Page 1

ITT

Goulds Pumps

G&L SERIES SSH-C and SSH-F

Installation, Operation and

Maintenance Instructions

Commercial Water

Goulds Pumps is a brand of ITT Water Technology, Inc.

- a subsidiary of ITT Industries, Inc.

www.goulds.com

Engineered for life

1

Page 2

Table of Contents

SUBJECT PAGE

Safety Instructions ...................................................................... 3

Important Instructions ................................................................ 3

Installation ..................................................................................3

Alignment ...................................................................................4

Suction Piping .............................................................................4

Discharge Piping .........................................................................4

Rotation ......................................................................................4

Operation....................................................................................4

Maintenance ...............................................................................5

Disassembly ................................................................................ 5

Reassembly.................................................................................. 5

Troubleshooting Guide...............................................................6

Components ...............................................................................7

SSH S-Group – Engineering Data ............................................. 9

SSH S-Group Close-Coupled – Dimensions & Weights ........10

SSH S-Group Frame-Mounted – Dimensions & Weights ......11

SSH M-Group – Engineering Data .........................................12

SSH M-Group Close Coupled – Dimensions & Weights ......13

SSH M-Group Frame-Mounted – Dimensions & Weights ....14

Goulds Pumps Limited Warranty ............................................15

Declaration of Conformity ...................................................... 35

Owner’s Information

Please fill in data from your pump nameplate.

Warranty information is on page 15.

Pump Model:

Serial Number:

Dealer:

Dealer’s Phone Number:

Date of Purchase:

Installation Date:

2

Page 3

SAFETY INSTRUCTIONS

DANGER

WARNING

CAUTION

WARNING

Hazardous fluids

can cause fire,

burns or death.

WARNING

Hazardous voltage

can shock, burn or

cause death.

CAUTION

NOTICE: INSPECT UNIT FOR DAMAGE AND

REPORT ALL DAMAGE TO THE CARRIER

OR DEALER IMMEDIATELY.

1. Inspect unit for damage. Report damage to carrier

2. Electrical supply must be a separate branch circuit

TO AVOID SERIOUS OR FATAL PERSONAL INJURY

OR MAJOR PROPERTY DAMAGE, READ AND

FOLLOW ALL SAFETY INSTRUCTIONS IN MANUAL

AND ON PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump

or in the manual, look for one of the following signal words and be alert to the

potential for personal injury or property

damage.

Warns of hazards that WILL cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause personal injury or property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND

MUST BE FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

UNIT NOT DESIGNED FOR USE

WITH HAZARDOUS LIQUIDS

OR FLAMMABLE GASES. THESE

FLUIDS MAY BE PRESENT IN

CONTAINMENT AREAS.

1. Important Instructions

immediately.

with fuses or circuit breakers, wire sizes, etc., per

National and Local electrical codes. Install an all-leg

disconnect switch near pump.

ALWAYS DISCONNECT

ELECTRICAL POWER WHEN

HANDLING PUMP OR CONTROLS.

3. Motors must be wired for proper voltage (check

nameplate). Wire size must limit maximum voltage

drop to 10% of nameplate voltage at motor terminals,

or motor life and pump performance will be lowered.

4. Single-Phase: Thermal protection for single-phase units

is sometimes built-in (Check nameplate). If no built-in

protection is provided, use a contactor with proper

overload. Fusing is permissible if properly fused.

5. Three-Phase: Provide three-leg protection with proper

size magnetic starter and thermal overloads.

6. Maximum Liquid Temperatures:

212ºF (100ºC) with standard seal.

250ºF (120ºC) with optional high-temperature seal.

7. Maximum allowable operating pressure: 230 PSI

(15 bars).

8. Maximum number of starts per hour: 20, evenly

distributed.

9. Regular Inspection and Maintenance will increase

service life. Base schedule on operating time.

2. Installation

1. Close-coupled units may be installed inclined or vertical.

DO NOT INSTALL WITH MOTOR

BELOW PUMP. CONDENSATION

WILL BUILD UP IN MOTOR.

2. Locate pump as near liquid source as possible (below

level of liquid for automatic operation).

3. Protect from freezing or floods.

4. Allow adequate space for servicing and ventilation.

5. For close-coupled pumps, the foundation must be flat

and substantial to eliminate strain when tightening

bolts. Use rubber mounts to minimize noise and

vibration. Tighten motor hold-down bolts before

connecting piping to pump.

6. For frame-mounted pumps, permanent and solid

foundation is required for smooth operation. Bedplate

must be grouted to a foundation with solid footing.

7. Place unit in position on wedges located at four points

(Two below approximate center of driver and two

below approximate center of pump). Adjust wedges to

level unit, bringing coupling halves into reasonable

alignment. Level or plumb suction and discharge

flanges.

8. Make sure bedplate is not distorted and final coupling

alignment can be made within the limits of movement

of motor and by shimming if necessary.

9. Tighten foundation bolts finger tight and build dam

around foundation. Pour grout under bedplate making

sure the areas under pump and motor feet are filled

solid. Allow grout to harden 48 hours before further

tightening foundation bolts.

10. All piping must be supported independently of the

pump, and must “line-up” naturally. Never draw

piping into place by forcing the pump suction and

discharge connections!

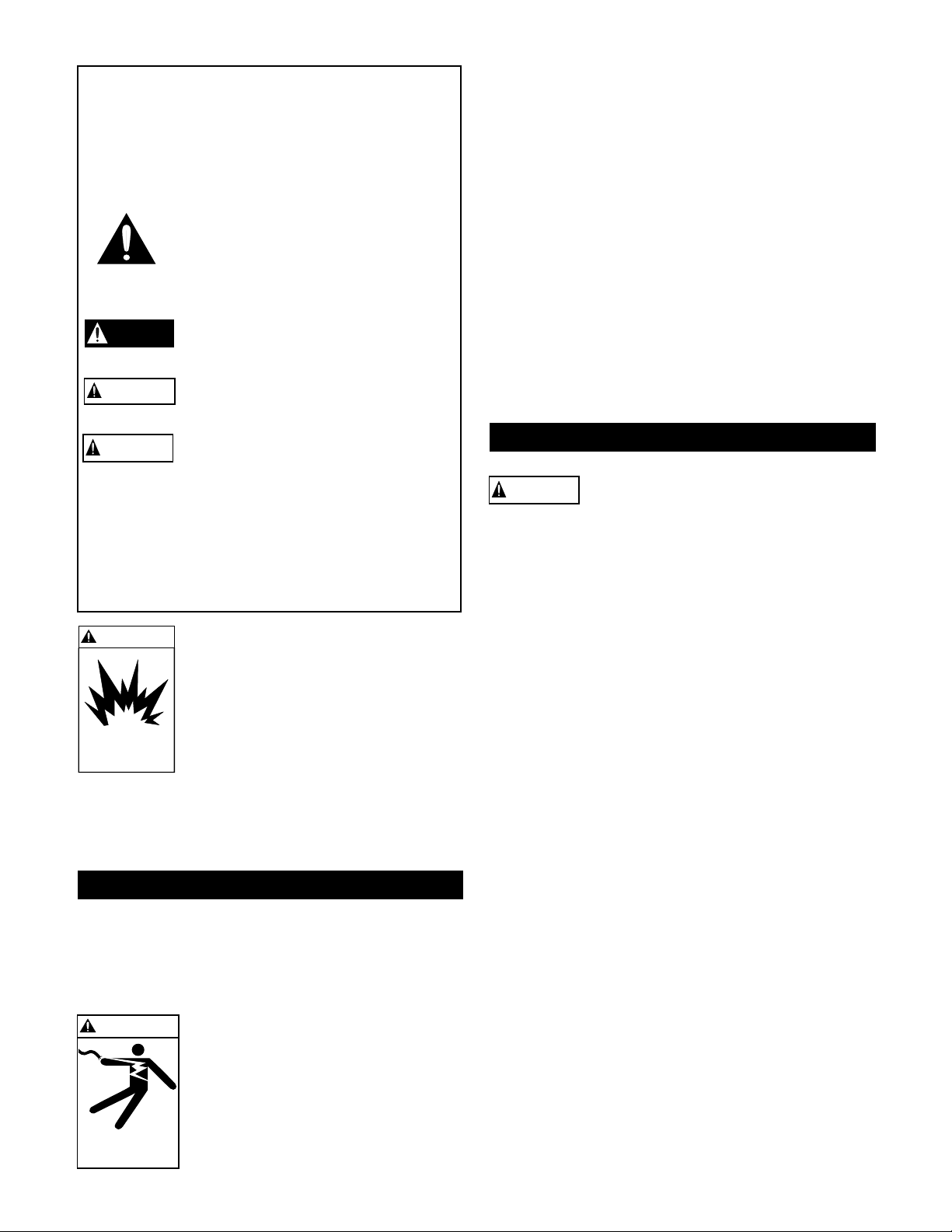

11. Angular alignment of the flanges can best be accom-

plished using calipers at bolt locations (See illustration).

3

Page 4

CAUTION

Hazardous Machinery

WARNING

CAUTION

12. On frame-mounted units, tighten foundation, pump

and driver hold-down bolts before connecting piping

to pump.

13. Avoid unnecessary fittings. Select sizes to keep fric-

tion losses low.

14. After completing piping, rotate unit by hand to check

for binding. Note: A screwdriver slot or flats are provided in end of motor shaft.

3. Alignment

1. No field alignment is necessary on close-coupled

pumps.

2. Even though the pump-motor unit may have a factory

alignment, in transit this alignment could be disturbed

and must be checked prior to running.

3. Check the tightness of all hold-down bolts before

checking the alignment.

4. If re-alignment is necessary, always move the motor.

Shim as required.

5. Final alignment is achieved when parallel and angular

requirements are achieved with both pump and motor

hold down bolts tight.

ALWAYS RECHECK BOTH

ALIGNMENTS AFTER MAKING

ADJUSTMENTS.

6. Parallel misalignment exists when the shafts are not

concentric. Place dial indicator on one hub and rotate

this hub 360º while taking readings on the outside

diameter of the other hub. Parallel alignment occurs

when Total Indicator Reading is .005" or less.

7. Angular misalignment exists when the shafts are not

parallel. Place dial indicator on one hub and rotate this

hub 360º while taking readings on the face of the

other hub. Angular alignment is achieved when Total

Indicator Reading is .005" or less.

4. Suction Piping

1. Low static lift and short, direct suction piping is

desired. For suction lift over 15 feet, consult pump

performance curve for Net Positive Suction Head

Required.

2. Suction pipe size must be at least equal to suction

connection of pump.

3. If larger pipe is used, an eccentric pipe reducer (with

straight side up) must be used at the pump.

4. Installation with pump below source of supply:

4.1. Install isolation valve in piping for inspection and

maintenance.

4

4.2. Do not use suction isolation valve to throttle

pump!

5. Installation with pump above source of supply:

5.1. To avoid air pockets, no part of piping should be

higher than pump suction connection. Slope

piping upwards from liquid source.

5.2. All joints must be airtight.

5.3. Foot valve to be used only if necessary for prim-

ing, or to hold prime on intermittent service.

5.4. Suction strainer open area must be at least triple

the pipe area.

6. Size of inlet from liquid source, and minimum submer-

gence over inlet, must be sufficient to prevent air

entering pump.

5. Discharge Piping

1. Arrangement must include a check valve located

between a gate valve and the pump. The gate valve is

for regulation of capacity, or inspection of pump or

check valve.

2. If reducer is required, place between check valve and-

pump.

6. Rotation

DO NOT PLACE HANDS IN PUMP

WHILE CHECKING MOTOR

ROTATION. TO DO SO WILL CAUSE

SEVERE PERSONAL INJURY.

1. Pumps are right-hand rotation (Clockwise when

viewed from the driver end). Switch power on and

off. Observe shaft rotation. On frame-mounted units,

check rotation before coupling pump to motor.

2. Single-Phase: Refer to wiring diagram on motor if

rotation must be changed.

3. Three-Phase: Interchange any two power supply leads

to change rotation.

7. Operation

1. Before starting, pump must be primed (free of air and

suction pipe full of liquid) and discharge valve partially open.

PUMPED LIQUID PROVIDES

LUBRICATION. IF PUMP IS RUN

DRY, ROTATING PARTS WILL SEIZE

AND MECHANICAL SEAL WILL BE

DAMAGED.

2. Make complete check after unit is run under operating

conditions and temperature has stabilized. Check for

expansion of piping. Check coupling alignment.

