Page 1

Application Guide

Page 2

i-ALERT2 Application Guide 2 of 64

Page 3

TABLE OF CONTENTS

INTRODUCTION ................................................................................................................................................ 5

OW I-ALERT2 MONITOR AUGMENTS A CONDITION MONITORING PROGRAM .................................................................... 7

H

Improved Program Efficiency .............................................................................................................................................................. 7

Improved Program Effectiveness......................................................................................................................................................... 7

Improved Worker Safety ..................................................................................................................................................................... 7

RELIABILITY OVERVIEW .................................................................................................................................... 8

INTRODUCTION TO CONDITION MONITORING ................................................................................................................... 9

Step 1.NOTICE: Detection of Problems ............................................................................................................. 10

Step 2.INVESTIGATE: Analyze the problem ...................................................................................................... 10

Step 3.RESOLVE: Correction and Improvement ................................................................................................ 11

Step 4.DOCUMENT ........................................................................................................................................... 11

SYSTEM OVERVIEW ........................................................................................................................................ 12

D

EVICE TECHNOLOGY BACKGROUND ........................................................................................................................... 12

Device Overview ............................................................................................................................................... 13

Vibration and Temperature Specifications ........................................................................................................................................ 13

Trending Specifications ..................................................................................................................................................................... 13

Hardware Specifications .................................................................................................................................................................... 14

APPLICATION BEST PRACTICES ....................................................................................................................... 14

C

HOOSING THE CORRECT MEASURES AND ASSETS ......................................................................................................... 14

Equipment Criticality ........................................................................................................................................ 14

Machine selection criteria ................................................................................................................................ 15

Where to Start? ................................................................................................................................................................................. 16

Condition Monitoring Measures ...................................................................................................................... 18

Temperature ...................................................................................................................................................................................... 18

Vibration – RMS Velocity ................................................................................................................................................................... 18

Kurtosis .............................................................................................................................................................................................. 19

INSTALLATION BEST PRACTICES...................................................................................................................... 20

M

OUNTING LOCATIONS ............................................................................................................................................. 20

General Guidelines ........................................................................................................................................... 20

i-frame pump .................................................................................................................................................... 21

End suction pump ............................................................................................................................................. 22

Horizontal Electric Motors ................................................................................................................................ 23

Between Bearings pump .................................................................................................................................. 24

Vertical Electric Motors .................................................................................................................................... 25

Vertical Pump ................................................................................................................................................... 26

Mixers ............................................................................................................................................................... 26

Vacuum Pumps ................................................................................................................................................. 26

M

OUNTING METHODS .............................................................................................................................................. 27

COMMISSIONING ........................................................................................................................................... 27

TEPS TO ACTIVATE THE I-ALERT2 EQUIPMENT HEALTH MONITOR: ................................................................................. 27

S

i-ALERT2 Application Guide 3 of 64

Page 4

TO RESET THE I-ALERT2: ........................................................................................................................................... 28

I-ALERT2 EQUIPMENT HEALTH MONITOR ROUTINE OPERATION ...................................................................................... 29

I-ALERT2 EQUIPMENT HEALTH MONITOR TROUBLESHOOTING ........................................................................................ 29

®

I-ALERT2

I

NSTALLING THE APP ................................................................................................................................................. 30

C

D

T

MOBILE APP OPERATION ................................................................................................................ 30

ONNECTING TO I-ALERT2 DEVICES ............................................................................................................................ 30

ASHBOARD ............................................................................................................................................................ 34

RENDING ............................................................................................................................................................... 35

Weekly View ..................................................................................................................................................... 40

Kurtosis ............................................................................................................................................................. 41

A

DVANCED TOOLS .................................................................................................................................................... 42

FFT and TWF Data ............................................................................................................................................ 43

Stored and Alarm Generated FFT Data ............................................................................................................ 44

E

QUIPMENT INFORMATION ........................................................................................................................................ 45

Alarms / Warnings ........................................................................................................................................... 45

Equipment Details ............................................................................................................................................ 47

Parts List / BOM ............................................................................................................................................... 48

Pump Curve ...................................................................................................................................................... 49

Commands ........................................................................................................................................................ 50

R

EPORT GENERATOR ................................................................................................................................................. 51

H

ELP/FAQ .............................................................................................................................................................. 60

ERVICE LOCATOR .................................................................................................................................................... 61

S

USER SETTINGS ........................................................................................................................................................ 62

TECHNICAL REFERENCES ................................................................................................................................. 62

i-ALERT2 Application Guide 4 of 64

Page 5

INTRODUCTION

Electromechanical Sensors (MEMS) and Bluetooth® wireless communications

This guide is designed to assist reliability practitioners in optimizing the performance of their rotating equipment assets

using modern condition monitoring technologies.

Traditional condition monitoring techniques and budget constraints force practitioners to make difficult choices as to which

pieces of equipment they can focus on while relegating many of the less critical assets to a suboptimal time based

maintenance regime or a “fix it when it breaks” mentality. Even in those plants that do perform periodic predictive

maintenance (PdM) inspections, the frequency or time between inspections is a month or more, sometimes up to a year.

Many failure mechanisms can develop and progress into catastrophic failure well before the next inspection, rendering the

PdM program ineffectual for “balance of plant” equipment.

Using the latest Micro-

technologies ITT has created a tool that better fits the needs of reliability practitioners.

Continuous monitoring of machinery health is an ideal solution to prevent unplanned downtime, but has historically come

with a big price tag that couldn’t be justified except on the most critical assets. Using the latest Micro-Electromechanical

Sensors (MEMS) and Bluetooth® wireless communications technologies ITT has created a tool to better fit the needs of

reliability practitioners. The i-ALERT2 Equipment Health Monitor is a low cost alternative that continuously trends key

machinery health parameters including overall vibration and temperature and allows users to access that trend data during

routine inspections. Leveraging new technology allows the i-ALERT2 condition monitor to offer improved utility and

reduced cost compared to a typical “walk-around” monthly vibration program.

i-ALERT2 Application Guide 5 of 64

Page 6

Allows your highly skilled vibration analysts to focus on

solving chronic problems instead of routine monitoring.

Operators can collect high quality,

repeatable, vibration and

temperature data with no training.

Figure 1: Condition Monitoring Technology Comparison

Equipment

Improves

Safety

Enables

ODR

Wireless communication allows a user to collect data a

safe distance from rotating equipment hazards.

Optimizes

Reliability

i-ALERT2 Application Guide 6 of 64

Page 7

HOW I- ALERT2 MONITOR AUGMENTS A CONDITION MONITORING PROGRAM

IMPROVED PROGRAM EFFICIENCY

• Faster data collection and less time spent walking routes because the need to physically mount a temporary

sensor is eliminated.

• Easily visible indication of equipment condition during data collection through the device’s onboard LEDs.

• Data collection can be easily integrated into existing operator rounds.

• Allows your highly skilled vibration analysts to focus on solving chronic problems instead of routine monitoring.

This is becoming increasingly more important as these skill sets are in short supply.

• Users can simultaneously view any machine’s current overall condition for any device in range. No need to

actually touch each machine to get the data.

IMPROVED PROGRAM EFFECTIVENESS

• Continuous data collection allows for diagnosis of transient and process related problems which are traditionally

very hard if not impossible to spot with monthly or quarterly data collection cycles. Especially effective for batch

process equipment.

• Traditional monthly walk around monitoring with a portable data collector requires at least 2 months to generate

2 points or a “trend” upon which a baseline condition can be established. In 2 months, the i-ALERT2 monitor can

measure and store 720 points, giving the PdM practitioner a superior level of confidence and understanding of the

equipment’s behavior.

• Changes in machine state automatically trigger the device to capture spectral and time waveform data. The ability

to capture this diagnostic data in conjunction with the trend and timestamp information improves a reliability

practitioner’s ability to troubleshoot process related problems.

• Temperature and Kurtosis trending enhance the traditional overall vibration dataset, yielding more accurate

condition assessment than overall RMS vibration alone.

IMPROVED WORKER SAFETY

• No need to get close to dangerous rotating equipment hazards to collect the data. Just be in the same room with

it.

i-ALERT2 Application Guide 7 of 64

Page 8

RELIABILITY OVERVIEW

Time

Failure Curves

Maintenance and Reliability (M&R) practices including condition monitoring are largely governed by the type of assets

being maintained and the associated failure patterns of those assets. Numerous studies have been conducted in both the

Industrial and Aeronautical / Military markets that show the relative frequency or “probability” of failure of equipment. This

data is summarized in Figure 2. What should immediately become apparent is that very few failures are attributable to

“wearing out” or what might be termed an “age-related” failure

1

pattern.

UAL 1968

Bromberg

1973

US Navy

1982

4% 3% 3%

2% 1% 17%

5% 4% 3%

7% 11% 6%

Conditional Probability of Failure

14% 15% 42%

68% 66% 29%

Figure 2: Failure curves

1

Those that are age-related are almost all corrosion in seawater applications with a relatively predictable lifecycle.

i-ALERT2 Application Guide 8 of 64

Page 9

The majority of industrial equipment will tend to have a failure probability distribution similar to that of Figure 3, where the

Random

Higher risk at startup

Time

risk of failure for equipment is highest upon startup, sometimes termed “infant mortality” and will decrease to some

relatively constant probability of failure over time.

Figure 3: Most common failure probability pattern for industrial equipment

Knowing that most equipment will follow the failure pattern of Figure 3 should guide M&R practitioners to select condition

monitoring equipment that can:

1. Quickly identify defects or problems when new equipment is started before they cause severe damage

2. Help establish confidence that a newly commissioned machine is operating within specific limits

3. Maximize the ability to detect randomly occurring failures after a successful startup.

The i-ALERT2 Equipment Health Monitor is designed to provide all of these functions while still maintaining cost

effectiveness. Always consider the benefits a new condition monitoring technology will provide against these proven failure

curves to ensure it will be effective. Implementing new technology just for the sake of saying you have the latest and

greatest technology will lead to a lot of wasted money and effort.

INTRODUCTION TO CONDITION MONITORING

CM and PdM tools available today are great enhancements to the traditional visual / audible Inspections and augment

regular operators’ inspections. Whether performing a simple visual inspection or using the most sophisticated tools

available the process is fundamentally the same. There are 4 Steps:

o NOTICE

• We have to notice or detect that we have a problem with a piece of equipment.

o INVESTIGATE

• Once detected, we can investigate and analyze the problem to determine the root cause.

o RESOLVE

• After determining the root cause, we can correct the problem and, if possible, improve the machine by leaving

it in a precise state.

o DOCUMENT

• By documenting our results, we are able to verify that the problem has been solved and communicate our

successes to others.

