ITT SSV User Manual

ITT

Goulds Pumps

G&L SERIES

MODEL SSV

Installation, Operation and

Maintainence Instructions

Commercial Water

Goulds Pumps is a brand of ITT Water Technology, Inc.

- a subsidiary of ITT Industries, Inc.

www.goulds.com

Engineered for life

SUBJECT PAGE

SSV Product Line Numbering System ............................................................................................................................3

Safety Instructions .........................................................................................................................................................5

Overview .......................................................................................................................................................................5

Product Description.......................................................................................................................................................5

Applications ..................................................................................................................................................................5

Pre-Installation Checks ..................................................................................................................................................5

Transportation and Storage ............................................................................................................................................6

Installation ....................................................................................................................................................................7

Start-Up .........................................................................................................................................................................9

Operation ....................................................................................................................................................................10

Maintenance................................................................................................................................................................10

Mechanical Seal Replacement (Sizes 1SV-4SV) ............................................................................................................10

Mechanical Seal Replacement (Sizes 33SV-92SV) ........................................................................................................11

Mechanical Seal Replacement (Sizes 33SV-92SV) Fitted with Cartridge Seals ..............................................................13

Motor Replacement .....................................................................................................................................................13

Troubleshooting ..........................................................................................................................................................13

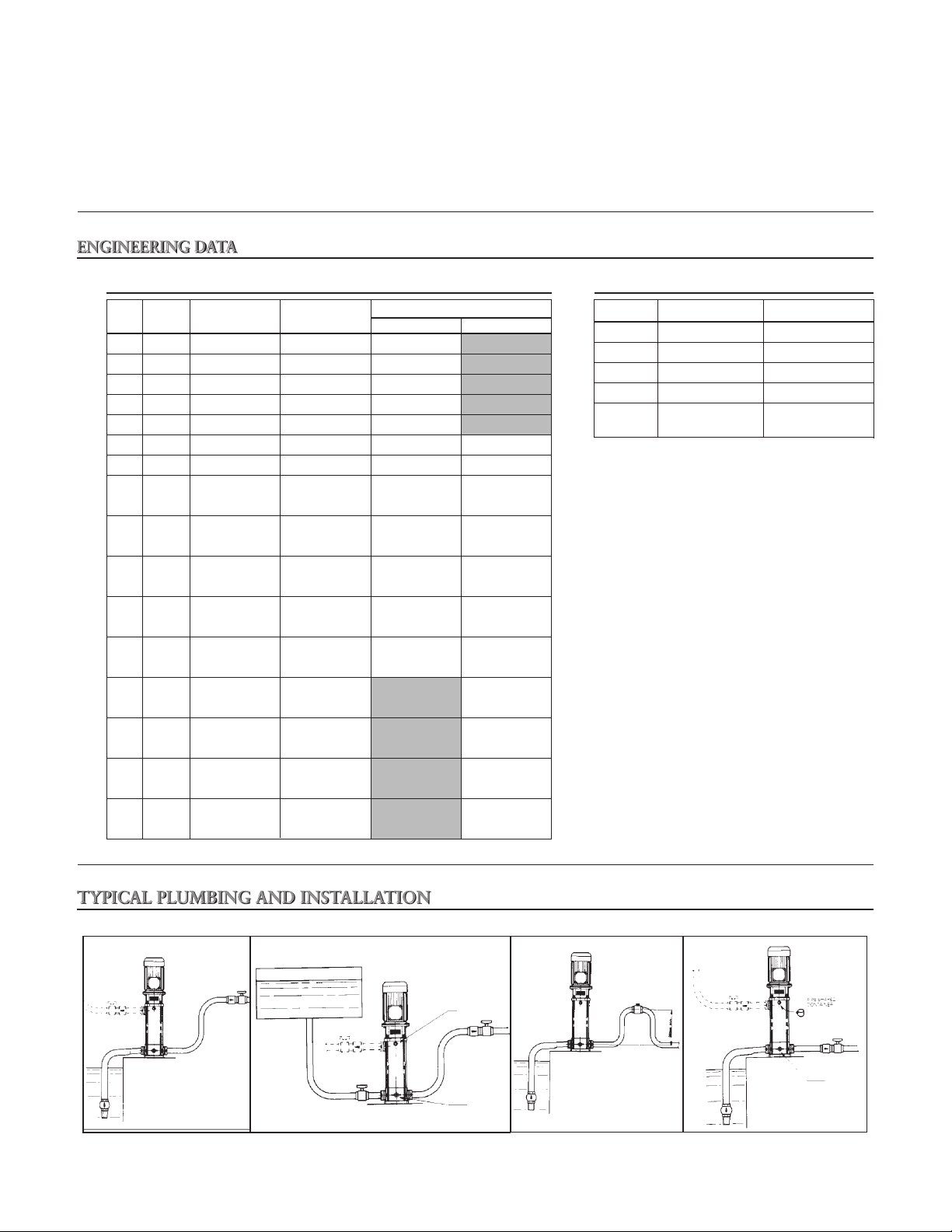

Engineering Data .........................................................................................................................................................14

Typical Plumbing and Installation ................................................................................................................................14

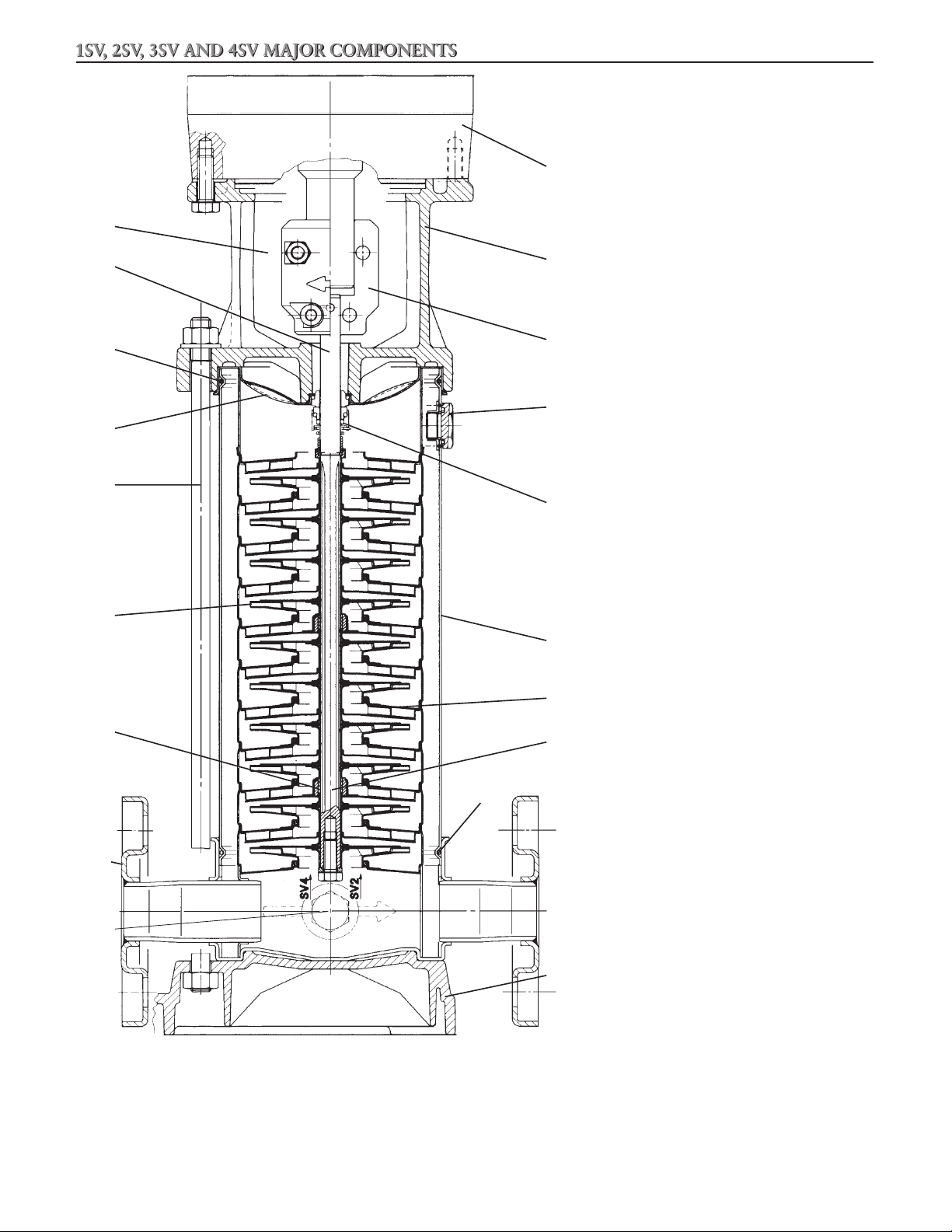

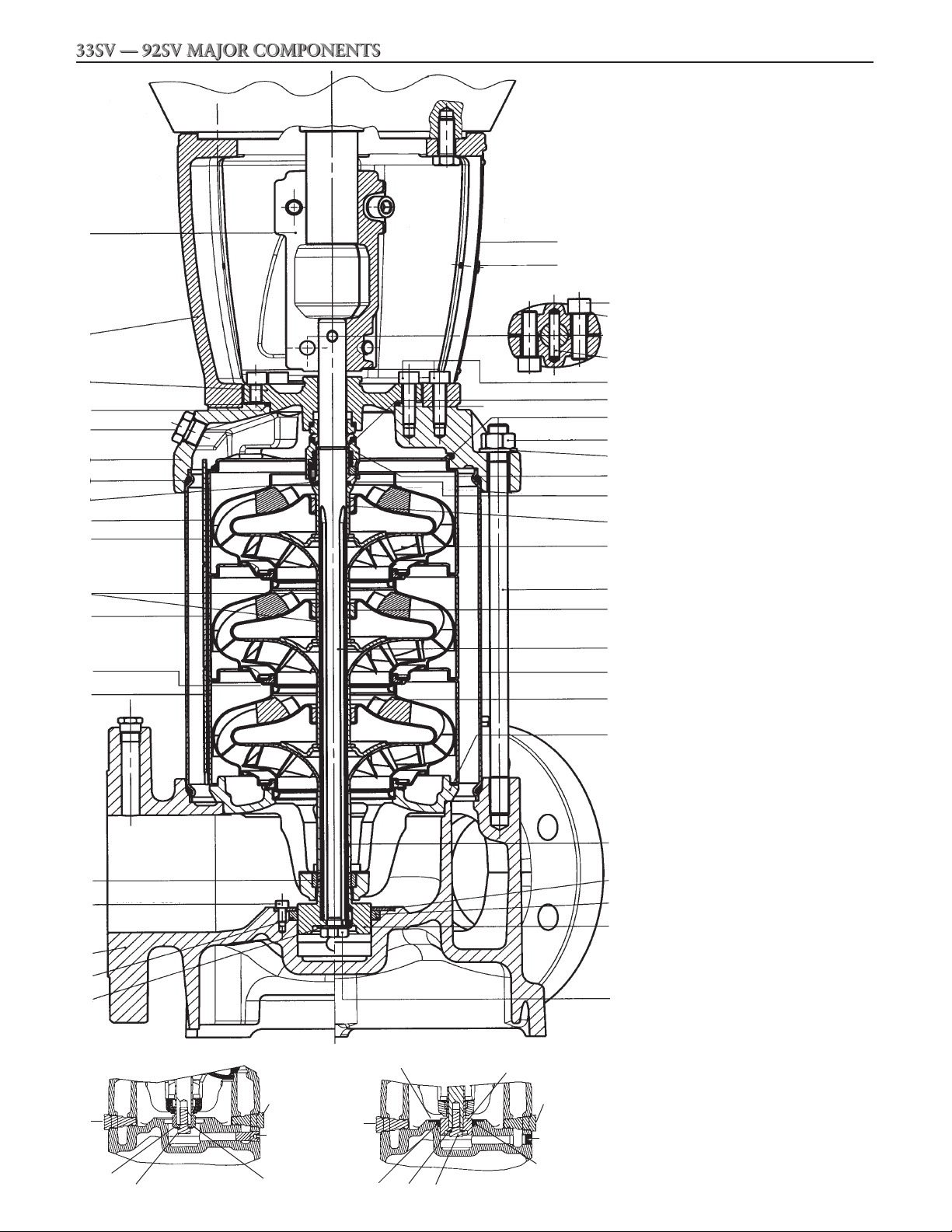

SSV Major Components ..............................................................................................................................................15