3. Do not operate at or near zero flow. Energy imparted

to the liquid is converted into heat. Liquid may flash

to vapor. Rotating parts require liquid to prevent scoring or seizing.

Page 5

8. Maintenance

WARNING

Hazardous

voltage

FAILURE TO DISCONNECT AND

LOCKOUT ELECTRICAL POWER

BEFORE ATTEMPTING ANY

MAINTENANCE CAN CAUSE

SHOCK, BURNS OR DEATH.

1. Bearings are located in and are part of the motor. For

lubrication procedure, refer to manufacturer’s instructions.

2. On frame-mounted units, regrease at 2,000 hours use

or after 3 months. Use #2 Sodium or Lithium grease

and fill until grease comes out of the relief fitting.

9. Disassembly

1. Always turn power off.

2. Drain system. Flush if necessary.

3. Remove motor hold-down bolts on close-coupled or

disconnect coupling and remove spacer.

4. Remove casing bolts and pump hold-down bolts.

5. Remove motor and rotating element from casing.

6. Unscrew impeller bolt with a socket wrench. Do not

insert screwdriver between impeller vanes to prevent

rotation. It may be necessary to use a strap wrench

around the impeller if impacting the socket wrench

will not loosen the impeller bolt.

7. Remove impeller o-ring.

8. Insert two pry bars (180º apart) between impeller and

seal housing. Pry off impeller.

9. Remove shaft sleeve, seal spring, cupwasher, seal

rotary and impeller key.

10. Remove seal housing.

11. Place seal housing on flat surface. Press out stationary

seal parts.

12. Remove deflector from shaft on frame-mounted

units.

13. Remove bolts holding bearing cover to frame and

remove bearing cover (frame-mount).

14. Remove lip seals from bearing frame and bearing

cover (frame-mount).

15. Remove shaft and bearings from frame (frame-

mount).

16. Remove bearing retaining ring (frame-mount).

17. Use bearing puller or arbor press to remove ball

bearings (frame-mount).

18. Remove wear ring if excessively worn. Use pry bar

and/or vicegrips.

10. Reassembly

1. All parts should be cleaned before assembly.

2. Refer to parts list to identify required replacement

items.

3. Reassembly is the reverse of the disassembly proce-

dure.

4. Replace lip seals if worn or damaged (frame-mount

only).

5. Replace ball bearings if loose, rough or noisy when

rotated (frame-mount only).

6. Check shaft for maximum runout of .005" TIR. Bear-

ing seats and lip seal areas must be smooth and free of

scratches or grooves. Replace if necessary (framemount only).

7. All mechanical seal components must be in good

condition or leakage may result. Replacement of

complete seal assembly, whenever seal has been

removed, is good standard practice.

8. If wear ring is being replaced, do not use lubricants on

the metal-to-metal fit when pressing in the replacement.

9. If the impeller is removed, as for example to effect a

mechanical seal change, this procedure must be

followed: Old impeller bolt and impeller o-ring cannot

be reused.

10. Install the mechanical seal stationary seat in the seal

housing, using soapy water as a lubricant to ease

insertion.

11. S-Group – Install the mechanical seal spring retainer,

spring and rotary assembly on the shaft sleeve using

soapy water to lubricate. Slide the shaft sleeve over

the pump shaft, be sure that a new shaft sleeve o-ring

is used.

NOTE: THE SHAFT SLEEVE O-RING AND IMPEL LER WASHER O-RING ARE ALMOST

IDENTICAL IN DIAMETER. BE SURE TO

USE THE SQUARE CROSS-SECTION

O-RING IN THE IMPELLER WASHER. THE

ROUND CROSS-SECTION O-RING IS USED

IN THE SHAFT SLEEVE.

11. M-Group – Install the mechanical seal spring and

rotary on the shaft sleeve using soapy water to lubricate. Slide the shaft sleeve over the pump shaft. Be

sure that a new shaft sleeve o-ring is used. Place the

mechanical seal spring retainer over the impeller hub.

12. Place the impeller key into the shaft keyway and slide

the impeller in place. Install the impeller stud and

impeller washer. Be sure that a new impeller o-ring is

used. Tighten S-Group (3⁄8" thread) to 17 lb.ft. and

M-Group (½" thread) to 38 lb.ft.

13. Replace casing bolts and tighten in a crossing se-

quence to the torque values indicated below.

S-Group – 25 lb.-ft. (35 N-m)

M-Group – 37 lb.-ft. (50 N-m)

14. Check reassembled unit for binding by rotating shaft

with appropriate tool from motor end.

15. If rubbing exists, loosen casing bolts and proceed

with tightening sequence again.

5

Page 6

11. Troubleshooting

1. Motor does not start, and no noise or vibration oc-

curs:

1.1. Power supply not connected.

1.2. Fuses or protection device tripped or defective.

1.3. Loose or broken electrical connections.

2. Motor will not start, but generates noise and vibration:

2.1. Motor not wired as directed on diagram.

2.2. Shaft locked due to mechanical obstructions in

motor or pump.

2.3. Low voltage or phase loss on three phase supply.

3. Pump does not deliver rated capacity:

3.1. Pump not filled and primed.

3.2. Pump has lost prime due to leaks in suction line.

3.3. Direction of rotation incorrect. See Rotation.

3.4. Head required is higher than that originally

specified. (Valve may be partially closed.)

3.5. Foot valve clogged.

3.6. Suction lift too high.

3.7. Suction pipe diameter too small.

4. Protection trips as unit starts:

4.1. Phase loss on three-phase supply.

4.2. Protection device may be defective.

4.3. Loose or broken electrical connections.

4.4. Check motor resistance and insulation to ground.

5. Protection device trips too often:

5.1. Protection may be set to a value lower than motor

full load.

5.2. Phase loss due to faulty contacts or supply cable.

5.3. Liquid is viscous or its specific gravity is too high.

5.4. Rubbing occurs between rotating and stationary

parts.

6. Shaft spins with difficulty:

6.1. Check for obstructions in the motor or the pump.

6.2. Rubbing occurs between rotating and stationary

parts.

6.3. Check bearings for proper conditions.

7. Pump vibrates, runs noisily, and flow rate is uneven:

7.1. Pump runs beyond rated capacity.

7.2. Pump or piping not properly secured.

7.3. Suction lift too high.

7.4. Suction pipe diameter too small.

7.5. Cavitation caused by insufficient liquid supply or

excessive suction losses.

7.6. Impeller blockage.

8. When stopped, unit turns slowly in the reverse direc-

tion:

8.1. Leaks on air locks in suction pipe.

8.2. Partial blockage in check valve.

9. In pressure boosting applications, the unit starts and

stops too often:

9.1. Pressure switch settings are incorrect.

9.2. Tank size may be incorrect.

10. In pressure boosting applications, the unit does not

stop:

10.1. Pressure switch maximum setting is higher than

was specified.

10.2. Direction of rotation incorrect. See Rotation.

6

Page 7

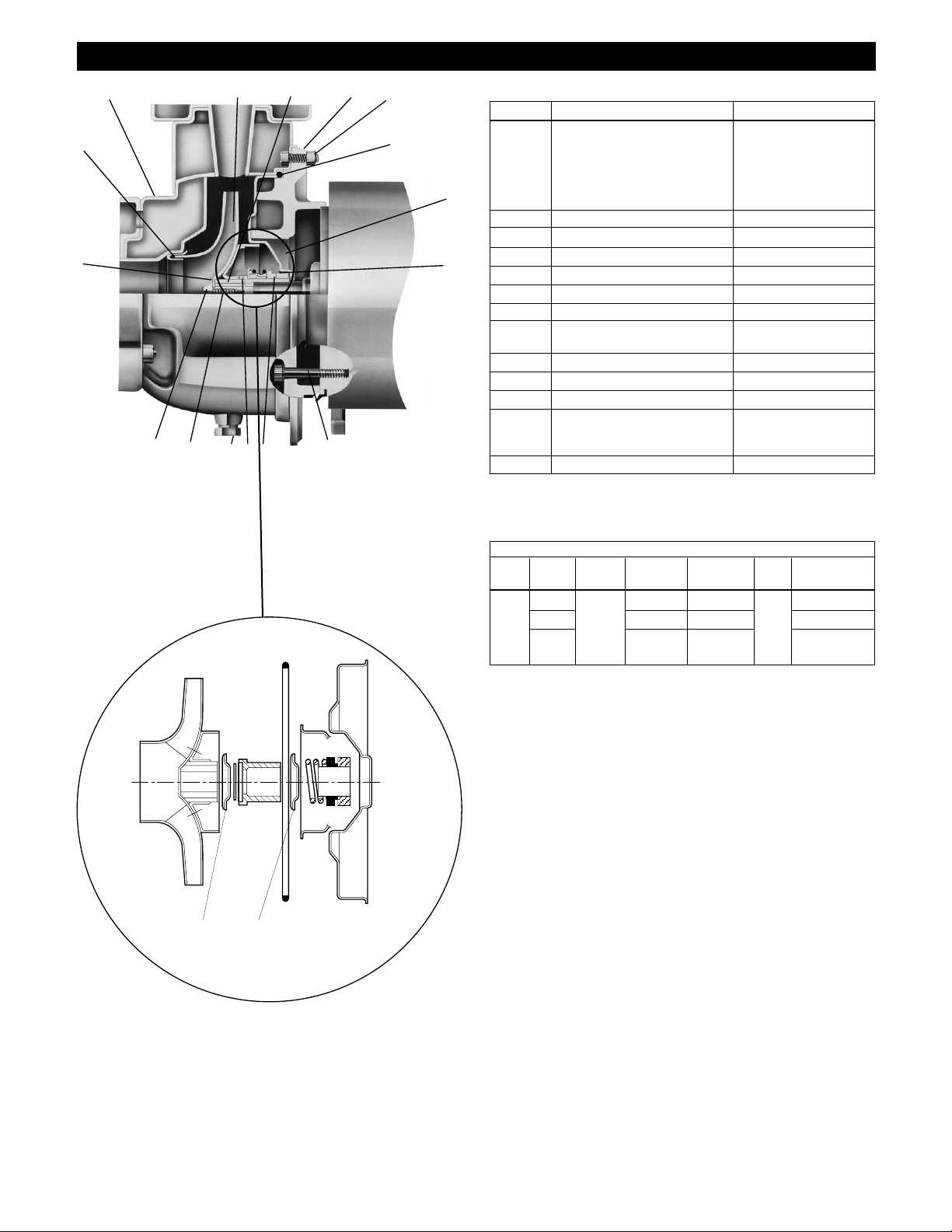

SSH-C Components

383A

(S-GROUP

LOCATION)

383A

(M-GROUP

LOCATION)

100 101 178 108 370

103

412A

199 422 408 126 371

412F

513

MATERIALS OF CONSTRUCTION

Item Description Material

100 Casing

101 Impeller

103 Wear Ring

184 Seal Housing

370 Socket Head Cap Screw

184

(Casing to Adapter)

408 Drain Plug — 3⁄8 NPT AISI TYPE 316 SS

126 Shaft Sleeve 316 SS

178 Impeller Key Steel

383

422 Impeller Stud Steel

199 Impeller Washer 316 SS

108 Adapter Cast Iron ASTM A48CL20

Hex Head Cap Screw

371

(Adapter to Motor)

