Page 1

WEDECO Aquada

GB

DE

F

Installation and Maintenance Instructions

Installations- und Wartungsanleitung

Notice d’installation et de Maintenance

I

Istruzioni di Installazione e Manutenzione

Page 2

Contents

1. General&Applications

2. Assembly&Installation

2.1. Reactor

2.1.1. Assembly of Reactor

2.1.2. Installation of Quartz Sleeve and of UV Lamp

2.1.2.1. Cleaning and Replacement of Quartz Sleeve

2.1.2.2. Fitting of UV Sensor (only for Maxima)

2.1.3. Connection to the Water Line Network

2.2. ControlSystem

2.2.1. Assembly of Control Box

2.2.2. Electrical Connection

2.2.3. Connection of UV Lamp

3. Commissioning

3.1. Units with Solenoid Valve

3.1.1. Units without Solenoid Valve

3.2. Tightness Test

4. Software

4.1. Alarm Messages

4.2. New Start after Replacement of UV Lamp

5. ExplodedDiagram

6. SparePartsList

7. Declarationofconformity(page82)

ATTENTION:

Please read this manual carefully and follow the instructions given in it.

Installation must be carried out only by authorized technicians.

2

Page 3

1. General & Applications

Disinfection by means of ultraviolet light (UV) is an efficient, economic and particularly environmentally friendly process.

UV light kills pathogene microorganisms within a few seconds without leaving any

residues, harmful by-products or affecting the sense of smell or of taste.

Thanks to this the operators‘ exposure to danger by handling harmful chemicals is

excluded.

The effect of the UV light is used by very effective UV-C radiation (254 Nm). Within

a few seconds this brings about a photochemical reaction in DNA (desoxyribonucleic acid) which is vital for all microorganisms. By this microorganisms are either killed

or their ability to increase is destroyed.

The rate of kill depends on minimum UV radiation (UV dose), i.e. the time that a microorganism is exposed to a certain intensity of UV radiation (W/m²). At a UV dose

of 400 J/m² the most important human pathogene bacteria and virus are reduced

by 4 logs (decimal exponents), which corresponds to international requirements

and ensures safe disinfection.

The disinfection performance of a UV system is essentially based on the fact that

each volume element obtains the necessary UV dose when it passes through the UV

reactor. To ensure this the radiation field and hydraulic properties in the UV system

have been optimally adapted to each other.

UV radiation of drinking water does not cause any undesired secondary reactions

based on the UV doses we use for disinfection.

As we do not add efficient disinfective substances to the water by UV radiation,

there are no deposit effects when the volume element has passed through the UV

reactor.

ATTENTION:

Correct function (disinfection performance) can only be guaranteed when original ITT Water & Wastewater spare parts (lamps,

ballasts, etc. ) are used.

Should you have any questions please contact:

www.wedeco.com

Tel.: +49 (0) 5221 930-777

Fax : +49 (0) 5221 930-196

3

GB

Page 4

General Safety Instructions

ELECTRIC SHOCK!

Attention - dangerous electrical voltage. The non-observance of this

instruction can cause serious personal injuries.

ENSURE EYE PROTECTION IS WORN!

IMPORTANT!

Instruction regarding useful tips or other information.

CAUTION!

UV-C radiation is harmful to the eyes and skin! UV lamps should be used

only in the irradiation chamber if suitable protection caps have been fitted.

Persons should never be exposed to UV-C radiation.

• Make sure this disinfection unit is only used for the intended purpose as describ ed in the operating instructions. The use of additional apparatus, which have not

been recommended by and are not sold by ITT Water & Wastewater can cause an

unsafe situation.

• This disinfection unit is to be installed properly before use according to the opera ting instructions

• Do not use a unit with damaged electrical lead or plug, or a unit with faulty func tions, or a unit, which has been dropped or has been damaged in some way

• Make sure the unit is unplugged when it is not being used before fitting, or remo ving any parts, or before cleaning the unit. Do not remove the plug from the

socket by pulling the electrical lead, but take the plug directly out of the socket.

4

Page 5

• Ensure the disinfection unit is electrically isolated before:

A. Carrying out repairs

REMARK:

Werecommendthatanymaintenanceiscarriedoutbyqualifiedpersons.

B. Cleaning

C. Replacement of the UV lamp

• The unit is to be depressurized before maintenance

• Do not use the UV lamp outside of the UV disinfection reactor

UV systems, which have been equipped with a solenoid valve,

should not be used without flowing water for long periods

(max. 48 hours). In cases of longer absence the system is to be

put out of operation.

WEDECO UV lamps have been designed for permanent operation

to reach their best disinfection capacity.

Frequent switching on and off reduces the life of the UV lamp!

Max. 200 switching operations!

5

GB

Page 6

2. Assembly & Installation

The following items must be checked prior to installation:

• A max. operating pressure of 1000 K Pa (10 bar) must not be exceeded

• The max. ambient temperature is 40° C

• The max. water temperature is 25° C

• The max. flow rate must not be exceeded (see section 2.1.)

• The installation site of the reactor must be frost-protected and dry

2.1. Reactor

The following reactor types are available in the Aquada series:

*

Flow rate: 400 J/m2, UV-Transmission: 94 %

Make sure the national standards and prescriptions for assembly and installation are observed. Installation must be carried

out only by qualified technicians.

Type Length Diameter Connections„Min. free space

above reactor

Max. flow rate*

m

3

/h

1 470 mm 70 mm R 1/2 370 mm 0,70

2 670 mm 70 mm R 3/4 570 mm 1,77

4 670 mm 101,6 mm R 3/4 570 mm 3,01

7 1030 mm 101,6 mm R1 920 mm 6,20

10 1030 mm 140 mm R1 1/2 920 mm 9,00

6

Page 7

2.1.1. Assembly of Reactor

• Before installation ensure you know which reactor type you are using.

(Information about the reactor type can be found on the type plate)

• Make sure that there is enough free space above the reactor (for dimensions see

section 2.1.), otherwise it will not be possible to install the UV lamp and to

maintain the system

• The reactor is to be fixed by means of the enclosed assembly clips either on the

wall or on a special holder

• In units with a UV sensor the reactor can only be assembled in a vertical position

• The assembled reactor is to be protected from frost exposure

UV lamp

Outlet

UV sensor (optional)

Control box

Inlet

7

GB

Page 8

2.1.2. Installation of Quartz Sleeve and of UV Lamp

The reactor is supplied together with a built-in quartz sleeve. The black head piece

in which the UV lamp is to be inserted has been screwed to a tightness of 5 Nm

in our factory. Prior to commissioning all screw connections are to be checked for

tightness.

ForinstallationofUVlampseesection2.2.3.

2.1.2.1. Cleaning and Replacement of Quartz Sleeve

The transparent plug of the lamp connection is to be turned slightly to the left or

the right (up to the raised part in the head piece) and then removed.

Remove UV lamp from the reactor by pressing the two transparent catching tabs.

Unscrew head piece from reactor and then carefully remove it together with the

quartz sleeve.

Then remove any coating from the quartz sleeve and reassemble it after cleaning.

The quartz sleeve and the head piece are two single parts.

In case of disassembly, hold both parts in order to avoid the

quartz sleeve slipping out of the head piece!

UV lamp

O-ring

Lamp filament wiring

Quartz sleeve

Head piece Catching tabs

UV lamp

O-ring

8

Page 9

Assembling manual

The transparent lamp connector must properly snap

into the groove on the head

piece.

The UV lamp is also to be

cleaned before assembly.

It is to be inserted into the

head piece from above until

the two transparent catching

tabs of the connecting plug

lock into place in the head

piece.

After the assembly of the UV

lamp the transparent lamp

connecting plug is to be fitted on the head piece. Make

sure that it locks into place.

(Seeguideintheplug)

This figure shows the transparent lamp connector

pushed too far.

Head piece UV lamp

Transparent connecting plug

Put the connection plug onto

the head piece until it clicks

in.

The connection plug is

properly installed. It does not

seperate when pulled away

from the head piece.

UV lamp

Transparent lamp

connection

Head piece

9

GB

Page 10

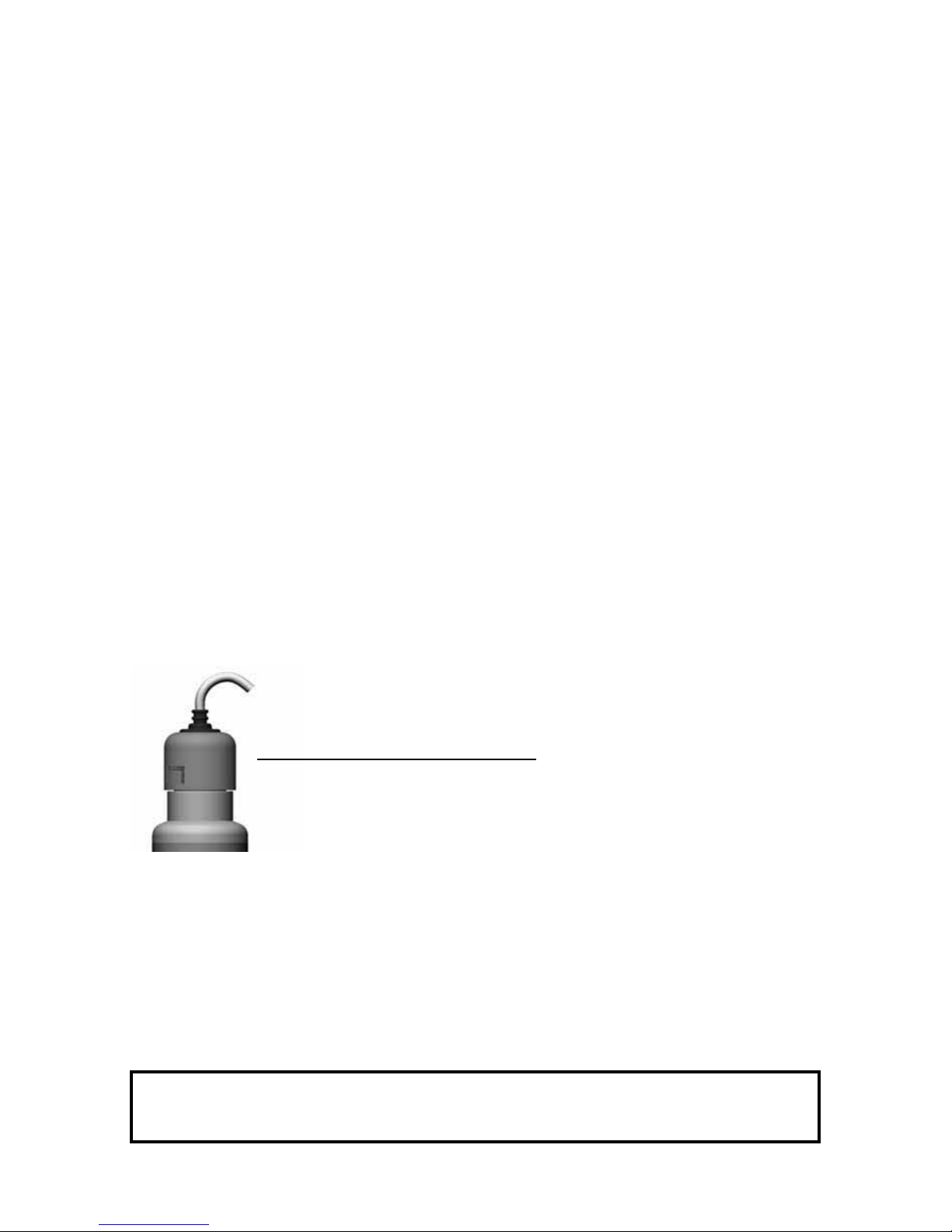

2.1.2.2. Fitting of UV Sensor

In our factory the UV sensor has been fitted to the control (only for Maxima model).