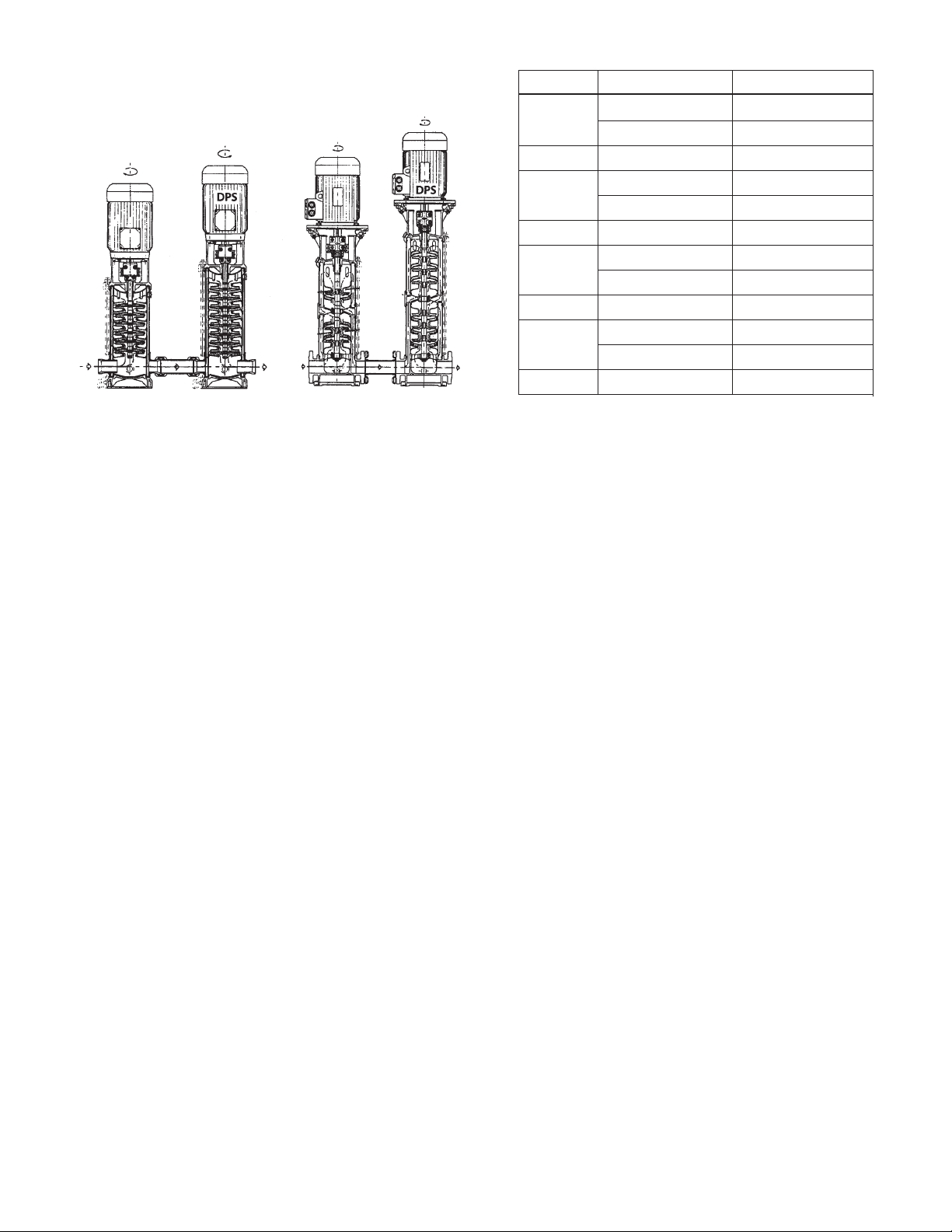

DPS Versions ...............................................................................................................................................................17

Limited Warranty ........................................................................................................................................................18

Declaration of Conformity ..........................................................................................................................................56

Pump Model Number:

Pump Serial Number:

Control Model Number:

Dealer:

Dealer Phone No.:

Date of Purchase: Installation:

Current Readings at Startup:

1 Ø 3 Ø L1-2 L2-3 L3-1

Amps: Amps:

Volts: Volts:

2

SERIES/SÉRIE/SERIES

1SV 3SV 33SV 66SV

2SV 4SV 46SV 92SV

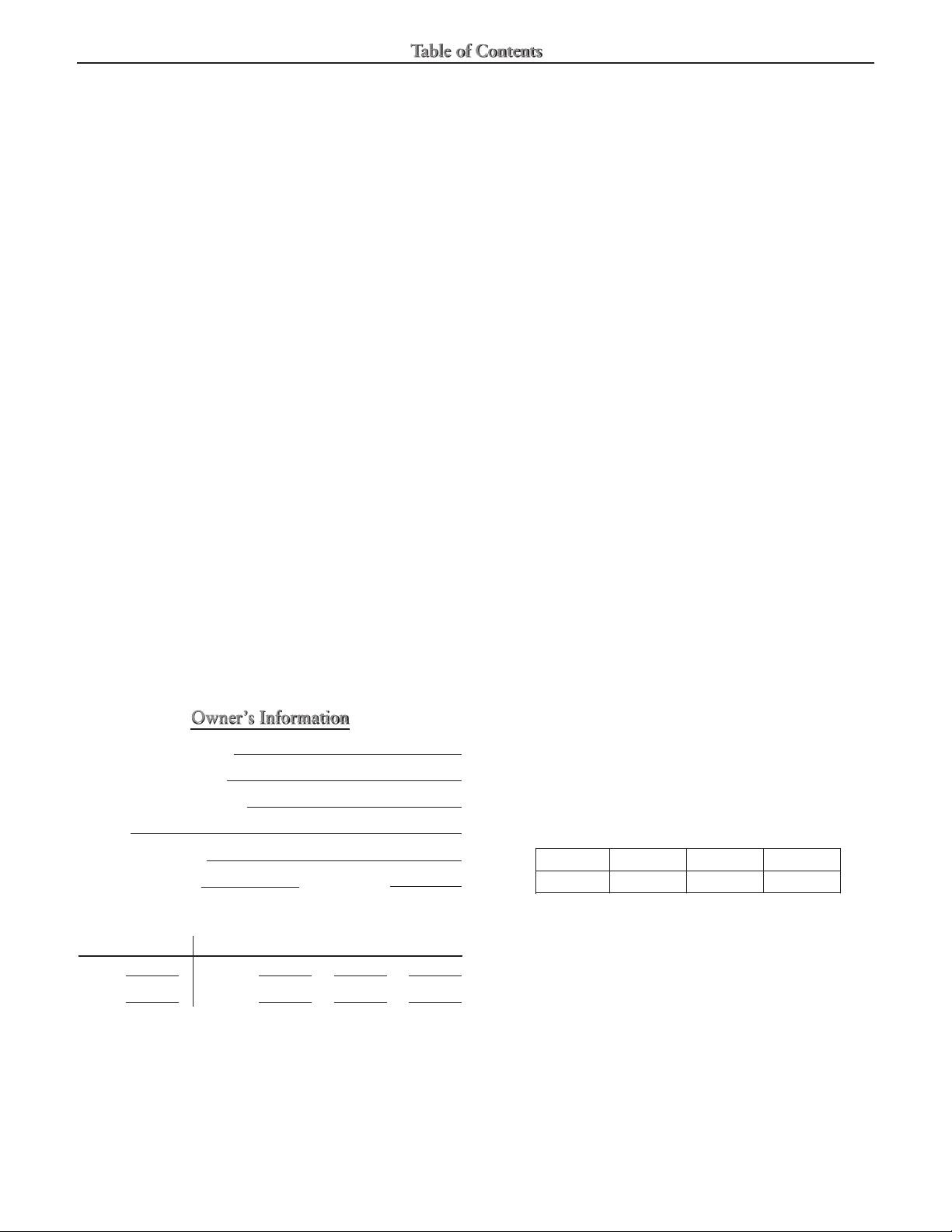

SSV PRODUCT LINE NUMBERING SYSTEM

The various versions of the SSV line are identified by a product code number on the pump label. This number is also the catalog number for the pump. The

meaning of each digit in the product code number is shown below. Note: Not all combinations are possible. Consult your G&L Pumps distributor.

MODEL NOMENCLATURE (Sizes 1SV - 4SV)

2 SV A 1 D 2 B 0 H EXAMPLE PRODUCT CODE

➤

H = Horizontal Mount VIC = Victaulic Connection (1SVB/D – 4SVB/D only)

Mechanical Seal Options:

Code No. Rotary Stationary Elastomer Reference Application

High

0 Temperature

Carbon Silicon Viton

Silicon Carbide

4

Graphite Filled

High Filled

6

Carbon

Temperature EPR Boiler Feed

Carbide

Graphite

Number of Stages:

B = 2 F = 6 K = 10 P = 14 V = 20

C = 3 G = 7 L = 11 Q = 15 X = 22

D = 4 H = 8 M = 12 R = 16 Z = 24

E = 5 J = 9 N = 13 T = 18

Driver:

(50 Hz, no single phase number 0, 1, 4)

1 = 1PH ODP 5 = 3PH TEFC 9 = 3PH TEFC with premium efficiency

2 = 3PH ODP 6 = 575V TEFC 0 = 1PH XP

3 = 575V ODP 7 = 3PH XP

4 = 1PH TEFC 8 = 575V XP

General

Service

Abrasive

HP Rating:

C = ½ F = 1½ J = 5 M = 15

D = ¾ G = 2 K = 7½ N = 20

E = 1 H = 3 L = 10 P = 25

Hertz/RPM:

1 = 60 Hz/3500 RPM 4 = 50 Hz/2900 RPM, 460 V

2 = 50 Hz/2900 RPM,

3 = 60 Hz/3500 RPM, 380 V 6 = 60 Hz/3500 RPM,

190-380 V, (50 Hz motor)

5 = 60 Hz/3500 RPM,

220-380 V, D.O.L.

380 V, Y-DELTA

Material and Suction/Discharge:

A = 304 stainless steel, in-line NPT threaded oval flange connections (1, 2, 3 only)

B = 304 stainless steel, in-line ANSI flange (1, 2, 3, 4SV)

C = 304 stainless steel, top/bottom ANSI flange connections

D = 316 stainless steel, in-line ANSI flange

Product Line: Stainless Vertical

Nominal Flow:

1 = 15 GPM 3 = 55 GPM

2 = 28 GPM 4 = 86 GPM

Always specify the unit model and catalog number from pump nameplate when service or

technical assistance is required.

NOTICE: INSPECT UNIT FOR DAMAGE AND REPORT ALL DAMAGE TO THE CARRIER

OR DISTRIBUTOR/DEALER IMMEDIATELY.

