Page 1

AAMM-01

and

Advantage

®

Actuator

Maintenance Manual

This manual provides installation and maintenance instructions for ADVANTAGE®ACTUATOR operated

diaphragm valves. If additional information is required, please contact:

ITT Industries

33 Centerville Road

Lancaster, PA 17603

(717) 509-2200

Attention: Sales Department

WARNING

ITT INDUSTRIES VALVES AND VALVE ACTUATORS ARE DESIGNED AND

MANUFACTURED USING GOOD WORKMANSHIP AND MATERIALS, AND

THEY MEET ALL APPLICABLE INDUSTRY STANDARDS. THESE VALVES ARE

AVAILABLE WITH COMPONENTS OF VARIOUS MATERIALS, AND THEY

SHOULD BE USED ONLY IN SERVICES RECOMMENDED IN OUR PRODUCT

CATALOG OR BY A COMPANY VALVE ENGINEER.

MISAPPLICATION OF THE PRODUCT MAY RESULT IN INJURIES OR PROPERTY DAMAGE. A SELECTION OF VALVE COMPONENTS OF THE PROPER

MATERIAL CONSISTENT WITH THE PARTICULAR PERFORMANCE REQUIREMENT, IS IMPORTANT FOR PROPER APPLICATION.

EXAMPLES OF THE MISAPPLICATION OR MISUSE OF ITT INDUSTRIES

VALVES INCLUDE USE IN AN APPLICATION IN WHICH THE PRESSURE/TEMPERATURE RATING IS EXCEEDED OR FAILURE TO MAINTAIN VALVES AS

RECOMMENDED.

IF VALVE EXHIBITS ANY INDICATION OF LEAKAGE, DO NOT OPERATE.

ISOLATE VALVE AND EITHER REPAIR OR REPLACE.

CONTENTS:

1.0 Advantage®Installation

2.0 Advantage

®

Operation & Adjustment

3.0 Advantage®Maintenance

4.0 Advantage®Accessories

4.1 Travel (Closing) Stop Adjustment

4.2 Manual Over-Ride (Open) and

Adjustable Opening Stop

4.3 Manual Over-Ride (Close) and

Adjustable Opening Stop

5.0 Switch Pack 2.0

6.0 Switch Pack 2.5

7.0 Switch Pack 3.0

8.0 Positioner

T

ABLES:

1. Fastener Torques

2. Actuator Travel and Weights

3. Actuator Internal Data

4. O-Ring Sizes

FIGURES:

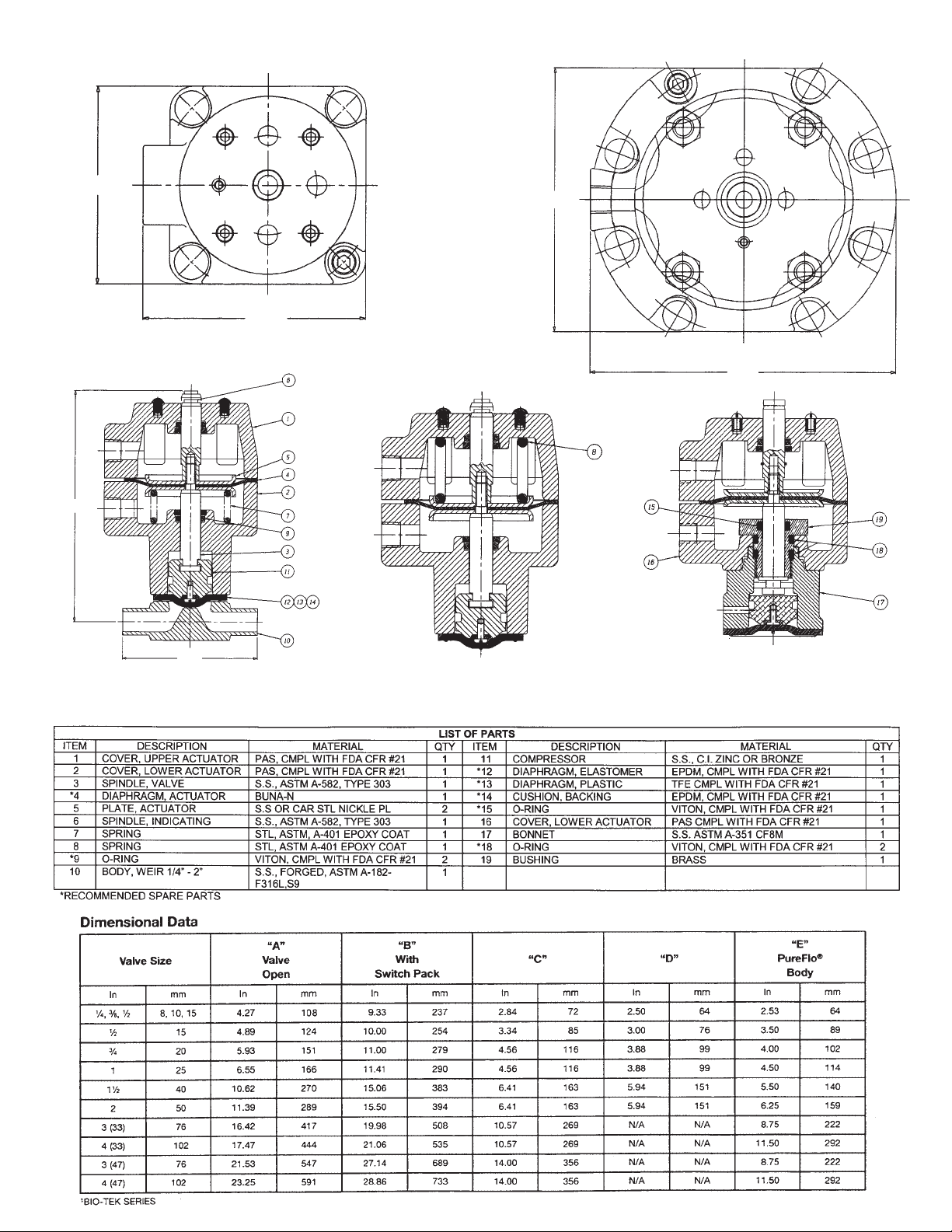

1. Actuator Drawings

2. Accessories:

- Travel Stops

- Manual Over-Ride (Open) with

Adjustable Opening Stop

- Manual Over-Ride (Close) with

Adjustable Opening Stop

3. Switch Pack 2.0

3A. Switch Pack 2.5

3B. Switch Pack 3.0

4. Positioner

5. Valve Diaphragm Identification

6. PTFE Diaphragm Detail

7. Advantage Assembly & Disassembly Fixture

Pure-Flo

®

Dia-Flo

®

Page 2

2

CAUTION - WELD END VALVES

Weld end valves for schedule 10 and heavier pipe require

actuator removal prior to welding in line. Schedule 5 and

lighter pipe and tubing may be welded with automatic

equipment only without removing the actuator. The valve

must be in the open position and properly purged with an

inert gas. Manual welding requires actuator removal for all

tubing gages and pipe schedules.

1 INSTALLATION

1.1 Dia-Flo

®

diaphragm valves may be installed in any

orientation. For horizontal piping systems to be

drained through the valve, install the valve stem

between 0 and 30 degrees above horizontal. Note:

Pure-Flo

®

valves have either raised hash marks

(castings) or small machined dots (forgings) on

the valve body to indicate the correct drain angle.

Locate these marks at the 12 o’clock position to

achieve the optimum drain angle.

1.2 Prior to pressurization (with the valve

slightly open), tighten the bonnet bolts in

a crisscross pattern in accordance with

Table 1.

Retightening 24 hours after the system reaches operating temperature and pressure is recommended. If

leakage occurs at the body/diaphragm seating area,

immediately depressurize system and tighten bonnet

bolts as noted above. If leakage continues,

diaphragm replacement is required. Follow applicable steps in Section 3.6.1, 3.7.1 or 3.8.1.

1.3 The travel stop (closing stop), if equipped, is factory

set and should not require adjustment at time of

installation. However, if adjustment is required, see

section 4.1.

1.4 Maximum valve operating pressure is 150 PSIG

(10.34 bar). This pressure is applicable up to 100

degrees F (38 degrees C), valves at maximum pressure cannot be used at maximum temperatures.

CAUTION: The actuator size/configuration may limit

the actual operating pressure, consult Engineering

Catalog for actuator sizing. Consult factory or

Engineering Catalog for vacuum operation.

