ITT GT30, GT07, GT20, GT10, GT15 User Manual

Installation,

Operation and

™

IRRI-GATOR

Maintenance

Instructions

Self Priming Model

GT

Models and Owner’s Information

Single Phase

GT07

GT10

GT15

GT20

GT30

Three Phase

GT073

GT103

GT153

GT203

GT303

Model Number:

Serial Number:

Dealer:

Dealer Telephone:

Purchase Date:

Installation Date:

Table of Contents

Safety Instructions ........................................................ 2

Description and Specifications ...................................... 2

Engineering Data .......................................................... 2

Piping Suction.............................................................. 2

Discharge .......................................................... 3

Wiring and Grounding ................................................. 3

Rotation ....................................................................... 3

Operation ..................................................................... 3

Maintenance ................................................................. 3

Disassembly .................................................................. 4

Reassembly ................................................................... 4

Electrical Data .............................................................. 4

Trouble Shooting .......................................................... 4

Electrical Data .............................................................. 5

Repair Parts .................................................................. 5

Goulds Pumps Limited Warranty.................................. 8

IM049R02

1

Safety Instructions

TO AVOID SERIOUS OR FATAL PERSONAL

INJURY OR MAJOR PROPERTY DAMAGE, READ AND

FOLLOW ALL SAFETY INSTRUCTIONS IN MANUAL AND

ON PUMP.

This is a SAFETY ALERT SYMBOL. When

you see this symbol on the pump or in the

manual, look for one of the following signal

words and be alert to the potential for

personal injury or property damage.

DANGER

Warns of hazards that WILL cause serious

personal injury, death or major property

damage.

WARNING

Warns of hazards that CAN cause serious

personal injury, death or major property

damage.

CAUTION

Warns of hazards that CAN cause personal

injury or property damage.

NOTICE: Indicates special instructions which are very

important and must be followed.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE PUMP.

THOROUGHLY REVIEW ALL INSTRUCTIONS AND

WARNINGS PRIOR TO PERFORMING ANY WORK

ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

NOTICE:INSPECT UNIT FOR DAMAGE AND

REPORT ALL DAMAGE TO THE CARRIER

OR DEALER IMMEDIATELY. DO NOT USE

PUMP IF DAMAGE IS SUSPECTED.

WARNING

UNITS NOT DESIGNED FOR USE

WITH HAZARDOUS LIQUIDS OR

FLAMMABLE GASES.

Hazardous Fluids

can cause fire,

burns or death.

Description and Specifications

• The Model GT embraces a line of end suction, single

stage, self-priming centrifugal pumps for lawn sprinkling,

HVAC systems, and general water transfer.

• Casing is cast iron construction with tapped openings

provided for vacuum gauge and casing drain.

• Impellers are enclosed design, glass filled Noryl

TM

,

threaded directly on motor shaft.

• Standard motors are NEMA standard, 3500 RPM, open

drip proof enclosure.

