

4

TIME

CHANNEL MODEE MENU

STANDARD

STANDARD with dot

DOT

RANDOM LENGTH

STANDARD

MODE

STOP

Page 4-- 21

3: 0 m/min

4: 0 m/min

RETURN

2

RETURN

Enter the desired time out value via the

numeric keypad.

Press the Enter Button.

Press F4 to return to the previous menu.

1: 0 m/min

2: 0 m/min

CHAN.

1

STOP

TIME OUT MENU

TIME

2 sec.4

3: 0 m/min

4: 0 m/min

RETURN

Page 40

Page 4-- 22

Manual #50-14 Revised 8/08

Change Security Lock

In this menu it is possible to lock individual functions to

prevent unauthorized modification. Additionally it is

possible to change the access code. You can

lock/unlock every above mentioned function. After

locking, these functions are only available via an

access code. Locking/Unlocking is possible only if you

know the access code.

C. 1998

Press button 9.

Enter Access Code.

Press Enter Button.

Use the numeric keys to select the function

that you want to lock or unlock.

Note! Functions labeled with a are

protected against modifying by an access

code.

Change Access Code

Press button 9.

Enter the new access code using the

numeric keys.

1: 0m/min

1: 0 m/min

CONTRAST+

1: 0 m/min

STOP

ACCESS CODE: ----

STOP

LOCK SERVICE SETTINGS 1 OF 3

LANGUAGE

LOAD PROGRAM

CHANNEL : TRIGGER

TRIGGER LOCK

CHANNEL : ENCODER

ENCODER SCALING

MIN/MAX SPEED SET.

CHANNEL MODE

CHANGE ACCESS CODE

CONTRAST--

ENTER NEW ACCESS CODE: ----

STOP

1

2

3

4

5

6

7

8

9

Code

--

--

--

--

--

--

--

--

RETURN

RETURN

Press Enter Button.

Note! Write down the access code and store in a

safe place.

RETURN

Press F4 to return to previous menu.

1: 0 m/min

CONTRAST +

STOP

SERVICE SETTINGS 1 OF 3

LANGUAGE

LOAD PROGRAM

CHANNEL : TRIGGER

TRIGGER LOCK

CHANNEL : ENCODER

ENCODER SCALING

MIN/MAX SPEED SET.

CHANNEL MODE

CHANGE SECURITY LOCK

CONTRAST-

123

RETURN

Code

1

--

2

--

3

--

4

--

5

--

6

--

7

--

8

--

9

123

RETURN

Page 41

C. 1998

Manual #50-14 Revised 8/08

Service Settings Menu 2 (of 3) Programming

Assure STOP is active.

Press Service Button until you see the menu

at right.

Use the buttons 1 to 9 to select one of the listed

functions.

Trigger Setup

Use this menu to select the properties of the trigger

devices used (NPN or PNP).

1: 0 m/min

2: 0 m/min

CONTRAST+

STOP

SERVICE SETTINGS 2 OF 3

TRIGGER SETUP

PRESSURE SIGNALING

PRESSURE ASSIGNMENT

PRESSURE CURVE

SPIKE VOLTAGE

SPIKE DURATION

SHUTTER ASSIGNMENT

SHUTTER DWELL TIME

CHANGE SECURITY LOCK

CONTRAST-

Page 4-- 23

3: 0 m/min

4: 0 m/min

Code

--

1

--

2

--

3

--

4

--

5

--

6

--

7

--

8

9

RETURN

123

1

Press button 1.

Enter Access Code if this function is

protected.

Press Enter Button.

Use button F1 or F2 to select a trigger input.

Press button F3 to change the trigger type

from NPN to PNP and vice versa.

Press Enter button and repeat previous

steps for additional trigger inputs.

1: 0 m/min

2: 0 m/min

2: 0 m/min

TRIGGER

1

2

3

4

2: 0 m/min

TRIGGER

1

2

3

4

STOP

ACCESS CODE: ----

STOP1: 0 m/min

TRIGGER SETUP MENU

NPN / PNP

NPN

NPN

NPN

NPN

STOP1: 0 m/min

TRIGGER SETUP MENU

NPN / PNP

NPN

NPN

NPN

NPN

3: 0 m/min

4: 0 m/min

RETURN

3: 0 m/min

4: 0 m/min

RETURN

3: 0 m/min

4: 0 m/min

RETURN

Page 42

Page 4-- 24

Manual #50-14 Revised 8/08

C. 1998

RETURN

Press F4 to return to previous menu.