1.5 Air line connections should be made with care as

damage may occur to the standard plastic actuator

covers. Connection size is 1/8” NPT for 1/4” through

2” (DIN 8 - 50) and 1/4” NPT for 3” and 4” (DIN 80 -

100).

1.6 3” and 4” (Series 33 and 47) (DIN 80 and 100)

Advantage

®

actuators must not be lifted by the

air fittings. Prepare an eye bolt with a 0.625“ -18

female thread to attach to the adjusting bushing,

use a hoist to lift with this attachment. (Series 47

only)

1.7 The stainless steel bonnet Advantage

®

Actuator

(1/4”-2”) (DIN 8-50) can have the air inlets positioned in any quadrant. The actuator must be

removed from the valve body and the actuator

diaphragm replacement steps followed. Unthread

the bushing, lift and rotate the lower cover to position the air inlet in the desired quadrant. Press down

on the cover to insure it sits square on the bonnet

and re-assemble the bushing to the proper torque.

Bio-tek: . . . . . . . . . . . . . . . . . . . . . . . . . . .150 in-lb

.50 - 1.0”: . . . . . . . . . . . . . . . . . . . . . . . . .200 in-lb

1.5/2.0”: . . . . . . . . . . . . . . . . . . . . . . . . . .240 in-lb

2 OPERATION & ADJUSTMENT

2.1 The Advantage

®

actuator is a spring-and diaphragm,

or double acting diaphragm, pneumatic actuator.

The actuator model number is located on the ITT

i.d. tag. The model number is a four or five digit

number defining the actuator as follows:

AXYYZ

A = Advantage” Actuator

X = 1 Direct Acting (Spring to Open)

X = 2 Reverse Acting (Spring to Close)

X = 3 Double Acting

YY = Nominal Size. Available sizes

(approximate effective diaphragm area in

square inches): #03, 05, 08, 16, 33, 34, 47, 48.

Z = 6 60 PSI Spring Package

Z = 9 90 PSI Spring Package

Z is only used for Reverse Acting Units

(Spring to Close) sizes 1/4” - 2” (DIN 8 - 50). Note

that for the 3” & 4” actuators A233, A247 represent a 60 PSI Spring Package and A248 represents a

80 PSI Spring Package. A234 represents a 90 PSI

Package.

2.2 Maximum permitted air supply pressure is

90 psig (6.2 bar, 620 kPa).

ACTUATOR PRESSURE RATING

The Advantage actuator has a pressure rating of 90 psig.

However, the actuator will withstand pressures well in excess of

the rated pressure without risk of bursting.

Maintaining operating pressure at or below 90 psig will ensure

optimum life of the operating components, such as the actuator

diaphragm. However, operation at pressures up to 95 psig, for

limited periods of time, will not noticeably affect the life of

these components.

2.3 For operation and adjustment of actuator acces-

sories, see Section 4.0.

2.4 Valve and actuator travel are shown in Table 2.

3 MAINTENANCE

3.1 Periodic Inspection

Periodically inspect condition of external valve parts.

Replace all parts showing excessive wear or corrosion. Leakage from the lower cover or bonnet weep

hole indicates diaphragm rupture. For diaphragm

replacement, see Section 3.6.1, 3.7.1, or 3.8.1. On

sealed bonnet valves, back off the v-notch vent plug

two or three turns. CAUTION: When the process

fluid is hazardous or corrosive, extra precautions

should be taken, the user should employ appropriate safety devices and should be prepared to

control a leak of the process fluid. Fluid weeping

from the plug indicates a diaphragm failure.

Replace diaphragm immediately.

3.2 Pressurized Bonnet

Air pressure from the lower cover or bonnet weep

hole may indicate o-ring failure. Follow applicable

replacement instructions in Section 3.6, 3.7 or 3.8.

Page 3

3

3.3 Diaphragm-Flange Leakage

If valve diaphragm flange area leaks, depressurize

system and open valve slightly, using the wrench

opening device (3” & 4”Series 47 only, DIN 80 & 100

only) or a local bleed type regulator. Tighten bonnet

bolts as described in Section 1.2. If leakage continues, valve diaphragm replacement is required.

3.4 Lubrication

Standard lubricant is Chevron Poly FM2 (FDA

Compliant) for all Pure

-Flo® valves (1/4” through 4”,

DIN 8 - 100) and 1/4” through 2” (DIN 8 - 50)

Dia

-Flo®valves. Sunoco 991EP is standard for 3” or

4” (DIN 80 or 100) Dia

-Flo® valves. The 3” & 4” (DIN

80 & 100) unit requires Never-Seez on the adjusting

bushing/spindle threaded joint and on the travel stop

nuts/adjusting bushing threaded joint. Actuators

should be lubricated in the spindle/o-ring area whenever the actuator is disassembled.

3.5 Advantage

®

Actuator to Valve Body

Mounting Instructions

For double acting (A3YY) and spring-to open (A1YY)

actuators, regulate air pressure in upper cover to

extend the compressor and assemble valve

diaphragm. Correctly position the diaphragm with

bolt holes then back the regulator off until the

diaphragm just rest against the lower cover.

Spring-to close (A2YY) units require air pressure regulated in the lower cover to properly locate the valve

diaphragm.

1/4” through 2” (DIN 8 - 50):

Apply a dab of Dow Corning

®

111, which has FDA

compliance to Title 21 CFR 175.300, to the lead

thread of each lower cover insert. (DO NOT

OVER-LUBRICATE.) No lubricants are permissible

on the diaphragm seal face or body interior/seal

area.

Assemble valve body using the torques shown in Table

1.

3.6 Double Acting

(REMOVE ALL LINE PRESSURE)

3.6.1 Valve Diaphragm Replacement

3.6.1.1 Disconnect air lines. Remove bonnet

bolts, lift actuator assembly from valve

body.

3.6.1.2 Unscrew diaphragm from compressor

by turning counterclockwise.

3.6.1.3 For PTFE assemblies only: Replace backing cushion and PTFE diaphragm.

Note: To engage the threads of the

diaphragm stud invert the PTFE

diaphragm. To invert the diaphragm,

press on the center of the

diaphragm face with thumbs while

holding the edge of the diaphragm

with fingers.

3.6.1.4 Screw new diaphragm into compressor

until hand tight. DO NOT OVERTIGHT-

EN. Then back off until bolt holes in

diaphragm and bonnet flange align.

3.6.1.5 Replace actuator assembly on body

and tighten bonnet bolts with a

wrench, crisscrossing from corner to

corner. See Table 1 for recommended

torques.

3.6.1.6 Travel stop, if equipped, must

be reset

at this time to assure proper closure.

See Section 4.1.

3.6.2 Actuator Diaphragm Replacement:

(1/4” through 2”, DIN 8 - 50)

3.6.2.1 Disconnect air lines. Remove actuator

bolts and remove top cover.

3.6.2.2 Remove indicating spindle, diaphragm

top plate and actuator diaphragm.

3.6.2.3 Install new diaphragm top hat up, use

Blue Loctite #242 on the indicating

spindle.

3.6.2.4 Assemble top cover, using care to keep

the air fitting in line with the lower

cover air fitting.

3.6.2.5 See Table #1 for fastener

torques.

3.6.3 Actuator Diaphragm Replacement:

(3” & 4” Series 47, DIN 80 & 100)

3.6.3.1 Disconnect air lines. It is best to

remove the bonnet bolts, lift actuator

assembly from the valve body and

move the unit to a bench. Remove

clear plastic cap, travel stop nuts,

roller-bearing/races, actuator bolts and

nuts. Remove top cover.

3.6.3.2 Remove adjusting bushing, spindle

nut, diaphragm top plate and actuator

diaphragm.

3.6.3.3 Install new diaphragm, top hat up.

Reassembly is the reverse of the above,

use Blue Loctite #242 on the spindle

nut. Be sure to set the adjusting bushing at the correct position 4.06”

(10.31 cm) from top of the spindle nut

to bottom of adjusting bushing), see

Figure 1. See Table 1 for fastener

torques.

(3” & 4” Series 33, DIN 80 & 100)

3.6.3.4 Disconnect air lines. It is best to

remove the bonnet bolts, lift actuator

assembly from the valve body and

move the unit to a bench. Remove

actuator bolts and remove top cover.

3.6.3.5 Remove extension spindle, both nuts,

diaphragm top plate and actuator

diaphragm.

