Page 1

Enidine / Conoflow

105 Commerce Way

Westminster, SC 29693

Tel: (864) 647-9521

Fax: (864) 647-7993

INSTRUCTION AND MAINTENANCE MANUAL

GFH45 PRESSURE REGULATOR

CAUTION: These instructions should be read

carefully prior to installation, use or

maintenance.

GENERAL PRODUCT OVERVIEW

Conoflow’s GFH45 Series Airpak®, Filter-Regulator is

used to provide clean, accurate air to instruments,

valves, positioners, transducers and other pneumatic

control devices. This unit’s design provides high flow

capability, durable materials of construction and bubble

tight shut-off.

The GFH45 Regulator has a maximum supply pressure

capability of 300 PSIG (2.07 MPa) with control output

settings of 0-25, 0-60 and 0-125 PSIG (0-172, 0-414 and

0-862 kPa). This brass filter regulator boasts a high flow

delivery rate and excellent droop characteristic.

This regulator is offered with ¼” NPT inlet and outlet

ports, two outlet gauge ports, and brass construction. A

handwheel or wrench knob adjustments are standard.

CAUTION: Maximum Supply Pressure is 300

PSIG (2.07 MPa)

WARNING: This product is not recommended

for use with flammable liquids or gasses.

WARNING

Conoflow’s products are designed and

manufactured using materials and

workmanship required to meet all applicable

standards. The use of these products

should be confined to services specified

and/or recommended in the Conoflow

catalogs, instructions, or by Conoflow

application engineers.

To avoid personal injury or equipment

damage resulting from misuse or

misapplication of a product, it is necessary

to select the proper materials of

construction and pressure-temperature

ratings which are consistent with

performance requirements.

MATERIALS OF CONSTRUCTION

Nozzle Assembly: Brass with Buna N Soft Seat

Range Spring: Zinc Plated Carbon Steel

Diaphragm Assembly: see CED Code

Bowl: Brass

Body: Brass

Bonnet: Brass

SPECIFICATIONS

Maximum Supply Pressure: 300 psig (2.07 MPa)

Outlet pressure ranges are determined by the last

character in the regulator model number.

“C” 25 psig (172 kPa)

“F” 60 psig (414 kPa)

“G” 125 psig (862 kPa)

Proof Pressure: 150% of maximum operating

Burst Pressure: 400% of maximum operating

Flow Capacity: 20 scfm (see flow chart)

Temperature Range: -20 °F to 165 °F

(-29 °C to 74 °C)

Sensitivity: 0.02 psi (0.14 kPa)

Connections: ¼” NPT Inlet and Outlet Ports,

Two-¼” NPT Gauge Ports

(90° from Outlet Port)

Weight: 3.4 lb (1.55 kg)

REGULATOR CLEANING

The GFH45 pressure regulator is cleaned to ITT

Conoflow specification ES8A 01 1 when option B is

selected in position 6 of the model number.

GFH45-IOM Rev. 0 12/18

Printed in USA

Page 2

INSTALLATION

CAUTION: The regulator must be installed with the

draincock downward to allow accumulated fluid to

drain out when the draincock is opened.

CAUTION: Moisture and particulates can be

discharged at high speed when draincock is

opened.

The GFH45 can be line mounted, panel mounted, or wall

mounted (reference G6018006 wall-mount bracket).

Teflon tape is the preferred thread sealant for the 1/4”

NPT connections.

Connect the supply to the port marked “IN”. The other

ports are outlet and factory plugged outlet gauge ports.

WARNING

port, regulator damage or unexpected flow through the

regulator could occur.

Prior to applying inlet pressure, double check the

connections and assure the wrench knob or hand wheel

is backed out sufficiently to unload the range spring in

the bonnet.

Carefully apply inlet pressure and check the supply

connection for leakage. Adjust the output pressure by

rotating the wrench knob or hand wheel clockwise and

check the outlet connection for leakage.

: If the supply line is connected to the outlet

WARNING: The handwheel or wrench knob can vibrate

loose and fall out if the jam nut is not tightened.