It is important to thoroughly understand each of these steps. Valuable time is often wasted when too much emphasis is

placed on any one component.

i-ALERT2 Application Guide 9 of 64

Page 10

STEP 1.NOTICE: DETECTION OF PROBLEMS

Since analysis of machine problems is a time consuming process and there are many

machines in a typical plant, it is important NOT to try to analyze all machines. The

first step in an effective condition monitoring program is to identify the problem

machines. This is the purpose of the detection phase of the program. Measurements

and machines are organized into a series of logical routes and data is collected on

them in a routine manner. Route functionality is a cornerstone of the i-ALERT2

condition monitor’s value. One of the strengths of the i-ALERT2 monitor is the ability

to broadcast the machine’s condition without having to wirelessly connect to it. The

data collected is designed to indicate when a change has occurred or when a preset

limit has been exceeded. After the data has been collected, it is reviewed and

exceptions are noted and reported.

After identifying machines in need of further analysis using detection, the next step is

to determine the root cause of the problem. This is

achieved during the INVESTIGATE or ANALYSIS phase.

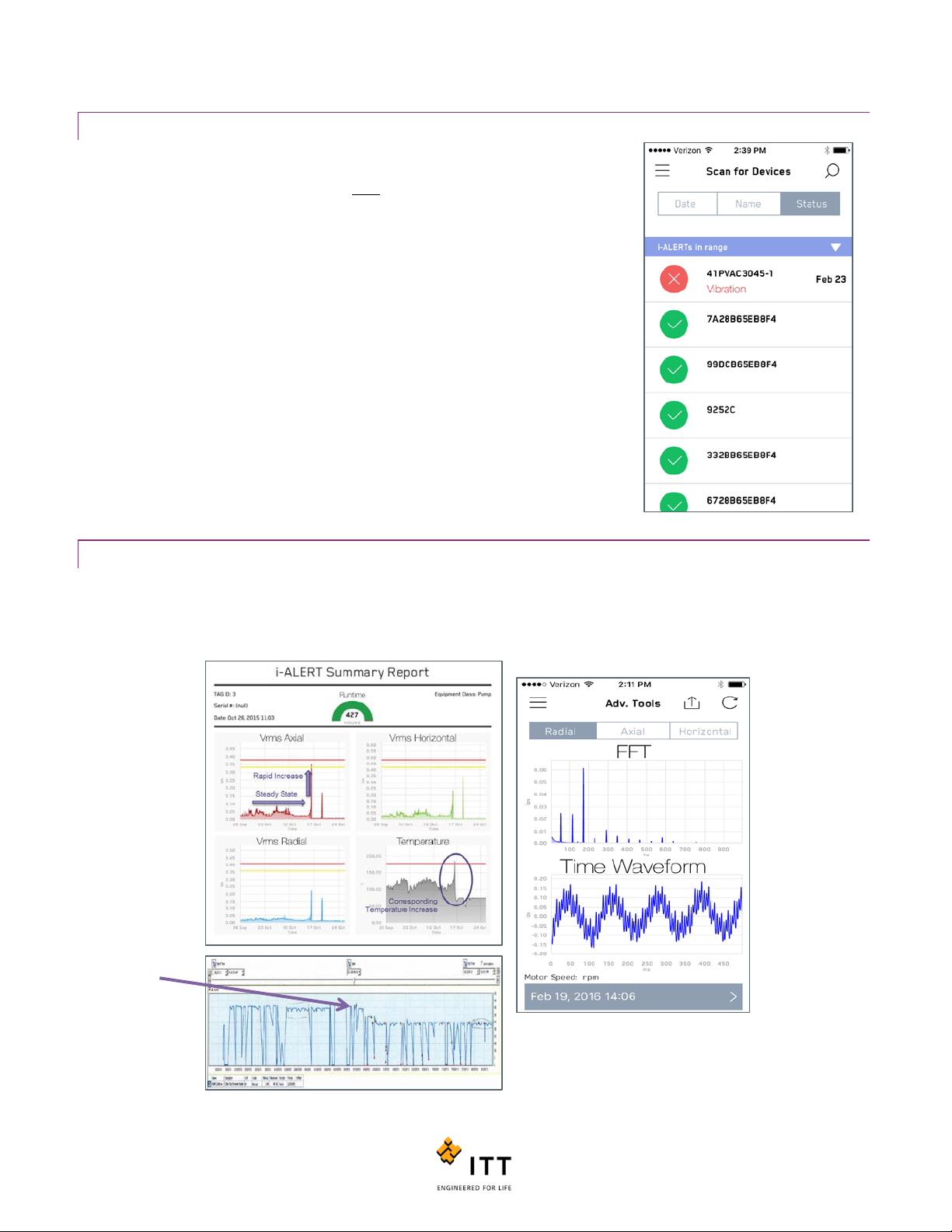

Figure 4: Simultaneously view

states of all devices in range

STEP 2.INVESTIGATE: ANALYZE THE PROBLEM

The analysis phase involves gathering more detailed diagnostic data which can include process conditions, flows, pressures,

FFT, TWF, Timestamps and Trend data. Performing such analysis is a time consuming process and should NOT be

attempted on all machines, only the ones that have exceeded alarm limits.

Process change

Figure 5: Process data related to

condition monitoring data

i-ALERT2 Application Guide 10 of 64

Page 11

If process data is available from the control system it should be overlaid with the vibration/temperature trends of the iALERT2 to help determine root cause. Often the root cause of a vibration problem is a process upset.

STEP 3.RESOLVE: CORRECTION AND IMPROVEMENT

After determining the root cause of the problem, it can be

corrected. Cost effective corrective actions will depend on the

machine in question and the findings of the failure analysis. In

order to maximize the reliability of the machine in question, it is

also advisable to improve the vibration levels on the machine to

“precision state” levels after it has been repaired. This will extend

the life of the machine.

Figure 6: Precision repair at an ITT PRO Service center

STEP 4.DOCUMENT

After determining the root cause of the problem, correcting the problem and improving the machine, it is important to

verify that the correction/improvement has occurred and document the findings. One mechanism for this verification is

comparing the vibration levels after restarting the machine with those taken before shutdown and the original baseline

data. Other common verification methods include:

o Measuring reduced energy consumption

o Capturing Infrared Thermography Images

o Oil analysis

o Confirming precision alignment

Figure 7: Document results to verify corrective action was effective

i-ALERT2 Application Guide 11 of 64

Page 12

SYSTEM OVERVIEW

DEVICE TECHNOLOGY BACKGROUND

Micro-Electro-Mechanical Systems, or MEMS, is a technology that is best defined as miniaturized mechanical and electromechanical elements that are made using the techniques of microfabrication. MEMS represent the next generation of

sensing technology. OEMs in all industries including automotive, industrial and aerospace are migrating away from older

macro-scale transducers due the various advantages MEMS can provide. The physical dimensions of MEMS devices can be

less than a micron up to several millimeters. MEMS devices can vary from relatively simple structures having no moving

elements, to extremely complex electromechanical systems with multiple moving elements under the control of integrated

microelectronics. One of the most prevalent uses for MEMS is the construction of miniaturized sensors that convert energy

from one form to another, known as transducers. In the case of MEMS sensors, the device typically converts a measured

mechanical signal into an electrical signal.

Over the past several decades a large number of micro-sensors have been developed for almost every type of physical

measurement including temperature, pressure, inertial forces, vibration, magnetic fields, etc. Surprisingly many of these

MEMS sensors have proven to be more accurate and precise than their macro-scale counterparts. In example, the MEMS

version of a pressure transducer usually outperforms a pressure sensor made using the most precise macro-scale level

machining techniques. Not only is the performance of MEMS devices exceptional, but their method of production leverages

the same batch fabrication techniques used in the integrated circuit industry – which translates into low per-unit

production costs.

The latest generation of MEMS includes micro-sensors, micro-actuators and micro-electronics integrated onto a single

microchip. This has resulted in the explosive development of smart products which integrate computing intelligence with

sensing and control. Because MEMS devices are manufactured using batch fabrication techniques, similar to integrated

circuits, high levels of reliability are being achieved at very low costs. The i-ALERT2 monitor leverages recent advancements

in MEMS vibration transducers to achieve impressive performance at a minimum cost. The sensors’ data gathering

capabilities are then mated to another leading technology known as Bluetooth Smart or Bluetooth Low Energy.

Bluetooth is a wireless signal protocol that was first developed in 1994 as a way for computers to communicate to other

devices without cables. Bluetooth is an open standard that allows disparate devices to communicate using the same

“language”. Over the last few decades the technology has been steadily improved to be able to transmit more data faster

while simultaneously reducing the amount of power the wireless radios consumed. Bluetooth Smart allows tiny batteries to

power wireless radios for years at a time without recharging and is one of the technologies enabling the rapid rise of the

Industrial Internet of Things (IIOT). IIOT is a term that describes the reality of hundreds (or thousands) of smart devices

communicating hordes of data to enable smarter, more efficient operations.

Many of the existing condition monitoring hardware manufacturers are aware of the potential for MEMS and Smart sensors

however they are reluctant to offer this new technology due to the potential for cannibalization of their existing macroscale sensor products. ITT is free from this commercial constraint and will continue to utilize the best and latest technology

that allows our customers to optimize the reliability of their rotating equipment assets.

i-ALERT2 Application Guide 12 of 64

Page 13

DEVICE OVERVIEW

Warning and Alarm Values Variable

Limit

Temperature (default

80°C (176°F)

Vibration Alarm (0.1-1.5 ips)

100% increase over the baseline level

Vibration Warning (0.1-1.5 ips)

75% increase over the baseline level

The i-ALERT2 Equipment Health Monitor is a compact, battery-operated monitoring device that continuously measures the

vibration and temperature of a piece of rotating equipment. The i-ALERT2 Equipment Health Monitor uses blinking red LED

and wireless notification to alert operators when the equipment exceeds vibration and temperature limits. This allows the

operator to make changes to the process or the equipment before catastrophic failure occurs. The Equipment Health

Monitor is also equipped with a single green LED to indicate when it is operational and has sufficient battery life.

The i-ALERT2 Equipment Health Monitor also contains a Bluetooth radio that communicates to certain Bluetooth 4.0

equipped devices through a mobile application. Data is shared between the i-ALERT2 Equipment Health Monitor, the

mobile application, phone, and the data servers.

The i-ALERT2 Equipment Health Monitor will communicate sensor related data (such as vibration, temperature, runtime

information, and device statistics) stored in the device to the mobile application. The mobile application will send

commands to the device.

The Mobile application will back up device data as well as app usage information on the data servers.

The data servers will send the mobile application equipment technical data. For full details about data storage and rights

please review the Privacy Policy.

The i-Alert2 may use Version 1 or Version 2 firmware. To determine which version you have, in the App go to “Equipment

Info, i-ALERT Information” where the device version number will be shown., Alternatively, for the Version 2 units, the

sticker on the back of the device will have a manufacturing date after 8/22/2016.

Alarm mode

The i-ALERT2 Equipment Health Monitor enters alarm mode when either vibration or temperature limits are exceeded over

two consecutive readings within a 10 minute period. Alarm mode is indicated with 1 (one) red flashing LED within 2 (two)

second intervals.

VIBRATION AND TEMPERATURE SPECIFICATIONS

• Axial / Horizontal Sensor Frequency Range 10 Hz to 1000 Hz

• Radial Sensor Frequency Range 10 Hz to 600 Hz

• 15g Dynamic Range

• Spectral vibration measurements have a frequency bandwidth resolution of 1 Hz.

