ITT Goulds Pumps 3700, Goulds Pumps 3710 Installation, Operation And Maintenance Instructions

In stal la tion, Op era tion and Main te nance In struc tions

Model 3700 10th Edi tion (ISO 13709)

These instructions also apply to Model 3710.

Pump Safety Tips

Safety Apparel:

• Insulated work gloves when handling hot

bearings or using bearing heater

• Heavy work gloves when handling parts with

sharp edges, especially impellers

• Safety glasses (with side shields) for eye

protection, especially in machine shop areas

• Steel-toed shoes for foot protection when

handling parts, heavy tools, etc.

• Other personal protective equipment to protect

against hazardous/toxic fluids

Coupling Guards:

• Never operate a pump without a coupling guard

properly installed

Flanged Connections:

• Never force piping to make a connection with a

pump

• Use only fasteners of the proper size and

material

Operation:

• Do not operate below minimum rated flow, or

with suction/discharge valves closed

• Do not open vent or drain valves, or remove

plugs while system is pressurized

Maintenance Safety:

• Always lock out power

• Ensure pump is isolated from system and

pressure is relieved before disassembling pump,

removing plugs, or disconnecting piping

• Use proper lifting and supporting equipment to

prevent serious injury

• Observe proper decontamination procedures

• Know and follow company safety regulations

Observe all cautions and warnings highlighted in

pump Installation, Operation and Maintenance

Instructions.

• Ensure there are no missing fasteners

• Beware of corroded or loose fasteners

FOREWORD

This manual provides instructions for the Installation, Operation, and Maintenance of the Goulds Model

3700 High Pressure, High Temperature Process Pump designed to meet the requirements of the

10th Edition of API* Standard 610 (ISO 13709). This manual covers the standard product plus common

options that are available. For special options, supplemental instructions are supplied. This manual

must be read and understood before installation and maintenance.

The design, materials, and workmanship incorporated in the construction of Goulds pumps make them capable of

giving long, trouble-free service. The life and satisfactory service of any mechanical unit, however, is enhanced

and extended by correct application, proper installation, periodic inspection, condition monitoring and careful

maintenance. This instruction manual was prepared to assist operators in understanding the construction and the

correct methods of installing, operating, and maintaining these pumps.

ITT Industries - Goulds Pumps shall not be liable for physical injury, damage or delays caused by a failure

to observe the instructions for Installation, Operation, and Maintenance contained in this manual.

NOTE: When pumping unit is installed in a potentially explosive atmosphere, the instructions after

!

the Ex symbol must be followed. Personal injury and/or equipment damage may occur if these

instructions are not followed. If there is any question regarding these requirements or if the

equipment is to be modified, please contact a Goulds representative before proceding.

Warranty is valid only when genuine ITT Industries - Goulds Pumps parts are used.

Use of the equipment on a service other than stated in the order will nullify the warranty, unless written approval is

obtained in advance from ITT Industries - Goulds Pumps.

Supervision by an authorized ITT Industries - Goulds representative is recommended to assure proper

installation.

Additional manuals can be obtained by contacting your local ITT Industries - Goulds representative or by calling

1-(800)-446-8537.

THIS MAN UAL EX PLAINS

Proper In stal la tion

n

Start- up Pro ce dures

n

Op era tion Pro ce dures

n

Rou tine Main te nance

n

Pump Over haul

n

Trou ble shoot ing

n

Ordering Spare or Re pair Parts

n

* American Petroleum Institute

1220 L Street, Northwest

Washington, D.C. 20005

3700-10th IOM 12/04 3

4 3700-10th IOM 12/04

TABLE OF CONTENTS

PAGE

7 SAFETY

11 GEN ERAL IN FOR MA TION

15 IN STAL LA TION

21 OP ER A TION

27 PRE VEN TIVE MAIN TE NANCE

SECTION

1

2

3

4

5

31 DIS AS SEM BLY & RE AS SEM BLY

61 SPARE PARTS

63 AP PEN DIX

6

7

8

3700-10th IOM 12/04 5

6 3700-10th IOM 12/04

SAFETY

DEFI NI TIONS ..................................7

GEN ERAL PRE CAU TIONS...........................8

EX PLO SION PRE VEN TION ..........................8

SPE CIAL ATEX CON SID ER ATIONS......................8

ATEX IDEN TI FI CA TION ............................9

IN TENDED USE ................................9

CON DI TION MON I TOR ING...........................9

DEFINITIONS

1

This pump has been designed for safe and reliable

operation when properly used and maintained in

accordance with instructions contained in this manual.

A pump is a pressure containing device with rotating

parts that can be hazardous. Operators and

maintenance personnel must realize this and follow

safety measures. ITT Industries - Goulds Pumps

shall not be liable for physical injury, damage or

delays caused by a failure to observe the instructions

in this manual.

Throughout this manual the words WARNING,

CAUTION, and NOTE are used to indicate

procedures or situations which require special

operator attention:

! WARN ING

s

Warning is used to indicate the presence of a

hazard which can cause severe

death, or substantial property damage if the

warning is ignored.

$

Caution is used to indicate the presence of a

hazard which will

injury or property damage if the warning

is ignored.

NOTE: If equipment is to be installed in a

!

potentially explosive atmosphere and these

procedures are not followed, personal injury

or equipment damage from an explosion may

result.

CAUTION

or can cause minor personal

personal injury,

NOTE: Particular care must be taken when

"

the electrical power source to the equipment

is energized.

NOTE: Operating procedure, condition, etc.

which is essential to observe.

EXAMPLES

! WARN ING

s

Pump shall never be operated without coupling

guard installed correctly.

$

Throttling flow from the suction side may cause

cavitation and pump damage.

NOTE: Improper impeller adjustment could

!

cause contact between the rotating and

stationary parts, resulting in a spark and heat

generation.

NOTE: Lock out driver power to prevent

"

electric shock, accidental start-up and

physical inury.

NOTE: Proper alignment is essential for long

pump life.

CAUTION

3700-10th IOM 12/04 7

GENERAL PRECAUTIONS

! WARN ING

s

Personal injuries will result if procedures

outlined in this manual are not followed.

NEVER operate pump without coupling

s!

A

AD

AD

AD

guard correctly installed.

NEVER operate pump beyond the rated

conditions to which the pump was sold.

NEVER start pump without proper prime

(sufficient liquid in pump casing).

NEVER run pump below recommended

minimum flow or when dry.

CB

AC

AD

A

ALWAYS lock out power to the driver before

performing pump maintenance.

NEVER operate pump without safety devices

C

installed.

NEVER operate pump with discharge valve

closed.

NEVER operate pump with suction valve

closed.

DO NOT change con ditions of ser vice

without ap proval of an au thorized Goulds

rep re sen ta tive.

EXPLOSION PREVENTION

In order to reduce the possibility of accidental explosions in atmospheres containing explosive

!

gasses and/or dust, the instructions under the ATEX symbol must be closely followed. ATEX

certification is a directive enforced in Europe for non-electrical and electrical equipment installed in

Europe. ATEX requirements are not restricted to Europe, and are useful guidelines for equipment

installed in any potentially explosive environment.

