ITT Goulds Pumps 3298 Series, Goulds Pumps SP 3298, Goulds Pumps V 3298 Installation, Operation And Maintenance Instructions

Installation, Operation and Maintenance Instructions

3298

Frame Mounted

V 3298

3298

Close Coupled

3298 Family

SP 3298

Close Coupled

Pump Safety Tips

Safety Apparel:

Insulated work gloves when handling

·

hot bearings or using bearing heater

Heavy work gloves when handling

·

parts with sharp edges, especially impellers

Safety glasses (with side shields) for

·

eye protection, especially in machine

shop areas

Steel-toed shoes for foot protection when

·

handling parts, heavy tools, etc.

Other personal protective equipment to protect against

·

hazardous/toxic fluids

Coupling Guards:

Never operate a pump without a coupling guard properly

·

installed

Flanged Connections:

· Never force piping to make a connection with a pump

· Use only fasteners of the proper size and material

Operation:

Do not operate below minimum rated flow, or with

suction/discharge valves closed

Do not open vent or drain valves, or remove plugs while

system is pressurized

Maintenance Safety:

Always lockout power

·

Ensure pump is isolated from system and pressure is

·

relieved before disassembling pump, removing plugs, or

disconnecting piping

Use proper lifting and supporting equipment to prevent

·

serious injury

Observe proper decontamination procedures

·

Know and follow company safety regulations

·

· Never apply heat to remove impeller

· Observe all cautions and warnings highlighted in pump

Installation, Operation and Maintenance Instructions.

· Ensure there are no missing fasteners

· Beware of corroded or loose fasteners

IMPORTANT SAFETY REMINDER

To: Our Valued Customers

Goulds' pumps will provide safe, trouble-free service when properly installed, maintained, and operated. We have an

extensive network of experienced sales and service professionals to assist in maximizing your satisfaction with our products.

Safe installation, operation, and maintenance of Goulds' equipment are an essential end user responsibility. This Instruction,

Operation, and Maintenance (IOM) manual identifies specific safety risks that must be considered at all times during product

life. Understanding and adhering to these safety warnings is mandatory to ensure person- nel, property, and/or the environment

will not be harmed. Adherence to these warnings alone, however, is not sufficient — it is anticipated that the end user will also

comply with industry and corporate safety standards. Identifying and eliminating unsafe installation, operating and maintenance

practices is the responsibility of all individuals involved in the installation, operation, and maintenance of industrial equipment.

Specific to pumping equipment, two significant risks bear reinforcement above and beyond normal safety precautions.

! WARNING

▲

Operation of any pumping system with a blocked suction and discharge must be avoided in all cases. Operation, even

for a brief period under these conditions, can cause superheating of enclosed pumpage and result in a violent

1

explosion. All necessary measures must be taken by the end user to ensure this condition is avoided.

! WARNING

▲

Pumping equipment Instruction, Operation, and Maintenance manuals clearly identify accepted methods for

disassembling pumping units. These methods must be adhered to. Specifically, applying heat to impellers and/or

2

impeller retaining devices to aid in their removal is strictly forbidden. Trapped liquid can rapidly expand and result

in a violent explosion and injury.

Please take the time to review and understand the safe installation, operation, and maintenance guidelines outlined in this

manual.

FOREWORD

This manual provides instructions for the Installation, Operation, and Maintenance of the Goulds Model

3298 family of Magnetic Drive Process Pumps. This manual must be read and understood before

installation and start-up.

The design, materials, and workmanship incorporated in the construction of Goulds pumps makes them

capable of giving trouble-free service. The life and satisfactory service of any mechanical unit, however,

is enhanced and extended by correct application, proper installation, periodic inspection, condition

monitoring and careful maintenance. This instruction manual was prepared to assist operators in

understanding the construction and the correct methods of installing, operating, and maintaining these

pumps.

ITT Industries - Goulds shall not be liable for physical injury, damage or delays caused by a failure to

observe the instructions for Installation, Operation, and Maintenance contained in this manual.

Warranty is valid only when genuine ITT Industries - Goulds Pumps parts are used.

Use of the equipment on a service other than stated in the order could nullify the warranty, unless

written approval is obtained in advance from ITT Industries, Goulds Pumps.

Supervision by an authorized ITT Industries - Goulds representative is recommended to assure proper

installation.

Additional manuals can be obtained by contacting your local ITT Industries - Goulds representative, by

calling 1-800-446-8537, or visiting our website at www.gouldspumps.com.

THIS MANUAL EXPLAINS

Proper Installation

n

Start-Up Procedures

n

Operation Procedures

n

Routine Maintenance

n

Pump Overhaul

n

Troubleshooting

n

Ordering Spare or Repair Parts

n

4 3298 Family Rev. 4/07

TABLE OF CONTENTS

PAGE

7 SAFETY

11 GENERAL INFORMATION

15 INSTALLATION

27 OPERATION

33 PREVENTIVE MAINTENANCE

39 DISASSEMBLY & REASSEMBLY

SECTION

1

2

3

4

5

6

113 SPARE AND REPAIR PARTS

125 APPENDICES

I Hydraulic Coverage Charts

II Coupling Guard Installation

III Impeller Trim Procedures

IV Power Monitors

V Reliability Tips for Operating Lined Magnetically-Driven

Sealless Pumps (Quick Reference Guide

VI Polyshield®ANSI Combo Installation, Operation and

Maintenance Instructions

7

8

3298 Family Rev. 4/07 5

6 3298 Family Rev. 4/07

SAFETY

DEFINITIONS ................................7

MEDICAL PRECAUTIONS ........................8

GENERAL PRECAUTIONS ........................8

DEFINITIONS

1

These pumps have been designed for safe and reliable

operation when properly used and maintained in

accordance with instructions contained in this manual. A

pump is a pressure containing device with rotating parts

that can be hazardous. Operators and maintenance

personnel must realize this and follow safety measures.

ITT Industries Goulds Pumps shall not be liable for

physical injury, damage or delays caused by a failure to

observe the instructions in this manual.

Throughout this manual the words WARNING,

CAUTION, ELECTRICAL, ATEX, and NOTE are used

to indicate procedures or situations which require special

operator attention:

! WARNING

s

Operating procedure, practice, etc. which, if not

correctly followed, could result in personal injury or

loss of life.