It is only to be screwed to the reactor. Tightening should be carried out with a light

tool only. A starting torque of 5 Nm is sufficient. Make sure this torque is not exceeded, otherwise the quartz glass in the sensor may be damaged.

To avoid breakage, do not remove the quartz glass plate (located in the sensor)

when cleaning it. The glass plate should only be cleaned with a soft, clean cloth.

2.1.3. Connection to the Water Line Network

• When carrying out the connection to the water line network make sure to fit stop

valves on the inlet and outlet of the reactor to make maintenance easier

• UV resistant material is to be used for the connections to the water line network.

For the connection sizes please refer to the table in section 2.1.

• The connection to water line network is to be carried out in accordance with the

national regulations

• A solenoid valve is offered as an optional (Proxima, Maxima). This prevents wa ter flowing through in the case of power failure or insufficient UV intensity in the

reactor

UV sensor

NOTE:

The sensor is to be cleaned in regular intervals depending on the water

quality. For this purpose unscrew sensor after it has been depressurized

and is free from water, and then clean the quartz glass with the cleaner.

10

Page 11

2.2. Control System

The following equipment variants can be supplied:

1.Altima

• Visual function control of UV lamp by transparent lamp connection

• Control box which can be fastened easily (assembly on the wall or reactor)

2.Proxima

• As Altima variant

• Possibility of connecting a solenoid valve which allows water flow only in the case

of a shining UV lamp

• Control of the solenoid valve by a micro-controller

• Remaining life of UV lamp shown on the display

• Visual and acoustic alarm in the case of lamp failure

3.Maxima

• As Proxima variant

• A UV sensor which continuously monitors the intensity, switches off the solenoid

valve when the minimum intensity is not reached and emits a visual and acoustic

alarm. The intensity is shown on the display.

11

GB

Page 12

2.2.1. Assembly of the Control Box

The control box can be fitted directly to the reactor by means of the supplied fastening bands.

• Assembly on the wall is also possible. For this method drill two holes

(hole spacing 134 mm) and fit dowels and screws. Then the control

housing can be hung on the screws.

• In the case of wall mounting the lengths of the supplied cables are to be taken

into account

» Connecting line to the mains: 200 cm

» Sensor cable: 150 cm (only for Maxima)

» Lamp cable : 150 cm

» Solenoid valve cable: 150 cm (optional)

2.2.2. Electrical Connection

Pull bands through the opening

of the housing and fasten them

to the reactor.

The supplied cables must not be shortened or lengthened!

When the control box is connected to the mains make sure to

observe the valid national regulations as well as the indications

on the type plate (supply voltage, frequency, etc). The unit shall

only be operated with power lines including a ground wire (PE).

Installation work is to be carried out only by qualified electricians. Make sure to remove mains plug from socket before

carrying out work at the unit.

The grounding cable (earth) is to be connected to the reactor!

Do not open the housing of the control unit, otherwise the guarantee will become void!

12

Page 13

2.2.3. Connection of UV Lamp

• Unpack UV lamp and wipe it with a clean cloth (do not touch the lamp with your

fingers)

• Insert the lamp into the head piece until the transparent catching tabs of the

lamp connecting plug lock into place in the head piece (when you insert the lamp,

slightly press in catching tabs with two fingers; see figure 1 page 8)

• When inserting the UV lamp, make sure that the lamp filament wirings (see fig. 1

page 8) do not attenuate the sensor signal. The wirings must not be in front of

the sensor window.

Make sure to check all important items of the operating instructions

prior to commissioning.

3.1. Units with Solenoid Valve

• Loosen head piece by two turns

• Open stop valve of domestic water supply system

• Air escapes through the head piece. Leave the head piece open until water flows

out. After that relock the head piece. Becarefulofsplashwater!

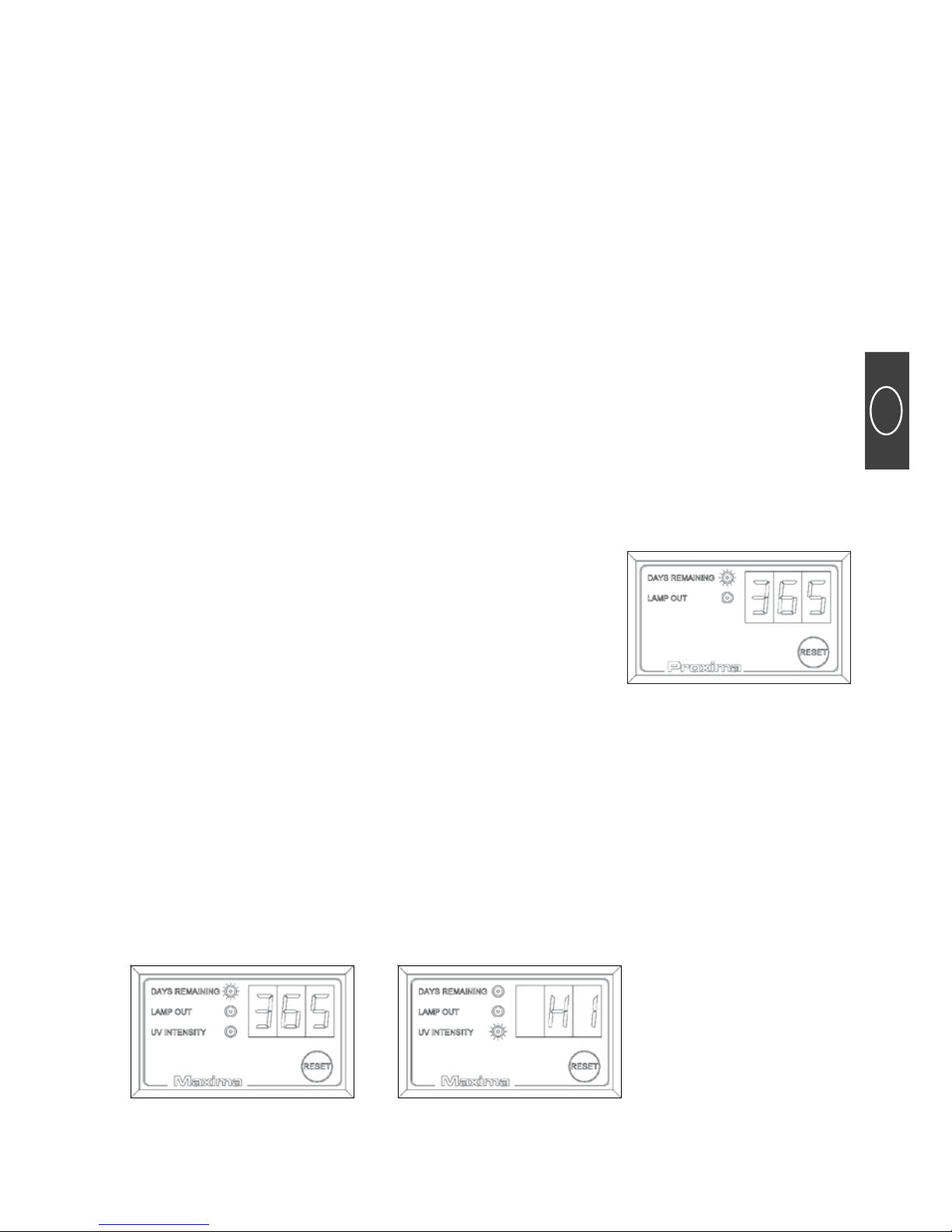

• Commission UV system. Insert plug into socket. The display shows:

3. Commissioning

Sample Proxima

13

GB

Page 14

• Press Reset button for approx. 10 seconds after having switched on the unit, until

you hear a signal

• The unit is now in the warm up phase. After 5 minutes the solenoid valve is

switched on and fully opened.

• Now open the stop valve slowly but completely. At the same time a water tap is

to be opened to ensure that the rest of the air escapes from the unit.

3.1.1. Units without Solenoid Valve

• Open a water tap

• Open slowly the main water tap of the domestic water supply plant until the air

has completely escaped from the unit

• Insert the mains plug into the socket. The display of the Proxima and Maxima unit

shows 365 days

• Press the Reset button for approx. 10 sec. after switching on (Proxima, Maxima)

• Now the unit is in the warming up phase. After 5 minutes it has reached the

highest intensity and is ready for use.

The function control of the Altima units can be seen through the

blue shiny cap.

All UV systems must only be switched on after the reactor has been filled

with water.

14

Page 15

3.2. Tightness Test

4. Software

The Aquada units (Proxima & Maxima) are equipped with a monitoring unit which

is controlled by a micro-controller. The Aquada unit (Altima) is equipped with an

visual function control (section 3.1.1.)

• After first commissioning 365 is shown on the display and the LED „days of use“

is lit up (Proxima, Maxima)

• Press the RESET button for approx. 10 sec. (directly after switching on)

• The initialization time is 5 minutes

• After this the unit is ready for operation and the outlet solenoid valve is switched

on

• The display of the Maxima version now changes every 2 seconds from the display

of the days of use to the display of the UV intensity. The Proxima display remains

showing the days of use. In normal rating operation, the intensity is shown by HI

in the display.

• The display always shows the remaining number of days of use

After commissioning, all screw connections are to be checked

for tightness.

ITT Water & Wastewater do not assume any responsibility for

water damage(s)!