Pressure Signaling

Use this menu to configure the pressure control

outputs.

2

Press button 2.

Enter Access Code if this function is

protected.

1: 0 m/min

2: 0 m/min

CONTRAST+

1: 0 m/min

STOP

SERVICE SETTINGS 2 OF 3

TRIGGER SETUP

PRESSURE SIGNALING

PRESSURE ASSIGNMENT

PRESSURE CURVE

SPIKE VOLTAGE

SPIKE DURATION

SHUTTER ASSIGNMENT

SHUTTER DWELL TIME

CHANGE SECURITY LOCK

CONTRAST-

STOP

ACCESS CODE: ----

3: 0 m/min

4: 0 m/min

Code

1

2

3

4

5

6

7

8

9

--

--

--

--

--

--

--

--

123

RETURN

123

RETURN

Press Enter Button.

Note! Refer to the data sheet of the I/P-- or

U/P--transducer for proper setting.

Press F1 or F2 to select the pressure output

(#1 = X24, #2 = X25, #3 = X26, #4 = X27 on

back of control).

Press button F3 to toggle between 0 to

10V/0--20mA or 4 to 20mA.

Confirm the selection with the Enter button

and repeat the procedure for the next

pressure output.

RETURN

Press F4 to return to previous menu.

2: 0 m/min

OUTPUT

1

2

3

4

1: 0 m/min

2: 0 m/min

CONTRAST+

STOP1: 0 m/min

PRESSURE SIGNALING MENU

0-10V or 0-20mA 4-20mA

STOP

SERVICE SETTINGS 2 OF 3

TRIGGER SETUP

PRESSURE SIGNALING

PRESSURE ASSIGNMENT

PRESSURE CURVE

SPIKE VOLTAGE

SPIKE DURATION

SHUTTER ASSIGNMENT

SHUTTER DWELL TIME

CHANGE SECURITY LOCK

CONTRAST-

3: 0 m/min

4: 0 m/min

1

2

3

4

5

6

7

8

9

3: 0 m/min

4: 0 m/min

4-20mA

4-20mA

4-20mA

4-20mA

Code

--

--

--

--

--

--

--

--

RETURN

RETURN

123

Page 43

C. 1998

Manual #50-14 Revised 8/08

Pressure Assignment

Use this menu to assign each of the pressure control

outputs to one of the encoders or to shut the output off.

Page 4-- 25

Press button 3.

Enter Access Code if this function is

protected.

Press Enter Button.

Use buttons F1 or F2 to select the pressure

output.

Press button F3 to select the encoder you

want to assign the pressure output to or to

shut the output off.

Confirm the selection with the Enter button

and repeat the procedure for the next

pressure output.

1: 0 m/min

ACCESS CODE: ----

2: 0 m/min

PRESSURE : ENCODER ASSIGNMENT MENU

OUTPUT

1

EN.1

2

EN.1

3

EN.1

4

EN.1

2: 0 m/min

PRESSURE : ENCODER ASSIGNMENT MENU

OUTPUT

EN.2

1

1

EN.1

2

EN.1

3

EN.1

4

ENCODER

ENCODER

EN.2

STOP

STOP1: 0 m/min

STOP1: 0 m/min

123

RETURN

3: 0 m/min

4: 0 m/min

RETURN

3: 0 m/min

4: 0 m/min

RETURN

RETURN

Press F4 to return to previous menu.

1: 0 m/min

2: 0 m/min

CONTRAST+

STOP

SERVICE SETTINGS 2 OF 3

TRIGGER SETUP

PRESSURE SIGNALING

PRESSURE ASSIGNMENT

PRESSURE CURVE

SPIKE VOLTAGE

SPIKE DURATION

SHUTTER ASSIGNMENT

SHUTTER DWELL TIME

CHANGE SECURITY LOCK

CONTRAST-

3: 0 m/min

4: 0 m/min

Code

1

2

3

4

5

6

7

8

9

--

--

--

--

--

--

--

--

123

RETURN

Page 44

Page 4-- 26

Manual #50-14 Revised 8/08

Pressure Curve Configuration

Use this m enu to select either 2 or 12-point pressure

curves.

Press button 4.

1: 0 m/min

C. 1998

STOP

ACCESS CODE: ----

Enter Access Code if this function is

protected.

Press Enter Button.

Press F1 or F2 to select a pressure output.

Use button F3 to toggle between 2-- point

and 12point pressure curve

Confirm the selection with the Enter button

and repeat the procedure for the next

pressure output.