! CAUTION

$

Operating procedure, practice, etc. which, if not

followed, could result in damage or destruction of

equipment.

Particular care must be taken when electrical power

"

source to the equipment is energized.

EXAMPLES

! WARNING

s

Pump shall never be operated without coupling guard

installed correctly.

! CAUTION

$

Throttling flow from the suction side may cause

cavitation and pump damage.

Improper impeller adjustment could cause contact

!

between the rotating and stationary parts, resulting

in a spark and heat generation.

Lock out driver power to prevent electric shock,

!

accidental start-up, and physical injury.

Lock out driver power to prevent electric shock,

"

accidental start-up and physical injury.

NOTE: Proper alignment is essential for long pump life.

If equipment is to be installed in a potentially

!

explosive atmosphere and these procedures are not

followed, personal injury or equipment damage from

an explosion may result.

NOTE: Operating procedure, condition, etc. which is

essential to observe.

3298 Family Rev. 4/07 7

MEDICAL PRECAUTIONS

! WARNING

s

Magnetic drive pumps contain very strong magnets

which may pose health risks. The following guidelines

shall always be observed.

1. When disassembled and magnets are exposed,

individuals with artificial cardiac pacemakers,

implanted defibrillators, metallic prosthetic heart

valves, internal wound clips (from surgery), prosthetic

joints, metallic wiring, or other metallic prosthetic

devices shall avoid working with, being in proximity

of, or handling the magnets contained in the pumps.

GENERAL PRECAUTIONS

! WARNING

s

Personal injuries will result if procedures outlined in

this manual are not followed.

NEVER use heat to disassemble pump due to risk of

C

explosion from trapped liquid.

NEVER operate pump without coupling guard

AC

AD

AD

correctly installed.

NEVER operate pump beyond the rated conditions

to which the pump was sold.

NEVER start pump without proper prime (all

models), or proper liquid level in self-priming

pumps (Model SP3298).

2. When disassembled and magnets are exposed,

individuals who have had previous surgeries (especially

chest or head surgery) and who do not know if they have

metallic clips internally should avoid work on this unit

unless it can be established by his or her physician that no

risk exists while working on a magnet drive pump.

NEVER run pump below recommended minimum

A C

C

AC

AD

AC

flow or when dry.

ALWAYS lock out power to the driver before

B

performing pump maintenance.

NEVER operate pump without safety devices

C

installed.

NEVER operate pump with discharge valve closed.

NEVER operate pump with suction valve closed.

DO NOT change conditions of service without

approval of an authorized ITT-Goulds representative.

EXPLOSION PREVENTION

In order to reduce the possibility of accidental explosions in atmospheres containing explosive gases and/or dust, the

!

instructions under the ATEX symbol must be closely followed. ATEX certification is a specification enforced in

Europe for non-electrical and electrical equipment installed in Europe. The usefulness of the ATEX requirements is

not limited to Europe. They are useful guidelines for equipment installed in any potentially explosive environment.

NOTE: When pumping unit is installed in a potentially explosive atmosphere, the instructions after the Ex symbol

!

must be followed. Personal injury and/or equipment damage may occur if these instructions are not followed. If

there is any question regarding these requirements or if the equipment is to be modified, please contact a Goulds

representative before proceeding.

8 3298 Family Rev. 4/07

SPECIAL ATEX CONSIDERATIONS

All installation and operation instructions in this manual

must be strictly adhered to. In addition, care must be taken

to ensure that the equipment is properly maintained. This

includes but is not limited to:

1. Monitoring the pump frame and liquid end temperature.

ATEX IDENTIFICATION

For a pumping unit (pump, seal, coupling, motor and pump

accessories) to be certified for use in an ATEX classified

environment, the proper ATEX identification must be

present.

The ATEX tag would be secured to the pump or the

baseplate on which it is mounted. A typical tag would look

like this:

The CE and the Ex designate the ATEX compliance. The

code directly below these symbols reads as follows:

=

II

2=

G/D =

Tx =

Group 2

Category 2

Gas and Dust present

Temperature class, can be T1 to T4

(see Table 1)

2. Maintaining proper bearing lubrication.

3. Ensuring that the pump is operated in the intended

hydraulic range.

Table 1

Max

Max

permissible surface

temperature

Code

T1 842 (450) 700 (372)

T2 572 (300) 530 (277)

T3 392 (200) 350 (177)

T4 275 (135) 235 (113)

T5 212 (100)

T6 185 (85)

The code classification marked on the equipment should be

in accordance with the specified area where the equipment

will be installed. If it is not, please contact your

ITT/Goulds representative before proceeding.

o

F(oC)

permissible

liquid

temperature

o

F(oC)

Option not

available

Option not

available

2

INTENDED USE

The ATEX conformance is only applicable when the pump

unit is operated within its intended use. All instructions

within this manual must be followed at all times. Operating, installing or maintaining the pump unit in any way that

is not covered in this manual can cause serious personal

injury or damage to the equipment. This includes

3298 Family Rev. 4/07 9

any modification to the equipment or use of parts not

provided by ITT/Goulds. If there is any question regarding

the intended use of the equipment, please contact an

ITT/Goulds representative before proceeding.

CONDITION MONITORING

For additional safety precautions, and where noted

!

in this manual, condition monitoring devices should

be used. If applicable, devices should comply with

ATEX. This includes, but is not limited to:

Pressure gauges

u

Flow meters

u

Level indicators

u

Motor load readings

u

Temperature detectors

u

Bearing monitors

u

Leak detectors

u

PumpSmart

u

®

control system

For assistance in selecting the proper instrumentation and

its use, please contact your ITT/Goulds representative.

10 3298 Family Rev. 4/07

GENERAL INFORMATION

PUMP DESCRIPTION ...........................11

NAMEPLATE INFORMATION .....................12

RECEIVING THE PUMP .........................13

Storage Requirements ..........................13

Handling .................................13

PUMP DESCRIPTION

2

The Model 3298 is a sealless close coupled or frame

mounted centrifugal pump with an enclosed impeller that is

driven by a synchronous magnetic coupling and meets

1

dimensional standards of ANSI B73.1. (The 1x1

-5 is not

2

ANSI dimensional.)