Engineering Data

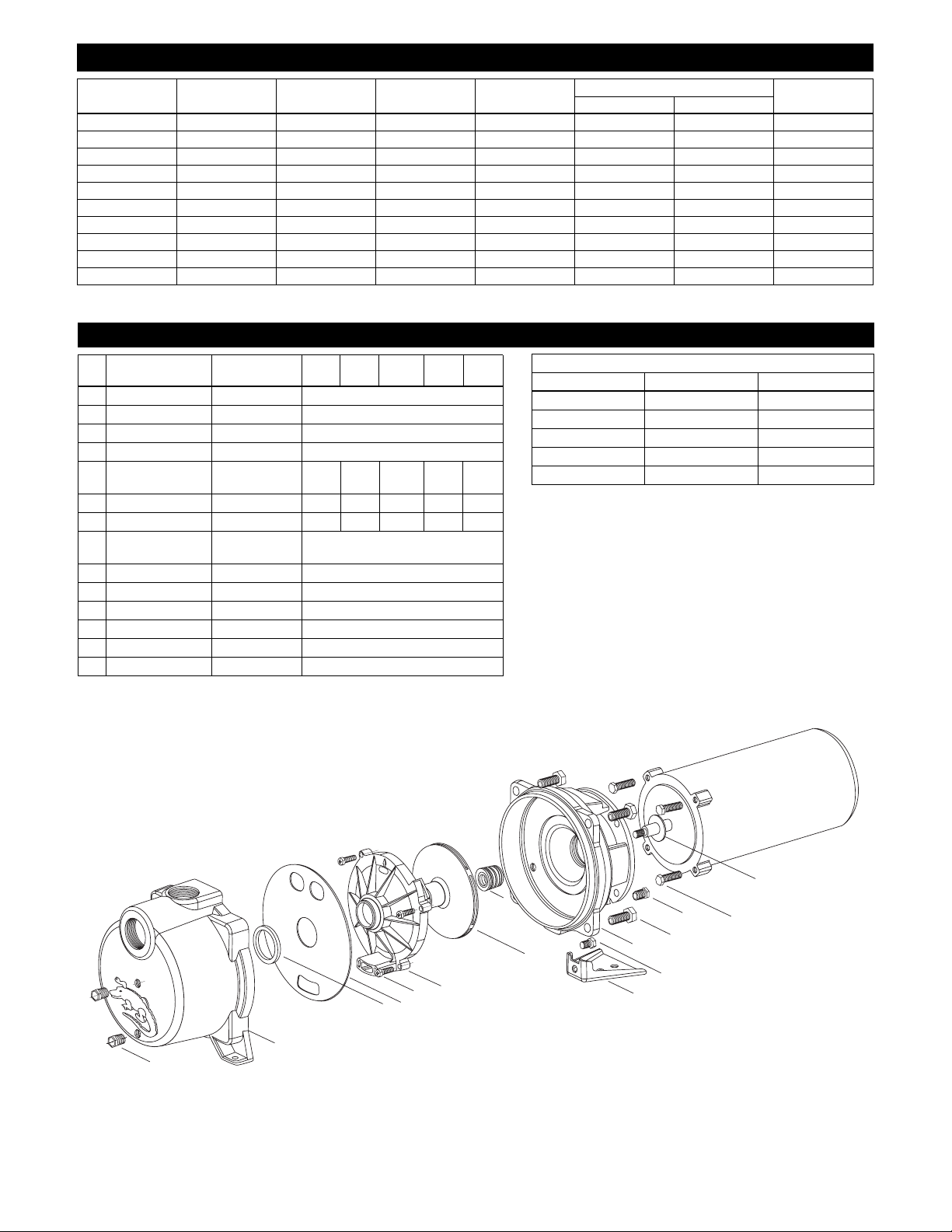

Model HP Ph/Hz Suction Discharge Wt. lbs.

GT07

GT10 1 52

GT15 11⁄2 1/60 60

GT20 2 65

GT30 3 76

GT073

GT103 1 52

GT153 11⁄2 3/60 55

GT203 2 69

GT303 3 71

3

⁄4 48

3

⁄4 49

11⁄2” NPT 11⁄2” NPT

• Maximum Liquid Temperature: 160ºF (71ºC)

• Maximum Starts per Hour: 20 – evenly distributed

Piping

• Pump MUST be installed horizontally on a solid flat

surface, with discharge on top.

• Allow adequate space for servicing and ventilation.

Protect the unit from weather and water damage due to

rain or flooding or freezing temperatures.

• Piping should be no smaller than the suction and

discharge connections and kept short as possible,

avoiding unnecessary fittings to minimize friction losses.

• All piping MUST be independently supported and

MUST NOT place any piping loads on the pump.

NOTICE: DO NOT FORCE PIPING INTO PLACE

AT PUMP SUCTION AND DISCHARGE

CONNECTIONS.

• All pipe joints MUST be airtight.

• The use of Teflon

for ALL pipe joints.

