IM223

ITT

Commercial Water

Goulds Pumps

Hydrovar Pump Control

Installation, Operation and Maintenance

Goulds Pumps is a brand of ITT Corporation.

www.goulds.com

Engineered for life

INDEX

1 Important Safety Instructions ......................................................................................................4

2 System Design ..............................................................................................................................5

2.1 Pressure tank ...........................................................................................................................6

3 Product Overview .........................................................................................................................7

3.1 Hardware configurations .......................................................................................................... 7

3.2 Operation modes .....................................................................................................................7

3.2.1 Actuator (for single pump operation only!) ......................................................................7

3.2.2 Controller .......................................................................................................................7

3.2.3 Cascade Relay .................................................................................................................7

3.2.4 Cascade Serial/Synchron .................................................................................................8

4 Model Number ...........................................................................................................................10

5 Technical Data ............................................................................................................................12

5.1 General technical data ............................................................................................................13

5.2 EMC requirements (Electromagnetic compatibility) ................................................................. 14

6 Dimensions and Weights ........................................................................................................... 15

7 Additional Components ............................................................................................................. 17

7.1 Cable glands provided ...........................................................................................................17

7.2 Assembly Instructions – All models ........................................................................................18

8 Electrical Installation and Wiring .............................................................................................. 19

8.1 Equipment protection ............................................................................................................. 19

8.2 EMC- electromagnetic compatibility .......................................................................................21

8.3 Recommended Wire Types ..................................................................................................... 22

8.4 Wiring and connections ..........................................................................................................22

8.4.1 Input voltage terminals ................................................................................................. 23

8.4.2 Motor connection .........................................................................................................24

8.4.3 Power unit .................................................................................................................... 24

8.4.3.1 Solo run (Hand Mode) ......................................................................................25

8.4.3.2 Addressing .......................................................................................................26

8.4.4 Control unit ..................................................................................................................28

2

INDEX

9 Programming .............................................................................................................................. 35

9.1 Display – Control panel of the Master / Single Inverter ......................................................... 35

9.2 Function of the push buttons ................................................................................................35

9.3 Basic Drive Display ...............................................................................................................36

9.4 Software parameters ............................................................................................................36

00 MAIN MENU .................................................................................................................37

20 SUBMENU STATUS ........................................................................................................ 40

40 SUBMENU DIAGNOSTICS ..............................................................................................43

60 SUBMENU SETTINGS ..................................................................................................... 44

0100 SUBMENU BASIC SETTINGS....................................................................................... 45

0200 SUBMENU CONF INVERTER ....................................................................................... 47

0300 SUBMENU REGULATION ...........................................................................................53

0400 SUBMENU SENSOR ...................................................................................................55

0500 SUBMENU SEQUENCE CNTR .....................................................................................57

0600 SUBMENU ERRORS ...................................................................................................61

0700 SUBMENU OUTPUTS ................................................................................................. 62

0800 SUBMENU REQUIRED VALUES ...................................................................................63

0900 SUBMENU OFFSET ....................................................................................................65

1000 SUBMENU TEST RUN ................................................................................................68

1100 SUBMENU SETUP ......................................................................................................69

1200 SUBMENU RS485-INTERFACE ....................................................................................70

10 Failure Messages ......................................................................................................................71

10.1 Basic Inverter .....................................................................................................................71

10.2 Master / Single Inverter ...................................................................................................... 72

10.3 Internal errors ....................................................................................................................75

11 Maintenance ............................................................................................................................. 76

12 Programming Flow Chart .........................................................................................................77

Goulds Pumps Limited Warranty ..................................................................................................80

3

! Safety Instructions

DANGER

WARNING

CAUTION

Hazardous

voltage

DANGER

Hazardous

Pressure

CAUTION

Section 1

Important: Read all safety information prior to installation of the

Controller.

Note

This is a SAFETY ALERT SYMBOL. When you see this symbol on the controller, pump or in this

manual, look for one of the following signal words and be alert to the potential for personal

injury or property damage. Obey all messages that follow this symbol to avoid injury or death.

Indicates an imminently hazardous situation which, if not avoided, will result in death

or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death

or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

CAUTION

NOTE Indicates special instructions which are very important and must be followed.

