Page 1

NEO-D

YN

801P5 S

MART SWITCH

TM

INSTALLATION AND

OPERATION MANUAL

PN 610-0002 Rev D

ECO 71349

Page 2

WARNING

CAUTION

NOTE

Manual No. 610-0002 Rev. D

Neo-Dyn

28150 Industry Drive

Valencia, CA 91355

Tel: (661) 295-4000

Fax: (661) 294-1750

World Wide Web: www.neodyn.com

Copyright 2002

ITT Industries

Important Information

The product warranty applicable to this ITT Neo-Dyn® instrument

is as stated on page 41 of this manual.

Should any after-delivery problems arise, please contact

ITT Neo-Dyn’s Customer Service using the information above.

Our normal business hours are weekdays, 7:00 am to 3:30 pm,

Pacific Time.

Before installing the Smart-SwitchTM, become familiar with the

installation instructions in Chapter 2.

Indicates a hazard which can cause severe personal injury,

death, or substantial property damage if the warning is

ignored.

Indicates a hazard which will or can cause minor personal injury

or property damage if the caution is ignored.

Indicates additional information about a particular item necessary

to the operation of the unit.

This document contains proprietary information which is the

property of Neo-Dyn, a unit of ITT Industries. This document

may not be reproduced, either in part or in full, without the

consent of ITT Industries.

801P5 Smart SwitchTM Page i

Page 3

TABLE OF CONTENTS

PAGE

CHAPTER 1 INTRODUCTION................................................. 1

ABOUT THIS MANUAL ......................................................... 4

KEYS ........................................................................................ 4

DISPLAY .................................................................................. 4

CUSTOMER SERVICE............................................................ 4

CHAPTER 2 INSTALLATION .................................................. 5

MOUNTING ............................................................................. 5

PRESSURE CONNECTION .................................................... 5

ELECTRICAL CONNECTIONS ............................................. 6

CHAPTER 3 OPERATION & PROGRAMMING ................... 11

OPERATION MODE.............................................................. 11

FRONT PANEL CONTROLS ................................................ 12

INPUT CONTROLS ............................................................... 13

DISPLAYING PRESSURE .................................................... 13

DISPLAYING SET POINTS.................................................. 14

STANDARD VS. WINDOW MODE ..................................... 15

PROGRAMMING MODE ...................................................... 17

ENTER PROGRAMMING MODE ........................................ 17

CHANGING THE SET POINTS............................................ 19

ADDITIONAL FEATURES ................................................... 20

CHAPTER 4 ANALOG OPTION............................................. 25

ANALOG OPTION WIRING................................................. 25

TURNING ANALOG OUTPUT ON AND OFF(LOOP)...... 25

4-20 MILLIAMPERE OUTPUT CALIBRATION (4CAL)... 26

4-20 MILLIAMPERE OUTPUT SCALING .......................... 27

CHAPTER 5 TROUBLESHOOTING ...................................... 29

ERROR MESSAGES.............................................................. 29

Page ii Installation and Operation Manual

Page 4

TABLE OF CONTENTS

PAGE

CHAPTER 6 SERIAL COMMUNICATIONS (Z Option) ....... 35

GENERAL ..................................................................................35

WIRING ......................................................................................35

CHAPTER 7 SPECIFICATIONS.............................................. 37

STANDARD ........................................................................... 37

OPTIONS ................................................................................40

WARRANTY INFORMATION ................................................. 41

801P5 Smart SwitchTM Page iii

Page 5

CHAPTER

1

INTRODUCTION

The Neo-Dyn® 801P5 Smart-SwitchTM is a solid-state pressure

switch designed for a wide range of applications in pneumatic and

hydraulic systems up to 3,000 psig. Pressure indication, switch

status and operational status are continually displayed on the front

panel. The unit can be configured to display pressure readings in a

variety of formats.

The Smart-SwitchTM can be configured on-site, using the front

panel keypad and 4 digit display, or remotely via the optional

RS-232 connection. The 4-20 mA output option offers remote

monitoring capabilities.

A built-in password security system prevents unauthorized

adjustments. When locked, pressure can be monitored and set

points may be viewed, but no adjustments can be made without

entering the correct password.

The Smart-SwitchTM may be ordered to operate on 115 VAC

50/60 Hz, 230 VAC 50/60 Hz, or 18-30 VDC input power.