15

GB

Page 16

4.1. Alarm Messages

Thefollowingalarmmessagescanoccurduringoperation:

AL1 » UV lamp failed

AL2 » UV intensity less than 55 % of set value

AL3 » End of lamp life (days of use = 0)

AL4 » UV intensity between 55 % and 70 % of set value

AL5 » UV lamp life < 30 days of use

Alarm 1

• UV lamp has not ignited

• UV lamp is defect

• Lamp failure LED is lit up

» Check plug connection of UV lamp

» Remove transparent cap as described and fit it once more

» Insert new UV lamp

» Have ballast checked by authorized service technician

Alarm 2

• Quartz sleeve is dirty

• Sensor is dirty

• End of UV lamp life (due to frequent switching on and off)

• Unit has been operated too long without flowing water (reactor is heated up)

• Lamp filament wiring is in front of the sensor window

» Disassemble quartz sleeve as described in section 2.1.2.1. and clean with a cleaner

» Disassemble sensor and clean sensor window

» Avoid frequent switching on and off, as the unit has been designed for

continuous operation

» Switch unit off and let it cool down

» Turn transparent lamp connector by 45°

Alarm 3

• End of UV lamp life

» Install new lamp (Use only original WEDECO spare parts)

16

Page 17

Alarm 4

• Normal UV lamp ageing (disinfection is still given)

• Cleaning could be required soon

• Lamp filament wiring is in front of the sensor window

» Normal operating conditions can be restored by cleaning the unit

» In the display „HI“ is replaced by „LO“ (only Maxima)

» Turn transparent lamp connector by 45°

Alarm 5

• End of lamp life in 30 days

» Order new UV lamp

4.2. New Start after Replacement of UV Lamp

The quartz sleeve and sensor should be cleaned

after each replacement of the UV lamp. The reactor

should be cleaned when necessary.

For the new start of the system proceed in the same

way as for first commissioning. When you press the

RESET button (press for 10 sec.), directly after switching on, the day counter is reset to 365 and the

unit is newly initialized.

All alarm messages are also given acoustical. The acoustical signal can be

reset by pressing the RESET button.

17

GB

Page 18

5. Exploded Diagram

1 » control box

2 » reactor

3 » quartz sleeve

4 » UV lamp

5 » head piece

6 » O-ring (head piece)

7 » lamp connection

8 » O-ring (quartz sleeve)

9 » UV sensor

10 » sensor connection

11 » control fastening band

12 » reactor fastening band

13 » reactor fastening band

18

Page 19

6. Spare Parts List

Spare Part No. Description

760054 Control Box AQUA 1 Altima

760055 Control Box AQUA 2 & 4 Altima

760056 Control Box AQUA 7 & 10 Altima

760057 Control Box AQUA 1 Proxima

760058 Control Box AQUA 2 & 4 Proxima

760059 Control Box AQUA 7 & 10 Proxima

760060 Control Box AQUA 1 Maxima

760061 Control Box AQUA 2 & 4 Maxima

760062 Control Box AQUA 7 & 10 Maxima

703321 Quartz sleeve 25 x 1,3 x 360 (inc. seal)

703322 Quartz sleeve 25 x 1,3 x 560 (inc. seal)

703323 Quartz sleeve 25 x 1,3 x 910 (inc. seal)

37085 UV Lamp NLR 1825 WS (Aquada 1)

37086 UV Lamp NLR 1845 WS (Aquada 2 & 4)

37087 UV Lamp NLR 1880 WS (Aquada 7 & 10 )

36538 Head piece

Ø 48 x 40 PBT Crastin S 600

35492 O-Ring 24,77 x 5,33 FPM

37126 Assembly Lamp cable Ölflex 5 x 0,75 mm² 1,5 m

703324 Assembly Sensor window 18 x 2 (inc. Seal)

37250 Assembly UV Sensor (inc. Seal)

38127 power cord swiss

37155 power cord european

37156 power cord italian

36944 power cord british

36623 Reactor R1 (304)

36622 Reactor R2 (304)

36621 Reactor R4 (304)

36620 Reactor R7 (316 L)

36619 Reactor R10 (316 L)

36628 Reactor (Sensor) R1 (304)

36627 Reactor (Sensor) R2 (304)

36626 Reactor (Sensor) R4 (304)

36625 Reactor (Sensor) R7 (316 L)

36624 Reactor (Sensor) R10 (316 L)

37360 Face Spanner

37361 Torque-controlled Spanner „Slipper“ 2 - 10 Nm

19

GB

Page 20

Page 21

21

WEDECO Aquada

GB

DE

F

Installation and Maintenance Instructions

Installations- und Wartungsanleitung

Notice d’installation et de Maintenance

I

Istruzioni di Installazione e Manutenzione

Page 22

Inhalt

1. Allgemeines&Anwendungen

2. MontageundInstallation

2.1. Reaktor

2.1.1. Montage des Reaktors

2.1.2. Einbau des Quarzrohres und des UV-Strahlers

2.1.2.1. Säubern und Austauschen des Quarzrohres

2.1.2.2. Anbringen des UV-Sensors (nur Maxima)

2.1.3. Wasseranschlüsse herstellen

2.2. Steuerung

2.2.1. Montage der Steuerung

2.2.2. Elektrische Anschlüsse

2.2.3. Anschluss des UV-Strahlers

3. Inbetriebnahme

3.1. Geräte mit Magnetventil

3.1.1. Geräte ohne Magnetventil

3.2. Dichtigkeitsprüfung

4. Software

4.1. Fehlermeldungen

4.2. Neustart nach Tausch des UV Strahlers

5. Explosionszeichnung

6. Ersatzteilliste

7. EG-Konformitätserklärung(Seite82)

ACHTUNG:

Bitte lesen Sie dieses Handbuch sorgfältig und befolgen Sie die darin

gegebenen Hinweise. Die Installation darf nur von autorisierten Fachleuten

durchgeführt werden.

22

Page 23

1. Allgemeines & Anwendungen

Die Desinfektion mittels ultraviolettem Licht (UV) ist ein wirksames, wirtschaftliches

und besonders umweltfreundliches Verfahren.

UV-Licht tötet pathogene Mikroorganismen innerhalb von Sekunden ohne Rückstände, schädliche Nebenprodukte oder Geruchs- und Geschmacksbeeinträchtigungen. Eine Gefährdung des Betriebspersonals durch den Umgang mit gesundheitsschädlichen Chemikalien ist dadurch ebenfalls ausgeschlossen.

Die Wirkungsweise des UV-Lichts wird durch den Einsatz besonders effektiver UV-C

Strahlung (254 Nm) genutzt. Sie bewirkt eine sekundenschnelle, photochemische

Reaktion in der für alle Mikroorganismen lebensnotwendigen DNS (Desoxyribonucleinsäure). Dadurch wird der Mikroorganismus entweder abgetötet oder seine

Vermehrungsfähigkeit zerstört.

Die Reduktionsrate ist abhängig von der UV-Mindestbestrahlung (UV-Dosis), das bedeutet der Zeit in der ein Mikroorganismus einer bestimmten UV-Bestrahlungsstärke

(W/m²) ausgesetzt ist. Für die sichere Desinfektion von Trinkwasser wird bei einer

UV-Dosis von 400 J/m² die geforderte Reduktion der wichtigsten humanpathogenen

Bakterien, Parasiten und Viren um 4 Zehnerpotenzen erreicht.

Die Desinfektionsleistung einer UV-Anlage beruht im Wesentlichen darauf, dass

jedes Volumenelement beim Durchströmen des UV-Reaktors die notwendige UVDosis erhält. Um dies zu gewährleisten, sind Bestrahlungsfeld und Hydraulik in der

UV-Anlage optimal aufeinander abgestimmt.

Die UV-Bestrahlung von Trinkwasser führt bei den zur Desinfektion eingesetzten

UV-Dosiswerten zu keinen unerwünschten Nebenreaktionen. Da dem Wasser durch

die UV-Bestrahlung keine desinfektionswirksame Substanz zugesetzt wird, ist nach

Passieren des UV-Reaktors keine Depotwirkungen vorhanden.

ACHTUNG:

Nur bei Verwendung von orginal WEDECO Ersatzteilen (Strahler,

EVG, usw.) kann die Funktion (Desinfektionsleistung) sichergestellt werden.

Bei Fragen wenden Sie sich an:

www.wedeco.com

Tel.: +49 (0) 5221 930-777

Fax : +49 (0) 5221 930-196

23

DE

Page 24

Allgemeine Sicherheitshinweise

ELEKTROSCHOCK!

Achtung gefährliche elektrische Spannung. Die Nichtbeachtung dieses

Hinweises kann zu schwerwiegenden körperlichen Schäden führen.

EIN AUGENSCHUTZ IST ZU TRAGEN!

WICHTIG!

Hinweis auf einen nützlichen Tipp oder eine andere Information.

VORSICHT!

UV-C Strahlung ist schädlich für Augen und Haut! UV-Lampen dürfen nur

in der Strahlungskammer benutzt werden, wenn geeignete Schutzabdeckungen angebracht sind. Personen sollten niemals der UV-C Strahlung

ausgesetzt werden.

• Verwenden Sie dieses Desinfektionsgerät nur für den vorgesehenen Zweck wie in

der Betriebsanleitung beschrieben. Die Verwendung von Zusatzgeräten, die nicht

von ITT Water & Wastewater empfohlen oder vertrieben werden, können einen

unsicheren Zustand hervorrufen.

• Dieses Desinfektionsgerät ist vor Gebrauch ordnungsgemäß und in Übereinstimm ung mit der Betriebsanleitung zu installieren.

• Betreiben Sie kein Gerät, das eine beschädigte Anschlussleitung oder Stecker hat,

das Fehlfunktionen aufweist oder fallengelassen oder auf irgendeine Weise

beschädigt wurde.

• Der Stecker eines Gerätes, das nicht in Gebrauch ist, muss stets aus der Steck dose entfernt werden, bevor Teile angebracht oder abgenommen werden oder

das Gerät gereinigt wird. Ziehen Sie das Desinfektionsgerät niemals an der An schlussleitung aus der Steckdose. Fassen Sie den Stecker fest an und ziehen Sie

diesen direkt aus der Steckdose.

24

Page 25

• Das UV-Desinfektionsgerät ist immer vom Stromkreis zu trennen bevor:

A. Irgendwelche Reparaturen durchgeführt werden

ANMERKUNG:

Wirempfehlendringend,dassjeglicheWartungsarbeitendurchqualifi ziertesFachpersonalausgeführtwird.

B. Eine Reinigung durchgeführt wird

C. Der Austausch des UV-Strahlers vorgenommen wird

• Vor Wartungsarbeiten das Gerät immer drucklos machen.

• Den UV-Strahler nicht außerhalb des UV-Desinfektionsgerätes betreiben.

UV-Anlagen, die mit Magnetventil ausgestattet sind dürfen nicht

längere Zeit (max. 48 Stunden) ohne Wasserdurchfluss betrieben

werden. Bei längerer Abwesenheit ist die Anlage außer Betrieb

zu nehmen.

Die WEDECO UV-Strahler sind für den Dauerbetrieb ausgelegt

und erreichen dann ihre größte Desinfektionsleistung.

Häufiges Ein- und Ausschalten vermindert deutlich die Lebensdauer des UV-Strahlers!

Maximal 200 Schaltvorgänge!