412A O-ring, impeller BUNA-N

412F O-ring, shaft sleeve BUNA-N

513 O-Ring BUNA-N

Carbon/Ceramic

383 Mechanical Seal Part No. 10K13 Buna Elastomers

316 SS Metal Parts

383A Spring Retainer AISI Type 316 SS

AISI TYPE 316L

Stainless Steel

OPTIONAL MECHANICAL SEALS

John Crane Type 21 Mechanical Seals

Part

Item

No. Parts

10K19 Ni-Resist EPR Hi-Temperature

383

10K25

Options

10K27 Tungsten

Carbide Mild Abrasive

Rotary Stationary Elastomers

Ni-Resist Viton Chemical

Carbon

Metal

316

SS

Hi-Temperature

EPR

Steel

Intended Duty

7

Page 8

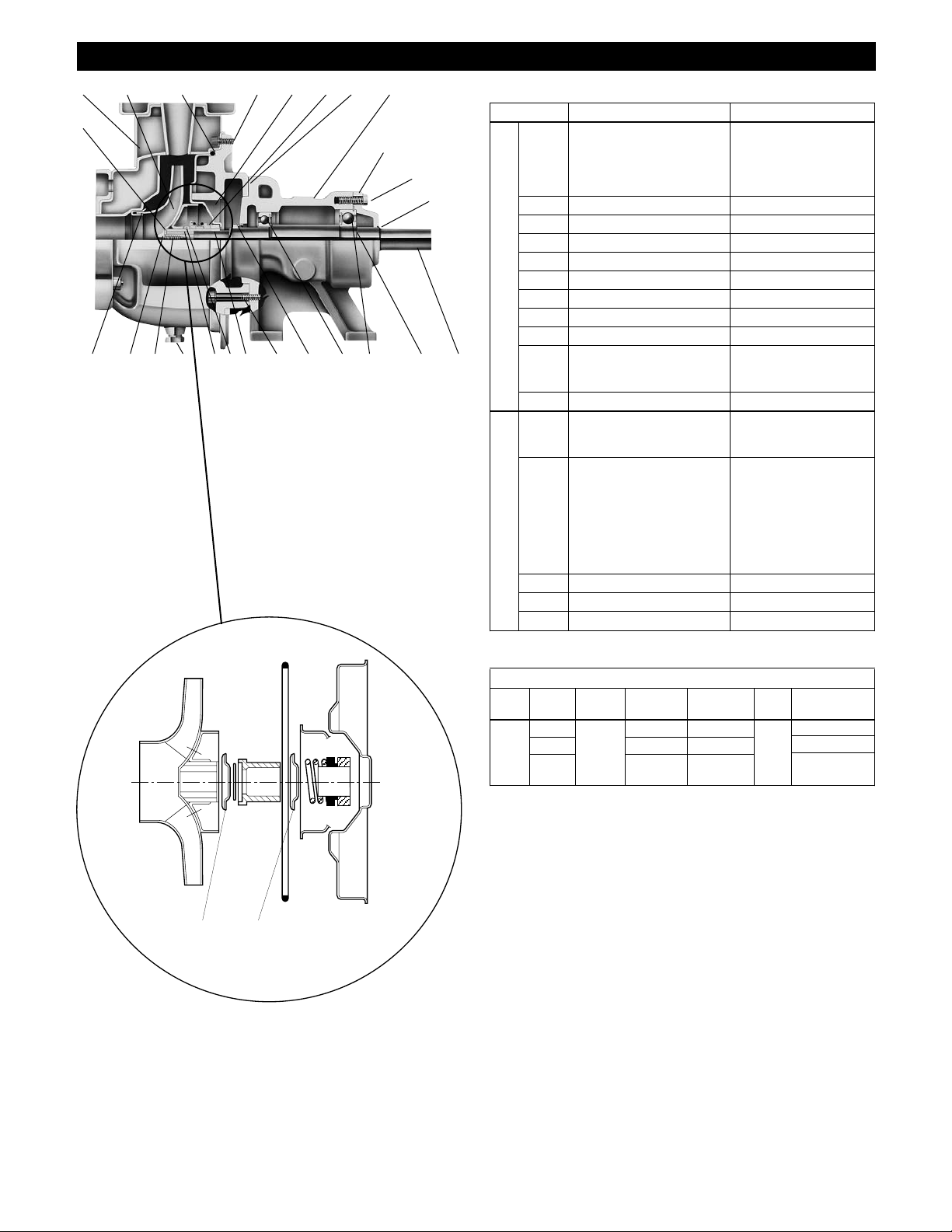

SSH-F Components

383A

(S-GROUP

LOCATION)

383A

(M-GROUP

LOCATION)

383100 101 513 370 184 108 228

412A

134

103 199 422 408 178 370B 123 168 112 136

412F

126

370C

333A

MATERIALS OF CONSTRUCTION

Item Description Material

100 Casing

101 Impeller

103 Wear Ring

184 Seal Housing

370 Socket Head Cap Screw

408 Drain plug – 3⁄8 NPT AISI TYPE 316 SS

126 Shaft Sleeve 316 SS

178 Impeller Key Steel

422 Impeller Stud Steel

199 Impeller Washer 316 SS

412A O-ring, impeller BUNA-N

412F O-ring, shaft sleeve BUNA-N

Pump End Components

513 O-Ring BUNA-N

Mechanical Seal Carbon/Ceramic

122

383 Standard Part BUNA-N Elastomers

No. 10K13 316 SS Metal Parts

383A Spring Retainer AISI Type 316SS

108 Adapter

228 Bearing Frame Cast Iron ASTM A48 CL20

134 Bearing Cover

122 Pump Shaft

168 Ball Bearing (Inboard)

112 Ball Bearing (Outboard)

136 Retaining Ring

370B Hex Head Cap Screw Steel

(Adapter to Bearing Frame)

370C Hex Head Cap Screw

(Bearing Frame to Cover)

Power End Components

333A Lip Seal BUNA-N

193 Grease Fitting Steel

123 V-Ring Deflector BUNA-N

AISI TYPE 316L

Stainless Steel

OPTIONAL MECHANICAL SEALS

John Crane Type 21 Mechanical Seals

Part

Item

No. Parts

10K19 Ni-Resist EPR Hi-Temperature

10K25

383

Options

Carbide Mild Abrasive

Rotary Stationary Elastomers

Ni-Resist Viton Chemical

Carbon

Tungsten

10K27

Metal

Intended Duty

316

SS

Hi-Temperature

EPR

8

Page 9

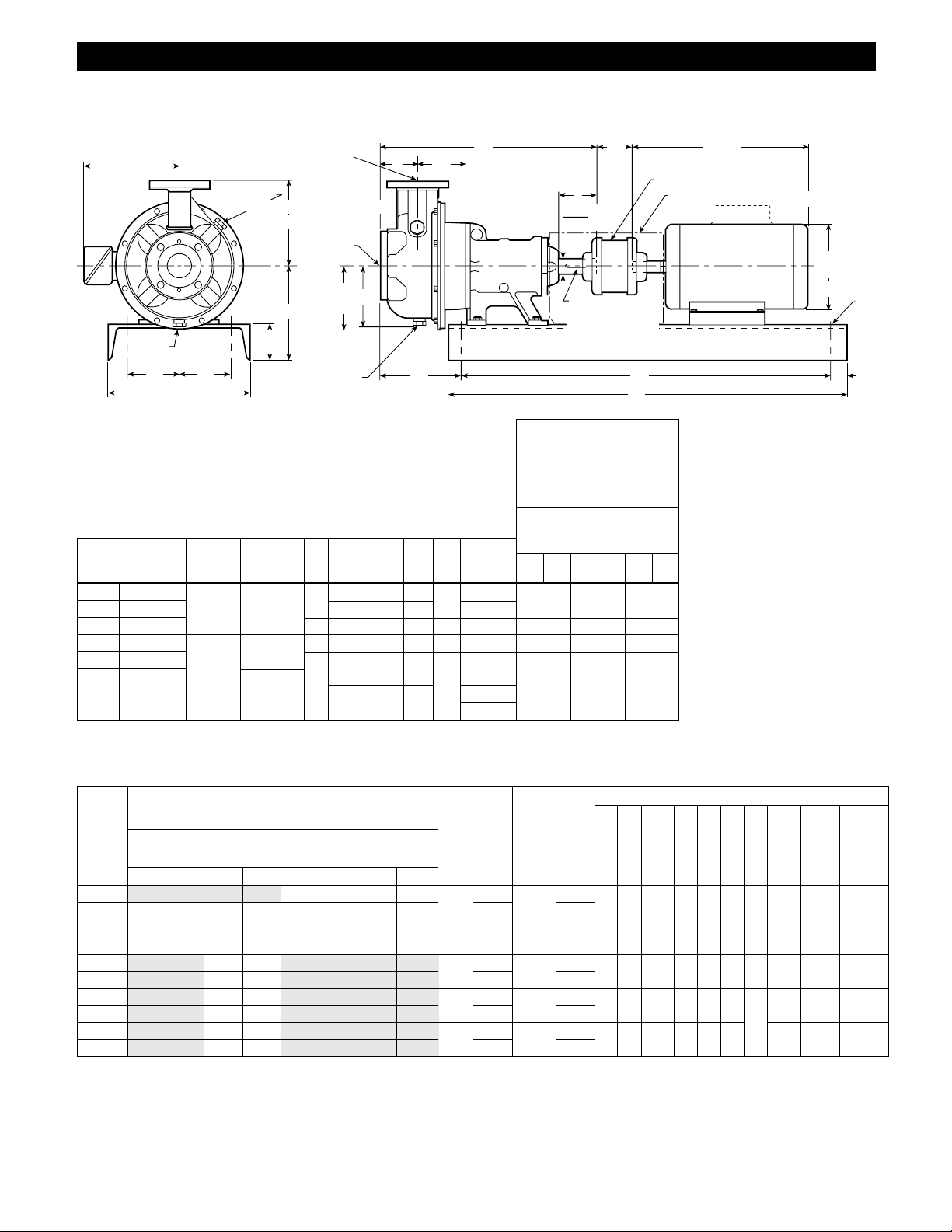

SSH S-Group – Engineering Data, Información Técnica, Données techniques – SSH, groupe S

Channel Steel Bedplate, Clockwise Rotation Viewed from Drive End;

Fundación de Acero, Rotación en Dirección de las Agujas del Reloj Visto desde el Extremo del Motor;

Plaque de base profilée en U et rotation en sens horaire (vue de l’extrémité du moteur)

CP 3¾

8

35⁄

3

1.125

1.124

1,125

1,124

SPACER COUPLING

ACOPLE DEL ESPACIADOR;

ACCOUPL. À PIÈCE D’ÉCART.

Ø

AB

MAX.

DISCHARGE

DESCARGA

REFOULEMENT

Y

PRIME PLUG,

TAPÓN DE PURGA, BOUCHON D’AMORÇAGE

X

SUCTION

SUCCIÓN

ASPIRATION

DC

HD

MAX.

DD

KEYWAY 1⁄8 x ¼

CHAVETERO 1⁄8 x ¼

LOGEMENT DE

DRAIN PLUG,

BOUCHON DE VIDANGE

TAPÓN DE DRENAJE

HE HE

HA

HG

3

⁄8" GAS THREAD;

UNI ISO 228/1;

3

⁄8, PAS DU GAZ

HL

CLAVETTE, 1⁄8 x ¼

HF

HB

(UNI ISO 228/1)

Dimension “HL” Determined

Dimensions and Weights – Determined by Pump,

by Pump and Bedplate,

Dimensiones y Pesos – Determinados por la Bomba;

Dimensions et poids – pompe

la bomba y el motor,

Dimensión “HL” determinada

Dimensions HL

– pompe et plaque de base

Pump, Suction Discharge DC Max., Wt. (lbs.),

Bomba, Succión ➀ Descarga

➀ CP

DC Máx.

DD X Y

Peso (lib.)

Pompe Aspir. Refoul. DC max. Poids

9SH 1 X 2–6

10SH 1 X 2–8 2 1 55⁄8 53⁄8 71⁄8 64

5 4¾ 63⁄8

163⁄

8

31⁄

8

56

Motor Frame Size,

Tamaño del bastidor del motor,

Carcasse de moteur

143/ 183/ 213/ 254/ 284/

145 184 215 256 286

91⁄8 75⁄8 37⁄

8

11SH 1 X 2–10 17¼ 67⁄8 65⁄8 87⁄8 86 10 8½ 4¾

4SH 1½ X 2½–6

7SH 1½ X 2½–8 2½ 55⁄8 53⁄8

5SH 2 X 2½–6

8SH 2 X 2½–8

6SH 2½ X 3–6 3 2½ 59

Available Motor and Bedplate Dimensions and Weights,

Pesos y Dimensiones Disponibles de la Fundación y del Motor

16½ 5 4¾ 63⁄8 3¼ 57 9¼ 7¾ 4

1½

2 17¼

5 4¾ 4 57

6 5¾ 715⁄

66

71⁄

8

68

16

10 8½ 4¾

➀ For use with ANSI class 150 mating flanges.

Para usar con bridas que casan ANSI clase 150.

À utiliser avec des contre-brides ANSI, classe 150.