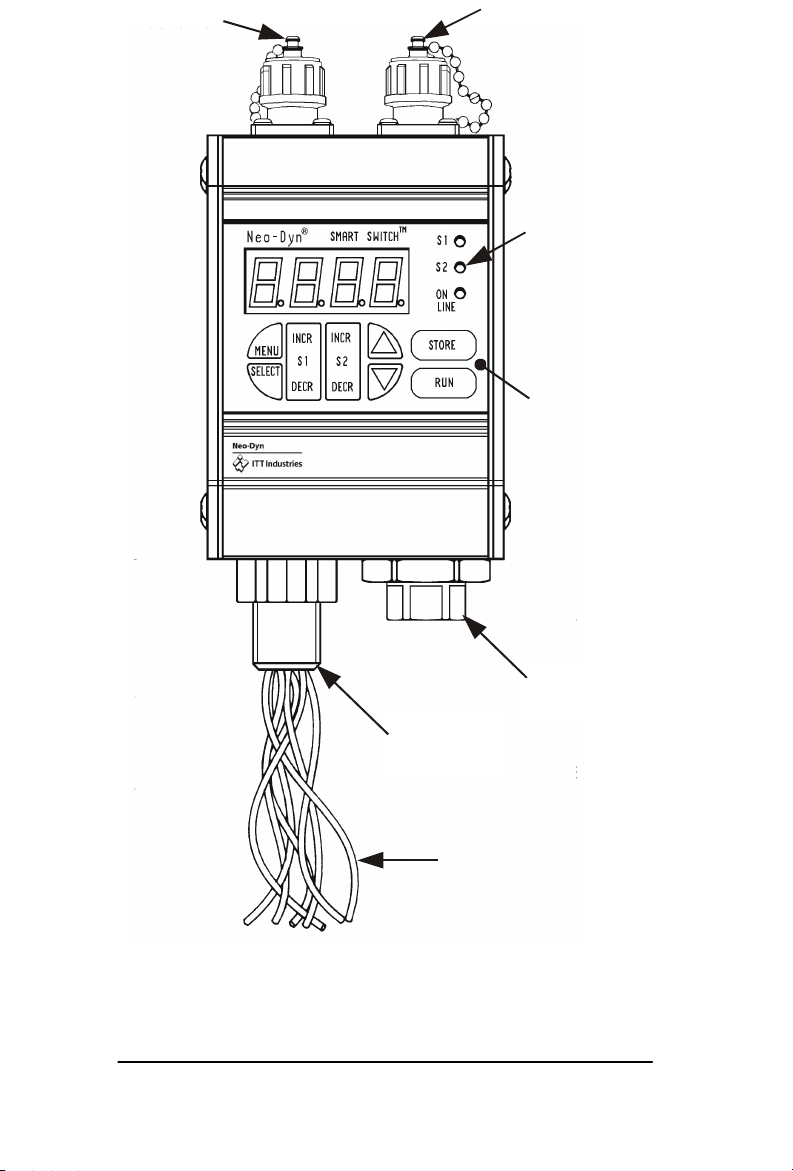

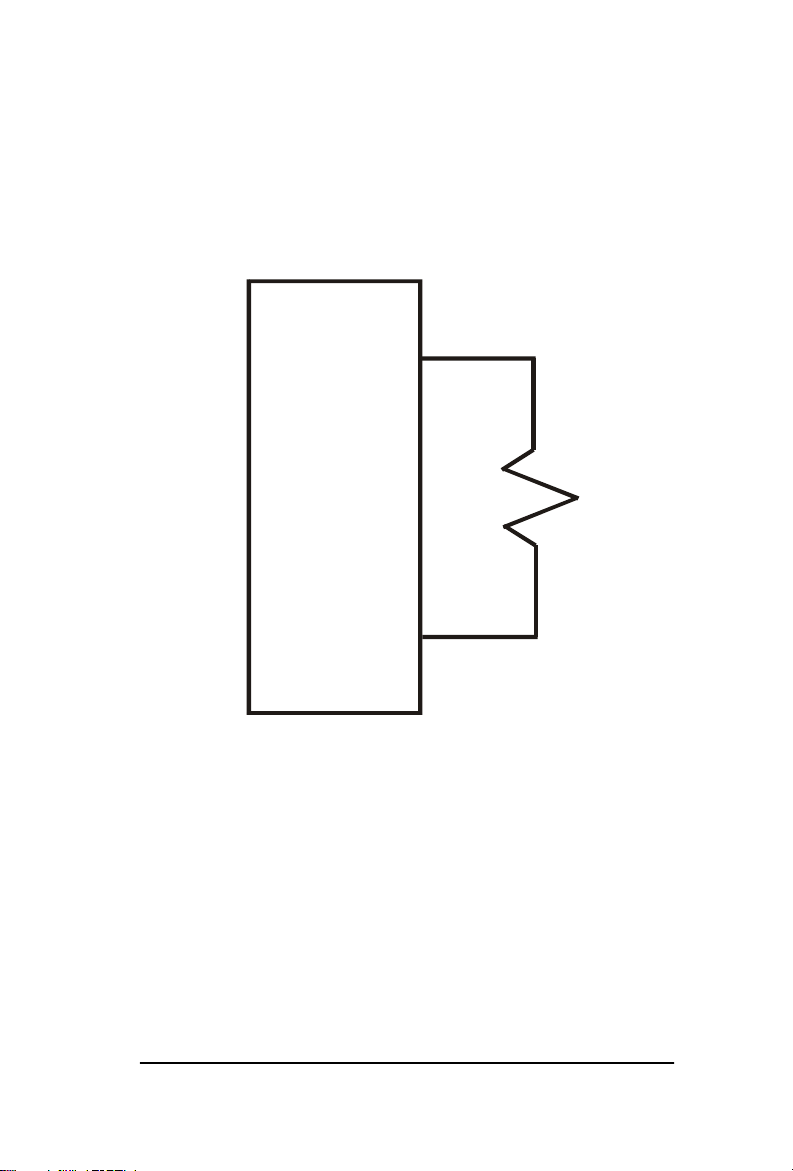

The external configuration of the Smart-SwitchTM is shown in

Figure 1 on the next page.

Page 1 801P5 Smart SwitchTM

Page 6

Conduit

Connection

1/2-14 NPT

Pressure

1/4-18 NPT

4-20 mA

RS232

Keypad

COM Port

Output

Status

Indicators

Port

Std

18” free leads

#22 AWG

Figure 1 Model 801P5 Smart-SwitchTM

(Mounting Brackets not Shown)

Page 2 Installation and Operation Manual

Page 7

The standard electrical interface is 22 AWG free leads exiting

from a ½” - 14 NPT male conduit connection. The standard

pressure connection is ¼” - 18 NPT female; a 7/16” - 20 SAE

pressure connection is available as Option E.

Output options available for the Smart-SwitchTM include a

4-20 mA analog output (Option V), scalable display units

(Option Q), and RS232 communications (Option Z).

The RS232 option can be used to configure and monitor the unit

remotely. This option includes Windows®-based software.