25

DE

Page 26

2. Montage und Installation

Vor der Installation sind folgende Punkte sicherzustellen:

• Der max. Betriebsdruck von 1000 K Pa (10 bar) darf nicht überschritten werden

• Die max. Umgebungstemperatur beträgt 40° C

• Die max. Wassertemperatur beträgt 25° C

• Die max. Durchflussmenge darf nicht überschritten werden (siehe 2.1. Reaktor)

• Der Einbauort des Reaktors und der Steuerung muss frostfrei und trocken sein.

2.1. Reaktor

Folgende Reaktortypen sind in der Aquada-Serie erhältlich:

*

Durchfluss: 400 J/m2, UV-Transmission: 94 %

Bei der Montage und Installation sind die landesüblichen Normen und Vorschriften einzuhalten. Die Installation darf nur von

Fachkräften durchgeführt werden.

Typ Länge Durchmesser Anschlüsse

„

Min. Freiraum

oberh. des Reaktors

Max. Durchfluss*

m

3

/h

1 470 mm 70 mm R 1/2 370 mm 0,70

2 670 mm 70 mm R 3/4 570 mm 1,77

4 670 mm 101,6 mm R 3/4 570 mm 3,01

7 1030 mm 101,6 mm R1 920 mm 6,20

10 1030 mm 140 mm R1 1/2 920 mm 9,00

26

Page 27

2.1.1. Montage des Reaktors

• Stellen Sie bitte vor dem Einbau sicher, welchen Reaktortyp sie verwenden.

(Informationen über den Reaktortyp finden Sie auf dem Typenschild)

• Es ist sicherzustellen, dass sich genügend Freiraum oberhalb des Reaktors befindet

(Maße siehe Tabelle 2.1. Reaktor), da sonst das Einsetzen des UV-Strahlers und

die Wartung der Anlage nicht möglich sind.

• Der Reaktor ist mit den beiliegenden Montageschellen auf der Wand oder einem

anzufertigenden Gestell zu befestigen.

• Bei Geräten mit UV-Sensor ist nur eine vertikale Montage des Reaktors zulässig.

• Der Reaktor ist frostsicher zu montieren.

• ITT Water & Wastewater empfiehlt den Reaktor mit einer Metallleitung anzu schließen (Kupfer, Stahl) Kunststoffleitungen müssen aus UV beständigem

Material sein!

Strahleranschluss

Auslauf

UV Sensor

Steuerung

Zulauf

27

DE

Page 28

2.1.2. Einbau des Quarzrohres und des UV-Strahlers

Der Reaktor wird mit eingebautem Quarzrohr geliefert. Das schwarze Kopfstück, in

das der UV-Strahler eingeführt wird, ist mit 5 Nm werksseitig verschraubt worden.

EinbauUV-StrahlersiehePunkt2.2.3.

2.1.2.1. Säubern und Austauschen des Quarzrohres

Der transparente Stecker des Strahleranschlusses ist durch leichtes drehen nach

links oder rechts (bis auf die Erhöhung im Kopfstück) abzuziehen.

Den UV-Strahler durch Drücken der beiden transparenten Rastfahnen aus dem

Reaktor entfernen. Kopfstück aus dem Reaktor rausdrehen und dann vorsichtig

mit dem Quarzrohr entfernen. (BeideTeilefesthalten)

Anschließend den Belag mit einem feuchten Tuch (ggf. Reiniger verwenden) vom Quarzrohr

entfernen und im sauberen, trockenen Zustand wieder einbauen.

Das Quarzrohr und das Kopfstück sind zwei Einzelteile. Beim

Ausbau beide Teile festhalten, da sonst das Quarzrohr aus dem

Kopfstück rutschen könnte!

Reaktor

O-ring

O-ring

Strahler Rückführung

Quarzrohr

Kopfstück Rastfahnen

UV-Strahler

28

Page 29

Montageanleitung

Richtig eingebauter Strahler

Anschluss!

Der UV-Strahler ist ebenfalls

vor dem Einbau mit einem

trockenen Tuch zu säubern.

Er wird von oben durch das

Kopfstück geführt, bis die

beiden transparenten Rastfahnen des Anschlusssteckers im Kopfstück einrasten.

Nach dem Einsetzen des UVStrahlers ist der transparente

Strahleranschlussstecker auf

das Kopfstück aufzustecken

bis er einrastet.

(AufFührungimStecker

achten)

Falsch eingebauter Strahler

Anschluss!

Kopfstück UV Strahler

Stecken Sie den Steck er

richtig auf das Kopfstück

(Achten Sie auf die Führung)

Stecken Sie den Anschlussstecker auf, bis er einrastet.

UV-Strahler

Transparenter

Strahleranschluss

Kopfstück

Transparenter Strahleranschlussstecker

29

DE

Page 30

2.1.2.2. Anbringen des UV-Sensors

Der UV-Sensor ist werksseitig an der Steuerung angebracht (nur Maxima). Er muss

lediglich an den Reaktor geschraubt werden. Die Verschraubung darf nicht mit

schwerem Werkzeug erfolgen. Der Sensor sollte handfest (ca. 5 Nm) angezogen

werden. Bei Missachtung kann es zur Zerstörung der im Sensor befindlichen Quarzglasscheibe kommen.

Zur Reinigung darf die Quarzglasscheibe, die sich im Sensor befindet, nicht ausgebaut werden, da es sonst zur Zerstörung des Quarzglases kommen kann! Sie sollte

lediglich mit einem weichen, sauberen Tuch gereinigt werden.

2.1.3. Wasseranschlüsse herstellen

• Bei den Wasseranschlüssen ist darauf zu achten, dass am Zu- und Ablauf des

Reaktors Absperrvorrichtungen angebracht werden, da diese die Wartungs arbeiten erleichtern

• Für die Wasseranschlüsse ist UV beständiges Material zu verwenden. Anschluss größen entnehmen Sie bitte der Tabelle unter 2.1. Reaktor.

• Die Wasseranschlüsse sind gemäß den geltenden Vorschriften durchzuführen

• Es wird optional ein Magnetventil angeboten (Proxima, Maxima), welches den

Durchfluss bei Ausfall der Versorgungsspannung sowie zu geringer UV-Intensität

im Reaktor verhindert

UV-Sensor

HINWEIS:

Der Sensor ist abhängig von der Wasserbeschaffenheit in regelmäßigen

Intervallen zu reinigen. Dazu Sensor im druck und wasserlosen Zustand

abschrauben und die Quarzscheibe reinigen.

30

Page 31

2.2. Steuerung

Es sind folgende Ausstattungsvarianten erhältlich:

1.Altima

• Optische Funktionskontrolle des UV-Strahlers durch transparenten Strahleran schluss

• leicht zu befestigende Steuerung (Wand oder Reaktormontage)

2.Proxima

• Zusätzlich zum Umfang der Altima-Variante

• Anschlussmöglichkeit eines Magnetventils, das einen Durchfluss nur bei einge schaltetem UV Strahler zulässt

• Steuerung des Magnetventils durch einen Microcontroler

• Displayanzeige der verbleibenden Lebensdauer des

UV-Strahlers

• Optisch und akustischer Alarm bei Strahlerausfall

3.Maxima

• Zusätzlich zum Steuerumfang der Proxima-Variante

• Ein UV-Sensor, der ständig die Intensität überwacht und bei Unterschreiten der

min. Intensität das Magnetventil schaltet und einen optischen und akustischen

Alarm herausgibt. Intensität wird im Display angezeigt.

31

DE

Page 32

2.2.1. Montage der Steuerung

Die Steuerung kann mit den mitgelieferten Befestigungsbändern direkt am Reaktor

befestigt werden.

• Eine Wandmontage ist ebenfalls möglich. Hierbei sind zwei Löcher zu bohren

(Lochabstand 134 mm) und mit Dübeln und Schrauben zu versehen. Dann lässt

sich das Steuergehäuse mit den dafür vorgesehenen Löchern auf die Schrauben

einhängen.

• Bei einer Wandmontage ist auf die mitgelieferten Leitungslängen zu achten:

» Netzanschlussleitung: 200 cm

» Sensorleitung: 150 cm (nur Maxima)

» Strahleranschluss: 150 cm

» Magnetventilleitung: 150 cm (Optional)

2.2.2. Elektrische Anschlüsse

Befestigungsbänder durch die

Ge häuse-Öffnung ziehen und fest

am Reaktor befestigen.

Eine Auftrennung oder Verlängerung der Leitungen ist nicht

zulässig!

Beim Anschluss der Steuerung sind die national geltenden Vorschriften, sowie die Angaben auf dem Typenschild einzuhalten

(Netzspannung, Frequenz, etc.). Das Gerät ist nur an Netzformen

zu betreiben , die einen Schutzleiter (PE) beinhalten. Die Installationsarbeiten sind nur von Elektrofachkräften durchzführen. Bei

Arbeiten am Gerät ist grundsätzlich der Netzstecker zu ziehen.

Die elektrischen Anschlussdaten entnehmen Sie bitte dem Typenschild auf dem Gerät.

Der Potentialausgleichsleiter (Erde) ist am Reaktor anzuschließen!

Das Öffnen des Steuerghäuses führt zum Verlust der Garantie!

32

Page 33

2.2.3. Anschluss des UV Strahlers

• Der UV-Srahler ist aus der Verpackung zu entfernen und mit einem sauberen

Tuch abzuwischen (nicht mit den Fingern auf den Strahler fassen)

• Den Strahler in das Kopfstück einführen bis die transparenten Rastfahnen des

Strahlersteckers im Kopfstück einrasten. (Rastnasen beim Einführen mit zwei

Fingern leicht eindrücken; siehe Bild 1, Seite 32)

• Es muß beim Einführen des UV-Strahlers darauf geachtet werden, dass die Rück führungen (siehe Bild 1, Seite 32) das Sensorsignal nicht schwächen. Sie dürfen

nicht vor dem Sensorfenster verlaufen.

Vor der Inbetriebnahme sollten alle wichtigen Punkte der Bedienungsanleitung nochmals überprüft werden.

3.1. Geräte mit Magnetventil

• Das Kopfstück zwei Umdrehungen lösen

• Den Absperrhahn der Hauswasseranlage leicht öffnen

• Durch das Kopfstück entweicht Luft. Das Kopfstück solange geöffnet lassen bis

Wasser austritt. Dann das Kopfstück wieder fest verschließen.

Achtung Spritzwasser!

• Die UV-Anlage in Betrieb nehmen. Den Netzstecker in die Steckdose stecken.

Das Display zeigt (Beispiel Maxima):

3. Inbetriebnahme

Anzeige nach der Inbetriebnahme des Gerätes.

Nach 5 Minuten wechselt

das Gerät zwischen beiden

Anzeigen.

33

DE

Page 34

• Den Reset Button nach dem Einschalten ca. 10 sek. gedrückt halten bis ein Signal ton zu hören ist

• Das Gerät befindet sich nun in der Aufwärmphase. Nach 5 Minuten wird das

Magnetventil eingeschaltet und hat nun vollen Durchfluss.