3.6.3.6

Install new diaphragm, top hat up. Be

sure the diaphragm is positioned so

the diaphragm bolt holes line up with

Page 4

4

the cover bolt holes with no stretching

of the diaphragm. The compressor

extends 0.72” from the bonnet face in

this relaxed position, reference p. 10

for a view of the compressor position.

Re-assembly is the reverse of the

above, use Blue Loctite #242 on the

spindle nut. See Table 1 for fastener

torques.

3.6.4 Spindle O-Ring Replacement

(All Sizes)

3.6.4.1 Disconnect air lines, remove actuator

assembly from valve body and dismantle actuator following instructions

above for removing actuator

diaphragm.

3.6.4.2 Withdraw valve diaphragm, compressor and spindle assembly from the

bonnet.

3.6.4.3 Remove old o-rings, taking care not to

damage machined surfaces. Lubricate

new o-rings per Section 3.4 and install

in grooves. Reassemble reversing the

above instructions. Care must be used

on the Bio-Tek to align the compressor

T-slot with molded tabs in lower cover.

3.7 Reverse Acting

(REMOVE ALL LINE PRESSURE)

3.7.1 Valve Diaphragm Replacement

3.7.1.1 Load the bottom chamber of the actuator with sufficient air to partially open

valve. This will ease the spring tension

holding the valve diaphragm to the

body weir.

3.7.1.2 Remove the bonnet bolts. Lift actuator

assembly from valve body. Release air

and disconnect air line.

3.7.1.3 Unscrew diaphragm from compressor

by turning counterclockwise.

3.7.1.4 For PTFE assemblies only: Replace backing cushion and PTFE diaphragm.

Note: To engage the threads of the

diaphragm stud invert the PTFE

diaphragm. To invert the diaphragm,

press on the center of the

diaphragm face with thumbs while

holding the edge of the diaphragm

with fingers.

3.7.1.5 Screw new diaphragm into compressor

by turning hand tight. DO NOT OVER-

TIGHTEN. Then back off until bolt

holes in diaphragm and bonnet flange

register.

3.7.1.6 Connect air line to lower air chamber

and load chamber with sufficient air

to move the diaphragm upward until

the backing cushion or elastomer

diaphragm rests against the

Advantage Act. lower cover. Do not

apply excessive air pressure that

results in inversion of the diaphragm.

3.7.1.7 Replace actuator assembly on body,

and tighten bonnet bolts hand tight.

3.7.1.8 Tighten bonnet bolts with a wrench,

crisscrossing from corner to corner.

See Table 1 for recommended

torques.

3.7.1.9 Apply sufficient air pressure to the

lower cover to fully open the valve. If

necessary, retighten bonnet bolts.

3.7.1.10 Travel stop (Closing Stop), if

equipped, must

be reset at this time

to assure proper closure. See Section

4.1.

3.7.2 Actuator Diaphragm or Spring Replacement:

(1/4” through 2”, DIN 8 - 50) If present, the switch package must be removed.

Spring-to-Close actuators contain powerful springs

and should not be disassembled unless properly fixtured.

One fixture exists for 1/2”, 3/4”, and 1” (DIN 15, 20, 25)

sizes, and another one for 1.5” and 2” (DIN 40 and 50)

sizes. No special fixtures are required for the 3” & 4” (DIN

80 & 100) sizes. Consult factory for details, see Figure 7.

3.7.2.1 Remove actuator from the valve body.

Apply air to lower cover to simplify disassembly, then release air.

3.7.2.2 Remove valve diaphragm and plastic

indicator spindle plug (found on the

1/4” through 2” (DIN 8 - 50) spindles),

both unthread by turning counterclockwise.

3.7.2.3 Position actuator centrally in fixture,

locating the compressor over the correct spacer in the fixture lower plate.

3.7.2.4 Drop the stem guide through center of

fixture handwheel and position in actuator indicator spindle #10-24 UNC

tapped hole (former plug location).

3.7.2.5 Turn handwheel clockwise until stop

rests on actuator top cover.

3.7.2.6 Remove all cover to cover

caps, bolts, and washers.

3.7.2.7 Turn handwheel counterclockwise until

spring load is relieved.

3.7.2.8 Remove top cover, lift out spring(s),

unthread indicator spindle, remove top

actuator plate and diaphragm.

3.7.2.9 Replace parts using the following pro-

cedure: Place the correct spacer,

dependent on valve size, over the pin

in the fixture lower plate. The 1 1/2”

Page 5

5

and 2” (DIN 40 & 50) sizes require four

(4) threaded rod guides in the lower

cover prior to assembly. Position the

actuator sub-assembly, including

spring(s) and top cover, over the spacer

(i.e., the compressor rests on the spacer). Drop the stem guide through center of the fixture handwheel, actuator

top cover, and locate in the actuator

indicator. Position the upper actuator

cover so the 1/8” NPT inlets in the

upper and lower covers are in line and

the rod guides slide through the clearance holes. Turn the handwheel clockwise to compress the spring(s) until

the covers almost touch. Remove the

four(4) threaded rod guides. Start the

cover bolts and then continue to compress the spring(s) until the covers

touch. Place remaining washers and

bolts in top cover and tighten bolts to

torques shown in Table 1.

3.7.3 Actuator Diaphragm or Spring Replacement

(3” & 4” Series 47, DIN 80 & 100)

If present, the switch package must be removed.

3.7.3.1

Disconnect air lines. It is best to

remove the bonnet bolts, lift actuator

assembly from the valve body and

move the unit to a bench. Remove

clear plastic cap, travel stop nuts,

roller-bearing and races.

3.7.3.2 Turn adjusting bushing clockwise until

contact is made with spring package,

record the number of turns. Remove

actuator bolts and nuts, lift off top

cover. Unscrew spring package from

valve spindle by turning counterclockwise.

3.7.3.3 Remove spindle nut, diaphragm top

plate and actuator diaphragm.

3.7.3.4 Install new diaphragm, top hat up.

Reassembly is the reverse of the above,

use Blue Loctite #242 on the spindle

nut. If the original spring package is

used, turn the adjusting bushing counterclockwise the number of turns

recorded in 3.7.3.2. only after assembling the top cover and fasteners.

Should replacement of the spring

package be required, simply thread the

new spring package onto the valve

spindle. A gap may exist between the

covers until properly bolted together

using a crisscross pattern. See Table 1

for fastener torques.

(3” & 4” Series 33, DIN 80 & 100)

3.7.3.5 Disconnect air lines. It is best to

remove the bonnet bolts, lift actuator

assembly from the valve body and

move the unit to a bench. Remove

actuator bolts and remove top cover.

3.7.3.6 Unthread adjusting bushing, this

relieves the spring load, until it is free

of the valve spindle. Remove the

adjusting bushing/spring plate subassembly and the springs. Remove

spindle nut, top actuator plate and

actuator diaphragm.

3.7.3.7

Install new diaphragm, top hat up. Be

sure the diaphragm is positioned so

the diaphragm bolt holes line up with

the cover bolt holes with no stretching

of the diaphragm. The compressor

should extend 0.72” from the bonnet

face in this relaxed position, reference

p. 10 for a view of the compressor

position. Re-assembly is the reverse of

the above, use Blue Loctite #242 on

the spindle nut. Thread the adjusting

bushing down until it shoulders. A gap

will exist between the covers until

properly bolted together using a crisscross pattern. Use three long bolts to

pull down the upper cover and pinch

the diaphragm. Tighten the standard

cover bolts, replace the three long

bolts and complete the assembly. See

Table 1 for fastener torques.

3.7.4 Spindle O-Ring Replacement (All sizes)

3.7.4.1 Disconnect air lines. Remove actuator

from valve body and dismantle actuator following instructions above for

removing actuator diaphragm and

springs.

3.7.4.2 Withdraw valve diaphragm, compressor and spindle assembly from the

bonnet.

3.7.4.3 Replace o-rings and reassemble by

reversing the instructions and following the steps for replacing a valve

diaphragm. Care must be used on the

Bio-Tek to align the compressor T-slot

with molded tabs in lower cover.

Lubricate o-rings prior to installation

per Section 3.4.

3.8 Direct Acting

(REMOVE ALL LINE PRESSURE)

3.8.1 Valve Diaphragm Replacement

3.8.1.1 Disconnect air lines. Remove bonnet

bolts, lift actuator assembly from valve

body. Pressurize actuator by applying

air to upper cover, extending compressor and diaphragm.

