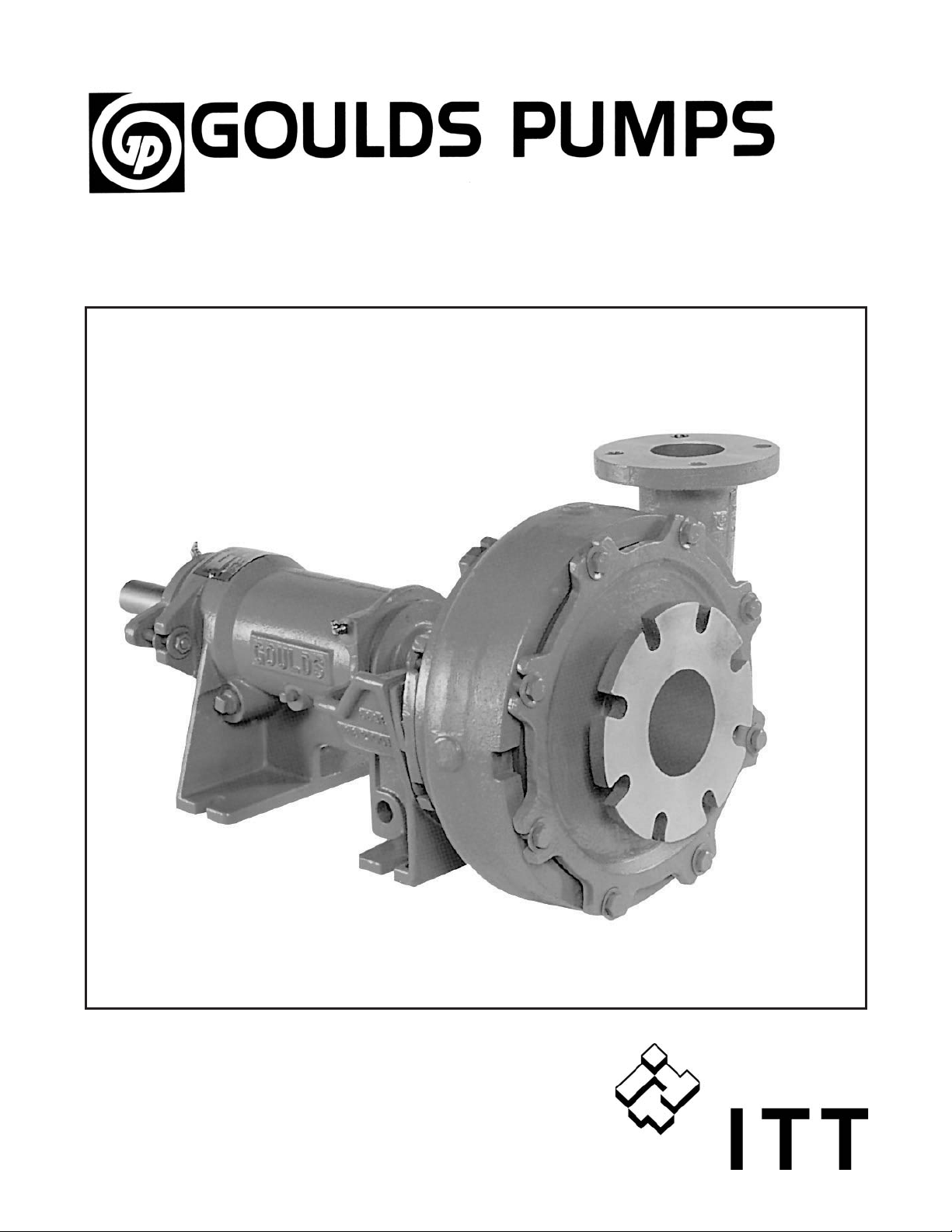

Installation, Operation and Maintenance Instructions

Model JC

Pump Safety Tips

Safety Apparel:

Insulated work gloves when handling

•

hot bearings or using bearing heater

Heavy work gloves when handling

•

parts with sharp edges, especially impellers

Safety glasses (with side shields) for

•

eye protection, especially in machine

shop areas

Steel-toed shoes for foot protection when

•

handling parts, heavy tools, etc.