Dimensions et poids – moteur et plaque de base

Motor

HP @ 3500 RPM, HP @ 1750 RPM,

Frame,

Armazón

Carcasse

de moteur

143T 1 1 1 1 133⁄8 45

5¼ 6

145T 2 2 2 or

10 28 8 3¾ 24 2¾ ¾ 48 1¾ –

182T 3 3 5 3 2 2 3 3 165⁄8 74

57⁄8 77⁄

184T 5 5 7½ 5

213T 10 7½ 18 116

73⁄8 95⁄8 12 31 8¼ 4¼ 29 3 1 65 – –

215T 15 10 191⁄8 136

254T 20 15 215⁄8 266

101⁄8 13 13 42 9¼ 5¼ 38½ 4 110 – 1

256T 25 20 233⁄8 264

1¾

284TS 30 25 247⁄8 392

125⁄8 15 15 44 10½ 5¾ 40½ 3½ 124 – 1¾

286TS 40 30 265⁄8 432

HP a 3500 RPM, HP a 1750 RPM,

hp à 3 500 tr/min hp à 1 750 tr/min

del

Single Phase, Three Phase, Single Phase, Three Phase,

Motor,

Monofásicos, 1 Ø Trifásicos, 3 Ø Monofásicos, 1 Ø Trifásicos, 3 Ø

ODP TEFC ODP TEFC ODP TEFC ODP TEFC

ou

3 2 1½ 1½

3 or

ou 5 3 5 3 181⁄8 95

1½ or ou 2 1½ or ou 2

AB C P Wt.

Max., Max., Max., Max.,

AB C P Peso

Máx., Máx., Máx., Máx.,

AB C P Poids

max. max. max. max.

5

14¼ 53

⁄8

8

Dimensions and weights vary with manufacturers. Dimensions in inches and weights in lbs.

“HP” Dimensions at motor end only.

* “HD” Dimension for 254T/256T motor frame on 1 x 2-10 only is 11"; A ¾" motor shim and a 1¾" bearing frame shim are required.

Dimensiones y pesos varían con los fabricantes. Dimensiones en pulgadas y pesos en libras.

Dimensiones “HP” sólo en el extremo del motor.

* La dimensión “HD” para el bastidor del motor 254T/256T de 1 x 2 - 10 es sólo 11

"

; se requieren una cuña del motor de ¾

ODP = carcasse abritée (à ouvertures de ventilation protégées) ; TEFC = carcasse fermée autoventilée.

*Dimensions HP à l’extrémité du moteur seulement. La dimension HD pour la carcasse 254T ou 256T, version 1X2-10 seulement, est de 11 po ; une cale de moteur de ¾ po et une cale de

palier de 1¾ po sont requises.

Bedplate Data,

HA HB HD* HE HF HG HP*

"

y una cuña del bastidor de apoyo de 1¾".

C MAX.

COUPLING GUARD,

GUARDA ACOPLE;

CARTER D’ACCOUPL.

(4) AGUJEROS

P

MAX.

(4) HOLES

5

8

⁄

DIA.

5

8

⁄

DIA.;

SINGLE PHASE ONLY,

SOLO UNIFÁSICOS;

MONOPHASÉ SEULEMENT

4 TROUS, DIAM. : 5⁄

HP

NOTES:

1. All pumps shipped in vertical discharge

position. May be rotated in 90° increments.

Tighten 3⁄8 – 16 casing bolts to 12 ft./lbs.

torque.

2. Dimensions in inches.

3. Motor dimensions may vary with

motor manufacturer.

4. Not to be used for construction purposes.

NOTAS:

1. Todas las bombas transportadas en posición de

descarga vertical. Pueden rotarse en aumentos

de 90º. Apretar 3⁄8 – 16 tornillos de carcasa a

12 pies/libras potencia.

2. Las dimensiones en pulgadas.

3. Las dimensiones puede que varíen con los

fabricantes..

4. No para propósitos de construcción.

NOTA :

1. L’orifice de refoulement est orienté vers le haut.

On peut le tourner de 90° en 90°. Serrer les vis

3

⁄8 - 16 du corps de pompe à 12 lbf·pi.

2. Les dimensions sont en pouces, et le poids,

en livres.

3. Les dimensions et le poids du moteur peuvent

varier selon le fabricant.

4. Ne pas utiliser les dimensions pour la construction si elles ne sont pas certifiées à cette effet.

Datos de la Fundación, Plaque de base

Motor

Shim,

Plancha

Cale de

moteur

Bearing

Frame Shim,

Plancha

de relleno

del bastidor

del cojinete,

Cale de

palier

Wt.

(lbs.),

Peso

(libras),

Poids

de relleno

del motor

8

9

Page 10

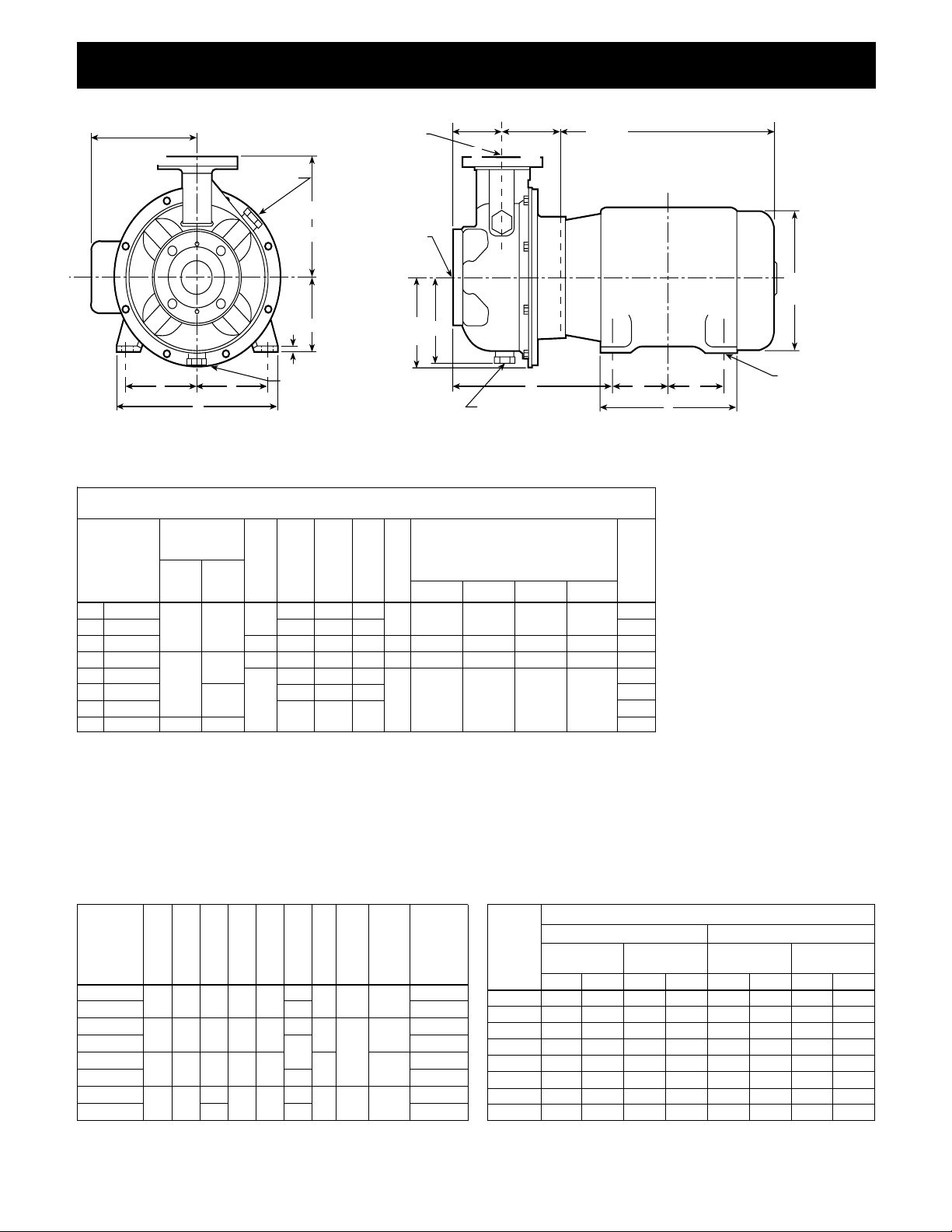

SSH S-Group Close Coupled – Dimensions and Weights, SSH Acople Cerrado – Dimensiones y Pesos,

Dimensions et poids – SSH montée sur moteur, groupe S

(All dimensions in inches and weights in lbs. Do not use for construction purposes.)

(Todas las dimensiones en pulgadas y pesos en libras. No usar para propósitos de construcción.)

CP MAX.

AB MAX.

DISCHARGE

DESCARGA

REFOULEMENT

PRIME PLUG,

TAPÓN DE PURGA,

BOUCHON D’AMORÇAGE

Y

35⁄

8

X

SUCTION

SUCCIÓN

ASPIRATION

D

G

E

E

A

DRAIN PLUG

TAPÓN DE DRENAJE

BOUCHON DE VIDANGE

DC

MAX.

DD

L

3

⁄8" GAS THREAD

UNI ISO 228/1

3

⁄8, PAS DU GAZ

(UNI ISO 228/1)

Dimensions “L” Determined by Pump and Motor,

Dimensiones “L” Determinadas por la Bomba y el Motor,

Dimensions L – pompe et moteur

150 lb. Flange,

Pump,

Bomba,

Pompe

143/145 182/184 213/215 254/256

Brida de 150 lib.,

Bride, 150 lb/po

2

Suct. Disch.

Succ. ➀ Desc.

➀

Aspir. Refoul.

9SH 1 x 2 – 6

10SH 1 x 2 – 8 2 1 5

11SH 1 x 2 – 10 27

4SH 1½ x 2½ – 6

7SH 1½ x 2½ – 8

5SH 2 x 2½ – 6

2½

8SH 2 x 2½ – 8

25½ 5 4¾ 63⁄8 3¼ 9¾ 103⁄8 113⁄8 — 25

1½

55⁄8 53⁄8 71⁄8 34

2 277⁄

6SH 2½ x 3 – 6 3 2½ 27

DC

CP

Max.,

Max.,

DC

CP

Máx.,

CP

max.

5 4¾ 63⁄8

253⁄

8

7

⁄8 67⁄8 65⁄8 87⁄8 4 10½ 111⁄8 121⁄8 123⁄8 54

5 4¾ 63⁄8

8

DD X Y

Máx.,

DC

max.

5

⁄8 53⁄8 71⁄8 32

6 4¾ 7

31⁄8 95⁄8 10¼ 11¼

4 10½ 111⁄8 121⁄8 123⁄

36

15

⁄

16

Motor Frame Size,

Tamaño del Armazón del Motor,

Carcasse de moteur

—

Wt.

(lbs.),

Pesos

(libras),

Poids

24

25

8

➀ For use with ANSI class 150 mating flanges.

Para usar con bridas que casan ANSI clase 150.

À utiliser avec des contre-brides ANSI, classe 150.

Dimensions Determined by JM Motor Frame,

Dimensiones Determinadas por el Armazón del Motor JM,

Dimensions – carcasse de moteur JM

Motor Frame Selections,

Selecciones del Armazón del Motor,

Choix de carcasses de moteur

P

MAX.

F F

B

NOTE:

1. Pumps shipped in vertical discharge as standard.

For other orientations, remove casing bolts, rotate

discharge to desired position, and tighten 3⁄

bolts to 12 ft./lbs., 7⁄

2. ALL dimensions in inches.

3. Motor dimensions may vary with motor manufacturer.

4. Not for construction purposes.

NOTA:

1. Las bombas se transportarán en descarga vertical

como estándar. Para otras orientaciones, retirar los

tornillos de la carcasa, rotar la descarga a la posición

deseada, y apretar 3⁄8 – 16 tornillos a 12 pies/libras,

7

⁄16 – 14 tornillos a 20 pies/libras.

2. TODAS las dimensiones en pulgadas.

3. Las dimensiones puede que varíen con

los fabricantes.

4. No para propósitos de construcción.

NOTA :

1. L’orifice de refoulement est orienté vers le haut. Pour

l’orienter autrement, enlever les vis de fixation du

corps de pompe, placer l’orifice dans le sens voulu,

puis reposer et serrer les vis 3⁄8 - 16 à 12 lbf·pi et 7⁄16

- 14 à 20 lbf·pi.

2. Les dimensions sont en pouces, et le poids, en livres.

3. Les dimensions et le poids du moteur peuvent varier

selon le fabricant.

4. Ne pas utiliser les dimensions pour la construction si

elles ne sont pas certifiées à cette effet.

H-(4) HOLES

H-(4) AGUJEROS

H (4 TROUS)

– 14 bolts to 20 ft./lbs.

16

8

– 16

H

JM Frame,

A AB B D E F G

JM Armazón,

Carcasse

Dia.,

H

Diám.,

H

(diam.)