3.8.1.2 Unscrew diaphragm from compressor

by turning counterclockwise.

3.8.1.3 For PTFE assemblies only: Replace backing cushion and PTFE diaphragm.

Note: To engage the threads of the

diaphragm stud invert the PTFE

diaphragm. To invert the diaphragm,

press on the center of the

Page 6

6

diaphragm face with thumbs while

holding the edge of the diaphragm

with fingers.

3.8.1.4 Screw new diaphragm into compressor

until hand tight. DO NOT OVERTIGHT-

EN. Then back off until bolt holes in

diaphragm and bonnet register.

3.8.1.5 Reduce air pressure until back of

diaphragm is flat against bonnet.

Replace actuator and bonnet assembly

on body, and tighten bonnet bolts

hand tight.

3.8.1.6 Tighten bonnet bolts with a wrench,

crisscrossing from corner to corner. See

Table 1 for recommended torques.

3.8.1.7 Release air and permit the valve to

open. If necessary, retighten bonnet

bolts.

3.8.1.8 Travel stop, if equipped, must

be reset

at this time to assure proper closure.

See Section 4.1.

3.8.2 Actuator Diaphragm or Spring Replacement:

(1/4” through 2”, DIN 8 - 50)

If present, the switch package must be removed.

Spring-to-Open actuators contain powerful

springs and should not be disassembled unless

properly fixtured.

One fixture exists for the 1/2”, 3/4”, and 1“ (DIN 15,

20, 25) sizes, and one for 1 1/2” and 2” (DIN 40

and 50) sizes.

No fixture required for 3” & 4”(DIN 80 & 100).

Consult factory for details, see Figure 7.

3.8.2.1 Remove cover bolts and lift off top

cover.

3.8.2.2 Caution: actuator plates are under

load. Loosen the indicator spindle two

turns before placing centrally in the fixture, locating the compressor over the

correct spacer in the fixture lower

plate. Place the slotted fixture plate

and spacer plate on the actuator top

plate; turn the fixture handwheel

clockwise to remove the load from the

indicator spindle. Remove the spindle

and turn the handwheel counterclockwise until the spring load is relieved.

Use care - the diaphragm may pinch

the spindle thread and restrict spring

extension. Examine the diaphragm

through hole for damage and replace,

if necessary.

3.8.2.3 Place the spring in the lower cover and

set an actuator plate, concave side

down, over the valve spindle. Position

in the fixture over the spacer and place

the slotted fixture plate on the actuator plate. Set the spacer plate on top,

turn the fixture handwheel clockwise

and compress the spring until the actuator plate shoulders on the spindle.

Use care to insure the spindle goes

through the actuator plate center hole.

Slide the actuator diaphragm over the

valve spindle using care to insure the

top hat is in the upper cover. Position

the actuator diaphragm so the bolt

clearance holes line up with threaded inserts in lower cover. Place an

actuator plate, concave side up, over

the valve spindle. Apply Blue Loctite

#242 and thread the indicating spindle

on the valve spindle by hand. Turn the

handwheel counterclockwise to

remove the load and remove the actuator from the fixture. Clamp the slotted plate in a vise and pull so the actuator slips free. Tighten the indicator

spindle with a wrench using care to

insure the actuator diaphragm remains

properly aligned.

3.8.2.4 Position the upper actuator cover so

the 1/8” NPT inlets in the upper and

lower covers are in line.

3.8.3 Actuator Diaphragm or Spring Replacement:

(3” & 4” Series 47, DIN 80 & 100) If present,

switch package must be removed.

3.8.3.1 Disconnect air lines. It is best to

remove the bonnet bolts, lift actuator

assembly from the valve body and

move the unit to a bench.

3.8.3.2 Remove clear plastic cap, travel stop

nuts and roller bearing/races.

3.8.3.3 Remove actuator bolts and nuts, lift off

top cover.

3.8.3.4 Remove adjusting bushing, spindle nut

(under load due to spring force),

diaphragm plates, actuator diaphragm

and spring.

3.8.3.5 Using replacement parts, reverse

instructions for reassembly. Use Blue

Loctite #242 on the spindle nut. Be

sure to set the adjusting bushing at

the correct location (4.06” (10.31 cm)

from top of the spindle nut to bottom

of adjusting bushing), see Figure 1.

(3” & 4” Series 33, DIN 80 & 100)

3.8.3.6 Disconnect air lines. It is best to

remove bonnet bolts, lift actuator

assembly from the valve body and

move the unit to a bench. Remove

actuator bolts an remove top cover.

3.8.3.7 Remove extension spindle, both nuts,

diaphragm top plate, actuator

diaphragm and spring.

3.8.3.8 Reassembly is the reverse of the above,

Page 7

7

use Blue Loctite #242 on the spindle

nut. The diaphragm is to be assembled

top hat up. See Table 1 for fastener

torques.

3.8.4 Spindle O-Ring Replacement (All sizes)

3.8.4.1 Disconnect air lines. Remove actuator

from valve body and dismantle actuator following instructions above for

removing actuator diaphragm and

spring.

3.8.4.2 Withdraw valve diaphragm, compressor and spindle assembly from the

bonnet.

3.8.4.3 Replace o-rings and reassemble by

reversing the instructions and following the steps for replacing a valve

diaphragm. Care must be used on the

Bio-Tek

®

to align the compressor T-slot

with molded tabs in lower cover.

Lubricate o-rings prior to installation

per Section 3.4.

4 ACCESSORIES

4.1 Travel (Closing) Stop Adjustment

This feature is standard on 3” - 4” Series 47 (DIN

80-100) actuators and optional on the 1/4” - 2” (DIN

8-50). It is not available on 3” - 4 “ Series 33 (DIN

80-100).

The purpose of the travel stop is to prevent overloading of the diaphragm, thus prolonging

diaphragm life. Travel stops are factory set and

do not require routine adjustment. However, with

replacement of valve diaphragms, travel stop

adjustment is recommended.

4.1.1 All Operating Modes:

4.1.1.1 Remove switch Package if present.

4.1.1.2 Release air pressure in actuator covers.

4.1.1.3 Remove clear plastic cap.

4.1.1.4 To adjust travel (closing) stop, first

loosen jam nuts and back off one turn.

If double or direct acting, apply

enough pressure in top cover to close

the valve. While preventing the adjusting bushing from rotating, turn lower

nut clockwise until valve leaks. Then

turn lower nut counterclockwise until

valve stops leaking while continuing to

insure the adjusting bushing does not

rotate. Tighten jam nuts together, the

travel stop is now set. Replace plastic

cap.

4.2 Combination Manual Over-ride (Open) and

Adjustable Opening Stop

(Manual Over-ride (Open) not available on 1/4”

through 2”, DIN 8 - 50 or 3” & 4”, DIN 80 - 100

Series 33.)

4.2.1 Operation of Manual Over-ride (Open): (3” &

4” Series 47 only, DIN 80 & 100 only)

4.2.1.1 Remove switch Package if present.

4.2.1.2 Release any air pressure in top cover.

4.2.1.3 Remove clear plastic cap and loosen

jam nuts.

4.2.1.4 Use a wrench to hold the adjusting

bushing from rotating, turn the lowest

jam nut clockwise. This opens the valve

0.056” (1.42 mm) per rotation. Rotate

the nut counterclockwise to return

valve to closed position. Note: Travel

stop adjustment is recommended at

this time. See Section 4.1 to adjust

travel stop.

4.2.1.5 Tighten jam nuts together and assemble plastic cap.

4.2.2 Operation of Adjustable Opening Stop:

(1/4” through 2”, DIN 8 - 50)

4.2.2.1 Remove switch package if present.

4.2.2.2 Using air pressure and bleed type regulator, open valve to desired position.

4.2.2.3 Rotate adjusting bushing counterclockwise until resistance is felt.

4.2.2.4 Opening stop is now set. NOTE: VALVE

CLOSED SWITCH REQUIRES ADJUSTMENT.

4.2.3 Operation of Adjustable Opening Stop:

(3” & 4” Series 47, DIN 80 & 100)

4.2.3.1 Remove switch package if present.

4.2.3.2 Remove clear plastic cap.

4.2.3.3 Using air pressure and bleed type regulator, open valve to desired position.

4.2.3.4 Rotate adjusting bushing counterclockwise until resistance is felt. Count and

record the number of turns.