• Amplitude accuracy +/- 10%

• Diagnose machine faults with vibration tools Fast Fourier Transform & Time Waveform analysis

• Maximum temperature of 183°F

TRENDING SPECIFICATIONS

• Sensors and onboard memory tracks vibration, temperature, & run-time hours continuously

• Devices checks every five minutes & alarms if equipment is outside normal operating conditions

• Stores overall RMS trend data once per hour & on alarm for 60 days (Version 1) or 170 days (Version 2)

• Stores the weekly average, minimum & maximum up to 5 years

• Calculates and stores Kurtosis values

i-ALERT2 Application Guide 13 of 64

Table 1: Default Alarm Values

Page 14

HARDWARE SPECIFICATIONS

1 Plant

1-1 Business Unit

1-1-1 Operating System

1-1-1-1 Equipment

1-1-1-1-1 Component

1-1-1-1-1-1 Sub-component

Equipment Hierarchy

• Rated for most industrial environment. IP67 water & dust resistant. Class 1 Division 1, ATEX Certified

• Intrinsically Safe with a 3 year battery life (use dependent).

• The following determines the “normal operating conditions” in which the 3 year battery life is determined:

o Temperature: 18°C (65°F)

o Dashboard connections (including trend download): Once per day

o FFT and Time Waveform usage: One tri-axial request per 14 days

o Operation time in Alarm: 25% of time

• Sync data via Bluetooth Smart enabled smartphones and tablets.

• Wireless Range Approximately 10m (33ft) to 30m (100ft)

APPLICATION BEST PRACTICES

CHOOSING THE CORRECT MEASURES AND ASSETS

EQUIPMENT CRITICALITY

The initial step in building a predictive maintenance program is to

identify which systems will be analyzed and prioritizing the order

in which the analysis will take place. To get the most return on the

time invested, the most logical place to start is with the equipment

hierarchy that exists in the Computerized Maintenance

Management System (CMMS). This is typically a breakdown of all

existing equipment from Plant Level to Business Unit to Operating

System to Equipment to Component and to Sub-component,

where necessary.

Figure 8: Example Asset Hierarchy for a CMMS

For a first cut at prioritization for the analysis, it is practical to review the hierarchy at the Operating System level to

determine which systems are business critical to the organization.

Business Critical - A failure of that specific system at the operating system level would have a direct and immediate

financial impact on the facility output.

For systems deemed critical, a full Reliability Centered Maintenance (RCM) analysis should be performed. One approach to

determine criticality is to use tables similar to those below to assess consequence and probability.

i-ALERT2 Application Guide 14 of 64

Page 15

Ranking

Hazard

Potential Safety, Health or Environmental issue. Failure

will occur without

warning.

Hazard

Potential Safety, Health or Environmental issue. Failure

will occur with

warning.

Very High

Very high disruption to facility function. All of Production is lost.

Significant delay in restoring function.

High

High disruption to facility function. Some portion of Production is

lost. Significant delay in restoring function.

Moderate to

High

Moderate disruption to facility function. Some portion of Production

is lost. Moderate delay in restoring function.

Moderate

Moderate disruption to facility function. 100% of Production may need

to be reworked or pro cess delayed.

Low to

Moderate

Moderate disruption to facility function. Some portion of Production

may need to be reworked o r process delayed.

Low

Minor disruption to facility function. Repair of failure may be longer

than trouble call but does not delay Production.

Very Low

Minor disruption to facility function. Repair of failure can be

accomplished during trouble call.

None

No reason to expect fail ure to have any effect on Safety, Health,

Environment or Production.

2

1

4

3

7

6

5

Consequence (Severity) Comment

10

9

8

Ranking

Very High Very High failure rate. Almo st cert ain to cause problems.

High to Very

High

High to very high failure rate. Highly likely to cause problems.

High

High failure rate. Similar to past design that has, in the past, had high

failure rates that have caused problems.

Moderate to

High

Moderate to high failure rate. Similar to past design that has, in the

past, had high f ailure rates that have caused problems.

Moderate

Moderate failure rate. Similar to past design that has, in the past, had

moderate failure rates for given volume.

Occasional to

Moderate

Occasional to mod erat e f ailure rate. Similar to past desig n that has, in

the past, had moderat e f ailure rates for given volume.

Occasional

Occasional failure rate. Similar to past design that has, in the past,

had similar failure rates for given volume.

Low

Low failure rate. Similar to past design that has, in the past, had low

failure rates for given volume.

Very Low

Very low failure rate. Similar to past design that has, in the past, had

very low failure rates fo r given volume.

Remote Remote probabili t y of occurrence; unlikely for failure to occur.

Relative Probability of Occurrence

1098

7

6

5

432

1

Table 2: Example of RCM Methodology based on consequence and probability of failure

Risk is defined as Probability x Consequence. So by multiplying the assigned values from each table a criticality number can

be determined.

The value assigned for equipment will be based on the consequence of the failure of the equipment (called Severity)

multiplied by the probability that the failure will occur (called Probability). The asset matrix (list of all assets that have had

the business criticality determined) can then be sorted by priority. The equipment with the largest number as figured by

Severity x Priority is the most business critical equipment.

MACHINE SELECTION CRITERIA

Just as with every existing condition monitoring system, there are certain applications that best fit the technology

being leveraged. For instance, monitoring casing vibration on a large, slow moving shaft mounted in fluid film

bearings would yield very little quality information as to the health of the machinery. In order to maximize the

return on investment for any given CM system, it has to be applied to the correct machinery. The following tables

and comments help illustrate the best fits for the i-ALERT2 condition monitoring system.

i-ALERT2 Application Guide 15 of 64

Page 16

Equipment Type

Good

Limited

Centrifugal Pumps

Positive Displacement Pumps

Electri c Motors

Fans / Blowers

Paper Machine Bearings

Centrifugal Compressor

Reciprocating Compressors

Low Speed

Limitations

Engines

Steam Turbines

Casi ng

Temper a ture

Gearbox / Reducers

Mes h

Frequency

Some general limitations to keep in mind when selecting machinery are:

• The i-ALERT2 monitor is designed to measure casing vibration, so machines with sleeve/fluid-film bearings are

inherently not going to be as good a fit due to attenuation of the shaft vibration via the fluid-film. Now that

does not mean i-ALERT2 cannot be used for sleeve bearing machinery, only that the casing vibration measured

will not reflect the true shaft vibration amplitudes.

• The upper and lower frequency cutoffs for the i-ALERT2 devices are 1000 Hz and 10 Hz respectively. Just as

with any condition monitoring instrumentation, it is recommended that the machinery shaft speed and

primary potential fault frequencies fall within this range. For diagnostic purposes, you want to be able to see

more than just the shaft speed and ITT recommends a minimum frequency range of 10x the shaft speed, AKA

the first order. This translates to an effective upper limit on shaft speeds of 6,000 RPM. It can be applied on

higher speed machinery, but the upper frequency cut off will limit its usefulness in that application.

Table 3: Recommended machinery applications for i-ALERT2 (Note: Shaft Speeds

must be greater than 600 RPM)

WHERE TO START?

I. Bad Actors. Start with the “bad-actors” list. All plants track their worst performing assets to one degree or

i-ALERT2 Application Guide 16 of 64

another. (High maintenance cost and effort, low availability, etc.) The reasons for the poor performance

of these assets can be myriad but chances are that one of the reasons they are on the bad actors list is

because not enough information is currently available to diagnose and correct the problems.

Continuous monitoring of vibration and temperature combined with any available process control data

can go a long way towards helping the proactive reliability engineer eliminate the sources of a bad actors

poor performance.

Page 17

II. Machinery that is dangerous or difficult to access for inspections. We’ve all seen these poor pumps or

motors in the darkened corner of the plant basement. Often leaking, corroded, and installed in poorly lit

process areas. Regular inspection routes miss them as their hidden by piping or other equipment.

Installing i-ALERT2 devices on these neglected machines helps give them a voice and allows them to

communicate potential failures that otherwise would have gone undetected. The same is true of

machinery with particularly hazardous operating environments. Collecting data on equipment installed on

platforms or in pits can be difficult if not impossible while the equipment is running. Modern machinery

guarding can also obscure typical measuring points, and removing it to take a vibration reading typically

won’t be allowed. The i-ALERT2 wireless communication enables data collection at a safe proximity from

the equipment hazards.

III. Equipment that doesn’t run often. It is difficult and sometimes nearly impossible to try and collect data

on a machine that only runs intermittently or at odd hours a hand-held data collector. Batch processes

run at all hours of the day or night. Unless someone is assigned to be in front of the machine ready to

collect data 24/7, it’s likely you won’t have a great deal of data to analyze should a problem arise.

IV. Equipment that has no permanent machinery protection/monitoring system. Critical assets are

sometimes “protected” by permanently installed systems that have the ability to shut down the

machinery if it exhibits signs of failure. However these systems are generally very expensive and cannot

be applied to all assets in a plant. The low cost and ease of installation of the i-ALERT2 monitor make it a

perfect device to bridge the gap between machinery protection systems and periodic inspections. In fact,

the i-ALERT2 monitor can completely supplant the use of portable data collectors for monthly inspections.

The exception report and alarm / trend information generated by the i-ALERT2 monitor will show a user

which machines should be prioritized for further vibration analysis. If a machine generates an alarm or

alert, the reliability practitioner can initiate a work order for the in house team or bring in a consultant to

perform a diagnostic of the equipment using powerful multichannel vibration analyzers and other

advanced instrumentation to investigate the root cause.

V. New or Recently Repaired Equipment. As mentioned earlier in the user guide, the risk of equipment

failure due to some defective component or faulty repairs is much more likely to manifest as a failure

right at start-up. By installing i-ALERT2 devices on new equipment and recently repaired equipment being

commissioned, start-up failures can be reduced, and faulty equipment can be diagnosed right away,

protecting the plant from low quality equipment repairs or parts.

i-ALERT2 Application Guide 17 of 64

Page 18

CONDITION MONITORING MEASURES

Implementing a condition monitoring technology requires the user to first understand the equipment failure modes and

what physical parameters are responsive to changes in the equipment’s state. Since not one single device can hope to cover

all possible machine configurations or physical measures we will instead offer recommendations for utilizing temperature

and casing vibration to detect some of the most common failure modes.

TEMPERATURE

Monitoring and trending the Temperature of a bearing housing provides

insight into many common problems with rotating machinery such as:

• Inadequate lubrication of rolling element bearings

• Damaged rolling element bearings

• Excessive loading of rolling element bearings

• Inadequate cooling flow from housing fins, jacketed

cooling systems or cooling fans

• Excessive ambient or process fluid temperatures

VIBRATION – RMS VELOCITY

Monitoring and trending RMS velocity of a bearing housing provides an

assessment of how much overall energy is contained in the machines vibration.

This can be used to indicate changes to both process conditions and machinery

health. Numerous failure modes or machine faults can cause the RMS velocity

to increase so an exhaustive discussion of them here is not going to be

attempted. RMS velocity increases can also corroborate a Temperature

increase, which assists the reliability practitioner in narrowing down potential

Figure 9: Example weekly trend data

failure modes. RMS velocity is by far the most common vibration parameter

utilized to gauge overall machine condition.