The SP 3298 is a self-priming sealless close coupled or

frame mounted centrifugal pump with an enclosed impeller

that is driven by a synchronous magnetic coupling. The

pump and frame / adapter feet locations meet ANSI B73.1

dimensional standards.

The V 3298 is a vertical in-line sealless close coupled

centrifugal pump with an enclosed impeller that is driven

by a synchronous magnetic coupling and meets the

dimensional standards of ANSI B73.2.

Casing - The casings are one piece cast ductile iron lined

with 1/8" TEFZEL

a TEFZEL

®

®1

and have ANSI class 150 flanges with

raised face. The 3298 and SP 3298 are end

suction, top centerline discharge and are self-venting. The

V 3298 is side suction, side discharge and is also

self-venting.

Impeller Magnet Assembly - The 3298 family utilizes a

one or two piece impeller magnet assembly. The magnet

ring is balanced to ISO 1940 G6.3 levels and is sealed

within the solid enclosed TEFZEL

®

impeller magnet

assembly.

Stationary Shaft - The impeller magnet assembly rotates

about a solid stationary silicon carbide shaft. The shaft is

supported at one end by the containment shell and the other

end by the TEFZEL

®

bearing spider.

Rear Impeller Wear Ring - is standard on M and L group

size pumps and is not required on S group sizes. The wear

ring is pressed into the rear of the impeller assembly. The

wear ring reduces axial thrust in the M and L group size

pumps.

Magnetic Coupling - is a coaxial synchronous type using

rare earth magnets. This concept results in a compact

design and allows the impeller to turn at the same speed as

the motor, (i.e. there is no slip between the drive and driven

magnets.)

Magnets - Neodymium Iron (NdFe).

Containment Shell - isolates the pumped liquid from the

atmosphere. The containment shell construction is backed

with vinylester FRP.

Radial Bearings and Thrust Bearings - Goulds standard

bearing material is carbon with optional Pure Sintered

Alpha Grade Silicon Carbide or DryGuard™ Pure Sintered

Alpha Grade Silicon Carbide.

Standard Close Coupled Mounting - The drive magnet

assembly is keyed, set screwed and mounted directly to the

motor shaft. This arrangement eliminates the need to

perform pump/motor alignment.

Optional Power End

3

- The standard configuration is cast

iron with flood oil lubricated ball bearings. Pure oil mist

systems are available as an option. For protection and

reliability of the bearings and the lubricant, a labyrinth seal

is provided. On the inboard side a lip seal is used to prevent

leakage of oil into the magnetic drive assembly.

Bearing Spider - The bearing spider constructed from

solid TEFZEL

®

houses one of the key silicon carbide thrust

bearings in the pump and supports the stationary shaft at

one end.

1

TEFLON®and TEFZEL®: Registered trademarks for fluoropolymer resins, films and fibers made by DuPont.

2

The 1x1

3

Frame mounted power end not available on the V 3298.

3298 Family Rev. 4/07 11

1

-5 is tangential discharge.

2

NAMEPLATE INFORMATION

Every pump has two Goulds nameplates that provide

information about the pump. The tags are located on the

casing and bearing frame.

Fig.

Description

Pump Casing Tag - provides information about

the pump’s hydraulic characteristics.

Note the format of the pump size:

Discharge x Suction - Nominal maximum

Impeller Diameter in inches

(Example: 2x3-8)

No. Example

Fig. 1

English

When ordering spare parts, you will need to identify pump

model, size, serial number, and the item number of required

parts. Information can be taken from the pump casing tag.

Item numbers can be found in this manual

(Figs.1&2).

Bearing Frame Tag - provides information on

the lubrication system used (Fig. 3).

ATEX Tag - If applicable, your pump unit may

have the following ATEX tag affixed to the

pump and/or baseplate. See the Safety section for

a description of the symbols and codes (Fig. 4).

Fig. 2

Metric

Fig. 3

Fig. 4

12 3298 Family Rev. 4/07

RECEIVING THE PUMP

Inspect the pump as soon as it is received. Make notes of

damaged or missing items on the receipt and freight bill.

File any claims with the transportation company

immediately.

STORAGE REQUIREMENTS

Short Term - (Less than 3 months) Goulds normal

packaging procedure is designed to protect the pump

during shipping. Upon receipt store in a covered and dry

location.

Long Term - (More than 6 months) Preservative treatment

of bearings and machined surfaces will be required. Rotate

shaft several times every 3 months. Refer to driver and

coupling manuals for their long term storage procedures.

Store in a dry covered location.

HANDLING

! WARNING

s

Failure to properly lift and support equipment could

result in serious injury or damage to pumps.

Use care when moving pumps. Lifting equipment must be

able to adequately support the entire assembly. Hoist bare

pumps, using a sling under the suction flange and bearing

housing. (Fig. 5)

Baseplate mounted units are moved with slings under the

pump and driver. (Figs.5&7)

2

Fig. 6

! WARNING

s

These pumps use ceramic silicon carbide components.

Do not drop pump or subject to shock loads, this may

damage internal ceramic components.

Fig. 5

Fig. 7

3298 Family Rev. 4/07 13

Complete vertical pumps are lifted with straps under the

pump and motor (Fig. 8). Bare vertical pumps (without a

motor) are lifted with straps under the pump and motor

adapter (Fig. 9).

Fig. 8

Fig. 9

14 3298 Family Rev. 4/07

INSTALLATION

BASEPLATE INSPECTION........................15

SITE/FOUNDATION............................15

LEVEL BASEPLATE ...........................16

Cast Iron/Fabricated Steel ........................16

Feature Fabricated Steel/API Style....................17

Baseplate Leveling Worksheet ......................18

ALIGNMENT AND ALIGNMENT PROCEDURE ...........19

Alignment Checks ............................19

Alignment Criteria ............................19

SetUp...................................20

Measurement ...............................20

Angular Alignment ............................20

Parallel Alignment ............................21

Complete Alignment ...........................21

Alignment Troubleshooting .......................22

GROUT BASEPLATE ...........................22

PIPING....................................23

General ..................................23

Suction Piping ..............................23

Discharge Piping .............................25

Final Piping Check ............................25

3

Equipment that is to be installed in a potentially explosive environment must be done so in accordance with the

!

following installation instructions.