143JM 2 41

6½ 5¼ 6 3½ 2¾

145JM 2½ 57

182JM 2¼ 77

8½ 57⁄8 6½ 4½ 3¾ 3⁄16 77⁄

184JM 97

2¾ 13⁄

213JM 122

9½ 73⁄8 8 5¼ 4¼ 7⁄32 95⁄

215JM 3½ 155

254TCZ 9½ 41⁄8 265

11¼ 9 6¼ 5 ¼ 17⁄32 11½

256TCZ 11¾ 5 320

1

⁄8 11⁄32 65⁄

32

P Max.,

P Máx.,

P max.

8

8

8

Motor Wt.

(lbs.)

Peso Motor

(lib.),

Poids du

moteur

10

Motor

Frame,

Armazón

del Motor,

Carcasse

ODP TEFC ODP TEFC ODP TEFC ODP TEFC

Motor Horsepower,

3500 RPM,

1Ø,

3500 RPM, 3 500 tr/min

Monofásicos

1 Ø 3 Ø 1 Ø 3 Ø

Potencia del Motor, Puissance (hp)

1750 RPM,

3Ø,

Trifásicos

1Ø,

Monofásicos

1750 RPM, 1750 tr/min

3Ø,

Trifásicos

143JM – – – – – – 1 1

145JM 2 2 2-3 2 1-1½ 1-1½ 1½-2 1½-2

182JM 3 3 5 3 2 2-3 3 3

184JM 5 5 7½ 5 3 – 5 5

213JM 7½ – 10 7½ 5 – 7½ 7½

215JM 10 – 15 10-15 – – – –

254TCZ – – 20 – – – – –

256TCZ – – 25 20-25 – – – –

ODP = carcasse abritée (à ouvertures de ventilation protégées) ;

TEFC = carcasse fermée autoventilée.

Page 11

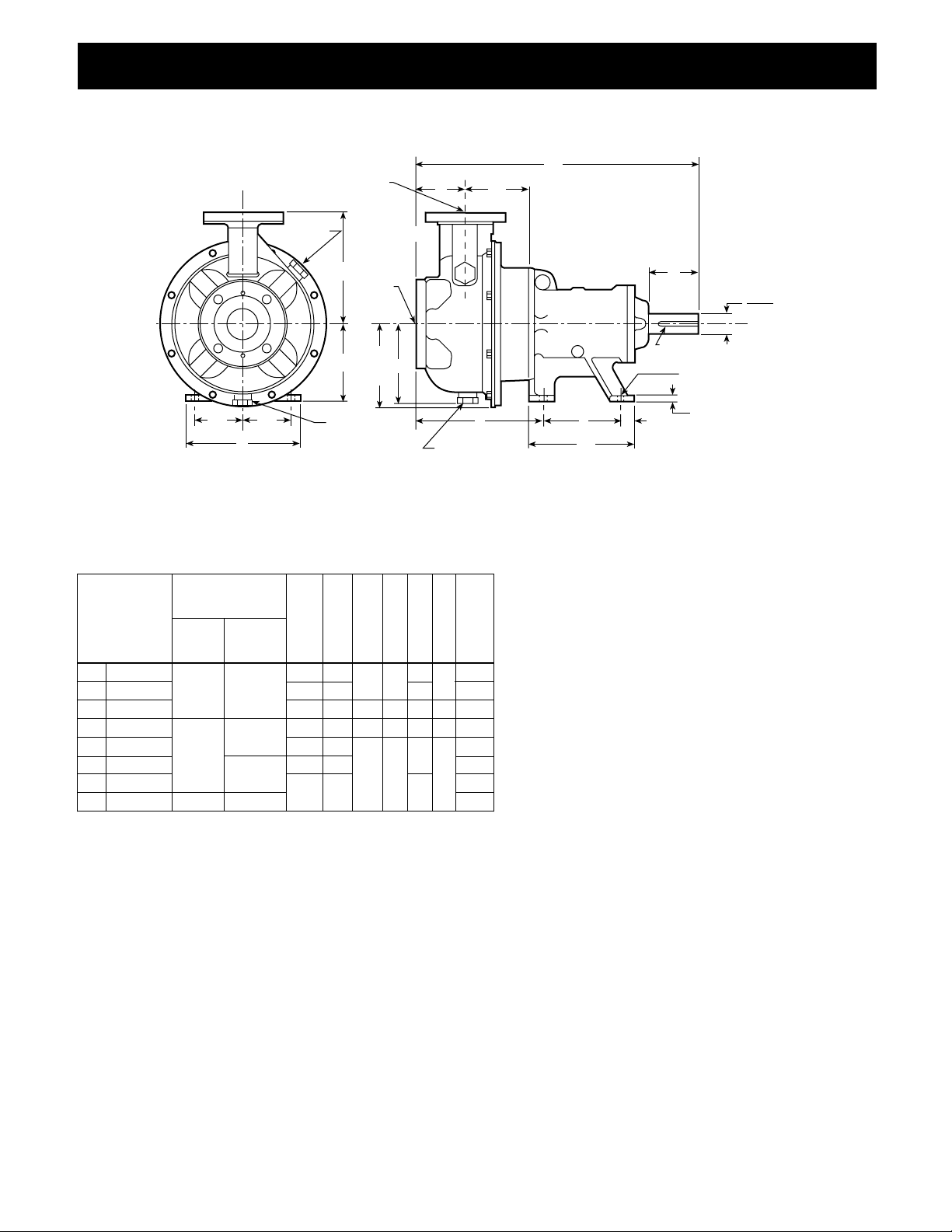

SSH S-Group Frame-Mounted – Dimensions and Weights, SSH Armazón Montado – Dimensiones y Pesos,

Dimensions et poids – SSH montée sur palier, groupe S

DISCHARGE

DESCARGA

Y

REFOULEMENT

PRIME PLUG,

TAPÓN DE PURGA,

BOUCHON

D’AMORÇAGE

X

SUCTION

SUCCIÓN

ASPIRATION

DC

2¾ 2¾

7

5¼

DRAIN PLUG,

TAPÓN DE DRENAJE, BOUCHON DE

VIDANGE

MAX.

DD

3

⁄8" GAS THREAD

UNI ISO 228/1

3

⁄8" PAS DU GAZ

(UNI ISO 228/1)

Dimensions and Weights – Bare Pump Only,

Dimensiones y Pesos – Solamente Bomba,

Dimensions et poids – pompe nue seulement

150 lb. Flange,

Pump,

Bomba,

Pompe

Brida de 150 lib.,

Bride, 150 lb/po

Suction Discharge

Succión ➀ Descarga

Aspir. Refoul.

9SH 1 x 2 – 6 5 4¾

10SH 1 x 2 – 8 2 1 55⁄8 53⁄8 71⁄8 64

11SH 1 x 2 – 10 67⁄8 65⁄8 17¼ 8½ 87⁄8 4 86

4SH 1½ x 2½ – 6

7SH 1½ x 2½ – 8

5SH 2 x 2½ – 6

2½

8SH 2 x 2½ – 8

1½

55⁄8 53⁄8

2

6SH 2½ x 3 – 6 3 2½ 57

➀ For use with ANSI class 150 mating flanges.

Para usar con bridas que casan ANSI clase 150.

À utiliser avec des contre-brides ANSI, classe 150.

DC

Max.,

2

DC

Máx.,

DC

➀

max.

CP

Max.,

CP

DD L X Y

Máx.,

CP

max.

63⁄8

163⁄8 75⁄

31⁄

8

(libras),

56

8

5 4¾ 16½ 7¾ 63⁄8 3¼ 56

64

71⁄

5 4¾

6 5¾ 63⁄

16½ 8½

8

4 57

66

8

Wt.

(lbs.),

Peso

Poids

CP

35⁄

8

L

5

6½

NOTE:

1. Pumps will be shipped with top

vertical discharge as standard.

For other orientations, remove

casing bolts, rotate discharge to

desired position, and tighten 3⁄

–16 bolts to 12 ft./lbs., 7⁄16 – 14

bolts to 20 ft./lbs.

2. ALL dimensions in inches.

3. Not for construction purposes.

3

1.125

1,125

1.124

1,124

DIA.

(DIAM.)

KEYWAY 1⁄8 x 1⁄4,

LOGEMENT DE CLAVETTE, 1⁄8 x ¼

¾

CHAVETERO 1⁄8 x ¼

7

⁄

DIA. – (4) HOLES,

16

(4) AGUJEROS, 4 TROUS, DIAM. : 7⁄

,

7⁄

DIA. –

16

½

NOTA:

1. Las bombas se transportarán con

la descarga vertical superior como

estándar. Para otras orientaciones,

retirar los tornillos de la carcasa,

rotar la descarga a la posición

8

deseada, y apretar 3⁄8 – 16 tornillos

a 12 pies/libras, 7⁄16 – 14 tornillos a

20 pies/libras.

2. TODAS las dimensiones en

pulgadas.

3. No para propósitos de construcción.

NOTA :

1. L’orifice de refoulement est orienté

vers le haut. Pour l’orienter autrement, enlever les vis de fixation du

corps de pompe, placer l’orifice

dans le sens voulu, puis reposer et

serrer les vis 3⁄8 – 16 à 12 lbf·pi et

7

⁄16 – 14 à 20 lbf·pi.

2. Les dimensions sont en pouces, et

le poids, en livres.

3. Ne pas utiliser les dimensions pour

la construction si elles ne sont pas

certifiées à cette effet.

16

11

Page 12

4 H OL ES

5

∨

8

4 TROUS,

DIAM. : 5∨

8

AB

MAX.

HE HE

HA

HG

HD

SUCTION

SUCCIÓN,

ASPIRATION

DISCHARGE

DESCARGA,

REFOULEMENT

DC

MAX.

3

∨8" GAS THREAD

UNI ISO 228/1,

3

∨8, PAS DU GAZ (UNI ISO 228/1)

DD

CP

Y

L

HB

HF

1

3

∨

4

P

MAX.

C

MAX.

3 3∨

4

1.625,

1,625

1.624,

1,624

37∨

8

COUPLING GUARD,

CARTER D’ACCOUPL.

SINGLE PHASE ONLY

MONOPHASÉ SEULEMENT

KEYWAY 3∨

16

X 3∨

8

LOGEMENT DE CLAVETTE, 3∨16 x 3∨

8

X

PRIME PLUG,

TAPÓN DE PURGA, BOUCHON D’AMORÇAGE

SPACER COUPLING,

ACCOUPL. À PIÈCE D’ÉCART.

DRAIN PLUG,

TAPÓN DE DRENAJE, BOUCHON DE VIDANGE

SSH-F M-Group – Engineering Data, SSH-F – Información Técnica, Données techniques – SSH-F, groupe M

Channel Steel Bedplate, Clockwise Rotation Viewed from Drive End;

Fundación de Acero, Rotación en Dirección de las Agujas del Reloj Visto desde el Extremo del Motor;

Plaque de base profilée en U et rotation en sens horaire (vue de l’extrémité du moteur)

Dimensions and Weights – Determined by Pump,

Dimensiones y Pesos – Determinados por la Bomba,

Dimensions et poids – pompe

Pump,

Bomba,

Pompe

Pump Size,

Tamaño de

la Bomba,

Dimensions

24SH 1½ x 2½-10

25SH 2 x 2½-10 2

22SH 2½ x 3-8

27SH 2½ x 3-10

23SH 3 x 4-8

28SH 3 x 4-10 75⁄8 73⁄8 111⁄8 148

➀ ➀

Suction Discharge

Succión Descarga

Aspir. Refoul.

1½

2½

3 2½

61⁄8 57⁄8 125

4 3 24

➀ For use with ANSI class 150 mating flanges.

Para usar con bridas que casan ANSI clase 150.

À utiliser avec des contre-brides ANSI, classe 150.

DC

Max.,

DC

CP

Máx.,

DC

max.

67⁄8 65⁄8

23

67⁄8 65⁄8

DD L X Y

125

815⁄16 4 125

101⁄8

915⁄16

5 136

111⁄8

134

(libras),

NOTE:

1. Pumps will be shipped with top

vertical discharge as standard. For

other orientations, remove casing

Wt.

(lbs.),

Peso

Poids

bolts, rotate discharge to desired

position and tighten 3⁄8 – 16 bolts

to 12 ft./lbs.

2. ALL dimensions in inches.

3. Not for construction purposes.

NOTA:

1. Las bombas se transportarán con

la descarga vertical superior como

estándar. Para otras orientaciones,

retirar los tornillos de la carcasa,

rotar la descarga a la posición

deseada, y apretar 3⁄8 – 16 tornillos

a 12 pies/libras.