There are no “absolute” levels of vibration that can be used to indicate if a machine is good or bad. There are too many

factors that influence of the overall vibration from one machine to the next. The chart below is provided to assist the user

to establishing warning and alarm limits and is taken directly from the ISO 10816 standard. These limits can and should be

modified based on the equipment’s actual vibration data and user’s experience. Remember, a doubling of the overall

vibration is almost always related to a change in machine condition.

i-ALERT2 Application Guide 18 of 64

Page 19

Table 4: Condition based on overall vibration velocity in RMS

Figure 10: Trend of Kurtosis

KURTOSIS

Monitoring of Kurtosis is a somewhat unique feature in condition monitoring

equipment that separates the i-ALERT2 monitor from traditional overall

vibration meters. Kurtosis is a mathematical function that indicates how

“peaky” a data set is. It is related to Crest Factor which is another commonly

used vibration parameter used to assess machine condition. Kurtosis will tend

to increase in the event the machinery starts to experience increases in

Impacting and is relatively insensitive to changes in speed or load. Impacting

can come from many sources such as bearing faults, cavitation, or mechanical

looseness. It is recommended that the user first establish baseline levels of

Kurtosis and then adjust warning/alarm limits accordingly as some machinery

will naturally have widely varying levels of Kurtosis in their vibration data sets.

Kurtosis values around 3 are considered “Normal.”

Kurtosis is subject to the same limitations as Crest Factor when determining

bearing failure progression. If there is no significant impacting such as with

long shallow spalls in a bearings race or inadequate lubrication the Kurtosis

measure will not change significantly.

i-ALERT2 Application Guide 19 of 64

Page 20

INSTALLATION BEST PRACTICES

Figure 11: Recommended monitoring points

MOUNTING LOCATIONS

GENERAL GUIDELINES

In general the ideal place to mount the i-ALERT2 device is as close as possible to the machines bearings in a place where the

LEDs can be easily observed. Since the primary function of the i-ALERT2 device is to monitor for changes in condition, it is

not critical that the device be placed in the “load zone” of the bearing. Doing so may give a more accurate amplitude

reading, but may obscure the LEDs which are used for local status indication.

In general, a standard machine train consisting of a driver and driven piece of equipment can be monitored by 2 i-ALERT2

devices. Up to 4 monitors can be installed per machine train, one at each bearing if necessary.

Machine Type

Non-Drive End

Bearing

Drive End Bearing Drive End Bearing

Driver Optional Recommended

Driven Machine

Recommended Optional

Non-Drive End

Bearing

i-ALERT2 Application Guide 20 of 64

Page 21

I-FRAME PUMP

Figure 12: ITT Goulds 3196 i-FRAME contains milled slot for mounting the monitor

On any ITT Goulds Pumps that come equipped with the i-ALERT2 device, a slot will be machined in the bearing housing to

mount the device within close proximity to both bearings. See figure 12.

i-ALERT2 Application Guide 21 of 64

Page 22

END SUCTION PUMP

Figure 14: Chemical Process pump, side mounted to bearing frame

Figure 13: PD pump, side mounted to frame

On end-suction (overhung) style pumps where the thrust and radial bearings are contained within the same bearing

housing, ITT Goulds Pumps recommends mounting the i-ALERT2 device centrally on the bearing housing in an area where

the LEDs can easily be observed.

i-ALERT2 Application Guide 22 of 64

Page 23

HORIZONTAL ELECTRIC MOTORS

Figure 16: Close coupled motor, mounted over drive end bearing housing

Figure 15: Horizontal motor, mounted over drive end bearing housing

Mount the i-ALERT2 monitor directly over the bearing housing on the drive-end bearing. A second monitor can be mounted

over the non-drive end bearing if desired. Never mount a monitor on a fan cover!

i-ALERT2 Application Guide 23 of 64

Page 24

BETWEEN BEARINGS PUMP

Figure 18: Double Suction , Horizontal Split case pump, mounted on thrust bearing housing

Figure 17: Between Bearings Pump (BB3), mounted on each bearing housing

On between bearings pumps, it is recommended to mount i-ALERT2 monitors to both bearing housings. If only one device is

to be installed on a pump, then it should be installed on the bearing housing that contains the thrust bearing. Note, that

this is not always the drive end bearing housing. Be sure to check the pumps cross sectional drawing to verify location of

the thrust bearing.

i-ALERT2 Application Guide 24 of 64

Page 25

VERTICAL ELECTRIC MOTORS

Figure 20: Vertical Hollow Shaft Motor, at thrust bearing

The best mounting location for the i-ALERT2 device will depend on which class of vertical motor is being monitored. For

vertical solid shaft motors with 2 rigid bearings, instrument the upper thrust bearing housing first since this is the primary

bearing absorbing thrust loads. The lower bearing can also be instrumented if desired.

Figure 19: Vertical Motor with 2 Bearings,

monitor at each bearing

For vertical hollow shaft (VHS) motors it is recommended to mount the i-ALERT2 device adjacent to the thrust bearing at

the top of the motor. Most VHS motors do not have lower bearings and therefore there is no need for a second monitor.

i-ALERT2 Application Guide 25 of 64

Page 26

VERTICAL PUMP

Figure 22: Vacuum Pump, side mounted to bearing housing

Vertical pumps can be instrumented with the i-ALERT2 device at the pump discharge head. See image below. Mount the

device at the top of the discharge head where the LEDs are clearly visible.

Figure 21: Arrows show recommended mounting location for vertical pumps (On Discharge Head)

MIXERS

Mixer configurations can vary widely so ITT does not recommend any single best location. Use good engineering judgment

and knowledge of the machine design to appropriately locate the monitor. Nearer to the bearings and sources of potential

vibration energy is best.

VACUUM PUMPS

ITT recommends monitoring the drive end bearing housing for vacuum pumps.

i-ALERT2 Application Guide 26 of 64

Page 27

MOUNTING METHODS

Mill a Slot

Drill and Tap

Epoxy

Screw: ¼-28 x 1.125in

Screw: ¼-28 x 1.5in

Screw: ¼-28 x 1.125in

Slot: 2.25in L x 1.6in W

Tap: ¼-28 UNF x ¼in deep

Epoxy: application specific

There are three methods that can be used to mount the i-ALERT2 device to a machine. They are shown in the figure below.

On new pumps and pumps repaired through ITT PRO Services, a slot will be milled into an appropriate location on the

bearing housing and the device will be secured with a screw. Alternatively, a hole can be drilled and tapped and a small

adapter plate can then be used to secure the device. Lastly, the device can be epoxied directly the machine via the

mounting plate. Make sure to use a good quality, rigid epoxy. Do not use RTV or Silicon to mount the device.

CAUTION:

Always wear protective gloves. The equipment and the i-ALERT2 device can be hot.

Figure 23: Mounting Methods

COMMISSIONING

STEPS TO ACTIVATE THE I -ALERT2 EQUIPMENT HEALTH MONITOR:

1. Remove the sticker.

2. The i-ALERT2 device will look for light. Note: If in a dark environment use light source to activate.

3. When activated a sequence of flashing LEDs will start to indicate that the unit is powered on.

4. When sequence is completed the green LED will flash every 5 sec under normal operating conditions

i-ALERT2 Application Guide 27 of 64

Page 28

TO RESET THE I-ALERT2:

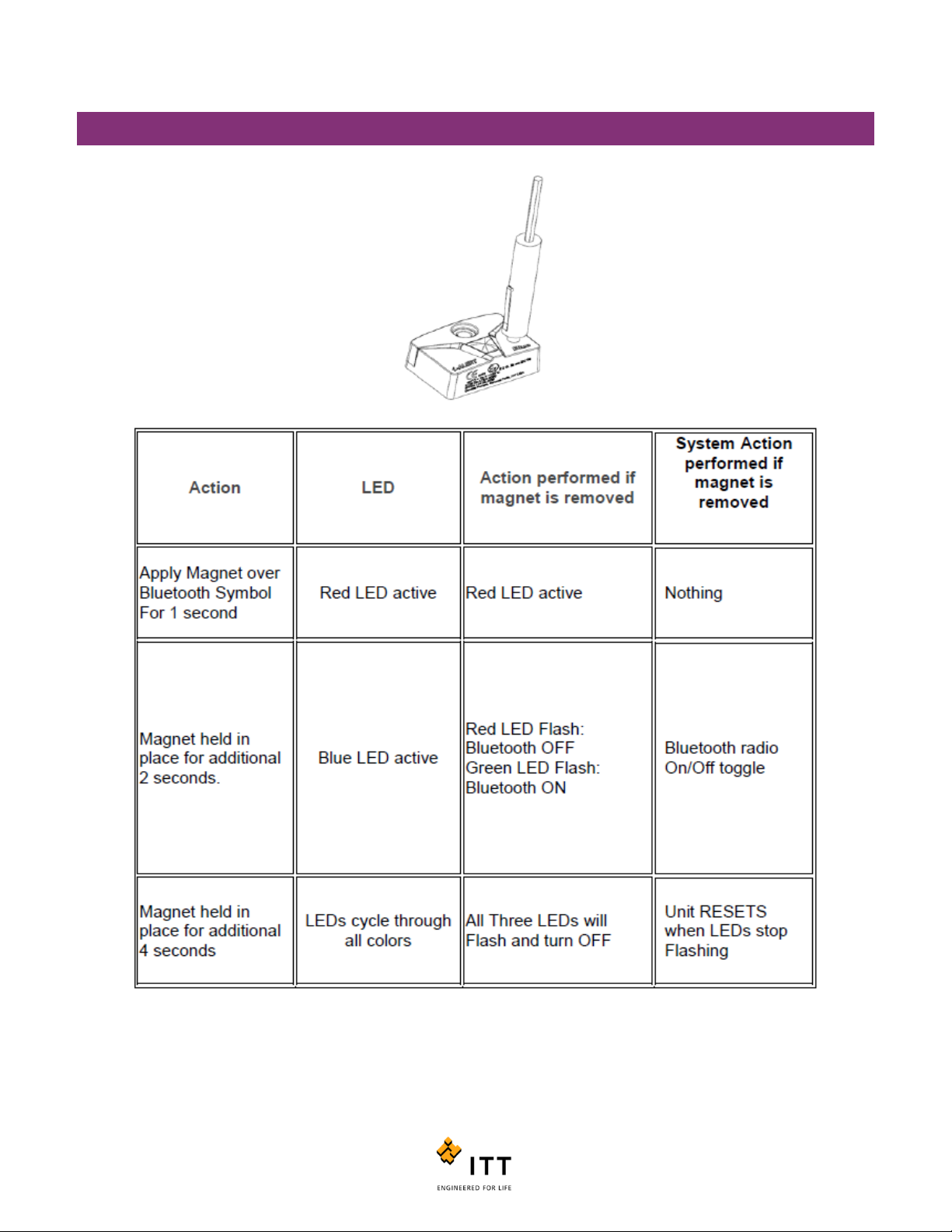

Figure 24: Using a magnet to reset an i-ALERT2

*Using a magnet to reset a Version 1 i-Alert2 will permanently erase stored trend and FFT data; a

Version 2 device will retain all data after a magnetic reset.

i-ALERT2 Application Guide 28 of 64

Page 29

I-ALERT2 EQUIPMENT HEALTH MONITOR ROUTINE OPERATION

Measurement interval

The measurement interval for the condition monitor during normal and alarm operation is 5 minutes.