SPECIAL ATEX CONSIDERATIONS

All installation and operation instructions in this

manual must be strictly adhered to. In addition, care

must be taken to ensure that the equipment is

properly maintained. This includes but is not limited

to:

1. monitoring the pump frame and liq uid end

tem per a ture

2. maintining proper bear ing lu bri ca tion

3. ensuring that the pump is op erated in the

in tended hy drau lic range

8 3700-10th IOM 12/04

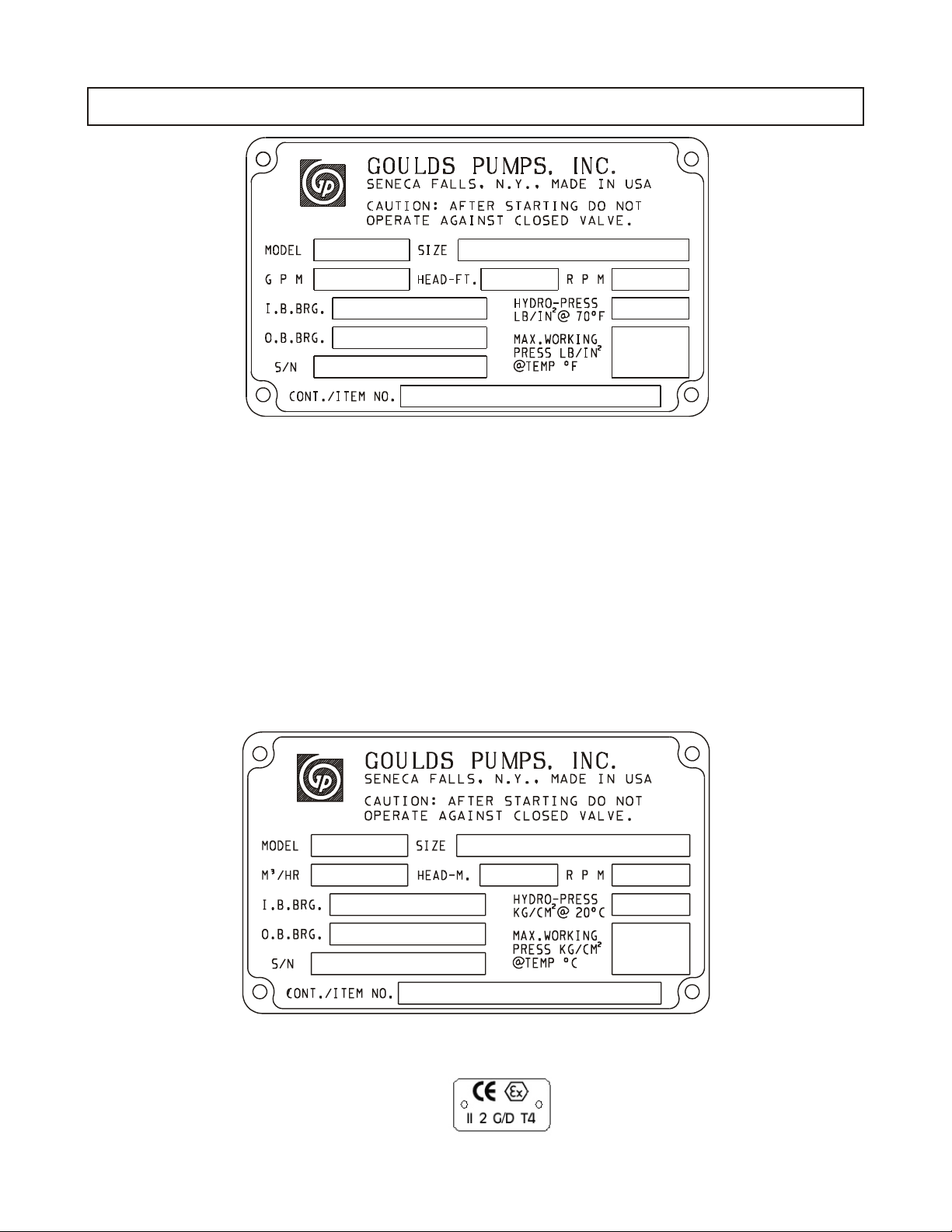

ATEX IDENTIFICATION

For a pumping unit (pump, seal, coupling, motor and

pump accessories) to be certified for use in an ATEX

classified environment, the proper ATEX identification

must be present. The ATEX tag will be secured to the

pump or the baseplate on which it is mounted. A

typical tag will look like this:

The CE and the Ex designate the ATEX compliance.

The code directly below these symbols reads as

follows:

II = Group 2

2 = Category 2

G/D = Gas and Dust present

= Temperature class, can be T1 to T6

T4

(see following table 1)

Ta ble 1

Max per mis si ble

Code

sur face tem per a ture,

T1 842 (450) 700 (372)

T2 572 (300) 530 (277)

T3 392 (200) 350 (177)

T4 275 (135) 235 (113)

T5 212 (100) Option not available

T6 185 (85) Option not available

The code classification marked on the equipment

should be in accordance with the specified area

where the equipment will be installed. If it is not,

please contact your ITT/Goulds representative before

proceeding.

°F (°C)

Max per mis si ble

liq uid tem per a ture,

°F (°C)

INTENDED USE

The ATEX conformance is only applicable when the

pump unit is operated within its intended use. All

instructions within this manual must be followed at all

times. Operating, installing or maintaining the pump

unit in any way that is not covered in this manual can

cause serious personal injury or damage to the

CONDITION MONITORING

For additional safety precautions, and where

!

noted in this manual, condition monitoring

devices should be used. This includes, but is

not limited to:

• Pressure gauges

• Flow meters

• Level indicators

• Motor load readings

• Temperature detectors

• Bearing monitors

• Leak detectors

• PumpSmart control system

equipment. This includes any modification to the

equipment or use of parts not provided by ITT/Goulds.

If there is any question regarding the intended use of

the equipment please contact an ITT/Goulds

representative before proceeding.

For assistance in selecting the proper instrumentation

and its use, please contact your ITT/Goulds

representative.

3700-10th IOM 12/04 9

10 3700-10th IOM 12/04

GENERAL INFORMATION

PUMP DE SCRIP TION.............................11

NAME PLATE IN FOR MA TION.........................12

RE CEIV ING THE PUMP ............................13

Stor age Re quire ments ...........................13

Han dling ..................................13

PUMP DESCRIPTION

2

The Model 3700 is a high pressure, high temperature

centrifugal pump that meets the requirements of

API Standard 610 10th Edition (ISO 13709).

The model is based on 6 power ends and 38 hydraulic

pump sizes.

Casing - The casing is a centerline mounted design.

The gasket is fully confined. ANSI Class 300 raised

face serrated flanges are standard; ANSI Class 300

flat face serrated and ring joint flanges are available.

Also available are ANSI class 600 flanges in the same

types.

Impeller - The impeller is fully enclosed and key

driven by the shaft. An impeller bolt with lockwasher

or impeller nut with locking set screw prevents axial

movement.

Seal Chamber Cover - The Model 3700 seal

chamber cover meets API 682 2nd Edition

dimensions for improved performance of mechanical

seals.

Power End - Ring oil lubricated bearings are

standard. The power end is sealed with labyrinth

seals. Pure and purge oil mist lubrication are options.

Some machining is required to convert from ring oil

lubrication to oil mist.

Shaft - The standard shaft is machined and ground to

comply with API 610 10th Edition (ISO 13709) criteria.

Bearings - The inboard (radial) bearing carries only

radial load; it is free to float axially in the frame. The

outboard (thrust) bearing is shouldered and locked to

the shaft and retained in the bearing frame to enable

it to carry radial and thrust loads. All fits are precision

machined to industry standards. The inboard bearing

is a single row deep groove ball bearing. The

outboard bearing is a duplex angular contact bearing,

which uses a pair of single row angular contact ball

bearings mounted back-to-back.

Baseplate - The fabricated steel baseplate is

designed to support the pump, driver and accessories

in accordance with API-610 10th Edition (ISO 13709)

requirements.

Direction of Rotation - Counterclockwise (left hand)

as viewed from the driver, looking at the pump shaft.

