Page 1

BPHV

ITT

Commercial Water

Goulds Pumps

PHV – Packaged Hydrovar Series

Variable Speed Water Booster with

Vertical Multistage Pump and

Fused Disconnect

Engineered for life

U

L

®

C US

Listed

Page 2

Goulds Pumps

PHV - Packaged Hydrovar Series

CONTENTS

Selection Chart …………………………………………………………………………………………… 3

Main Components ………………………………………………………………………………………… 4

Part Numbering …………………………………………………………………………………………… 5

Markets and Applications ……………………………………………………………………………… 6-8

Hydrovar Specifications / Listings ……………………………………………………………………… 9-11

Multi-Pump Example ……………………………………………………………………………………… 12

Operation / Selecting ……………………………………………………………………………………… 13

Fused Disconnect ………………………………………………………………………………………… 15

Motor Data ………………………………………………………………………………………………… 17

Variable Speed Curves ……………………………………………………………………………… 19-36

Technical Data - Pump Hydraulics ………………………………………………………………… 37-40

Dimensions / Weights ……………………………………………………………………………… 41-46

Technical Data - References …………………………………………………………………………

48-49

2

Page 3

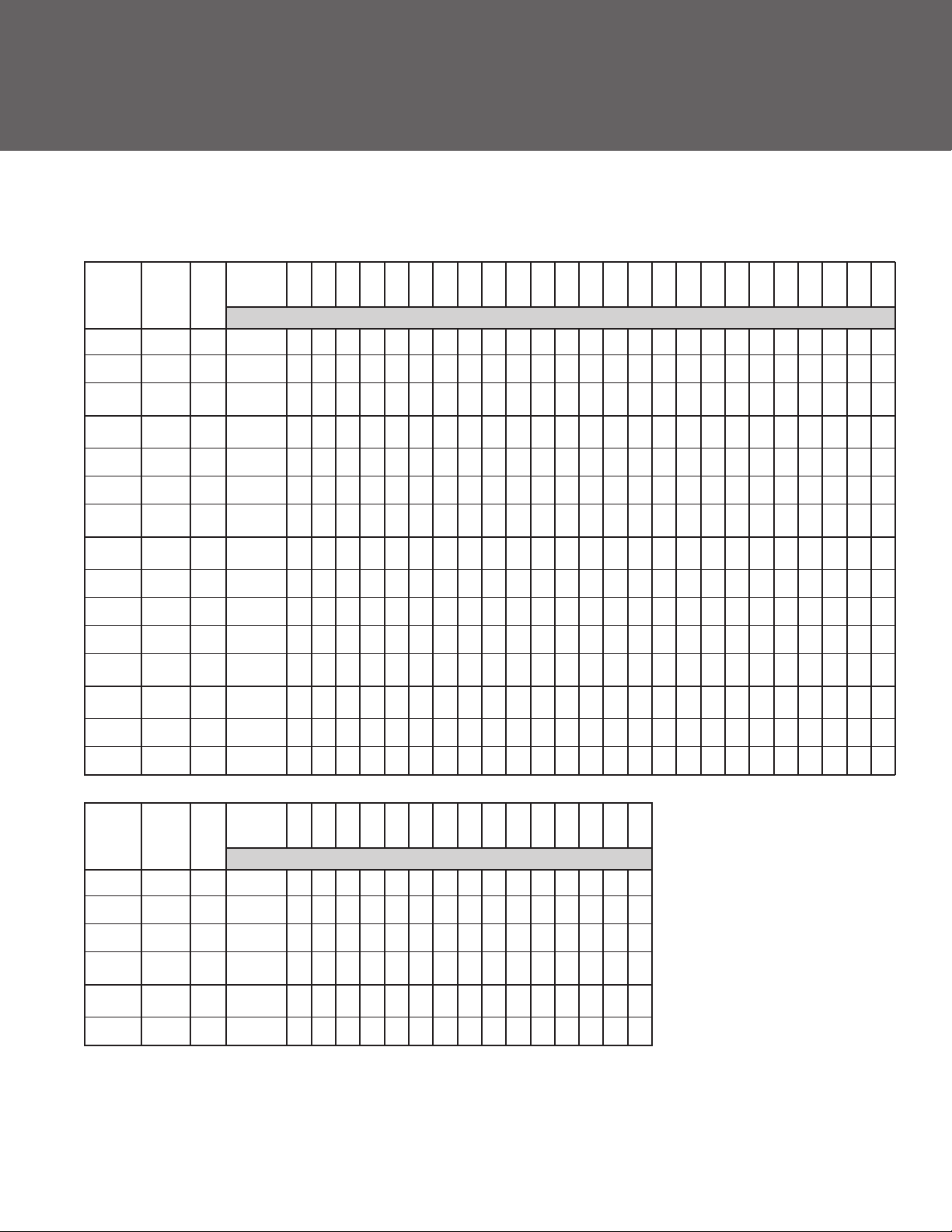

PHV SERIES SELECTION CHART (PACKAGED HYDROVAR)

HYDRAULIC PERFORMANCE RANGE AT 60 Hz

SSV FLOW

Pump Stage HP 0 GPM

Model

1SV 6 2

1SV 9 3

1SV 15 5

2SV 5 2

2SV 8 3

2SV 13 5

2SV 16 7.5

3SV 2 2

3SV 4 5

3SV 7 7.5

3SV 9 10

3SV 13 15

4SV 2 5

300 279 265 247 226 200 173 142

442 416 395 369 338 300 259 212

732 692 657 615 564 505 436 359

217 211 206 200 196 189 182 174 156 135 112 85

353 340 331 325 315 304 292 279 249 215 178 136

586 560 546 530 513 493 473 451 400 347 286 219

710 687 671 654 634 611 585 559 496 426 344 254

124 123 122 120 118 115 111 107 103 98 92 85 79 71 63

245 245 244 241 237 231 217 208 197 186 173 159 143 128

440 435 430 423 414 403 390 377 360 343 323 303 280 256 229

565 559 552 544 530 518 503 484 464 441 415 388 358 326 292

817 809 801 788 772 750 730 703 673 639 603 562 519 470 419

149 149 149 149 148 146 145 143 141 139 136 133 130 126 123 118 114 109 105 99

5 7.5 10 12.5 15 17.5 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105 110

HEAD IN FEET

4SV 4 7.5

4SV 7 15

SSV FLOW

Pump Stage HP 0 GPM

Model

33SV 1/0 5

33SV 2/2 7.5

33SV 2/0 10

33SV 3/0 15

46SV 1/0 10

46SV 2/0 15

NOTE: Head in feet is boost pressure.

300 300 300 300 300 295 291 286 283 277 272 265 258 250 242 233 223 213 203 191

530 530 530 530 523 518 512 504 497 487 478 465 451 439 423 407 388 371 352 332

110 110 109 108 105 102 96 91 84 76 68

163 163 161 157 152 144 135 124 112 97 81

222 222 220 216 210 202 193 181 168 153 137

334 334 330 323 314 302 288 272 253 231 206

124 121 119 117 114 110 107 103 98 93 88 82 75 69 62 55

253 249 246 242 238 232 226 220 213 204 196 186 176 165 153 140

40 60 80 100 120 140 160 180 200 220 240 260 280 300 320

HEAD IN FEET

3

Page 4

Goulds Pumps

PHV - Packaged Hydrovar Series

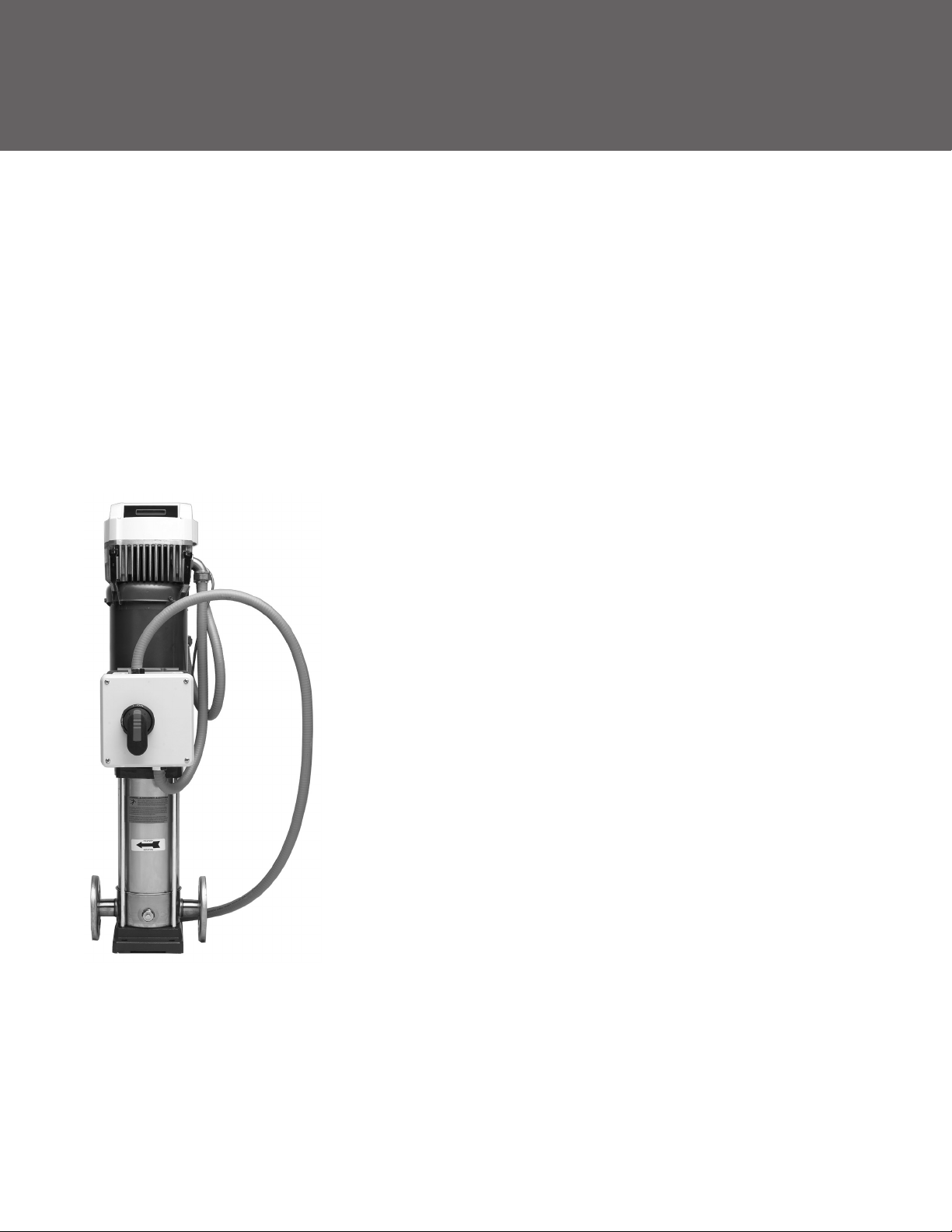

MAIN COMPONENTS

of PHV Series constant pressure variable

speed system

• One multistage vertical pump, Goulds Pumps SSV series.

• Hydrovar® pump mounted variable speed drive

• Pressure transducer for constant pressure control,

connected to the Hydrovar drive.

• NEMA 4X fused disconnect panel with corrosion resistant

durable plastic; external on/off switch with lockout/tagout. Panel

is bracket mounted directly to pump.

• Electrical panel for control and protection, with casing made

of plastic material, NEMA 4X, equipped with:

– fast acting fuses. The panel is mounted on the electric pump

using a bracket.

U

L

®

C US

Listed

“QCZJ7 Packaged Pumping System”

The pump package comes pre-assembled and tested,

complete with operating instructions and panel wiring diagram.

1) Vertical multi-stage stainless pump

2) TEFC standard NEMA 2-pole motor

3) NEMA 4X fused disconnect panel

4) ITT Hydrovar® variable speed controller

5) cUL flexible liquid tight conduit/wiring

6) Pressure transducer (sensor) with cable

7) Outdoor use

4

Page 5

PART NUMBERING / IDENTIFICATION CODES — PHV SERIES

PACKAGED HYDROVAR VARIABLE SPEED SSV PRODUCT LINE NUMBERING SYSTEM

The various versions of the PHV line are identified by a product code number on the pump label. The number is

also the catalog number for the package. The meaning of each digit in the product code is shown below.

PHV 02 M 2 1 B E 0 P

Option List in order shown:

P = Premium Efficiency F = Harmonic Filter T = 500 PSI Transducer

Reduced Stages (33-46SV Only) (can be 0, 1 or 2)*:

0 = 0 reduced 1 = 1 reduced 2 = 2 reduced

Number of Stages:

A = 1 E = 5 J = 9 N = 13 S = 17 Z = 24

B = 2 F = 6 K = 10 P = 14 T = 18

C = 3 G = 7 L = 11 Q = 15 V = 20

D = 4 H = 8 M = 12 R = 16 X = 22

Flange Type:

A = NPT Oval B = ANSI D = 316SS ANSI

Pump Model:

1 = 1SV 2 = 2SV 3 = 3SV 4 = 4SV

5 = 33SV 6 = 46SV 7 = 66SV 8 = 92SV

Voltage:

2 = 230V

4 = 460V

Hydrovar Type:

M = Master Controller

HP Rating:

02 = 2 HP 03 = 3 HP 05 = 5 HP

07 = 7½ HP 10 = 10 HP 15 = 15 HP

PHV - Series (SSV & Hydrovar Package)

Notes:

1. Not all combinations are available. 4. Fuse box contains class J or equal fast acting fuses.

2. Standard motor is Baldor TEFC, 3 Phase, TC frame. 5. Tank, piping and valves sold separately.

3. Standard Hydrovar VSD is master - capable of multi-control. 6. Includes 300 PSI transducer.

* Notes: Indicates num-

ber of reduced diameter

impellers in the total staging.