4.2.3.5 Loosen the two jam nuts and turn the

lower nut clockwise the same number

of turns recorded above. Lock the nuts

together. Note: Travel stop adjust-

ment is recommended at this time.

See Section 4.1 to adjust travel stop.

4.2.3.6 Replace cap.

4.3 Combination Manual Over-ride (Close) and

Adjustable Opening Stop

(Wrench closing not available on 1/4” through

2”, DIN 8 - 50 or 3” & 4”, DIN 80 & 100, Series 33.)

4.3.1 Operation of Manual Over-ride (Close):

(3” & 4” Series 47 (DIN 80 & 100)

Direct & Double only)

Page 8

8

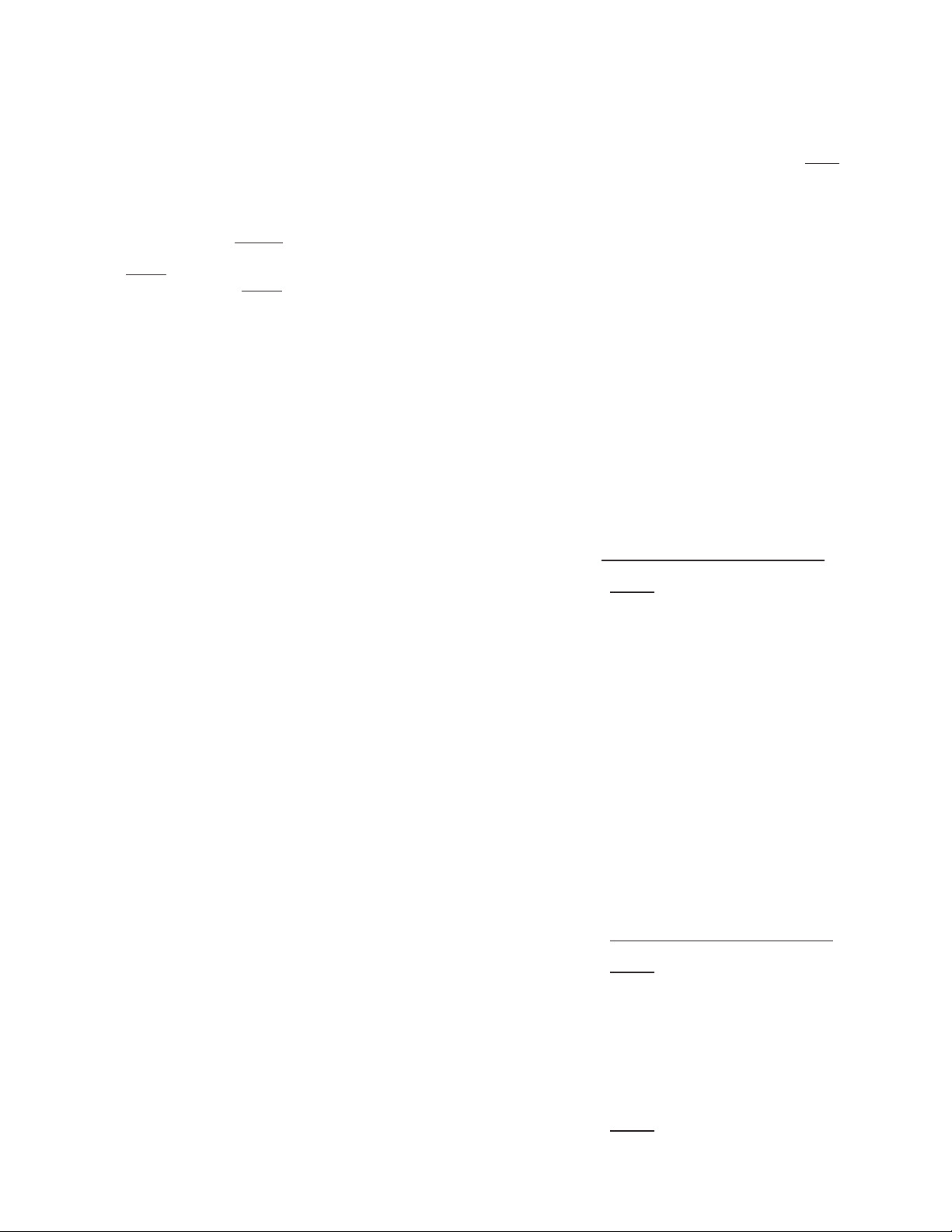

ADVANTAGE®ACTUATOR

FIGURE 1

1/4” - 2”

(DIN 8-50)

3

⁄4”-2”

“D”

“D”

“C”

“TOP VIEW”

1

⁄4”-1⁄2”

“C”

“E”

DOUBLE ACTING

&

SPRING TO OPEN AIR CLOSE

SPRING TO CLOSE AIR TO OPEN LOW PROFILE

“A/B”

Page 9

9

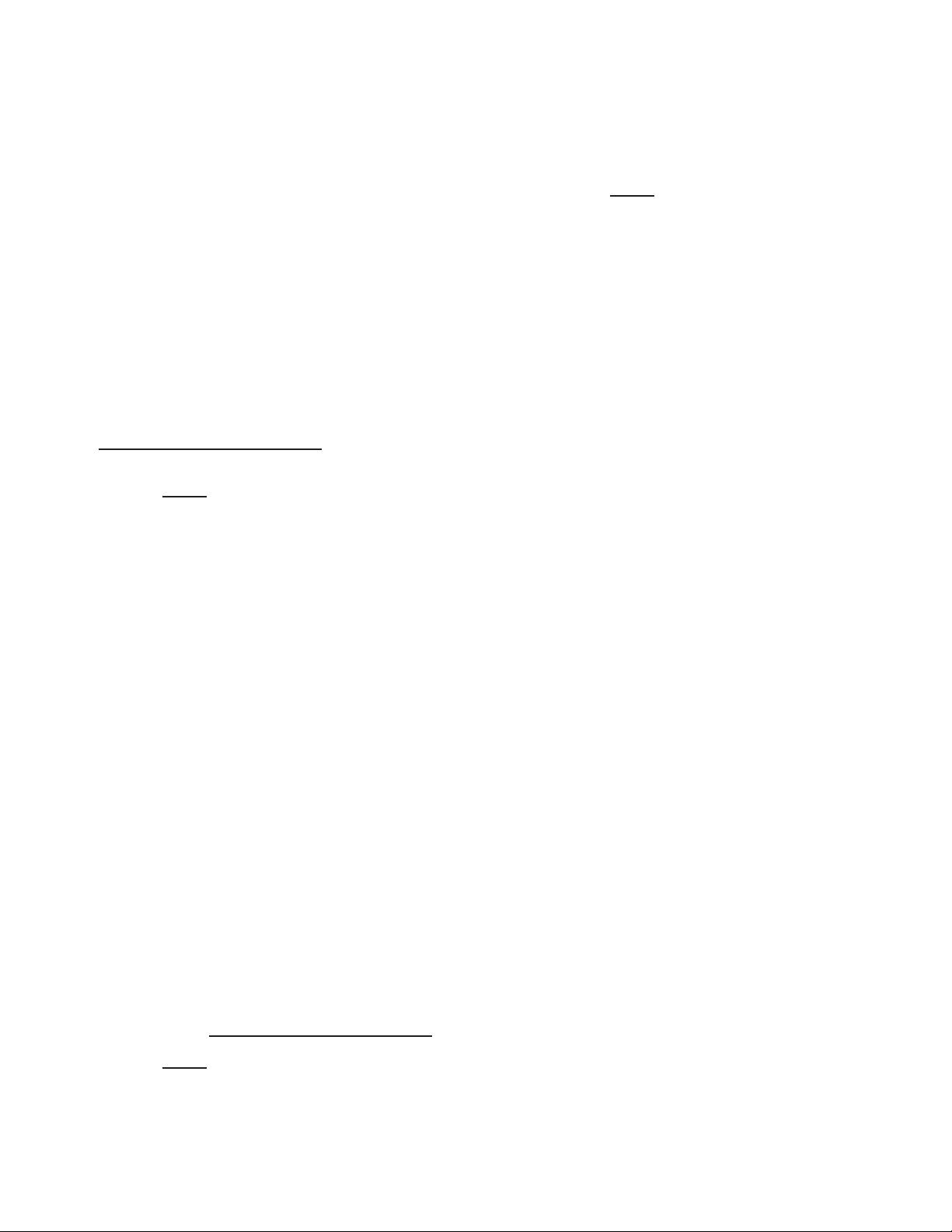

ADVANTAGE®ACTUATOR

3” - 4” (SERIES 47)