Chapter 7 on page 37 contains complete specifications for the

801P5 Smart-SwitchTM.

Page 3 801P5 Smart SwitchTM

Page 8

ABOUT THIS MANUAL

The following paragraphs describe the format conventions used in

this manual.

KEYS

Most of the instructions contain directions to press a key, which is

one of the blue touchpads on the display surface of the

Smart-SwitchTM. When included in instructions, the keys are

shown in brackets, as [STORE].

DISPLAY

When shown in the text, the LED displays are formatted as

279.3.

CUSTOMER SERVICE

If you have any questions about the 801P5 Smart-SwitchTM that

are not covered in this manual, you can contact Neo-Dyn in several

ways:

The customer service phone number is (661) 295-4000. Our

customer service department is open from 7:00 am to 3:30

p.m. Pacific Time.

Our Internet site is: www.neodyn.com.

Page 4 Installation and Operation Manual

Page 9

WARNING

WARNING

WARNING

WARNING

CAUTION

CHAPTER

2

INSTALLATION

Installation of the Smart-SwitchTM is relatively straightforward.

However, the Smart-SwitchTM must be installed by a qualified

electrician, in compliance with all local and national electrical codes.

Electrical Hazard

Do not make electrical connections while power is on.

Always check for multiple circuits.

Always make sure grounding is adequate.

MOUNTING

The Smart-SwitchTM can be mounted directly to the pressure

connection, or it can be attached to a flat surface, such as a wall,

near the connection to be monitored. For surface mounting, slide

the two mounting brackets into the slots on the back of the

Smart-SwitcTM and use #10 (.190 in. dia.) fasteners.

PRESSURE CONNECTION

The standard pressure connection for the 801P5 Smart-SwitchTM

is a ¼”- 18 NPT female pipe thread. A 7/16” - 20 SAE boss is

also available as Option E. When installing the Smart-SwitchTM,

always:

• Make sure that the unit and your system have the same fittings.

• Use the wrench flats provided.

• Seal all joints with pipe joint sealing compound.

Avoid excessive torque on all threaded connections.