(2 would indicate 2 reduced

diameter impellers.)

CAUTION: 500 PSI transducer measures accurately to

400 PSI. Pump, flanges and

other piping system components must also be rated

for the maximum system

pressure. See SSV technical

manual and other appropriate technical manuals to verify

all equipment is rated to

maximum system pressure.

HYDROVAR VARIABLE SPEED CONTROLLERS

Hydrovar variable speed drives are identified by the following code. The meaning of each digit in the product code

is shown below.

HV M 3 4 10

Filter (optional):

Standard = Blank Residential = B

HP Rating:

02 = 2 HP 03 = 3 HP 05 = 5 HP

07 = 7 HP 10 = 10 HP 15 = 15 HP

Voltage:

2 = 230V 4 = 460V

Phase:

1 = Single Phase 3 = Three Phase

Type:

M = Master S = Single B = Basic

HV - Series

5

Notes:

1. Not all combinations are

2. Includes drive, mounting

available.

hardware, 300 PSI transducer and conduit gland

and plugs.

Page 6

Goulds Pumps

PHV - Packaged Hydrovar Series

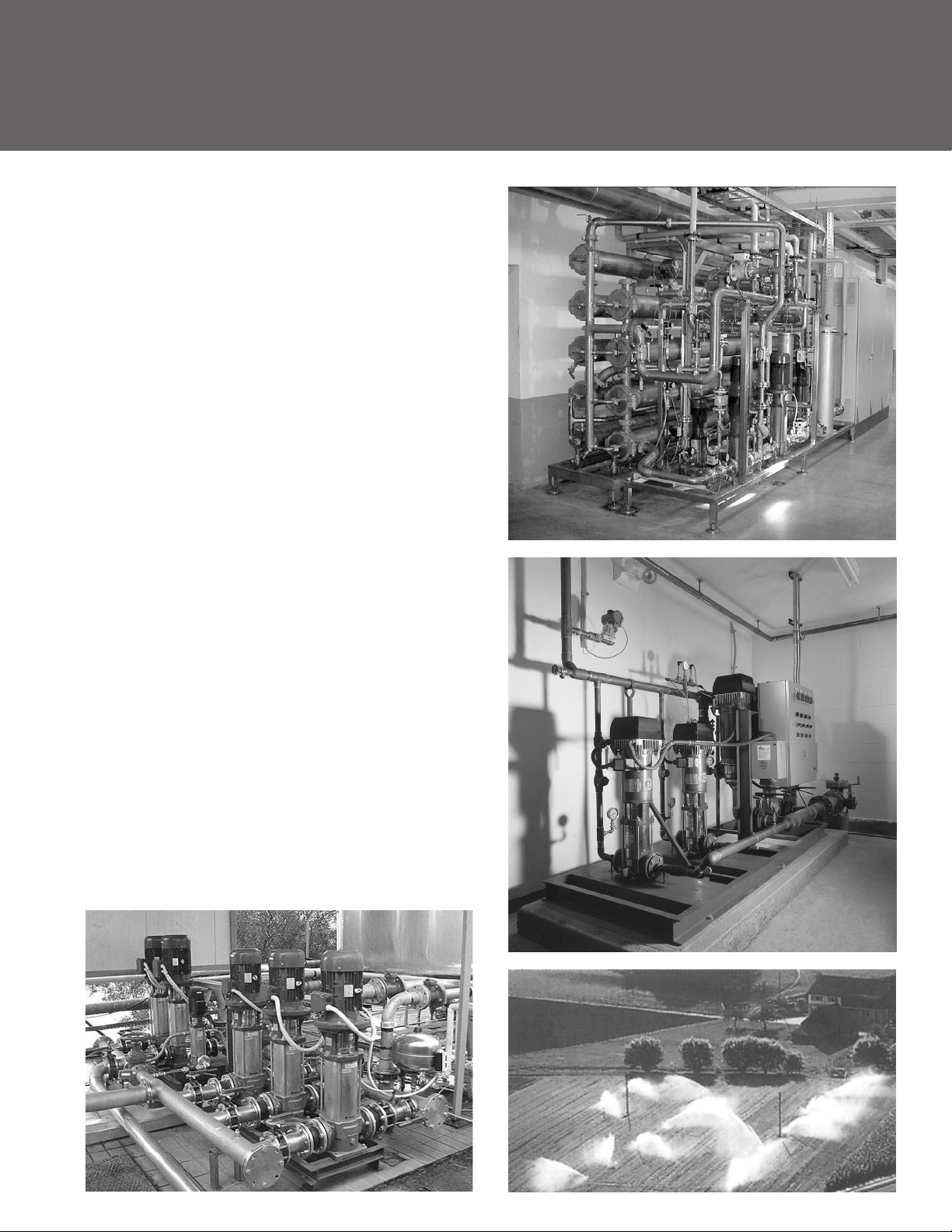

MARKETS AND APPLICATIONS

Booster

Sets

MARKETS SERVED

MUNICIPAL, COMMERCIAL, INDUSTRIAL

APPLICATIONS

• Water network supply in condominiums, offices, hotels,

shopping centers, factories, water treatment, process control.

• Water supply to agricultural water networks (e.g. irrigation).

• Variable flow / demand applications requiring constant pressure control.

PHV Series

SPECIFICATIONS

• Flow rate up to 320 GPM.

• Head up to 692’ TDH.

• Supply voltage:

1Ø, 230V ± 10% up to 3 HP.

3Ø, 400V ± 10% for 3 HP – 15 HP.

• Input Frequency: 50 or 60 Hz.

• External control voltage:

0-5 VDC; 0-10 VDC; 0-20 mA.

• Protection class

- panel: NEMA 4X.

- drive: NEMA 4 up to 15 HP.

- outdoor use.

• Maximum HP: 15 HP.

• Soft motor start.

• Vertical design pump:

- SV..T series (motor insulation

class, F, TEFC enclosure).

• Maximum operating pressure:

360 PSI for sets with SV..T electric

pumps.

• Maximum temperature of pumped

liquid: 180° F.

6

Page 7

MARKETS AND APPLICATIONS

(continued)

WATER SUPPLY AND PRESSURE BOOSTING

• Pressure boosting in buildings, hotels,

residential complexes

• Pressure booster stations, supply of water networks

• Booster packages

WATER TREATMENT

• Ultraltration systems

• Reverse osmosis systems

• Water softeners and de-mineralization

• Distillation systems

• Filtration

LIGHT INDUSTRY

• Washing and cleaning plants (washing and degreasing of

mechanical parts, car and truck wash tunnels, washing of

electronic industry circuits)

• Commercial washers

• Fireghting system pumps

IRRIGATION AND AGRICULTURE

• Greenhouses

• Humidiers

• Sprinkler irrigation

HEATING, VENTILATION AND AIR CONDITIONING (HVAC)

• Cooling towers and systems

• Temperature control systems

• Refrigerators

• Induction heating

• Heat exchangers

• Boilers

• Water recirculation and heating

7

Page 8

Goulds Pumps

PHV - Packaged Hydrovar Series

MARKETS AND APPLICATIONS

(continued)

MUNICIPAL, AGRICULTURAL, LIGHT INDUSTRY,

WATER TREATMENT, HEATING AND AIR CONDITIONING

APPLICATIONS

• Handling of water, free of suspended solids, in the municipal, industrial and agricultural markets

• Pressure boosting and water supply systems

• Fire ghting jockey pumps

• Irrigation systems

• Wash systems

• Water treatment plants: reverse osmosis

• Handling of moderately aggressive liquids, demineralized water, water and glycol, etc.

• Circulation of hot and cold water for heating, cooling and conditioning systems

• Boiler feed

SPECIFICATIONS

PUMP

The SSV pump is a non-self priming vertical multistage pump coupled to a standard motor.

The liquid end, located between the upper cover and the pump casing, is held in place by tie rods.

The pump casing is available with different configurations and connection types.

• Delivery: up to 600 GPM

• Head: up to 1200 feet

• Temperature of pumped liquid: -20ºF to 250ºF (-30ºC to 120ºC) standard version

• Maximum operating pressure – with oval anges: 230 PSI (15 bar)

– with round flanges or Victaulic: 360 PSI (25 bar)

– SV33, 46: 230, 360 or 575 PSI (16, 25 or 40 bar)*

– SV 66, 92: 230 or 360 PSI (16 or 25 bar)*

• Direction of rotation: clockwise looking at the pump from the top down (marked with an

arrow on the adapter and on the coupling).

MOTOR

• Standard NEMA TC Frame motors totally enclosed fan cooled.

• Efciency is 75.5% or higher, Class “F” insulation

• 3500 RPM nominal

• Standard voltage:

• Single phase version: 115-208/230 V, 60 Hz up to 3 HP or 208-230 V for 5 HP

• Three phase version, 2 pole: 208-230/460 V, 60 Hz up to 75 HP

* Based on pump staging

8

Page 9

MAIN CHARACTERISTICS OF FREQUENCY CONVERTERS USED IN THE

PHV BOOSTER SETS

The PHV series booster sets use a Hydrovar® variable frequency drive, an automatic device that adjusts the speed of the

electric pump in order to maintain constant pressure in the system.

Converters with power up to 30 HP can be mounted directly on

to the motor. Models with over 30 HP power, are designed for wall

mounting only. The pressure is measured by a pressure transmitter

which uses a standard 4..20 mA current signal. The system pressure

value can be read on the converter’s display. A simple user interface

allows you to set the desired pressure value for optimal adjustment,

as well as to view the operating data, such as the hours of

operation and any alarms triggered. Included diagnostic menu to view

temperature, current and voltage values facilitates diagnostics and

failure analisys. Indicator lights signal power status, pump running and

malfunctions.

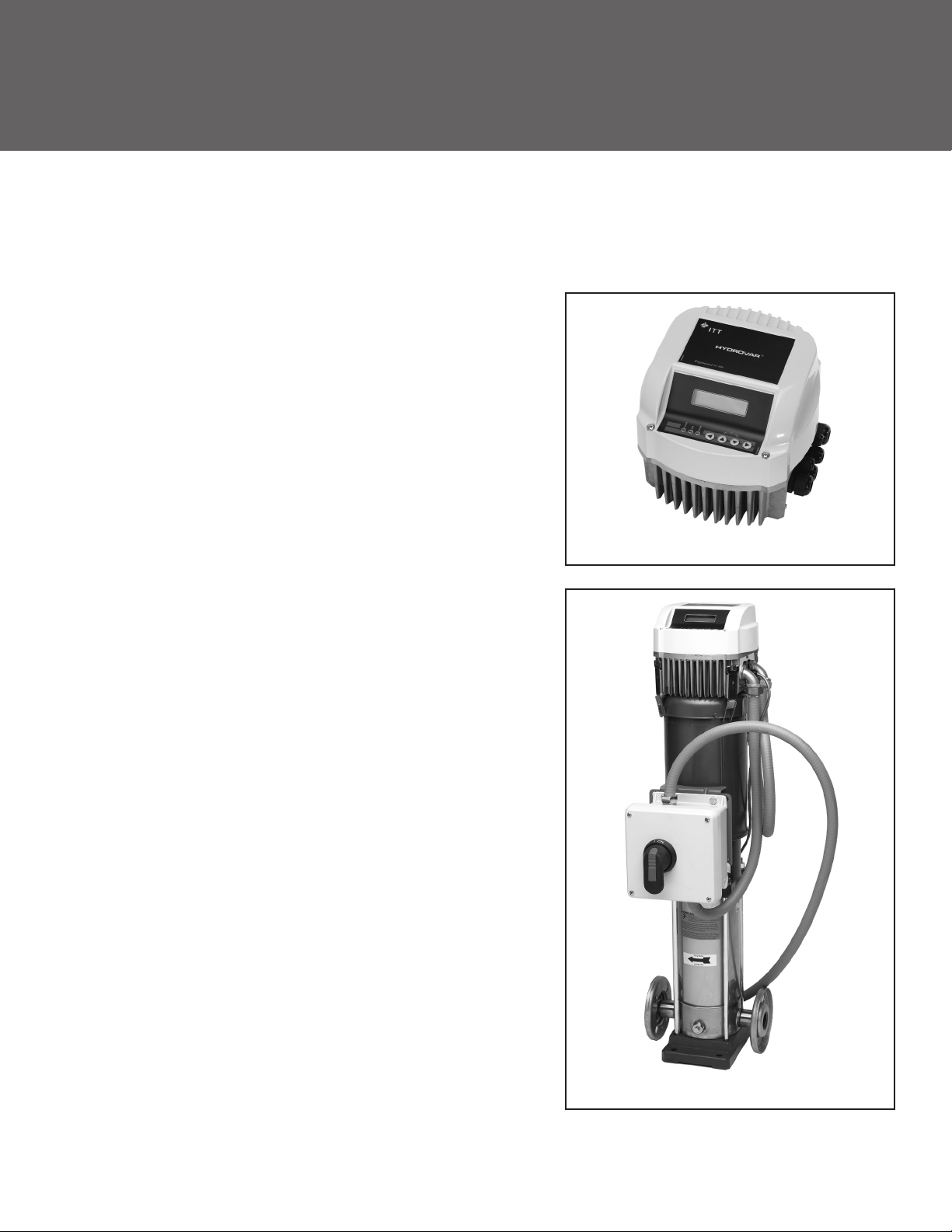

Modular Hydrovar, Bare Unit

A password is required to access sensitive settings that allow you

to program the Hydrovar in order to adapt it to any control

requirements, such as flow resistance compensation, external

control, periodic testing and so on. When more than one pump is

used, the converters exchange information with each other through an

RS485 serial line which can connect up to 8 Hydrovar devices plus

one external unit for remote control. The Pump-link and Pump-watcher

dedicated systems, connected to the Hydrovar®, enable remote

control through a traditional telephone line or mobile telephony. A

serial port available as standard up to 15 HP allows you to control the

Hydrovar® converters from a Modbus® field serial bus line.