Used without a safety alert symbol indicates a potentially hazardous situation which, if

not avoided, could result in property damage.

Note

All operating instructions must be read, understood, and followed by the operating personnel.

Goulds Pumps accepts no liability for damages or operating disorders which are the result of

non-compliance with the operating instructions.

1. This manual is intended to assist in the installation, operation and repair of the system and must be kept with

the system.

2. Installation and maintenance MUST be performed by properly trained and qualified personnel.

3. Review all instructions and warnings prior to performing any work on the system.

4. Any safety decals MUST be left on the controller and/or pump system.

5. The system MUST be disconnected from the main power supply before removing the cover or

attempting any operation or maintenance on the electrical or mechanical part of the system.

Failure to disconnect electrical power before attempting any operation or maintenance can result

in electrical shock, burns, or death.

6. When in operation, the motor and pump could start unexpectedly and cause serious injury.

Section 1A

Review Hydrovar components and ensure that all parts are included. Inspect all components supplied for

shipping damage.

Included Hydrovar components:

1. Hydrovar motor mount variable 4. 4 Attachment brackets, (bottom hook,

speed drive extender, and screws)

2. Pressure transducer with cable 5. Precision screwdriver.

3. Conduit plate caps and reducers 6. Instruction and Operation Manual

4

Hazardous

Pressure

CAUTION

System Design

Section 2

The following diagrams show typical single and multi-pump systems using the HYDROVAR Variable Speed

Drive. Connect directly to water supply. Use of a low suction pressure switch is recommended.

NOTE

Systems MUST be designed by qualified technicians only and meet all applicable state and local

code requirements.

Single Pump Layout Multi-Pump Layout

2

(1) pump with HYDROVAR (4) gate valve (7) pressure gauge

(2) diaphragm tank (5) check valve or ball valve (8) pressure transducer

(3) fusible disconnect (6) low suction pressure switch (9) pressure relief valve

General

Note

All plumbing work must be performed by a qualified technician. Always follow all local, state and

provincial codes.

6 7 7

8

1

4 45

3

8

9

7

6

4

1

4 45

8

1

4 45

8

1

4 45

2

9

7

4

A proper installation requires a pressure relief valve, a ¼" female N.P.T. threaded fitting for the pressure sensor,

and properly sized pipe. Piping should be no smaller than the pump discharge and/or suction connections.

Piping should be kept as short as possible. Avoid the use of unnecessary fittings to minimize friction losses.

Some pump and motor combinations supplied with this system can create dangerous pressure.

Select pipe and fittings according to your pipe suppliers’ recommendation. Consult local codes for

piping requirements in your area.

All joints must be airtight. Use Teflon tape or another type of pipe sealant to seal threaded connections. Use

caution when using thread sealant as any excess that gets inside the pipe may plug the pressure sensor.

Galvanized fittings or pipe should never be connected directly to the stainless steel discharge head or casing as

galvanic corrosion may occur. Barb type connectors should always be double clamped.

5

System Design

Hazardous

Pressure

CAUTION

Pressure Tank, Pressure Relief Valve and Discharge Piping

Use only “pre-charged” tanks on this system. Do not use galvanized tanks. Select an area that is always above

34º F (1.1º C) in which to install the tank, pressure sensor and pressure relief valve. If this is an area where a

water leak or pressure relief valve blow-off may damage property, connect a drain line to the pressure relief

valve. Run the drain line from the pressure relief valve to a suitable drain or to an area where water

will not damage property.

Pressure Tank, System Pressure

Sizing – A diaphragm tank (not included) is used to cushion the pressure system during start-up and shutdown. It should be sized to at least 20% of the total capacity of your pump. Example: If your pump is sized for

100 GPM then size your tank for at least 20 gal. total volume, not draw down. Pre-charge your bladder tank to

10-15 PSI below your system pressure. The controller is pre-set for 50 PSI at the factory. Therefore a 35-40 PSI

pre-charge in your tank would be required. Use the higher tank pre-charge setting if the system drifts over

5 PSI at a constant flow rate. NOTE: Pre-charge your tank before filling with water!

Caution

Maximum working pressure of HydroPro diaphragm tank is 125 psi.