3

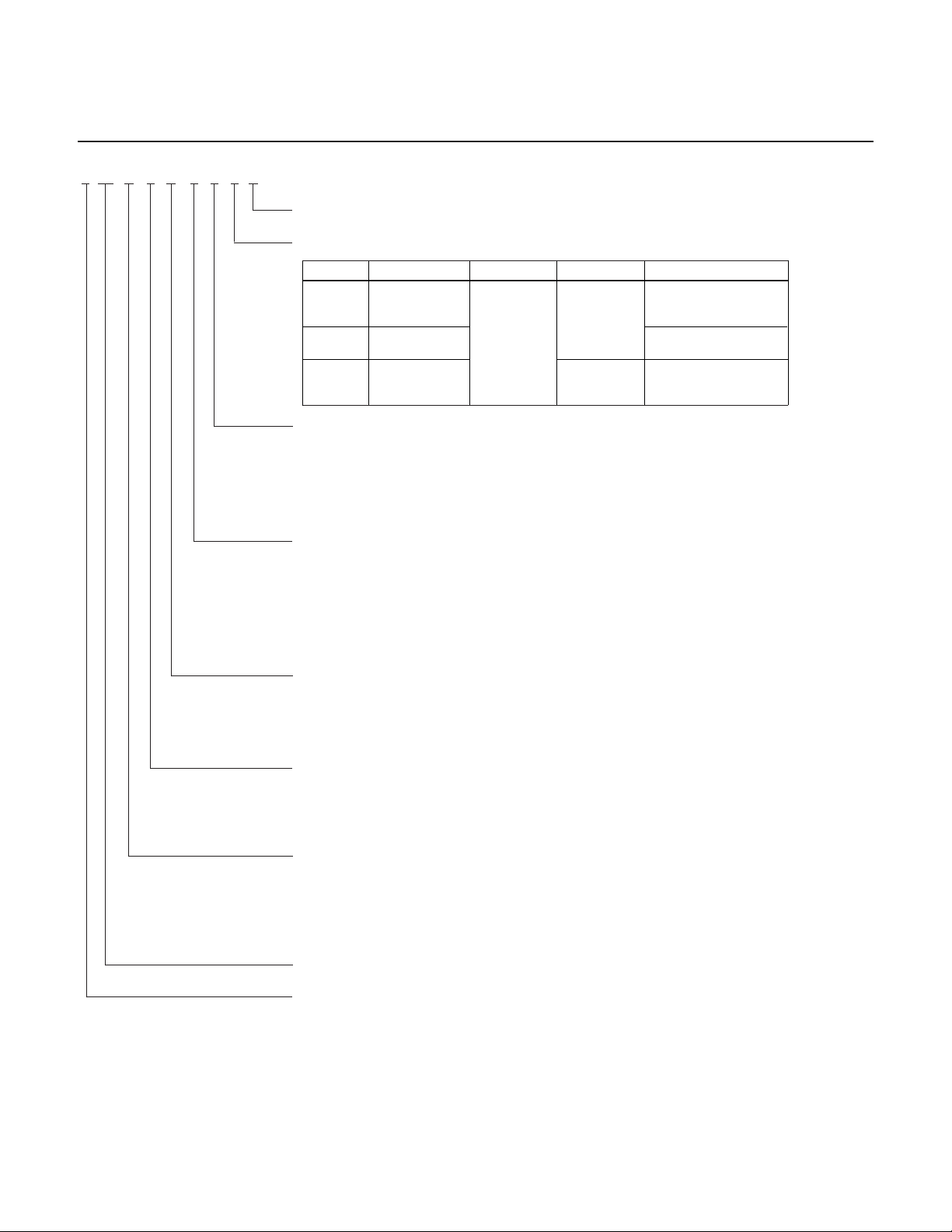

SSV PRODUCT LINE NUMBERING SYSTEM

MODEL NOMENCLATURE (Sizes 33SV - 92SV)

The various versions of the SSV line are identified by a product code number on the pump label. This number is also the catalog number for the pump. The

meaning of each digit in the product code number is shown below. Note: Not all combinations are possible. Consult your G&L Pumps distributor.

➤

33 SV B G 1 2 R 6 T A H

EXAMPLE PRODUCT CODE

Pump Options (optional):

H = Horizontal mounting D = High Pressure Pump (DPS)

Q= 1.0 Service Factor Version (AQ) T = Alternative Motor Frame

Seal Options:

Code No. Rotary Stationary Elastomers

A

Mechanical Seal

C

D EPR

Cartridge Seal

P Silicon Carbide Aflas

– Metal parts on all seals are 316SS.

– Silicon carbide is graphite filled.

B EPR

Silicon Carbide Silicon Carbide

L Carbon Viton

Viton

Carbon

Viton

Motor Enclosure:

D = ODP T = TEFC

X = Explosion Proof P = TEFC Premium Effy

Motor Voltage:

1 = 115/230 3 = 230/460 5 = 575 7 = 200

2 = 230 4 = 460 6 = 208-230/460 8 = 190/380

HP Rating:

G = 2 HP M = 15 HP S = 50 HP

H = 3 HP N = 20 HP T = 60 HP

J = 5 HP P = 25 HP U = 75 HP

K = 7½ HP Q = 30 HP

L = 10 HP R = 40 HP

Motor Hertz/Speed/Phase:

1 = 60 Hz/3500/1 4 = 60 Hz/1750/3 7 = 50 Hz/1450/1

2 = 60 Hz/3500/3 5 = 50 Hz/2900/1 8 = 50 Hz/1450/3

3 = 60 Hz/1750/1 6 = 50 Hz/2900/3 9 = 60 Hz/Variable/3

Number of Reduced Impellers (can be 0, 1, 2) *

Total Bowls/Stages:

A = 1 E = 5 J = 9

B = 2 F = 6 K = 10

C = 3 G = 7

D = 4 H = 8

Flange Orientation:

B = Cast Iron/316 stainless steel, in-line ANSI flange

D = 316 stainless steel, in-line ANSI flange

Product Line:

Stainless Vertical Vertical

Nominal Flow:

33 = 150 GPM 66 = 350 GPM

46 = 225 GPM 92 = 450 GPM

* NOTE: Indicates number of reduced diameter impellers in the total staging.

(Two would indicate 2 reduced diameter impellers.)

4

SAFETY INSTRUCTIONS

DANGER

WARNING

CAUTION

WARNING

Hazardous fluids

can cause fire,

burns or death.

TO AVOID SERIOUS OR FATAL PERSONAL INJURY

OR MAJOR PROPERTY DAMAGE, READ AND

FOLLOW ALL SAFETY INSTRUCTIONS IN MANUAL

AND ON PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump

or in the manual, look for one of the

following signal words and be alert

to the potential for personal injury or

property damage.

Warns of hazards that WILL cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause personal injury or property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND

MUST BE FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

in contact with the pumped liquid are made of stainless

steel. They are available in different versions according

to the position of the suction and delivery ports and the

shape of the connection flanges. For the sizes 33SV-92SV,

some of the metal parts in contact with the pumped

liquid are made of stainless steel, others are made of

cast iron. A special version is available, in which all the

metal parts in contact with the pumped liquid are made

of stainless steel. If you purchase a pump without the

electric motor, make sure that the motor you use is suitable for coupling to the pump. The 33SV-92SV pumps

are equipped with a special mechanical seal designed

for easy replacement without having to disassemble the

entire pump.

These pumps are suitable for civil and industrial water

distribution systems, pressure booster, irrigation (agriculture, sporting facilities), water treatment, boiler feed,

parts washing, cooling - air conditioning - refrigeration

and fire fighting applications.

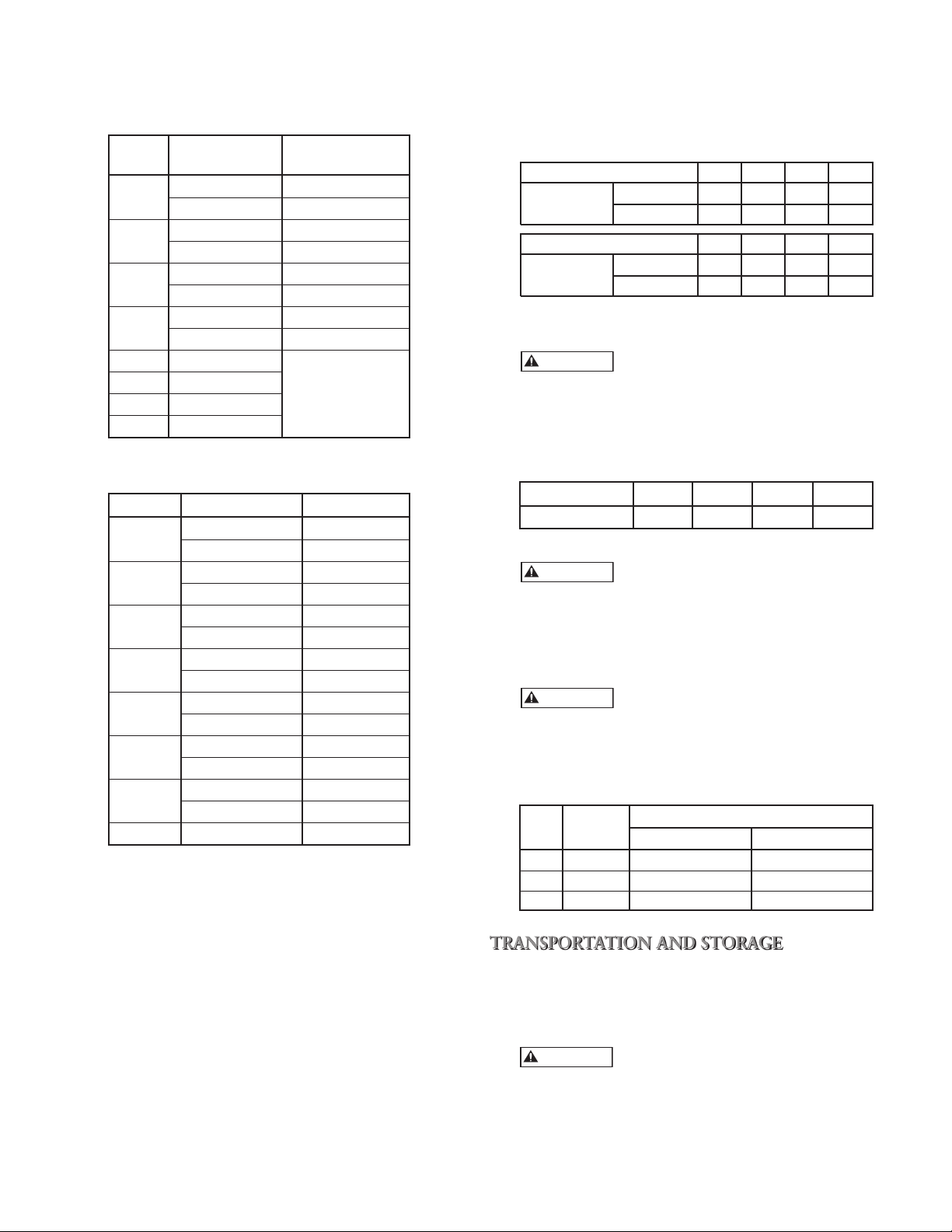

3

2

5

DO NOT OPERATE AT CLOSED DISCHARGE

G&L Pumps

SSV™

CATALOG NUMBER

GPM FEET RPM

Goulds Pumps, ITT Industries, Inc.

1

4

7

8

UNIT NOT DESIGNED FOR USE

WITH HAZARDOUS LIQUIDS OR

FLAMMABLE GASES. THESE

FLUIDS MAY BE PRESENT IN

CONTAINMENT AREAS.

The purpose of this manual is to provide the necessary information for proper installation, operation and

maintenance of the SSV pump. The instructions and

warnings provided below concern the standard version,

as described in the sale documents. Special versions may

be supplied with supplementary instructions leaflets.