When the monitor measures a reading beyond the specified temperature and vibration limits, the appropriate red LED

flashes (after 2 consecutive readings). After the process or pump condition that causes the alarm is corrected, the condition

monitor returns to normal mode after one normal-level measurement.

Alarm mode

The condition monitor’s alarm mode is activated after two consecutive readings. When the alarm mode is on, you should

investigate the cause of the condition and make necessary corrections in a timely manner.

Magnetic device considerations

Be careful when you use magnetic devices in close proximity of the condition monitor, such as magnetic vibrationmonitoring probes or dial indicators. These magnetic devices can accidentally activate or deactivate the condition monitor

resulting in improper alarm levels or loss of monitoring.

Wireless Integration

A Bluetooth Low Energy Radio is utilized to communicate condition monitoring information to a mobile Smart device that

the operator can easily view and react to.

I-ALERT2 EQUIPMENT HEALTH MONITOR TROUBLESHOOTING

Figure 25: Troubleshooting

i-ALERT2 Application Guide 29 of 64

Page 30

I-ALERT2® MOBILE APP OPERATION

INSTALLING THE APP

To download the app to your mobile device you must navigate to the Apple App Store or Google Play application on your

mobile device and search for “i-ALERT2”. The App icon should match the one shown below. Note that your device must be

compliant with Bluetooth Smart / 4.0 for the App to function properly.

Once you have downloaded and installed the app, you will need to register with a valid email address in order to log in.

Many helpful videos are also available at

monitor/i-ALERT2-app-videos/.

http://ittproservices.com/aftermarket-products/monitoring/i-ALERT2-condition-

CONNECTING TO I- ALERT2 DEVICES

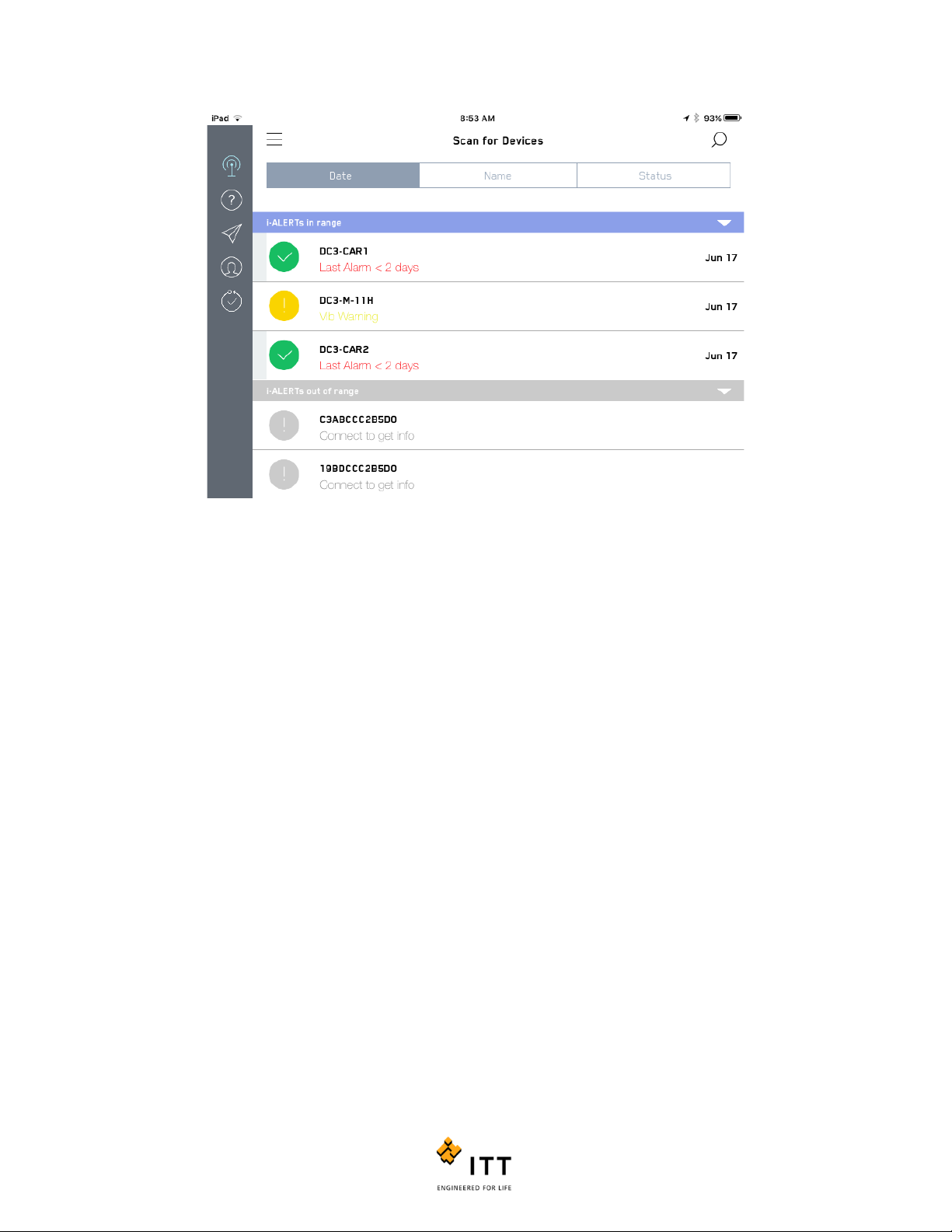

Upon gaining access to the app you will be brought to the “Scan for Devices” page, see Figure 26 below. This page will

display any i-ALERT2 devices within range of your mobile device. Devices that are in range will have a colored icon to the

left of them. Click on the devices name to connect to it. (You can reach the scan for devices option at any time by tapping

icon in the upper left hand corner to bring up the main menu options. A green icon indicates no alarms or warnings, a

yellow icon indicates a warning condition, and a red icon indicates an alarm condition. If a date exists to the right of the

device tag, the date corresponds to the last time the currently connected tablet or phone interacted with the device.

On version 2 units the last alarm status is located below the tag name in red, on the Scan for Devices screen or Active

Routes screen. If the message is present, it will indicate if the i-Alert2 has been in alarm in the last 2, 7, or 30 days. Once the

device has been out of alarm for 30 days, the message will disappear.

i-ALERT2 Application Guide 30 of 64

Page 31

Figure 26: Scan for devices

Devices that are no longer in range will have a grey icon next to their names. See Figure 27.

i-ALERT2 Application Guide 31 of 64

Page 32

Figure 27: Devices in range and out of range

i-ALERT2 Application Guide 32 of 64

Page 33

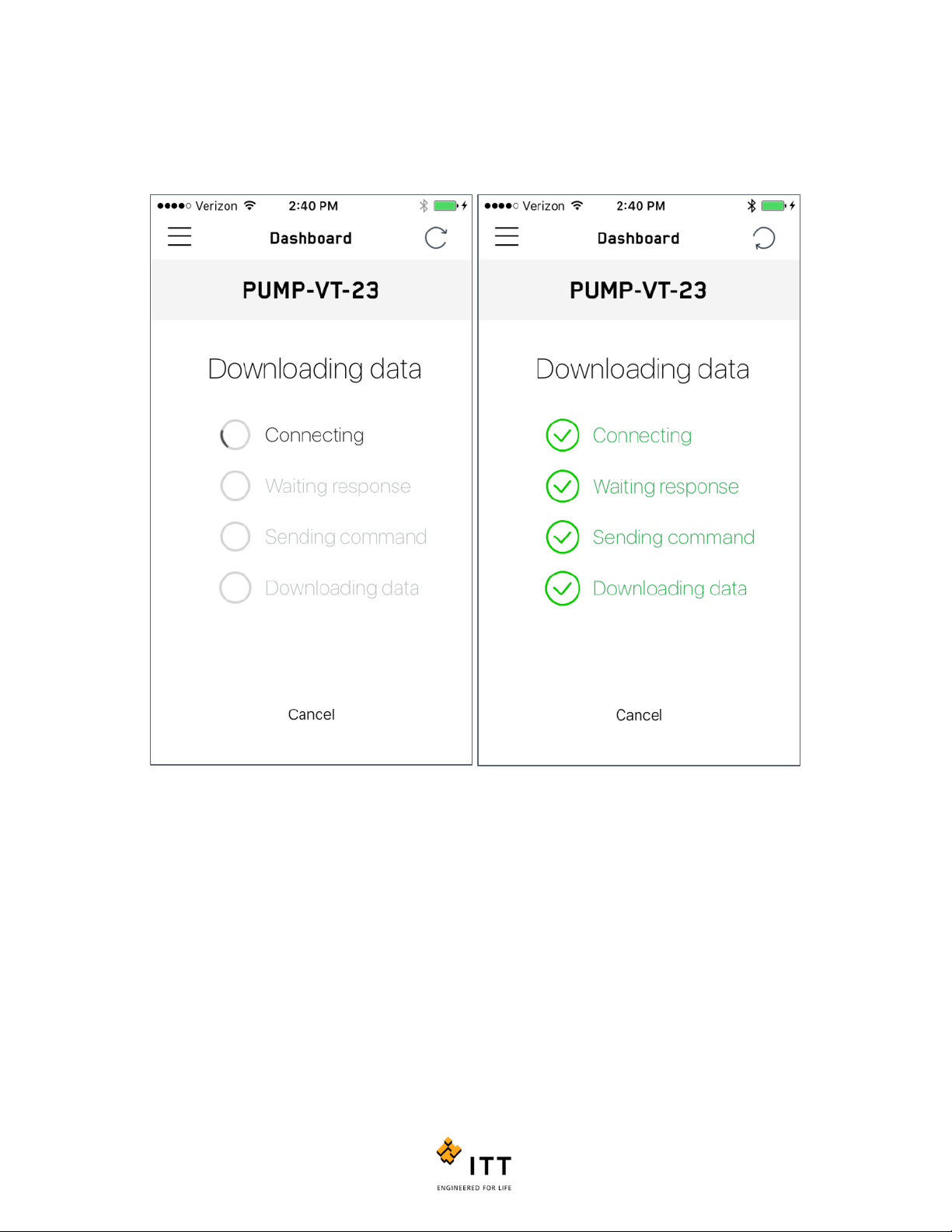

After clicking on the device’s name, the screen shown in figure 28 will come up as the phone and i-ALERT2 device begin to

communicate. Once all 4 steps are completed and green checkmarks are shown you will be taken to the device dashboard

showing the latest data.