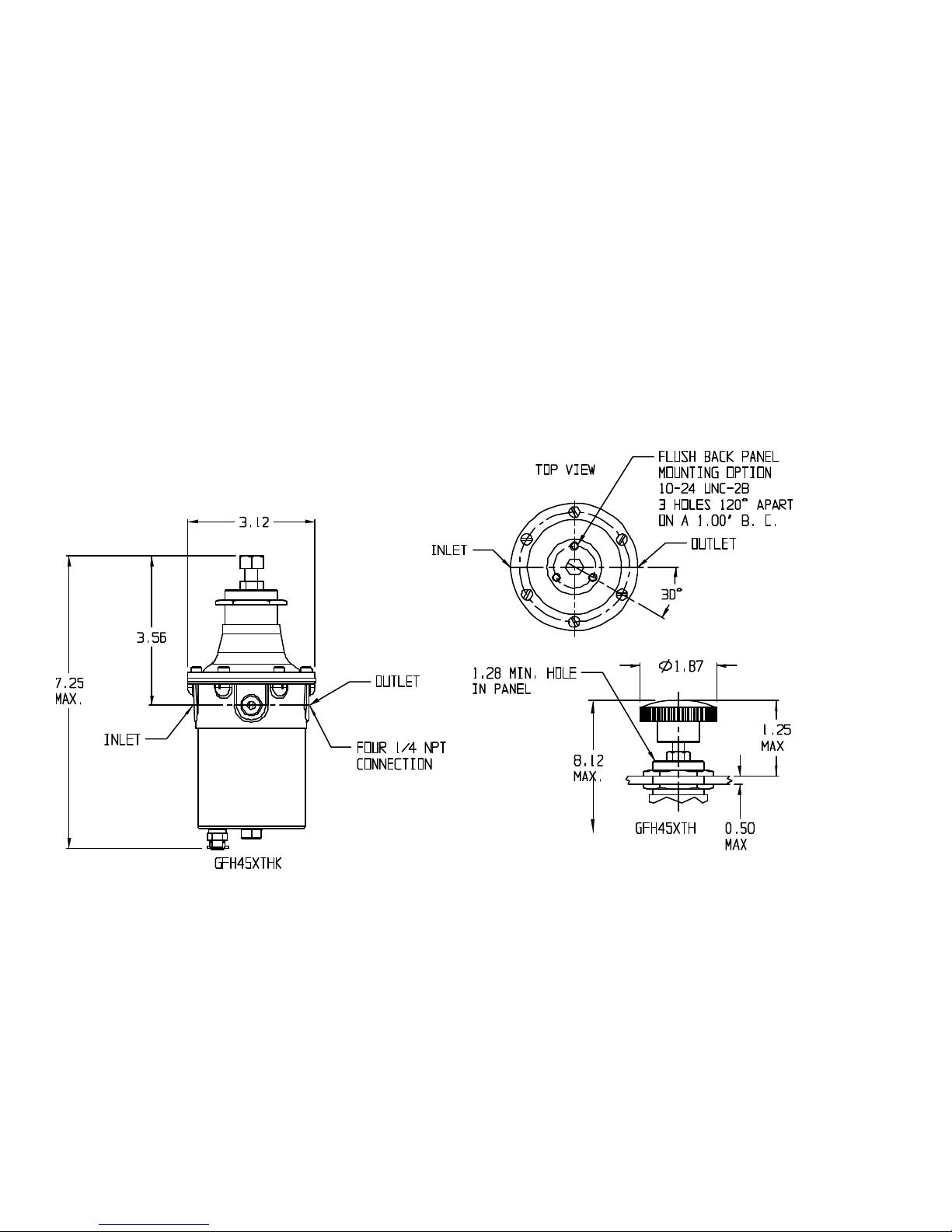

Figure 1 – Regulator dimensions with 1/4” NPT connections. For certified dimensional drawing, see A17-83.

Page 2 of 6 GFH45-IOM Rev. 0 12/18 Printed in USA

Page 3

CONTROL ENGINEERING DATA

Control Engineering Data is intended to provide a single

source from which one can determine, in detail, the full

scope of the product line. In addition to materials of

construction, diaphragm selection, filtering capabilities, it

also provides all necessary data for the mounting

options and control output setting ranges. Control

Engineering Data also provides a means of

communicating, by way of an 12 digit model number, a

full description of the product selection.

Characters 1-5: (Filter Regulator Model No.)

GFH45

Character 6: Filter Options

A = Cellulose (10 micron) – optional

B = Stainless Steel (40) micron-cleaned for

oxygen service) – optional

C = Stainless Steel (40 micron) – optional

X = Polypropylene (35 micron) – standard

Character 7: Bonnet Options

F = Front mount - optional

T = Threaded Bonnet - standard

Character 8: Adjustment Options

H = Handwheel - optional

K = Knob (Wrench Style) – standard

P = Preset (Factory Output Setting CAN be field

adjusted) – optional

C = Tamperproof (Factory Output Setting

Cannot be field adjusted)- optional

NOTE: 1. Customer must specify OUTPUT

SETTING, SUPPLY PRESSURE, and

FLOW.

Character 9: Diaphragm Selection

E = Buna “N” (w/Relief, No Bleed) – Standard

F = Viton on Nomex (No Bleed, No Relief)

J = Viton on Nomex (w/Relief, No Bleed)

M = Buna “N” (No Bleed, No Relief)

Character 10: Gauge Selections

X = No Gauge – standard

Character 11: Filter Bowl Option

1 = Standard (Bowl Size)

NOTE: Materials of construction and cleaning specifications

are the user’s responsibility.

Character 12: Control Ranges

C = 25 psig (172 kPa)

F = 60 psig (414 kPa)

G = 125 psig (862 kPa)

OPERATION IN SERVICE

Open upstream controls to provide the regulator supply

pressure. To increase the output set pressure, rotate the

knob or handwheel clockwise. To decrease the output set

pressure, rotate the knob or handwheel counterclockwise.

For non-relieving models (option “M” or “F” in character 9

position of the CED code), rotate the knob or handwheel

counterclockwise to reduce the output pressure when the

system is flowing.