3700-10th IOM 12/04 11

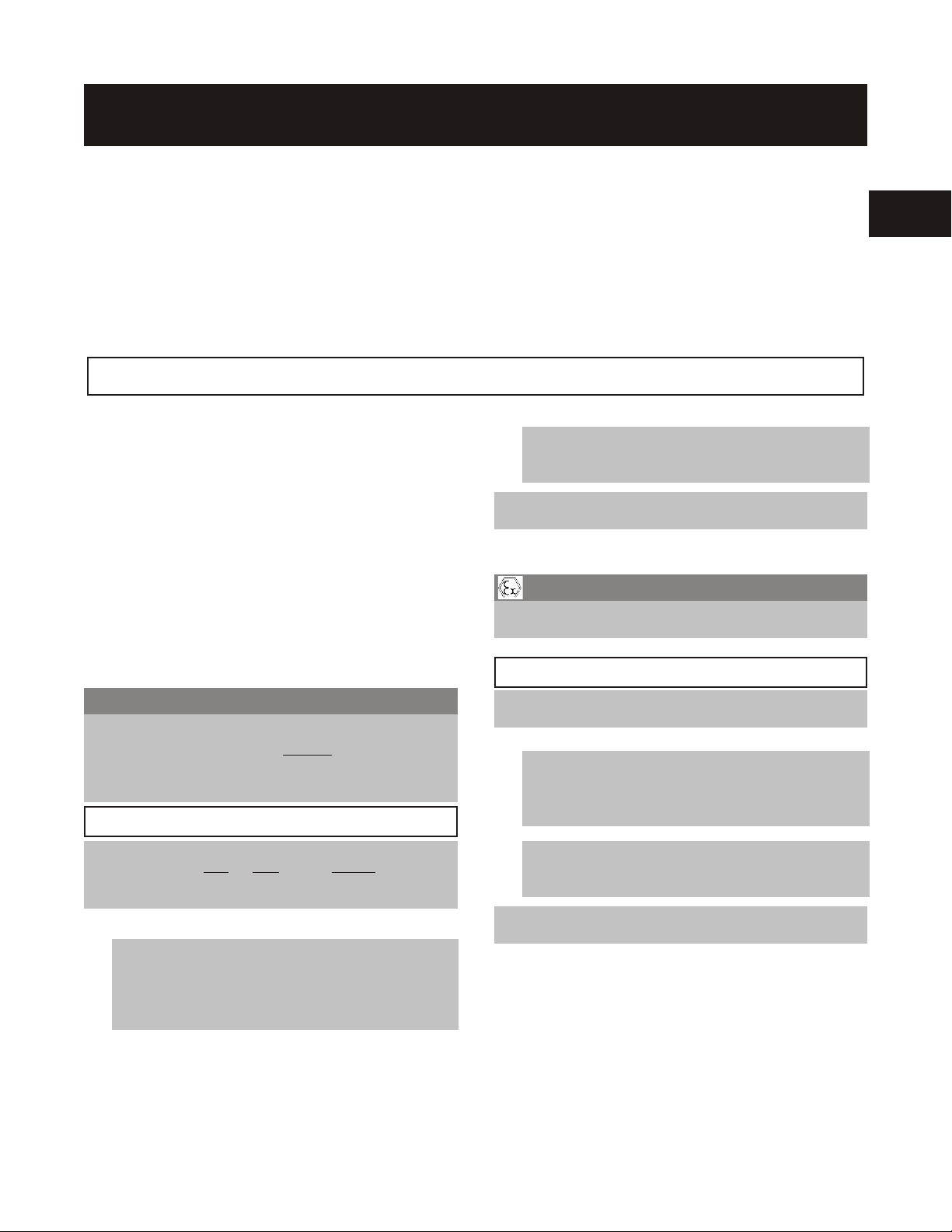

NAMEPLATE INFORMATION

Fig. 1

Every pump has a Goulds nameplate that provides

information about the pump. The nameplate is located

on the pump casing.

Special tags which provide additional information

(mechanical seal data, etc.) and special tagging

required by customers are located on the pump

casing or on the bearing frame.

The standard nameplate provides information about

the pump’s size, rating, bearings, serial number,

hydrostatic test pressure of pressure containment

parts, maximum allowable working pressure at

designated temperature and construction / customer’s

item number. Rating and hydrostatic test pressure

are expressed in English units. Note the format of

pump size: Discharge x Suction - Nominal Impeller

Diameter in inches, for example, 2x3-13 (Fig. 1).

The standard nameplate is also available in a version

which expresses the rating and hydrostatic test

pressure in metric units (Fig. 2).

When ordering spare parts you will need to identify

pump model, size, serial number, and the item

number of required parts. Pump information can be

taken from the Goulds nameplate. Item numbers can

be found in this manual.

Fig. 2

NOTE: If ap plicable, your pump unit may have the following ATEX tag affixed to the pump and/or base plate.

See the Safety sec tion for a de scription of the sym bols and codes.

12 3700-10th IOM 12/04

RECEIVING THE PUMP

Inspect the pump as soon as it is received. Carefully

check that everything is in good order. Make notes of

damaged or missing items on the receipt and freight

bill. File any claims with the transportation company

as soon as possible.

STORAGE REQUIREMENTS

Short Term (Less than 6 months)

Goulds normal packaging procedure is designed to

protect pump during shipping. Upon receipt, store in a

covered and dry location.

Long Term (More than 6 months)

Preservative treatment of bearings and machined

surfaces will be required. Rotate shaft several times

every 3 months. Refer to driver and coupling

manufacturers for their long term storage procedures.

Store in a covered and dry location.

2

NOTE: Long term storage treatment may be

purchased with initial pump order.

HANDLING

! WARN ING

s

Pump and components are heavy. Failure to

properly lift and support equipment could result

in serious physical injury, or damage to pumps.

Use care when moving pumps. Lifting equipment

must be able to adequately support the entire

assembly. Hoist bare pump using suitable slings

under the outboard end of the bearing frame and under

the suction flange (Fig. 3).

Fig. 4

Fig. 5

Fig. 3

Baseplate mounted units with or without drivers are

moved with slings through the baseplate’s lifting lugs

(Fig. 4 & 5).

3700-10th IOM 12/04 13

14 3700-10th IOM 12/04

INSTALLATION

GEN ERAL ...................................15

SITE/FOUN DA TION..............................15

BASE PLATE IN STAL LA TION PRO CE DURE.................16

Base plate Prepa ra tion ...........................16

Foun da tion Prepa ra tion ..........................16

Set ting and Lev el ing Base plate.......................16

ALIGN MENT AND ALIGN MENT CRI TE RIA .................17

Gen eral Con sid era tions ..........................17

Align ment Cri te ria .............................17

ALIGN MENT TROU BLE SHOOT ING.....................18

BASE PLATE GROUT ING PRO CE DURE ...................18

Gen eral Pro ce dure .............................18

Align ment Check ..............................18

PIP ING.....................................19

Suc tion Pip ing ...............................19

Dis charge Pip ing..............................20

By pass Pip ing ...............................20

Aux il iary Pip ing...............................20

Fi nal Pip ing Check .............................20

3

NOTE: Equipment that will op erate in a po tentially ex plosive en vironment must be installed in

!

ac cor dance with the fol low ing in struc tions.

GENERAL

Procedures for installation described within this section

are general in nature. It is assumed that the installer

has a basic knowledge of acceptable methods. More

detailed procedures are described in various publi-

cations, including API Recommended Practice 686/

PIP (Process Industry Practices) REIE 686,

“Recommended Practices for Machinery Installation

and Installation Design.”