The converter is equipped with two potential-free relays which can

be used for remote signalling of pump running and malfunction

status, plus a programmable voltage analogue output for signalling

the frequency or pressure. Standard version with two sensor inputs

for implementing of two actual values signals within one system (min/

max, difference) or for a second sensor for safety reasons. Specific

digital inputs are used for protection against water failure, motor

overtemperature, as well as for external enable signal and remote

control. The converter also incorporates a dry running protection

function via an adjustable minimum pressure threshold.

FCC Class A filter standard for Hydrovar three-phase power supply.

E.g. Industrial areas, technical areas of any building fed from a

dedicated transformer are examples of environment locations.

PHV Series Hydrovar with SSV Pump

FCC Class B filter standard for Hydrovar single-phase power supply.

E.g. Houses, apartments, commercial premises or offices in a residential building are examples of environment locations.

Further information is available in the Hydrovar manual.

9

Page 10

Goulds Pumps

PHV - Packaged Hydrovar Series

CHARACTERISTICS OF THE ELECTRIC PUMPS USED IN PHV SERIES

BOOSTER PACKAGE

1, 2, 3 AND 4 SSV VERTICAL MULTI-STAGE PUMPS

• Multistage centrifugal vertical electric pumps. All metal

parts in contact with pumped liquid are made of

304/316 stainless steel.

• A version: round anges, in-line discharge and suction

ports, AISI 304

• B version: ANSI anges, in-line discharge and suction

ports, AISI 316

SV33 AND 46 MULTI-STAGE PUMPS

• Vertical multistage centrifugal pump with impellers,

diffusers and outer sleeve made entirely of stainless steel,

and with pump casing and upper head made of cast

iron in the standard version.

• High hydraulic efciency for signicant energy savings.

• Innovative axial load compensation system on pumps

with higher head. This ensures reduced axial thrusts and

enables the use of standard motors that are easily found

on the market.

• Reduced axial thrusts enable the use of standard

motors that are easily found on the market.

• Standard Baldor, NEMA motors

• Easy maintenance. No special tools required for assembly

or disassembly.

• ANSI/NSF 61 certified by CSA for potable

drinking water.

• Standard NEMA Baldor® motors.

• Mechanical seal can easily be replaced without

disassembling the motor from the pump.

• Mechanical sturdiness and easy maintenance. No special

tools required for assembly or disassembly.

• ANSI/NSF 61 certified by CSA for potable

drinking water.

REFERENCE STANDARDS

• cUL Listed as pumping packaged unit, 42UC

• VFD (Hydrovar) UL recognized

• Baldor motor UL recognized

• Pumps meet ANSI/NSF 61 certification by CSA for potable drinking water

• Pumps meet ANSI/UL778 standards

• Control/disconnect meet UL508A standards

10

Page 11

HYDROVAR VERSIONS

INTRODUCTION

The HYDROVAR Concept consists mechanically of two main parts, the Power Unit and the

Control Card. In its basic configuration (consists only of the Power Unit) the HYDROVAR can be used as a

“Basic Inverter” without the need of the Control Card. In that form the HYDROVAR can be used as a sequence pump in

a multi pump system, with at least one master inverter.

By extending this “Basic Inverter” with the additional Control Card and LCD display, the HYDROVAR “Master Unit” is able

to work in different modes and can be extended by the implementation of different modules.

STANDARD OPTIONAL FEATURES VERSIONS

CASCADE SERIAL (MASTER + BASIC)

In this mode there are various possibilities to combine the different versions of the HYDROVAR.

In general, each of the pumps is equipped with a HYDROVAR unit. Each pump of the system (extended up to 8 pumps) is

equipped with a HYDROVAR unit (at least one “Master Inverter” and the others can be

“Basic Inverters” in order to ensure a proper control of the system) which are connected via the serial interface.

Minimum requirement: One “Master Inverter” and the others equipped with “Basic Inverters”.

The whole control is performed via the “Master Inverter” every time, but also an automatic change over of the lag pumps

to achieve even operating hours is possible.

Following versions are available:

• Power size 3 HP up to 15 HP motor mounted single phase and/or three phase power supply.

- PHV: one pump with wiring, fused disconnect, master Hydrovar drive, transducer, conduit.

11

Page 12

Goulds Pumps

PHV - Packaged Hydrovar Series

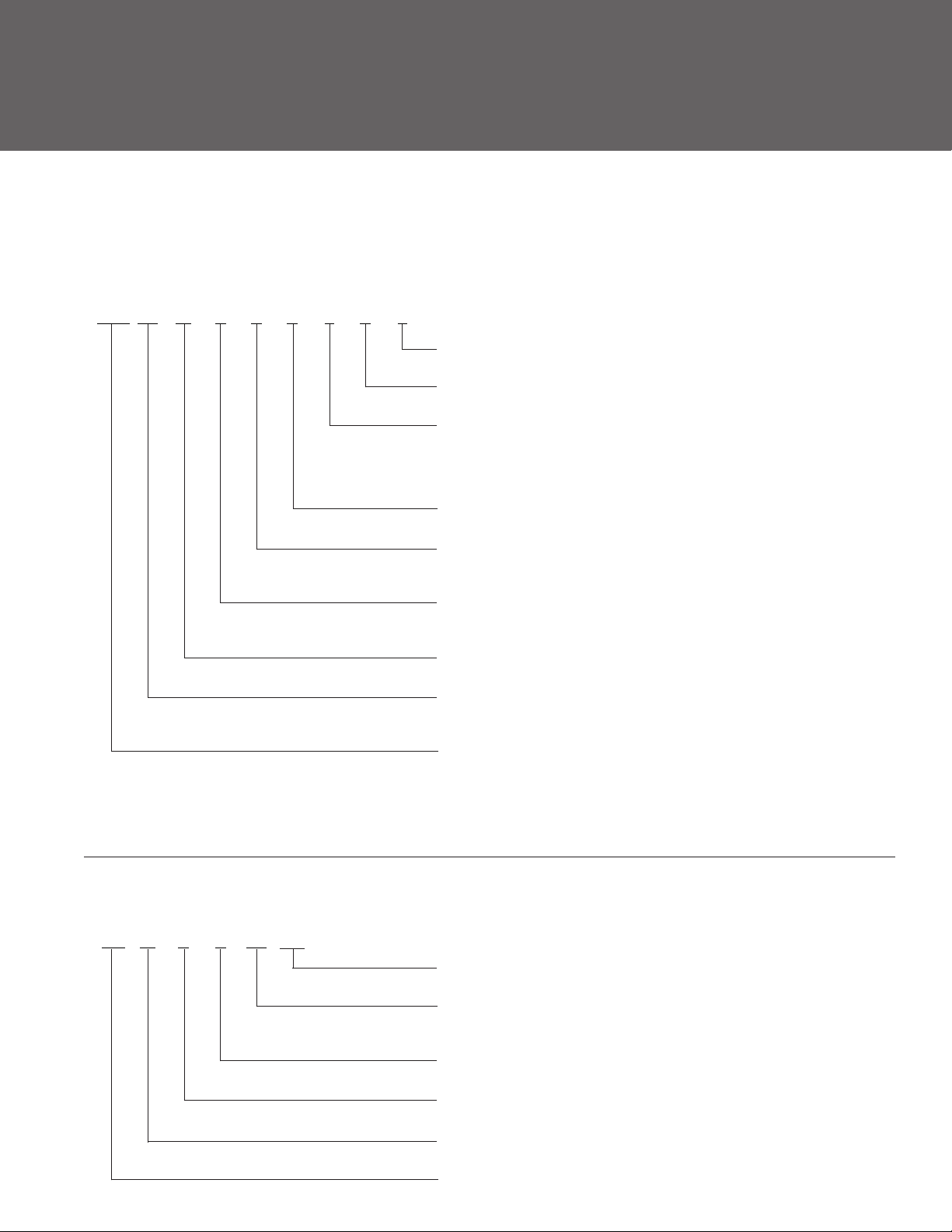

APPLICATION EXAMPLE – MULTI-PUMP “CASCADE”

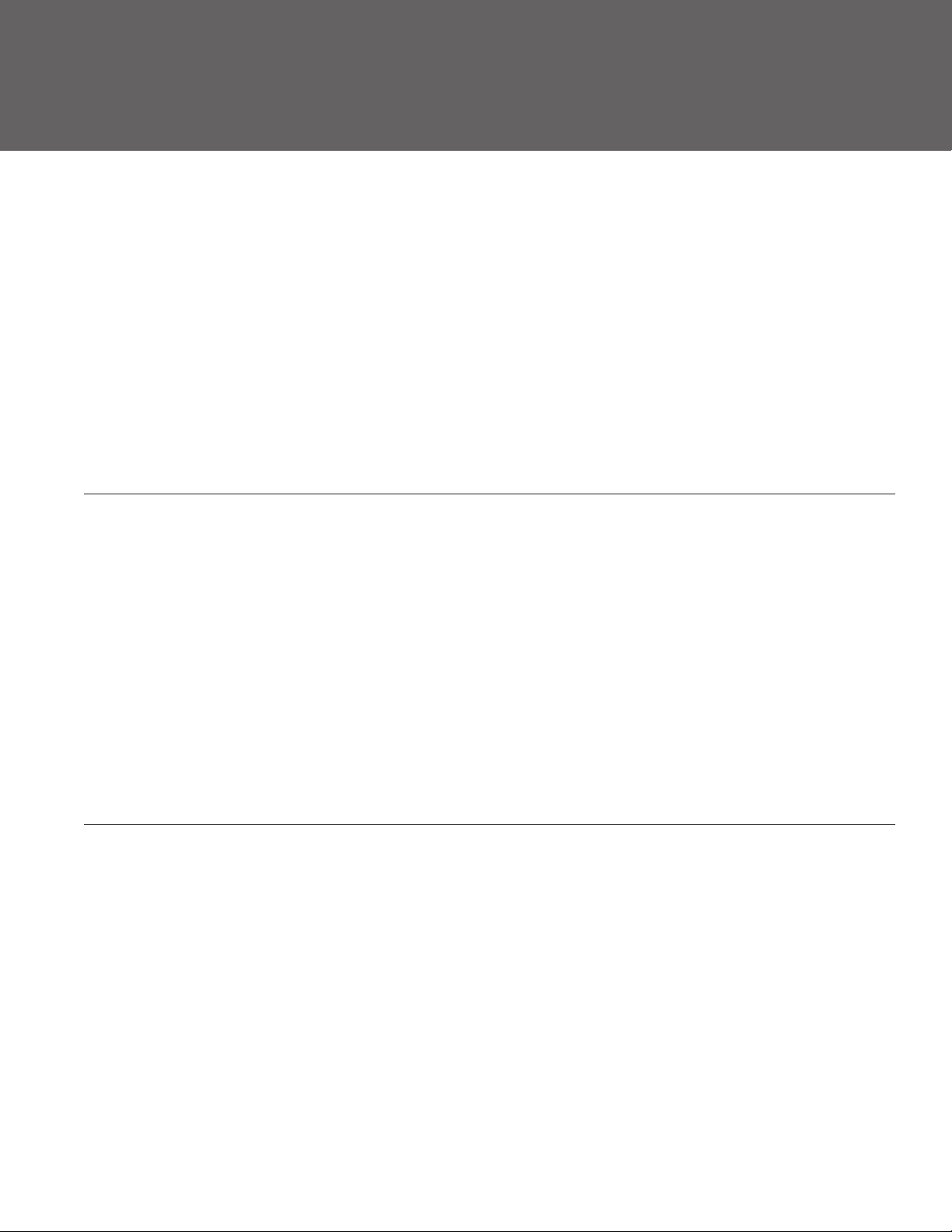

MASTER

INVERTER

RS 485

CONNECTION

MASTER

INVERTER

MASTER

INVERTER

MASTER

INVERTER

With the “master” version of the Hyrdrovar, it is possible to connect up to 8 Hydrovar controller pumps together in

parallel. Complete lead/lag and auto alternation.

MASTER

INVERTER

RS 485

CONNECTION

BASIC

INVERTER

BASIC

INVERTER

BASIC

INVERTER

Reduction of overall cost for multi-pump system is possible using one “master” controller and several “basic” controllers. The Hydrovar “master” will still control lead/lag, alternation.