Page 5 801P5 Smart SwitchTM

Page 10

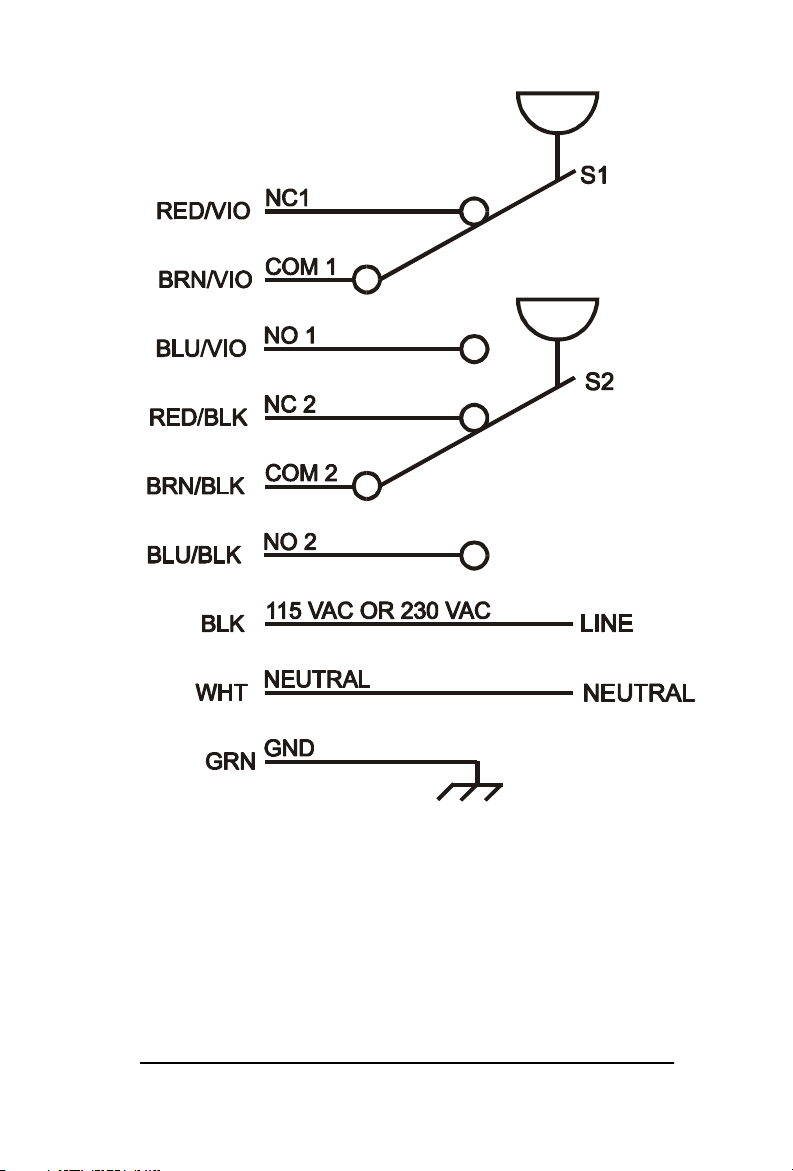

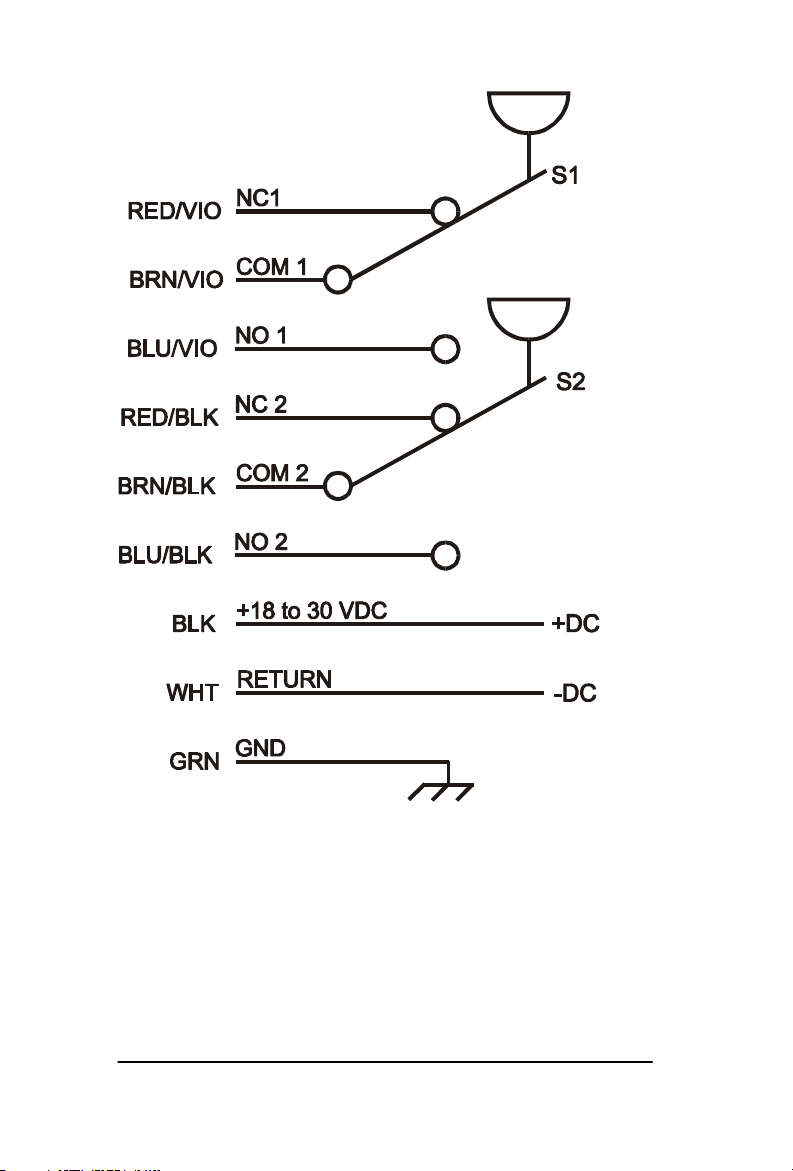

ELECTRICAL CONNECTIONS

Units are supplied with 22 AWG free leads exiting from a ½”-14

NPT male conduit connection. The leads are-color coded and

marked. See Figure 2 for AC operation and Figure 3 for DC

operation.

4-20 mA output (option letter V) is connected to the 2-pin

connector on the top-right of the unit per Figure 4, using the

supplied mating connector. This mating connector has solder cups

that will take wires as large as #18 AWG. See Chapter 4 for

operating instructions.

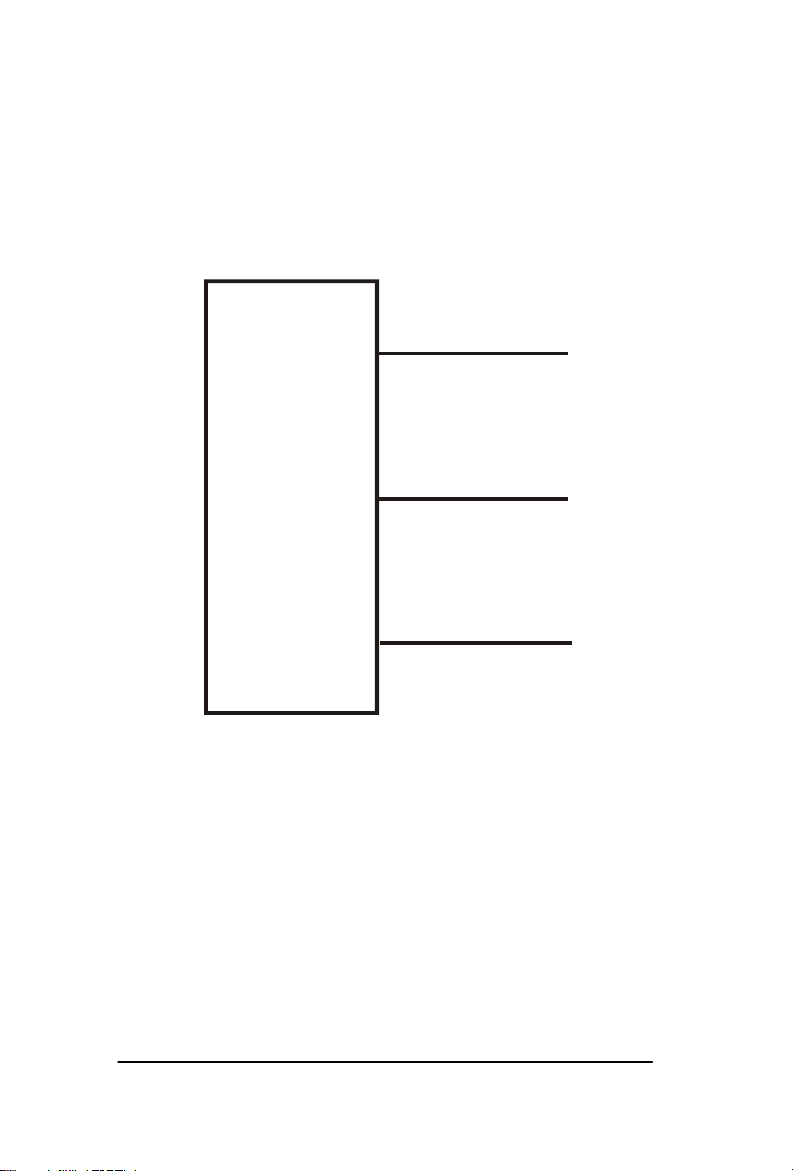

The RS232 communications (option letter Z) are connected to the

3-pin connector on the top-left of the unit (See Figure 5), using

the supplied mating connector. This mating connector has solder

cups that will take wires as large as #18 AWG. Cable length must

not exceed 50 feet. See Chapter 6 for operating instructions.