SITE/FOUNDATION

A pump should be located near the supply of liquid

and have adequate space for operation, maintenance,

and inspection. Be sure to allow for crane or hoist

service.

Baseplate mounted pumps are normally grouted on a

concrete foundation which has been poured on a

solid footing. The foundation must be able to absorb

any vibration and to form a permanent, rigid support

for the pumping unit.

3700-10th IOM 12/04 15

NOTE: All equipment being installed must be

!

properly grounded to prevent unexpected

static electric discharge.

The location and size of foundation bolts are shown

on the outline assembly drawing provided with the

pump data package.

Foundation bolts commonly used are sleeve type

(Fig. 6) and J type. If using the sleeve type, the inside

diameter of the sleeve should be 2 1/2 - 3 times the bolt

diameter. A washer should be placed between the bolt

head and the sleeve. Both foundation bolt types permit

movement for final bolt adjustment.

BASEPLATE INSTALLATION PROCEDURE

Fig. 6

Industry standard procedures, such as API RP 686/

PIP REIE 686, and/or the following procedure should

be followed prior to grouting the baseplate. The

procedure assumes the installer has a basic

knowledge of baseplate and foundation design and

installation methods.

BASEPLATE PREPARATION

1. Inspect all surfaces of baseplate that will contact

grout for contamination (e.g. - rust, oil, grime, etc.).

2. Thoroughly clean all surfaces of the baseplate

that will contact grout with a cleaner that will not

leave any residue.

NOTE: It may be necessary to sandblast the

contact surfaces and coat with a primer compatible with the grout. If sandblasting is necessary,

remove all equipment prior to sandblasting.

3. Inspect all machined surfaces for burrs, rust, paint

or any other type of contamination. If necessary,

use a honing stone to remove burrs.

FOUNDATION PREPARATION

1. Chip top of foundation a minimum of 25 mm

(1.0 in.) to remove porous or low strength

concrete. If using a pneumatic hammer, assure

that it is not contaminating the surface with oil,

moisture, etc.

$

Do not use heavy tools such as jackhammers,

as they could damage the structural integrity of

the foundation.

2. Remove water and/or debris from foundation bolt

holes/sleeves. If the sleeve type bolts are being

used, fill the sleeves with nonbinding moldable

CAUTION

material and seal to prevent grout from entering.

3. Coat exposed portion of anchor bolts with a

non-bonding compound such as paste wax to

prevent grout from adhering to anchor bolts.

NOTE: Do not use oils or liquid wax.

4. If recommended by grout manufacturer, coat

foundation surface with a compatible primer.

SETTING AND LEVELING BASEPLATE

1. Lower baseplate carefully onto foundation bolts

(Fig. 7).

Fig. 7

2. Use leveling (jack) screws to raise bottom edge of

the baseplate 25 - 50 mm (1-2 in.) above

foundation to allow for adequate grouting. This

will provide even support for the baseplate once it

is grouted.

3. Level baseplate to within 0.20 mm/m (.002 in./ft.)

of length or width of the baseplate, respectively,

by adjusting leveling screws. Maximum total

variation from one end or side of the baseplate to

the other is 0.38 mm (.015 in.).

16 3700-10th IOM 12/04

Equipment mounting surfaces should be utilized

to establish level.

4. Coat portions of leveling screws that will contact

grout with a non-bonding compound such as

paste wax to facilitate their removal after grouting.

ALIGNMENT AND ALIGNMENT CRITERIA

NOTE: Do not use oils or liquid wax.

5. Thread nuts on foundation bolts and hand tighten.

NOTE: Alignment procedures must be

!

followed to prevent unintended contact of

rotating parts. Follow coupling

manufacturer's installation and operation

procedures.

GENERAL CONSIDERATIONS

! WARN ING

s

Before beginning any alignment procedure,

make sure driver power is locked out. Failure

to lock out driver power will result in serious

physical injury.

To remove coupling guard, refer to coupling guard

installation and disassembly instructions in Appendix I.

The times at which alignment is checked and adjusted

are:

Initial Alignment (Cold Alignment) is done prior to

operation when the pump and the driver are at

ambient temperatures.

Before Grouting Baseplate - To ensure

•

alignment can be obtained.

After Connecting Piping and Grouting

•

Baseplate - To ensure pipe strains haven’t

altered alignment.

Accurate alignment of the equipment must be

attained. Trouble-free operation can be accomplished

by achieving alignment within the levels specified in

the following section.

Three common alignment methods are utilized:

Reverse Dial Indicator method is most common.

•

Laser method is similar to reverse dial

•

indicator method, but uses a laser to obtain the

necessary measurements.

Dial Indicator (rim-and-face) method.

•

Follow alignment equipment manufacturers’

procedures when utilizing reverse dial indicator or

laser methods. A detailed procedure for alignment

using the dial indicator (rim-and-face) method is

included as Appendix II.

ALIGNMENT CRITERIA

Good alignment is attained when readings as specified in

this section have been achieved with pump and driver at

operating temperatures (final alignment).

Table 1 shows maximum allowable Total Indicator

Reading (T.I.R.) for parallel and angular misalignment.

3

Final Alignment (Hot Alignment) is done after

operation when the pump and driver are at operating

temperatures.

After First Run - To obtain correct alignment

•

when both pump and driver are at operating

temperature. Thereafter, alignment should be

checked periodically in accordance with plant

operating procedures.

NOTE: Alignment check must be made if

process temperature changes, piping changes

and/or pump service is performed.

Alignment is achieved by adding or removing shims

from under the driver and/or shifting driver horizontally

as needed.

NOTE: Proper alignment is the responsibility

of the installer and user of the unit.

3700-10th IOM 12/04 17

Par al lel and An gu lar Mis align ment

NOTE A: For electric motors, motor shaft initial

(cold) parallel vertical alignment setting should be

0.05 - 0.10 mm (.002-.004 in.) lower than pump

shaft.

NOTE B: For other drivers (turbines, engines, etc.),

follow driver manufacturers’ recommendations.

Maxi mum Al low able

Group

All

Ta ble 1

Maxi mum Al low able Mis align ment

Par al lel An gular

0.03 de grees

0.05 mm

(.002 in.)

[0.125 mm/cm

(.0005 in. /in.) of cou -

pling face

di ame ter]

ALIGNMENT TROUBLESHOOTING

Prob lem Prob able Cause Rem edy

Can not ob tain hori zon tal (Side- to- Side)

align ment, an gu lar or par al lel

Can not ob tain ver ti cal (Top- to- Bottom) align ment,

an gu lar or par al lel

BASEPLATE GROUTING PROCEDURE

Driver feet bolt bound.

Baseplate not lev eled

prop erly, proba bly twisted.

Baseplate not lev eled

prop erly, proba bly bowed.

Loosen pump hold down bolts and slide pump

and driver un til hori zontal align ment is achieved.

Determine which cor ner(s) of the base plate are

high or low and ad just lev eling screws at the

ap pro pri ate cor ner(s) and rea lign.

Determine if cen ter of base plate should be raised or

low ered and cor rect by ad just ing lev el ing screws

equally at the cen ter of the base plate.

GENERAL PROCEDURE

Use of non-shrink epoxy grout is recommended.

NOTE: Grout manufacturer’s instructions

should be consulted and followed.

The following are general procedures for grouting

baseplates. Additional information may be found in

API Standard 610, 8th Edition, Appendix L, API

RP 686, Chapter 5, and other industry standards.

Baseplate Installation Procedure should be followed

prior to grouting baseplate.

1. Build dam (form) around foundation to level of

bottom of baseplate (Fig. 8).

3. Strike along top of dam with trowel to give a neat

finished appearance.

4. Allow grout to set.

5. Fill remainder of baseplate with grout, removing

air as before (Fig. 9).