SUCTION

TM

tape, or equivalent, is recommended

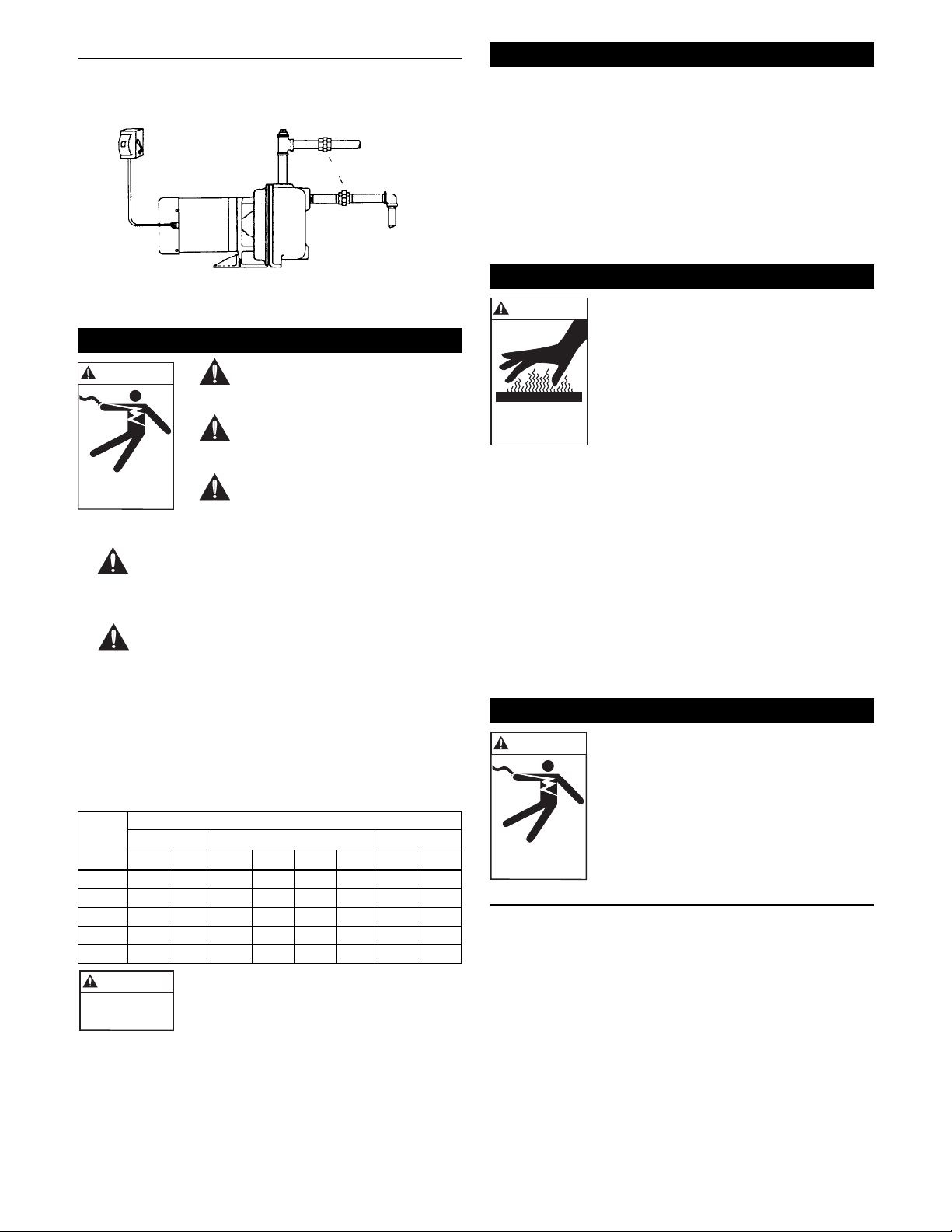

• Total suction lift, including elevation and pipe friction

loss, should not exceed 25 feet of head.

• Install an airtight union in the suction line close to the

pump. See Figure 1.

• Installation of a foot valve at liquid source is

recommended.

NOTICE: FOR INSTALLATIONS WITH LONG

SUCTION PIPING, BOTH A FOOT VALVE

AND A CHECK VALVE ARE

RECOMMENDED.

• To avoid air pockets, no part of the piping should be

above the pump suction connection and piping should

slope upward from liquid source.

• For installations with long suction piping, fill the suction

pipe with water before connecting to pump.

2

DISCHARGE

• Install a tee at the discharge connection of the pump.

The top opening of the tee is required for initial priming.

See Figure 1.

PRIMING OPENING

FUSED OR

CIRCUIT BREAKER

DISCONNECT MEANS

UNION

SUCTION

Figure 1

Wiring and Grounding

WARNING

Hazardous voltage

can shock, burn or

cause death.

Electrical supply MUST match pump’s

nameplate specification. Incorrect voltage can

cause fire or damage to the motor and voids

warranty.

Motors without built-in protection MUST be

provided with contactors and thermal overloads

for single phase motors, or starters with heaters

for three phase motors. See motor nameplate.

Install, ground and wire

according to local and National

Electrical Code requirements.

Install an all leg electrical power

disconnect switch near the

pump.

Disconnect electrical power

before installing or servicing

pump.

• Follow motor manufacturer’s wiring diagram on the

motor nameplate or terminal cover carefully.

• Use only copper wire to motor and ground. The ground

wire MUST be at least as large as the wire to the motor.

Wires should be color coded for ease of maintenance.