Please refer to the sale contract for any modifications or

special version characteristics. Always specify the exact

pump type and identification code when requesting

technical information or spare parts from our Sales and

Service department. For instructions, situations or events

not considered in this manual or in the sale documents,

please contact your distributor.

Read this manual before installing and using the product.

Improper use may cause personal injury and

damage to property and lead to the forfeiture of

the warranty coverage.

The SSV pump is a vertical multistage, non-self priming

pump which can be coupled to standard electric motors.

For the pump sizes 1SV-4SV, all the metal parts that are

6

1 Goulds Pumps Catalog Number

2 Capacity Range

3 TDH Range

4 Rated Speed

5 Rated Horsepower

6 Maximum Operating Pressure

7 Maximum Operating Temperature

8 Pump Serial Number

Confirm that the pump is capable of meeting the desired

operating conditions.

1. MINIMUM INLET (SUCTION) PRESSURE

In general, the minimum suction pressure required

is that which provides adequate NPSHA necessary to

feed the pump. The required NPSHr, expressed in

feet, can be found on the performance curve for the

pump at the specific duty point. It is recommended

that the NPSHA exceeds the NPSHr by a minimum

of (2) two feet as a safety margin and to insure long

term reliable performance of your SSV pump.

PS

= NPSHr + 2 ft.

MIN

NOTE: THE NPSHA MUST BE CALCULATED FOR

THE SPECIFIC SYSTEM TO WHICH THE

SSV PUMP IS TO BE INSTALLED. PLEASE

CONTACT YOUR DEALER/DISTRIBUTOR IF

YOU REQUIRE ASSISTANCE.

5

2. MAXIMUM INLET PRESSURE

WARNING

WARNING

WARNING

WARNING

The following table shows the maximum permissible

inlet pressure. However, the actual inlet pressure +

pressure against a closed valve must always be lower

than the maximum permissible operating pressure.

of Stages Inlet Pressure

Number Maximum

Pump

2-16 Stages 250 psi (17 bar)

1SV

17-22 Stages 250 psi (17 bar)

2-15 Stages 250 psi (17 bar)

2SV

16-22 Stages 250 psi (17 bar)

2-13 Stages 250 psi (17 bar)

3SV

14-16 Stages 250 psi (17 bar)

2-10 Stages 250 psi (17 bar)

4SV

11-12 Stages 250 psi (17 bar)

33SV 1-10 Stages

46SV 1-10 Stages

250 psi (17 bar)

66SV 1-6 Stages

92SV 1-6 Stages

3. MAXIMUM OPERATING PRESSURE

(staging at 3500 RPM)

Series At 250º F PSI / Bar

2-16 Stages 325 / 25

1SV

17-22 Stages 580 / 40

2-15 Stages 325 / 25

2SV

16-22 Stages 580 / 40

2-13 Stages 325 / 25

3SV

14-16 Stages 580 / 40

2-10 Stages 325 / 25

4SV

11-12 Stages 580 / 40

1-6 Stages 362 / 25

33SV

7-10 Stages 580 / 40

1-5 Stages 362 / 25

46SV

6-10 Stages 580 / 40

1-5 Stages 362 / 25

66SV

6 Stages 580 / 40

92SV 1-5 Stages 362 / 25

NOTE: Oval flange (1-3SV) maximum working

pressure is 232 psi (16 bar).

4. TEMPERATURE CAPABILITY

The SSV pump is capable of pumping liquids within

the below temperature range:

1-4SV -22º F to 250º F (-30º C to 120º C)

33SV-92SV -22º F to 250º F (-30º C to 120º C)

NOTE: In order to provide adequate cooling for the

electric motor, the ambient temperature must

be 32º F to 104º F and the relative humidity at

104º F must not exceed 50%.

For temperatures above 104º F and for installations

sites located at elevation in excess at 3000 feet above

sea level it may be necessary to derate the motor

performance. Please contact your distributor/dealer for

assistance.

5. MINIMUM NOMINAL FLOW RATE

To prevent overheating of the internal pump components, make sure that a minimum water flow is

always guaranteed when the pump is running.

For continuous operation the minimum flow rate

recommended is specified below.

Pump Size 1SV 2SV 3SV 4SV

Min. Flow

(gpm)

3500 RPM 3 6 12 17

2900 RPM 3 6 10 14

Pump Size 33SV 46SV 66SV 92SV

Min. Flow

(gpm)

3500 RPM 35 40 70 100

2900 RPM 8 10 14 20

NOTE: If this cannot be archived, then a bypass/

recirculate line is recommended.

Do not run the pump against a closed

discharge for longer than a few seconds.

6. NUMBER OF STARTS PER HOUR

For electric pumps coupled to motors supplied by

Goulds Pumps, the maximum number of work cycles

(starts and stops) in one hour are as follows:

HP

3

/4-3 5-10 15-20 25-75

# of Starts 5 5 5 5

For more details, refer to technical manual.

If you use a different motor from

the standard one supplied by Goulds

Pumps, please consult with the motor manufacturer

to find out the maximum number of work cycles

allowed.

7. POWER SUPPLY REQUIREMENTS

Make sure that the supply voltages

and frequencies are suited to the

characteristics of the electric motor. Check the

motor rating plate.

In general, the supply voltage tolerances for motor

operation are as follows:

Hz Phase

V ±%

N

U

60 1 230 10

60 3 230 / 460 10

60 3 460 10

1. TRANSPORTATION AND HANDLING OF

PACKED PRODUCT

The SSV pump is packed in cartons or wooden

crates having different dimensions and shapes.

Some cartons (the supporting base

is made of wood) are designed to be

transported and handled in the vertical position.

Other cartons, as well as the wooden crates, are

designed to be transported and handled in the horizontal position.

Protect the product against humidity, heat sources and mechanical damage (collisions,

falls, ...). Do not place heavy weights on the cartons.

6

Lift and handle the product carefully,

L1

L3

L2

L4

ø A x N

using suitable lifting equipment. Observe all

the accident prevention regulations.

When you receive the pump, check the outside of

the package for evident signs of damage. If the product bears visible signs of damage, notify our distributor within 8 days from the delivery date.

2. STORING THE PACKED PRODUCT

Ambient temperature 32º F to 104º F.

Short Term: (Less than 6 months) Goulds Pumps

normal packaging procedure is designed to protect

the pump during shipping. Upon receipt, store in a

covered and dry location.

Long Term: (More than 6 months) Rotate shaft

several times every 3 months. Refer to driver and

coupling manufacturers for their long term storage

procedures. Store in a covered dry location.

3. UNPACKING THE PRODUCT

Use suitable equipment. Observe all the

accident prevention regulations in force. Lift

and handle the product carefully, using suitable lifting equipment.

When you receive the pump, check the outside of

the package for evident signs of damage. If the product bears visible signs of damage, notify our distributor within 8 days from the delivery date.

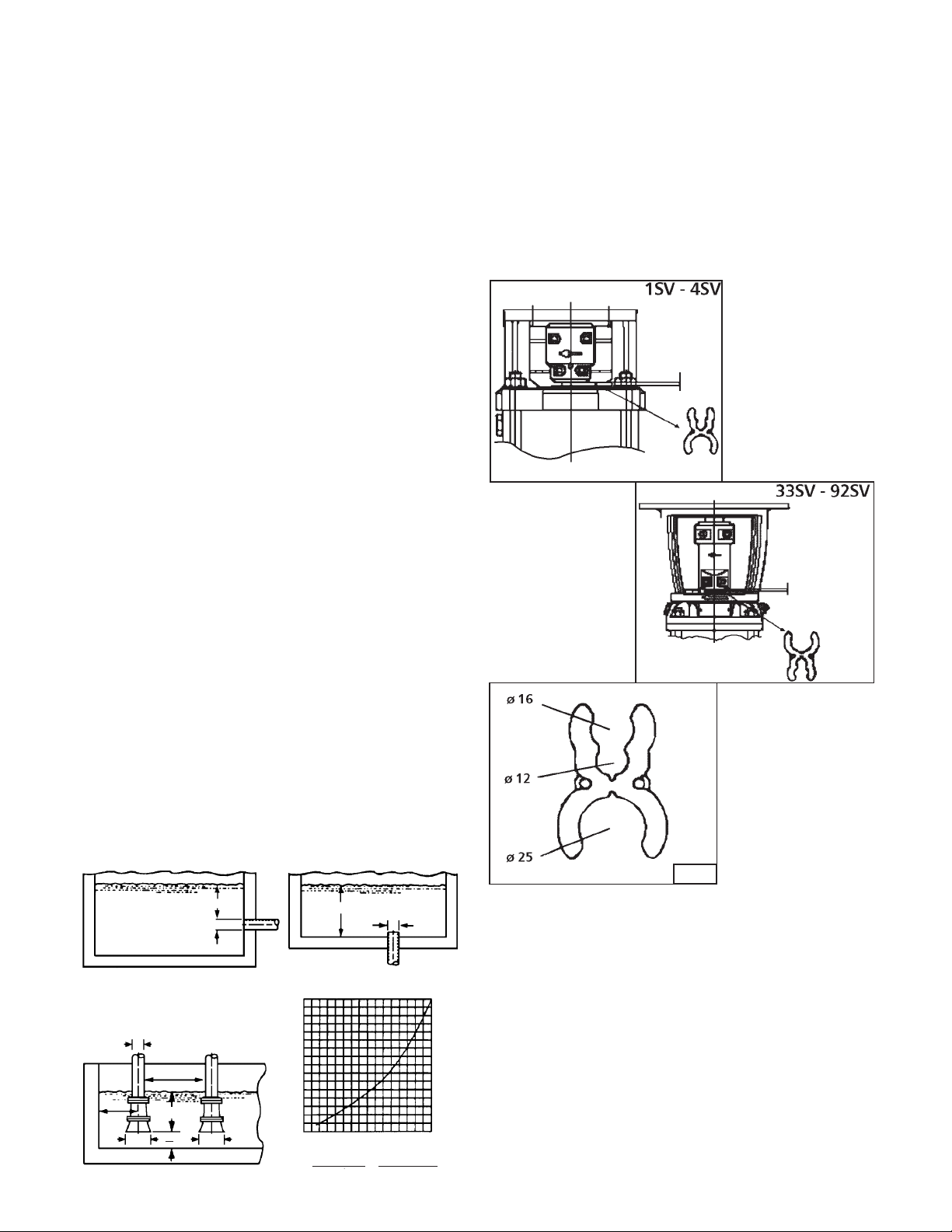

4. HANDLING THE PRODUCT

Lift and handle the product carefully, using

suitable lifting equipment. Observe the

accident prevention regulations in force.

The product must be securely harnessed

for lifting and handling. Some electric pumps have

eyebolts that can be used for this purpose.