12

Page 13

OPERATION DESCRIPTION

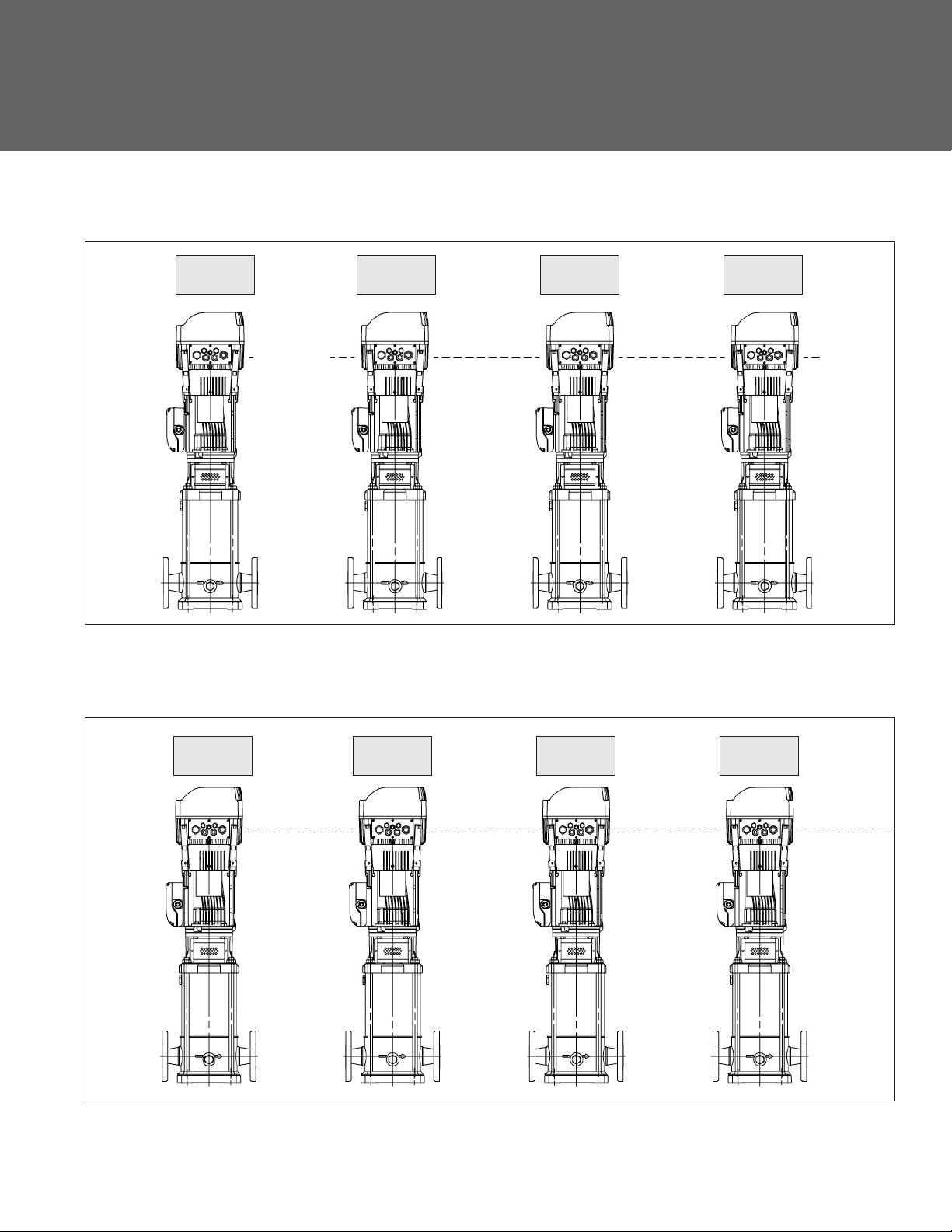

SETS WITH VARIABLE-SPEED MOTORS AND PRESSURE TRANSDUCER CONTROL

The starting and stopping of the pumps are determined based on the pressure values set on the controller.

Each frequency converter is connected to a pressure transducer.

The controllers exchange information with each other and provide for cyclic changeover.

The figure shows the operating mode of a two-pump booster set

(Typical Field Set).

• On demand, water is drawn from the tank.

• When the pressure drops belows the PS setting the first pump

starts and the speed is adjusted to maintain a costant pressure as

demand increases.

• If the water consumption increases and the pump reaches

maximum speed, the second pump starts and the speed is adjusted

to maintain constant pressure.

• When demand decreases, the speed is reduced until minimum

speed is reached and one of the pumps are switched off.

• If consumption keeps decreasing the pump slows down, fills the

tank and stops at the pressure setting.

Pressure

Pmax

PS

Figure 3

Duplex

OPERATING CHARACTERISTICS AND LIMITS

Type of pumped liquids Water containing no gas or corrosive and/or aggressive substances

Fluid temperature Above 0° F to 180° F, Pressure transducer limited

Ambient temperature Above 0° F to 104° F, VFD/Display, keep away from direct sun

Maximum operating pressure 360 PSI (Pump without transducer)

Minimum inlet pressure According to NPSH curve and losses, with a minimum margin of 0.5 m

Maximum inlet pressure

than the maximum operating pressure of the set (suction and discharge).

Installation

elevation 3300 feet ASL. Maximum humidity 50% without condensation.

Hourly starts

hour. Variable speed drive starts.

Indoors/outdoors, protected from the direct sun. Away from heat sources. Maximum

Maximum 60 up to 10 HP. Above 10 HP and up to 50 HP, maximum 40 starts per

Sound emission See table

* Note: For higher temperature it is necessary to use special materials (only on request).

The inlet pressure added to the pressure of the pump at zero flow must be lower

Flow

NOISE EMISSION LEVELS

60 Hz 3500 RPM LpA (dB ±4)

HP NEMA Motor Frame PHV

1 56 < 70

2 56 < 70

3 56 < 70

5 145 < 70

7½ 182-184 < 70

10 215 < 70

15 254 73

20 256 75

25 284 75

30 284 75

* Note: Adjusted from 50 Hz data, may vary.

13

Page 14

Goulds Pumps

PHV - Packaged Hydrovar Series

SELECTING A SET

The first thing to do when selecting a package is to determine the quantity of water required and the pressure it must

supply.

CALCULATING THE FLOW RATE

• The quantity of water called water requirement depends on the type of users, e.g. homes, offices, schools, as well

as their number. The theoretic requirement is the total amount of water required by all the users. In actual fact, since it

is very unlikely that there should be a simultaneous demand by all the users, the real requirement is lower than the

theoretic one.

CALCULATING THE HEAD

• The pressure required depends on the type of user. A number of factors must be taken into account, including the

height of the building, the suction conditions and the flow resistance in the pipes.

SELECTING A BOOSTER SET

• According to the required flow rate and head values, it is possible to identify the most suitable type of electric pump.

On two-pump sets the pumps normally act as back-up for one another. A single pump is normally sufficient to

provide for average requirements, while in conditions of high demand the back up pump may be called in to assist.

With the cyclic changeover function duty assignment is rotated to ensure both pumps remain active and with

even running hours, so wear is uniform and the use factor is reduced for longer pump life. This system also ensures

continuity of operation in case one of the pumps needs maintenance.The Hydrovar provides automatic lead/lag,

alternation when programmed in multi-control and wired via RS485 communication terminals.

TANK

• Frequent demand or small system losses determine pressure variations that may be compensated for by using a

tank. Correct selection of a diaphragm tank reduces the number of pump starts and, if it is installed near the

booster set, helps reduce the effect of water hammer, or fast acting flush valves.

The booster sets are ready for installation of diaphragm tanks directly on the delivery manifold, and additional tanks

can be connected to the unused end of the manifold.

For peak performance, variable speed booster sets need smaller tanks compared to traditional systems.

Generally speaking, a tank with a capacity of just 20% of the nominal capacity of a single pump, expressed in gallons

per minute, is required. Example: If my pump is sized for 100 GPM, then we would size a 20 gallon (total capacity)

diaphragm tank.

• Pre-charge the tank with air, 10-15 PSI below your system pressure. Charge dry tank without water pressure or before

installing in system.

14

Page 15

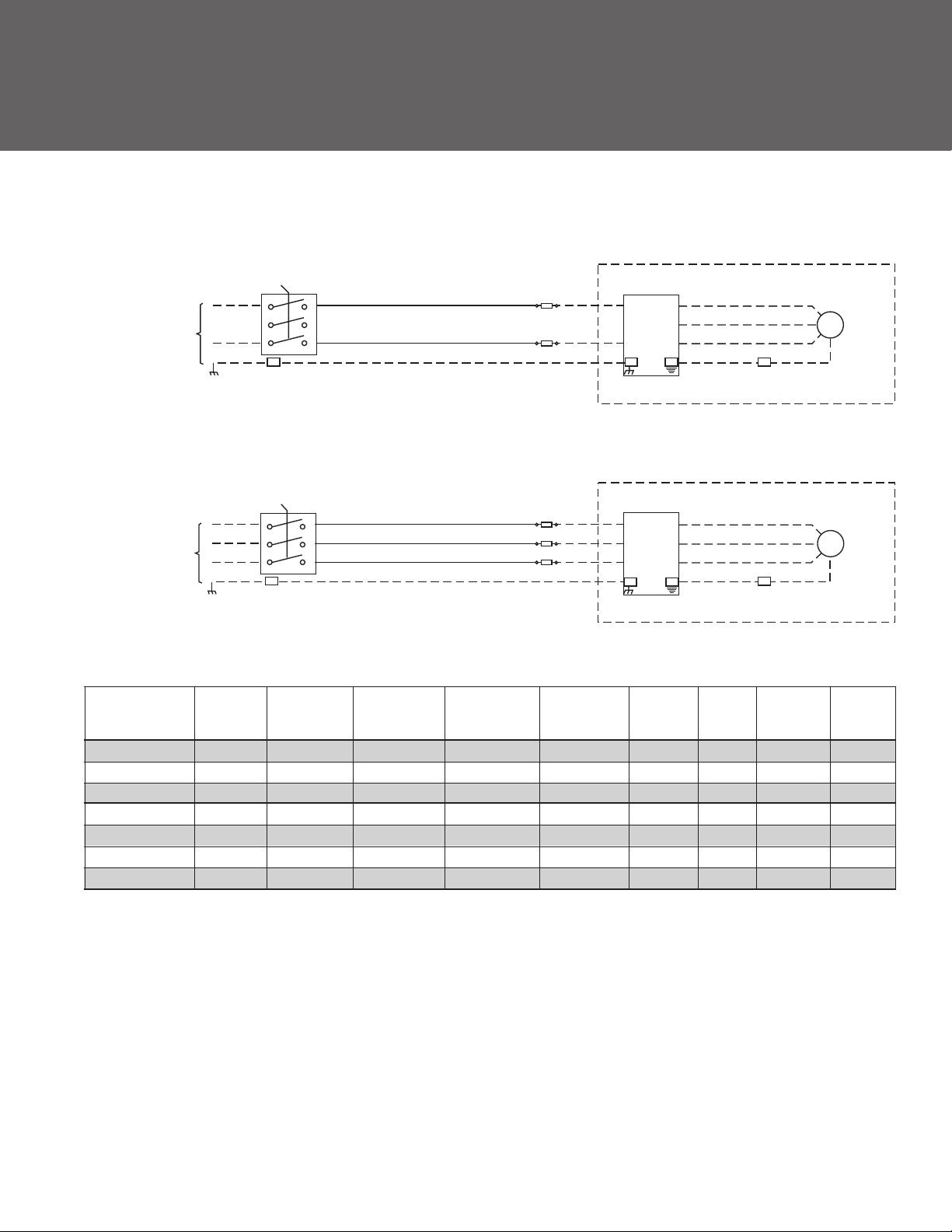

FUSED DISCONNECT BOX:

CUSTOMER SUPPLIED

HYDROVAR

U1

U2

V1

V2

W1

W2

16 AWG

GND

PE

CUSTOMER SUPPLIED

HYDROVAR

U1

U2

V1

V2

W1

W2

16 AWG

GND

PE

MTR

MOTOR

GND

MTR

MOTOR

GND

SINGLE

PHASE

CUSTOMER SUPPLIED

VOLTAGE

THREE

PHASE

CUSTOMER SUPPLIED

VOLTAGE

ITT

Disconnect

Part Number

L1

L2

L1

L2

L3

Input

Voltage

DISCONNECT

1

3

5

DISCONNECT

1

3

5

2

4

6

GND

2

4

6

GND

Disconnect

FUSE BLOCK

12 AWG

12 AWG

FUSE BLOCK

12 AWG

12 AWG

12 AWG

HP / AMP Wire Tightening Fuse AMP Part Voltage

Rating Range Torque Supplier Rating Number Rating

HFD512C1 230/1/60 OT25F3 2 HP / 25A #18-8AWG 7 IN/LB Bussman 20 KTK-R-20 600V

HFD512E1 230/1/60 OT40F3 3 HP / 40A #18-8AWG 7 IN/LB Bussman 30 KTK-R-30 600V

HFD534A1 460/3/60 OT16F3 3 HP / 16A #18-8AWG 7 IN/LB Bussman 10 KTK-R-10 600V

HFD534B1 460/3/60 OT16F3 3 HP / 16A #18-8AWG 7 IN/LB Bussman 15 KTK-R-15 600V

HFD534C1 460/3/60 OT25F3 3 HP / 25A #18-8AWG 7 IN/LB Bussman 20 KTK-R-20 600V

HFD534C2 460/3/60 OT25F3 3 HP / 25A #18-8AWG 7 IN/LB Bussman 20 KTK-R-20 600V

HFD534E2 460/3/60 OT40F3 3 HP / 40A #18-8AWG 7 IN/LB Bussman 30 KTK-R-30 600V

NOTE: Recommended protection (not included with drive only). This fused disconnect is available as part of the PHV series packaged Hydrovar, see price book.