2. TODAS las dimensiones en

pulgadas.

3. No para propósitos de

construcción.

NOTA :

1. L’orifice de refoulement est orienté vers le haut. Pour l’orienter

autrement, enlever les vis de

fixation du corps de pompe,

placer l’orifice dans le sens voulu,

puis reposer et serrer les vis

3

⁄8 - 16 à 12 lbf·pi.

2. Les dimensions sont en pouces,

et le poids, en livres.

3. Les dimensions et le poids du

moteur peuvent varier selon le

fabricant.

4. Ne pas utiliser les dimensions

pour la construction si elles ne

sont pas certifiées à cette effet.

Available Motor and Bedplate Dimensions and Weights,

Pesos y Dimensiones Disponibles de la Fundación y del Motor,

Dimensions et poids – moteur et plaque de base

Motor

HP @ 3500 RPM, HP @ 1750 RPM – T-Frame Only Bedplate Data,

Frame,

hp à 3 500 tr/min hp à 1 750 tr/min – carc. T seulem. Plaque de base

Armazón

del

Three Phase, Single Phase, Three Phase,

Motor,

Trifásicos, 3 Ø Monofásicos, 1 Ø Trifásicos, 3 Ø

Carcasse

de moteur

184T 3 or

ODP TEFC ODP TEFC ODP TEFC

ou

5 3 5 5 57⁄8 181⁄8 77⁄8 95

AB C P Wt.

Max., Max., Max., Max.,

AB C P Peso

Máx., Máx., Máx., Máx.,

AB C P Poids

max. max. max. max.

HA HB HD HE HF HG

213T 71⁄2 71⁄2 18 116

215T 15 10 10 191⁄8 136 13 42 101⁄4 51⁄4 381⁄2 4 111

254T 20 15 15 15 215⁄8 266

256T 25 20 20 20 233⁄8 264

284TS/T 30 25 25 25 247⁄8 392

286TS/T 40 30 265⁄8 422

324TS/T 50 40 283⁄4 592

326TS/T 60 50 301⁄4 634

364TS/T 75 60 315⁄8 834

365TS/T 100 75 325⁄8 1000

405TS/T 100 18 367⁄8 205⁄8 1060 22 56 14 7¼ 52½ 4 214

Dimensions and weights vary with manufacturers. Dimensions in inches and weights in lbs.

73⁄8 95⁄8

91⁄2 13

125⁄8 15 15 44 101⁄2 53⁄4 401⁄2 31⁄2 124

141⁄8 173⁄8 12

18 48 71⁄4 441⁄2 4 183

151⁄8 187⁄8 13

Dimensiones y pesos varían con los fabricantes. Dimensiones en pulgadas y pesos en libras.

ODP = carcasse abritée (à ouvertures de ventilation protégées) ; TEFC = carcasse fermée autoventilée.

12

Datos de la Fundación,

Wt. (lbs.),

Peso

(libras),

Poids

Page 13

DRAIN PLUG,

TAPÓN DE DRENAJE,

BOUCHON DE VIDANGE

D

A

SUCTION,

SUCCIÓN,

ASPIRATION

DISCHARGE,

DESCARGA,

REFOULEMENT

Y

CP

L

DC

MAX.

3

∨8" G AS THR EAD

UN I I SO 228 /1,

3

∨8, PAS DU GAZ

(UNI ISO 228/1)

DD

E

AB

MAX.

E

G

MAX.

B

F F

P

MAX.

H-4 HOLES,

H (4 TROUS)

X

PRIME PLUG,

TAPÓN DE PURGA, BOUCHON D’AMORÇAGE

SSH M-Group Close Coupled – Dimensions and Weights, SSH Acople Cerrado – Dimensiones y Pesos,

Dimensions et poids – SSH montée sur moteur, groupe M

(All dimensions in inches and weights in lbs. Do not use for construction purposes.)

(Todas las dimensiones en pulgadas y pesos en libras. No usar para propósitos de construcción.)

Dimensions “L” Determined by Pump and Motor,

Pump,

Bomba,

Pompe

Pump Size,

Tamaño de

la Bomba,

Dimensions

24SH 11⁄2 x 2 1⁄2-10

➀ ➀

Suction Discharge

Succión Descarga

Aspir. Refoul.

1

21⁄2

1

⁄2 341⁄2

Dimensiones “L” Determinadas por la Bomba y el Motor, Dimensions L – pompe et moteur

CP

Max.,

CP

Máx.,

CP

max.

DC

Max.,

DC

Máx. ,

DC

max.

67⁄8 65⁄8

DD X Y

(libras),

75 10

Wt.

(lbs.),

Peso

140 180 210 250 280 320 360

Poids

25SH 2 x 21⁄2-10 2 815⁄16 4 75 111⁄8

22SH 21⁄2 x 3-8

3 21⁄2

27SH 21⁄2 x 3-10

23SH 3 x 4-8

4 3 37

36 61⁄8 57⁄8 72 -

67⁄8 65⁄8 915⁄16

84 - -

5 86 111⁄2 121⁄8

28SH 3 x 4-10 75⁄8 73⁄8 111⁄8 98 - -

➀ For use with ANSI class 150 mating flanges.

Para usar con bridas que casan ANSI clase 150.

À utiliser avec des contre-brides ANSI,

classe 150.

NOTES:

1. Pumps shipped in vertical discharge as

standard. For other orientations, remove

casing bolts, rotate discharge to desired

position, and tighten 3⁄8 – 16 bolts to

12 ft./lbs., 7⁄

½ – 13 bolts to 35 ft./lbs.

2. Motor dimensions may vary with motor

manufacturer.

3. Not for construction purposes.

– 14 bolts to 20 ft./lbs.,

16

Dimensions Determined by JM Motor Frame,

Dimensiones Determinadas por el Armazón del Motor JM,

Dimensions – carcasse de moteur JM

Frame,

A B D E F G H

Armazón,

Carcasse

AB

Max.,

AB

max.

145JM 61⁄2 51⁄4 6 31⁄2 23⁄4 21⁄2 1⁄8 11⁄32 73⁄16

182JM 21⁄4

184JM

213JM

215JM 31⁄2

254JM 41⁄8

256JM 5

284JM 43⁄4

286JM 51⁄2

324JM 51⁄4

326JM 51⁄2

364TCZ 5

365TCZ 61⁄8

364TCZ and 365TCZ frames are built with 326JM shaft extensions.

Dimensions may vary with manufacturer.;

Los armazones 364TCZ y 365TCZ se construyen con extensiones del eje 326JM.

1

8

⁄2 57⁄8 61⁄2 41⁄2 33⁄4 3⁄16

23⁄4 13⁄32

91⁄2 73⁄8 8 51⁄4 41⁄4 7⁄32 103⁄16

111⁄4 9 113⁄4 61⁄4 5 131⁄4

1⁄4 17⁄32

121⁄4 121⁄4 121⁄4 7 51⁄2

14 13

1

⁄4 14 8 61⁄4 5⁄16 1615⁄16

173⁄4 151⁄8 151⁄2 9 7 1 19

5

⁄8

Las dimensiones puede que varíen con los fabricantes.;

Les carcasses 364TCZ et 365TCZ possèdent la rallonge d’arbre de la 326JM.

P Max.,

P Máx.,

21

⁄32

P

max.

1

8

⁄2

15

NOTAS:

1. Las bombas se transportarán en descarga

vertical como estándar. Para otras orientaciones, retirar los tornillos de la carcasa, rotar

la descarga a la posición deseada, y apretar

3

⁄8 – 16 tornillos a 12 pies/libras, 7⁄

tornillos a 20 pies/libras, ½ – 13 tornillos a

35 pies/libras.

2. TODAS las dimensiones en pulgadas.

3. No para propósitos de construcción.

Motor Frame Selections,

Selecciones del Armazón del Motor,

Choix de carcasses de moteur

Frame,

Armazón,

Carcasse

ODP TEFC ODP TEFC ODP TEFC

145JM – – – – 2 2 57

182JM – – 2 2, 3 3 3 77

184JM – – 3 – 5 5 97

213JM 10 – 5 – 7½ 7½ 141

215JM 15 10 – – 10 10 155

254JM 20 15 – – 15 15 265

256JM 25 20 – – 20 20 320

284JM 30 25 – – 25 25 419

286JM 40 30 – – – – 422

324JM 50 40 – – – – 562

326JM 60 50 – – – – 625

364TCZ 75 60 – – – – 775

365TCZ 100 75, 100 – – – – 905

364TCZ and 365TCZ frames are built with 326JM shaft extensions.

Los armazones 364TCZ y 365TCZ se construyen con extensiones del eje 326JM.

ODP = carcasse abritée (à ouvertures de ventilation protégées) ; TEFC = carcasse fermée

autoventilée. Les carcasses 364TCZ et 365TCZ possèdent la rallonge d’arbre de la 326JM.

Motor Horsepower,

3500 RPM,

3500 tr/min

3 PH,

Trifásicos, 3 Ø 1 PH,

Motor Frame Size,

Tamaño del Armazón del Motor,

Carcasse de moteur

1

⁄2 -

121⁄8 137⁄8 143⁄8

15

133⁄8 147⁄8 153⁄8 16

NOTA :

1. L’orifice de refoulement est orienté vers le haut.

Pour l’orienter autrement, enlever les vis de fixation du

16

corps de pompe, placer l’orifice dans le sens voulu,

puis reposer et serrer les vis

à 20 lbf·pi et ½ - 13 à 35 lbf·pi.

– 14

2. Les dimensions sont en pouces, et le poids, en livres.

3. Les dimensions et le poids du moteur peuvent varier

selon le fabricant.

4. Ne pas utiliser les dimensions pour la construction si

elles ne sont pas certifiées à cette effet.

3

⁄

- 16 à 12 lbf·pi, 7⁄16 - 14

8

Potencia del Motor, Puissance (hp)

1750 RPM,

Monofásicos, 1 Ø

1750 tr/min

3 PH,

Trifásicos, 3Ø

Wt.

Max.,

Peso

Máx.,

Poids

max.

13

Page 14

DRAIN PLUG,

TAPÓN DE DRENAJE

BOUCHON DE VIDANGE

61∨4

31∨231∨2

81∨

2

SUCTION,

SUCCIÓN,

ASPIRATION

DISCHARGE,

DESCARGA,

REFOULEMENT

Y

CP

L

DC

MAX.

3

∨8" GAS THREAD

UNI ISO 228/1

3

∨8, PAS DU GAZ (UNI ISO 228/1)

DD

61∨2

81∨2

1 ”

KEYWAY 3∨

16

X

3

∨8,

CHAVETERO 3∨16 X 3∨8,

LOGEMENT DE CLAVETTE, 3∨16 x 3∨8

4 HOLES 9∨16 DIA.,

9

∨16 DIAM. - (4) AGUJEROS,

4 TROUS, DIAM. : 9∨16

1

∨2

1.625

(1,625)

1.624

(1,624)

DIA. (DIAM.)

37∨8

X

PRIME PLUG,

TAPÓN DE PURGA, BOUCHON D’AMORÇAGE

SSH M-Group Frame Mounted – Dimensions and Weights, SSH Armazón Montado – Dimensiones y

Pesos, Dimensions et poids – SSH montée sur palier, groupe M

Dimensions and Weights – Bare Pump Only,

Dimensiones y Pesos – Solamente Bomba

Dimensions et poids – pompe nue seulement

Pump,

Bomba,

Pompe

Pump Size,

Tamaño de

la Bomba,

Dimensions

➀ ➀

Suction Discharge

Succión Descarga

Aspir. Refoul.

CP

Max.,

DC

DD L X Y

Máx.,

DC

max.

DC

24SH 1½ x 2½-10

25SH 2 x 2½-10 2

22SH 2½ x 3-8

27SH 2½ x 3-10

23SH 3 x 4-8

28SH 3 x 4-10 75⁄8 73⁄8 111⁄8 148

1½

2½

3 2½

61⁄8 57⁄8 125

4 3 24

67⁄8 65⁄8

23

67⁄8 65⁄8

125

815⁄16 4 125

10½

915⁄16 134

5 136

11½

➀ For use with ANSI class 150 mating flanges.

Para usar con bridas que casan ANSI clase 150.

À utiliser avec des contre-brides ANSI, classe 150.

NOTES:

1. Pumps will be shipped with top vertical discharge as standard. For other orientations, remove casing bolts, rotate

discharge to desired position, replace

and tighten 3⁄

2. Motor dimensions may vary with motor manufacturer.

3. Not for construction purposes.

–16 bolts to 12 ft./lbs.