RECOMMENDED MINIMUM WIRE SIZE

Distance from Service Entrance to Motor

HP 50 Ft. (15 m) 100 Ft. (30 m) 150 Ft. (46 m) 200 Ft. (61 m)

115 V 230 V 115 V 230 V 115 V 230 V 115 V 230 V

3

⁄4 12 14 10 14 8 14 6 12

1 12 14 8 14 8 12 6 12

11⁄2 10 14 8 14 – 12 – 10

2 10 14 8 14 – 12 – 10

3 – 12 – 12 – 10 – 10

WARNING

Hazardous

voltage

FAILURE TO PERMANENTLY

GROUND THE PUMP, MOTOR AND

CONTROLS BEFORE CONNECTING

TO ELECTRICAL POWER CAN

CAUSE SHOCK, BURNS, OR DEATH.

Rotation

NOTICE: INCORRECT ROTATION MAY CAUSE

DAMAGE TO THE PUMP AND VOIDS THE

WARRANTY.

• Correct rotation is right hand, CLOCKWISE when

viewed from the motor end.

• Three phase unit rotation may be checked by removing

motor end cap or plug and observing rotation of motor

shaft. To reverse rotation, reverse any two of the three

motor leads.

Operation

WARNING

Extreme heat can

cause personal injury

or property damage

OPERATION WITHOUT PRIME, OR

AGAINST A CLOSED DISCHARGE

VALVE, CAN GENERATE HOT

WATER OR STEAM CAUSING

INJURY OR PROPERTY DAMAGE.

NOTICE: DO NOT OPERATE PUMP

WITHOUT PRIME OR SEAL

DAMAGE WILL RESULT.

• Prime pump by filling pump and piping through opening

in top of tee with clean water. See Figure 1.

• Install pipe plug in top of tee using Teflon

TM

tape or

equivalent.

NOTICE: IF PUMP IS DRAINED OR SHUT OFF

DURING PRIMING PERIOD, CASING

MUST BE REFILLED BEFORE

RESTARTING PUMP.

• Start the pump and partially open discharge valve and

wait for system pressure to stabilize. If system pressure is

surging, or prolonged pressure drop is experienced, the

system may not be completely primed.

Maintenance

WARNING

FAILURE TO DISCONNECT

ELECTRICAL POWER BEFORE

ATTEMPTING ANY MAINTENANCE

CAN CAUSE SHOCK, BURNS OR

DEATH.

• No lubrication is required on pump.

Hazardous voltage

can shock, burn or

cause death.

SEASONAL SERVICE

For motor lubrication, refer to and

follow manufacturer’s instructions.

• To REMOVE pump from service, remove all drain plugs

and drain all piping.

• To RETURN pump to service, replace all drain plugs

using TeflonTM tape or equivalent.

• Reconnect suction line if removed, examine union and

repair if necessary.

• Reprime and operate pump following all instructions

and warnings in the “OPERATION” section of manual.

3

Disassembly

WARNING

Hazardous voltage

can shock, burn or

cause death.

1. Remove foot bolt (10).

2. Remove casing bolts (12).

3. Remove back pull-out assembly from casing (2).

4. Remove diffuser seal ring (3) and diaphragm (4).

5. Remove diffuser screws (5) from adapter (11).

6. Remove motor end plug or cover.

7. Restrain motor shaft from rotation by utilization of

the screwdriver slot, or 7⁄16" shaft flats, accessible at the

motor shaft end.

8. Remove impeller (7), turning COUNTER-

CLOCKWISE.