15

Page 16

Goulds Pumps

PHV - Packaged Hydrovar Series

SPECIFICATIONS

Hydrovar VFD Motor

HP Model * Power Supply (V) NEMA Class Install. Power Supply (V) HP

2 HVM1202 1x230 4 TEFC Motor 3x230 2

3 HVM1203 1x230 4 TEFC Motor 3x230 3

3 HVM3403 3x460 4 TEFC Motor 3x460 3

5 HVM3405 3x460 4 TEFC Motor 3x460 5

7½ HVM3407 3x460 4 TEFC Motor 3x460 7½

10 HVM3410 3x460 4 TEFC Motor 3x460 10

15 HVM3415 3x460 4 TEFC Motor 3x460 15

* The new Hydrovar is available single-phase up to 3 HP and 3 HP through 15 HP, 460 volt.

ELECTRICAL PANELS - PHV (Packaged Hydrovar

The GHV sets come with a fused disconnect on which are installed automatic line protection fast acting fuses for

each drive. Class J, 600 volt.

Single-pump sets are supplied as standard with an electrical panel encased in NEMA 4X enclosure, with 2-pole or 3-pole (3

phase) up to 30 amps and featuring a main switch.

The fused disconnect is rated for UL508A.

®

Series)

16

Pump Disconnect Switch

Page 17

MOTOR DATA

3500 RPM, 60 Hz

HP Phase Enclosure

Voltage Frame PN ¹ Class

1

Prem. Eff. TEFC 230/460 56C V06742PE 2.8/1.4 3.12/1.56 12.1 1.25 84.5 B

1½ 3

Prem. Eff. TEFC 230/460 56C V07742PE 4.0/2.0 4.5/2.25 20.1 1.15 85.5 B

2* 3

Prem. Eff. TEFC 208-230/460 56C V08742PE 5/4.75-2.5 6.4-5.8/2.9 30 1.15 86.5 B

3*

Prem. Eff. TEFC 208-230/460 184TC V09742PE 6.8/3.4 8.5-7.7/3.8 32 1.15 88.5 F

5*

Prem. Eff. TEFC 208-230/460 184TC V10742APE 11.2/5.7 14.4-13/6.5 55 1.15 90.2 F

7½* 3

Prem. Eff. TEFC 230/460 213TC V11742APE 17.8/8.9 20.2/10.1 75 1.15 90.2 F

10*

Prem. Eff. TEFC 230/460 215TC V12742PE 23.8/11.9 27.6/13.8 112 1.15 89.5 F

15*

Prem. Eff. TEFC 208-230/460 254TC V13742PE 34.4/17.2 43.8-39.6/19.8 112 1.15 91.7 F

20 3

Prem. Eff. TEFC 208-230/460 256TC V14742PE 46/23 57.5-52/26 201 1.15 92.4 F

25 3

Prem. Eff. TEFC 230/460 284TC V15742PE 56/28 69.9-63.2/31.6 236 1.15 93 F

30 3

Prem. Eff. TEFC 230/460 286TC V16742PE 66/33 83.8-75.8/37.9 281 1.15 93 F

40 3

Prem. Eff. TEFC 230/460 324TSC V17742PE 90/45 102.2/51.1 286 1.15 93.6 F

50 3

Prem. Eff. TEFC 230/460 326TSC V18742SPE 108/54 124.8/62.4 422 1.15 94.1 F

NOTES:

¹ Locked rotor amps are for high voltage only.

* Currently available on Packaged Hydrovar.

• Motors are suitable for AQUAVAR® Variable Speed Drive.

Above data is for Baldor® TC and TSC frame motors. Specications subject to change without notice.

TEFC 230/460 56C V06742 3.7-3.6/1.8 3.99-3.8/1.9 11 1.25 75.5 B

3

TEFC 230/460 56C V07742 4.9-4.6/2.3 5.3-5.1/2.54 18.4 1.15 80 B

TEFC 208-230/460 56C V08742 6.2-5.8/2.9 7.2-6.52/3.26 22 1.15 80 B

TEFC 208-230/460 56C V09742 8.1-7.6/3.8 9.5-8.6/4.3 32.9 1.15 82.5 F

3

TEFC 208-230/460 184TC V10742A 13.2-12/6 15-13.6/6.8 47 1.15 85.5 F

3

TEFC 208-230/460 184TC V11742A 18.5/17.4 21.7-19.6/9.8 94 1.15 88.5 F

TEFC 208-230/460 215TC V12742 25-24/12 30.5-27.6/13.8 105 1.15 85.5 F

3

TEFC 208-230/460 254TC V13742 35/17.5 43-39/19.5 165 1.15 86.5 F

3

TEFC 208-230/460 256TC V14742 46/23 59.3-53.6/26.8 160 1.15 89.5 F

TEFC 230/460 284TC V15742 59/29.5 74.8-67.6/33.8 182 1.15 88.5 F

TEFC 230/460 284TC V16742 68/34 86.7-78.4/39.2 225 1.15 91 F

TEFC 230/460 284TC V17742 90/45 103.2/51.6 322 1.15 90.2 F

TEFC 230/460 326TSC V18742S 112/56

Nameplate NEMA Goulds

FLA SFA

141.8-128.2/64.1

LRA

430 1.15 92.4 F

S.F. Efficiency

Insulation

17

Page 18

Goulds Pumps

PHV - Packaged Hydrovar Series

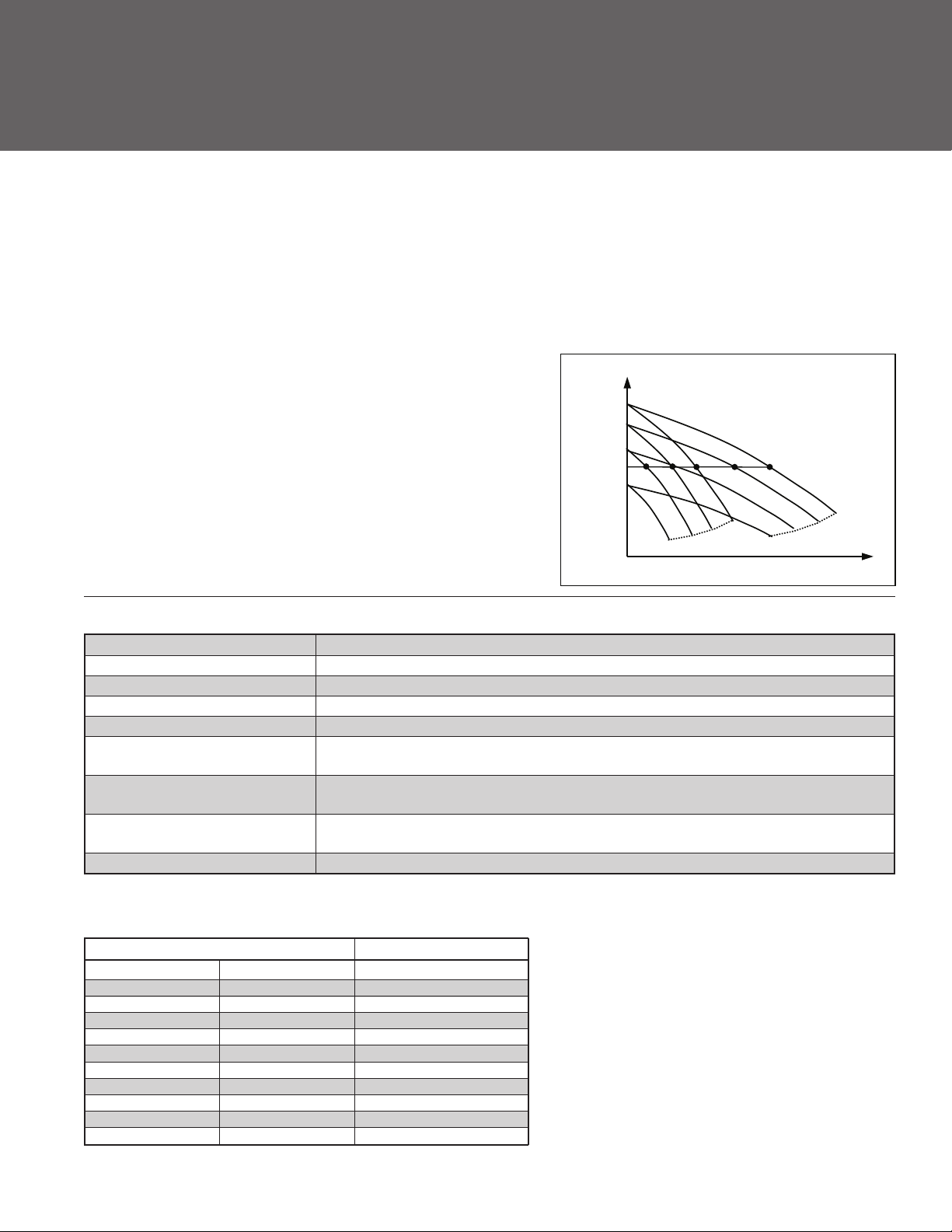

PERFORMANCE WITH VARYING SPEED FOR CENTRIFUGAL PUMPS

Fitting the electric pump with a variable speed drive makes it possible to vary the pump rotation speed, normally according to the system pressure parameter. Variations in electric pump speed result in modified performances

according to the equivalence relations, called affinity laws.

Head

Flow Rate

Q1=n1

Q2 n2

H

n1

H1

n2

Head

H1=n1

2

H2 n2

H2

B

A

P1=n1

3

Power

n1 = initial speed; n2= speed required.

Q1 = initial flow rate; Q2= flow rate required.

H1 = initial head; H2= head required.

P1 = initial power; P2= power required

Frequency ratios can be used instead of speed in practical applications, keeping 30 Hz as the bottom limit.

Example : 2-pole 50 Hz electric pump n1 =2900 (point A)

Flow rate (A) = 100 l/min; Head (A) = 50m

By reducing the frequency to 30 Hz the speed is reduced to approx. n2 = 1740 rpm (point B)

Flow rate (B) = 60 l/min; Head (B) = 18 m

The power of the new work point B is cut to about 22% of the initial power.

P2 n2

Q1Q2

Q

Flow

SIZING THE DIAPHRAGM TANK IN SYSTEMS WITH SPEED VARIATION

Variable speed booster sets need smaller tanks compared to traditional systems. Generally speaking, a tank with a

capacity of just 20% of the nominal capacity of a single pump, expressed in gallons per minute, is needed. The gradual

starting of the pumps controlled by the drive reduces the need to limit the number of hourly starts; the main purpose

of the tank is to compensate for small system losses, stabilize the pressure and make up for pressure variations caused by

sudden demand (fast acting valves).

Make the following calculation:

Set made up of three electric pumps, each with a maximum flow rate of 100 GPM, for a total capacity of 300 GPM. The

volume required for the tank is 20 gallons. This is total capacity, not drawdown. Mount downstream of the check valves

in discharge manifold.