Installing the Pressure Sensor

The pressure sensor requires a ¼" FNPT fitting for installation. Install the pressure sensor with the electrical

connector pointing up to avoid clogging the pressure port with debris. Install the pressure sensor in a straight

run of pipe away from elbows or turbulence. For optimum pressure control install the pressure sensor in the

same straight run of pipe as the pressure tank. Ensure the pressure sensor is within 10ft of the pressure tank.

Installing the pressure sensor far away from the pressure tank may result in pressure oscillations. Do not

install the pressure sensor in a location where freezing can occur. A frozen pipe can cause damage to the

pressure sensor.

The pressure sensor cable is 30' as standard. The cable can be shortened for a cleaner installation. Longer

cable lengths are available, consult factory. Maximum recommended pressure sensor cable length is 300 feet.

Avoid leaving a coil of pressure sensor cable as this can induce unwanted transient voltages and noise into the

system. Do not run the pressure sensor cable alongside the input or output wiring. Maintain a distance of at

least 8” between the pressure sensor cable and input or output wiring.

Warning

Discharge pressure within the piping system prior to removing pressure transducer or disconnecting any part of the piping system. Open a valve until pressure on an external gauge reads 0 psi.

6

Product Overview

Section 3

3.1 Hardware Configurations

The HYDROVAR variable speed drive consists of two separate components: the power unit and the control

card. In its basic configuration (consisting of only the power unit) the HYDROVAR can be used as a Basic

Inverter. In that configuration the HYDROVAR can be used as a sequence pump in a multi pump system, or as a

simple soft starter for single pump applications.

By extending this Basic controller with the additional control card, the HYDROVAR is able to work in different

modes and can be used for multipump applications.

Three types of drives are available. They are each capable of different levels of control. They are:

Master controller:

• Full variable speed controller of itself in a single pump conguration, with more features than the Single

controller

• Full variable speed control of the attached motor and up to 7 additional Master or Basic controllers.

• Full variable speed control of the attached motor and on/off, xed speed control of up to 5 additional pumps.

(This requires an additional relay card.)

Basic controller:

• Single pump soft start control

• Full variable speed control when connected to a Master controller

Single controller:

• Full variable speed control of a single pump with fewer features than the Master controller

3.2 Modes of Operation

3.2.1 Actuator (for single pump operation only!)

In this mode the HYDROVAR operates as an actuator with external speed signal or switching between 2

programmed frequencies by using the corresponding digital input. For this application the HYDROVAR operates

like a standard frequency converter when an external controller is used.

Note

This mode can only be programmed with a Master or Single controller, and is for single pump

systems only.

3.2.2 Controller

This mode should be selected if only one HYDROVAR pump is in operation and there is no connection to any

other HYDROVAR via RS485 interface.

→ Typical single pump operation

3.2.3 Cascade Relay

One pump is fitted with a HYDROVAR Master controller and up to 5 fixed speed pumps can be switched ON

and OFF on demand. For this purpose an additional Relay Card with 5 relays is used in the Master controller.

Separate motor starters are needed for each motor relay, because the relays in the HYDROVAR are control

contacts only.

Lead/Lag switching of the fixed speed pumps to provide even wear and achieve even operating hours can be

programmed in this mode.

7

Product Overview

This configuration is a cost effective alternative compared with other solutions using VFD’s on each pump, but

additional equipment is required, and you only have fixed speed control of the pumps.

Application Example

Booster sets up to 6 pumps where only one pump is speed controlled by the HYDROVAR and the others are

fixed speed (1 HYDROVAR Master Inverter+5 fixed speed). This should be the standard configuration when the

additional Relay Card is used.

3.2.4 Cascade Serial and Cascade Synchron

In these modes each of the pumps is equipped with a HYDROVAR unit. All units are connected and

communicate via the RS485 interface.

At least one Master controller is used. The other pumps can be controlled by Basic or Master drives. The Master

controller continually reads the status and failures of the Basic controllers. All failures are indicated on the

master unit, including the date and time.

The Master controller has complete control of all pumps in the system, including automatic alternation of the

lead and lag pumps, which provides even wear and achieves even operating hours for each pump.