All field wiring for the 801P5 must comply with requirements of

the NEC or applicable local electrical codes.

Page 6 Installation and Operation Manual

Page 11

Figure 2 - Schematic for AC Operation

Page 7 801P5 Smart SwitchTM

Page 12

Figure 3 - Schematic for DC Operation

Page 8 Installation and Operation Manual

Page 13

A

B

+ 4-20 Ma

RETURN

Figure 4 - Wiring for 4-20 mA Analog Output

Page 9 801P5 Smart SwitchTM

Page 14

A

DATA SEND

DATA RECEIVE

B

C

Figure 5 - Wiring for RS-232 Communications

SIGNAL GROUND

Page 10 Installation and Operation Manual

Page 15

CHAPTER

3

OPERATION & PROGRAMMING

This section describes the regular (normal) operation of the

Smart-SwitchTM as it monitors pressure after installation and

initial setup, and the Programming Mode for changing the

settings.

Both modes rely on the front panel for information and input. See

Figure 6 on the next page.

OPERATION MODE

To begin operation, apply correct power to the appropriate free

leads (there is no on-off switch).

In normal operation mode, the display shows:

• Online LED (green) indicates operation mode

• S1 and S2 LED's (red) indicate the switch status (illuminated

when the relay coil is energized or the solid-state switch is

actuated)

• System pressure is displayed

You can also check the set points in operating mode; all other

actions are done in programming mode. However, If you have the

RS232 option, you can program the unit remotely using its

Windows® software on a personal computer; see Chapter 6.

Page 11 801P5 Smart SwitchTM

Page 16

FRONT PANEL CONTROLS

Figure 6 The Front Panel,

with Function Keys Below the Display

Indicators

Display

The display shows the actual system pressure in normal

operation.

S1 and S2 (Switch) Indicators

The S1 and S2 (red LED's) indicate switch status (illuminated

with the relay coil energized or the solid-state switch actuated).

Online Indicator

The Online indicator (green LED) is lit when the unit is

online and active. If the indicator is not lit, the unit is offline.

Page 12 Installation and Operation Manual

Page 17

NOTE

INPUT CONTROLS

S1 and S2 INCR/DECR

Push the [S1] and [S2] [INCR] and [DECR] keys to see what

values the set points are configured for.

MENU

Use the [MENU] key to enter program mode.

UP/DOWN ARROW

The [UP/DOWN ARROW] keys are used to move through

the list of submenus.

SELECT

The [SELECT] key is used to move into the desired submenu.

STORE

The [STORE] key is used to temporarily save changes made

to the current submenu and return to the main menu.

RUN

The [RUN] key is used to lock in the programming changes

made.

After pressing [RUN], to return to operation mode (go back

online), you must press [SELECT]. Otherwise, any programming

changes will be lost after 2 minutes.

DISPLAYING PRESSURE

When the Smart-SwitchTM is in operation mode, system pressure

is displayed on the front panel.

Page 13 801P5 Smart SwitchTM

Page 18

NOTE

DISPLAYING SET POINTS.

Programmed set points can be viewed on the front panel display

by pressing the corresponding [S1] or [S2] key. To view the

increasing value for Switch 1, press [S1 INCR]. To view the

decreasing value for Switch 2, press [S2 DECR].

Figure 7 Press the Incr / Decr Buttons

to Display Set Points for S1 / S2

After 5 seconds of keypad inactivity, the display automatically

changes back to the system pressure display. While viewing set

points, the output functions remain active.

Page 14 Installation and Operation Manual

Page 19

STANDARD VS. WINDOW MODE

DEACTUATES

SWITCH

The terms “Standard” and “Window” describe two methods for

setting up the Smart-SwitchTM to monitor pressure.

Standard Mode

In Standard Mode, illustrated in Figure 8, the SP1i (or SP2i) set

point actuates when the pressure being monitored goes above the

set value. At this point, the Smart-SwitchTM might turn off

whatever electrical power is being applied to a pump, for

example, which is increasing or maintaining the pressure. The

switch de-actuates, or resets, when the pressure drops below the

preset decreasing set point (SP1d or SP2d). At this time, the

electrical power to the pump would be turned back on.

ACTUATES

INCREASING SET POINT

DEADBAND

DECREASING SET POINT

Figure 8 Standard Mode

Page 15 801P5 Smart SwitchTM

SWITCH

Page 20

Deadband

(INCREASING SET POINT)

(DECREASING SET POINT)

NO = CLOSED

NO = CLOSED

The deadband is the separation between the increasing set point

and the decreasing set point, as shown in Figure 8. The deadband

can be anywhere from 1% to 99% of Full-Scale Output (F.S.O.).

In the case above where the Smart-SwitchTM is controlling a

pump, a wider deadband reduces the frequency at which the pump

cycles on and off.