BASEPLATE INSPECTION

1. Remove all equipment.

2. Completely clean the underside of baseplate. It is

sometimes necessary to coat the underside of the

baseplate with an epoxy. This may have been

purchased as an option.

3. Remove the rust preventative solution from the

machined pads with an appropriate solution.

SITE / FOUNDATION

A pump should be located near the supply of liquid and

have adequate space for operation, maintenance, and

inspection.

Baseplate mounted pumps are normally grouted to a

concrete foundation, which has been poured on a solid

footing. The foundation must be able to

absorb any vibration and to form a permanent, rigid

support for the pumping unit.

The location and size of the foundation bolts are shown on

the outline assembly drawing, provided with the pump data

package.

3298 Family Rev. 4/07 15

All equipment being installed must be properly

!

grounded to prevent unexpected static electric

discharge. This includes ensuring that the PFA

lined pumps are pumping fluids that are conductive.

If not, a static electric discharge may occur when the

pump is drained and disassembled for maintenance

purposes.

Foundation bolts commonly used are sleeve type (Fig. 10)

and J type (Fig. 11). Both designs permit movement for

final bolt adjustment.

1. Inspect foundation for dust, dirt, oil, chips, water, etc.

and remove any contaminants. Do not use oil-based

cleaners as grout will not bond to it.

2. Prepare the foundation in accordance with the grout

manufacturer’s recommendations.

Fig. 10

Fig. 11

LEVEL BASEPLATE

CAST IRON / FABRICATED STEEL

1. Place two sets of wedges or shims on the foundation,

one set on each side of every foundation bolt

(Fig. 12, 13). The wedges should extend .75 in.

(20 mm) to 1.5 in. (40 mm) above the foundation, to

allow for adequate grouting. This will provide even

support for the baseplate once it is grouted.

2. Remove water and/or debris from anchor bolt

holes/sleeves. If the sleeve type bolts are being used,

fill the sleeves with rags to prevent grout from

entering.

3. Carefully lower baseplate onto foundation bolts.

4. Level baseplate to within .125 in.(3mm) over the length of

the base and .062 in. (1.5 mm) over the width of the base by

adjusting shims or wedges.

5. Hand tighten bolts.

Fig. 13

Fig. 12

16 3298 Family Rev. 4/07

FEATURE FABRICATED STEEL/

API STYLE

(BASEPLATES PROVIDED WITH VERTICAL

LEVELING ADJUSTORS)

1. Coat the jack screws with an anti-seizing compound to

allow for easy removal after the grout has been cured.

2. Cut round circular plates from bar stock to set the jack

screws on. The edges of the plates should be

chamfered to reduce stress concentrations.

3. Set the baseplate on the foundation and use the four

corner jack screws to raise the baseplate off the

foundation 0.75" to 1.5" (Fig. 14). The two center jack

screws should not be touching the foundation.

Fig. 14

4. Place two machinist levels on the motor pads, one

lengthwise on a single motor pad, and another across the

ends of both motor pads (Fig 15).

NOTE: When using a machinist level, it is important

that the surface being leveled is free of all

contaminants, such as dust, to ensure an accurate

reading.

7. Place the two levels on the pump pads, one lengthwise

on a single pump pad, and another across the middle of

both pump pads. (Fig. 16)

Fig. 16

3

8. Level the pump pads as close to zero as possible, in

both directions, by adjusting the jack screws.

9. Install the anchor bolts until they are hand tight.

10. Return the levels to the motor pads and check the level

measurements.

11. Adjust the jack screws and anchor bolts, if necessary,

until all level measurements are within the design

requirements of 0.002 in./ft.

12. When taking readings, center the level over the pad

being measured.

NOTE: The Baseplate Leveling Worksheet provided

may be used when taking readings.

5. Level the motor pads as close to zero as possible, in

both directions, by adjusting the four jack screws.

6. Next, turn down the center jack screws so that they are

resting on their metal discs on the foundation.