When the system is being shut down, it is an established

safety practice to reduce the output pressure under flow then

shut off the supply pressure to the regulator. After all

pressure is relieved from the system, back out the control

knob until there is no spring resistance felt on the control

knob. This will assure that no output pressure will be

generated when the supply pressure to the regulator

resumes, the next time the system is used.

NOTE: The downstream pressure will change as the flow

changes. As the flow increases, the delivery pressure will

decrease.

NOTE: The outlet set pressure will change as the inlet

pressure changes. The output set pressure will increase as

the supply pressure decreases at an approximate rate of 0.3

psi per 25 psi decrease in the inlet pressure.

Page 3 of 6 GFH45-IOM Rev. 0 12/18 Printed in USA

Page 4

TROUBLESHOOTING GUIDE

Symptom: Outlet pressure continues to rise after flow

ceases.

Potential Cause: Valve seat leakage

Repair: Disassemble and clean regulator

components. Install new valve plug and filter element

(if applicable). Reassemble.

Symptom: External leakage

Potential Cause: Diaphragm to body joint seal

leakage.

Repair: Disassemble. Inspect regulator body where

diaphragm seals. Replace diaphragm assembly.

Potential Cause: Bowl to body joint leakage.

Repair: Disassemble. Inspect regulator body where

bowl o-ring contacts. Inspect bowl where o-ring

contacts. Replace o-ring.

Symptom: External leakage

Potential Cause: Draincock leakage.

Repair: Tighten draincock by turning handle

clockwise.

Symptom: Outlet pressure cannot be adjusted to

maximum control range.

Potential Causes:

1. Control knob positive stop adjustment.

2. Flow induced droop.

Repair:

1. Adjust positive stop of control knob.

2. A higher output range regulator may be required.

Symptom: Noisy operation.

Potential Causes: Turbulence in adjacent piping.

Repair: Insure that there are no elbows, line tees or

other turbulence creating piping directly upstream or

downstream of the pressure regulator.

Page 4 of 6 GFH45-IOM Rev. 0 12/18 Printed in USA

Page 5

FIGURE 2 – Cross Section of GFH45 Regulator

REPAIR AND MAINTENANCE

WARNING: To prevent equipment damage or injury, insure

that all system pressure is relieved and the supply valve for this

regulator is secured in the off position.

Cleanliness is critical to successful maintenance and repair of

this product. Perform all repair work in a clean environment, with

clean tools, and the correct materials and supplies.

Tools and Materials Required:

1. A vise, or other suitable fixture, to secure the regulator.

2. Phillips screwdriver

3. Socket wrenches

4. Torque Wrench

5. Lint free swabs or wipes to clean components

DISASSEMBLY

1. Secure the body of the regulator.

2. Turn control knob counterclockwise until the range

spring is unloaded.

3. Remove the six screws holding the bonnet to the body.

4. Remove the bonnet.

5. Remove the spring button and spring.

6. For 125 psi output units, remove the restricting plate

(note: the 0-60 psi model is shown in figure 2 and does

not have this restricting plate).

7. Remove the diaphragm assembly.

8. Unscrew the bolt and seal washer.

9. Remove the dripwell by pulling downward away from the

body.

10. Remove the filter.

11. To remove the plug spring and valve plug, unscrew the

retainer, then grip the plug spring and pull downward

away from the body. The plug and plug spring should

slide out of the body together.

ASSEMBLY

1. Replace worn or damaged components with new

components.

2. Clean and inspect components for reuse. Sealing

surfaces must be smooth and free of wear or scratches.

3. Install the valve plug and plug spring into the body.

Secure with the retainer. Torque retainer to 80 in-lb.

4. Replace the o-ring around the bowl with a new

lubricated o-ring.

5. If previously removed, install a new seal washer onto

the bolt. Install the filter plate, grommet and spring into

the dripwell, on the bolt.

6. Place a new filter in the body.

7. Install the dripwell by firmly pressing it over the o-ring.

The dripwell may be rotated to align the draincock to the

desired orientation. Secure the dripwell with the bolt,

tightened to 80 in-lb.

8. Assemble the diaphragm assembly, the restrictor plate

(for 125 psi models only), range spring, spring button

and bonnet. Secure bonnet with the six (6) bonnet

screws. Tighten snug (32 in-lb).

9. Lubricate (grease) and install the adjustment ( wrench

knob or handwheel), jam nut and any panel nuts and/or

mounting hardware.

Page 5 of 6 GFH45-IOM Rev. 0 12/18 Printed in USA

Page 6

FIGURE – 3 Exploded View of the GFH45

NOTES:

1. When ordering spare parts, specify complete Regulator Model Number., and Item Description. This will permit

positive identification and rapid handling of order.

2. Spare parts kit (standard configuration only)

a. G6385516 for the 0-25/60 psi (172/414 kPa) models

b. G6385517 for the 0-125 psi (862 kPa) model

3. For other model configurations or non-CED codeable models, consult factory for correct part number.

Page 6 of 6 GFH45-IOM Rev. 0 12/18 Printed in USA

Loading...

Loading...