Other personal protective equipment to protect

•

against hazardous/toxic fluids

Coupling Guards:

• Never operate a pump without a coupling guard

properly installed

Flanged Connections:

• Never force piping to make a connection with a

pump

• Use only fasteners of the proper size and material

Operation:

Do not operate below minimum rated flow, or with

suction/discharge valves closed

Do no open vent or drain valves, or remove plugs while

system is pressurized

Maintenance Safety:

Always lockout power

•

Ensure pump is isolated from system and pressure is

•

relieved before disassembling pump, removing plugs,

or disconnecting piping

Use proper lifting and supporting equipment to

•

prevent serious injury

Observe proper decontamination procedures

•

• Know and follow company safety regulations

• Never apply heat to remove impeller

• Observe all cautions and warnings highlighted in

pump instruction manual.

• Ensure there are no missing fasteners

•

Beware of corroded or loose fasteners

2 JC IOM 11/06

IMPORTANT SAFETY REMINDER

To: Our Valued Customers

Goulds' pumps will provide safe, trouble-free service when properly installed, maintained, and operated. We have an

extensive network of experienced sales and service professionals to assist in maximizing your satisfaction with our products.

Safe installation, operation, and maintenance of Goulds' equipment are an essential end user responsibility. This Instruction,

Operation, and Maintenance (IOM) manual identifies specific safety risks that must be considered at all times during product

life. Understanding and adhering to these safety warnings is mandatory to ensure person- nel, property, and/or the environment

will not be harmed. Adherence to these warnings alone, however, is not sufficient — it is anticipated that the end user will also

comply with industry and corporate safety standards. Identifying and eliminating unsafe installation, operating and maintenance

practices is the responsibility of all individuals involved in the installation, operation, and maintenance of industrial equipment.

Specific to pumping equipment, two significant risks bear reinforcement above and beyond normal safety precautions.

! WARNING

▲

Operation of any pumping system with a blocked suction and discharge must be avoided in all cases. Operation, even

for a brief period under these conditions, can cause superheating of enclosed pumpage and result in a violent

1

explosion. All necessary measures must be taken by the end user to ensure this condition is avoided.

! WARNING

▲

Pumping equipment Instruction, Operation, and Maintenance manuals clearly identify accepted methods for

disassembling pumping units. These methods must be adhered to. Specifically, applying heat to impellers and/or

2

impeller retaining devices to aid in their removal is strictly forbidden. Trapped liquid can rapidly expand and result

in a violent explosion and injury.

Please take the time to review and understand the safe installation, operation, and maintenance guidelines outlined in this

manual.

JC IOM 11/06

3

This page intentionally left blank.

4 JC IOM 11/06

TABLE OF CONTENTS

PAGE SECTION

7 SAFETY

11 GENERAL INFORMATION

13 INSTALLATION

17 OPERATION

21 PREVENTIVE MAINTENANCE

27 SPARE PARTS

1

2

3

4

5

6

31 APPENDIX

7

JC IOM 11/06 5

This page intentionally left blank.

6 JC IOM 11/06

SAFETY

DEFINITIONS......................................7

GENERAL PRECAUTIONS ..............................8

EXPLOSION PREVENTION .............................8

SPECIAL ATEX CONSIDERATIONS ........................8

ATEX IDENTIFICATION ...............................9

INTENDED USE ....................................9

CONDITION MONITORING .............................9

DEFINITIONS

1

These pumps have been designed for safe and reliable

operation when properly used and maintained in

accordance with instructions contained in this manual. A

pump is a pressure containing device with rotating parts

that can be hazardous. Operators and maintenance

personnel must realize this and follow safety measures.