• Nun den Absperrhahn langsam ganz öffnen. Gleichzeitig ist ein Wasserhahn zu

öffnen, um die restliche Luft aus dem Gerät zu bekommen.

3.1.1. Geräte ohne Magnetventil

• Es ist eine Wasserentnahmestelle zu öffnen

• Den Haupthahn der Hauswasseranlage langsam öffnen bis die gesamte Luft aus

dem Gerät entwichen ist

• Den Netzstecker in die Steckdose stecken. Die Geräte Proxima und Maxima zeigen

beide 365 Tage im Display.

• Den Reset Button nach dem Einschalten ca. 10 sek. gedrückt halten bis ein Signal ton zu höhren ist (Proxima, Maxima)

• Das Gerät befindet sich nun in der Aufwärmphase und hat nach 5 Minuten die

höchste Intensität erreicht und ist voll einsatzfähig

Bei den Altima Geräten ist die

Funk tionskontrolle des UVStrah lers nur durch die blau

schimmernde Anschlusskappe

zu sehen.

Alle UV Anlagen dürfen nur eingeschaltet werden, wenn der Reaktor mit

Wasser gefüllt ist.

34

Page 35

3.2. Dichtigkeitsprüfung

4. Software

Die Aquada-Geräte (Proxima & Maxima) verfügen über eine Mikrokontroler gesteuerte Überwachungseinheit. Das Aquada-Gerät (Altima) verfügt über eine optische

Funktionskontrolle (Punkt 3.1.1.)

• Nach der Erst-Inbetriebnahme erscheint im Display die Anzeige 365 und die LED

„Nutzungstage“ leuchtet. (Proxima, Maxima)

• Der RESET Button ist für 10 sek. zu drücken, bis ein Signalton zu höhren ist

(direkt nach dem Einschalten)

• Die Initialisierungszeit beträgt 5 Minuten

• Danach sind die Geräte betriebsbereit und der Magnetventilausgang wird ge schaltet

• Das Display der Maxima Version wechselt nun im 2 sek. Takt die Anzeige zwischen

Nutzungstage und UV-Intensität. Das Proxima Display verbleibt bei der Anzeige

Nutzungstage. Die Intensität wird im Nennbetrieb durch „HI“ im Display ange zeigt.

• Das Display zeigt immer die noch verbleibenden Nutzungstage an

Nach der Inbetriebnahme sind alle Schraubverbindungen auf

Dichtigkeit zu überprüfen.

ITT Water & Wastewater übernimmt keine Haftung für Wasserschäden!

35

DE

Page 36

4.1. Fehlermeldungen

FolgendeFehlermeldungenkönnenwährenddesBetriebesauftreten:

AL1 » UV-Strahler ausgefallen

AL2 » UV-Intensität unter 55 % des Sollwertes

AL3 » Ende der Strahler Lebensdauer (Nutzungstage = 0)

AL4 » UV-Intensität zwischen 55 % und 70 % des Sollwertes (Display Anzeige „LO“)

AL5 » UV-Strahler Lebensdauer < 30 Nutzungstage

Alarm 1

• UV-Strahler hat nicht gezündet

• UV-Strahler ist defekt

• „Lampenausfall“ LED leuchtet

» Steckverbindung am Strahler überprüfen

» Transparente Kappe wie beschrieben entfernen und nochmals aufstecken

» Neuen UV-Strahler einsetzen

» EVG durch autorisierten Service überprüfen lassen

Alarm 2

• Quarzrohr verschmutzt

• Sensor verschmutzt

• UV-Strahler am Ende der Lebensdauer (durch häufiges Ein & Ausschalten)

• Gerät zu lange ohne Wasserdurchfluss betrieben (Reaktor heizt sich auf)

• Strahlerrückführung verläuft vor dem Sensorfenster

» Quarzrohr wie beschrieben (Ab.: 2.1.2.1.) ausbauen und mit Reiniger reinigen

» Sensor ausbauen und Sensorscheibe reinigen

» Häufiges Ein- & Ausschalten vermeiden. Gerät ist für Dauerbetrieb ausgelegt.

» Gerät ausschalten und abkühlen lassen

» Transparenten Strahleranschlussstecker um 45° drehen

Alarm 3

• UV-Strahler am Ende der Lebensdauer

» Neuen UV-Strahler einbauen (Nur orginal WEDECO Ersatzteile verwenden)

36

Page 37

Alarm 4

• Normale UV-Strahler Alterung (Entkeimung ist noch gegeben)

• Eine Reinigung kann bald erforderlich sein

• Strahlerrückführung verläuft vor dem Sensorfenster

» Durch die Reinigung des Gerätes wird der Normale Betriebszustand wieder er reicht

» Die Displayanzeige „HI“ wird durch „LO“ ersetzt (nur Maxima)

» Transparenten Strahleranschlussstecker um 45° drehen

Alarm 5

• Ende der Strahlernutzungsdauer in 30 Tagen

» Neuen UV-Strahler bestellen

4.2. Neustart nach Tausch des UV-Strahlers

Bei jedem Tausch des UV Strahlers sollten auch das

Quarzrohr und der Sensor gereinigt werden. Der

Reaktor sollte nach Bedarf einer Reinigung unterzogen werden.

Beim Neustart der Anlage ist wie bei der ersten Inbetriebnahme zu verfahren. Durch das Betätigen des

Reset Buttons (10 sek. gedrückt halten) direkt nach

dem Einschalten wird der Tageszähler wieder auf

365 gesetzt und das Gerät wird neu initialisiert.

Alle Alarm-Meldungen werden auch akustisch wiedergegeben. Der Signalton lässt sich durch betätigen des RESET Buttons zurücksetzen.

37

DE

Page 38

5. Explosionszeichnung

1 » Steuerung

2 » Reaktor

3 » Quarzrohr

4 » UV-Strahler

5 » Kopfstück

6 » O-Ring (Kopfstück)

7 » Strahleranschluss

8 » O-Ring (Quarzrohr)

9 » UV-Sensor (Maxima)

10 » Sensor Befestigung

11 » Befestigung Steuerung

12 » Reaktor Befestigung

13 » Reaktor Befestigung

38

Page 39

6. Ersatzteilliste

Ersatzteil-Nr. Ersatzteil-Bezeichnung

760054 Baugr. Schaltkasten AQUA 1 Altima

760055 Baugr. Schaltkasten AQUA 2 & 4 Altima

760056 Baugr. Schaltkasten AQUA 7 & 10 Altima

760057 Baugr. Schaltkasten AQUA 1 Proxima

760058 Baugr. Schaltkasten AQUA 2 & 4 Proxima

760059 Baugr. Schaltkasten AQUA 7 & 10 Proxima

760060 Baugr. Schaltkasten AQUA 1 Maxima

760061 Baugr. Schaltkasten AQUA 2 & 4 Maxima

760062 Baugr. Schaltkasten AQUA 7 & 10 Maxima

703321 Baugr. Quarzglasrohr 25 x 1,3 x 360 (inkl. Dichtung)

703322 Baugr. Quarzglasrohr 25 x 1,3 x 560 (inkl. Dichtung)

703323 Baugr. Quarzglasrohr 25 x 1,3 x 910 (inkl. Dichtung)

37085 UV-Strahler NLR 1825 WS (Aquada 1)

37086 UV-Strahler NLR 1845 WS (Aquada 2 & 4)

37087 UV-Strahler NLR 1880 WS (Aquada 7 & 10)

36538 Kopfstück

Ø 48 x 40 PBT Crastin S 600

35492 Runddichtring 24,77 x 5,33 FPM

37126 Konfektionierung Leitung Ölflex 5 x 0,75 mm² 1,5 m

703324 Baugruppe Sensorquarzglasscheibe (inkl. Dichtung)

37250 Baugruppe UV-Sensor (inkl. Dichtung)

38127 Anschlußleitung schweizerisch

37155 Anschlussleitung europäisch

37156 Anschlussleitung Italienisch

36944 Anschlussleitung britisch

36623 Reaktorgehäuse R1 (304)

36622 Reaktorgehäuse R2 (304)

36621 Reaktorgehäuse R4 (304)

36620 Reaktorgehäuse R7 (316 L)

36619 Reaktorgehäuse R10 (316 L)

36628 Reaktorgehäuse (Sensor) R1 (304)

36627 Reaktorgehäuse (Sensor) R2 (304)

36626 Reaktorgehäuse (Sensor) R4 (304)

36625 Reaktorgehäuse (Sensor) R7 (316 L)

36624 Reaktorgehäuse (Sensor) R10 (316 L)

37360 Stirnlochschlüssel 35 mm

37361 Drehmomentschlüssel „Slipper“ 2 - 10 Nm

39

DE

Page 40

40

Page 41

41

WEDECO Aquada

GB

DE

F

Installation and Maintenance Instructions

Installations- und Wartungsanleitung

Notice d’installation et de Maintenance

I

Istruzioni di Installazione e Manutenzione

Page 42

Sommaire

1. Généralitésetapplications

2. Montageetinstallation

2.1. Réacteur

2.1.1. Montage du Réacteur

2.1.2. Installation de la gaine de quartz et de la lampe UV

2.1.2.1. Nettoyage et remplacement de la gaine de quartz

2.1.2.2. Mise en place du capteur UV

2.1.3. Raccordement au circuit d’eau

2.2. Systèmedecommande

2.2.1. Montage du boîtier de commande

2.2.2. Branchements électriques

2.2.3. Mise en place de la lampe UV

3. Miseenservice

3.1. Système avec électrovanne

3.1.1. Système sans électrovanne

3.2. Contrôle d‘étanchéité

4. Logiciel

4.1. Messages d‘alarme

4.2. Nouvelle mise en service après le remplacement de la lampe UV

5. Vueéclatée

6. Listedespiècesderechange

7. Déclarationdeconformité(page82)

ATTENTION:

Lisez soigneusement cette notice et conformez-vous aux instructions

qu’elle contient. L’installation ne peut être effectuée que par des techniciens qualifiés.

42

Page 43

1. Généralités et applications

La désinfection de l’eau par la lumière ultraviolette (UV) est un procédé efficace,

économique et particulièrement respectueux de l’environnement.

La lumière UV détruit les micro-organismes pathogènes en quelques secondes sans

laisser de résidus, de sous-produits nocifs et sans altérer l’odeur et le goût de l’eau.

Les opérateurs n’ont pas à manipuler des produits chimiques dangereux.

L’effet de la lumière ultraviolette est particulièrement efficace à la longueur d’onde

de 254 Nm. En quelques secondes elle provoque une réaction photochimique dans

l’acide désoxyribonucléique (ADN), vital pour tous les micro-organismes. Ces microorganismes sont soit détruits, soit empêchés de proliférer.