Window Mode

This mode is useful when you want to maintain pressure within a

certain range, and want to be notified when pressure either goes

above or falls below that range. In Window Mode, the SmartSwitch® starts out actuated, then deactuates when it reaches its

lower set-point (SP1d or SP2d). As pressure continues to

increase, the switch actuates again when it reaches the upper

set-point (SP1i or SP2i). This range between the lower and upper

set-points is the "window". When pressure decreases, the

sequence reverses, with a deadband of 1% of F.S.O. at each of the

set-points. See Figure 9.

In this mode, the Smart SwitchTM might be wired to, say, an alarm

bell, which would sound if the pressure either rose above SP1i or

fell below SP1d.

Page 16 Installation and Operation Manual

WINDOW

UPPER BOUNDARY

NO = OPEN

LOWER BOUNDARY

Figure 9 Window Mode

Page 21

NOTE

PROGRAMMING MODE

In Programming Mode, you can:

• Change the set points

• Perform field pressure calibration

• Program Window or Standard Mode

• Change the password

• Program display update time

• Program delays for both switches

• Scale the readout

• Reset the Smart-SwitchTM to factory defaults

If your unit includes the 4-20 mA option, you can:

• Activate 4-20 mA mode

• Calibrate the 4-20 mA

• Scale the 4-20 mA output

If your unit includes the RS232 option, you can:

• Set the BAUD rate

The unit will not function as a switch while in programming

mode.

ENTER PROGRAMMING MODE

To access the programming mode, press the [MENU] key (See

Figure 7). On the initial startup, no password is required. If you

have previously set up a password, you must enter it at this time:

1. When the displays show ---O, press the [UP/DOWN

ARROW] keys to set the first digit.

2. Press [SELECT] to move to the next digit.

3. Repeat this process until display shows the correct password.

4. Press [STORE] to enter programming mode.

Page 17 801P5 Smart SwitchTM

Page 22

NOTE

You can now use the arrow keys to move throughout the menu

system. Then:

1. When the menu item you want to change is displayed, press

[SELECT].

2. After changing the value, use the [STORE] key to temporarily

save the changes. If you make a mistake while entering

values, press the [MENU] key to return to the menu system

and restart.

3. To change another item, press the [UP/DOWN ARROW]

keys to display that item, and repeat steps 1 and 2.

4. After you are done, press the [RUN] key to lock in the

changes. Then press the [SELECT] key to return online.

You must press the [SELECT] key when RUN is displayed to

permanently save any changes you have made. If you do not, all

changes will be lost after two minutes of inactivity.

When RUN is displayed, you have two additional choices, REDO

and UNDO. Use the [UP/DOWN ARROW] keys to scroll

through the menu. Press the [SELECT] key to make your choice.

REDO puts the unit back into program mode to allow

further changes.

UNDO returns the unit online without making the changes

you may have entered.

RUN returns the unit online, saving all changes.

Page 18 Installation and Operation Manual

Page 23

CHANGING THE SET POINTS

To change the set points, press the [MENU] key (See Figure 7).

The first menu item is SP1i, for Set point 1, increasing. To change

a set point:

1. If you want to change a set point other than SP1i, select the

set point by pressing the arrow keys, then press [SELECT].

The furthest right digit will blink.

2. Use the [SELECT] key to move to the digit you want to

change.

3. Use the [UP/DOWN ARROW] keys to change the value of

the digit.

4. When the value is correct, press the [SELECT] key to move to

another digit. Repeat this until you have the correct value for

this set point.

5. Use the [STORE] key to temporarily save the changes and

return to the main menu.

6. Press [RUN]and then [SELECT] to permanently save the

setting and return to On-Line operation.

If you have set an invalid set point, the error message EROR will

be displayed. Possible causes for errors are:

• INCREASE value is equal to or lower than DECREASE value.

• Values exceed range limits

• Deadband is less than 1% of F.S.O.

Page 19 801P5 Smart SwitchTM

Page 24

ADDITIONAL FEATURES

To alter the settings of the Smart-SwitchTM, press the [MENU] key

and use the [UP/DOWN ARROW] keys to move through the

menu.

Mode (MOD)

Mode allows you to choose between Standard and Window

Mode. After MOD is displayed, use the [SELECT] key to

enter the Mode submenu and use the [UP/DOWN ARROW]

keys to toggle between STD and WIN. Press the [STORE]

key to temporarily save your setting.

Delay (DELY)

This menu item allows you to delay the actuation and

deactuation of the relay switches controlled by the set points.

After DELY is displayed, use the [SELECT] key to enter the

submenu. Use the [UP/DOWN ARROW] keys to cycle

through the available delay times. Your choices are 0, 40,

100, 300, 1000, 3000 or 5000 mSec. Press the [STORE]

key to temporarily save your settings.

Display (DISP)

This item sets how often the pressure display is updated.

This can be useful when there is a lot of fluctuation in the

pressure reading. After DISP appears, use the [SELECT] key

to enter the submenu. Use the [UP/DOWN ARROW] keys

to cycle through the available display settings. This option

can be set at OFF, 0.5, 1.0, 2.0, 3.0, 4.0, or 5.0 seconds.

Press the [STORE] key to temporarily save your setting.

Password (PASS)

The Password function allows you to set a password to limit

access to all menu functions. After PASS is displayed, use

the [SELECT] key to enter the submenu. Use [SELECT] to

find the digit of the value you want to change. The digit will

blink. Use the [UP/DOWN ARROW] keys to change the

value of the digit. When the value is correct, press the

[SELECT] key. Use this procedure until all digits of the

password are changed to the correct values. Then press the

[STORE] key to temporarily save your setting.

Page 20 Installation and Operation Manual

Page 25

Scalable Readout: Option Q

With this option installed, you can change the scale factor of

the display to read in different units of pressure, or in

arbitrary numbers that you choose.