ITT Industries Goulds Pumps is not liable for physical

injury, damage or delays caused by a failure to observe the

instructions in this manual.

Throughout this manual the words WARNING,

CAUTION, ELECTRICAL, ATEX, and NOTE are used

to indicate procedures or situations which require special

operator attention:

! WARNING

s

Operating procedure, practice, etc. which, if not

correctly followed, could result in personal injury or

loss of life.

! CAUTION

$

Operating procedure, practice, etc. which, if not

followed, could result in damage or destruction of

equipment.

EXAMPLES

! WARNING

s

Pump must never be operated without coupling guard

installed correctly.

$

Throttling flow from the suction side may cause

cavitation and pump damage.

Improper impeller adjustment could cause contact

!

between the rotating and stationary parts, resulting

in a spark and heat generation.

Lock out driver power to prevent electric shock,

"

accidental start-up and physical injury.

NOTE: Proper alignment is essential for long pump

life.

CAUTION

If equipment is to be installed in a potentially

!

explosive atmosphere and these procedures are not

followed, personal injury or equipment damage from

an explosion may result.

Particular care must be taken when electrical power

"

source to the equipment is energized.

NOTE: Operating procedure, condition, etc. which is

essential to observe.

JC IOM 11/06

7

GENERAL PRECAUTIONS

NEVER apply heat to remove impeller. It may

!

s

explode due to trapped liquid.

NEVER use heat to disassemble pump due to risk

!

s

of explosion from trapped liquid.

NEVER operate pump without coupling guard

!

s

correctly installed.

NEVER operate pump beyond the rated

!

l

conditions to which the pump was sold.

NEVER start pump without proper prime or

!

l

proper liquid level in self-priming pumps.

Cooling systems such as those for bearing

lubrication, mechanical seal systems, et, where

provided, must be operating properly to prevent

excess hear generations, sparks, and premature

failure.

s

NEVER run pump below recommended

!

l

minimum flow or when dry.

ALWAYS lock out power to the driver before

!

performing pump maintenance.

NEVER operate pump without safety devices

!

s

installed.

NEVER operate pump with discharge valve

!

s

closed.

DO NOT change conditions of service without

approval of an authorized Goulds representative.

Rotate shaft by hand to ensure it rotates smoothly

and there is no rubbing which could lead to

excess hear generation and or sparks

Ensure that pump and systems are free of foreign

objects before operating and that objects cannot

enter the pump during operation. Foreign objects

in the pumpage or piping system can cause

blockage of flow which can result in excess heat

generation, sparks and premature failure.

EXPLOSION PREVENTION

In order to reduce the possibility of accidental explosions in atmospheres containing explosive gasses and/or dust, the

!

instructions under the ATEX symbol must be closely followed. ATEX certification is a directive enforced in Europe for

non-electrical and electrical equipment installed in Europe. ATEX requirements are not restricted to Europe, and are

useful guidelines for equipment installed in any potentially explosive environment.

SPECIAL ATEX CONSIDERATIONS

All installation and operation instructions in this manual

must be strictly adhered to. In addition, care must be taken

to ensure that the equipment is properly maintained. This

includes but is not limited to:

1. Monitoring the pump frame and liquid end

temperature.

2. Maintaining proper bearing lubrication.

3. Ensuring that the pump is operated in the intended

hydraulic range.

8 JC IOM 11/06

ATEX IDENTIFICATION

For a pumping unit (pump, seal, coupling, motor and pump

accessories) to be certified for use in an ATEX classified

environment, the proper ATEX identification must be

present.