Le taux de destruction dépend de la dose d’exposition UV, c’est-à-dire du temps

d’exposition d’un micro-organisme à une certaine intensité de rayonnement UV (W/

m²). À une dose UV de 400 J/m² , les virus et les agents pathogènes les plus importants sont réduits de 4 « unités log », ce qui correspond aux normes internationales

et garantit une désinfection sûre.

Les performances de désinfection d’un système UV reposent essentiellement sur le

fait que chaque unité de volume traversant le réacteur UV reçoit la dose UV nécessaire. Pour cela, on a optimisé le champ de rayonnement et les propriétés hydrauliques du système UV.

L’irradiation de l’eau potable par les ultraviolets ne provoque aucune réaction secondaire indésirable aux doses UV que nous utilisons pour la désinfection.

Comme nous n’ajoutons pas de désinfectant à l’eau, il n’y a pas de dépôt après le

passage du volume unitaire dans le réacteur UV.

ATTENTION:

Une désinfection correcte ne peut être garantie que si des pièces de rechange WEDECO d’origine (lampes, ballasts, etc.) sont

utilisées.

Pour toute question, contactez:

www.wedeco.com

Tel.: +33 (0) 1 49 90 01 40

Fax : +33 (0) 1 49 90 01 41

43

F

Page 44

Consignes générales de sécurité

RISQUE D’ÉLECTROCUTION!

Attention – tension électrique dangereuse. Le non-respect de cette consigne peut entraîner des blessures graves.

UNE PROTECTION OCULAIRE EST INDISPENSABLE!

IMPORTANT!

Conseils utiles ou autres informations.

ATTENTION!

Le rayonnement UV-C est dangereux pour les yeux et pour la peau !

N’utilisez les lampes UV que dans la chambre d’irradiation et seulement si

des dispositifs de protection appropriés sont en place.

Les personnes ne doivent jamais être exposées aux rayonnements UV-C.

• Veillez à ce que cet appareil de désinfection ne soit utilisé que dans le but prévu,

conformément à la notice d’utilisation. L’utilisation d’appareils supplémentaires

qui n’ont pas été recommandés ni vendus par WEDECO peut nuire à la sécurité.

• Cet appareil de désinfection doit être installé correctement avant son utilisation

conformément à la notice

• N’utilisez pas l’appareil si le câble ou la prise électrique est en mauvais état, s’il

fonctionne incorrectement ou s’il a subi des dommages quelconques

• Veillez à ce que l’appareil soit débranché lorsqu’il n’est pas en service avant de

démonter ou de remonter des pièces ou avant de le nettoyer. Ne débranchez pas

le câble d’alimentation secteur en tirant dessus : sortez la fiche directement de la

prise de courant.

44

Page 45

• Vérifiez l’isolement électrique de l’appareil de désinfection avant d’effectuer les

opérations suivantes:

A. Préparation

REMARQUE:

Nousrecommandonsdeconfierlesopérationsdemaintenanceàdes

personnesqualifiées.

B. Nettoyage

C. Remplacement de la lampe UV

• Avant toute opération d’entretien, dépressurisez l’appareil

• N’utilisez pas la lampe UV à l’extérieur du réacteur UV

Les systèmes UV équipés d’une électrovanne ne doivent pas être

utilisés sans débit d’eau pendant une période prolongée (48

heures maximum).

Sinon, le système doit être arrêté.

Les lampes UV WEDECO ont été conçues pour atteindre leur

meilleure capacité de désinfection en service continu.

Des cycles marche-arrêt fréquents abrègent la durée de vie de la

lampe UV!

Max . 200 opérations de commutation!

45

F

Page 46

2. Montage et installation

Effectuez les vérifications suivantes avant l’installation:

• Il ne faut pas dépasser une pression de service maximal de 1000 KPa

• La température ambiante maximale est de 40° C

• La température maximale de l’eau est de 25° C

• Le débit maximal ne doit pas être dépassé (voir paragraphe 2.1.)

• Le site d’installation du réacteur doit être sec et à l’abri du gel

2.1. Réacteur

Les types de réacteurs suivants sont disponibles pour la série AQUADA:

*

pour une transmittance UV (à 254 Nm sur 10 mm) de 94% et une dose UV délivrée de 400 J/m²

Attention de respecter les normes et règles nationales pour

le montage et l’installation. L’installation doit être effectuée

uniquement par des techniciens qualifiés.

Type Longueur Diamètre Raccords Espace libre minimal

au-dessus du réacteur

Débit maxi*

m

3

/h

1 470 mm 70 mm R 1/2 370 mm 0,70

2 670 mm 70 mm R 3/4 570 mm 1,77

4 670 mm 101,6 mm R 3/4 570 mm 3,01

7 1030 mm 101,6 mm R1 920 mm 6,20

10 1030 mm 140 mm R1 1/2 920 mm 9,00

46

Page 47

2.1.1. Montage du Réacteur

• Avant l’installation, vérifiez le type de réacteur. (Voir la plaquette signalétique).

• Veillez à ce qu’il y ait assez d’espace libre au-dessus du réacteur (pour les dimen sions, voir paragraphe 2.1.) pour installer la lampe UV et entretenir le système

• Le réacteur doit être fixé à l’aide des pièces de fixation fournies soit au mur, soit

sur un support spécial

• Dans les systèmes comportant un capteur UV, le réacteur doit être monté vertical ement

• Le réacteur monté doit être protégé contre le gel

Lampe UV

Sortie

Capteur UV (facultatif)

Boîtier de commande

Entrée

47

F

Page 48

2.1.2. Installation de la gaine de quartz

et de la lampe UV

Le réacteur est fourni avec une gaine de quartz. La tête de couleur noire qui doit

recevoir la lampe UV a été serrée à un couple de 5 Nm dans notre usine. Avant la

mise en service, vérifiez le serrage de tous les raccords vissés.

Pourl’installationdelalampeUV,voirparagraphe2.2.3.

2.1.2.1. Nettoyage et remplacement de la gaine de quartz

La fiche transparente de la lampe doit être tournée légèrement vers la gauche ou

vers la droite (jusqu’à la partie en relief de la tête), puis retirée.

Retirez la lampe UV du réacteur en pressant les deux pattes transparentes. Dévissez la tête du réacteur, puis sortez-la soigneusement avec la gaine de quartz.

Éliminez les dépôts éventuels de la gaine de quartz et remontez-la après nettoyage.

La gaine de quartz et la pièce de tête sont deux éléments séparés. En cas de démontage, maintenir les deux pièces afin

d‘éviter que la gaine quartz ne se désolidarise de la tête.

Réacteur

Joint torique

Joint torique

Câblage de la lampe

Gaine de quartz

Tête Pattes

Lampe UV

48

Page 49

Notice de montage

Le connecteur transparent de

la lampe doit être correctement clipsé dans la gorge de

la pièce de tête.

La lampe UV doit également être nettoyée avant

sa mise en place. Il faut

l’introduire dans la tête par

le dessus jusqu’à ce que les

deux pattes transparentes

s’enclenchent.

Ce schéma montre que le

connecteur transparent de

lampe a été poussé trop loin.

Pièce de tête noire Lampe UV

Emboîter le capuchon transparent sur l‘épaulement et

encliqueter sur la pièce de

tête.

La connection est bien réalisée. Tourner le capuchon sur

l‘épaulement pour dégager la

connection.

Après la mise en place de la

lampe UV, montez la fiche

transparente sur la tête.

Veillez à ce qu’elle se bloque

correctement en position

(voir le guide dans la prise).

Lampe UV

Connecteur transparent

de lampe

Pièce de têtenoire

Capuchon et connecteur transparent

49

F

Page 50

2.1.2.2. Mise en place du capteur UV

Dans notre usine, le capteur UV a été mis en place (seulement pour le modèle Maxima). Il reste à le visser sur le réacteur. Le serrage doit être effectué uniquement avec

un outil léger. Un couple initial de 5 Nm est suffisant. Attention de ne pas dépasser

ce couple, sinon vous risquez d’endommager le quartz du capteur.

Afin d’éviter toute casse, ne pas retirer la plaque de verre de quartz (situé dans le

capteur) lors du nettoyage. La plaque de verre doit uniquement être nettoyée avec

un chiffon doux et propre.

2.1.3. Raccordement au circuit d’eau

• Pour le raccordement au circuit d’eau, installez des robinets d’arrêt à l’entrée et à

la sortie du réacteur pour faciliter l’entretien

• Un matériau résistant aux UV doit être utilisé pour le raccordement au circuit

d’eau. Pour les dimensions des raccords, reportez-vous au tableau du paragraphe

2.1.

• Le raccordement au circuit d’eau doit être effectué conformément à la réglemen tation nationale

• Une électrovanne est proposée en option (Proxima, Maxima). Elle a pour but de

couper l’eau en cas de panne d’alimentation électrique ou d’intensité UV insuffi sante dans le réacteur.

Capteur

NOTA:

Il faut nettoyer le capteur à intervalles réguliers en fonction de la qualité

de l’eau. Pour ce faire, dévissez le capteur après l’avoir dépressurisé, et

vidé de son eau, puis nettoyez le tube quartz avec le produit de nettoyage.

50

Page 51

2.2. Système de commande

Les variantes d’équipement suivantes peuvent être fournies:

1.Altima

• Contrôle visuel de la lampe UV par le raccord de lampe transparent

• Boîtier de commande facile à fixer (au mur ou sur le réacteur)

2.Proxima

• Comme variante du système Altima

• Possibilité d’installer une électrovanne qui ne laisse s’écouler l’eau que lorsque

l’intensité UV est suffisante

• Commande de l’électrovanne par un microcontrôleur

• Affichage de la durée de vie restante de la lampe

UV sur l’écran

• Alarmes visuelle et sonore en cas de panne de

lampe

3.Maxima

• Comme variante du système Proxima

• Un capteur UV qui contrôle continuellement l’intensité coupe l’alimentation de

l’élecrovanne lorsque l’intensité minimale n’est pas atteinte et émet une alarme

visuelle et sonore. L’intensité est affichée sur l’écran.

51

F

Page 52

2.2.1. Montage du boîtier de commande

Le boîtier de commande peut être monté directement sur le réacteur à l’aide des

colliers fournis.

• Le boîtier de commande peut aussi être fixé au mur. Dans ce cas, percez deux

trous (espacés de 134 mm) et mettez des chevilles et des vis. Vous pouvez ensuite

accrocher la boîte de commande aux vis.

• Dans le cas du montage mural, il faut tenir compte de la longueur des câbles

fournis:

» Câble d’alimentation secteur: 200 cm

» Câble de capteur: 150 cm (pour Maxima seulement)

» Câble de lampe: 150 cm

» Câble d’électrovanne: 150 cm (option)

2.2.2. Branchements électriques

Sortez les colliers par l’ouverture

du boîtier et fixez-les au réacteur.