If the control card of a Master

controller fails, each of the

Basic controllers can be

manually started by an external

switch (manual operation) for

“emergency operation” of the

system.

Application Example

Each pump, (up to 8 pumps),

is equipped with a HYDROVAR

unit. At least one Master

controller will be connected to

up to seven Basic controllers.

All units are connected via the

serial interface (RS485).

The combination of the different

HYDROVAR units that are used

8

Product Overview

in a multi-pump-system depends on the system requirements (i.e. in a 6 pump system 2 or more Master

controllers can be used to increase reliability, and up to 4 Basic controllers without control card.

Minimum requirement: 1 Master controller and the other pumps equipped with Basic controllers.

To increase the reliability of a system, (in the event of a Master controller failure) a second Master controller can

be used.

Full-featured possibility: Each pump is equipped with a Master controller.

In this mode it is possible to run all pumps in cascade serial mode and synchronous mode as well.

This configuration allows each pump to become the lead pump. This also ensures a proper operation if one

Master controller fails. In this case another HYDROVAR takes control. This ensures that the operating hours of

each pump will be the same to ensure even wear of the pumps.

9

Model Number Code

Section 4

Hydrovar Variable Speed Drive Type and Catalog Number

Hydrovar Example Product Code

HV M 3 4 20 0

Filter (optional): Standard = 0, (no filter)

Residential = B

HP Rating: 02 = 2 03 = 3 05 = 5

07 = 7.5 10 = 10 15 = 15

Volts: 2 = 230V 4 = 460V

Phase: 1 = Single Phase 3 = 3 Phase

Type: M - Master

S - Single

B - Basic

Series: HV

The following applies to this example:

HV - Hydrovar Variable Speed Drive

M - Master Drive, (full control and communications)

3 - 3 Phase input power

4 - 460 Volt input power

20 - 20 Horsepower rated

Blank: Standard Commercial Filter, (not residential)

10

Model Number Code

Section 4 (continued)

Hydrovar Product Numbering Chart

Voltage Phase Normal Duty HP Drive Type Model Number

MASTER HVM1202

2 BASIC HVB1202

MASTER HVM1203

3 BASIC HVB1203

SINGLE HVS1203

MASTER HVM3403

3 BASIC HVB3403

SINGLE HVS3403

MASTER HVM3405

5 BASIC HVB3405

SINGLE HVS3405

MASTER HVM3407

460 V 3 7.5 BASIC HVB3407

SINGLE HVS3407

MASTER HVM3410

10 BASIC HVB3410

SINGLE HVS3410

MASTER HVM3415

15 BASIC HVB3415

SINGLE HVS3415

230 V 1

SINGLE HVS1202

11

Technical Data

Section 5

Hydrovar Power Supply

Current Line Protection Wire Size

Cat #* HP V Amps Amps AWG

HVM1202 2

HVM1203 3

HVM3403 3 7.6 10 14

HVM3405 5

HVM3407 7.5

HVM3410 10 19.6 20 10

HVM3415 15 27.8 30 8

* Listed catalog numbers are for master drives. Details also apply to corresponding basic and single units.

Rated Output Voltage Limits 48-62 HZ

1 Ph, 220-240V -10%,

+15%

20 25 10

3 Ph, 380-460V

15.1 20 12

+-15%

Rated Input Recommended Maximum

14 20 14

11.4 15 14

Hydrovar Output to the Motor

Output

Cat #* HP V A AWG

HVM1202 2

HVM1203 3 10 14

HVM3403 3 5.7 14

HVM3405 5 9 14

HVM3407 7.5 3 Ph, 480V 13.5 14

HVM3410 10 17 12

HVM3415 15 23 10

Rated Output Voltage Limits 48-62 HZ

3 Ph, 240V

Rated Current

7 14

Motor Connection Wires

12

Technical Data

5.1 General Technical Data

Ambient temperature: 0° C ... +40° C, 32º F... +104º F

At higher temperatures reduce the output current as shown below or

upsize to the next largest HYDROVAR.

110

100

90

80

70

60

50

40

30

Maximum Output Current (%)

20

10

0

0 10 20 30 40 50 60

Maximum Ambient Temperature (ºC)

The enclosure rating of the HYDROVAR is IP55 however, please note

the following:

• Protect the HYDROVAR from direct sunlight!