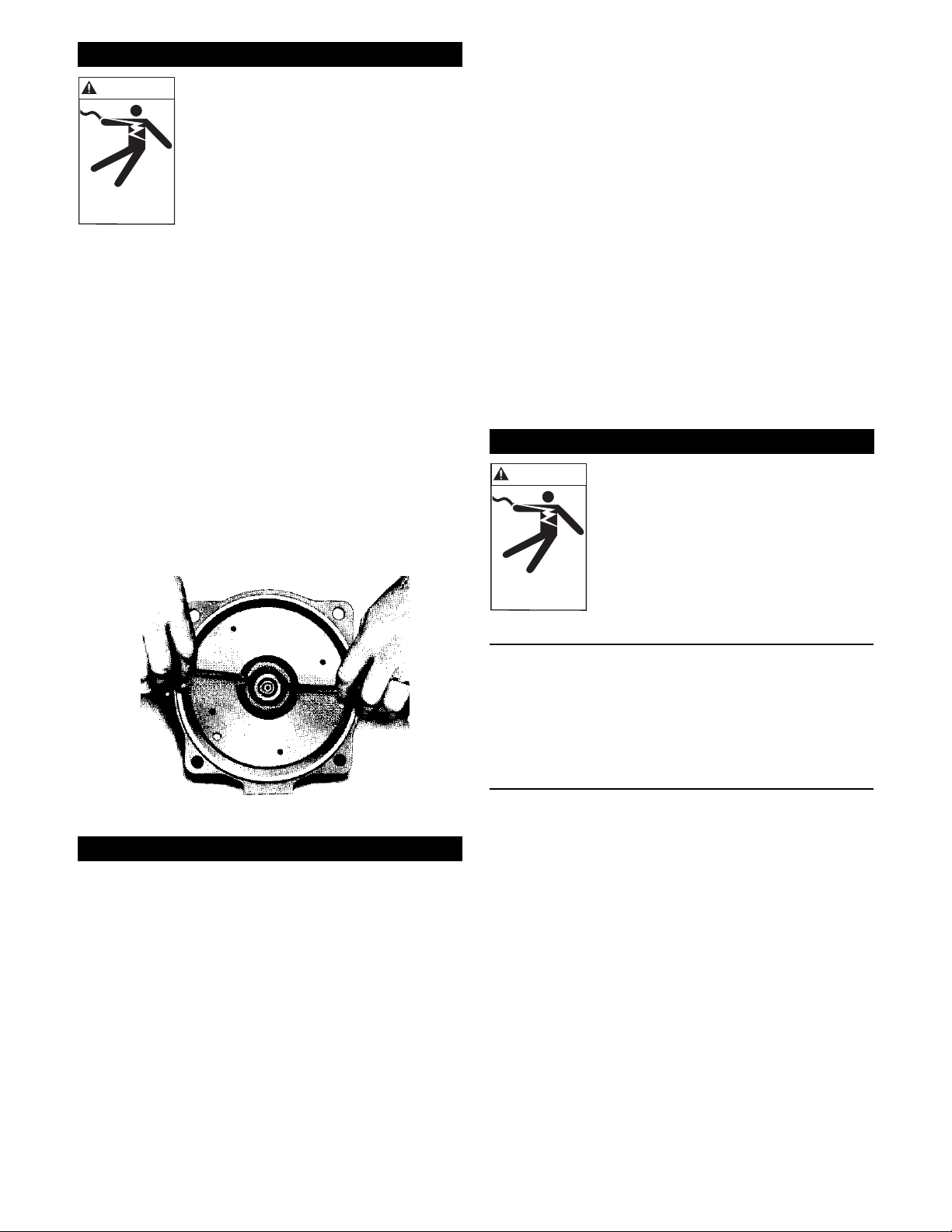

9. Using two screwdrivers, pry off rotary section of

mechanical seal (8). Discard. See Figure 2.

10. Remove motor adapter bolts (12) and remove motor

adapter from motor.

11. Push stationary seat of mechanical seal out of

motor adapter. Discard seal seat.

FAILURE TO DISCONNECT

ELECTRICAL POWER BEFORE

ATTEMPTING ANY MAINTENANCE

CAN CAUSE SHOCK, BURNS OR

DEATH.

4. Fully and squarely install the seal rotary assembly

against the stationary seat. Be sure rotating seal face

does not drop out of holding collar and DO NOT

damage seal face.

5. On three phase units, impeller MUST be installed with

LOCTITE® “Purple”. Hold shaft from rotating, as

explained in the “DISASSEMBLY” section of the

manual, and install impeller by turning CLOCKWISE

until tight against motor shaft shoulder.

6. Replace diffuser. Align to prevent impeller rub.

7. Install new diaphragm and new diffuser seal ring.

8. Install motor and liquid end into casing.

9. Check impeller for binding by rotating the motor shaft.

If binding occurs, loosen casing bolts, readjust diffuser

until impeller hub turns freely. Retighten casing bolts in

a crossing pattern.

10. Replace all drain plugs and motor end components.

11. Reprime and operate according to instructions in the

“OPERATION” section of this manual.

Trouble Shooting

WARNING

Hazardous voltage

can shock, burn or

cause death.

FAILURE TO DISCONNECT

ELECTRICAL POWER BEFORE

ATTEMPTING ANY MAINTENANCE

CAN CAUSE SHOCK, BURNS OR

DEATH.