Les câbles fournis ne doivent être ni raccourcis ni allongés!

Pour le raccordement du boîtier de commande au secteur,

respectez la réglementation nationale en vigueur ainsi que

les indications figurant sur la plaquette signalétique (tension

d’alimentation, fréquence, etc.) L’installation ne doit être effectuée que par des électriciens qualifiés. Avant toute intervention

sur le matériel, débranchez le câble secteur de la prise de courant.

Le câble de mise à la terre doit être connecté au réacteur!

NE PAS OUVRIR le boîtier de commande; cela annulerait la garantie!

52

Page 53

2.2.3. Mise en place de la lampe UV

• Déballez la lampe UV et essuyez-la avec un chiffon propre (ne la touchez pas avec

les doigts)

• Introduisez la lampe dans la tête jusqu’à l’enclenchement des pattes transparen tes (en introduisant la lampe, pressez légèrement les pattes entre deux doigts; voir

figure 1 page 52)

Vérifiez tous les points importants de la notice d’utilisation avant la

mise en service.

3.1. Système avec électrovanne

• Dévissez la tête (deux tours)

• Ouvrez le robinet d’arrêt du circuit d’eau

• L’air s’échappe par la tête. Laissez la tête ouverte jusqu’à ce que de l’eau en sorte.

Rebloquez la tête. Attention aux éclaboussures!

• Mettez le système UV en service. Branchez le câble sur la prise de courant.

L’écran affiche:

3. Mise en service

Sample Proxima

53

F

Page 54

• Appuyer sur le bouton de réinitialisation environ 10 secondes après avoir mis le

système sous tension jusqu’à ce qu’un signal soit audible

• Le système est en phase de préchauffage. Au bout de 5 minutes, l’électrovanne

est sous tension et complètement ouverte.

• Ouvrez le robinet d’arrêt lentement mais complètement. Parallèlement, ouvrez un

robinet d’eau pour que le reste de l’air s’échappe.

3.1.1. Système sans électrovanne

• Ouvrez un robinet d’eau

• Ouvrez lentement le robinet principal du circuit d’eau jusqu’à ce qu’il n’y ait plus

d’air dans le système

• Branchez le câble sur la prise de courant. L’écran du système Proxima ou Maxima

affiche 365 jours

• Appuyez sur le bouton de réinitialisation pendant environ 20 secondes après la

mise sous tension (Proxima, Maxima)

• Le système est en phase de préchauffage. Au bout de 5 minutes, l’intensité est

maximale et le système est prêt à fonctionner.

Le fonctionnement de la lampe

peut être contrôlé à travers le

capuchon transparent.

Tous les systèmes UV ne doivent être mis sous tension uniquement si le

réacteur est rempli d’eau.

54

Page 55

3.2. Contrôle d’étanchéité

4. Logiciel

Les appareils Aquada (Proxima & Maxima) sont équipés d’un système de surveillance piloté par un microcontrôleur. L’appareil Aquada Altima est équipé d’un

contrôle de fonctionnement visuel (paragraphe 3.1.1.)

• Après la mise en service initiale, 365 est affiché sur l’écran et le voyant lumineux

«jours d’utilisation» est allumé (Proxima, Maxima)

• Appuyez sur le bouton de réinitialisation pendant environ 10 secondes

(juste après la mise sous tension)

• Le temps d’initialisation est de 5 minutes

• Le système est alors prêt à fonctionner et l’électrovanne de sortie est sous tension

• L’écran de la version Maxima alterne entre l’affichage des jours d’utilisation et

l’affichage de l’intensité UV à 2 secondes d’intervalle. L’écran de la version Proxi ma affiche en permanence le nombre de jours d’utilisation.

• En fonctionnement normal, l’intensité est indiquée par „HI“ sur l’écran

• L’écran affiche toujours le nombre de jours d’utilisation restants

Après la mise en service, il faut vérifier l’étanchéité de tous les

raccords vissés.

ITT Water & Wastewater ne saurait être tenu responsable de

dégâts occasionnés par l’eau.

55

F

Page 56

4.1. Messages d’alarme

Lesmessagesd’alarmesuivantspeuvents’afficherencoursdefonctionnement:

AL1 » Panne de lampe UV

AL2 » Intensité UV inférieure à 55 % de la valeur de consigne

AL3 » Fin de vie de la lampe (jours d’utilisation = 0)

AL4 » Intensité comprise entre 55 % et 70 % de la valeur de consigne

AL5 » Durée de vie restante de la lampe UV < 30 jours

Alarme 1

• La lampe UV ne s’est pas allumée

• La lampe UV est défectueuse

• Le voyant de panne de lampe est allumé

» Vérifiez la connexion de la lampe UV

» Retirez le chapeau transparent comme indiqué et remettez-le en place

» Installez une lampe UV neuve

» Faites vérifier le ballast par un technicien qualifié

Alarme 2

• La gaine de quartz est sale

• Le capteur est sale

• Lampe UV en fin de vie (à cause de cycles marche-arrêt fréquents)

• Le matériel a fonctionné trop longtemps sans débit d’eau

(échauffement du réacteur)

• Le câblage de la lampe à filament est en face de la fenêtre du capteur

» Démontez la gaine de quartz comme indiqué au paragraphe 2.1.2.1. et nettoyez la avec le produit de nettoyage

» Démontez le capteur et nettoyez la fenêtre du capteur

» Évitez les cycles marche-arrêt fréquents car l’appareil a été conçu pour un service

continu

» Mettez le système hors tension et laissez-le refroidir

» Tourner le connecteur transparent de la lampe de 45°

Alarme 3

• Lampe UV en fin de vie

56

Page 57

» Installez une lampe neuve (utilisez exclusivement des pièces de rechange WEDECO

d’origine)

Alarme 4

• Vieillissement normal de la lampe UV (la désinfection est toujours assurée)

• Nettoyez la lampe à bref délai

• Le câblage de la lampe à filament est en face de la fenêtre du capteur

» Les conditions normales de fonctionnement peuvent être établies en nettoyant

l’appareil

» Sur l’écran, „HI“ est remplacé par „LO“ (Maxima seulement)

» Tourner le connecteur transparent de la lampe de 45°

Alarme 5

• Fin de vie de la lampe dans 30 jours

» Commandez une lampe UV neuve

4.2. Nouvelle mise en service après le remplacement

de la lampe UV

Après chaque remplacement de la lampe UV, il faut

nettoyer la gaine de quartz et le capteur. Le réacteur

doit être nettoyé lorsque le besoin s’en fait sentir.

Pour une nouvelle mise en service du système, procédez de la même manière que pour la première mise

en service. Lorsque vous appuyez sur le bouton de

réinitialisation (pendant 10 secondes), juste après la

mise sous tension, le compteur de jours est remis à

365 et l’appareil est réinitialisé.

Tous les messages d’alarme sont accompagnés d’un signal sonore.

Appuyez sur le bouton de réinitialisation pour faire cesser ce signal.

57

F

Page 58

5. Vue éclatée

1 » boîtier de commande

2 » réacteur

3 » gaine de quartz

4 » lampe UV

5 » pièce de tête

6 » joint torique (tête)

7 » connecteur transparent

de lampe

8 » joint torique (gaine de

quartz)

9 » capteur UV

10 » connecteur du capteur UV

11 » collier de fixation du

boîtier de commande

12 » collier de fixation du

réacteur

13 » collier de fixation du

réacteur

58

Page 59

6. Liste des pièces de rechange

Rev. Fabricant Description

760054 Boitier électrique AQUA 1 Altima

760055 Boitier électrique AQUA 2 & 4 Altima

760056 Boitier électrique AQUA 7 & 10 Altima

760057 Boitier électrique AQUA 1 Proxima

760058 Boitier électrique AQUA 2 & 4 Proxima

760059 Boitier électrique AQUA 7 & 10 Proxima

760060 Boitier électrique AQUA 1 Maxima

760061 Boitier électrique AQUA 2 & 4 Maxima

760062 Boitier électrique AQUA 7 & 10 Maxima

703321 Gaine de Quartz 25 x 1,3 x 360 (inclus joint)

703322 Gaine de Quartz 25 x 1,3 x 560 (inclus joint)

703323 Gaine de Quartz 25 x 1,3 x 910 (inclus joint)

37085 Lampe UV NLR 1825 WS (Aquada 1)

37086 Lampe UV NLR 1845 WS (Aquada 2 & 4)

37087 Lampe UV NLR 1880 WS (Aquada 7 & 10)

36538 Joint torique pour connecteur 46 x 1,5

35492 Pièce de tête

Ø 48 x 40 PBT Crastin S 600

37126 Joint torique pour gaine de quartz 24,77 x 5,33 FPM

703324 Connecteur de lampe + Câble Ölflex 5 x 0,75 mm² 1,5 m

37250 Capteur UV (inc. joint torique)

37155 Cable d‘alimentation (Europe)

36623 réacteur R1 (304)

36622 réacteur R2 (304)

36621 réacteur R4 (304)

36620 réacteur R7 (316 L)

36619 réacteur R10 (316 L)

36628 réacteur (Capteur) R1 (304)

36627 réacteur (Capteur) R2 (304)

36626 réacteur (Capteur) R4 (304)

36625 réacteur (Capteur) R7 (316 L)

36624 réacteur (Capteur) R10 (316 L)

59

F

Page 60

Page 61

61

WEDECO Aquada

GB

DE

F

Installation and Maintenance Instructions

Installations- und Wartungsanleitung

Notice d’installation et de Maintenance

I

Istruzioni di Installazione e Manutenzione

Page 62

Contenuti

1. Generale&Applicazioni

2. AssemblaggioedInstallazione

2.1. Reattore

2.1.1. Assemblaggio del reattore

2.1.2. Installazione del tubo in quarzo e della lampada UV

2.1.2.1. Pulizia e sostituzione del tubo in quarzo

2.1.2.2. Installazione del sensore UV (solo per modello Maxima)

2.1.3. Connessioni al circuito idaulico esistente

2.2. Sistemadicontrollo

2.2.1. Assemblaggio dell’unità di controllo

2.2.2. Collegamenti elettrici

2.2.3. Collegamento della lampada UV

3. Collaudo

3.1. Unità con valvola solenoidale

3.1.1. Unità senza valvola solenoidale

3.2. Test di tenuta idraulica

4. Software

4.1. Messaggi di allarme

4.2. Nuova accensione dopo la sostituzione della lampada UV

5. Diagrammaesploso

6. Garanzia

7. Dichiarazionediconformità(pagina82)

ATTENZIONE:

Leggere attentamente il manuale e seguire le istruzioni contenute in esso.

Si consiglia di far eseguire l’installazione solo da personale autorizzato.

62

Page 63

1. Generale & Applicazioni

La disinfezione per mezzo della luce ultravioletta (UV) è un processo economico e particolarmente rispettoso dell’ambiente.