2: 0 m/min

OUTPUT

1

1

2

3

4

2: 0 m/min

System

1

2

3

4

STOP1: 0 m/min

PRESSURE CURVE MENU

2 POINT / 12 POINT

2 POINT

2 POINT

2 POINT

2 POINT

STOP1: 0 m/min

PRESSURE CURVE MENU

2 POINT / 12 POINT

2 POINT

2 POINT

2 POINT

12-POINT

RETURN

3: 0 m/min

4: 0 m/min

1

RETURN

3: 0 m/min

4: 0 m/min

123

RETURN

Press F4 to return to previous menu.

1: 0 m/min

2: 0 m/min

CONTRAST+

STOP

SERVICE SETTINGS 2 OF 3

TRIGGER SETUP

PRESSURE SIGNALING

PRESSURE ASSIGNMENT

PRESSURE CURVE

SPIKE VOLTAGE

SPIKE DURATION

SHUTTER ASSIGNMENT

SHUTTER DWELL TIME

CHANGE SECURITY LOCK

CONTRAST-

3: 0 m/min

4: 0 m/min

Code

1

2

3

4

5

6

7

8

9

RETURN

--

--

--

--

--

--

--

--

123

RETURN

Page 45

C. 1998

Manual #50-14 Revised 8/08

Page 4-- 27

Spike Voltage Adjustment

Caution!

The factory default overexcitation voltage for applicator heads is “off”. Make

sure this setting is appropriate for the equipment used in your system. If

necessary change this value.

Note! ITW Dynatec DynaCold Series applicators must always be operated with

170V spike voltage.

Press button 5.

Enter Access Code if this function is

protected.

Press Enter Button.

Use button F1 or F2 to select a channel.

Press button F3 to choose the spike voltage

of “55V”, “170V” or “OFF”.

Press Enter button and repeat the

procedure for additional channels.

1: 0 m/min

2: 0 m/min

2: 0 m/min

SPIKE VOLTAGE

CHAN.

1

2

3

4

2: 0 m/min

CHAN.

1

1

2

3

4

STOP

ACCESS CODE: ----

STOP1: 0 m/min

SPIKE VOLTAGE MENU

55V

55V

55V

55V

STOP1: 0 m/min

SPIKE VOLTAGE MENU

SPIKE VOLTAGE

170V

55V

55V

55V

3: 0 m/min

4: 0 m/min

RETURN

3: 0 m/min

4: 0 m/min

RETURN

3: 0 m/min

4: 0 m/min

RETURN

Press F4 to return to previous menu.

1: 0 m/min

2: 0 m/min

CONTRAST+

STOP

SERVICE SETTINGS 2 OF 3

TRIGGER SETUP

PRESSURE SIGNALING

PRESSURE ASSIGNMENT

PRESSURE CURVE

SPIKE VOLTAGE

SPIKE DURATION

SHUTTER ASSIGNMENT

SHUTTER DWELL TIME

CHANGE SECURITY LOCK

CONTRAST-

3: 0 m/min

4: 0 m/min

Code

1

2

3

4

5

6

7

8

9

RETURN

--

--

--

--

--

--

--

--

123

RETURN

Page 46

Page 4-- 28

Manual #50-14 Revised 8/08

Spike Duration Adjustment

This menu allows selection of the duration for the

“SPIKE VOLTAGE” programmed in the previous

section.

Press button 6.

1: 0 m/min

2: 0 m/min

STOP

ACCESS CODE: ----

C. 1998

3: 0 m/min

4: 0 m/min

Enter Access Code if this function is

protected.

Press Enter Button.

Note! Time values range from 0.50 to 2.50ms;

1.60ms (default) is recommented for most

applications.

Use button F1 or F2 to select a channel.

PressbuttonF3toswitchtothespiketime

field.

+0.05 ms

Press button F1 to increase the spike

duration time by a step of 0.05 ms.

-0.05 ms

Press button F2 to decrease the spike

duration time by a step of 0.05 ms.

2: 0 m/min

CHAN.

1

2

3

4

2: 0 m/min

CHAN.

1

2

3

4

+0.05 ms

STOP1: 0 m/min

SPIKE DURATION MENU

TIME

1.60 ms

1.60 ms

1.60 ms

1.60 ms

STOP1: 0 m/min

SPIKE DURATION TIME

TIME

.90 ms

.90 ms

1.60 ms

1.60 ms

1.60 ms

-0.05 ms

RETURN

3: 0 m/min

4: 0 m/min

RETURN

3: 0 m/min

4: 0 m/min

123