Fig. 9

6. Allow grout to set at least 48 hours. Leveling

screws should be removed when grout has

hardened.

7. Tighten foundation bolts.

Fig. 8

2. Pour grout through grout hole in baseplate, up to

level of dam. Remove air bubbles from grout as it

is poured by puddling or by pumping the grout into

place.

ALIGNMENT CHECK

Re-check alignment before continuing, using criteria

previously stated.

18 3700-10th IOM 12/04

PIPING

Guidelines for piping are given in the “Hydraulic

Institute Standards,” available from:

Hydraulic Institute

30200 Detroit Road

Cleveland, OH 44145-1967

and in API RP 686, and must be reviewed prior to

pump installation.

! WARN ING

s

Never draw piping into place by forcing at the

flanged connections of the pump. This may

impose dangerous strains on the unit and

cause misalignment between pump and driver.

Pipe strain will adversely affect the operation

of the pump resulting in physical injury and

damage to the equipment.

NOTE: Flange loads from the piping system,

!

including those from thermal expansion of

the piping, must not exceed the limits of the

pump. Casing deformation can result in

contact with rotating parts which can result

in excess heat generation, sparks and

premature failure.

1. Piping runs should be as short as possible to

minimize friction losses.

2. It is suggested that expansion loops be properly

designed and installed in suction and/or discharge

lines when handling liquids at elevated

temperatures, so thermal expansion of piping will

not draw pump out of alignment.

3. The piping should be arranged to allow pump

flushing prior to removal of the unit on services

handling hazardous liquids.

4. Carefully clean all pipe parts, valves and fittings,

and pump branches prior to assembly.

5. All piping must be supported independently of,

and line up naturally with, the pump flanges.

Table 2 shows piping flange alignment criteria.

Ta ble 2

Piping Flange Alignment

Type Cri te ria

Ax ial

Par al lel

Con cen tric Flange bolts should eas ily in stall by hand.

In no case should loads on the pump flanges

Flange gas ket thick ness ± 0.8 mm (.03 in.).

0.001 mm/mm (.001 in./in.) of flange di ameter

to a maxi mum of 0.8 mm (.03 in.).

exceed the limits stated in API Standard 610,

10th Edition (ISO 13709).

6. Piping must not be connected to the pump until

the grout has thoroughly hardened and the

foundation bolts, as well as driver and pump holddown bolts, have been tightened.

SUCTION PIPING

$

NPSHA must always exceed NPSHRas shown

on Goulds performance curves received with

order. (Reference Hydraulic Institute for NPSH

and pipe friction values needed to evaluate

suction piping).

Properly designed and installed suction piping is a

necessity for trouble-free pump operation. Suction piping

should be flushed BEFORE connection to the pump.

1. Use of elbows close to the pump suction flange

should be avoided. There should be a minimum

of two (2) pipe diameters of straight pipe [five (5)

pipe diameters is preferred] between the elbow

and suction inlet. Where used, elbows should be

long radius.

2. Use suction pipe one (1) or two (2) sizes larger

than the pump suction, with a reducer at the

suction flange. Suction piping should never be of

smaller diameter than the pump suction.

3. Reducers, if used, should be eccentric and

located at the pump suction flange with sloping

side down.

! !! CAUTION

$

Pump must never be throttled on suction side.

4. A suction screen should be installed prior to initial

start-up and when suction system has been

opened for work. The screen should be of the

cone type with a net area equal to at least three

(3) times the cross sectional area of the suction

pipe. The mesh of the screen should be sized to

prevent particles larger than 1.6 mm (1/16 in.)

from entering the pump and should be installed in

a spool piece to allow removal for cleaning. The

screen should remain in the system until periodic

inspection shows system is clean.

5. Separate suction lines are recommended when

more than one pump is operating from the same

source of supply.

ACAU TION

3

3700-10th IOM 12/04 19

Suction Lift Conditions

1. Suction pipe must be free from air pockets.

2. Suction piping must slope upwards to pump.

3. All joints must be air tight.

4. A means of priming the pump must be provided.

bypass line to preclude bypassing excessive flows.

Consult nearest sales office or factory for assistance

in sizing orifice.

An automatic recirculation control valve and/or

solenoid operated valve should be considered if a

constant bypass (i.e. orifice) is not possible.

Suction Head/Flooded Suction Conditions

1. An isolation valve should be installed in the

suction line at least two (2) pipe diameters from

the pump suction to permit closing of the line for

pump inspection and maintenance.

2. Keep suction pipe free from air pockets.

3. Piping should be level or slope gradually

downward from the source of supply.

4. No portion of the piping should extend below

pump suction flange.

5. The size of entrance from supply should be one

(1) or two (2) sizes larger than the suction pipe.

6. The suction pipe must be adequately submerged

below the liquid surface to prevent vortices and air

entrainment at the supply.

DISCHARGE PIPING

Properly designed and installed discharge piping is a

necessity for trouble-free pump operation. Discharge

piping should be flushed BEFORE connection to

the pump.

1. Isolation and check valves should be installed in

discharge line. Locate the check valve between

isolation valve and pump; this will permit

inspection of the check valve. The isolation valve

is required for priming, regulation of flow, and for

inspection and maintenance of pump. The check

valve prevents pump or seal damage due to

reverse flow through the pump when the driver is

turned off.

AUXILIARY PIPING

NOTE: The mechanical seal must have an

!

appropriate seal flush system. Failure to do

so will result in excess heat generation and

seal failure.

NOTE: Cooling systems such as those for

!

bearing lubrication, mechanical seal

systems, etc, where provided, must be

operating properly to prevent excess heat

generation, sparks and premature failure.

NOTE: Sealing systems that are not self

!

purging or self venting, such as plan 23,

require manual venting prior to operation.

Failure to do so will result in excess heat

generation and seal failure.

Auxiliary piping may be required for bearing cooling,

seal chamber cover cooling, mechanical seal flush or

other special features supplied with the pump.

Consult pump data sheet for specific auxiliary piping

recommendations.

If bearing cooling and/or seal chamber cover cooling is

required, follow guidelines listed below.

1. Flows of 4 l/min. (1 GPM) will generally satisfy

cooling requirements for each component. If both

bearing and seal chamber cover cooling are

provided, a minimum flow of 8 l/min. (2 GPM) will

be necessary.

2. Cooling water pressure should not exceed

7.0 kg/cm

2

(100 psig).

2. Increasers, if used, should be placed between

pump and check valves.

3. Cushioning devices should be used to protect the

pump from surges and water hammer if

quick-closing valves are installed in system.

BYPASS PIPING

Systems that require operation at reduced flows for

prolonged periods should be provided with a bypass

line connected from the discharge side (before any

valves) to the source of suction.

A minimum flow orifice can be sized and installed in

FINAL PIPING CHECK

After connecting the piping to pump:

Rotate shaft by hand to ensure it rotates

!

smoothly and there is no rubbing which

could lead to excess heat generation and or

sparks.

Check alignment, per alignment criteria

!

outlined previously, to determine if pipe

strain has affected alignment. If pipe strain

exists, correct piping.

20 3700-10th IOM 12/04

OPERATION

PREPA RA TION FOR START- UP.......................21

Check ing Ro ta tion .............................21

Coupling Pump and Driver .........................21

Lu bri cat ing Bear ings ............................22

Shaft Seal ing................................22

Prim ing Pump ...............................22

Start- up Pre cau tions ............................24

START ING PUMP ...............................24

OP ERA TION..................................25

Gen eral Con sid era tions ..........................25

Op era tional Checks ............................25

Op er at ing at Re duced Ca pac ity ......................25

Op er at ing Un der Freez ing Con di tions ...................25

SHUT DOWN ..................................26

FI NAL ALIGN MENT ..............................26

DOW EL ING PUMP CAS ING .........................26

4

PREPARATION FOR START-UP

NOTE: When installing in a potentially

!

explosive environment, ensure that the motor

is properly certified.