Figure 2

Reassembly

• Clean and inspect all parts before reassembly.

1. Inspect seal seat bore for wear and debris, clean and

replace as necessary.

NOTICE: MECHANICAL SEAL MUST BE REPLACED

WHENEVER SEAL HAS BEEN REMOVED.

FOLLOW SEAL MANUFACTURER’S

INSTRUCTIONS CAREFULLY.

2. If necessary, seat ring may be lubricated with water or

glycerin to aid in installation. DO NOT contaminate

the seal face. Fully and squarely install the stationary

seat into the adapter. With a clean, lint free cloth,

CAREFULLY wipe the seat face clean of debris. DO

NOT damage the seal seat face.

3. Reinstall the motor adapter on the motor, making sure

that the motor shaft does not dislocate or damage the

stationary seal seat.

SYMPTOM

Motor Not Running:

See Probable Causes 1 through 5.

Little or No Water Delivered:

See Probable Causes 3, 4, 6 through 12, 15.

Excessive Noise and Vibration:

See Probable Causes 3, 6, 7, 10, 12, 13, 14.

PROBABLE CAUSES

1. Motor thermal protector tripped.

2. Open circuit breaker or blown fuse.

3. Impeller binding.

4. Motor improperly wired.

5. Defective motor.

6. Pump is not primed, air or gases in pumpage.

7. Discharge, suction plugged or valve closed.

8. Incorrect rotation. (3 phase only)

9. Low voltage or phase loss.

10. Impeller worn or plugged.

11. System head too high.

12. NPSHA too low – excessive suction lift or loss.

13. Discharge head too low – excessive flow rates.

14. Pump, motor or piping loose.

15. End of suction piping not submerged.

4

Electrical Data

Model HP Voltage Full Load Amps Fuse Ph/Hz

GT07

3

⁄4 115/230 13.8/6.9 45/25 45/25 25/15 1/60

Circuit Breaker

Standard Delay

GT10 1 115/230 16/8 50/25 50/25 30/15 1/60

GT15 11⁄2 115/230 20/10 60/30 60/35 35/20 1/60

GT20 2 230 13.9 40 40 25 1/60

GT30 3 230 17 60 60 30 1/60

GT073

3

⁄4 208-230/460 3.1-2.8/1.4 10-10/10 10-10/10 10-10/10 3/60

GT103 1 208-230/460 4-3.6/1.8 15-15/10 15-15/10 15-10/10 3/60

GT153 11⁄2 208-230/460 5.7-5.2/2.6 20-20/10 20-20/10 15-10/10 3/60

GT203 2 208-230/460 7.5-6.8/3.4 25-25/15 25-25/15 15-15/10 3/60

GT303 3 208-230/460 10.6-9.6/4.8 35-30/15 35-30/15 20-20/10 3/60

Repair Parts List

Item GT07/ GT10/ GT15/ GT20/ GT30/

Description Material

No. GT073 GT103 GT153 GT203 GT303

11⁄4" NPT Pipe Plug Plated Steel 6K2

2 Casing Cast Iron 1K324

3 Guidevane Seal Ring BUNA 5K231

4 Diaphragm Neoprene 5K256

Fillister Head

5 Stainless Steel 13K4 13K4 13K2 13K2 13K2

Machine Screw

6 Guidevane Lexan® 10% G.F. 3K72 3K71 3K70 3K70 3K69

7 Impeller Noryl® 20% G.F. 2K715 2K716 2K714 2K713 2K712

8 Mechanical Seal 10K10

Carbon/Ceramic/

BUNA

9 Pump Foot Steel 4K408

10 Pump Foot Bolt Steel 13K252

11 Motor Adapter Cast Iron 1K310

12 Casing Bolt Steel 13K102

13 Motor Adapter Bolt Steel 13K89

14 Deflector BUNA 5K7

HP 1Ø – ODP 3Ø – ODP

.75 J05853R C05873

1.0 J06853R C06873

1.5 J07858R C07878

2.0 J08854R C08874

3.0 J09854 C09874

Motor Codes

14

8

7

6

5

4

3

11

9

10

12

1

13

2

1

5

Notes

6

Notes

7

GOULDS PUMPS LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by Goulds Pumps.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall

exist for a period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Pumps distributor from whom the pump was purchased and furnish complete

details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Pumps Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds Pumps and the dealer in

purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing pumps to

customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation, limited

liability company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

©1999 Goulds Pumps

August, 1999

Printed in U.S.A.

8

Loading...

Loading...