• Protect the HYDROVAR from direct rainfall

• Outdoor installation without protection from sun will void warranty!

Storage temperature: -25° C ... +55° C, -10º F ... +130º F

Humidity: RH maximum 50% at 104º F, unlimited

RH maximum 90% at 70º F, maximum 30 days per year

75% average per year (class F)

Condensation is not allowed and will void warranty!

During long periods of inactivity or shutdown, the HYDROVAR should

remain connected to the power supply but turned off to prevent

inadvertant pump run. This will maintain power to the internal heater and

reduce internal condensation.

Air pollution: The air may contain dry dust as found in workshops where there is

excessive dust due to machines. Excessive amounts of dust, acids,

corrosive gases, salts etc. are not permitted

Altitude: Maximum 1000 m, 3280 feet above sea level.

At sites over 1000 m above sea level, the maximum output power should

be de-rated by 1% for every additional 100 m. For installations higher than

2000 m above sea level, please contact your local distributor.

Class of protection: IP 55, NEMA 4 (Indoor use only)

Certifications: CE, UL, C-Tick, cUL

13

Technical Data

5.2 EMC Requirements (Electromagnetic Compatibility)

The EMC requirements depend on the intended use.

• Class B environment (EN 61800-3: Class C2)

Environment that includes domestic premises, it also includes establishments directly connected without

intermediate transformers to a low-voltage power supply network which supplies buildings used for

domestic purposes. Examples of class B environments include houses, apartments, commercial premises

or offices in a residential building.

Caution: The relevant EMC regulations for which the HYDROVAR was tested in class B environments is

based on the restricted use of the product and the following limitations:1) the drive voltage is less than

1000 V; 2) it is neither a plug in device nor a movable device and, 3) when used in the class B environment, it is intended to be installed and utilized by technicians with the necessary training and skills

required for installing and/or using power drive systems, including specific training with respect to EMC

requirements.

• Class A environment (EN 61800-3: Class C3)

Environment that includes all establishments other than those directly connected to a low voltage

power supply network which supplies buildings used for domestic purposes e.g. Industrial areas, technical areas of any building fed from a dedicated transformer are typical examples of class A environment

locations.

The HYDROVAR complies with the general EMC regulations and is tested according to the following standards: EN 61800-3/2004

EN 55011 (2002) Disturbance voltages / Disturbance field strength

First environment Second Environment

– class B / class C2 – class A / class C3

Disturbance voltages OK OK

Disturbance field strength * OK

* Warning - In a domestic environment, this product may cause radio interference, in which case supplementary mitigation measures may be required.