(DIN 80-100)

“A/B”

DOUBLE & DIRECT

ACTING

REVERSE ACTING

QUANTITY

REQUIRED,

1 FOR DIR. ACT.

2 FOR DBL ACT.

1

⁄4” NPI

FURNISHED WITH

DIR. ACT. ONLY

1

⁄4” NPI

*

*

*

*

*

*

* RECOMMENDED SPARE PARTS

PLASTIC CAP

(TRANSPARENT)

ROLLER BEARING

& RACES

O-RING

TOP

COVER

SPRING

PLUNGER

TRAVEL

STOP

NUTS

VALVE

SPINDLE

ADJUSTING

BUSHING

THRUST

WASHER

O-RING

TRAVEL, STOP, ADJUSTABLE OPENING

STOP & MANUAL OVER-RIDES

FIGURE 2

3” - 4” (SERIES 47)

(DIN 80-100)

Page 10

10

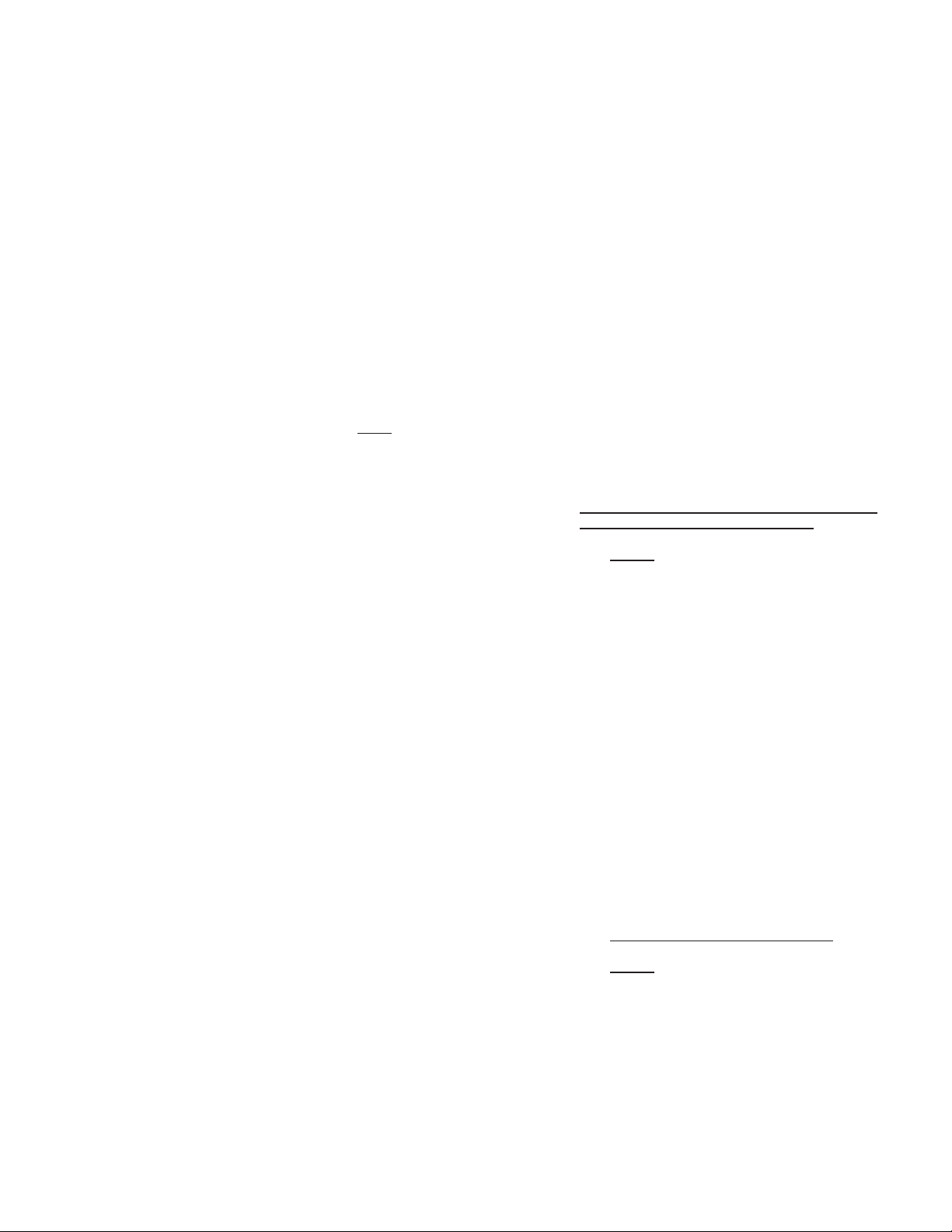

ADVANTAGE®ACTUATOR

3” - 4” (SERIES 33)

(DIN 80-100)

QTY. REQUIRED,

1 FOR REV. ACT.

REVERSE ACTING

DOUBLE & DIRECT

ACTING

QTY. REQUIRED,

1 FOR DIR. ACT.

2 FOR DBL. ACT.

FURNISHED

WITH DIR.

ACT. ONLY

REVERSE ACTING

ACTUATOR DIAPHRAGM REPLACEMENT

Page 11

11

4.3.1.1 If present, the switch package must be

removed.

4.3.1.2 Release any air pressure in bottom

cover.

4.3.1.3 Remove clear plastic cap.

4.3.1.4 Use a wrench to turn the adjusting

bushing counter clockwise to close the

valve (record the number of turns).

Turn the adjusting bushing clockwise

the same number of turns to return

valve to open position.

4.3.1.5 Tighten Travel Stop nuts and assemble

plastic cap.

5 SWITCH PACK 2.0

(The switch package is not autoclavable,

maximum temperature is 150˚ F 65.5˚C)

(Switches and Positioners cannot be used

together)

Retrofit - The switch package as received from

the factory is pre-set, only minimal adjustment

is required to adapt to the actuator.

5.1 Field Mounting (1/4” through 2”, DIN 8 - 50, 3” &

4”, DIN 80 & 100, Series 33)

5.1.1 Remove the four(4) stainless steel screws on

the actuator top cover. Place the valve in the

open position.

5.1.2 Remove the plastic plug from the indicating

spindle.

5.1.3 Thread the switch indicating spindle into the

valve indicating spindle. Use Blue Loctite #242.

5.1.4 Mount the adapter, insure that both O-Rings

are on the adapter and lubricated with Dow

111. The correct torque is 5 in-lbs (.656 Joules).

5.1.5 Slide the switch sub assembly down over the

adapter, position the conduit entrances in the

location most desirable, (45˚ increments), press

down and tighten the set screw located on the

side of the lower housing to lock the unit in

place. The set screw torque should not exceed

5 in-lbs (.656 Joules).

5.1.6 Holding the lower housing stationary, unscrew

the top switch package cover and wire to the

terminal strip (Reference factory wiring decal).

Verify the switches operate correctly by cycling

the valve, see 5.3 for switch adjusting procedure. Screw the switch package cover on,

insure the O-Ring remains in the groove.

5.2 Field Mounting

(3” and 4” Series 47, DIN 80 and 100)

5.2.1 Remove the clear plastic cap from the actuator.

5.2.2 Thread the switch indicating spindle into the

valve indicating spindle. Use Blue Loctite #242.

5.2.3 Thread on the adapter, insure that the O-Ring

is in place at the base of the adapter.

5.2.4 Slide the switch sub assembly down over the

adapter, position the conduit entrances in the

location most desirable, (45˚ increments), press

down and tighten the set screw located on the

side of the lower housing to lock the unit in

place. The set screw torque should not exceed

5 in-lbs (.656 Joules).

5.2.5 Holding the lower housing stationary unscrew

the top switch package cover and wire to the

terminal strip (Reference factory wiring decal).

Verify the switches operate correctly by cycling

the valve, see 5.3 for switch adjusting procedure. Screw the switch package cover on,

insure the O-Ring remains in the groove.