Fig. 15

3298 Family Rev. 4/07 17

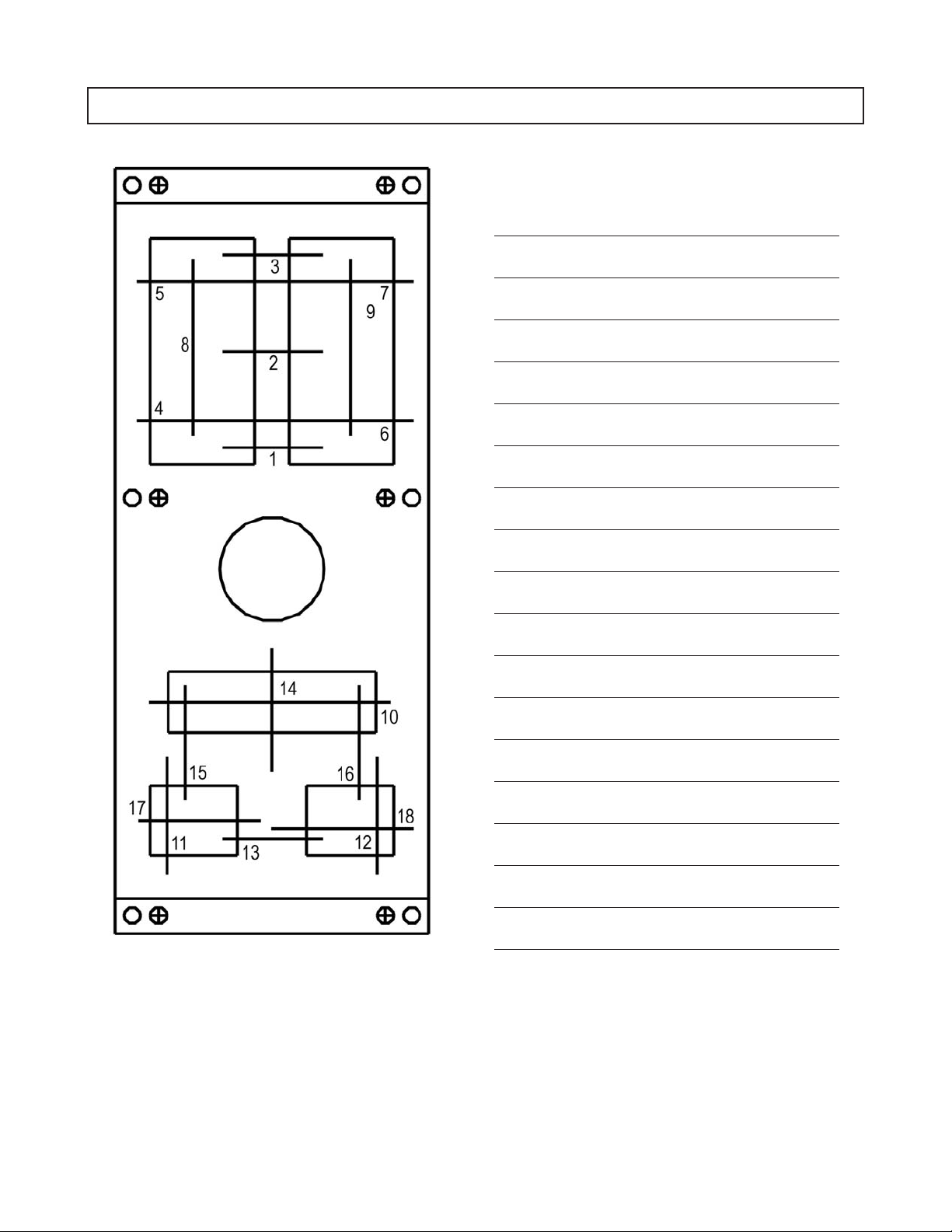

BASEPLATE LEVELING WORKSHEET

LEVEL MEASUREMENTS

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

11)

12)

13)

14)

15)

16)

17)

18)

18 3298 Family Rev. 4/07

ALIGNMENT AND ALIGNMENT PROCEDURE

! WARNING

B

s

Before beginning any alignment procedure, make sure

driver power is locked out. Failure to lock out driver

power can result in serious personal injury.

Alignment procedures must be followed to prevent

!

unintended contact of rotating parts. Follow

coupling manufacturer's coupling installation and

operation procedures.

To remove guard, refer to coupling guard assembly/

disassembly instructions.

The points at which alignment is checked and adjusted are:

Initial Alignment is done prior to operation when

·

the pump and the driver are at ambient temperature.

Final Alignment is done after operation when the

·

pump and driver are at operating temperature.

Alignment is achieved by adding or removing shims from

under the feet of the driver and shifting equipment

horizontally as needed.

NOTE: Proper alignment is the responsibility of the

installer of the unit.

Accurate alignment of the equipment must be attained.

Trouble-free operation can be accomplished by following

these procedures:

ALIGNMENT CHECKS

Initial Alignment (Cold Alignment)

Before Grouting Baseplate - To ensure alignment can be

·

obtained.

Final Alignment (Hot Alignment)

After First Run - To obtain correct alignment when both

·

pump and driver are at operating temperature.

Thereafter, alignment should be checked periodically in

accordance with plant operating and maintenance

procedures.

NOTE: Alignment check must be made if process

temperature changes, piping changes, and/or pump

service is performed.

ALIGNMENT CRITERIA

Good alignment is achieved when the dial indicator

readings as specified in the alignment procedure are .002

in. (.05 mm) Total Indicated Reading (T.I.R.) or less when

the pump and driver are at operating temperature (Final

Alignment).

During the installation phase, however, it is necessary to

set the parallel alignment in the vertical direction to a

different criteria due to differences in expansion rates of

the pump and driver. Table 2 below shows recommended

cold settings for electric motor driven pumps based on

different pumpage temperatures. Driver manufacturers

should be consulted for recommended cold settings for

other types of drivers (steam turbines, engines, etc.).

Table 2

Cold Settings of Parallel

Vertical Alignment

Pumpage

Temperature Set Driver Shaft

50°F (10°C) .002in. (.05mm) LOW

150°F (65°C) .001in. (.03mm) HIGH

250°F (120°C) .005in. (.12mm) HIGH

3

After Grouting Baseplate - To ensure no changes to

·

alignment have occurred during grouting process.

After Connecting Piping - To ensure that pipe strains

·

haven’t altered alignment. If changes have occurred,

alter piping to remove pipe strains on pump flanges.

3298 Family Rev. 4/07 19

SET UP

1. Mount two dial indicators on one of the coupling

halves (X) so they contact the other coupling half (Y)

(Fig. 17).

2. Check setting of indicators by rotating coupling half X

to ensure indicators stay in contact with coupling half

Y but do not bottom out. Adjust indicators

accordingly.

Fig. 17

MEASUREMENT

1. To ensure accuracy of indicator readings, always rotate

both coupling halves together so indicators contact the

same point on coupling half Y. This will eliminate any

measurement problems due to runout on coupling half

Y.

2. Take indicator measurements with driver feet hold

down bolts tightened. Loosen hold down bolts prior to

making alignment corrections.

3. Take care not to damage indicators when moving

driver during alignment corrections.

Fig. 18

4. Repeat steps 1 through 3 until indicator A reads .002

in (.05 mm) or less.

Horizontal Correction (Side to Side)

1. Zero indicator A on left side of coupling half Y, 90°

from top dead center (9 o’clock).

2. Rotate indicators through top dead center to the right

side, 180° from the start (3 o’clock). Observe needle

and record reading.

3. Negative Reading - The coupling halves are further

apart on the right side than the left. Correct by either

sliding the shaft end of the driver to the left or the

other end to the right.

Positive Reading - The coupling halves are closer

together on the right side than the left. Correct by

either sliding the shaft end of the driver to the right or

the other end to the left (Fig. 19).

4. Repeat steps 1 through 3 until indicator A reads .002

in. (.05 mm) or less.

ANGULAR ALIGNMENT

A unit is in angular alignment when indicator A (Angular

indicator) does not vary by more that .002 in. (.05 mm) as

measured at four locations 90° apart.

Vertical Correction (Top to Bottom)

1. Zero indicator A at top dead center (12 o’clock) of

coupling half Y.