The ATEX tag would be secured to the pump or the

baseplate on which it is mounted. A typical tag would look

like this:

The CE and the Ex designate the ATEX compliance. The

code directly below these symbols reads as follows:

II = Group 2

2 = Category 2

G/D = Gas and Dust present

T4 =

Temperature class, can be T1 to T6

(see Table 1)

Table 1

Maximum Process Temperature

to Achieve Desired T Rating

Maximum

T Rating

per EN

1127-1

T1 450 410

T2 300 260

T3 200 165

T4 135 100

T5 100 65

T6 85 50

The code classification marked on the equipment should be

in accordance with the specified area where the equipment

will be installed. If it is not, please contact your

ITT/Goulds representative before proceeding.

Surface

Temperature

in Celsius

Maximum

Process

Temperature

in Celsius

1

INTENDED USE

The ATEX conformance is only applicable when the pump

unit is operated within its intended use. All instructions

within this manual must be followed at all times.

Operating, installing or maintaining the pump unit in any

way that is not covered in this manual can cause serious

personal injury or damage to the equipment. This

CONDITION MONITORING

For additional safety precautions, and where noted in

this manual, condition monitoring devices should be

used. This includes, but is not limited to:

Pressure gauges

•

Flow meters

•

Level indicators

•

Motor load readings

•

Temperature detectors

•

Bearing monitors

•

Leak detectors

•

PumpSmart

•

®

control system

includes any modification to the equipment or use of parts

not provided by ITT/Goulds. If there is any question

regarding the intended use of the equipment, please contact

an ITT/Goulds representative before proceeding.

For assistance in selecting the proper instrumentation and

its use, please contact your ITT/Goulds representative.

Do not insulate bearing housings as this can result

!

in excess heat generation, sparks and premature

failure.

Check for magnetism on the pump shaft and

!

degauss the shaft if there is any detectable

magnetism. Magnetism will attract ferritic objects to

the impeller, seal and bearings which can result in

excess heat generation, sparks and premature

failure.

JC IOM 11/06

9

Leakage of process liquid may result in creating an

!

explosive atmosphere. Ensure the materials of the

pump casing, impeller, shaft, sleeves, gaskets and

seals are compatible with the process liquid.

Leakage of process liquid may result in creating an

!

explosive atmosphere. Follow all pump and seal

assembly procedures.

A build up of gases within the pump, sealing system

!

and or process piping system may result in an

explosive environment within the pump or process

piping system. Ensure process piping system, pump

and sealing system are properly vented prior to

operation.

10 JC IOM 11/06

GENERAL INFORMATION

INTRODUCTION ...................................11

IMPORTANCE OF INSTRUCTIONS ........................11

SPECIAL WARNINGS ................................11

RECEIVING INSPECTION - SHORTAGES ....................11

INTRODUCTION

This instruction manual is intended to assist those involved

with the installation, operation and maintenance of Goulds

Ashland Operations slurry pumps. It is recommended that

this manual be thoroughly reviewed prior to installing or

performing any work on the pump or motor.

IMPORTANCE OF INSTRUCTIONS

2

The design, material and workmanship incorporated in the

construction of Goulds Ashland Operations slurry pumps

makes them capable of giving long, trouble-free service.

The life and satisfactory service of any mechanical unit,

however, is enhanced and extended by periodic inspection

SPECIAL WARNINGS

Goulds Ashland Operations will not be liable for any

damages or delay caused by failure to comply with the

provisions of this instruction manual. This pump is not to

be operated at speeds, working pressures, discharge

RECEIVING INSPECTION - SHORTAGES

Care should be taken when unloading pumps. If shipment is

not delivered in good order and in accordance with the bill

of lading, note the damage or shortage on both receipt and

freight bill. Make any claims to the transportation

company promptly.

and careful maintenance. This manual was prepared to

assist operators in understanding the construction and

correct methods of installing, operating, and maintaining

these pumps.

pressures, or temperatures higher than, nor used with

liquids other than, stated in the original order

acknowledgment, without written permission of the

Ashland Operations, Goulds Pumps, Inc.

JC IOM 11/06

11

Loading...

Loading...