If your system is set up with pressures in bars, for example,

you might want the Smart-SwitchTM display to show bars

instead of psig.

The r-Hi, r-Lo and .Loc menu functions allow you to scale

the readout to your preference. In the following example,

millibars are used:

You have a scalable 801P5 with the 15psig sensor. You

want to represent the pressure in millibars. The standard

conversion unit is 1 psi = 68.95 millibars.

You want to read zero for zero pressure, therefore,

r-Lo = 0.

Full-scale output pressure for the 801P5 for this example

is 15 psig. So, r-Hi = 68.95 x 15 = 1034.25 millibars,

which rounds to 1034. Therefore r-Hi should be set to

1034.

The unit now reads from 0 to 1034 millibars for 0 to

15 psig pressure. The accuracy is ± 2 millibars, which is

± 0.2% of 1034.

You can use the scalable readout to set the display to read

whatever units are most familiar to you, or arbitrary numbers

such as 0 to 10. With the 4-digit display, you can use

positive numbers to 9999, and negative numbers to -999 (for

fewer digits, use leading zeros).

Page 21 801P5 Smart SwitchTM

Page 26

NOTE

To change the (r-Lo)and (r-Hi):

1. Press the [MENU] key and use the [UP/DOWN ARROW]

keys to move through the menu selections to r-Lo.

2. Press [SELECT]. The furthest right digit will blink.

3. Change the digit’s value with the [UP/DOWN ARROW] keys.

4. When the value is correct, press the [SELECT] key to move to

the next digit and repeat step 3. Repeat for each digit until

you have the correct value for r-Lo.

5. Use the [STORE] key to temporarily save the changes and

return to the main menu.

6. Press [RUN]and then [SELECT] to permanently save the

setting and return to On-Line operation.

7. Repeat steps 1 through 6 for r-Hi. The setting should be at

least 2 display counts higher than r-Lo.

Decimal Location (.Loc)

You can change the location of the decimal point, thereby

changing the scale of the display, by using this function.

After .Loc displays, press [SELECT] to move the location

one digit left. When the correct location has been reached,

press [STORE] to temporarily save your setting.

When the decimal point is in the far right location, no decimal is

displayed during operation.

Page 22 Installation and Operation Manual

Page 27

NOTE

NOTE

Pressure Calibration (PCAL)

You can do a field pressure calibration using this function.

After PCAL is displayed, use the [SELECT] key to enter the

submenu. LO-P will be displayed for one second, and then

the switch’s interpretation of the actual pressure will be

displayed. Apply 0.0 psig to the unit. Use the [UP/DOWN

ARROW] keys to adjust the pressure display to zero psig.

Press the [STORE] key. The display will show HI-P for one

second, followed by the switch’s interpretation of the actual

pressure applied. Apply Full- Scale pressure to the unit. Use

the [UP/DOWN ARROW] keys to set the display equal to

Full- Scale pressure. Press the [STORE] key to return to the

main menu.

A pressure source is required for this operation. In addition,

calibration equipment used must have an accuracy of at least

± 0.02% F.S.O. of the switch being calibrated.

If re-calibration results in zero or Full-Scale readings that have

shifted by 4% F.S.O. or more from the factory calibration, an

error code of EROR will be displayed.

Reset (rSET)

This command resets the Smart-SwitchTM to factory default

settings. After rSET appears, press [SELECT], [STORE],

[RUN] and [SELECT] to reset the unit to factory defaults.

These are as follows:

r-Hi returns to factory F.S.O.

r-Lo is set to zero

Spli is set to 60% of the full range.

SPld is set to 40% of the full range.

SP2i is set to 70% of the full range.

SP2d is set to 30% of the full range.

Switch delay is set to 0 mSec.

Display update time is set to 0.5 seconds.

Page 23 801P5 Smart SwitchTM

Page 28

NOTE

If you have the 4-20 mA analog option, there are three additional

menu items that are reset. These are:

LooP is set to on.

ScHi is set to F.S.O.

ScLo is set to zero.

These three menu items are discussed in Chapter 4, Analog

Option.

Page 24 Installation and Operation Manual

Page 29

NOTE

CHAPTER

4

ANALOG OPTION

The analog option (V option) for the 801P5 allows you to equate

pressure with electrical current. If your Smart-SwitchTM includes

this option, the 4-20 mA output can be scaled; see page 27.

ANALOG OPTION WIRING

The 4-20 mA output connections are provided by the two pin

connector located on the top right of the unit:

Pin A is the + (positive) output

Pin B is the – (negative) output

The 801P5 generates its own loop power and it can operate with a

load resistance of 600 ohms maximum.

TURNING ANALOG OUTPUT ON AND OFF(LOOP)

Current Loop (LOOP)

This menu item enables or disables the current (4-20 mA) output.

To use this item:

1. Press [MENU]

2. Press the [UP/DOWN ARROW] key until LOOP displays,

the press the [SELECT] key to enter the submenu.

3. Press either [ARROW] key to change the display from OFF

to ON, and vice versa.

4. Press [STORE] to temporarily save your changes, then press

[RUN] followed by [SELECT] to lock in changes and return online.

Page 25 801P5 Smart SwitchTM

Page 30

NOTE

4-20 MILLIAMPERE OUTPUT CALIBRATION (4CAL)

The 801P5 is factory calibrated to generate 4 mA when the

pressure sensor is at 0 psig, and 20 mA when rated pressure is

applied. Tolerances in your signal conditioning equipment may

result in readings varying from these values, so you can calibrate

the 4-20 mA output as follows to correct these readings.

1. Connect a calibrated milliammeter to the 4-20 mA output.

2. Press [MENU], then press the [UP/DOWN ARROW] key

until 4CAL is displayed.