2. Rotate indicators to bottom dead center

(6 o’clock). Observe needle and record reading.

3. Negative Reading - The coupling halves are further

apart at the bottom than at the top. Correct by either

raising the driver feet at the shaft end (add shims) or

lowering the driver feet at the other end (remove

shims) (Fig. 18).

Positive Reading - The coupling halves are closer at

the bottom than at the top. Correct by either lowering

the driver feet at the shaft end (remove shims) or

raising the driver feet at the other end (add shims).

5. Re-check both horizontal and vertical readings to

ensure adjustment of one did not disturb the other.

Correct as necessary.

20 3298 Family Rev. 4/07

Fig. 19

PARALLEL ALIGNMENT

A unit is in parallel alignment when indicator P (parallel

indicator) does not vary by more than .002 in. (.05 mm) as

measured at four points 90° apart at operating temperature.

Note the preliminary cold setting criteria, Table 2.

Vertical Correction (Top to Bottom)

1. Zero indicator P at top dead center of coupling

(12 o’clock) half Y (Fig. 19).

2. Rotate indicator to bottom dead center

(6 o’clock). Observe needle and record reading.

3. Negative Reading - Coupling half X is lower than

coupling half Y. Correct by removing shims of

thickness equal to half of the indicator reading under

each driver foot.

Positive Reading - Coupling half X is higher than

coupling half Y. Correct by adding shims of thickness

equal to half of the indicator reading from each driver

foot (Fig. 20).

Positive Reading - Coupling half Y is to the

right of coupling half X. Correct by sliding driver

evenly in the appropriate direction.

Fig. 21

3

NOTE: Failure to slide motor evenly will affect

horizontal angular correction.

4. Repeat steps 1 through 3 until indicator P reads .002

in. (.05 mm) or less.

5. Re-check both horizontal and vertical readings to

ensure adjustment of one did not disturb the other.

Correct as necessary.

Fig. 20

NOTE: Equal amounts of shims must be added to or

removed from each driver foot. Otherwise the vertical

angular alignment will be affected.

4. Repeat steps 1 through 3 until indicator P reads within

.002 in. (.05 mm) or less when hot, or per Table 1

when cold.

Horizontal Correction (Side to Side)

1. Zero indicator P on the left side of coupling half Y,

90° from top dead center (9 o’clock).

2. Rotate indicators through top dead center to the right

side, 180° from the start. Observe needle and record

reading (3 o’clock).

3. Negative Reading - Coupling half Y is to the left of

coupling half X. Correct by sliding driver evenly in the

appropriate direction (Fig. 21).

COMPLETE ALIGNMENT

A unit is in complete alignment when both indicators A

(angular) and P (parallel) do not vary by more than .002 in.

(.05 mm) as measured at four points 90° apart.

Vertical Correction (Top to Bottom)

1. Zero indicators A and P at top dead center

(12 o’clock) of coupling half Y.

2. Rotate indicator to bottom dead center (6 o’clock).

Observe the needles and record the readings.

3. Make corrections as outlined previously.

Horizontal Correction (Side to Side)

1. Zero indicators A and P on the left side of coupling

half Y, 90° from top dead center (9 o’clock).

2. Rotate indicators through top dead center to the right

side, 180° from the start (3 o’clock). Observe the

needle, measure and record the reading.

3. Make corrections as outlined previously.

4. Recheck both vertical and horizontal readings to

ensure adjustment of one did not disturb the other.

Correct as necessary.

3298 Family Rev. 4/07 21

ALIGNMENT TROUBLESHOOTING

Alignment Troubleshooting

PROBLEM PROBABLE CAUSE REMEDY

Cannot obtain horizontal (Side-to-Side)

alignment, angular or parallel.

Cannot obtain vertical (Top to Bottom)

alignment, angular or parallel.

NOTE: With experience, the installer will understand

the interaction between angular and parallel and will

make corrections appropriately.

Driver feet bolt bound.

Baseplate not leveled properly,

probably bowed.

GROUT BASEPLATE

Table 3

Loosen pump hold down bolts and slide pump and driver

until horizontal alignment is achieved.

Determine if center of baseplate should be raised or

lowered and correct by evenly adding or removing shims

at the center of the baseplate.

1. Clean areas of baseplate that will contact grout. Do not

use an oil-based cleaner because grout will not bond to it.

2. Build a dam around foundation (Fig. 22). Thoroughly

wet foundation.

3. Pour grout through grout hole in baseplate up to level of

dam. Remove air bubbles from grout as it is poured by

puddling, using a vibrator, or pumping the grout into

place. Non-shrink grout is recommended (Fig. 22).

Fig. 22

4. Allow grout to set.

5. Fill remainder of baseplate with grout. Remove air as

before (Fig. 23).

Fig. 23

6. Allow grout to set at least 48 hours.

7. Tighten foundation bolts.

ALIGNMENT CHECK

Re-check alignment before continuing, using methods

previously described.

22 3298 Family Rev. 4/07

PIPING

Guidelines for piping are given in the Centrifugal Pump

section of the “Hydraulic Institute Standards” and should

be reviewed prior to pump installation.

A

! WARNING

s

Never draw piping into place by forcing at the flanged

connections of the pump. This will impose dangerous

strains on the unit and cause misalignment between

pump and driver. Pipe strain can adversely effect the

operation of the pump. That could result in serious

personal injury and damage to equipment.

Flange loads from the piping system, including

!

those from thermal expansion of the piping, must

not exceed the limits of the pump. Casing deformation can result in contact with rotating parts and

result in excess heat generation, sparks and

premature failure.

1. All piping must be supported independently and must

line up naturally with the pump flanges.

2. Piping runs shall be designed to minimize friction

losses.

3. DO NOT make final connection of piping to pump

until grout has hardened and pump and driver

hold-down bolts have been tightened.

4. It is suggested that expansion loops or joints, if used,

be properly installed in suction and/or discharge lines

when handling liquids at elevated temperatures, so

linear expansion of piping will not draw pump out of

alignment (Fig. 24 & 25).

Fig. 25

5. The piping should be arranged to allow pump flushing

prior to removal of the unit on services handling

corrosive liquids.

6. System should be thoroughly cleaned prior to

installation.