CHECKING ROTATION

$

Serious damage may result if pump is run in the

wrong rotation.

1. Lock out power to driver.

! WARN ING

s

Lock out driver power to prevent accidental

start-up and physical injury.

2. Make sure coupling hubs are securely fastened

to shafts.

! WARN ING

s

Do NOT jog a coupled pump.

NOTE: Pump is shipped with coupling spacer

removed.

3. Unlock driver power.

CAUTION

4. Make sure everyone is clear. Jog driver just long

enough to determine direction of rotation. Rotation

must correspond to arrow on bearing frame.

5. Lock out power to driver.

COUPLING PUMP AND DRIVER

! WARN ING

s

Lock out driver power to prevent accidental

rotation and physical injury.

NOTE: The coupling used in an ATEX

!

classified environment must be properly

certified.

1. Install and lubricate coupling per manufacturer’s

instructions.

NOTE: The coupling guard used in an ATEX

!

classified environment must be constructed

from a non-sparking material.

2. Install coupling guard. Refer to coupling guard

installation instructions in Appendix I.

3700-10th IOM 12/04 21

! WARN ING

s

Never operate a pump without coupling guard

properly installed. Refer to Appendix I for

coupling guard installation instructions.

Personal injury will occur if pump is run

without coupling guard.

LUBRICATING BEARINGS

NOTE: Bearings must be lubricated properly

!

in order to prevent excess heat generation,

sparks and premature failure.

Ring Oil Lubrication

Ring oil lubricated ball bearings are standard on

Model 3700 8th Edition units.

$

The bearings are not lubricated at the factory.

Assure that oil rings are properly seated in grooves in

shaft, as described in Disassembly & Reassembly

section.

See Preventive Maintenance section for lubrication

recommendations.

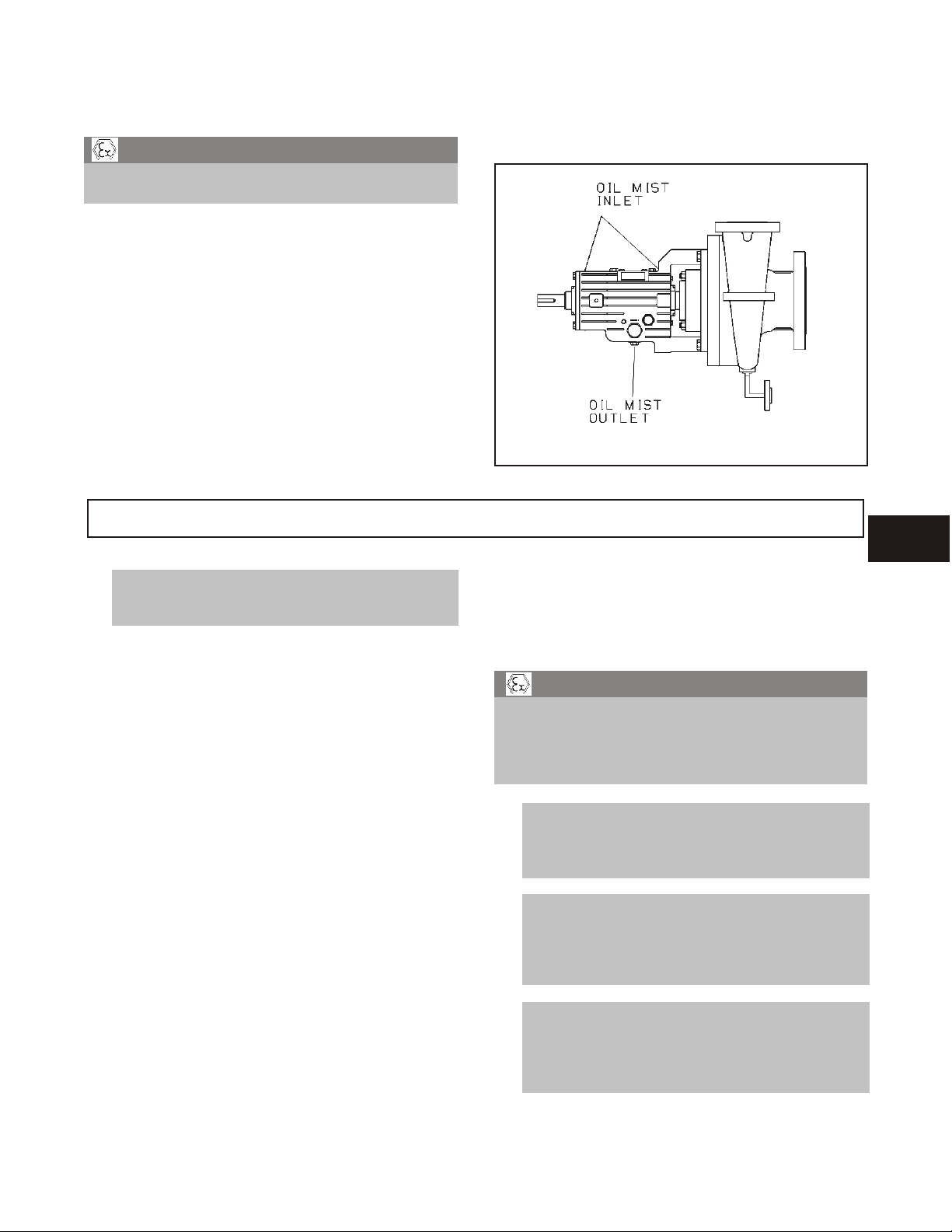

Pure or Purge Oil Mist Lubrication

Pure or purge oil mist are optional features for the

Model 3700 8th Edition. Follow oil mist generator

manufacturer’s instructions. The inlet and outlet

connections are located on the top and bottom,

respectively, of the bearing frame.

CAUTION

Connection of Sealing Liquid

NOTE: The mechanical seal must have an

!

appropriate seal flush system. Failure to do

so will result in excess heat generation and

seal failure.

NOTE: Cooling systems such as those for

!

bearing lubrication, mechanical seal

systems, etc, where provided, must be

operating properly to prevent excess heat

generation, sparks and premature failure.

NOTE: Sealing systems that are not self

!

purging or self venting, such as plan 23,

require manual venting prior to operation.

Failure to do so will result in excess heat

generation and seal failure.

For satisfactory operation, there must be a liquid film

between seal faces to lubricate them. Refer to seal

manufacturer’s drawing for location of taps. Some

methods which may be used to flush/cool the seal

are:

Product Flushing - In this arrangement, the

•

pumpage is piped from the casing (and cooled in

an external heat exchanger when required) then

injected into seal chamber.

External Flush - A clean, cool compatible liquid is

•

injected from an outside source directly into seal

chamber. Flushing liquid must be at a pressure

0.35-1.05 kg/cm

pressure. Injection rate should be 2-8 l/min. (

2

(5-15 psi) greater than seal chamber

1

-2 GPM).

2

See Preventive Maintenance section for lubrication

recommendations and connection locations.

! WARN ING

s

Operation of the unit without proper lubrication

will cause bearing failure and pump seizure.

SHAFT SEALING WITH MECHANICAL SEAL

NOTE: The mechanical seeal used in an

!

ATEX classified environment must be

properly certified.