8

14

NOTAS:

1. Las bombas se transportarán con la

descarga vertical superior como estándar.

Para otras orientaciones, retirar los

tornillos de la carcasa, rotar la descarga

a la posición deseada, y apretar

tornillos a 12 pies/libras.

2. TODAS las dimensiones en pulgadas.

3. No para propósitos de construcción.

Wt.

(lbs.),

Peso

(libras),

Poids

3

⁄8 – 16

NOTA :

1. L’orifice de refoulement est orienté vers

le haut. Pour l’orienter autrement, enlever

les vis de fixation du corps de pompe,

placer l’orifice dans le sens voulu, puis

reposer et serrer les vis 3⁄8 – 16 à 12 lbf·pi.

2. Les dimensions sont en pouces, et le

poids, en livres.

3. Les dimensions et le poids du moteur

peuvent varier selon le fabricant.

4. Ne pas utiliser les dimensions pour la

construction si elles ne sont pas certifiées

à cette effet.

Page 15

ITT

Commercial Water

This warranty applies to all water systems pumps manufactured by Goulds Pumps.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The

warranty period shall exist for a period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever

period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized GouldsPumps distributor from whom the pump was purchased and

furnish complete details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Pumps Customer Service

Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds Pumps

and the dealer in purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling

or leasing pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership,

corporation, limited liability company, association or other legal entity which may engage in any type of business.

GOULDS PUMPS LIMITED WARRANTY

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Goulds Pumps and the ITT Engineered Blocks Symbol are

registered trademarks and tradenames of ITT Industries Inc.

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

IM184R03 March, 2006

© 2006 ITT Water Technology, Inc.

Engineered for life

15

Page 16

ITT

Goulds Pumps

G&L SERIES SSH-C y SSH-F

Instrucciones de instalación,

operación y mantenimiento

Agua Industrial

16

Goulds Pumps son una marca de fábrica de ITT Water

Technology, Inc. - un subsidiario de ITT Industries, inc.

www.goulds.com

Engineered for life

Page 17

Índice

TEMA PÁGINA

Instrucciones de seguridad ................................................. 18

Instrucciones importantes .................................................. 18

Instalación ......................................................................... 18

Alineación .......................................................................... 19

Tubería de succión ............................................................. 19

Tubería de descarga ........................................................... 19

Rotación ............................................................................ 19

Operación .......................................................................... 20

Mantenimiento .................................................................. 20

Desmontaje ........................................................................ 20

Reensamblaje ..................................................................... 20

Investigación de averiás ..................................................... 21

Componentes .................................................................... 22

SSH S-Group – Información Técnica ...................................9

SSH S-Group Acople Cerrado – Dimensiones y Pesos ...... 10

SSH S-Group Armazón Montado –

Dimensiones Y Pesos ..................................................... 11

SSH M-Group – Información Técnica .............................. 12

SSH M-Group Acople Cerrado – Dimensiones y Pesos .... 13

SSH M-Group Armazón Montado –

Dimensiones y Pesos ...................................................... 14

Garantía limitada de Goulds Pumps .................................. 24

Declaración de Conformidad ............................................ 35

Información del propietario

Por favor complete los datos consultando la placa del fabricante de la bomba. La información de la garantía está en la

página 24.

Modelo de la Bomba:

Número de Serie:

Agente:

Nº. telefónico del agente:

Fecha de compra:

Fecha de instalación:

17

Page 18

PELIGRO

ADVERTENCIA

PRECAUCIÓN

ADVERTENCIA

Los fluidos peligrosos

pueden causar

incendios, quemaduras

o la muerte.

INSTRUCCIONES DE SEGURIDAD

PRECAUCIÓN

ADVERTENCIA

Un voltaje peligroso puede

producir golpes eléctricos,

quemaduras o la muerte.

AVISO: INSPECCIONE LA UNIDAD SI TIENE

DAÑOS Y REPORTE INMEDIATAMENTE

CUALQUIER DAÑO AL TRANSPORTISTA O

AL AGENTE.

1. Inspeccione la unidad para determinar si está dañada.

2. La alimentación eléctrica debe ser un circuito de rama

18

PARA EVITAR LESIONES CORPORALES SERIAS O

FATALES O DAÑOS MAYORES A LA PROPIEDAD,

LEA Y SIGA TODAS LAS INSTRUCCIONES DE

SEGURIDAD EN EL MANUAL Y EN LA BOMBA.

ES INTENCIÓN QUE ESTE MANUAL ASISTA EN

LA INSTALACIÓN Y OPERACIÓN DE ESTA UNIDAD Y

DEBE MANTENERSE CON LA BOMBA.

Este es un SÍMBOLO DE ALERTA DE

SEGURIDAD. Cuando vea este símbolo

en la bomba o en el manual, busque una

de las palabras de señal y esté alerta a las

lesiones corporales potenciales o daños a

la propiedad.

Advierte los peligros que CAUSARÁN

lesiones corporales serias, la muerte o

daños mayores a la propiedad.

Advierte los peligros que PUEDEN causar lesiones corporales serias, la muerte o

daños mayores a la propiedad.

Advierte los peligros que PUEDEN

causar lesiones corporales o daños a la

propiedad.

AVISO: INDICA INSTRUCCIONES ESPECIALES

QUE SON MUY IMPORTANTES Y

DEBEN SEGUIRSE.

EXAMINE A FONDO TODAS LAS

INSTRUCCIONES Y ADVERTENCIAS ANTES DE

REALIZAR ALGÚN TRABAJO EN ESTA BOMBA.

MANTENGA TODAS LAS CALCOMANÍAS DE

SEGURIDAD.

UNIDAD NO DISEÑADA PARA

USO CON LÍQUIDOS PELIGROSOS

O GASES INFLAMABLES. ESTOS

FLUIDOS PUEDEN ESTAR

PRESENTES EN LAS ÁREAS DE

CONTENCIÓN.

1. Instrucciones Importantes

Informe immediatemente los daños al transportista.

separada con los fusibles o interruptores automáticos,

tamaños de cables, etc., conforme a los códigos Eléctricos Nacional y local. Instale un interruptor de desconexión en todos los hilos exteriores cerca de la bomba.

SIEMPRE DESCONECTE

LA ALIMENTACIÓN ELÉCTRICA

CUANDO MANEJE LA BOMBA O

LOS CONTROLES.

3. Los motores deben estar alambrados para la tensión

apropiada (verifique la placa del fabricante). El tamaño

del alambre debe eliminar la máxima caída de tensión

a 10% de la tensión de la placa del fabricante en los

terminales del motor, o la vida del motor y de la

bomba serán disminuidos.

4. Unidades monofásicas: La protección térmica de las

unidades monofásicas a veces está incorporada

(verifique la placa del fabricante). Si no se proporciona

protección incorporada, use un contactor con la

sobrecarga apropiada. Se permite el uso de fusibles, los

que deben ser apropiados.

5. Unidades trifásicas: Proporcione la protección de tres

hilos exteriores con el arrancador magnético del

tamaño adecuado y sobrecargas térmicas.

6. Máximas temperaturas del liquido:

212ºF (100ºC) con sello estándar.

250ºF (120ºC) con sello de alta temperatura, opcional.

7. Máxima presión de operación permisible: 230 lib/

pulg2 (15 baras).

8. Máximo número de arranques/hora: 20 distribuidos

uniformemente.

9. La inspección y mantenimiento regulares aumentarán

la vida útil. Base el programa en el tiempo de funcionamiento.

2. Instalación

1. Las unidades compactas se pueden instalar inclinadas o

verticales.

NO INSTALE CON EL MOTOR DEBAJO DE LA BOMBA. LA CONDENSACIÓN SE ACUMULARÁ EN EL

MOTOR.

2. Coloque la bomba tan cerca de la fuente del líquido

como sea posible (abajo del nivel del líquido para

operación automática).

3. Proteja contra la congelación e inundaciones.

4. Deje suficiente espacio libre para darle servicio y

ventilación.

5. Para las bombas compactas, la cimentación debe ser

plana y substancial para eliminar las deformaciones

cuando se aprietan los pernos. Use montajes de goma

para minimizar el ruido y las vibraciones. Apriete los

pernos de sujeción del motor antes de conectar la

tubería a la bomba.

6. Para las bombas montadas en marco, se requiere una

cimentación sólida y permanente para funcionamiento

seguro. La placa de base debe adherirse con lechada a

la cimentación con una zapata sólida.

7. Coloque la unidad sobre cuñas puestas en cuatro

pumtos. (Dos aproximadamente abajo del centro del

motor y dos aproximadamente abajo de la bomba).

Ajuste las cuñas para nivelar la unidad, trayendo las

mitades del acoplamiento a una alineación razonable.

Nivele o ponga a escuadra las bridas de succión y de

descarga.

8. Asegúrese de que la placa de base no esté distorsionada

y que la alineación final del acoplamiento se pueda

hacer dentro de los límites del movimiento del motor

o poniendo calzas, si fuese necesario.

9. Apriete con los dedos los pernos de la cimentación, y

construya una presa alrededor de la cimentación.

Derrame lechada debajo de la placa de base,

Page 19

PRECAUCIÓN

Maquinaria peligrosa

ADVERTENCIA

asegurándose de que las áreas debajo de la bomba y

del motor estén bien llenas. Permita que la lechada

fragüe por 48 horas antes de apretar más los pernos de

la cimentación.

10. Toda la tubería debe estar soportada independiente-

mente de la bomba y debe “alinearse” naturalmente.

Nunca estire la tubería en el lugar forzando las

conexiones de la succión o descarga.

11. La alineación angular de las bridas se puede lograr

mejor usando calibradores en los lugares de los pernos (vea la ilustración).

12. En las unidades montadas en marco, apriete la

cimentación, la bomba y los pernos de sujeción del

impulsor, antes de conectar la tubería a la bomba.

13. Evite los accesorios innecesarios. Seleccione los tama-

ños para mantener bajas las pérdidas de presión.

14. Después de completar la tubería, gire a mano la uni-

dad para verificar el trabado. Nota: En el extremo del

eje del motor se proveen una ranura de destornillador

o filos normales al eje.

3. Alineación

1. Las bombas compactas no necesitan alineación en

el campo.

2. Aunque la unidad de bomba y motor pueda tener una

alineación de fábrica, la misma puede haberse alterado

en tránsito y se debe verificar antes del funcionamiento.

3. Verifique que todos los pernos de sujeción estén bien

apretados antes de verificar la alineación.

4. Si es necesario realinear, siempre mueve el motor,

Aplique calzas según se requiera.

5. La alineación final se logra cuando se cumplen los

requerimientos paralelo y angular, con los pernos de

sujeción y de la bomba y del motor, apretados.

SIEMPRE VUELVA A VERIFICAR AMBAS ALINEACIONES DESPUÉS DE

HACER AJUSTES.

6. La alineación paralela es incorrecta cuando los ejes no

están concéntricos. Ponga el indicador de cuadrante en

un cubo y gire este cubo 360º mientras hace lecturas

en el diámetro exterior del otro cubo. Hay alineación

paralela cuando la lectura total del indicador es de

0,005" o menos.

7. La alineación angular es incorrecta cuando los ejes no

están paralelos. Coloque el indicador de cuadrante en

un cubo y gire este cubo 360º mientras hace lecturas

en el diámetro del otro cubo. Hay alineación angular

cuando la lectura total del indicador

es de 0,005" o menos.

4. Tubería de succión

1. Es deseable tener una tubería de succión directa con

altura estática de aspiración baja y corta. Para una altura de succión superior a 15 pies, consulte la curva de

rendimiento de la bomba para ver la Altura de succión

positiva neta requerida.

2. El tamaño del tubo de succión debe ser por lo menos

igual a la conexión de succión de la bomba.

3. Si se usa un tubo más grande, un reductor de tubo

excéntrico (con el lado recto arriba) debe usarse en

la bomba.

4. Instalación con la fuente de suministro abajo de la

bomba:

4.1. Instale la válvula de aislación en la tubería para

inspección y mantenimiento.

4.2. No use la válvula de aislación de succión para

estrangular la bomba.

5. Instalación con la fuente de suministro arriba de la

bomba:

5.1. Para evitar bolsas de aire, ninguna parte de la

tubería debe estar más alta que la conexión de

succión de la bomba. Incline la tubería hacia arriba, partiendo de la fuente del líquido.