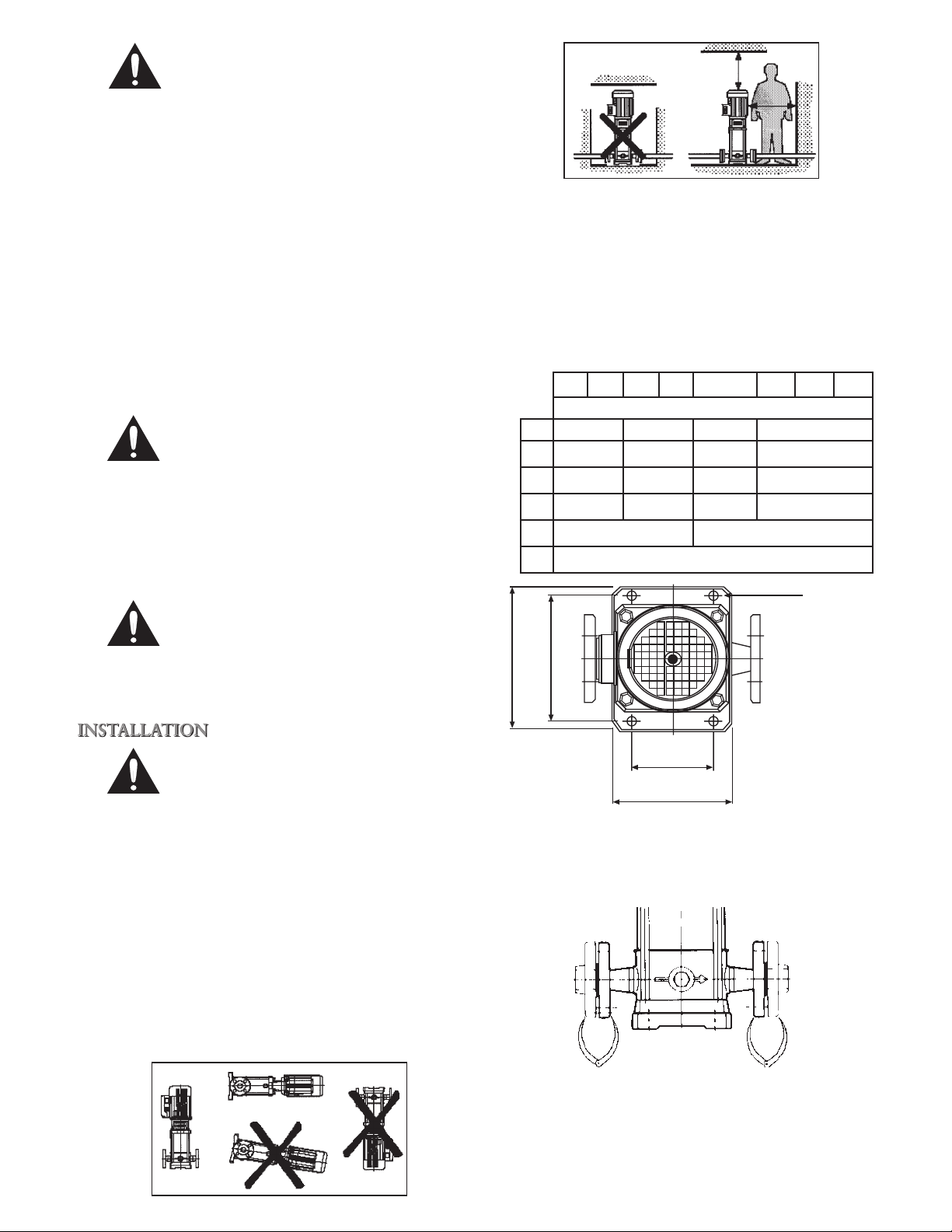

2. ANCHORING

The pump must be anchored securely with bolts to

a concrete foundation or equivalent metal structure

(shelf or platform). If the pump is large-sized and

needs to be installed near rooms inhabited by people,

suitable vibration-damping supports should be provided to prevent the transmission of the vibrations

from the pump to the reinforced concrete structure.

The dimensions of the pump base and anchoring

holes are shown

.

1SV 2SV 3SV 4SV 33SV 46SV 66SV 92SV

Inches (mm)

L1 3.94 (100) 5.12 (130) 6.69 (170) 7.48 (190)

L2 7.09 (180) 8.46 (215) 9.44 (240) 10.44 (265)

L3 5.91 (150) 7.48 (190) 8.66 (220) 9.44 (240)

L4 9.65 (245) 11.42 (290) 12.4 (315)

Ø A 0.50 (13) 0.60 (15)

N 4

Observe the accident prevention regulations in force

Always refer to the local and/or national regulations,

legislation and codes in force relating to the selection of the installation site and the water and power

connections

1. SITE SELECTION

Make

the normal flow of the cooling air delivered by the

motor fan. Make sure there is adequate clearance

around the pump for the maintenance operations.

Whenever possible, raise the pump slightly from

the level of the floor. See the figures below and at

the top of the next column for possible installation

configurations.

The installation operations must be carried

out by qualified and experienced personnel.

Use suitable equipment and protections.

.

sure that no obstructions or obstacles hinder

.

3. ANGULAR ALIGNMENT

Angular alignment of the suction and discharge

flanges can best be accomplished using calipers at the

bolt locations. See figure below

.

NOTICE: DO NOT DRAW PIPING INTO PLACE BY

FORCING THE PUMP SUCTION OR DISCHARGE CONNECTIONS.

7

4. PIPING

Discharge and suction piping should be no smaller

than the respective pump opening and should be

kept as short as possible, avoiding unnecessary fittings to minimize friction losses.

NOTICE: PIPING MUST BE INDEPENDENTLY SUP-

PORTED AND NOT PLACE ANY PIPING

LOADS ON THE PUMP.

If suction piping larger than pump suction is required, an eccentric pipe reducer, WITH THE

STRAIGHT SIDE UP, must be installed at the pump

suction.

If the pump is installed below the liquid source,

install a full flow isolation valve in the suction piping

for pump inspection or maintenance.

NOTICE: DO NOT USE THE ISOLATION VALVE

ON THE SUCTION SIDE OF THE PUMP

TO THROTTLE PUMP. THIS MAY CAUSE

LOSS OF PRIME, EXCESSIVE TEMPERATURES, DAMAGE TO PUMP AND VOID

WARRANTY.

If pump is installed above the liquid source, the following MUST be provided:

To avoid air pockets, no part of the suction piping should be above the pump suction.

On any horizontal piping sections, slope piping

upward from liquid source.

All suction pipe joints MUST be airtight.

Use a foot valve for priming, or for holding

prime during intermittent duty.

The suction strainer or suction bell MUST be at least

3 times the suction pipe diameter.

Insure that the size and minimum liquid submergence, over the suction inlet, is sufficient to prevent

air from entering through a suction vortex. See typical suction piping Figures 1 through 4.

Install a discharge check valve, suitable to handle the

flow and liquids, to prevent backflow.

Install an appropriately sized gate valve, AFTER the

discharge valve, to regulate the pump capacity, for

pump inspection and for maintenance.

When a pipe increaser is required, install between

the check valve and the pump discharge.

5. SHAFT ALIGNMENT – MOTOR TO PUMP

When the pump is purchased less motor, the pump

will be supplied with a motor assembly shim positioned between the motor adapter and the coupling.

To assemble the motor to the pump remove the

plastic shipping straps, the 2 stainless steel coupling

guard halves, and the expanded polyurethane.

Insure that the motor assembly shim is properly positioned between the coupling and the motor adapter.

If the motor assembly shim is not available, a 0.203"

(5 mm) shim may be used to locate the pump shaft

assembly and to set the correct height. See figures

below.

0.203"

(5 mm)

0.203"

(5 mm)

Shim

H min.

D

H min.

D

For motor frame sizes 213TC and larger, attach the

motor adapter flange to the motor using 4 hex cap

screws. Torque to values shown in the “ENGINEER-

ING DATA” section of this manual.

Figure 1 Figure 2

D

8D

min.

4D

min.

H min.

3D

min.

3D

3D

2

H

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

H = Min. Submergence in feet

0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 V

V = Velocity in feet per second

= GPM x 0.321

Area

GPM x 0.4085

2

D

Figure 3 Figure 4

8

Loosen the 4 coupling socket head screws enough

to provide an adequate opening in the coupling to

receive the motor shaft.

With an adequately sized crane, carefully lower

the motor assembly onto the pump motor adapter

and into the coupling. Secure the 4 motor hex cap

screws, torquing to the value provided in the “EN-

GINEERING DATA” section of this manual.

Torque the 4 coupling socket head screws to the

value provided in “ENGINEERING DATA” section

of this manual. After assembly, the gap between the

coupling halves should be equal.

WARNING

Hazardous voltage

can shock, burn or

cause death.

For the 33 through 92SV sizes using a cartridge seal,

WARNING

Hazardous

voltage

208-230V 3/60 460V 3/60

4

5

6

1

7

2

8

3

9

L

1

L

2

L

3

4

7

5

8

6

9

1

2

3

L

1

L

2

L

3

G

G

MOTOR LEADS

MOTOR LEADS

POWER CABLE LEADS

POWER CABLE LEADS

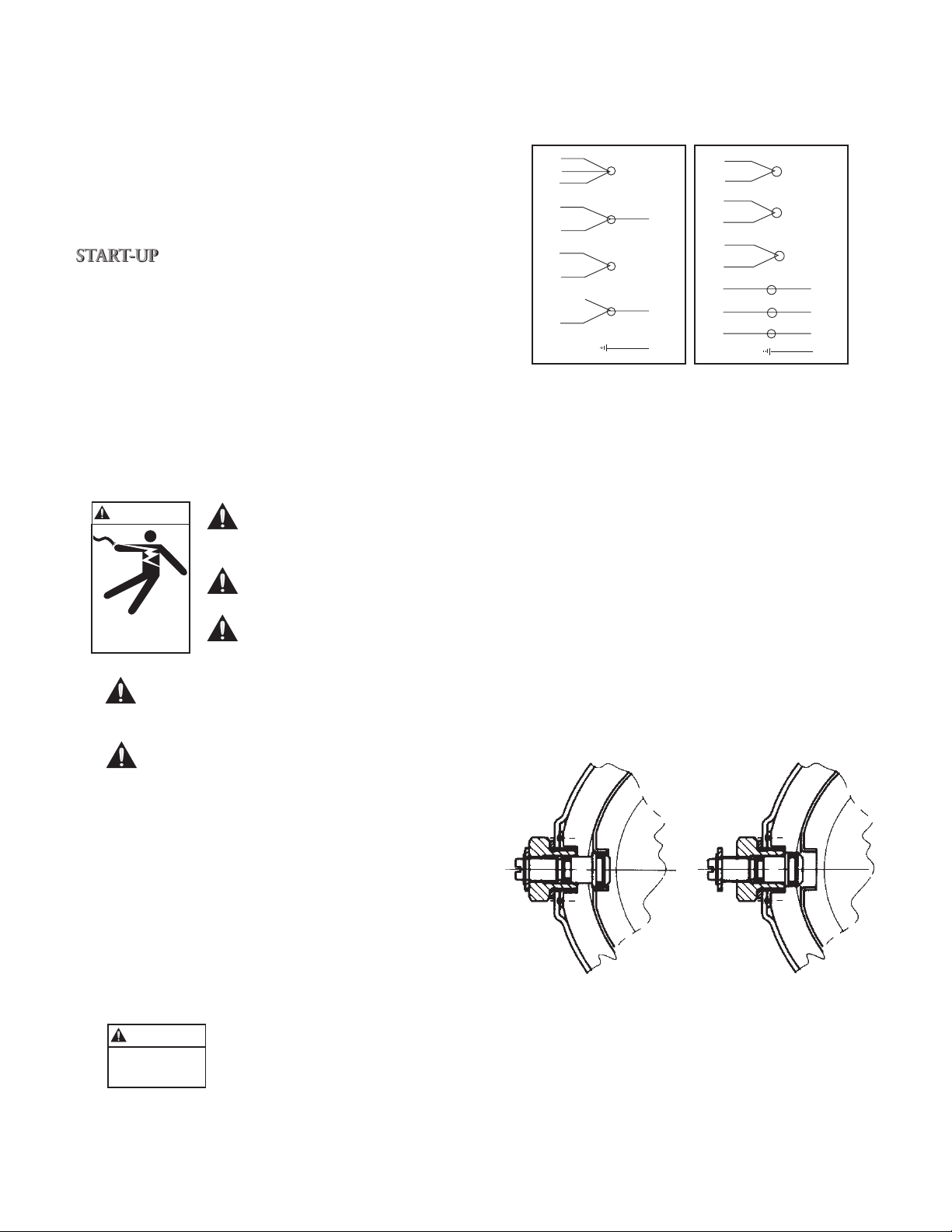

THREE PHASE MOTOR WIRING DIAGRAM

after coupling bolts have been properly torqued,

there are four set screws on the collar of the cartridge seal that require tightening before removing

the shim. The four hex head set screws require a 1/8"

allen wrench and are to be tightened hand-tight approximately 5 lbs.-ft. (7 N•m).