5.3 Setting Switches

(Switches are identified with decal)

5.3.1 Remove top switch package cover.

5.3.2 Place valve in full open position.

5.3.3 Connect test device to terminal strip on connections identified for SW (open) switch. The

switch type, inductive proximity versus dry contact mechanical, determines the type of test

device required. Contact switches use a traditional volt meter with resistance capability to

verify continuity, inductive proximity switches

cannot use this method. Proximity switches

require an inductive proximity tester, such as

Pepperl+Fuch’s model #1-1305, which supplies

the proper load and supply voltage to the

switch. Inductive proximity switches must be

energized with the correct load and supply

voltage to sense the target.

WARNING: DO NOT SHORT THE INDUCTIVE

PROXIMITY SWITCH BY DIRECTLY CONNECTING A POWER SUPPLY, IRREPARABLE AND

IMMEDIATE DAMAGE CAN OCCUR TO THE

SWITCH.

5.3.4 Loosen the two (2) screws on the open switch

slightly.

5.3.5 Use the adjusting screw accessible from the top

to move the switch up or down the bracket to

the optimum position. (Two turns past the trigger location is recommended.)

5.3.6 Tighten the two (2) screws on the switch.

5.3.7 Place the valve in the full closed position.

5.3.8 Repeat the above steps for the SW (closed)

switch.

5.3.9 Replace the top switch package cover.

6 SWITCH PACK 2.5

(The switch package is not autoclavable,

maximum temperature is 150˚F, 65.5˚C)

(Switches and Positioners cannot be used

together)

Page 12

12

SWITCH PACK 2, SP2.0

FIGURE 3

“A”

“A”

5.29

BIO-TEK

THRU 02.00

9.75

DETAIL “B”

(03.000 & 04.000 SERIES 47)

SEE DETAIL “B”

SECTION “A-A”

DETAIL “B”

(BIO-TEK - 01.000)

NOTE:

1. RECOMMENDED SPARE PARTS ARE MARKED WITH AN

ASTERISK (*) ON THE LIST OF PARTS.

2. ▲- USED ON BIO-TEK - 01.000

+ - USED ON BIO-TEK - 02.000

- USED ON 1.500 & 02.000

- USED ON 03.000 & 04.000

∆ 3. SWITCHES

PROX P&F #NJ3-V3-Z

PROX P&F #NJ3-V3-N

PROX P&F #NJ3-V3-E

PROX P&F #NJ3-V3-E2

MECH #X97173-V3L (SIL CONT)

MECH #X97174-V3L (GOLD CONT)

● 4. USED ONLY WITH PROXIMITY SWITCHES.

5. USED ONLY WITH MECHANICAL SWITCHES

➜

WIRING LABELS (ITEM 31)

Page 13

13

Retrofit - The switch package as received from

the factory is pre-set, only minimal adjustment

is required to adapt to the actuator.

6.1 Field Mounting (1/4” through 1”, DIN 8 - 25)

6.1.1 Remove the four(4) stainless steel screws on

the actuator top cover. Place the valve in the

open position.

6.1.2 Remove the plastic plug from the indicating

spindle.

6.1.3 Mount the adapter, insure that both 0-Rings

are on the adapter and lubricated with Dow

111. The correct torque is 5 in-lbs (.565 Joules).

6.1.4 Place the washer on the adapter. Thread the

switch indicating spindle (item 12) into the

actuator spindle. Use Blue Loctite #242.

6.1.5 Slide the switch sub assembly down over the

adapter, position the conduit entrances in the

location most desirable, (45˚ increments), press

down and tighten the set screw located on the

side of the lower housing to lock the unit in

place. The set screw torque should not exceed

5 in-lbs (.565 Joules).

6.1.6 Attach target assembly (item 9) to switch indicating spindle (item 12) using shoulder screw

with Belleville washers in place. Use Blue

Loctite #242. Run field wires and conduit to

terminal strip. (Reference factory wiring tag.)

Verify the switches operate correctly by cycling

the valve, see 6.2 for switch adjusting procedure. Screw the switch package cover on,

insure the O-Ring remains in the groove.

6.2 Setting Switches

(Switches are identified with decal)

6.2.1 Remove top switch package cover.

6.2.2 Place valve in full open position.

6.2.3 Connect test device to terminal strip on connections identified for open switch. The switch

type, inductive proximity versus dry contact

mechanical, determines the type of test device

required. Contact switches use a traditional

volt meter with resistance capability to verify

continuity, inductive proximity switches cannot

use this method. Proximity switches require an

inductive proximity tester, such as

Pepperl+Fuch’s model #1 - 1350, which supplies the proper load and supply voltage to the

switch. Inductive proximity switches must be

energized with the correct load and supply

voltage to sense the target.

WARNING: DO NOT SHORT THE INDUCTIVE

PROXIMITY SWITCH BY DIRECTLY CONNECTING A POWER SUPPLY, IRREPARABLE AND

IMMEDIATE DAMAGE CAN OCCUR TO THE

SWITCH.

6.2.4 Use the switch actuator (item 7) accessible

from the top to set the optimum position. (Two

turns past the trigger location is recommended.)

6.2.5 Place the valve in the full closed position.

6.2.6 Replace the top switch package cover.

7 SWITCH PACK 3.0

(The switch package is not autoclavable,

maximum switch temperature is 140˚F,

60˚C.) (Switches and Positioners cannot be

used together.)

Retrofit - The switch package as received from

the factory on valve assemblies is pre-set, only

minimal adjustment is required to adapt to the

actuator.

7.1 Field Mounting (1/4” through 2”, DN 8 - 50)

7.1.1 Remove the four (4) stainless steel screws on

the actuator top cover. Place the valve in the

open position.

7.1.2 Remove the plastic plug from the indicating

spindle.

7.1.3 Insure all O-Rings are on the adapter and lubricated with Dow 111. Slip the switch indicating

spindle, #10-24 UNC threads first, through the

adapter until the threads are exposed. Apply

Blue Loctite #242 to the threads, thread the

switch spindle into the actuator spindle until it

shoulders.

7.1.4 Attach the adapter to the upper cover. The correct torque is 5 in-lbs (.565 Joules).

7.1.5 Thread the appropriate switch actuator(s) on

the spindle.

7.1.6 Position the closed switch actuator approximately 0.14” (4 turns) from end of threads and

position the open switch actuator approximately 0.25” (7 turns) below the top of the spindle,

do not tighten the set screw.

7.1.7 Remove the switch package top cover, slide the

sub assembly down over the adapter using

care not to damage the switch internals

(specifically the mechanical switch levers).

Position the conduit entrance in the location

most desirable, press down and tighten the set

screw located on the side of the lower housing

to lock the unit in place. Note that the plastic

adapter has two molded counterbores.

Locating the set screw in one of these holes

provides maximum resistance to conduit rotation. The set screw torque should not exceed 5

in-lbs. (.565 Joules).

7.1.8 Run field wires and conduit to the terminal

strips. Verify the switches operate correctly by

cycling the valve. See 7.2 for switch adjusting

procedure. Screw the switch package top cover

on.

7.2 Setting Switches

Page 14

14

SWITCH PACK 2.5, SP2.5

FIGURE 3A

ASSEMBLE BELLEVILLE WASHERS IN

SERIES AS SHOWN

(3.70) DIA

(3.32)

SEE DETAIL “B”

SECTION “A-A”

DETAIL “B”

“A”

“A”

NOTE:

1. RECOMMENDED SPARE PARTS ARE MARKED WITH AN

ASTERISK (*) ON THE LIST OF PARTS.

● 2. SWITCHES

PROX P&F #NJ3-V3-Z

PROX P&F #NJ3-V3-N

PROX P&F #NJ3-V3-E

PROX P&F #NJ3-V3-E2

MECHANICAL X96324-UM (SIL CONT)

MECHANICAL X96325-UM (GOLD CONT)

▲ 3. USED ONLY WITH MECHANICAL SWITCHES.

WIRING DIAGRAM CARDS (ITEM 30)

Page 15

15

7.2.1 Remove top switch package cover.

7.2.2 Place valve in full open position.

7.2.3 Connect test device to terminal strip for open

switch. The switch type, inductive proximity

versus dry contact mechanical, determines the

type of test device required. Contact switches

use a traditional volt meter with resistance

capability to verify continuity, inductive proximity switches cannot use this method. Proximity

switches require an inductive proximity tester,

such as Pepperl+Fuch’s model #1-1350, which

supplies the proper load and supply voltage to

the switch. Inductive proximity switches must

be energized with the correct load and supply

voltage to sense the target.