Figure 28: Connecting

i-ALERT2 Application Guide 33 of 64

Page 34

DASHBOARD

Figure 29: Dashboard

The Dashboard page (Figure 29) shows the latest overall vibration amplitudes and temperature measurements as well as

the total Runtime hours and Battery Status. To refresh the dashboard and request the latest reading, tap the circular arrow

icon on the top right hand portion of the screen.

i-ALERT2 Application Guide 34 of 64

Page 35

TRENDING

Figure 30: Trending

Tap on any of the individual measurement icons on the Dashboard page to bring up the Trend page. Alternatively, you can

tap the icon in the top left corner that looks like 3 horizontal lines and select “Trending” from the drop list. (Figure 30)

The Trend page shows the historical values of each individual measurement. You can overlay or remove measurement

trends by clicking the radio buttons on the bottom of the screen. See Figure 31.

i-ALERT2 Application Guide 35 of 64

Page 36

DEVICE NAME

DEVICE NAME

Figure 31: Default Trend view on left, Trend view with several measurement de-selected shown on the right.

To change the trend chart to show a longer time frame, tap the “Weekly” button above the chart. This will change the chart

to display the last 4 weeks of trend data. To view the numerical values instead of the graphical trend, tap the icon that looks

like an arrow pointing up next to the devices name. See figure 32. To return to the graphical trend, click the “DONE” button

at the top left.

If you would like to export the numerical data click on the up arrow icon at the bottom left of the page. (Note: the upload

icon may not always be at the bottom left, in some cases it is at the upper right. Regardless of location the function remains

the same.) See figure 32. You will have a choice to print it directly to a local printer, or attach it to an email in the CSV file

format. CSV files are universal and can be imported to plant historians or opened with a spreadsheet processing program.

i-ALERT2 Application Guide 36 of 64

Page 37

DEVICE NAME

Figure 32: Tap the upward facing arrow to view numerical data, tap the icon again on the subsequent page to export the data

i-ALERT2 Application Guide 37 of 64

Page 38

Figure 33: Export trend data by printing or attaching to email

i-ALERT2 Application Guide 38 of 64

Page 39

The trend data may be difficult to see in the default window. Fortunately, you can zoom in and out as well as pan right or

DEVICE NAME

Zoom In

Zoom Out

left using standard mobile touchscreen commands. To pan, simply swipe right or left to move the chart. To Zoom In, touch

the trend chart with 2 fingers and spread them apart. You can use this gesture to change both the X and Y scales on the

chart. You can also zoom in on a specific area of the graph by double tapping. To Zoom Out, touch the screen with pinch

your fingers together. To reset the zoom to the default setting, you will have to leave this screen by either going into the

Kurtosis trend or switching to “Weekly” and back.

i-ALERT2 Application Guide 39 of 64

Figure 34: Trend graph zoomed in

Page 40

WEEKLY VIEW

Figure 35: Export trend data by printing or attaching to email

The weekly view option in the trend will look slightly different than the Hourly view. You will notice there is still the Trend

line showing the Average value but there is also a colored region accompanying the trend. The colored region shows the

maximim and minimum values measured during that time period. (Note that non run hours are dropped from the average

measurement calculation)

i-ALERT2 Application Guide 40 of 64

Page 41

KURTOSIS

DEVICE NAME

DEVICE NAME

Kurtosis is a measure of how “peaky” a data set is. (i.e. The many vibration data points recorded by the i-ALERT2 monitor

for a given sensor axis would constitute a data set) Higher values of kurtosis generally indicate increased crest factor of the

vibration signal. The crest factor is the ratio of the peak to standard deviation. Kurtosis is used for fault detection in

machinery, although it does not indicate the specific cause. Higher values indicate progressive states of fault progression.

ITT suggests utilizing Kurtosis to gauge machine condition in the same way the overall vibration amplitudes are used. As the

value trends up, it means that the machinery is spending more time vibrating at higher peak amplitudes, even though the

RMS (overall) value remains unchanged. This allows for earlier detection of faults.

To access the Kurtosis Trend, tap the small grey dot just below the trend graph. See figure 36. The Kurtosis value of the

temperature trend is likely to be very low and will skew the graph. Remove the temperature trend and zoom in to better

view the Kurtosis Trend values of each vibration axis sensor. To return to the Overall Vibration Trend, tap the small grey

button under the graph.

i-ALERT2 Application Guide 41 of 64

Figure36: Tap the small grey button under the Trend to display Kurtosis, Kurtosis Trend with Temperature removed on right

Page 42

ADVANCED TOOLS

Figure 37: Advanced Tools enables diagnostics

Figure 38: FFT and TWF

The i-ALERT2 device offers some advanced tools that can help in troubleshooting equipment. To access these tools, tap the

icon in the upper left that looks like 3 horizontal lines again and then tap “Advanced Tools”. See figure 37.

The Advanced Tools page will immediately open up to a new page showing that latest spectral or Fast Fourier Transform

(FFT) and time waveform (TWF) data captured on the Radial sensor axis. See figure 38.

i-ALERT2 Application Guide 42 of 64

Page 43

FFT AND TWF DATA

The FFT graph and TWF can be zoomed in or out using the same touchscreen commands as described in the “Trending”

section. To display the latest dataset from each different sensor axis, simply tap the “Axial” or “Horizontal” buttons at the

top of the spectrum. See figure 39. To request an updated FFT/TWF, tap the refresh (circular arrow) at the top right of the

page. This will bring up a new menu with several options to choose from. These options are; request new FFT, download

stored FFT, and download alarm FFT’s. (The i-Alert2 can store up to eight alarm FFT’s, and one user requested FFT).

Figure 39: Switch between sensor axes or request updated dataset

i-ALERT2 Application Guide 43 of 64

Page 44

After requesting an FFT, the LED on the i-Alert2 will stop flashing for 10-30 seconds while the FFT is being computed. Once

complete, the user will be prompted to download the FFT immediately or at a later time. By selecting Download Alarm

FFT’s, the user can download all alarm FFT’s. For Version 2 Devices, the App will only download FFT’s that do not currently

exist on the tablet or phone.

STORED AND ALARM GENERATED FFT DATA

You can access stored datasets including those stored when an alarm is triggered. This is a powerful feature that can assist

in resolving difficult or intermittent problems that would typically be missed with traditional walk around periodic vibration

monitoring, to access historical FFT and TWF data sets, simply tap the circular arrow icon at the top right of the page while

viewing any sensor’s FFT data in the Advanced Tools menu. A message will appear asking you what particular datasets you

would like to view or if you would like to request a new FFT. See figure 40.

Figure 40: Request new FFT or access stored FFT datasets

i-ALERT2 Application Guide 44 of 64

Page 45

EQUIPMENT INFORMATION

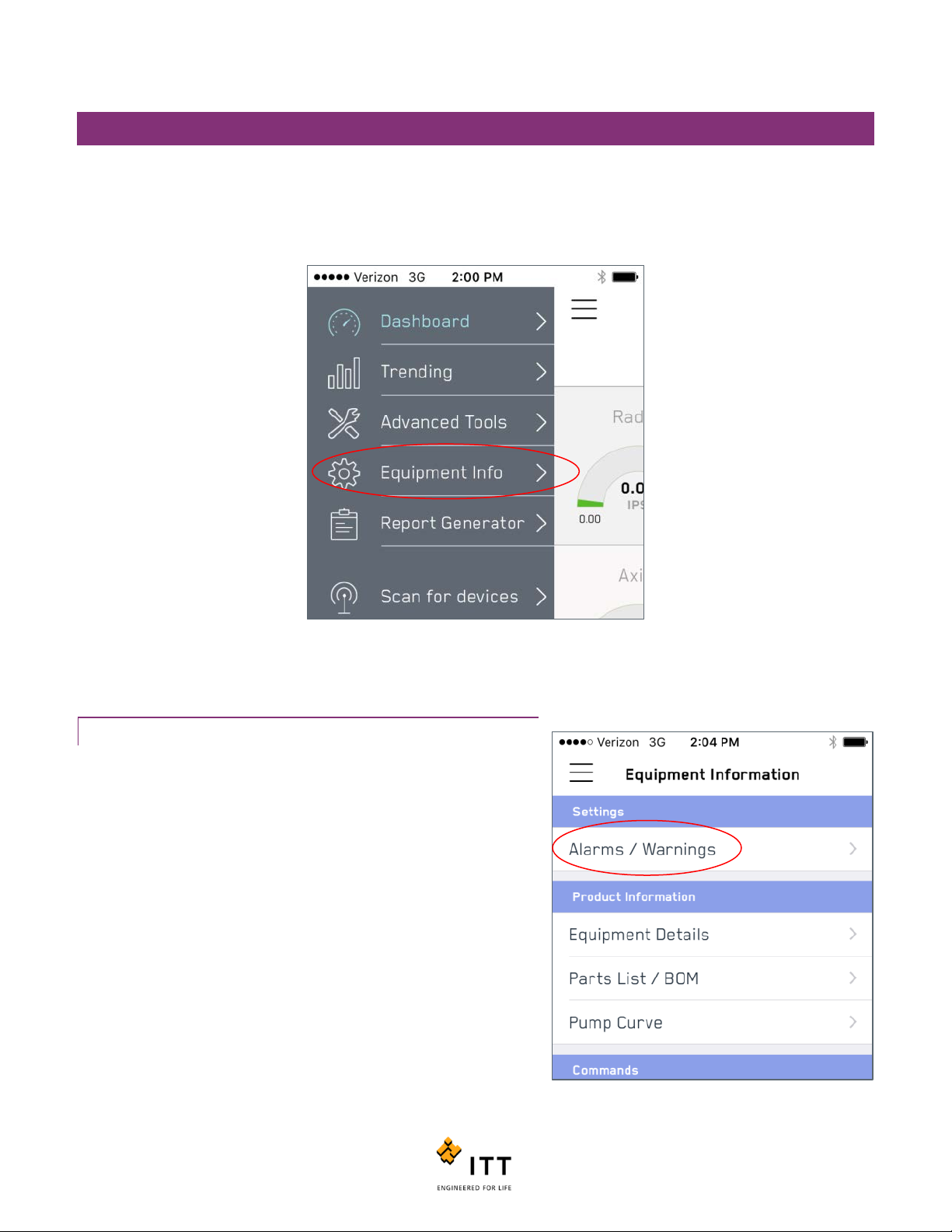

One of the most useful features of the i-ALERT2 mobile app is the ability to instantly access equipment details. The

“Equipment Information” page also includes functionality that allows a user to adjust alarm and warning limits as well as

send commands to the i-ALERT2 monitor to reset the device. To access the Equipment information page, tap the icon in the

upper left that looks like three horizontal lines and then choose “Equipment Info.” See figure 41.