Remove the motor assembly shim and retain for

future use.

Install the 2 coupling guard halves.

1. WATER CONNECTION

The water connections must be made by qualified

installation technicians in compliance with the regulations in force

In case of connection to the water system, the regulations issued by the competent authorities (municipal, public utility company) must be observed.

Authorities often require the installation of a backflow prevention device, such as a disconnector, check

valve or disconnection tank

2. WIRING AND GROUNDING

.

.

Install, ground and wire according to local and National Electrical Code requirements.

Install an all leg disconnect

switch near pump.

Single Phase Motors – Connect the BLACK wire to

the BLACK motor wire. Connect the WHITE wire

to the WHITE motor wire. Connect the GREEN

wire to the GREEN motor wire.

Three Phase Motors – See figure below.

NOTICE: UNIT ROTATION IS DETERMINED WHEN

VIEWED FROM MOTOR END. SEE PAGE 16

FOR MOTOR ROTATION DETAIL. INCORRECT ROTATION MAY CAUSE DAMAGE TO

THE PUMP AND VOIDS WARRANTY.

Check pump rotation by observing the motor fan or

the coupling THROUGH the coupling guard. DO

NOT confuse the flow arrows, stamped on the pump

body, with the rotation arrows on the coupling and

motor adapter. Three phase motors only – If rotation

is incorrect, have a qualified electrician interchange

any two of the three power cable leads.

Electrical supply MUST match pump’s nameplate specifications. Incorrect voltage can cause

fire, damage motor and voids warranty.

Motors equipped with automatic thermal protectors open the motor’s electrical circuit when

an overload exists. This can cause the pump to

start unexpectedly and without warning.

Use only stranded copper wire to motor and ground.

Wire size MUST limit the maximum voltage drop to

10% of the motor nameplate voltage, at the motor

terminals. Excessive voltage drop will affect performance and void motor warranty. The ground wire

must be at least as large as the wires to the motor.

Wires should be color coded for ease of maintenance.

Three phase motors require all leg protection with

properly sized magnetic starters and thermal overloads.

Connect the electrical leads to the motor, as follows:

Disconnect and lockout electrical power before installing or

servicing pump.

PERMANENTLY GROUND THE

PUMP, MOTOR AND CONTROLS

PER NEC OR LOCAL CODES

BEFORE CONNECTING TO

ELECTRICAL POWER. FAILURE

TO DO SO CAN CAUSE SHOCK,

BURNS OR DEATH.

3. PRIMING/VENTING

For installations with the liquid level above the pump:

Close the discharge valve.

Remove the vent plug.

For models 1SV and 2SV only, it is necessary to

fully unscrew the pin located in the drain plug.

See figure below.

DRAIN PLUG

WITH PIN CLOSED

DRAIN PLUG

WITH PIN OPEN

For sizes 33SV-92SV the vent plug is supplied

with an internal needle valve, so it is not necessary to remove the vent plug. Simply unscrew

the needle valve half way to open the valve

to allow air to escape. (For sizes 33SV-92SV,

if the pump is supplied with a cartridge seal,

remove the vent plug located on the gland plate

beneath the coupling.)

Open the suction valve until liquid flows out of

the vent plug opening.

9

NOTE: Place a loose rag over the open vent port to pre-

CAUTION

Hazardous machinery

can cause personal

injury or death.

WARNING

Extreme heat can

cause personal injury

or property damage.

WARNING

WARNING

WARNING

Hazardous

machinery

WARNING

Hazardous

voltage

vent large amounts of liquid from being sprayed

on the pump and adjacent equipment.

Care should be exercised if you

are pumping hot water or chemi-

cals to avoid personal injury.

Install and torque the vent plug to the values

provided in the “ENGINEERING DATA” sec-

tion of this manual. Close the drain plug pin

(1SV and 2SV only) and open the discharge

valve.

For installations with the liquid level below the

pump:

Install foot valve at suction end.

For models 1SV and 2SV only, it is necessary to

fully unscrew the pin located in the drain plug.

See figure on previous page.

With the provided plastic funnel, completely fill

the casing with liquid.

Install and torque the vent plug, close the drain

plug pin (1SV and 2SV only) and open the suction valve.

4. OPERATION

DO NOT OPERATE UNIT WITHOUT SAFETY GUARD IN PLACE.

TO DO SO CAN CAUSE SEVERE

PERSONAL INJURY.

Make sure that the drained liquid does not

cause damage or injuries.

After stabilizing the system at normal operating

conditions, check piping for correct alignments. If

necessary, adjust pipe supports.

HAZARDOUS MACHINERY.

MOTOR THERMAL PROTECTORS CAN RESTART MOTOR

UNEXPECTEDLY AND WITHOUT WARNING, CAUSING

SEVERE PERSONAL INJURY.

See the “ENGINEERING DATA” section in this

manual for the recommended maximum pump starts

per hour.

DISCONNECT AND LOCKOUT

ELECTRICAL POWER BEFORE

ATTEMPTING ANY MAINTENANCE. FAILURE TO DO SO

CAN CAUSE SHOCK, BURNS OR

DEATH.

MOTOR LUBRICATION

Recommended Motor Bearing Lubrication Intervals

Interval Service Environment

1 – 2 Years Light Duty in Clean Atmosphere

1 Year 8 – 16 hours/day – Clean, Dry Atmosphere

6 Months 12 – 24 hours/day – Moisture Present

3 Months 12 – 24 hours/day – Dirty, High Moisture

NOTICE: PUMP MUST BE COMPLETELY PRIMED

10

BEFORE OPERATION.

DO NOT OPERATE PUMP AT OR

NEAR ZERO FLOW. TO DO SO

CAN CAUSE EXTREME HEAT,

DAMAGE TO THE PUMP, INJURY

OR PROPERTY DAMAGE.

Start the pump, keeping the on-off valve downstream from the pump closed. Open the on-off

valve gradually. The pump must run smoothly and

noiselessly. If necessary, reprime the pump. Check

the current absorbed by the motor and, if necessary, adjust the setting of the thermal relay. Any air

pockets trapped inside the pump may be released by

loosening the fill plug, for the 1SV-4SV pumps, or by

turning the air screw for the 33SV-92SV pumps

If a pump installed in a location

where freezing may occur remains

inactive, you must drain it through the drain plugs.

This operation is not necessary if a suitable antifreeze has been added to the water.

.

When lubricants are operated at elevated temperatures, the lubrication frequency should be increased.

DO NOT intermix grease bases (lithium, sodium,

etc.). Completely purge old grease if changing grease

base.

0

Over greasing can cause excessive bearing temperatures, lubricant and bearing failure.

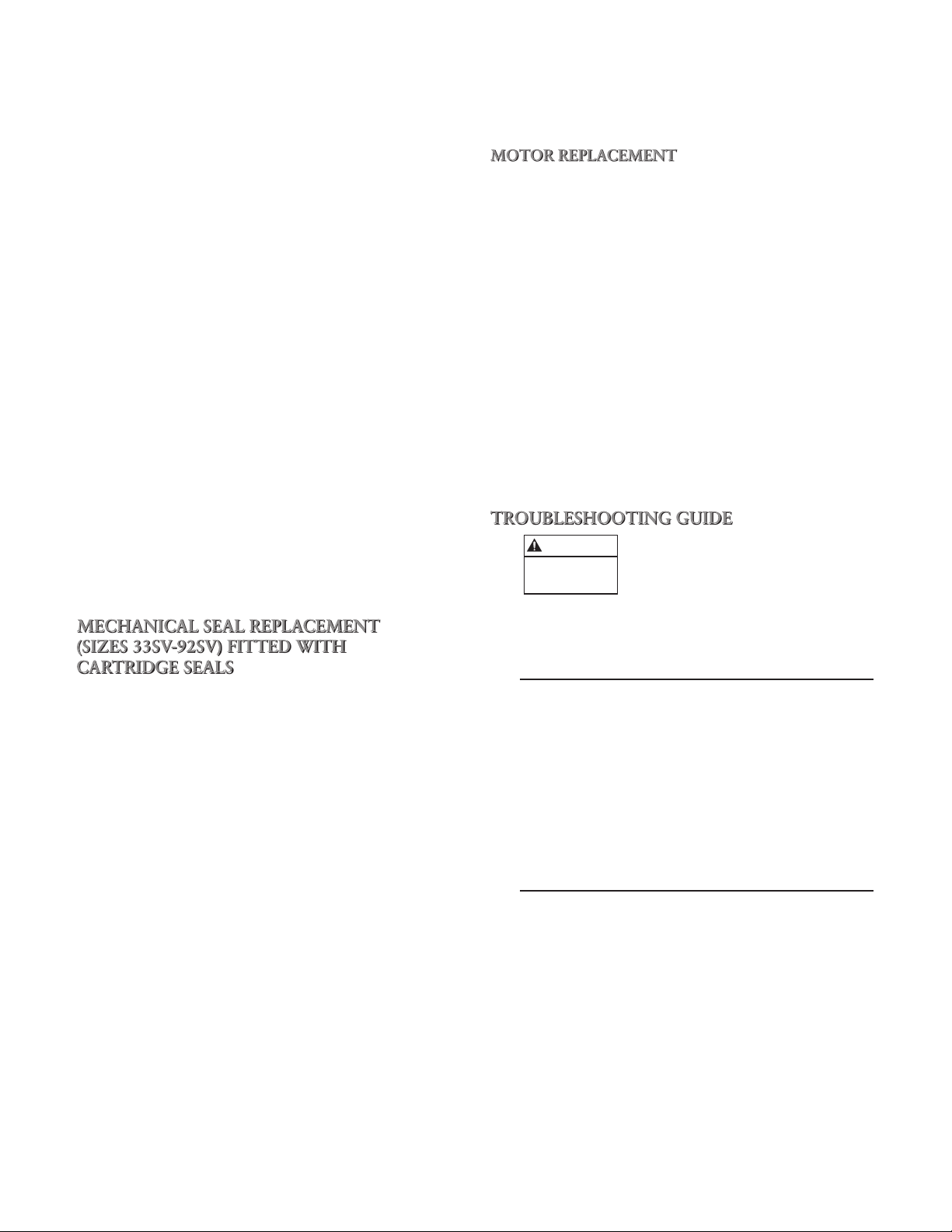

MECHANICAL SEAL OPTIONS

Code Reference

No.