SUCTION PIPING

A

! WARNING

s

NPSHAmust always exceed NPSHRas shown on

Goulds performance curves received with order.

Reference Hydraulic Institute for NPSH and pipe

friction values needed to evaluate suction piping.

Properly installed suction piping is a necessity for trouble

free pump operation. Suction piping should be flushed

BEFORE connection to the pump.

3

1. Use of elbows close to the pump suction flange should

be avoided. There should be a minimum of 2 pipe

diameters of straight pipe between the elbow and

suction inlet. Where used, elbows should be long

radius (Fig. 26)

Fig. 24

3298 Family Rev. 4/07 23

CORRECT

CORRECT PIPING

Fig. 26

Fig. 28

Suction Lift Conditions

1. Suction pipe must be free from air pockets

Fig. 27

2. Use suction pipe one or two sizes larger than the pump

suction, with a reducer at the suction flange. Suction

piping should never be of smaller diameter than the

pump suction.

3. Reducers should be eccentric at the pump suction

flange with sloping side down and horizontal side at

the top (Figs. 26, 27, 28).

$

Pump must never be throttled on suction side.

4. Suction strainers, when used, must have a net “free

area” of at least three times the suction pipe area.

5. Separate suction lines are recommended when more

than one pump is operating from the same source of

supply.

CAUTION

2. Suction piping must slope upwards to pump.

3. All joints must be air tight.

4. A means of priming the pump must be provided, such

as a foot valve, except for the self priming pump.

Suction Head/Flooded Suction Conditions

1. An isolation valve should be installed in the suction

line at least two pipe diameters from the suction to

permit closing of the line for pump inspection and

maintenance.

2. Keep suction pipe free from air pockets.

3. Piping should be level or slope gradually downward

from the source of supply

4. No portion of the piping should extend below pump

suction flnge.

5. The size of entrance from supply should be one or two

sizes larger than the suction pipe.

6. The suction pipe must be adequately submerged below

the liquid surface to prevent vortices and air

entrainment at the supply.

24 3298 Family Rev. 4/07

INCORRECT PIPING

DISCHARGE PIPING

1. Isolation and check valves should be installed in

discharge line. Locate the check valve between

isolation valve and pump, this will permit inspection of

the check valve. The isolation valve is required for

priming, regulation of flow, and for inspection and

maintenance of pump. The check valve prevents pump

or seal damage due to reverse flow through the pump

when the driver is turned off.

2. Increasers, if used, should be placed between pump

and check valves.

3. Cushioning devices should be used to protect the

pump from surges and water hammer, if quick-closing

valves are installed in system.

3

FINAL PIPING CHECK

After Connecting Piping to the Pump

CORRECT PIPING

Fig. 29

Rotate shaft by hand to ensure it rotates smoothly

!

and there is no rubbing which could lead to excess

heat generation and or sparks.

1. Rotate shaft several times by hand to be sure that there

is no binding and all parts are free.

2. Check alignment, per the alignment procedure outlined

previously to determine absence of pipe strain. If pipe

strain exists, correct piping.

A build up of gases within the pump, sealing system

!

and or process piping system may result in an

explosive environment within the pump or process

piping system. Ensure process piping system, pump

and sealing system are properly vented prior to

operation.

Fig. 30

3298 Family Rev. 4/07 25

26 3298 Family Rev. 4/07

OPERATION

PREPARATION FOR START-UP ....................27

Checking Rotation - Frame Mounted ..................27

Couple Pump and Driver .........................27

Install Coupling Guard ..........................27

Checking Rotation - Close Coupled ...................28

Lubricating Bearings ...........................28

Connect Condition Monitoring Devices .................28

Priming Pump ..............................28

STARTING PUMP .............................28

OPERATION ................................29

General Considerations..........................29

Operating at Reduced Capacity .....................29

Suction Valve Closed / Dry Run Operation ...............29

Draining Tanks / Dry Run Operation ..................29

Discharge Valve Closed .........................29

Operating Under Freezing Conditions ..................30

3298 MINIMUM CONTINUOUS RECOMMENDED FLOW .....30

SHUTDOWN ................................31

FINAL ALIGNMENT ...........................31

4

PREPARATION FOR START-UP

When installing in a potentially explosive environ-

!

ment, please ensure that the motor is properly

certified.

CHECKING ROTATION FRAME MOUNTED

$

Serious damage may result if pump is run in the

wrong rotation.

1. Lock out power to driver.

! WARNING

B

s

Lock out driver power to prevent accidental start-up

that could result in serious personal injury.

2. Make sure coupling spacer is removed and coupling

hubs are fastened tightly to the shafts and are not loose.

NOTE: Pump is shipped with coupling spacer removed.

3. Unlock driver power.

CAUTION

4. Make sure everyone is clear. Jog driver just long enough

to determine direction of rotation. Rotation must

correspond to arrow on bearing frame.

5. Lock out power to driver.

COUPLE PUMP AND DRIVER

! WARNING

B

s

Lock out driver power to prevent accidental start-up

that could result in serious personal injury.

Lubricate coupling per manufacturer’s instructions and

install coupling spacer.

INSTALL COUPLING GUARD

Install coupling guard as defined in the appendix.

! WARNING

s

Never operate a pump without a coupling guard

properly installed. Operating pump without a properly

installed coupling guard can result in serious personal

injury.

3298 Family Rev. 4/07 27

CHECKING ROTATION - CLOSE

COUPLED

! CAUTION

$

Serious damage may result if pump is run

in the wrong rotation.

1. Unlock driver power.

2. Make sure everyone is clear. Jog driver just long

enough to determine direction of rotation. Rotation of

motor fan must correspond to arrow on close coupled

frame.

LUBRICATING BEARINGS

Bearings must be lubricated properly in order to

!

prevent excess heat generation, sparks, and

premature failure.

Flood Oil Lubrication - Pumps are shipped without oil. Fill

bearing frame with oil through filler connection until oil

level reaches center of sight-glass (Fig. 31). A high quality

turbine type oil with rust and oxidation inhibitors should be

used as specified in Table 6.

Close Coupled Pumps - Pump does not have ball bearings.

Consult motor instruction book for required lubrication.