EN 61000-4-2 (2001) Electrostatic discharge

EN 61000-4-3 (2002) Electromagnetic field immunity test

EN 61000-4-4 (2001) Burst immunity test

EN 61000-4-5 (2001) Surge immunity test

EN 61000-4-6 (1996) Immunity of conducted RF-Disturbance

14

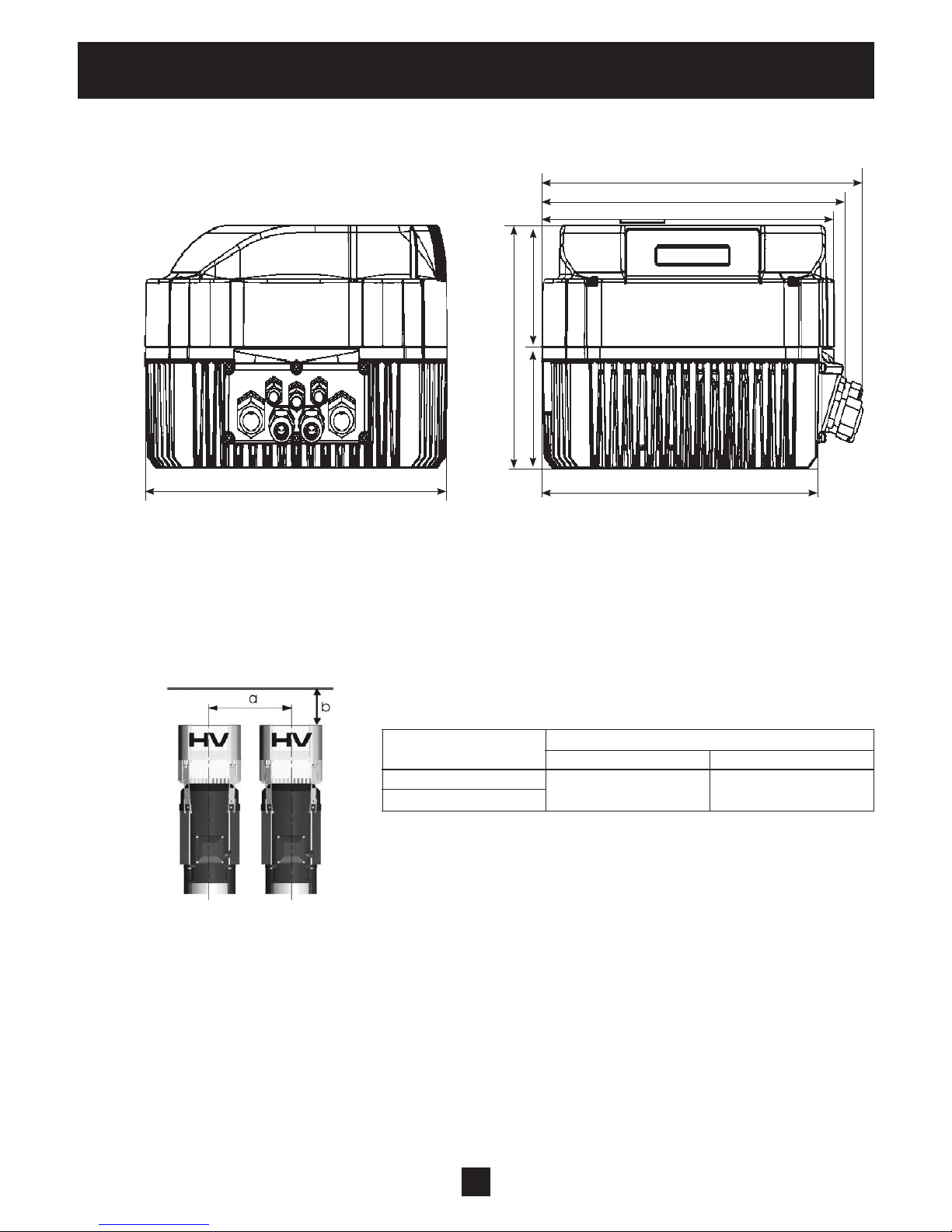

Dimensions and Weights

Section 6

HVM1202, HVM1203, HVM3403, 3405

8.9

8.2

7.9

3.353.35

6.7

7.9

7.4

All dimensions in inches! Drawings are not to scale!

Dimensions are nominal

Basic Master / Single

Weight [lbs]

Type

2, 3 HP

1 Ph

3, 5 HP

3 Ph

8.8 9.7

a … minimum center-distance between HYDROVARs 12"

b … header space for maintenance 12"

15

Dimensions and Weights

HVM3407, HVM3410, HVM3415

10.9

10.2

9.9

3.35

6.7

3.35

10.2

9.4

All dimensions in inches! Drawings are not to scale!

Dimensions are nominal

Basic Master / Single

7.5, 10, 15 HP

3 Ph

Weight [lbs]

Type

16.9 17.8

a … minimum centre-distance between HYDROVARs 17"

b … minimum header space for maintenance 12"

16

Additional Components

Section 7

7.1 Cable Glands Provided

Included Cable gland Conduit plugs Thermistor Mounting Centring components and lock nut clamps bit

12 16 20 25 12 16

Cable

size #8-#1 4,5-10 7-1 3 9-17

AWG

2.015- 2.022 2 (3) 2 2 3 1 1 4 1

4.022- 4.040 2 (3) 2 2 3 1 1 4 1

4.055- 4.110 2 (3) 2 2 3 1 1 4 1

Gland sizer

( ) maximum available cable entries

M M M M M M

7.2 Assembly Instructions – All models

To remove the HYDROVAR cover, loosen the 4 fastening screws.