High

0 Temperature

Carbon

4 Silicon Carbide Carbide

Graphite Filled

High

6

Carbon

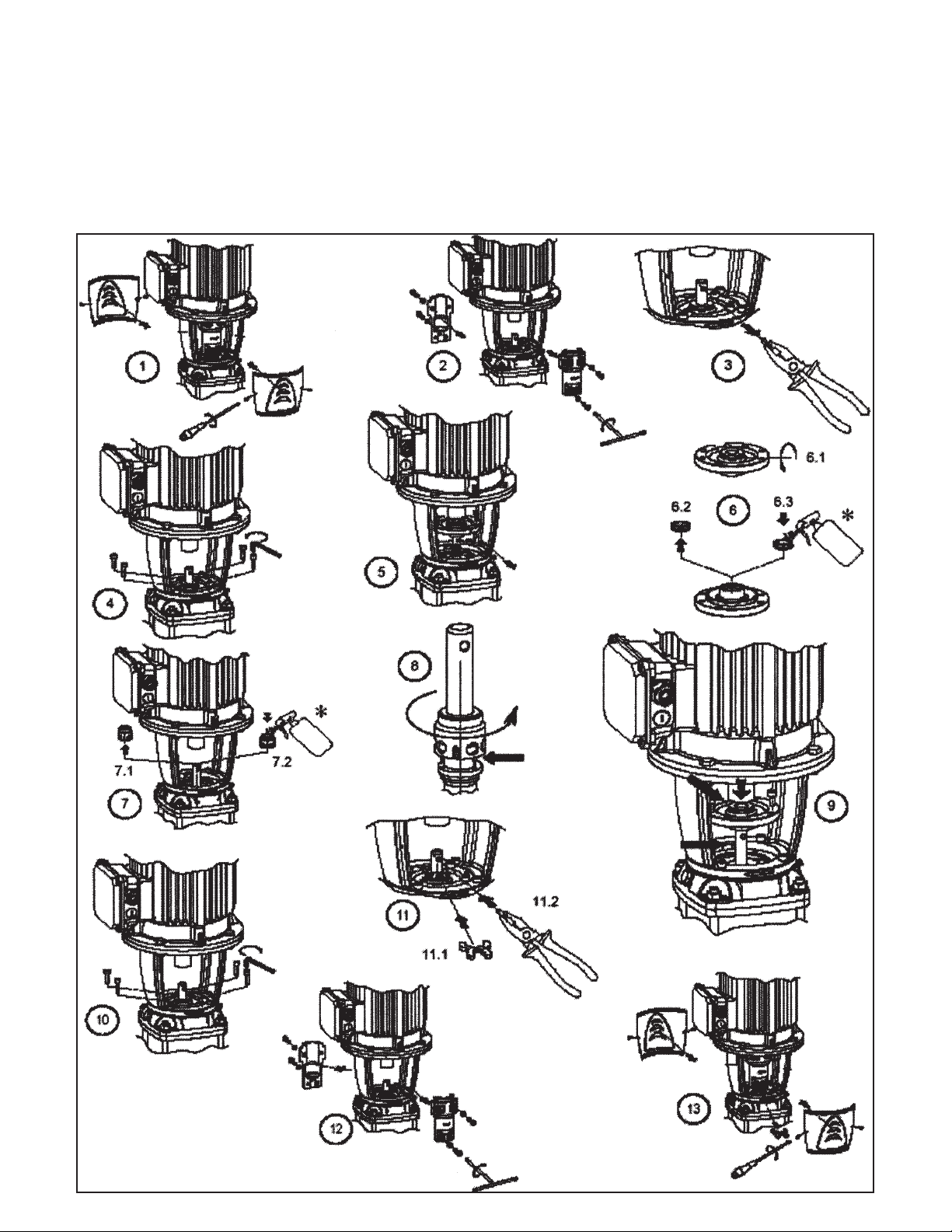

1. Close all necessary suction and discharge valves.

2. Drain the liquid from the pump by removing the

3. Remove the coupling guards, the 4 coupling hex

4. Remove the 4 motor hex cap screws. On units

Rotary Stationary Elastomers

Silicon

Graphite

Temperature EPR Boiler Feed

Filled

Viton

Application

lower drain plug and the upper vent plug.

cap screws, the coupling and coupling drive pin.

with motor frames 213TC and larger, remove the

4 motor adapter flange hex cap screws. With an

General

Service

Abrasive

adequately sized crane, carefully remove the motor. DO NOT rest the motor on the motor shaft.

5. Remove the 4 tie rod nuts and lock washers.

6. Carefully remove the motor adapter by sliding it

up the pump shaft. Larger units may require an

adequately sized crane to lift the motor adapter.

DO NOT damage the shaft.

NOTICE: EDGES OF THE STAINLESS STEEL PARTS

ARE SHARP. WEAR APPROPRIATE PROTECTIVE CLOTHING.

7. To gain access to the mechanical seal, it is neces-

sary to remove the stainless steel upper plate

which is held in place by an O-ring located under

the plate rim. Place a small block of wood against

the underside of the rim and, while moving

around the rim, tap with a mallet against the block

until the upper plate loosens. Remove the upper

plate and O-ring from the pump casing. Discard

the O-ring.

8. Remove the stationary element from the upper

plate. With a clean cloth, wipe the upper plate

bore clean and inspect for damage. Replace the

upper plate, as required.

9. Remove the top (vented) stainless steel inner cas-

ing. Grasp the pump shaft, below the mechanical

seal, and move it sharply back and forth to free

the first stage from the lower pump body. Remove

the entire stack assembly from the pump external

sleeve.

10. Slide the mechanical seal rotary element, spring

and washer from the pump shaft. Discard the

entire mechanical seal assembly.

11. Lubricate the inside of the new mechanical seal as-

sembly with a quality grade of O-ring lubricant.

12. To install a new mechanical seal rotary assembly,

slide the assembly onto the pump shaft, spring end

first. Be sure the top spring tip is in the hole of the

rotary portion of the seal. DO NOT scratch or

otherwise damage the seal face. With a clean, lint

free cloth, wipe the seal face clean of all lubricant

or debris.

13. Lubricate the outside of the new mechanical seal

stationary element with a quality grade of O-ring

lubricant.

14. Insert the stationary seat into the seal housing

with the seal face out. DO NOT scratch or otherwise damage the seal face. Insure that the stationary seat is fully seated into the seal housing. With

a clean, lint free cloth, wipe the seal face clean of

all lubricant or debris.

15. With a new O-ring, install the seal housing onto

the pump shaft, seating the plate fully and squarely onto the pump outer shell.

16. Place the motor adapter over the 4 tie rod bolts,

using an adequately sized crane when required,

and install the 4 lock washers and tie rod nuts.

Torque the nuts, in sequence, to the value provided in the “ENGINEERING DATA” section of

this manual.

17. With an adequately sized crane, carefully lower

the motor onto the motor adapter, lining up the

electrical conduit connection and the 4 motor

adapter bolt holes, as required.

18. Install the 4 motor hex cap screws, torquing to the

value provided in the “ENGINEERING DATA”

section of this manual.

19. Place the coupling drive pin into the pump shaft

and install the coupling halves onto the motor and

pump shafts. Install the 4 coupling socket head

screws, lock washers and nuts, DO NOT tighten.

20. Position the motor assembly shim between the

coupling and the motor adapter. If the motor

assembly shim is not available, a 0.203" (5 mm)

shim may be used to locate the pump shaft assembly and to set the correct height.

21. Tighten the 4 coupling socket head screws,

torquing screws to values provided in the “ENGI-

NEERING DATA” section of this manual. Tighten

evenly so that the gap between the halves is equal

side to side and top to bottom.

22. Install the 2 coupling guard halves.

A

MECHANICAL SEAL OPTIONS

Code

No.

A

Mechanical

D

Metal parts on all seals are 316SS. When reordering units with previous seal options 2, 3 or 5 review application and order new seal option from above chart.

B EPR

Seal

C

L Carbide Viton

Cartridge

Seal

P Sil/Carbide Aflas

Rotary Stationary Elastomers

Viton

Carbon

Silicon

Carbide

Viton

Silicon

Carbide

EPR

1. Close all necessary suction and discharge valves to

isolate the pump from the system.

2. Drain the liquid from the pump by removing the

drain plug and opening the needle valve on the

vent plug.

3. Remove the coupling guards, the 4 coupling hex

cap screws, the coupling and coupling drive pin.

See steps 1-3.

4. Remove the 4 motor hex cap screws (inner

screws) on the seal housing. See step 4.

5. Remove the seal housing plate using the two

tapped holes provided. Threading 2 of the hex

cap screws into these holes and evenly tightening the screws. Lift and remove the seal housing

between the pump and motor shaft. Exercise care

when sliding the seal housing between the shaft to

prevent damage to the stationary seat. See step 5.

6. Turn the seal housing upside down and remove

the stationary seat and o-ring. Remove and discard the large o-ring used to seal the seal housing

to the pump head. Inspect the seal seat for any

burrs or debris. Make sure that the seat is clean.

Lubricate the new o-ring for the seal seat with a

11

lubricant compatible with the o-ring and install

the new seat by pressing it into the seal housing

with your thumb. DO NOT USE EXCESSIVE

FORCE and, if possible, place a clean soft cloth

over the seal face to protect the seal faces during

installation.

7. Remove the rotary portion at the mechanical seal

by sliding the rotary unit axially upwards along

the pump shaft. Inspect the pump shaft for any

burns or debris. Any burrs should be around

smooth with (fine grit) emery paper. See step 7 in

Figure 5.

8. Lubricate the o-ring located in the ID of the rotary

unit of the mechanical seal with a lubricant compatible with the seal elastomers. Carefully slide

the rotary unit of the mechanical seal down the

shaft. Rotate the seal to locate the pin on the bottom of the seal with the holes in the shaft sleeve.

See step 8 in Figure 5.

Figure 5

12

WARNING

Hazardous

voltage

9. Install a new seal housing o-ring on the seal hous-

ing. A lubricant can be used to hold the o-ring on

the diameter of the seal housing.

Carefully reinstall the seal housing between the

pump and motor shaft and slide the seal housing

down the shaft into position. Use caution when

mounting the sealhousing between the

pump/motor shaft so that the seal face

on the stationary seat is not damaged.

See step 9 in Figure 5.

10. Reinstall the 4 hex cap screws, tightening

the screws evenly and then torquing them

to the values given in the engineering

data. See step 10 in Figure 5.

11. Reinstall the coupling pin and locate the

space shim on the shaft on the seal

housing. If the shim is not available, a

5 mm spacer can be used. See step 11 in

Figure 5.

12. Reinstall the coupling halves and evenly

tighten the coupling bolts and torque

them to the values given in the coupling

section. Remove the spacer shim and save

for future use. See step 12 in Figure 5.

13. Rotate the shaft by hand to insure that

the pump and motor rotate freely.

Reinstall the coupling guard.

14. The pump and system should be vented

prior to starting the pump. See Section 3,

page 8, for venting procedures.

1. Complete steps 1-4 as defined above for

conventional seals.

2. Loosen the 4 set screws located around the ID of

the pump shaft.

3. Remove the cartridge seal using the two tapped

holes provided on the gland of the cartridge seal

by threading two of the hex cap screws into these

holes and evenly tightening these screws. Lift and

remove the cartridge seal between the pump and

motor shaft.

4. Inspect the pump shaft for any burrs or debris.

Any burrs should be ground smooth with (fine

grit) emery paper.

5. Install a new o-ring on the turned fit of the new

cartridge seal. Lubricate the o-ring located in the

ID of the cartridge seal. Use a lubricant compatible with the seal elastomers to hold the o-ring.

6. Install the new cartridge seal on the pump by carefully sliding it between the pump and motor shaft

and then sliding it into position.

7. Complete steps 11-14 as defined above for the

conventional seals.

8. After installing the coupling, tighten the four set

screws located in the collar of the cartridge seal to

secure the seal to the pump shaft.

9. Rotate the shaft by hand to insure that the pump

and motor rotate freely. Reinstall the coupling

guard.

10. Use vent connections on cartridge seal for proper

venting.

To remove the motor follow steps 1 through 4, as

provided in the “MECHANICAL SEAL REPLACE-

MENT” section of this manual.

For motor frames 213TC and larger, remove the 4

motor hex cap screws and the motor adapter.

Install the motor adapter flange onto the new motor,

torquing the 4 hex cap screws to the values provided

in the “ENGINEERING DATA” section of this

manual.