WARNING: DO NOT SHORT THE INDUCTIVE

PROXIMITY SWITCH BY DIRECTLY CONNECTING A POWER SUPPLY, IRREPARABLE AND

IMMEDIATE DAMAGE CAN OCCUR TO THE

SWITCH.

7.2.4 Bio-1.50” (Two Switch Actuators)

7.2.4.1 Verify the switch package locking set

screw is tight.

7.2.4.2 Verify the circuit board is firmly seated.

7.2.4.3 For mechanical switches only, press on

the top of the circuit board to move it

toward the switch actuator. Thread the

switch actuator two (2) turns past the

initial switch indication.

7.2.4.4 Lock in place with the set screw on

switch actuator.

7.2.5 2.0” (One switch actuator)

7.2.5.1 Do not set the switch in the open

position, set the switch in closed position. Follow 7.2.4 with the valve in full

closed position. Confirm open switch

functions in full open position only

after setting in closed position.

7.2.6 Place the valve in the full closed position and

connect the appropriate test device to the terminal strip for valve CLOSE switch. Repeat section 7.2.4-7.2.5 for the valve CLOSED switch.

Note on SP 3.0 units, the closed switch actuator must never hit the adapter in the closed

position with body attached.

8 POSITIONERS

(Switches and Positioners cannot be used

together)

(A special adjusting bushing is required for 3”

& 4“ (DIN 80 & 100) Actuators with positioners)

8.1 Scope: Top-mounted positioners listed below

8.1.1 Moore 73N12F (A100 & A300 Series Actuators)

(Direct Acting Positioner, Top Loading)

8.1.2 Moore 73NB (A200 Series Actuators) (Direct

Acting Positioner, Bottom Loading)

8.1.3 Moore 73NFR (A100 & A300 Series Actuators)

(Reverse Acting Positioner, Top Loading)

8.2 Supply and Instrument Pressures

8.2.1 Instrument input pressure range - as specified:

3-15 psi (.21 - 1.03 bar) (standard), 3-9 psi

(.21-.62 bar), 6-30 psi (.41-2.07 bar) and others

are optional.

8.2.2 Supply pressure: 3 psi (.21 bar) above required

actuator pressure to a maximum of 90 psi (6.2

bar). A filtered air supply is recommended.

8.2.3 Caution: Pressure in excess of 90 psi (6.2

bar) to any connection may cause damage.

8.3 Description

The positioner is designed to operate a valve actuator to maintain the valve in a position determined by

the control instrument. The above positioners are

direct acting - with an increase in instrument pressure, the pressure to the actuator (positioner output)

will increase or reverse acting - with an increase in

instrument pressure, the pressure to the actuator

(positioner output) will decrease. On a bottom load-

ing positioner (73NB), output is connected to the

actuator lower chamber via an external tube.

Therefore, the valve will open as instrument pressure

increases. The 73NB is the only unit which can have

an O-ring in the actuator upper cover

. All others

operate on the concept that air feeds the upper

cover by flowing down the indicating shaft and into

the cover. (This means that a field retrofit for

Double and Direct units must have the O-ring

removed and a special slotted adjusting bushing.)

Double Acting (A300 Series) require the lower actuator cover to be pre-loaded, use a bleed off type regulator with gauge. (This is standard when ITT supplies

the assembly.)

8.4 Installation

The only task is to connect the supply and instrument air. All connections are 1/4” NPT. Use 1/4” O.D.

tubing for the instrument connection, either 1/4” or

3/8” O.D. (6.35 or 9.52 mm) tubing for the supply

connection. Blow out all piping before connections

are made to prevent the possibility of dirt or chips

entering the positioner. Use pipe sealant sparingly,

and then only on the male threads. A non-hardening

sealant is strongly recommended. Connect the positioner to a source of clean, dry oil-free air. A filtered

and regulated air source is recommended.

Note: Synthetic compressor lubricants in the air

stream at the instrument may cause the positioner to fail.

Note that a cushion loading regulator is furnished

with 3300 series actuators and a tee in the supply

connection is routed to this regulator, so an extra

hookup is not required. The cushion loading regulator should be set at the minimum pressure required

to open the valve wide open. Typically, this is 10 psi

(0.69 bar) or less.

Page 16

16

SWITCH PACK 3.0, SP3.0

FIGURE 3B

(ADAPTER)

ADVANTAGE

ACTUATOR

BIO-TEK - 1.00”

(INDICATING

SPINDLE)

ASSEMBLE WITH LOCTITE

SEALANT #242 (BLUE)

ADVANTAGE

ACTUATOR

(INDICATING

SPINDLE)

ASSEMBLE WITH LOCTITE

SEALANT #242 (BLUE)

1.50” & 2.00”

Page 17

17

8.5 Adjustment

The only adjustment that can be made on the positioner is a zero adjustment. The zero adjusting screw

is located under the positioner’s top cover. To make

this adjustment, set the instrument air pressure to

the midpoint of its span, and turn the zero adjustment until the valve is at the mid-point of its stroke.

Refer to Table #2 for stroke information. Recheck the

setting accuracy by changing instrument air pressure

to the maximum/minimum point to obtain full

open/closed valve position.

In some cases, valve shut-off or opening may be

required at a specific instrument pressure. To zero

the positioner at this point, set the instrument signal

at the specific pressure and turn the zero adjustment

screw until the valve reaches the required position. A

slight change of the instrument pressure should start

to move the valve. The valve stroke for a given span

may also be suppressed or shifted to the desired

range by means of the zero adjusting screw.

8.6 Maintenance

A clean, oil and moisture free air supply will reduce

maintenance problems. The supply air filter should

be blown down on a routine basis. The filter element

should be examined periodically and replaced if necessary. No lubrication is required on the valve positioner. The system should be shut down or the valve

isolated from the system before service or removal of

the positioner is accomplished.

For additional maintenance activities, refer to the

Manufacturer’s service manual.

Page 18

18

POSITIONER

FIGURE 4

3

⁄4” - 4”

(DIN 20-100)

Page 19

19

FIGURE 5

VALVE DIAPHRAGM IDENTIFICATION

ELASTOMER - 1 PIECE, MADE OF RUBBER, WITH

MOLDED IN STUD. (SEE TABS)

Page 20

120

13.56

20

Page 21

DWG. ITEM 13 7.9 14 10 12 13

03 #110 #110 #110, #112 N/A #117 #116 #152

05 #112 #112 #112, #114 N/A #117 #116 #152

08 #112 #112 #112, #114 N/A #117 #116 #152

16 #114 #114 #114, #118 N/A #117 #116 #152

*33 #208 #214 N/A N/A #117 #116 #152

*47 #212 #214 N/A #128 #128 #116 #152

ACT SIZE ACTUATOR ACTUATOR LOW ACTUATOR SP2 SP2 SP2

AXYY UPPER LOWER PROFILE CAP BASE ADAPTER/COVER UPPER COVER/

COVER COVER BUSHING • • • LOWER COVER

1) *FDA COMPLIANT BUNA N MATERIAL

2) STANDARD MATERIAL, UNLESS NOTED, IS FDA COMPLIANT VITON

21

TABLE 4

O RING CHART

ADVANTAGE ACTUATOR AND SWITCH PACKAGE, SP2

Page 22

22

NOTES

Page 23

23

NOTES

Page 24

Pure-Flo Solutions Group

For more information, please contact:

Engineered Valves Headquarters

33 Centerville Road, P.O. Box 6164

Lancaster, PA 17603-2064 USA

or call: (800) 366-1111

(717) 509-2200

Fax: (717) 509-2336

Website: www.engvalves.com

E-mail: engvalves_custserv@fluids.ittind.com

©2001 ITT Industries

Pure-Flo Solutions Group

Headquarters

33 Centerville Road

Lancaster, PA 17603

Phone 800-366-1111

Phone (717) 509-2200

Fax (717) 509-2336

Pure-Flo California

Formerly ITT Sherotec

725 East Cochran Street, Unit E

Simi Valley, CA 93065

Phone 800-926-8884

Phone (805) 520-7200

Fax (805) 520-7205

Pure-Flo Sweden

Formerly A.G. Johansons Metallfabrik

Box 26 Vasterasvagen 6

S-730 40 Kolbäck

Phone +46-220-403-20

Fax +46-220-405-23

Pure-Flo UK

Formerly Sinton Group

Richards Street

Kirkham, Lancashire

PR4 2HU, England

Phone +44-1772-682696

Fax +44-1772-686006

OFFICE LOCATIONS

Loading...

Loading...