• Verify that there is no liquid on the unit before you open the cover.

• The HYDROVAR is installed on the motor fan cover using the mounting brackets, the four screws and the

relevant washers.

• Center the HYDROVAR and tighten the four screws holding the brackets.

• Tighten each screw until the two bottom teeth in the brackets start to grip the fan cover.

• After the electrical components are connected, the top cover of the HYDROVAR can be mounted and

tightened by the four fastening screws.

• Ensure the integrity of the ground wire connection. Failure to properly ground the controller or motor

will create an electrical shock hazard.

• Ensure HYDROVAR cover gasket is in place before tightening the cover screws.

• Ensure cable glands are properly installed and close conduit openings that are not being used with

conduit plugs.

17

Additional Components

7.2 Assembly Instructions – All models (continued)

18

Electrical Installation and Wiring

Section 8

Note

All installations and maintenance must be performed by properly trained and

qualified personnel. Use personal protection equipment.

Note

In case of a failure, the electrical power must be disconnected or switched off. Wait

at least 5 minutes for capacitor discharge before servicing the HYDROVAR. Shock,

burns or death are possible hazards if the capacitor discharges during maintenance,

repair, or assembly.

8.1 Equipment Protection

Follow state, and local codes for proper equipment protection.

Applicable: • proper grounding

• AC and DC Ground Fault Circuit Interrupter (GFCI)

Proper grounding:

• Please note that leakage to ground can occur due to the capacitors in the input lter.

• A suitable protection unit has to be selected (according local regulations).

Ground Fault Circuit Interrupter (GFCI):

• When using a GFCI, make sure that it also releases in the event of a short circuit inside the DC-part of

the HYDROVAR to ground!

• single phase HYDROVAR => use pulse sensitive GFCI's

• three phase HYDROVAR => use AC/DC sensitive GFCI's

• The GFCI should be installed according to local regulations!

Fuses:

• Use Very fast acting Class T fuses

• Bussman T-tron type JJN and JJS fuses are acceptable (or equal)

Internal equipment protection:

• The Hydrovar has internal protections against the following malfunctions: short circuit; under and over-

voltage, overload and the overheating of the electronic components.

External protective devices:

• Additional protective functions like motor overheat and low water protection are controlled by separate

equipment.

19

Electrical Installation and Wiring

Fused Disconnect Box:

SINGLE

PHASE

CUSTOMER SUPPLIED

VOLTAGE

THREE

PHASE

CUSTOMER SUPPLIED

VOLTAGE

DISCONNECT

L1

L2

L1

L2

L3

1

3

5

GND

DISCONNECT

1

3

5

GND

2

4

6

2

4

6

12 AWG

12 AWG

12 AWG

12 AWG

12 AWG

FUSE BLOCK

FUSE BLOCK

CUSTOMER SUPPLIED

HYDROVAR

U1

U2

V1

V2

W1

W2

16 AWG

GND

PE

CUSTOMER SUPPLIED

HYDROVAR

U1

U2

V1

V2

W1

W2

16 AWG

GND

PE

MTR

MOTOR

GND

MTR

MOTOR

GND

ITT

Disconnect

Part Number

Input

Voltage

Disconnect

HP / AMP Wire Tightening Fuse AMP Part Voltage

Rating Range Torque Supplier Rating Number Rating

HFD512C1 230/1/60 OT25F3 2 HP / 25A #18-8AWG 7 IN/LB Bussman 20 KTK-R-20 600V

HFD512E1 230/1/60 OT40F3 3 HP / 40A #18-8AWG 7 IN/LB Bussman 30 KTK-R-30 600V

HFD534A1 460/3/60 OT16F3 3 HP / 16A #18-8AWG 7 IN/LB Bussman 10 KTK-R-10 600V

HFD534B1 460/3/60 OT16F3 3 HP / 16A #18-8AWG 7 IN/LB Bussman 15 KTK-R-15 600V

HFD534C1 460/3/60 OT25F3 3 HP / 25A #18-8AWG 7 IN/LB Bussman 20 KTK-R-20 600V

HFD534C2 460/3/60 OT25F3 3 HP / 25A #18-8AWG 7 IN/LB Bussman 20 KTK-R-20 600V

HFD534E2 460/3/60 OT40F3 3 HP / 40A #18-8AWG 7 IN/LB Bussman 30 KTK-R-30 600V

NOTE: Recommended protection (not included with drive only). This fused disconnect is available as part of the PHV series

packaged Hydrovar, see price book.