! WARNING

s

Operation of the unit without proper lubrication will

cause bearing failure and pump seizure.

STARTING PUMP

1. Make sure suction valve and any recirculation or

cooling lines are open.

2. Fully close or partially open discharge valve as

dictated by system conditions.

3. Start driver.

Fig. 31

CONNECT CONDITION

MONITORING DEVICES

If unit is equipped with power monitoring systems, this

must be connected.

PRIMING PUMP

Never start pump until properly primed (pump casing and

suction piping are full of liquid). Components such as

internal sleeve bearings depend on liquid for lubrication

and will quickly fail if run dry.

Your particular system conditions will dictate method used

to prime pump.

! CAUTION

$

Continuous operation against closed discharge valve

will cause pump to overheat. Overheating the

magnetic drive assembly will weaken or ruin the

magnets.

! CAUTION

$

Immediately observe pressure gauges. If discharge

pressure is not quickly attained, stop driver, reprime

and attempt to restart.

4. Slowly open discharge valve until the desired flow is

obtained.

Continuous operation against closed discharge valve

may vaporize liquid creating an explosive hazard due

to confined vapor under high pressure and

temperature.

! WARNING

s

28 3298 Family Rev. 4/07

OPERATION

GENERAL CONSIDERATIONS

Always vary capacity with valve in discharge line. NEVER

throttle flow from suction side.

Driver may overload or magnets de-couple if pumpage

specific gravity (density) is greater than originally assumed,

or rated flow rate is exceeded.

Always operate the pump at or near the rated conditions to

prevent damage resulting from cavitation or recirculation.

$

Do not operate above rated temperature range of

magnets as this will weaken or ruin the magnets.

Service temperature in an ATEX classified environ-

!

ment is limited by Table 1 in the Safety section.

CAUTION

Table 4

Temperature Ratings

Group Size Rated Temperature

XS 1x1.5-5 250° F (121° C)

S All 250° F (121° C)

M All 250° F (121° C)

L All 250° F (121° C)

$

Driver may overload if the pumpage specific gravity

(density) is greater than originally assumed, or the

rated flow rate is exceeded.

$

Always operate the pump at or near the rated

conditions to prevent damage resulting from cavitation

or recirculation.

$

Damage occurs from:

1. Increased vibration levels - Affects bearings.

2. Increased radial loads - Stresses on shaft and

bearings.

3. Heat build up - Vaporization causing rotating parts

to score or seize.

4. Cavitation - Damage to internal surfaces of pump.

Goulds recommends the use of a power monitor to prevent

pump damage from systems which have the potential for

dry run operation. Refer to Appendix for information on

power monitors.

CAUTION

CAUTION

CAUTION

DRAINING TANKS / DRY RUN

OPERATION

4

OPERATING AT REDUCED CAPACITY

! WARNING

s

Do NOT operate pump below minimum rated flows or

with discharge valve closed. These conditions may

vaporize liquid creating an explosive hazard due to

confined vapor under high pressure and temperature.

SUCTION VALVE CLOSED / DRY RUN

OPERATION

! WARNING

s

Do not operate pump with suction valve closed.

Operating pump after suction valve closed will cause

wear of thrust and radial bearings and pump failure.

Operating pump with suction valve closed may

vaporize liquid creating an explosvie hazard due to

confined vapor under high pressure and temperature.

$

Always vary capacity with regulating valve in the

discharge line. NEVER throttle flow from the suction

side.

CAUTION

! WARNING

s

After pump has drained tank, it should be shut down

immediately. Operating pump after the tank has been

drained of liquid will cause wear of thrust and radial

bearings and pump failure. Operating pump after

tank has been drained of liquid may vaporize liquid

creating an explosive hazard due to confined vapor

under high pressure and temperature.

Goulds recommends the use of a power monitor to prevent

pump damage from systems which have the potential for

dry run operation.

DISCHARGE VALVE CLOSED

! WARNING

s

Do not operate pump with discharge valve closed.

Operating pump with a closed discharge valve may

vaporize liquid creating an explosive hazard due to

confined vapor under high pressure and temperature.

Goulds recommends the use of a power monitor and/or a

minimum flow by-pass line to prevent pump damage from

systems which have the potential for closed discharge operation.

3298 Family Rev. 4/07 29

OPERATING UNDER

FREEZING CONDITIONS

Exposure to freezing conditions, while pump is idle, could

cause liquid to freeze and damage the pump. Liquid inside

pump should be drained. Liquid inside cooling coils, if

supplied, should also be drained.

3298 Minimum Continuous Recommended Flow

Group Pump Size

3298

XS

S

M

L

SP 3298

S

V 3298

S

M

NOTES:

1½x2-6 5 3 — 1 0.5 —

1½x3-7 20 10 6521

1½x3-8 30 15 8631

1x2-10 30 53532

1½x3-10 60 30 20 11 5 4

2x3-10 100 50 33 19 10 6

3x4-10G 175 90 60 33 16 11

3x4-10H — 90 30 — 17 3

4x6-10 —

1x1½-6532210.5

1½x2-6 532210.5

1½x2-10 30 5 3 5 0.7 0.5

Table 5 - Minimum Flow

1

60 Hertz 50 Hertz

GPM m3/hr

3600 1800 1200 3000 1500 1000

1 x 1 - 5 1 0.5 — 0.2 0.1 —

1x1-6532210.5

1x1-81584321

2x3-6 30 15 8631

2x3-8 50 95921

3x4-7 80 13 9 18 9 6

(5)

475

2x3-6 30 15 8631

1½2-8 60 30 20 11 7 4

2x3-6 60 30 20 11 7 4

(5)

325 —

(5)

95

(5)

55

1. All flows are continuous operation 24 hours/day - 7 days/week.

2. Based on water with a specific gravity of 1.0 and specific heat of 1.0

3. Pumps can be operated reliably at lower minimum flows under intermittent operating conditions. Contact

Goulds Pumps. Intermittent Operation = operating under these conditions less than 15% of the time.

4. Contact factory for pump efficiency at minimum flows.

5. Can be operated at substantially lower flows with adequate NPSH margin. Contact Goulds for details.

30 3298 Family Rev. 4/07

Loading...

Loading...