Figure 41: Equipment information

ALARMS / WARNINGS

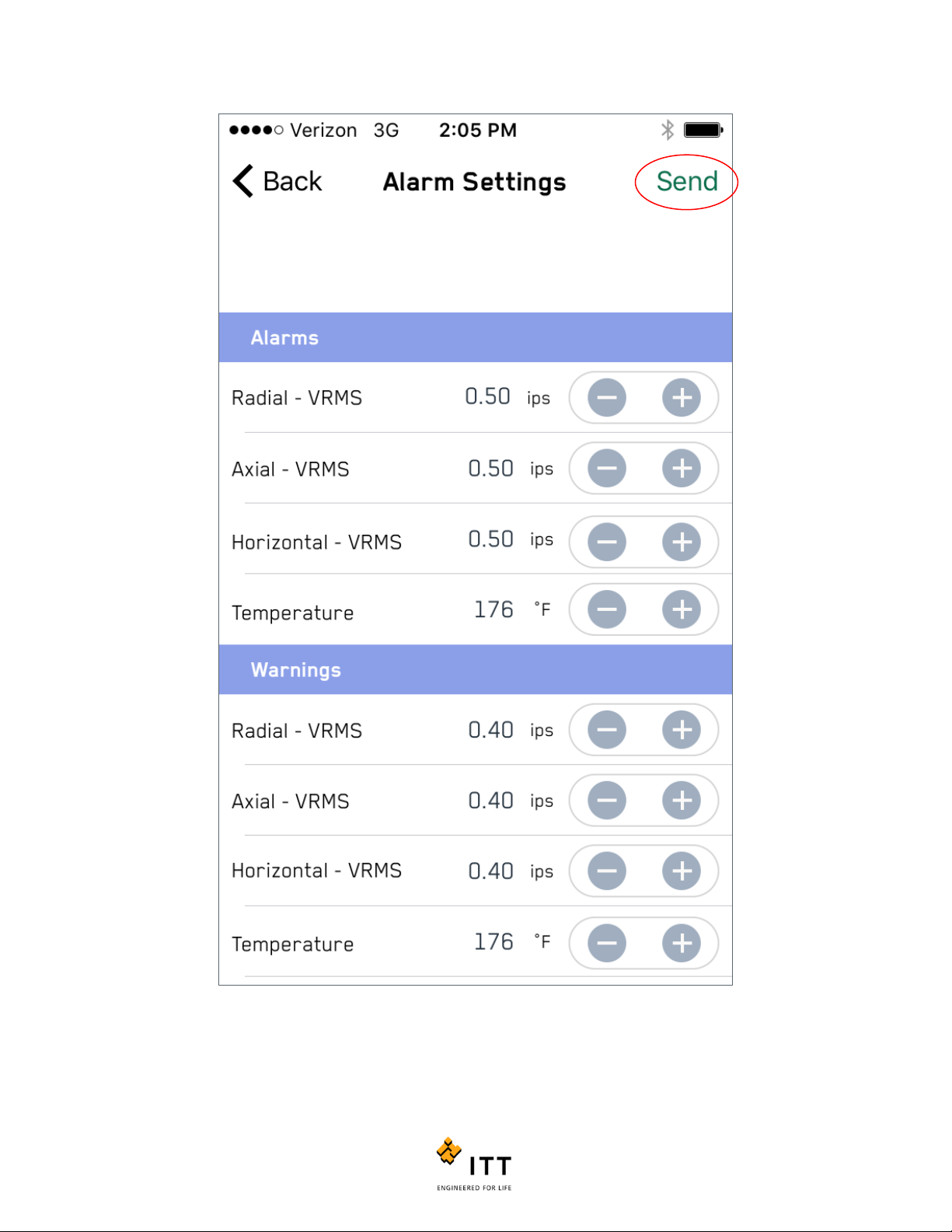

To view and change the Alarm/Warning limits in the i-ALERT2 monitor,

tap the “Alarms / Warnings” tag. See figure 24.

The “Alarm Settings” page will be displayed. (figure 42) From here a

user can adjust the overall vibration amplitudes and temperatures that

cause the device to go into alarm or warning modes. Tap the “ + “ or

“ – “ icons at the right hand side to adjust values.

After updating the alarm or warning settings, they must then be sent

down to the i-ALERT2 device in order to be programmed in. To do this,

tap the “Send” button at the top right. (Figure 43).

Figure 42: Alarms/Warnings

i-ALERT2 Application Guide 45 of 64

Page 46

DEVICE

Figure 43: Use the + and – buttons to adjust values. Tap “Send” to program the new device settings.

i-ALERT2 Application Guide 46 of 64

Page 47

EQUIPMENT DETAILS

Figure 45: Entering a Goulds S/N enables additional functions

The “Equipment Details” page allows the user to view and change fields that relate to the machine configuration as well as

the internal components. You’ll also note that this menu allows you to change between the “Current” configuration and the

“As Built” information, which allows a user to update the equipment information but keep the original data. See Figure 44.

Figure 44: Equipment Details

The Equipment Details page contains editable

information fields for a long list of machinery attributes

including Serial Numbers (S/N), Materials, Impeller

data, Bearing Data, Driver speed, Hydraulic ratings, etc.

To update this information in the i-ALERT2 monitor,

make sure you tap the “Save” tag at the top right hand

corner. Upon successful communication of the new

configuration data a message box will appear stating

“Success. The equipment information was saved.”

Note: Once a valid ITT Goulds Pumps S/N is entered into the “Equipment Details” page, there is no need to manually enter

any other data. The next time it connects to the internet the mobile app will communicate with the ITT servers and pull

down this information, auto-populating it within the app.

i-ALERT2 Application Guide 47 of 64

Page 48

PARTS LIST / BOM

The “Parts List / BOM” is not user editable and only applies to ITT Goulds Pumps products. If a valid ITT Goulds Pumps S/N is

entered into the Equipment Details page the user should be able to view all the parts on the bill of material. The user can

also choose to send part information via email to their purchasing department or local ITT Goulds Pumps sales

representative. To Send parts information via email (Email must be configured on the mobile device), simply tap each part

that you need and then tap the upwards arrow icon in the upper right portion of the screen. This will open your mobile

devices email application and insert the requested parts as text in the body of an email. See Figure 46.

Figure 46: Item 10 information selected for email export

i-ALERT2 Application Guide 48 of 64

Page 49

PUMP CURVE

The “Pump Curve” page allows users to easily download, view and save/send a PDF version of the pumps performance

curve. This feature is only available for valid ITT Goulds Pumps S/Ns. To view the curve, simply select “Pump Curve” under

the Product Information Heading. Once the curve loads you can zoom in and out using standard touchscreen commands or

you can save/send the file by tapping the upwards arrow in the upper right hand corner. See Figure 47.

Figure 47: Pump Curve can be saved or sent like standard image file

i-ALERT2 Application Guide 49 of 64

Page 50

COMMANDS

Occasionally the need may arise to refresh the i-ALERT2 devices stored data. For instance after a machine is repaired or if a

device is moved to another piece of equipment. The “Commands” page contains commands that can be sent to update or

refresh the i-ALERT2 monitor as necessary.

Figure 48: Allowed commands

A brief description of each command is listed below:

Put i-ALERT into sleep Mode: device will go into a very low power consumption mode and does not acquire any data until it

is awakened. (Note: A magnet is needed to reawaken the system.)

Start New Baseline: Tells the i-ALERT2 monitor to perform the baseline procedure to establish new Alarm/Warning limits.

The device will perform a series of measurements over approximately a day of running to calculate its new baseline.

Erase all stored data from i-ALERT: Completely erases all stored measurement data. Can be used to “wipe” an i-ALERT if it

is being transferred to another machine.

i-ALERT2 Application Guide 50 of 64

Page 51

REPORT GENERATOR

The Report Generator function allows the user to export several condition monitoring reports. Currently, reports can be

created that show 30 day and 90 day trends of the vibration/temperature as well as the stored FFTs on that i-ALERT2

device. See figure 49.

Figure 49: Standard reports are available

i-ALERT2 Application Guide 51 of 64

Page 52

Once a report has been generated it can be sent or saved using the upwards arrow icon in the upper right hand corner of

the page.

Figure 50: Export standard reports in PDF

i-ALERT2 Application Guide 52 of 64

Page 53

ROUTES

Route-based vibration data collection is a labor-intensive activity whereby data is gathered at multitudes of machine

collection points on regular intervals. Instead of creating reports one-by-one, the i-ALERT Route feature will help you collect

data across many pieces of equipment and then generate a single report upon completion.

The Routes Icon is located in the Main Menu at the bottom. Selecting that icon will bring the user to the Main Route List,

where you can create, edit and manage due dates for desired routes.

To create a Route, select the

“Add new route” icon . See

detailed instructions below.

To edit a route swipe left over

the route name, and select

Settings. From here you can

change any setting including the

start and due date. Note the

other options whereby the

report icon will generate a

report from the most recent

data collected on that route. To

delete a route swipe left over

the route name and select

“Delete”. Deleting a route will

permanently remove the route

from the list. Reports will no

longer be available for the route.

To begin any route, just select it

from the route list.

Figure 51: Main Route Screen

To establish a new route, select “Add new Route” from main route screen. This will direct you to the route settings page

where you can name the route, select the start date, set the desired interval and route type. The reminder slider will autopopulate the calendar with future route due dates for this route. At the bottom of the settings page you will find a field

where you can add email addresses that will automatically receive the report once completed.

The Route feature of the App allows three distinct types of routes to be executed as follows:

Quick: Only captures overall measurements

Agile: The app will selectively download data with a focus on units in alarm

Trends are downloaded for units in Alarm/Warning, or units with > 60 days since last trend download

FFTs are downloaded for units in Alarm

Traditional: Trend and FFTs are downloaded every time the route is run.

i-ALERT2 Application Guide 53 of 64

Page 54

Figure 52: Route Settings Page and Summary Table of Route Types

After the route settings are completed select “Next” in the upper right. This brings you to the device list, where you can add

or remove equipment from the route. A gray checkmark indicates the equipment has been added to your route; a clear icon

shows equipment that can be added.

i-ALERT2 Application Guide 54 of 64

Page 55

Figure 53: Adding Equipment to a Route

Figure 54: Main Route Screen

After all the equipment has been selected, select “Done”. This will finalize the

route and add it to the main route list.

On the active route screen, shown below, you will see:

1. Route timer (Note, to see previous time press and hold on text

“Previous”);

2. Ratio of checked devices to the total number;

3. A breakdown of the status for the “Checked” devices;

4. Listing of the “Devices on Route” that are not yet checked (meaning,

there still remains an action before it moves to checked status);

5. Followed by a listing of the “Checked Devices” (meaning there are no

remaining download actions or no actions required for that device.)

i-ALERT2 Application Guide 55 of 64

Page 56

The icons to the left of each device display

the current status. Green indicates “no

alarms or warnings”, whereas red indicates

“in alarm state”. Below the device tag

name you will find a description of the

alarm state. Above the tag name you will

find an assignable location for that device.

When the icons are empty, the devices are

not yet in range or unavailable.

On the right side of each device there is a

description of download actions required;

these actions will vary based on the route

type selected and the current status of the

device. When a download action is

required, tap each device icon one at a

time and wait for the download actions to

complete as indicated by the download

status bar.

If a device is to be skipped, swipe left and

select “Skip”. The device will then move

Figure 55: Active Route Screen

down to the checked device list and display a black icon.