20

Electrical Installation and Wiring

8.2 EMC – Electromagnetic Compatibility

To ensure electromagnetic compatibility the following points must be observed for cable installation:

Control Cables

General Recommendations

Use shielded cables, temperature rated at 60º C (140º F) or above:

• Control cables must be multi-core cables with a braided copper wire screen.

Double Shielded Single Shielded

Example: JAMAK by Draka NK Cables Example: NOMAK by Draka NK Cables

• The screen must be twisted together into a bundle not longer than ve times its width and con-

nected to terminal X1-1 (for digital and analog I/O cables) or to either X1-28 or X1-32 (for RS485

cables).

Route control cables to minimize radiation to the cable:

• Route as far away as possible from the input power and motor cables (at least 20 cm (8 in)).

• Where control cables must cross power cables make sure they are at an angle as near 90º as

possible.

• Stay at least 20 cm (8 in) from the sides of the drive.

Use care in mixing signal types on the same cable:

• Do not mix analog and digital input signals on the same cable.

• Run relay-controlled signals as twisted pairs (especially if voltage > 48 V). Relay-controlled sig-

nals using less than 48 V can be run in the same cables as digital input signals.

NOTE! Never mix 24 VDC and AC power signals in the same cable.

Motor Wires

To ensure the EMC compatibility and minimize noise level and leakage currents, use the shortest possible motor wires. Use shielded wires only if the total length exceeds 6 feet.)

Line Reactors

Line reactors are available as an option and should be mounted between the HYDROVAR and the main

fuse. The Line reactor should be as close to the HYDROVAR as possible, (max. 12").

Advantages:

• more efcient

• reduction of harmonic currents

21

Electrical Installation and Wiring

For the following applications additional line reactors are strongly recommended:

• high short circuit currents

• compensation-plants without a coil

• asynchronous motors which are responsible for a voltage drop >20% of the line voltage

EMC Summary

• Install proper grounds according to local codes and regulations

• Do not install the power wires in parallel to control wires

• Use screened control cables

• Connect both ends of the motor wire screen to ground

• Connect only one end of the control wire screen to ground

• Motor wires should be as short as possible

8.3 Recommended Wire Types

For maximum 40º C ambient temperature, recommend use of 75º C wire of the following types: RHW,

THHW, THW, THWN, XHHW, USE, ZW.

8.4 Wiring and Connections

Remove the screws holding the top cover of the HYDROVAR.

Lift off the top cover. The following parts can be seen on a HYDROVAR Master / Single Drive:

1 Ph 2, 3 HP 3 Ph 3, 5 HP 3 Ph 7.5, 10, 15 HP

(A) Power supply (B) Motor connections (C) Terminal block:

- START/STOP

(D) RS-485 Interface (E) Status-Relays - SOLORUN (hand mode)

- User interface - RS-485 Interface

- Internal interface (F) Optional Relay Card

22

Electrical Installation and Wiring

8.4.1 Input Voltage Terminals

The power supply is connected to the power section:

Terminal L + N (230 VAC, single-phase)

Terminal L1+ L2 + L3 (460 VAC, three-phase)

2, 3 HP / 1Ø 3, 5 HP / 3Ø

7.5, 10, 15 HP / 3Ø

23

Electrical Installation and Wiring

8.4.2 Motor Connection

Attaching the Thermistor

Method A : Method B :

1. Remove conduit box cover

2. Attach the thermistor (Method A or B)

3. Replace the terminal block, if necessary

4. Wire the motor according to the motor manufacturer's instructions.

NOTE! The thermistor must be attached to the motor. This is required to measure

the motor temperature!

8.4.3 Power Unit

The basic drive has two control terminal blocks.

HVB 1202, 1203

HVB 3403, 3405

HVB 3407, 3410, 3415

24

Loading...

Loading...