Complete the reassembly following steps 17 through

22 in the “MECHANICAL SEAL REPLACE-

MENT” section of this manual.

All additional unit service or maintenance, not addressed in this manual, should be performed at a

qualified service location. Contact your local dealer

or G&L Pumps distributor for assistance.

DISCONNECT AND LOCKOUT

ELECTRICAL POWER BEFORE

ATTEMPTING ANY MAINTENANCE. FAILURE TO DO SO

CAN CAUSE SHOCK, BURNS

OR DEATH.

SYMPTOM

MOTOR NOT RUNNING

See Probable Cause – 1 through 5

LITTLE OR NO LIQUID DELIVERED BY PUMP

See Probable Cause – 6 through 12

POWER CONSUMPTION TOO HIGH

See Probable Cause – 3, 12, 13, 15

EXCESSIVE NOISE AND VIBRATION

See Probable Cause – 3, 6 - 8, 10, 12, 13, 16

PROBABLE CAUSE

1. Motor thermal protector tripped.

2. Open circuit breaker or blown fuse.

3. Impellers binding.

4. Motor improperly wired.

5. Defective motor.

6. Pump is not primed, air or gases in liquid.

7. Discharge, suction plugged or valve closed.

8. Incorrect rotation (three phase only).

9. Low voltage or phase loss.

10. Impellers worn or plugged.

13

11. System head too high.

12. NPSHA too low – excessive suction lift or losses.

13. Discharge head too low – excessive flow rate.

14. Fluid viscosity, specific gravity too high.

15. Worn bearing.

16. Pump, motor or piping loose.

TORQUE VALUES

HP

Frame

¾ 56C 20 lbs ft (27 N .m) – 15 lbs ft (20 N .m)

1 56C 20 lbs ft (27 N .m) – 15 lbs ft (20 N .m)

1½ 56C 20 lbs ft (27 N .m) – 15 lbs ft (20 N .m)

2 56C 20 lbs ft (27 N .m) – 15 lbs ft (20 N .m)

3 56C 20 lbs ft (27 N .m) – 15 lbs ft (20 N .m)

5 184TC 20 lbs ft (27 N .m) – 15 lbs ft (20 N .m) 37 lbs ft (50 N .m)

7½ 184TC 20 lbs ft (27 N .m) – 15 lbs ft (20 N .m) 37 lbs ft (50 N .m)

10 213TC

215TC

15 215TC

254 TC

20 254TC

256TC

25 256TC

284TC

30 284TC

286TC

40 284TC

286TC

50 324TSC

326TSC

60 326TSC

364TSC

75

Motor

365TSC 45 lbs ft (61 N .m) 48 lbs ft (65 N .m)

Motor Bolt Adapter Flange

45 lbs ft (61 N .m) 30 lbs ft (40 N .m) 30 lbs ft (40 N .m) 48 lbs ft (65 N .m)

45 lbs ft (61 N .m)

45 lbs ft (61 N .m) 48 lbs ft (65 N .m) 48 lbs ft (65 N .m)

45 lbs ft (61 N .m) 48 lbs ft (65 N .m) 48 lbs ft (65 N .m)

45 lbs ft (61 N .m) 48 lbs ft (65 N .m) 48 lbs ft (65 N .m)

45 lbs ft (61 N .m) 48 lbs ft (65 N .m)

45 lbs ft (61 N .m) 48 lbs ft (65 N .m)

45 lbs ft (61 N .m) 48 lbs ft (65 N .m)

30 lbs ft (40 N .m) 30 lbs ft (40 N .m)

48 lbs ft (65 N .m) 48 lbs ft (65 N .m)

Coupling

1-4SV 33-92SV

48 lbs ft (65 N .m)

48 lbs ft (65 N .m)

48 lbs ft (65 N .m)

48 lbs ft (65 N .m)

48 lbs ft (65 N .m)

48 lbs ft (65 N .m)

48 lbs ft (65 N .m)

48 lbs ft (65 N .m)

TORQUE VALUES

Pump Size Tie Rod Nuts Vent and Drain

1SV 22 lbs ft (30 N .m) 15 lbs ft (20 N .m)

2SV 22 lbs ft (30 N .m) 15 lbs ft (20 N .m)

3SV 37 lbs ft (50 N .m) 15 lbs ft (20 N .m)

4SV 37 lbs ft (50 N .m) 15 lbs ft (20 N .m)

33, 46,

66, 92SV

44 lbs ft (60 N .m) 29 lbs ft (40 N .m)

NOTE: Discharge loop must be high enough to keep liquid in the bottom stages during shut-down.

14

1

3

2

7

6

10

11

13

16

17

4

15

9

5

8

12

14

7

9

1 Standard NEMA vertical motor

2 Rigid coupling

3 Motor adapter

4 Coupling guard

5 Stainless steel seal housing

6 Mechanical seal

7 Stainless steel fill and drain plugs

8 Tie-rods

9 O-ring

10 Stainless steel pump casing

11 Stainless steel diffuser

12 Stainless steel impeller

13 Tungsten carbide shaft sleeve

14 Ceramic bushing

15 Stainless steel shaft

16 Stainless steel pump body

17 Pump base

15

1 O-Ring, Piston Seal

2 O-Ring, Mechanical Seal

3 O-Ring, Seal housing

4 O-Ring, Sleeve

5 Mechanical Seal

5A Cartridge Seal (not shown)

6 Screw, Guard

45

44

29

3

16

19

4

38

30

24

31

26

39

25

35

7

42

1

12

28

18

18

16

15

12

10

LESS PISTON

34

18

1

12 10

3

23

WITH PISTON

36

6

8

11

13

9

41

49

46

48

5

2

30

20

21

47

35

37

27

27A

32

22

33

28

40

23

10

18

14

40

7 Screw, Piston Holding Disc

8 Screw, Coupling

9 Screw, MA and Seal Housing

10 Screw, Impeller

11 Washer, Coupling

12 Washer, Impeller

13 Pin, Coupling

14 Plug, with Piston

15 Plug, without Piston

16 Plug, Fill

17 Plug, Vent (not shown)

18 Plug, Drain

19 Pump Head

20 Impeller, Full Diameter

21 Impeller, Reduced Diameter

22 Lower Bearing Assembly

23 Piston

24 Diffuser, Final

25 Diffuser with Carbon Bushing

26 Diffuser with Tungsten Bushing

27 Outer Sleeve, 25 Bar

27A Outer Sleeve, 40 Bar

28 Holding Disc, Piston Seal

29 Seal Housing

30 Spacer, Impeller Final

31 Spacer, Shaft Bushing

32 Spacer, Impeller

33 Spacer, Impeller Lower (66-92SV)

34 Bushing, Non-Piston

35 Tungsten Carbide Bushing

36 Coupling Guard

37 Shaft

38 Mechanical Seal Shaft Sleeve

39 Wear Ring, Impeller

40 Piston Seal

41 Stop Ring, Impeller

42 Pump Body

43 Motor Adapter Plate (not shown)

44 Motor Adapter

45 Coupling, Half

46 Nut, Tie-Rod

47 Tie-Rod

48 Washer, Tie-Rod

49 Spring, Final Diffuser

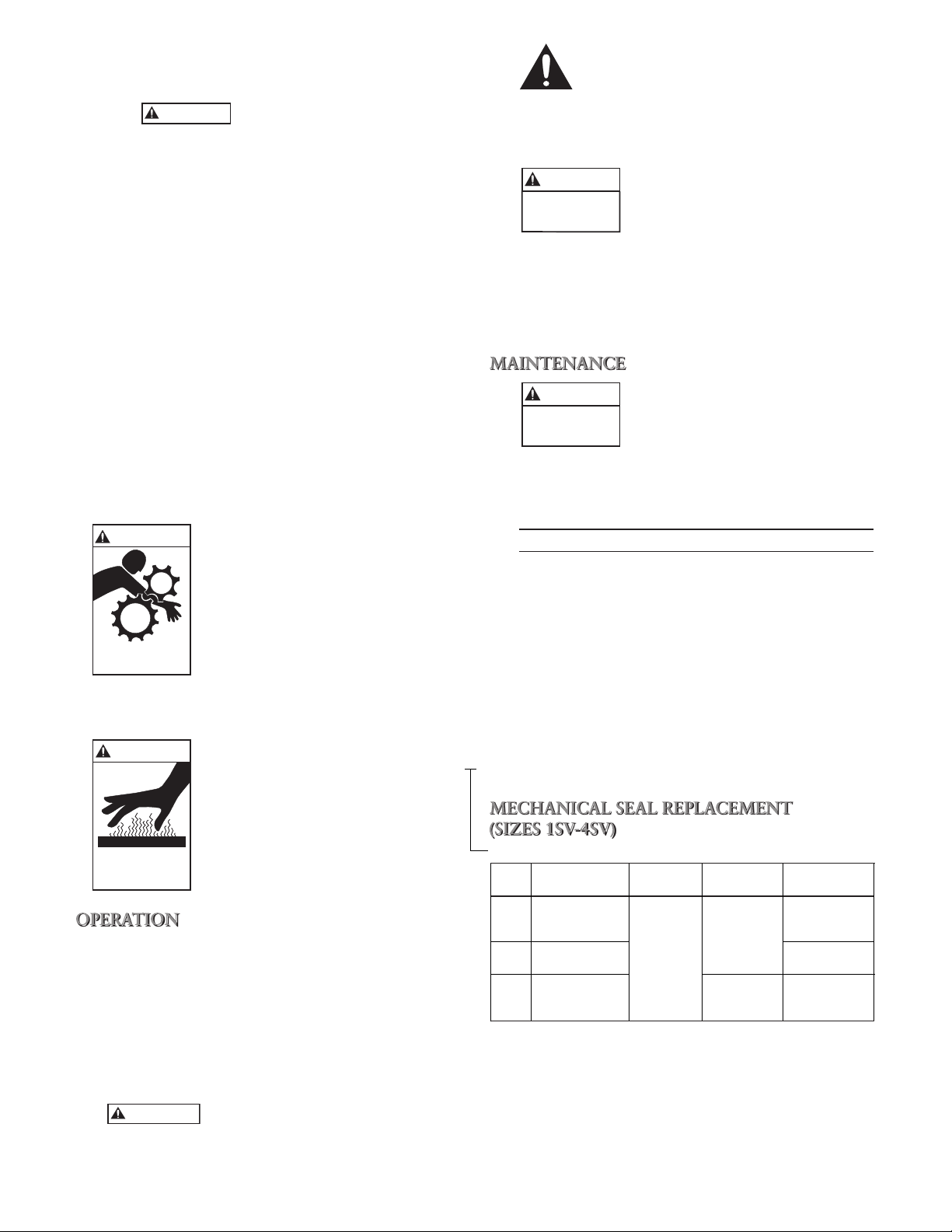

FLOW DIRECTION AND MOTOR ROTATION

CLOCKWISE

ROTATION

DIRECTION

CLOCKWISE

ROTATION

DIRECTION

Series 1SV, 2SV,

3SV and 4SV

COUNTER-

CLOCKWISE

ROTATION

DIRECTION

CLOCKWISE

ROTATION

DIRECTION

Series 5SV and 6SV

(Obsolete)

Refer to the above diagram for proper pump installation detailing flow direction and motor rotation. All

SSV units will be properly tagged with flow direction and motor rotation labels. Please ignore all cast

direction arrows. Note that the DPS pump is the

second unit after the lead SSV unit.

Size Stage Motor Rotation

2-16 CW

1SV

18-22 CCW

1SV DPS All CCW

2-15 CW

2SV

16-22 CCW

2SV DPS All CCW

2-13 CW

3SV

14-16 CCW

3SV DPS All CCW

2-10 CW

4SV

12 CCW

4SV DPS All CCW

17

Loading...

Loading...