18

Page 19

VARIABLE SPEED PERFORMANCE CURVES

1SV VARIABLE SPEED CURVE

SSVB 304SS Multi-Stage Pumps MODEL: 1SVB 6 Stage

Hydraulic Data

Maximum Flow Flow at Duty Point Maximum TDH TDH at Duty Point NPSH

22 US GPM 298 feet

Fluid: Water, pure Duty Chart: 3500 RPM

[FT]

Head

300

280

260

240

220

200

180

160

140

120

100

[FT]

[HP]

1.6

1.4

1.2

0.8

0.6

0.4

0.2

6

80

60

40

20

0

NPSH - values

7

6

5

4

3

2

1

0

Shaft power P2

6 (P2)

1

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 [US GPM]

Application Range

60 Hz

50 Hz

40 Hz

30 Hz

60 Hz

50 Hz

40 Hz

30 Hz

50 Hz

40 Hz

30 Hz

R

60 Hz

19

Page 20

Goulds Pumps

PHV - Packaged Hydrovar Series

VARIABLE SPEED PERFORMANCE CURVES

1SV VARIABLE SPEED CURVE

SSVB 304SS Multi-Stage Pumps MODEL: 1SVB 9 Stage

Hydraulic Data

Maximum Flow Flow at Duty Point Maximum TDH TDH at Duty Point NPSH

22 US GPM 442 feet

Fluid: Water, pure Duty Chart: 3500 RPM

[FT]

440

400

Head

9

Application Range

R

360

320

280

240

200

160

120

80

40

0

NPSH - values

[FT]

7

6

5

4

3

2

1

0

Shaft power P2

[HP]

2.4

2

1.6

1.2

0.8

0.4

9 (P2)

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 [US GPM]

44.5%

44.5%

44.5%

30 Hz

30 Hz

44.5%

60 Hz

50 Hz

40 Hz

60 Hz

50 Hz

40 Hz

60 Hz

50 Hz

40 Hz

30 Hz

20

Page 21

VARIABLE SPEED PERFORMANCE CURVES

1SV VARIABLE SPEED CURVE

SSVB 304SS Multi-Stage Pumps MODEL: 1SVB 15 Stage

Hydraulic Data

Maximum Flow Flow at Duty Point Maximum TDH TDH at Duty Point NPSH

22 US GPM 733 feet

Fluid: Water, pure Duty Chart: 3500 RPM

[FT]

Head

760

720

680

640

600

560

520

480

440

400

360

320

280

240

200

160

120

[FT]

[HP]

3.5

2.5

1.5

0.5

15

44.5%

80

40

0

NPSH - values

7

6

5

4

3

2

1

0

Shaft power P2

4

3

15 (P2)

2

1

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 [US GPM]

44.5%

Application Range

44.5%

44.5%

60 Hz

50 Hz

40 Hz

30 Hz

60 Hz

50 Hz

40 Hz

30 Hz

50 Hz

40 Hz

30 Hz

R

60 Hz

21

Page 22

Goulds Pumps

PHV - Packaged Hydrovar Series

VARIABLE SPEED PERFORMANCE CURVES

2SV VARIABLE SPEED CURVE

SSVB 304SS Multi-Stage Pumps MODEL: 2SVB 5 Stage

Hydraulic Data

Maximum Flow Flow at Duty Point Maximum TDH TDH at Duty Point NPSH

40 US GPM 217 feet

Fluid: Water, pure Duty Chart: 3500 RPM

Head

[FT]

220

210

200

190

180

170

160

150

140

130

120

110

100

90

80

70

60

50

40

30

20

10

0

NPSH - values

[FT]

10

8

6

5

57.1%

Application Range

57.1%

30 Hz

57.1%

57.1%

60 Hz

50 Hz

40 Hz

60 Hz

50 Hz

40 Hz

R

4

2

0

Shaft power P2

[HP]

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

0

5 (P2)

0 2 4 6 8 10 12 14 16 18 20 22 24 [US GPM]

30 Hz

60 Hz

50 Hz

40 Hz

30 Hz

26 28 30 32 34 36 38 40 42

22

Page 23

VARIABLE SPEED PERFORMANCE CURVES

2SV VARIABLE SPEED CURVE

SSVB 304SS Multi-Stage Pumps MODEL: 2SVB 8 Stage

Hydraulic Data

Maximum Flow Flow at Duty Point Maximum TDH TDH at Duty Point NPSH

40 US GPM 353 feet

Fluid: Water, pure Duty Chart: 3500 RPM

[FT]

Head

360

340

320

300

280

260

240

220

200

180

160

140

120

100

80

60

40

20

0

NPSH - values

[FT]

10

8

6

8

57.1%

Application Range

57.1%

30 Hz

57.1%

57.1%

60 Hz

50 Hz

40 Hz

60 Hz

50 Hz

40 Hz

R

4

2

0

Shaft power P2

[HP]

2.4

2

1.6

1.2

0.8

0.4

0

5 (P2)

0 2 4 6 8 10 12 14 16 18 20 22 24 [US GPM]

30 Hz

60 Hz

50 Hz

40 Hz

30 Hz

26 28 30 32 34 36 38 40 42

23

Page 24

Goulds Pumps

PHV - Packaged Hydrovar Series

VARIABLE SPEED PERFORMANCE CURVES

2SV VARIABLE SPEED CURVE

SSVB 304SS Multi-Stage Pumps MODEL: 2SVB 13 Stage

Hydraulic Data

Maximum Flow Flow at Duty Point Maximum TDH TDH at Duty Point NPSH

40 US GPM 586 feet

Fluid: Water, pure Duty Chart: 3500 RPM

[FT]

Head

600

560

520

480

440

400

360

320

280

240

200

160

120

80

40

0

NPSH - values

[FT]

10

8

6

4

2

13

57.1%

Application Range

57.1%

30 Hz

30 Hz

57.1%

57.1%

60 Hz

50 Hz

40 Hz

60 Hz

50 Hz

40 Hz

R

0

[HP]

Shaft power P2

4.5

4

3.5

3

2.5

2

1.5

0.5

13 (P2)

1

30 Hz

0

0 2 4 6 8 10 12 14 16 18 20 22 24 [US GPM]

24

40 Hz

26 28 30 32 34 36 38 40 42

50 Hz

60 Hz

Page 25

VARIABLE SPEED PERFORMANCE CURVES

3SV VARIABLE SPEED CURVE

SSVB 304SS Multi-Stage Pumps MODEL: 3SVB 7 Stage

Hydraulic Data

Maximum Flow Flow at Duty Point Maximum TDH TDH at Duty Point NPSH

78 US GPM 441 feet

Fluid: Water, pure Duty Chart: 3500 RPM

[FT]

440

400

360

320

280

240

200

Head

7

Application Range

60 Hz

R

160

120

80

40

0

NPSH - values

[FT]

12

10

8

6

4

2

0

[HP]

Shaft power P2

7

6

5

4

3

2

1

0

0 4 8 12 16 20 24 [US GPM]

7 (P2)

28 32 36 40

30 Hz

30 Hz

44 48 52 56 60 64 68 72 76 80 84

40 Hz

40 Hz

50 Hz

60 Hz

50 Hz

30 Hz

60 Hz

50 Hz

40 Hz

25

Page 26

Goulds Pumps

PHV - Packaged Hydrovar Series

VARIABLE SPEED PERFORMANCE CURVES

3SV VARIABLE SPEED CURVE

SSVB 304SS Multi-Stage Pumps MODEL: 3SVB 9 Stage

Hydraulic Data

Maximum Flow Flow at Duty Point Maximum TDH TDH at Duty Point NPSH

78 US GPM 565 feet

Fluid: Water, pure Duty Chart: 3500 RPM

Head

[FT]

560

520

480

440

400

360

320

280

240

200

160

120

[FT]

[HP]

9

80

40

0

NPSH - values

12

10

8

6

4

2

0

Shaft power P2

9

8

7

6

5

4

3

2

1

0

0 4 8 12 16 20 24 [US GPM]

9 (P2)

28 32 36 40

Application Range

60 Hz

50 Hz

40 Hz

30 Hz

60 Hz

50 Hz

40 Hz

30 Hz

30 Hz

44 48 52 56 60 64 68 72 76 80 84

R

60 Hz

50 Hz

40 Hz

26

Page 27

VARIABLE SPEED PERFORMANCE CURVES

3SV VARIABLE SPEED CURVE

SSVB 304SS Multi-Stage Pumps MODEL: 3SVB 13 Stage

Hydraulic Data

Maximum Flow Flow at Duty Point Maximum TDH TDH at Duty Point NPSH

78 US GPM 817 feet

Fluid: Water, pure Duty Chart: 3500 RPM

Head

[FT]

800

750

700

650

600

550

500

450

400

350

300

250

200

150

100

[FT]

[HP]

13

50

0

NPSH - values

12

10

8

6

4

2

0

Shaft power P2

12

10

8

6

4

2

0

0 4 8 12 16 20 24 [US GPM]

13 (P2)

28 32 36 40

Application Range

60 Hz

50 Hz

40 Hz

30 Hz

60 Hz

50 Hz

40 Hz

30 Hz

30 Hz

44 48 52 56 60 64 68 72 76 80 84

R

60 Hz

50 Hz

40 Hz

27

Page 28

Goulds Pumps

PHV - Packaged Hydrovar Series

VARIABLE SPEED PERFORMANCE CURVES

4SV VARIABLE SPEED CURVE

SSVB 304SS Multi-Stage Pumps MODEL: 4SVB 2 Stage

Hydraulic Data

Maximum Flow Flow at Duty Point Maximum TDH TDH at Duty Point NPSH

112 US GPM 148 feet

Fluid: Water, pure Duty Chart: 3500 RPM

Head

[FT]

150

140

130

120

110

100

[FT]

[HP]

4.5

3.5

2.5

1.5

0.5

2

90

80

70

60

50

40

30

20

10

0

NPSH - values

14

12

10

8

6

4

2

0

-2

Shaft power P2

4

3

2

1

0

2 (P2)

0 10 20 30 40 50 [US GPM]

Application Range

30 Hz

30 Hz

60 70 80 90

50 Hz

40 Hz

50 Hz

40 Hz

30 Hz

100 110

R

60 Hz

60 Hz

60 Hz

50 Hz

40 Hz

28

Page 29

VARIABLE SPEED PERFORMANCE CURVES

4SV VARIABLE SPEED CURVE

SSVB 304SS Multi-Stage Pumps MODEL: 4SVB 4 Stage

Hydraulic Data

Maximum Flow Flow at Duty Point Maximum TDH TDH at Duty Point NPSH

112 US GPM 299 feet

Fluid: Water, pure Duty Chart: 3500 RPM

Head

[FT]

300

280

260

240

220

200

180

160

140

120

100

[FT]

[HP]

4

80

60

40

20

0

NPSH - values

14

12

10

8

6

4

2

0

-2

Shaft power P2

8

7

6

5

4

3

2

1

0

4 (P2)

0 10 20 30 40 50 [US GPM]

Application Range

30 Hz

30 Hz

60 70 80 90

60 Hz

50 Hz

40 Hz

50 Hz

40 Hz

30 Hz

100 110

R

60 Hz

60 Hz

50 Hz

40 Hz

29

Page 30

Goulds Pumps

PHV - Packaged Hydrovar Series

VARIABLE SPEED PERFORMANCE CURVES

4SV VARIABLE SPEED CURVE

SSVB 304SS Multi-Stage Pumps MODEL: 4SVB 7 Stage

Hydraulic Data

Maximum Flow Flow at Duty Point Maximum TDH TDH at Duty Point NPSH

111 US GPM 526 feet

Fluid: Water, pure Duty Chart: 3500 RPM

Head

[FT]

520

480

440

400

7

Application Range

R

360

320

280

240

200

160

120

80

40

0

NPSH - values

[FT]

14

12

10

8

6

4

2

0

-2

[HP]

Shaft power P2

14

12

10

8

6

4

2

0

7 (P2)

0 10 20 30 40 50 [US GPM]

30 Hz

30 Hz

60 70 80 90

40 Hz

40 Hz

50 Hz

50 Hz

100 110

60 Hz

60 Hz

30 Hz

1205 15 25 35 45 55 65 75 85 95 105 115

60 Hz

50 Hz

40 Hz

30

Page 31

VARIABLE SPEED PERFORMANCE CURVES

33SV VARIABLE SPEED CURVE

SVB CI/316SS Multi-Stage Pumps MODEL: 33SVB 1/1 Stage

Hydraulic Data

Maximum Flow Flow at Duty Point Maximum TDH TDH at Duty Point NPSH

225 US GPM 83 feet

Fluid: Water, pure Duty Chart: 3500 RPM

[FT]

Head

85

STAGE 1/1

80

75

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0

NPSH - values

[FT]

30

25

20

15

10

5

STAGE 1/1

0

Shaft power P2

[HP]

3.5

3

2.5

2

1.5

0.5

STAGE 1/1 (P2)

1

0

0 20 40 [US GPM]

60 80

Application Range

30 Hz

30 Hz

30 Hz

100

120

60 Hz

50 Hz

40 Hz

60 Hz

50 Hz

40 Hz

60 Hz

50 Hz

40 Hz

140 160 180 200 220

R

31

Page 32

Goulds Pumps

PHV - Packaged Hydrovar Series

VARIABLE SPEED PERFORMANCE CURVES

33SV VARIABLE SPEED CURVE

SVB CI/316SS Multi-Stage Pumps MODEL: 33SVB 1 Stage

Hydraulic Data

Maximum Flow Flow at Duty Point Maximum TDH TDH at Duty Point NPSH

224 US GPM 110 feet

Fluid: Water, pure Duty Chart: 3500 RPM

[FT]

Head

115

110

105

100

[FT]

[HP]

4.5

3.5

2.5

1.5

0.5

STAGE 1

95

90

85

80

75

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0

NPSH - values

30

25

20

15

10

5

STAGE 1

0

Shaft power P2

5

4

3

STAGE 1 (P2)

2

1

0

0 20 40 [US GPM]

76.7%

60 80

Application Range

76.7%

30 Hz

30 Hz

30 Hz

100

120

76.7%

60 Hz

76.7%

50 Hz

40 Hz

60 Hz

50 Hz

40 Hz

60 Hz

50 Hz

40 Hz

140 160 180 200 220

R

32

Page 33

VARIABLE SPEED PERFORMANCE CURVES

33SV VARIABLE SPEED CURVE

SVB CI/316SS Multi-Stage Pumps MODEL: 33SVB 2/1 Stage

Hydraulic Data

Maximum Flow Flow at Duty Point Maximum TDH TDH at Duty Point NPSH

225 US GPM 191 feet

Fluid: Water, pure Duty Chart: 3500 RPM

[FT]

Head

200

190

180

170

160

150

140

130

120

110

100

[FT]

[HP]

STAGE 2/1

90

80

70

60

50

40

30

20

10

0

NPSH - values

30

25

20

15

10

5

STAGE 2/1

0

Shaft power P2

9

8

7

6

5

STAGE 2/1 (P2)

4

3

2

1

0

0 20 40 [US GPM]