Pumps may be shipped with or without mechanical

seal installed. Cartridge type mechanical seals are

commonly used for this model. Cartridge seals are

preset at the seal manufacturer’s facility and require

no field settings. Cartridge seals installed by the user

require disengagement of the holding clips prior to

operation, allowing the seal to slide into place. If the

seal has been installed in the pump by Goulds, these

clips have already been disengaged. For other types

of mechanical seals, refer to the seal manufacturer’s

instructions for installation and setting.

Other methods may be used which make use of

•

multiple gland connections and/or seal chamber

connections. Refer to documentation supplied with

the pump, mechanical seal reference drawing, and

piping diagrams.

PRIMING PUMP

NOTE: Pumps must be fully primed at all times

!

during operation.

Never start the pump until it has been properly

primed. Several different methods of priming can be

used, depending upon type of installation and service

involved.

Suction Supply Above Pump

1. Slowly open the suction valve (Fig. 10).

2. Open air vents on the suction and discharge piping,

casing, seal chamber, and seal piping, if provided,

until all air is vented and only liquid flows out.

3. Close the vents.

22 3700-10th IOM 12/04

Fig. 10

Suction Supply Below Pump

A foot valve and outside source of liquid may be used

to prime the pump. Outside source of liquid can come

from a priming pump, pressurized discharge line, or

other supply (Fig. 11 and 12).

Fig. 12

1. Close discharge valve and open air vents in

suction and discharge piping, casing, seal

chamber and seal piping, if provided.

2. Open valve in outside supply line until all air is

vented and only liquid flows out.

! WARN ING

s

When handling hazardous and/or toxic fluids,

proper personal protective equipment is

required. If pump is being drained, precautions

must be taken to prevent physical injury.

Pumpage must be handled and disposed of in

conformance with applicable regulations.

3. Close the vents and then the outside supply line.

Other Methods of Priming Pump

Priming by ejector.

•

Priming by automatic priming pump.

•

Fig. 11

3700-10th IOM 12/04 23

$

CAUTION

3. Variable speed drivers should be brought to rated

speed as quickly as possible.

START-UP PRE CAU TIONS

!

NOTE: Ensure that pump and systems are

!

free of foreign objects before operating and

that objects cannot enter the pump during

operation. Foreign objects in the pumpage or

piping system can cause blockage of flow

which can result in excess heat generation,

sparks and premature failure.

NOTE: A build up of gases within the pump,

!

sealing system and or process piping system

may result in an explosive environment

within the pump or process piping system.

Ensure process piping system, pump and

sealing system are properly vented prior to

operation.

1. All equipment and personal safety related devices

and controls must be installed and operating properly.

2. To prevent premature pump failure at initial

start-up due to dirt or debris in the pipe system,

ensure the pump can be run continuously at full

speed and flow for 2 to 3 hours.

4. Variable speed drivers should not be adjusted or

checked for speed governor or overspeed trip

settings while coupled to the pump at initial

start-up. If settings have not been verified,

uncouple the unit and refer to driver

manufacturer’s instructions for assistance.

5. Running a new or rebuilt pump at slow speeds

may not provide enough flow to adequately flush

and cool the wear ring and seal chamber cover

bushing close running surfaces.

6. Pumpage temperatures in excess of 93° C (200° F)

will require warm-up of pump prior to operation.

Circulate a small amount of pumpage through the

pump until the casing temperature is within 56° C

(100° F) of the pumpage temperature and evenly

heated.

NOTE: Warm-up rate should not exceed 1.4° C

(2.5° F) per minute.

STARTING PUMP

1. Make sure suction valve and any recirculation or

cooling lines are open.

2. Fully close or partially open discharge valve as

dictated by system conditions.

3. Start driver.

!

$

Immediately observe pressure gauges. If

discharge pressure is not quickly attained,

stop driver, reprime and attempt to restart.

CAUTION

4. Slowly open discharge valve until the desired flow

is obtained.

!

$

Observe pump for vibration levels, bearing

temperature and excessive noise. If normal

levels are exceeded, shut down and resolve.

CAUTION

24 3700-10th IOM 12/04

OPERATION

GENERAL CONSIDERATIONS

$

Always vary capacity with regulating valve in the

discharge line. NEVER throttle flow from the

suction side.

Driver may overload if the pumpage specific

gravity (density) is greater than originally

assumed, or the rated flow rate is exceeded.

Always operate the pump at or near the rated

conditions to prevent damage resulting from

cavitation or recirculation.

CAUTION

OPERATIONAL CHECKS

$

The following are minimum operational checks

for the pump only. Consult driver and auxiliary

equipment manufacturers’ literature for

additional information.

1. On ring oil lubricated units, remove oil ring

viewing port plugs to verify that oil rings are

properly positioned in grooves on shaft, are

turning and are throwing oil. Replace plugs.

2. On pure or purge oil mist lubricated units,

remove viewing port plugs and assure oil mist is

flowing properly. Replace plugs.

CAUTION

7. Monitor all gauges to ensure pump is

running at or near rating and that suction screen

(when used) is not clogged.

OPERATING AT REDUCED CAPACITY

! WARN ING

s

Do NOT operate pump below minimum rated

flows or with discharge valve closed. These

conditions may create an explosive hazard due

to vaporization of pumpage and can quickly lead

to pump failure and physical injury.

$

Damage occurs from:

1. Increased vibration levels - Affects bearings,

seal chambers, and mechanical seals.

2. Increased radial load - Increases stress on shaft

and bearings.

3. Heat build up - vaporization causes rotating

parts to score or seize.

4. Cavitation - Increases damage to internal

surfaces of pump.

CAUTION

OPERATING UNDER FREEZING

CONDITIONS

Exposure to freezing conditions while pump is idle

could cause liquid to freeze and damage the pump.

3. On ring oil and purge oil mist lubricated units,

check oiler to ensure oil level has remained

steady.

4. Check bearing temperatures using a

pyrometer or other accurate temperature

measuring device. Monitor bearing temperature

frequently during initial operation to determine

if a bearing problem exists as well as to

establish normal bearing operating

temperature.

5. On units equipped with auxiliary piping,

assure that proper flows have been established

and that equipment is operating properly.

6. Establish baseline vibration readings to

determine normal running conditions. If it is

determined that the unit is running rough,

consult factory.

3700-10th IOM 12/04 25

Liquid inside pump should be drained. Liquid inside

auxiliary piping, if supplied, should also be drained.

SHUTDOWN

required

1. Slowly close discharge valve.

2. Shut down and lock out driver to prevent

accidental rotation.

FINAL ALIGNMENT

Note: Alignment procedures must be

!

followed to prevent unintended contact of

rotating parts. Follow coupling

manufacturer's installation and operation

procedures.

1. Run the unit under actual operating conditions for a

sufficient length of time to bring the pump and driver

and associated systems to operating temperature.

2. Shut down and lock out driver as described

above.

s

! WARN ING

When handling hazardous and/or toxic fluids,

proper personal protective equipment is

required. If pump is being drained, precautions

must be taken to prevent physical injury.

Pumpage must be handled and disposed of in

conformance with applicable regulations.

3. Remove coupling guard. Refer to coupling guard

installation and disassembly instructions in

Appendix I.

4. Check alignment while unit is still hot per

alignment criteria in Section 3.

5. Reinstall coupling guard. Refer to coupling guard

installation and disassembly instructions in

Appendix I.

! WARN ING

s

Before beginning any alignment procedure,

make sure driver power is locked out. Failure

to lock out driver power will result in serious

physical injury.

DOWELING PUMP CASING

The pump casing may be doweled to the baseplate

pedestals, if desired, to positively maintain position.

Two (2) Number 7 taper pins are supplied for this

purpose.

NOTE: Doweling should only be done after

final alignment has been completed.