5.2. Todas las juntas deben ser estancas.

5.3. La válvula de pie debe usarse sólo si es necesario

para cebar, o sostener el cebado en el servicio

intermitente.

5.4. El área abierta del colador de succión debe ser por

lo menos el triple del área del tubo.

6. El tamaño de la entrada de la fuente del líquido y la

mínima inmersión sobre la entrada deben ser suficientes para impedir que el aire entre a la bomba.

5. Tubería de descarga

1. La disposición debe incluir una válvula de retención

localizada entre una válvula de compuerta y la bomba.

La válvula de compuerta es para regulación de la

capacidad, o la inspección de la bomba o de la válvula

de retención.

2. Si se requiere un reductor, instale entre la válvula de

retención y la bomba.

6. Rotación

NO PONGA LAS MANOS EN LA

SUCCIÓN DE LA BOMBA MIENTRAS VERIFICA LA ROTACIÓN DEL

MOTOR. HACERLO CAUSARÁ SEVERAS LESIONES CORPORALES.

1. Las bombas son de rotación derecha (sentido dextroso

visto desde el extremo del motor). Encienda y apague

el interruptor. Observe la rotación del eje. En las unidades montadas en marco, verifique la rotación antes

de acoplar la bomba al motor.

19

Page 20

ADVERTENCIA

Tensión

peligrosa

PRECAUCIÓN

2. Motor monofásico: Consulte el diagrama de cableado

en el motor si debe cambiarse la rotación.

3. Motor trifásico: Intercambie dos cualesquiera de los

conductores de alimentación para cambiar la rotación.

7. Operación

1. Antes de arrancar, se debe cebar la bomba (el tubo de

succión lleno y sin aire) y abrir parcialmente la válvula

de descarga.

EL LÍQUIDO BOMBEADO PROPORCIONA LUBRICACIÓN. SI LA BOMBA

FUNCIONA SECA, LAS PIEZAS

GIRATORIAS SE AGARROTARÁN Y

SE DAÑARÁ EL SELLO MECÁNICO.

2. Haga una verificación completa después que la unidad

funcione bajo condiciones de operación y se estabilice

la temperatura. Verifique la expansión de la tubería.

Verifique la alineación del acoplamiento.

3. No haga funcionar con caudal cero o cerca de cero.

La energía impartida al líquido se convierte en calor y

el líquido puede convertirse en vapor. Las piezas

giratorias requieren líquido para impedir las estrías o

agarrotamiento.

8. Mantenimiento

LA OMISIÓN DE DESCONECTAR

Y BLOQUEAR LA ALIMENTACIÓN

ELÉCTRICA ANTES DE INTENTAR NINGÚN MANTENIMIENTO

PUEDE CAUSAR CHOQUES, QUEMADURAS O LA MUERTE.

1. Los cojinetes están localizados adentro y son parte del

motor. Para el procedimiento de lubricación, consulte

las instrucciones del fabricante.

2. En las unidades montadas en marco, reengrase cada

2.000 horas de uso o cada 3 meses. Use grasa con base

de Litio o Sodio #2 y llene hasta que la grasa salga de

la grasera.

9. Desmontaje

1. Apague la alimentación eléctrica.

2. Drene el sistema. Lave con chorro de agua si es necesa-

rio.

3. Quite los pernos de sujeción del motor en las unidades

compactas o desconecte el acoplamiento y quite el

espaciador.

4. Quite los pernos de la carcasa y los pernos de sujeción

de la bomba.

5. Quite el motor y el elemento giratorio de la carcasa.

6. Destornille el perno del impulsor con una llave de

casquillo. No inserte un destornillador entre los álabes

del impulsor para impedir la rotación. Puede ser necesario usar una llave de correa alrededor del impulsor

si el impacto de la llave de casquillo no afloja el perno

del impulsor.

7. Quite la arandela del impulsor.

8. Inserte dos barras de hacer palanca (espaciadas 180º)

entre el impulsor y el alojamiento del sello. Haga

palanca sacando el impulsor.

20

9. Quite el resorte del sello, la arandela acopada y la

chaveta del impulsor.

10. Quite el alojamiento del sello, quitando con él las

partes del sello rotatorio. (donde sea necesario se

proveen ranuras para la barra de palanca).

11. Coloque el alojamiento del sello en una superficie

plana. Presione fuera las partes del sello estacionario.

12. Quite el deflector del eje, en las unidades montadas

en marco.

13. Quite los pernos que sujetan la tapa del cojinete al

marco y quite la tapa del cojinete (montado en

marco).

14. Quite los sello de reborde del marco del cojinete y la

tapa del cojinete (montado en marco).

15. Quite el eje y los cojinetes del marco (montado en

marco).

16. Quite el anillo de retención de los cojinetes.

17. Use un extractor de cojinete o prensa para quitar

cojinetes de bolas (montado en marco).

18. Quite la camisa del eje si está muy rayada. La camisa

del eje está adherida al eje y debe calentarse a unos

250ºF para facilitar quitarla.

19. Quite el anillo de desgaste si está excesivamente

dañado. Use una barra de hacer palanca y/o prensas

de mordazas.

10. Reensamble

1. Todas las piezas se deben limpiar antes de montar.

2. Consulte la lista de piezas para identificar las artículos

de reemplazo requeridos.

3. Reensamblar es lo contrario del procedimiento de

montar.

4. Cambie los sellos de reborde si están desgastados o

dañados (montado en marco solamente).

5. Cambie los cojinetes de bolas si están flojos, ásperos o

ruidosos cuando giran (montado en marco solamente).

6. Verifique que el valor máximo fuera de redondez del

eje no supere 0,005" de lectura total del indicador. Los

asientos de cojinetes y áreas de sello de reborde deben

ser suaves y estar libres de rayaduras o muescas. Cambie si es necesario (montado en marco solamente).

7. Todos los componentes de sello mecánico deben estar

en buenas condiciones o pueden producirse fugas. El

cambio del conjunto del sello completo, es buena

práctica normal, siempre que se quite el sello.

8. Si se cambia el anillo de desgaste, no use lubricantes en

el encaje de metal a metal cuando empuje la pieza de

reemplazo.

9. Si se quita el impulsor, como por ejemplo para efectuar

un cambio de sello mecánico, se debe seguir el

procedimiento siguiente: El perno viejo del impulsor y

las juntas de empaque del impulsor no se pueden

volver a usar.

10. Instale el asiento estacionario del sello mecánico en la

caja del sello, usando agua jabonosa como lubricante

para facilitar la inserción.

11. S-Grupo - instale al detenedor de resorte mecánico del

sello, al resorte y a ensamblaje rotatorio en la funda del

eje usando el agua jabonosa para lubricar. Resbale la

funda del eje sobre el eje de la bomba, sea seguro que

un anillo o nuevo de la funda del eje está utilizado.

Page 21

NOTA: EL ANILLO O DE LA ARANDELA DEL

ANILLO O Y DEL IMPULSOR DE LA FUNDA

DEL EJE ES CASI IDÉNTICO EN DIÁMETRO. SEA SEGURO UTILIZAR. EL ANILLO

O SECCIONADO TRANSVERSALMENTE

REDONDO SE UTILIZA EN LA FUNDA DEL

EJE.

11. M-Grupo - instale el resorte mecánico del sello y

rotatorio en la funda del eje usando el agua jabonosa

para lubricar. Resbale la funda del eje sobre el eje

de la bomba. Sea seguro que un anillo o nuevo de la

funda del eje está utilizado. Coloque el detenedor de

resorte mecánico del sello sobre el cubo del impulsor.

12. Ponga el clave del impulsor en la chavetera del eje y

resbale el impulsor en lugar. Instale la arandela del

poste del impulsor y del impulsor. Sea seguro que un

anillo o nuevo del impulsor está utilizado. Apriete el

S-Grupo (3/8” cuerda de rosca) a 17 pies-lb. y al MGrupo cuerda de rosca (de ½”) a 38 pies-lb.

13. Substituya los pernos de la cubierta y apriete en una

secuencia de la travesía a los valores de esfuerzo de

torsión indicados abajo.

S-Grupo – 25 pies-lb. (35 N-m)

M-Grupo – 37 pies-lb. (50 N-m)

14. Controle la unidad vuelta a montar para saber si hay

atar rotando el eje con la herramienta apropiada de

extremo del motor.

15. Si existe el frotamiento, afloje los pernos de la cubi-

erta y proceda con el ajuste de secuencia otra vez.

11. Investigación de averías

1. El motor no arranca y no hay ruido o vibración:

1.1. No está conectada la alimentación eléctrica.

1.2. Los fusibles o dispositivos de protección están

disparados o defectuosos.

1.3. Conexiones eléctricas flojas o rotas.

2. No arranca el motor pero hace ruido y vibra:

2.1. Motor no conectado como indica el diagrama.

2.2. Eje trabado debido a obstrucciones mecánicas en

el motor o en la bomba.

2.3. Tensión baja o pérdida de fase en el

abastecimiento trifásico.

3. La bomba no entrega la capacidad nominal:

3.1. La bomba no está llena o cebada.

3.2. La bomba perdió el cebado debido a fugas en la

línea de succión.

3.3. Dirección de rotación incorrecta.

Vea la Rotación.

3.4. La altura requerida es mayor que la especificada

originalmente. (La válvula puede estar parcialmente cerrada.)

3.5. La válvula de pie está taponada.

3.6. La altura de succión es demasiado alta.

3.7. El diámetro del tubo de succión es demasiado

pequeño.

4. La protección dispara al arrancar la unidad:

4.1. Pérdida de fase en la alimentación trifásica.

4.2. El dispositivo de protección puede estar

defectuoso.

4.3. Las conexiones eléctricas están flojas o rotas.

4.4. Verifique la resistencia del motor y la aislación a

tierra.

5. El dispositivo de protección dispara demasiado

frecuentemente:

5.1. La protección puede regularse a un valor inferior

al de la carga plena del motor.

5.2. Pérdida de fase debido a contactos defectuosos o

del cable de alimentación.

5.3. Líquido es viscoso o su gravedad específica

demasiado alta.

5.4. Ocurre roce entre las partes giratorias y

estacionarias.

6. El eje gira con dificultad:

6.1. Verifique si hay obstrucciones en el motor o en

la bomba.

6.2. Hay roce entre las partes giratorias y estaciona-

rias.

6.3. Verifique la buena condición de los cojinetes.

7. La bomba vibra, funciona ruidosamente y el caudal no

es uniforme:

7.1. La bomba funciona más allá de la capacidad

nominal.

7.2. Bomba o tubería no bien asegurada.

7.3. Altura de succión demasiado alta.

7.4. Diámetro de la tubería de succión demasiado

pequeño.

7.5. Cavitación causada por suministro inadecuado del

líquido o excesivas pérdidas de succión.

7.6. El impulsor está bloqueado.

8. Cuando se para, la unidad gira lentamente en la

dirección inversa:

8.1. Fugas u obturaciones de aire en la tubería de

succión.

8.2. Bloqueo parcial en la válvula de retención.

9. En aplicaciones de refuerzo de presión, la unidad

arranca y se para con demaisado frecuencia:

9.1. Los reglajes del interruptor de presión son

incorrectos.

9.2. El tamaño del tanque es incorrecto.

10. En aplicaciones de refuerzo de presión, la unidad no

se para:

10.1. El reglaje máximo del interruptor de presión es

mayor que el especifiado.

10.2. La dirección de rotación es incorrecta. Vea

Rotación.

21

Page 22

Componentes SSH-C

383A

(S-GROUP

LOCATION)

383A

(M-GROUP

LOCATION)

100 101 178 108 370

103

412A

199 422 408 126 371

412F

513

MATERIALES DE CONSTRUCCIÓN

Artículo Descripción Material

100 Carcasa

101 Impulsor

103 Anillo de desgaste

184 Alojamiento del sello

370 Tornillo de casquete de cabeza

184

hueca (carcasa al adaptador)

408 Tapón de drenaje — 3⁄8 NPT AISI A.I. Tipo 316

126 Camisa del eje 316 SS

178 Chaveta del impulsor Acero

383

422 Perno del impulsor Acero

199 Arandela del impulsor 316 SS

108 Adaptador

Tornillo de casquete de cabeza

371

hexagonal (adaptador al motor)

412A Anillo en O, impulsor Buna-N

412F Anillo en O, camisa del eje Buna-N

513 Anillo en O Buna-N

Carbono/cerámica

383 Sello mecánico, Pieza No. 10K13 elastómeros de buna

piezas metálicas A.I. 316

Tipo 316L

Hierro fundido ASTM A48 CL20