76.7%

60 80

76.7%

Application Range

30 Hz

30 Hz

30 Hz

100

120

76.7%

76.7%

50 Hz

40 Hz

50 Hz

40 Hz

50 Hz

40 Hz

140 160 180 200 220

60 Hz

60 Hz

60 Hz

R

33

Page 34

Goulds Pumps

PHV - Packaged Hydrovar Series

VARIABLE SPEED PERFORMANCE CURVES

33SV VARIABLE SPEED CURVE

SVB CI/316SS Multi-Stage Pumps MODEL: 33SVB 3/1 Stage

Hydraulic Data

Maximum Flow Flow at Duty Point Maximum TDH TDH at Duty Point NPSH

225 US GPM 310 feet

Fluid: Water, pure Duty Chart: 3500 RPM

[FT]

Head

320

300

280

260

240

220

200

180

160

140

120

100

[FT]

[HP]

STAGE 3/1

80

60

40

20

0

NPSH - values

30

25

20

15

10

5

STAGE 3/1

0

Shaft power P2

14

12

10

8

STAGE 3/1 (P2)

6

4

2

0

0 20 40 [US GPM]

76.7%

60 80

Application Range

76.7%

30 Hz

30 Hz

30 Hz

100

120

76.7%

76.7%

50 Hz

40 Hz

50 Hz

40 Hz

50 Hz

40 Hz

140 160 180 200 220

60 Hz

60 Hz

60 Hz

R

34

Page 35

VARIABLE SPEED PERFORMANCE CURVES

46SV VARIABLE SPEED CURVE

SVB CI/316SS Multi-Stage Pumps MODEL: 46SVB 1/1 Stage

Hydraulic Data

Maximum Flow Flow at Duty Point Maximum TDH TDH at Duty Point NPSH

319 US GPM 100 feet

Fluid: Water, pure Duty Chart: 3500 RPM

[FT]

Head

105

100

[FT]

[HP]

4.5

3.5

2.5

1.5

0.5

STAGE 1/1

95

90

85

80

75

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0

NPSH - values

16

14

12

10

8

6

STAGE 1/1

4

2

0

Shaft power P2

4

STAGE 1/1 (P2)

3

2

1

0

0 20 40 [US GPM]

60 80

77.6%

100

120

Application Range

77.6%

77.6%

40 Hz

30 Hz

40 Hz

30 Hz

40 Hz

30 Hz

140 160 180 200 220

77.6%

60 Hz

50 Hz

60 Hz

50 Hz

60 Hz

50 Hz

240 260 280 300 320 340

R

35

Page 36

Goulds Pumps

PHV - Packaged Hydrovar Series

VARIABLE SPEED PERFORMANCE CURVES

46SV VARIABLE SPEED CURVE

SVB CI/316SS Multi-Stage Pumps MODEL: 46SVB 1 Stage

Hydraulic Data

Maximum Flow Flow at Duty Point Maximum TDH TDH at Duty Point NPSH

319 US GPM 123 feet

Fluid: Water, pure Duty Chart: 3500 RPM

[FT]

Head

130

125

120

115

110

105

100

[FT]

[HP]

STAGE 1

95

90

85

80

75

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0

NPSH - values

16

14

12

10

8

6

STAGE 1/1

4

2

0

Shaft power P2

6

STAGE 1 (P2)

5

4

3

2

1

0

0 20 40 [US GPM]

60 80

100

77.6%

120

Application Range

77.6%

77.6%

40 Hz

30 Hz

40 Hz

30 Hz

40 Hz

30 Hz

140 160 180 200 220

77.6%

60 Hz

50 Hz

60 Hz

50 Hz

60 Hz

50 Hz

240 260 280 300 320 340

R

36

Page 37

TECHNICAL DATA – PUMP HYDRAULICS / MOTOR SIZING

1SV 3500 RPM

Number of

Stages

Draw Motor (1.0 SF) (Feet) (Bar)

22 6.7 7.5 7.5 1100 32.8

20 6.1 7.5 7.5 1005 30.0 580 PSI (40 Bar) CCW

18 5.4 5 7.5 905 27.0

16 4.8 5 5 795 23.7

15 4.6 5 5 742 22.2

13 4 5 5 642 19.2

11 3.4 3 5 550 16.4

9 2.7 3 3 445 13.3

8 2.4 3 3 398 11.9 362 PSI (25 Bar) CW

7 2 2 2 350 10.4

6 1.8 2 2 300 9.0

5 1.5 1.5 1.5 250 7.5

4 1.1 1 1.5 200 6.0

3 0.9 3/4 1 142 4.2

2 0.6 1/2 3/4 100 3.0

2SV 3500 RPM

Number of

Stages

Draw Motor (1.0 SF) (Feet) (Bar)

22 7.7 7.5 NA 950 28.4

20 6.8 7.5 7.5 860 25.7 580 PSI (40 Bar) CCW

18 6.2 7.5 7.5 760 22.7

16 5.3 5 7.5 726 21.7

15 4.9 5 5 680 20.3

13 4.6 5 5 595 17.8

11 4 5 5 500 14.9

9 3.3 3 5 407 12.2

8 2.9 3 3 360 10.7

7 2.4 3 3 315 9.4 362 PSI (25 Bar) CW

6 2.1 2 3 270 8.1

5 1.8 2 2 222 6.6

4 1.5 1.5 1.5 175 5.2

3 1.1 1 1.5 137 4.1

2 0.7 3/4 1 92 2.7

Maximum Motor HP for use Motor HP for use Shutoff Shutoff

HP With 1.15 SF With Hydrovar TDH TDH MAWP Motor Rotation

Maximum Motor HP for use Motor HP for use Shutoff Shutoff

HP With 1.15 SF With Hydrovar TDH TDH MAWP Motor Rotation

3SV 3500 RPM

Number of

Stages

Draw Motor (1.0 SF) (Feet) (Bar)

16 17.6 20 20 1010 30.2

14 15 15 15 894 26.7

13 14 15 15 830 24.8

12 12.8 15 15 760 22.7

11 11.5 10 15 700 20.9

10 10.7 10 15 640 19.1

9 9.7 10 10 575 17.2

8 8.5 7.5 10 505 15.1

7 7.5 7.5 7.5 450 13.4

6 6.5 7.5 7.5 380 11.3

5 5.4 5 7.5 320 9.6

4 4.3 5 5 250 7.5

3 3.3 3 5 190 5.7

2 2.2 2 3 128 3.8

Maximum Motor HP for use Motor HP for use Shutoff Shutoff

HP With 1.15 SF With Hydrovar TDH TDH MAWP Motor Rotation

37

580 PSI (40 Bar) CCW

362 PSI (25 Bar) CW

Page 38

Goulds Pumps

PHV - Packaged Hydrovar Series

TECHNICAL DATA – PUMP HYDRAULICS / MOTOR SIZING

4SV 3500 RPM

Number of

Stages

Draw Motor (1.0 SF) (Feet) (Bar)

12 26.4 25 NA 930 27.8 580 PSI (40 Bar) CCW

10 21.6 20 25 780 23.3

9 19.2 20 20 700 20.9

8 16.9 15 20 620 18.5

7 14.9 15 15 540 16.1

6 12.9 15 15 460 13.7 362 PSI (25 Bar) CW

5 10.7 10 15 390 11.6

4 8.6 7.5 10 305 9.1

3 6.3 7.5 7.5 228 6.8

2 4.3 5 5 150 4.5

33SV 3500 RPM

# of Impellers / Maximum Motor HP for use Motor HP for use Shutoff Shutoff Casing / Sleeve Stages requiring

# reduced HP with 1.15 SF with Hydrovar TDH TDH Pressure rating Thrust Balancing

Diameter Draw Motor (1.0 SF) (Feet) (Bar) (Standard Assy.) Piston

10 54.3 1125 34

10/2 52.8 60 1096 33

10/1 51.3

9 48.8 1012 30

9/1 47.4 983 29

9/2 45.9

8 43.4 900 27

8/1 41.9 871 26 Thrust Piston

8/2 40.5

7 38 787 23

7/1 36.5 758 23

7/2 35 40 729 22

6 32.6 576 20

6/1 31.1 30 646 19

6/2 29.6 617 18

5 27.1 30 562 17

5/1 25.7 25 533 16

5/2 24.2

4 21.7 450 13

4/1 20.2 20 421 13

4/2 18.8 20 392 12 25 Bar (362 PSI)

3 16.3 337 10 1

3/1 14.7 15 310 9

3/2 13.2 15 281 8 Class 125 / 150

2 10.9

2/1 9.4

2/2 7.9 7.5 167 5

1 5.4

1/1 4 5 84 3

1 Pump assembly may be modified for 40 bar (580 psi) application – contact factory.

Maximum Motor HP for use Motor HP for use Shutoff Shutoff

HP With 1.15 SF With Hydrovar TDH TDH MAWP Motor Rotation

Pump Flange

Rating

1066 32

50

954 28

50

842 25 Required

40

504 15

25

225 7

10

7.5 113 3

5

196 6

10

40 Bar (580 PSI)

Class 250 / 300

38

Page 39

TECHNICAL DATA – PUMP HYDRAULICS / MOTOR SIZING

46SV 3500 RPM

# of Impellers / Maximum Motor HP for use Motor HP for use Shutoff Shutoff Casing / Sleeve Stages requiring

# reduced HP with 1.15 SF with Hydrovar TDH TDH Pressure rating Thrust Balancing

Diameter Draw Motor (1.0 SF) (Feet) (Bar) (Standard Assy.) Piston

10/2 77.8 1210 36.1

9 73.2

9/1 71.5 1111 33.2

9/2 69.7

8 65 1010 30.2

8/1 63.3

8/2 61.6 959 28.6 40 Bar (580 PSI)

7 56.9 884 26.4

7/1 55.2 60 858 25.6

7/2 53.4

6 48.8 758 22.6 Required

6/1 47.1 50 732 21.9

6/2 45.3 706 21.1

5 40.7

5/1 38.9

5/2 37.2 580 17.3

4 32.5 505 15.1

4/1 30.8 30

4/2 29 453 13.5

3 24.4 25 379 11.3

3/1 22.7

3/2 20.9 327 9.8

2 16.3 20 253 7.6

2/1 14/5 15

2/2 12.8 200 6.0

1 8.5 10 10 127 3.8

1/1 6.7 7.5 7.5 102 3.0

1137 33.9

75

1085 32.4

75

984 29.4

60

832 24.8 Thrust Piston Class 250 / 300

50

632 18.9

40

25 353 10.5

20

605 18.1

40

479 14.3

30

226 6.7

15

25 Bar (362 PSI)

1

Pump Flange

Rating

Class 125 / 150

66SV 3500 RPM

# of Impellers / Maximum Motor HP for use Motor HP for use Shutoff Shutoff Casing / Sleeve Stages requiring

# reduced HP with 1.15 SF with Hydrovar TDH TDH Pressure rating Thrust Balancing

Diameter Draw Motor (1.0 SF) (Feet) (Bar) (Standard Assy.) Piston

6 73.2 850 25.4

6/1 70.2 75

6/2 67.2 796 23.8

5 61

5/1 58

5/2 55 655 19.6 Required

4 48.8 50 566 16.9

4/1 45.8 50 540 16.1

4/2 42.8

3 36.6

3/1 33.6

3/2 30.6 30 372 11.1

2 24.4 25

2/1 21.4

2/2 18.4 20 230 6.9

1 12.2 15 15 142 4.2

1/1 9.2 10 10 115 3.4

1 Pump assembly may be modified for 40 bar (580 psi) application – contact factory.

707 21.1

60

513 15.3

40

398 11.9

30

257 7.7

20

822 24.5 40 Bar (580 PSI)

75

681 20.3 Thrust Piston Class 250 / 300

60

424 12.7

40

283 8.4

25

25 Bar (362 PSI)

1

39

Pump Flange

Rating

Class 125 / 150

Page 40

Goulds Pumps

PHV - Packaged Hydrovar Series

TECHNICAL DATA

Maximum Inlet Pressure

The following table shows the maximum permissible inlet

pressure. However, the actual inlet pressure + pressure

against a closed valve must always be lower than the

maximum permissible operating pressure.

Pump Number of Stages Maximum Inlet Pressure

17-22 Stages 215 psi (15 bar)

16-22 Stages 215 psi (15 bar)

14-16 Stages 215 psi (15 bar)

11-12 Stages 215 psi (15 bar)

33SV 1-10 Stages

46SV 1-10 Stages

66SV 1-6 Stages

92SV 1-6 Stages

2-16 Stages 145 psi (10 bar)

1SV

2-25 Stages 145 psi (10 bar)

2SV

2-13 Stages 145 psi (10 bar)

3SV

2-10 Stages 145 psi (10 bar)

4SV

215 psi (15 bar)

40

Page 41

PHV — PACKAGED HYDROVAR SERIES — 1SVB

Stage

(ref.) End Box Weight

6

9 3 19.56 13.44 6.70 23.83 30 56 10 5 101

15 182-4TC 5 25.44 15.43 29.71 11.15 6.87 8.50 37 85 137

(3-Phase)

Frame

HP L1

TEFC

2 16.63 12.06 20.90

56C

DI

L2

(max.)

TEFC L6 L7 L8

MI

9.87 5.73 7.19

TEFC

Weights (lb.)