La luce UV, infatti, uccide i microorganismi patogeni nel giro di poche secondi, senza

lasciare alcun residuo, pericolosi sottoprodotti o sapori ed odori di alcun genere. Grazie

a questo specifico meccanismo di azione, viene anche scongiurato per gli operatori il

pericolo di esposizione e utilizzo di prodotti chimici pericolosi.

L’effetto della luce UV si esplica per mezzo della radiazione UV-C (254 Nm). Questa

radiazione, nel giro di pochi secondi, permette di ottenere una reazione fotochimica

distruttiva nel DNA (acido desossiribonucleico), elemento vitale per i microorganismi.

Questo permette di distruggere completamente tali microrganismi oppure di impedirne

la capacità riproduttiva.

La quantità di microorganismi uccisi dipende essenzialmente dalla radiazione UV minima

applicata (dose UV: ovvero il tempo che un determinato microrganismo viene esposto ad

una certa intensità di radiazione UV (W/m²). Con una dose UV di 400 J/m², le più importanti specie patogene ed i principali virus vengono ridotti di 4 log (esponenete decimale),

il che corrisponde a rispettare i dettami degli standard internazionali e ad assicurare una

sicura disinfezione.

La performance di disinfezione di un sistema UV è essenzialmente basata sul fatto che

ciascun elemento in volume (di acqua da trattare) riceva la necessaria dose UV durante il

passaggio all’interno del reattore UV. Per assicurare quanto appena detto, ogni sistema

UV WEDECO viene progettato per la ottimizzazione sia della geometria del campo di

radiazione, sia dell’idraulica di flusso.

La radiazione UV delle acque potabili, utilizzando i dosaggi adeguati per la disinfezione,

non causa alcuna reazione secondaria indesiderata. Dal momento che, utilizzando la

radiazione UV, non vengono aggiunte sostanze chimiche al processo di disinfezione,

viene anche scongiurata la possibilità di formazione di depositi durante il passaggio

dell’effluente attraverso il volume di radiazione (camera di reazione UV in acciaio inox).

ATTENZIONE:

Il corretto funzionamento (performance di disinfezione) può

essere garantito soltanto utilizzando pezzi di ricambio originali

WEDECO (lampade, ballasts, etc.).

Per ulteriori informazioni contattare::

www.wedeco.com

Tel.: +39 080-5910518

Fax : +39 080-5910514

63

I

Page 64

Istruzioni Generali di Sicurezza

SHOCK ELETTRICO!

Attenzione – scarica elettrica pericolosa. Il mancato rispetto di questa

prescrizione potrebbe provocare seri infortuni alle persone.

ASSICURARSI DI INDOSSARE PROTEZIONI PER GLI OCCHI!

IMPORTANTE!

Istruzioni per suggerimenti utili o informazioni di altro genere.

ATTENZIONE!

La radiazione UV-C è pericolosa per gli occhi e per la pelle! Le lampade UV

dovrebbero essere utilizzate soltanto all’interno della camera di irradiazione dopo aver fissato l’apposito cappuccio di protezione. Vietato esporsi

direttamente alla radiazione UV-C.

• Assicurarsi che l’unità di disinfezione sia utilizzata esclusivamente per lo scopo

proposto, così come descritto nelle istruzioni d’uso. L’uso di apparecchi

addizionali, di cui non se ne sia consigliato l’uso e che non siano commercializzati

da WEDECO potrebbero causare inefficienza delle performance di disinfezione.

• L’unità di disinfezione proposta deve essere installata in modo appropriato, se guendo le istruzioni di funzionamento indicate nel presente manuale, prima di

essere utilizzata

• Non utilizzare unità di disinfezione con apparati elettrici parzialmente danneggiati,

o funzionanti non al pieno delle potenzialità, oppure danneggiati in alcuni suoi

componenti più in generale

• Assicurarsi che l’unità sia scollegata elettricamente in caso di non utilizzo o prima

dell’installazione, o durante la sostituzione di qualsiasi componente, oppure

durante la pulizia. Non rimuovere la spina dalla presa elettrica tirando il condu tore isolato, estrarre la spina dalla presa agendo direttamente su di essa.

64

Page 65

• Assicurarsi che l’unità di disinfezione sia elettricamente isolata prima di:

A. Effettuare riparazioni

NOTA:

WEDECOraccomandadifareffettuarelemanutenzionisolodapersonale

qualificato.

B. Effettuare la pulizia periodica

C. Sostituire la lampada UV

• L’unità UV deve essere depressurizzata prima della manutenzione

• Non utilizzare la lampada UV al di fuori della camera di disinfezione

I sistemi UV equipaggiati con valvola solenoidale, non dovrebbero essere usati in assenza di flusso per lunghi periodi (max.

48 ore). In casi di arresti di flusso superiori alle 48 ore, il sistema

dovrebbe essere spento.

Le lampade WEDECO UV sono progettate per funzionamento in

continuo, al fine di assicurare le migliori performance di disinfezione. Frequenti cicli di accensione e spegnimento riducono la

vita utile delle lampade!

Max. 200 accensioni e spegnimenti!

65

I

Page 66

2. Assemblaggio ed Installazione

Verificare i seguenti punti prima dell’installazione:

• Non superare la massima pressione di funzionamento 1000 K Pa (10 bar)

• Massima temperatura ambiente 40° C

• Massima temperatura acqua 25° C

• Non superare la massima portata di progetto (vds. sezione 2.1.)

• Il luogo di installazione del reattore UV deve essere asciutto e protetto dal freddo

2.1. Reattore

La serie AQUADA contempla i seguenti tipi di reattori:

*

Portata: 400 J/m2, Trasmissione UV: 94 %

Assicurarsi che siano rispettati gli standard nazionali e le prescrizioni per l’assemblaggio e l’installazione. L’installazione dovrebbe essere effettuata solo da tecnici qualificati.

Tipo Lunghezza Diametro Connessioni„Spazio min. dispon. al

di sopra del reattore

Portata Max.

m

3

/h

1 470 mm 70 mm R 1/2 370 mm 0,70

2 670 mm 70 mm R 3/4 570 mm 1,77

4 670 mm 101,6 mm R 3/4 570 mm 3,01

7 1030 mm 101,6 mm R1 920 mm 6,20

10 1030 mm 140 mm R1 1/2 920 mm 9,00

66

Page 67

2.1.1. Assemblaggio del reattore

• Prima dell’installazione assicurarsi del tipo di reattore che si sta utilizzando.

(l’informazione del tipo di reattore è reperibile sulla targhetta di identificazione)

• Assicurarsi che ci sia spazio sufficiente al di sopra del reattore (per le dimensioni

vedere la sezione 2.1.), altrimenti non sarà possibile installare la lampada UV ed

effettuare le manutenzioni

• Il reattore deve essere fissato tramite le apposite staffe o a muro o su speciale

supporto

• Le unità dotate di sensore UV devono necessariamente essere istallate in posizione

verticale

• Il reattore assemblato deve essere protetto dalla esposizione al freddo

Lampada UV

Uscita

Sensore UV (opzione)

Quadro di controllo

Ingresso

67

I

Page 68

2.1.2. Installazione del tubo in quarzo e della

lampada UV

Il reattore è fornito unitamente ad un tubo in quarzo già assemblato. L’apposito

alloggiamento nero all’interno del quale deve essere inserita la lampada UV è stato

già fissato con una coppia di 5 Nm. Prima del collaudo, verificare la tenuta idraulica

di tutte le connessioni.

PerinstallarelalampadaUVvederelasezione2.2.3.

2.1.2.1. Pulizia e Sostituzione del tubo in quarzo

La presa trasparente di connessione della lampada UV deve essere girata lievemente o verso sinistra oppure verso destra (fino al punto di incastro con il pezzo

capo lampada) e poi rimossa.

Rimuovere la lampada UV dal reattore spingendo le due linguette di fissaggio

trasparenti. Svitare il pezzo capo lampada dal reattore e poi rimuoverlo con cautela

unitamente al tubo in quarzo.

Rimuovereogniresiduodaitubiinquarzoerimontareilsistemadopoaverpulito

internamenteancheilreattore.

Il tubo in quarzo ed il pezzo capo lampada sono componenti

indipendenti. In caso di smontaggio, reggere entrambi i componenti per evitare lo scivolamento del tubo in quarzo al di fuori

del pezzo capo lampada!

reattore

O-ring

filamenti elettrici lampada

Tubo in quarzo

Capo lampada Linguette di fissaggio

Lampada UV

O-ring

68

Page 69

Montaggio: introduzione

Pulire anche la lampada UV

prima di effettuare il nuovo

assemblaggio. Inserire quindi

la lampada UV dall’alto attraverso il pezzo capo lampada

fino a che le due linguette

di fissaggio trasparenti della

presa di connessione non

siano ben incastrate negli

appositi alloggiamenti del

pezzo capo lampada.

Dopo l’assemblaggio della

lampada UV, la presa di

connessione trasparente deve

essere fissata al pezzo capo

lampada. Assicurarsi che

la stessa sia perfettamente

incastrata negli appositi

alloggiamenti.

(Vedere la guida grafica sotto

riportata).

Il connettore trasparente

della lampada deve essere

adeguatamente incastrato

nella guida del pezzo capo

lampada.

Questa figura schematizza

il connettore trasparente

della lampada incastrato

all’interno della guida.

Capo lampada Lampada UV

Inserire la presa di

connessione sul pezzo di

testa fino a farla incastrare al

suo interno.

La presa di connessione è

installata correttamente. Non

è possibile estrarla tirandola

via verso l’esterno dal pezzo

capolampada.

Lampada UV

Connessione traspa-

rente lampada

Capo lampada

Presa di connessione trasparente

69

I

Page 70

2.1.2.2. Fissaggio del sensore UV

Il sensore UV viene già preventivamente fissato in fabbrica all’interno della camera

di reazione (solo per modelli Maxima) per i collaudi interni. E’ quindi solo necessario

svitarlo per normale manutenzione. La guarnizione di tenuta dovrebbe essere rimossa non a mano, ma solo usando un apposito arnese leggero. E’ sufficiente applicare

una coppia di torsione di circa 5 Nm. Assicucarsi di non superare questo valore

della coppia di torsione, altrimenti si potrebbe danneggiare la finestra di quarzo del

sensore.

Per evitare rotture, si consiglia di non rimuovere il disco di fissaggio del cristallo in

quarzo (interno al sensore) durante la pulizia. Il disco di fissaggio del cristallo dovrebbe essere pulito semplicemente con un panno soffice ed asciutto.

2.1.3. Connessione al circuito idraulico esistente

• Durante questa fase, assicurarsi anzitutto di poter disporre di valvole di arresto del

circuito a monte ed a valle del punto di alloggiamento del reattore UV, in modo

da escluderlo in caso di evenienza e per facilitare la manutenzione