1. Drill two holes, one in each casing mounting pad,

at the locations provided, using a 21/64 in. or “Q”

size drill.

The holes should be drilled through both the

casing mounting pads and the baseplate

pedestal, when possible. This makes cleaning

the metal chips produced from the drilling and

reaming operations easier. Take care to clean all

burrs and metal chips from the holes.

$

If water cooled pedestals have been provided,

do NOT drill through the baseplate pedestal or

leakage of cooling water will occur.

2. Ream the holes with a Number 7 taper pin

reamer to the proper fit with the taper dowel pins.

Pins should insert to a depth that leaves only the

threaded portion exposed when fully seated.

3. Seat taper pins firmly in holes with hardwood

block or soft faced hammer.

$

Failure to remove the dowel pins prior to

casing removal may result in casing damage.

CAUTION

CAUTION

26 3700-10th IOM 12/04

PREVENTIVE MAINTENANCE

GEN ERAL COM MENTS............................27

MAIN TE NANCE SCHED ULE.........................27

Rou tine Main te nance ............................27

Rou tine In spec tions ............................27

3 Month Inspections ............................27

An nual In spec tions .............................27

MAIN TE NANCE OF BEAR INGS .......................28

Ring Oil Lu bricated Bear ings ........................28

Pure or Purge Oil Mist Lu bricated Bear ings (Op tional) ...........29

MAINTENANCE OF SHAFT SEALS .....................29

TROU BLE SHOOT ING.............................30

GENERAL COMMENTS

A routine maintenance program can extend the life of your pump. Well maintained

equipment will last longer and require fewer repairs. You should keep maintenance

records as this will help pinpoint potential causes of problems.

5

NOTE: The preventive maintenance section must be adhered to in order to keep the applicable

!

ATEX classification of the equipment. Failure to follow these procedures will void the ATEX

classification for the equipment.

MAINTENANCE SCHEDULE

ROUTINE MAINTENANCE

Bearing lubrication

•

Seal monitoring

•

Vibration analysis

•

Discharge pressure monitoring

•

Temperature monitoring

•

ROUTINE INSPECTIONS

Check for unusual noise, vibration and bearing

•

temperatures.

Inspect pump and piping for leaks.

•

Check seal chamber for leakage.

•

Oil should be changed at least every 3 months

•

(2000 hours) or more often if there are any adverse

atmospheric conditions or other conditions which might

contaminate or break down the oil. Oil should also be

changed if it is cloudy or contaminated.

Check shaft alignment and realign if required.

•

ANNUAL INSPECTIONS

Check pump capacity, pressure and power. If pump

•

performance does not satisfy your process requirements, and process requirements have not changed,

pump should be disassembled, inspected, and worn

parts should be replaced. Otherwise, a system

inspection should be done.

3 MONTH INSPECTIONS

Check foundation and hold-down bolts for tightness.

•

If pump has been left idle, check mechanical seal.

•

Repair or replace if required.

3700-10th IOM 12/04 27

Inspection intervals should be shortened

!

appropriately if the pumpage is abrasive

and/or corrosive, or if the environment is

classified as potentially explosive.

MAINTENANCE OF BEARINGS

NOTE: Do not insulate bearing housings as

!

this can result in excess heat generation,

sparks and premature failure.

RING OIL LUBRICATED BEARINGS

Ring oil lubricated ball bearings are standard on

Model 3700 8th Edition pumps.

! WARN ING

s

Pumps are shipped without oil. Oil lubricated

bearings must be lubricated at the job site.

A high quality turbine oil with rust and oxidation inhibitors

should be used. For the majority of operational

conditions, bearing temperatures will run between 50° C

(120° F) and 82° C (180° F). In this range, an oil of ISO

viscosity grade 68 at 40° C (100° F) is recommended. If

bearing temperatures exceed 82° C (180° F), use oil of

ISO viscosity grade 100.

Bearing temperatures are generally about 11° C

(20° F) higher than bearing housing outer surface

temperature.

Some acceptable oils are:

Exxon Teresstic EP 68

Mobil Mobil DTE 26 300 SSU

@ 40° C (100° F)

Fig. 13

NOTE: Setting dimension of 0 may be

accomplished by removing and discarding the

oiler adjusting stem.

Oil reservoir in bearing frame should be filled by filling

oiler bottle with oil and placing it into the oiler housing.

Several fillings of the oiler bottle will be required. Do

not fill bearing frame oil reservoir through the vent or

through the oiler housing without using the bottle.

Oil capacities and oiler information for the various

bearing frames are shown in Table 3.

Sunoco Sunvis 968

Royal Purple SYNFILM ISO VG 68

Synthetic Lube

For extreme conditions, refer to the factory or a

lubrication expert.

Oil should be changed after 200 hours if bearings are

new. Thereafter, change oil every 2000 operating

hours or 3 months, whichever first occurs.

Ring oil lubricated pumps are supplied with an oiler

which maintains a constant oil level in the bearing

housing. The oiler must be adjusted to maintain the

oil at the level of the mark on the side of the frame,

which corresponds to the center of the bullseye sight

glass. This is accomplished by setting the oiler

adjusting stem. Refer to Fig. 13 for proper setting

dimensions.

Ta ble 3

Bearing Frame Oil Ca pacities

Frame Oil Ca pacity Trico

Group

SA 600 20

SX 1115 38

MA 950 32

LA, MX 1385 47

LX 2120 72

XLX 2625 89

Verify the correct oil level by comparing the oil level

as viewed in the bullseye sight glass with the oil level

line on the side of the bearing frame.

ml Ounces ml Ounces

Oiler No.

5 237 8

Oiler Ca pac ity

28 3700-10th IOM 12/04

OPTIONAL PURE OR PURGE OIL MIST

LUBRICATED BEARINGS

! WARN ING

s

Pumps are shipped without oil. Oil mist lubricated

bearings must be lubricated at the job site.

The same oil requirements applicable to ring oil

lubricated bearings also apply to oil mist lubricated

bearings.

For purge oil mist lubricated bearings, bearing frame

should be filled to the proper level as described under

ring oil lubricated bearings.

Below are listed the steps necessary for oil mist

lubrication:

1. Follow oil mist system supplier’s instructions.

MAINTENANCE OF SHAFT SEALS

NOTE: The mechanical seal used in an ATEX

!

classified environment must be properly

certified.

When mechanical seals are furnished by Goulds, a

manufacturer’s reference drawing is supplied with the

data package. This drawing should be kept for future

use when performing maintenance and adjusting the

seal. The seal drawing will also specify required flush

liquid and attachment points. The seal and all flush

piping must be checked and installed as needed prior

to starting the pump.

2. Connect oil mist supply lines to inlet connections

(Fig. 14).

3. Connect drain/vent lines to outlet connections.

Fig. 14

The life of a mechanical seal depends on various

factors such as cleanliness of the liquid handled and

its lubricating properties. Due to the diversity of

operating conditions it is, however, not possible to

give definite indications as to its life.

! WARN ING

s

NEVER operate the pump without liquid supplied

to mechanical seal. Running a mechanical seal

dry, even for a few seconds, can cause seal

damage and must be avoided. Physical injury

can occur if mechanical seal fails.

5

NOTE: The mechanical seal must have an

!

appropriate seal flush system. Failure to do

so will result in excess heat generation and

seal failure.

NOTE: Cooling systems such as those for

!

bearing lubrication, mechanical seal

systems, etc, where provided, must be

operating properly to prevent excess heat

generation, sparks and premature failure.

NOTE Sealing systems that are not self

!

purging or self venting, such as plan 23,

require manual venting prior to operation.

Failure to do so will result in excess heat

generation and seal failure.

3700-10th IOM 12/04 29

Loading...

Loading...