It is possible to resort the device list by tapping the triangle on the right of the title bar. To hide checked device, toggle

“Hide” and “Unhide” on the title bar.

After all the devices are checked, a report will automatically generate and email to the addresses specified in settings.

The first page of the report is shown below. Here you will find an overall summary of the health of each machine, as well as

tabular data showing overall RMS vibration for each axis and current temperature. The equipment type can be edited from

the Equipment Details. In the tabular data columns any values in red font indicate an alarm condition.

i-ALERT2 Application Guide 56 of 64

Page 57

Figure 56: Route Report Summary Page

After the Summary, the remaining pages of the report contain any trend data and FFT’s acquired during the most recent

route.

i-ALERT2 Application Guide 57 of 64

Page 58

Figure 57:Route Report Trend Details Screen

i-ALERT2 Application Guide 58 of 64

Page 59

Figure 58:Route Report FFT and TWF Screen

At the top of each page a summary of equipment details is found followed by either trends or FFT’s for that device. The

timestamp for each FFT is found in the upper right corner of each graph.

i-ALERT2 Application Guide 59 of 64

Page 60

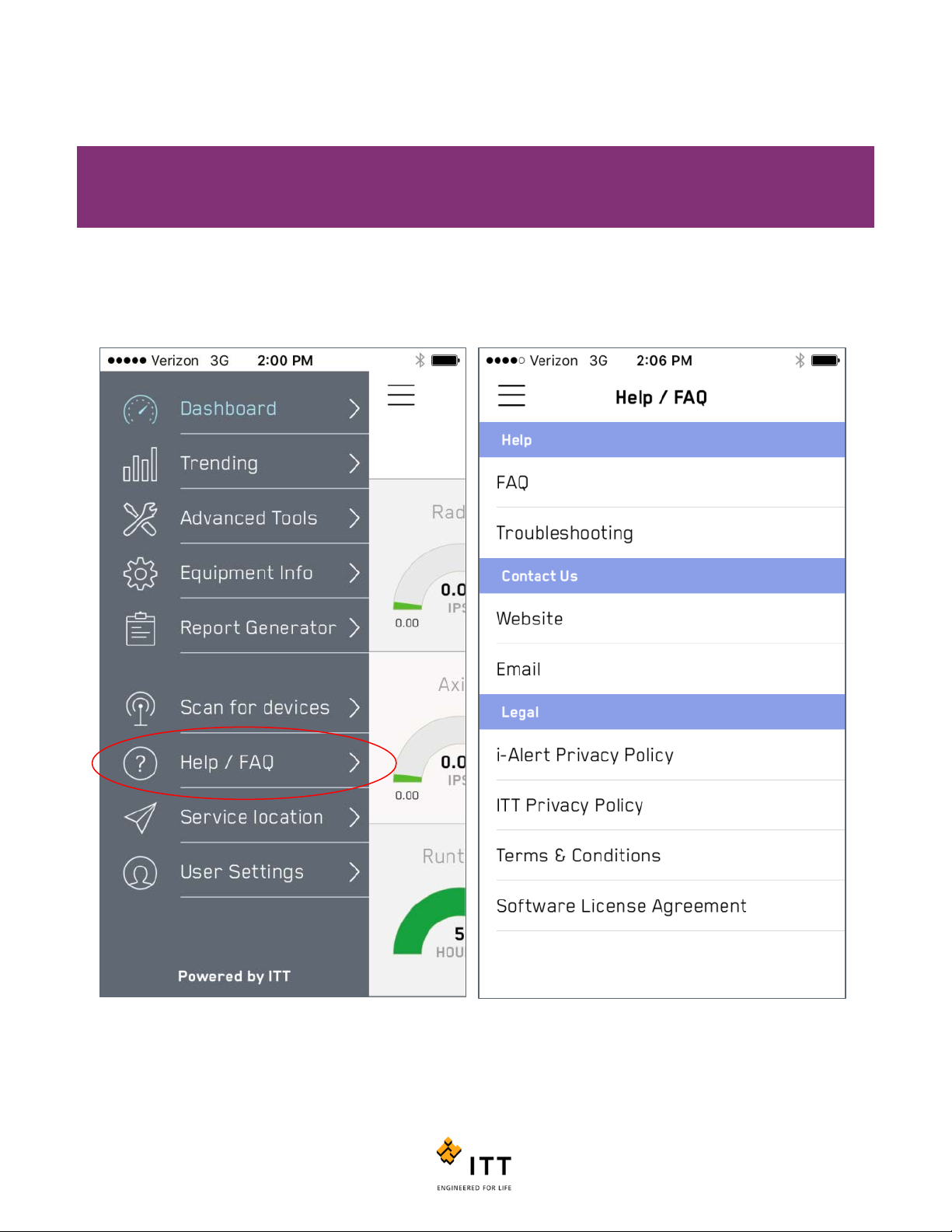

YOU SELECT THE EQUIPMENT THAT YOU WANT TO INSPECT AND THE APP WILL HELP MANAGE WHICH DEVICES YOU HAVE GATHERED DATA ON AND WHICH ONES YOU STILL NEED TO CHECK.HELP/FAQ

The Help/FAQ section provides useful tools In the event you encounter a problem or need additional assistance with the iALERT2 or mobile application. Within the Help/FAQ menu you can access the FAQ or Troubleshooting documentation for

the product. (Internet connection is required). You also access ITT’s website, contact us via email, or view the software

policy information.

Figure 59: Help/FAQ menu offers additional tools and links

i-ALERT2 Application Guide 60 of 64

Page 61

SERVICE LOCATOR

ITT makes it easy to get in touch with local resources that can assist with equipment repairs, spare parts, and field service.

Upon tapping the “Service Locator” tag in the main menu, you will be prompted to allow access to you location in order for

the application to locate the nearest service center or sales office. Tap the pin with the wrench icon to bring up the service

center contact information.

Figure 60: Service locator finds nearest sales or service centers

i-ALERT2 Application Guide 61 of 64

Page 62

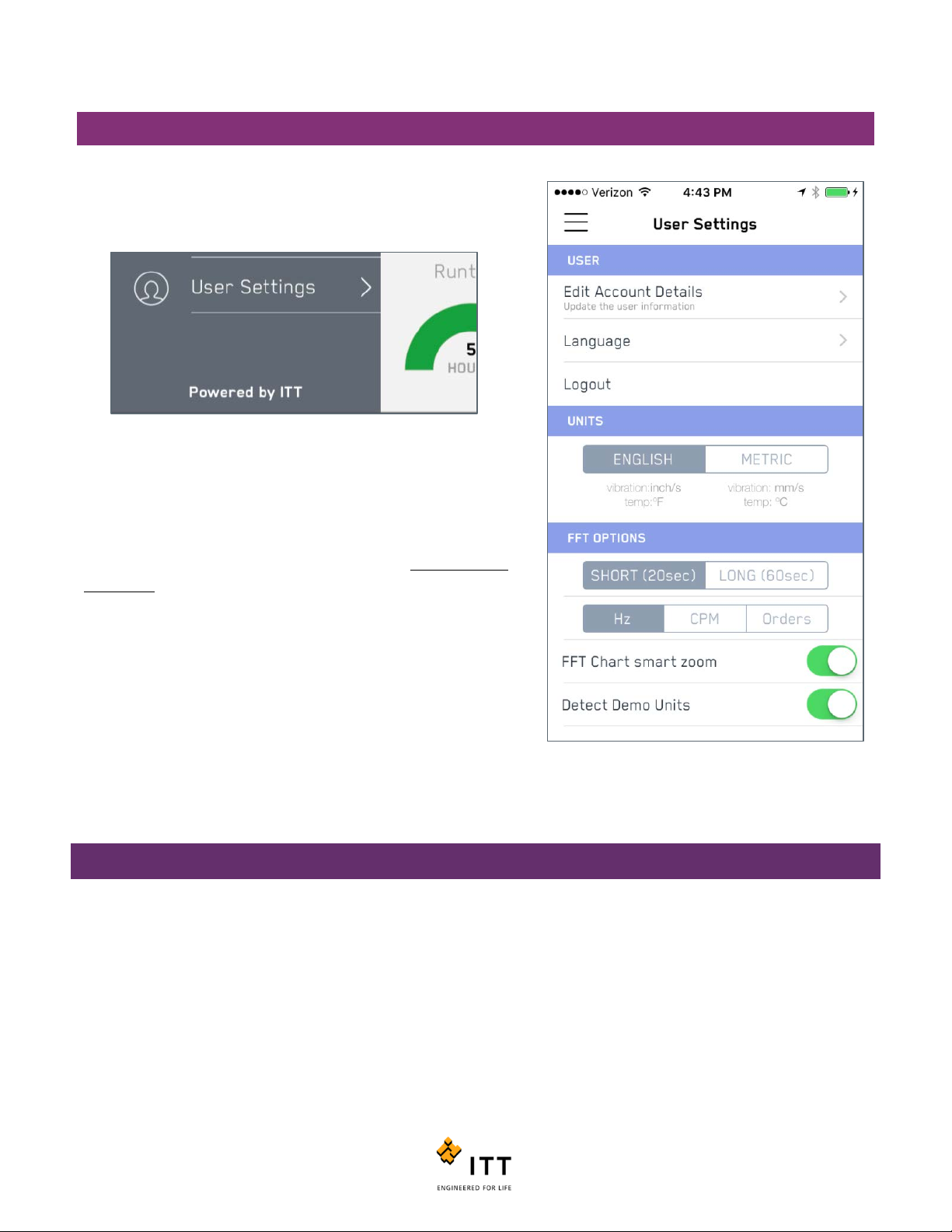

USER SETTINGS

Figure 61: Adjust units in user settings

The “User Settings” menu allows you to change your account details

including your name and password. It also allows you to adjust the

unit system and specify FFT options.

To change between English and Metric system units, use the function

buttons shown in Figure 60.

The FFT can be adjusted to either minimize data collection time or

maximize accuracy. For the shortest data collection time, choose Short

(20sec). To maximize amplitude accuracy for diagnostics and

troubleshooting, change this to Long (60sec). Note, resolution does

not change; it is fixed at 1 Hz and is not configurable.

The FFT display can also be adjusted to display in Hz, CPM (Cycles per

Minute) or Orders (multiples of shaft speed).

FFT Chart smart zoom: This feature minimizes white space on the FFT

chart. ITT Recommends leaving it enabled.

TECHNICAL REFERENCES

1. Moore, Ron. Making Common Sense Common Practice. Models for Manufacturing Excellence Third Edition,

Elsevier, Copyright 2004

2. Crawford, Arthur. The Simplified Handbook of Vibration Analysis Volume II, Computational Systems Incorporated,

Copyright 1992

3. Eshleman, Ronald. Machinery Vibration Analysis: Diagnostics, Condition Evaluation, and Correction, Vibration

Institute, Copyright 2002

i-ALERT2 Application Guide 62 of 64

Page 63

i-ALERT2 Application Guide 63 of 64

Page 64

i-ALERT2 Application Guide 64 of 64

G.iALERT2AppGuide.en-US.2016-10

Loading...

Loading...