Liquid

27 51 93

TEFC Hydrovar

Disconnect Total

41

Page 42

Goulds Pumps

PHV - Packaged Hydrovar Series

PHV — PACKAGED HYDROVAR SERIES — 2SVB

Stage

(ref.) End Box Weight

5

8 3 18.56 13.88

13

16 26.44 30.71 40 140

(3-Phase)

Frame

HP L1

TEFC

2 15.63 12.06 19.90

56C

182-4TC

23.50

5

DI

L2

(max.)

TEFC L6 L7 L8

27.77

15.44

MI

22.83 5.50 30 56

6.70

9.87

11.15 6.88 8.50

5.75

7.19

Liquid

TEFC

25 51 91

35

Weights (lb.)

TEFC Hydrovar

135

85

Disconnect Total

10 5

100

42

Page 43

PHV — PACKAGED HYDROVAR SERIES — 3SVB

Stage

(ref.) End Box Weight

2 56C 2 15.75 12.06 20.02 9.87 5.75 7.19 33 51 99

4

7 7½ 23.25 6.70 27.52

9 215TC 10 28.88 15.50 33.15 8.06 10.25 47 151 221

13 254TC 15 33.38 16.56 37.65 9.25 10.83 66 250 339

(3-Phase)

Frame

TEFC

182-4TC

HP L1

3 18.75

DI

L2

(max.)

TEFC L6 L7 L8

23.02

15.44

11.15

MI

6.88 8.50

45 124 10 5 184

Liquid

TEFC

37 85 137

Weights (lb.)

TEFC Hydrovar

Disconnect Total

43

Page 44

Goulds Pumps

PHV - Packaged Hydrovar Series

PHV — PACKAGED HYDROVAR SERIES — 4SVB

Stage

(ref.) End Box Weight

2

4 7½ 18.75 6.70 23.02 11.15 39 124 10 5 178

7 254TC 15 24.44 16.56 28.71 9.25 10.31 52 250 325

(3-Phase)

Frame

TEFC

182-4TC

HP L1

5 15.75

DI

L2

(max.)

TEFC L6 L7 L8

20.02

15.44

MI

6.88 8.50

Liquid

TEFC

33 85 133

Weights (lb.)

TEFC Hydrovar

Disconnect Total

44

Page 45

PHV — PACKAGED HYDROVAR SERIES — 33SVB

Stage

(ref.) End Box Weight

1/1

1

2/1 215TC 10 23.58 15.50 16.91 8.06 10.25 143 151

3/1 254TC 15 26.54 16.56 19.87 9.25 10.31 152 250 425

(3-Phase)

Frame

HP L1

TEFC

182-4TC 5 20.62 15.44 13.95 6.88 8.50 132 85 10

DI

L2

(max.)

TEFC L6 L7 L8

6.70

12.27

MI

TEFC

Liquid

Weights (lb.)

TEFC Hydrovar

18

Disconnect Total

317

5

232

45

Page 46

Goulds Pumps

PHV - Packaged Hydrovar Series

PHV — PACKAGED HYDROVAR SERIES — 46SVB

Stage

(ref.) End Box Weight

1/1 182-4TC 7½

1 215TC 10 15.50 6.70 12.27 8.06 10.25 151 5 313

2/1 254TC 15 25.19 16.56 18.52 9.25 10.31 158 250 18 431

(3-Phase)

Frame

TEFC

HP L1

22.19

DI

L2

(max.)

TEFC L6 L7 L8

15.44

15.52

MI

6.88 8.50

TEFC

Liquid

147

124

Weights (lb.)

TEFC Hydrovar

Disconnect Total

286

10

46

Page 47

NPSH

The minimum operating values that can be reached at the

pump suction end are limited by the onset of cavitation.

Cavitation is the formation of vapor-filled cavities within

liquids where the pressure is locally reduced to a critical

value, or where the local pressure is equal to, or just below

the vapor pressure of the liquid.

The vapor-filled cavities flow with the current and when

they reach a higher pressure ares the vapor contained in

the cavities condenses. The cavities collide, generating

pressure waves that are transmitted to the walls. These,

being subjected to stress cycles, gradually become deformed and yield due to fatigue. This phenomenon, characterized by a metallic noise produced by the hammering

on the pipe walls, is called incipient cavitation.

The damage caused by cavitation may be magnified by

electrochemical corrosion and a local rise in temperature

due to the plastic deformation of the walls. The materials

that offer the highest resistance to heat and corrosion are

alloy steels, especially austenitic steel. The conditions that

trigger cavitation may be assessed by calculating the total

net suction head, referred to in technical literature with

the acronym NPSH (Net Positive Suction Head).

The NPSH represents the total energy (expressed in feet) of

the liquid measured at suction under conditions of incipient cavitation, excluding the vapor pressure (expressed in

feet) that the liquid has at the pump inlet.

The maximum possible suction head for installation depends on the value of the atmospheric pressure (i.e. the

elevation above sea level at which the pump is installed)

and the temperature of the liquid.

To help the user, with reference to water temperature

(40ºF) and to the elevation above sea level, the following

tables show the drop in hydraulic pressure head in relation

to the elevation above sea level, and the suction loss in

relation to temperature.

Water

Temperature (°C)

Suction

Loss (ft)

Elevation Above

Sea Level (ft)

Suction

Loss (ft)

68 104 140 176 194 230 248

-.7 2.3 6.6 16.4 24.3 50.5 70.5

1600 3300 4900 6500 8200 9800

1.8 3.6 5.4 7.2 9.0 10.8

To reduce it to a minimum, especially in cases of high suction head (over 13 – 16 feet) or within the operating limits

with high flow rates, we recommend using a suction line

having a larger diameter than that of the pump’s suction

port. It is always a good idea to position the pump as close

as possible to the liquid to be pumped.

To find the static height (hz) at which to install the machine under safe conditions, the following formula must

be verified:

hp + hz ≥ (NPSHr + 2 feet) + hf + h

pv

where:

hp is the absolute pressure applied to the free liquid sur-

face in the suction tank, expressed in feet of liquid; hp

is the quotient between the barometric pressure and

the specific weight of the liquid.

hz is the suction lift between the pump axis and the free

liquid surface in the suction tank, expressed in feet;

hz is negative when the liquid level is lower than the

pump axis.

hf is the flow resistance in the suction line and its acces-

sories, such as: fittings, foot valve, gate valve, elbows,

etc.

hpv is the vapor pressure of the liquid at the operating

temperature, expressed in feet of the liquid. hpv is

the quotient between the Pv vapor pressure and the

liquid‘s specific weight.

0.5 is the safety factor.

47

Page 48

Goulds Pumps

PHV - Packaged Hydrovar Series

TECHNICAL DATA – WATER PROPERTY CHART

Temp ºF Temp ºC

(Cubic ft/lb) @ 39.2ºF @ 60ºF @ 68ºF (lb/cubic ft) (psi Abs)

32 0.0 0.01602 1.000 1.001 1.002 62.42 0.088

35 1.7 0.01602 1.000 1.001 1.002 62.42 0.100

40 4.4 0.01602 1.000 1.001 1.002 62.42 0.122

50 10.0 0.01603 0.999 1.001 1.002 62.38 0.178

60 15.6 0.01604 0.999 1.000 1.001 62.34 0.256

70 21.1 0.01606 0.998 0.999 1.000 62.27 0.363

80 26.7 0.01608 0.996 0.998 0.999 62.19 0.507

90 32.2 0.0161 0.995 0.996 0.997 62.11 0.698

100 37.8 0.01613 0.993 0.994 0.995 62.00 0.949

120 48.9 0.0162 0.989 0.990 0.991 61.73 1.692

140 60.0 0.01629 0.983 0.985 0.986 61.39 2.889

160 71.1 0.01639 0.977 0.979 0.979 61.01 4.741

180 82.2 0.01651 0.970 0.972 0.973 60.57 7.510

200 93.3 0.01663 0.963 0.964 0.966 60.13 11.526

212 100.0 0.01672 0.958 0.959 0.960 59.81 14.696

220 104.4 0.01677 0.955 0.956 0.957 59.63 17.186

240 115.6 0.01692 0.947 0.948 0.949 59.10 24.97

260 126.7 0.01709 0.938 0.939 0.940 58.51 35.43

280 137.8 0.01726 0.928 0.929 0.930 58.00 49.20

300 148.9 0.01745 0.918 0.919 0.920 57.31 67.01

320 160.0 0.01756 0.908 0.909 0.910 56.66 89.66

340 171.1 0.01787 0.896 0.898 0.899 55.96 118.01

360 182.2 0.01811 0.885 0.886 0.887 55.22 153.04

380 193.3 0.01836 0.873 0.874 0.875 54.47 195.77

400 204.4 0.01864 0.859 0.860 0.862 53.65 247.31

420 215.6 0.01894 0.846 0.847 0.848 52.80 308.83

440 226.7 0.01926 0.832 0.833 0.834 51.92 381.59

460 237.8 0.0196 0.817 0.818 0.819 51.02 466.9

480 248.9 0.02 0.801 0.802 0.803 50.00 566.1

500 260.0 0.0204 0.785 0.786 0.787 49.02 680.8

520 271.1 0.0209 0.765 0.766 0.767 47.85 812.4

540 282.2 0.0215 0.746 0.747 0.748 46.51 962.5

560 293.3 0.0221 0.726 0.727 0.728 45.30 1133.1

580 304.4 0.0228 0.703 0.704 0.704 43.90 1325.8

600 315.6 0.0236 0.678 0.679 0.680 42.30 1542.9

620 326.7 0.0247 0.649 0.650 0.650 40.50 1786.6

640 337.8 0.026 0.617 0.618 0.618 38.50 2059.7

660 348.9 0.0278 0.577 0.577 0.578 36.00 2365.4

680 360.0 0.0305 0.525 0.526 0.527 32.80 2708.1

700 371.1 0.0369 0.434 0.435 0.435 27.10 3093.7

Specific Volume Specific Gravity Weight Vapor Pressure

48

Page 49

VOLUMETRIC CAPACITY

Litres Cubic metres Cubic feet Cubic feet Imp. gal. US gal.

per minute per hour per hour per minute per minute per minute

l/min m3/h ft3/h ft3/min Imp. gal/min Us gal./min

1,0000 0,0600 2,1189 0,0353 0,2200 0,2640

16,6670 1,0000 35,3147 0,5886 3,6660 4,4030

0,4720 0,0283 1,0000 0,0167 0,1040 0,1250

28,3170 1,6990 60,0000 1,0000 6,2290 7,4800

4,5460 0,2728 9,6326 0,1605 1,0000 1,2010

3,7850 0,2271 8,0209 0,1337 0,8330 1,0000

0,1100 0,0066 0,2339 0,0039 0,0240 0,0290

PRESSURE AND HEAD

Newtons per kilopascal bar Pound force metre millimetre

square metre per square inch of water of mercury

N/m2 kPa bar psi m H2O mm Hg

1,0000 0,0010 1 x 105 1,45 x 10-4 1,02 x 10-4 0,0075

1000,0000 1,0000 0,0100 0,1450 0,1020 7,5000

100000,0000 100,0000 1,0000 14,5000 10,2000 750,1000

98067,0000 98,0700 0,9810 14,2200 10,0000 735,6000

6895,0000 6,8950 0,0690 1,0000 0,7030 51,7200

2984,0000 2,9840 0,0300 0,4330 0,3050 22,4200

9789,0000 9,7890 0,0980 1,4200 1,0000 73,4200

133,3000 0,1330 0,0013 0,0190 0,0140 1,0000

3386,0000 3,3860 0,0338 0,4910 0,3450 25,4000

LENGTH

millimetre centimetre metre inch foot yard

mm cm m in ft yd

1,0000 0,1000 0,0010 0,0394 0,0033 0,0011

10,0000 1,0000 0,0100 0,3937 0,0328 0,0109

1000,0000 100,0000 1,0000 39,3701 3,2808 1,0936

25,4000 2,5400 0,0254 1,0000 0,0833 0,0278

304,8000 30,4800 0,3048 12,0000 1,0000 0,3333

914,4000 91,4400 0,9144 36,0000 3,0000 1,0000

VOLUME

cubic metre litre millilitre imp. gallon US gallon cubic foot

m3 litre ml imp. gal. US gal. ft

1,0000 1000,0000 1 x 106 220,0000 264,2000 35,3147

0,0010 1,0000 1000,0000 0,2200 0,2642 0,0353

1 x 10-6 0,0010 1,0000 2,2 x 10-4 2,642 x 10-4 3,53 x 10-5

0,0045 4,5460 4546,0000 1,0000 1,2010 0,1605

0,0038 3,7850 3785,0000 0,8327 1,0000 0,1337

0,0283 28,3170 28317,0000 6,2288 7,4805 1,0000

3

49

Page 50

Goulds Pumps

PHV - Packaged Hydrovar Series

NOTES

50

Page 51

NOTES

51

Page 52

ITT

2881 East Bayard Street, Seneca Falls, NY 13148

Phone: (315) 568-7123 • Fax: (315) 568-7973

www.goulds.com

Goulds Pump s and G&L are regis tere d tr ademarks of ITT Corporation. I TT, th e En gineered Blocks

Symbol and Engineered for Life are reg istered trademarks of I TT Manu fact uring Enterprises, Inc.

Copy right © 2009 ITT Corpor ation BPHV S eptembe r, 200 9 Printe d in U. S.A.

SPEC IFICATIO NS ARE SUBJE CT TO CHANGE WITHO UT NOT ICE.

ITT

Engineered for life

Loading...

Loading...