3. Press [SELECT]. The display will show LO-C.

4. While reading the milliammeter, use the [UP/DOWN

ARROW] keys to adjust the output to 4 milliamperes.

5. Press the [STORE] key. The display will read HI-C.

6. Use the [UP/DOWN ARROW] keys to adjust the output to

20 mA, then press the [STORE] key to temporarily save the

calibration data and return to the main menu.

7. Press [RUN] and [SELECT] to save the changes and return

online.

If the 0 or Full Scale output has shifted by 4% of F.S.O. or more

from the factory calibration, EROR will be displayed.

Page 26 Installation and Operation Manual

Page 31

NOTE

NOTE

4-20 MILLIAMPERE OUTPUT SCALING

The 4-20 mA output is scaleable, allowing 4 mA to represent any

pressure between 0% and 66% F.S.O., and 20 mA to represent

any pressure between 33% and 100%F.S.O. This feature is helpful

in systems where the normal operating pressure falls within the

pressure range of the unit. For example, let’s assume that the

Smart-SwitchTM has a pressure range of 0 to 100 PSIG, and the

process that it is monitoring operates between 20 and 80 PSIG.

The equipment that is monitoring the 4-20 mA output expects 4

mA to represent 20 PSIG, and 20 mA to represent 80 PSIG. Using

the following instructions, by setting SCLO to 20 PSIG and SCHI

to 80 PSIG, these conditions will be met.

Scale Low (SCLO)

To set the pressure at which the output equals 4 mA, press the

[UP/DOWN ARROW] keys until SCLO is displayed. Press

[SELECT] to enter the submenu. Use the [SELECT] key to move

from digit to digit and use the [UP/DOWN ARROW] keys to

adjust each digit. Once you have set the pressure, press [STORE]

to save your setting. The range of adjustment for this function is

zero psig to 66% of F.S.O.

The difference between the SCLO setting and the SCHI setting

must be at least 33% of F.S.O.

Scale High (SCHI)

To adjust the pressure, at which the output equals 20 mA, use the

[UP/DOWN ARROW] keys until SCHI is displayed. Use the

[SELECT] key to enter the submenu. Use the [SELECT] key to

move from digit to digit and use the [UP/DOWN ARROW] keys

to adjust each digit. Once you have set the pressure that should

equal 20 mA output, press the [STORE] key to save your setting.

The range of adjustment for this function is 33% F.S.O to 100%

of F.S.O.

The difference between the SCLO setting and the SCHI setting

must be at least 33% of F.S.O.

Page 27 801P5 Smart SwitchTM

Page 32

Page 28 Installation and Operation Manual

Page 33

CHAPTER

5

TROUBLESHOOTING

It is unlikely that you’ll have any problems with the

Smart-SwitchTM. However, just in case, this chapter contains

information to help diagnose and correct any error messages you

may see.

ERROR MESSAGES

Below are error messages that you may see during operation or

programming, along with brief descriptions of how to correct

them. If you see an error that is not listed here, contact Neo-Dyn

Customer Service. The contact information is located in

Chapter 1.

Display Shows ---0

The [MENU] key has been pressed and the unit has a password

other than 0000. Use the [UP/DOWN ARROW] keys to set the

first digit at the correct value. Use the [SELECT] key to move to

the next digit. Repeat this process until the display shows the

correct password. Press the [STORE] key to enter the

programming menu.

Page 29 801P5 Smart SwitchTM

Page 34

Display Shows EROR

This message might appear while programming the 801P5

Smart-SwitchTM. The meaning depends on what is being

programmed. Following are the possible causes and solutions.

Incorrect password entered

You have entered an incorrect password. Re-enter the

correct password. If you have lost or forgotten the password,

contact Neo-Dyn Customer Service for assistance.

Incompatible switch set points.

You have entered incompatible set points. Switch 1 and

Switch 2 are independent of each other; however, the

following rules apply to each switch:

The increasing set point must be at or below the Full Scale

Output (F.S.O.) value; it cannot be less than 2% of F.S.O.,

and it must be at least 1% of F.S.O. above the decreasing set point.

The decreasing set point must be no lower than 1% of

F.S.O.; it can be no higher than 99% of F.S.O.; and it must

be at least 1% of F.S.O. below the increasing set point.

The minimum deadband is 1% of F.S.O.

Re-enter the set points to conform to the requirements.

Page 30 Installation and Operation Manual

Page 35

NOTE

NOTE

Pressure Calibration (PCAL) or Analog Output

Calibration (4Cal) is incorrect.

If you change the value for pressure or analog output

calibration more than 4% of the F.S.O. from the original

factory values, this error occurs. Contact Neo-Dyn Customer

Service for assistance.

If the power to the unit is turned off and then back on, the unit

will function using the new values. However, this is not

recommended, as a calibration error this large indicates imminent

component failure.

Display shows HHHH

This indicates that the unit is online and monitoring pressure, but

the pressure is at or greater than 110% of F.S.O. When the

pressure returns to less than 110% of F.S.O., the display will

return to its normal pressure display.

Display shows LLLL

This indicates that the unit is online and monitoring pressure, but

the pressure is less than 4% of the F.S.O. below zero psig (pulling

a vacuum). When the pressure returns to greater than 4% of the

F.S.O. below zero psig, the display will return to its normal

pressure display.

An unlikely possibility is that the pressure transducer's connector

has been dislodged from the internal circuit card. Check to insure

that the transducer connector is indeed connected. Contact

Neo-Dyn Customer Service for assistance.

Page 31 801P5 Smart SwitchTM

Page 36

Display alternates between OPEN and LOOP and the

pressure reading

The OPEN LOOP message is displayed with the V option

(4-20 mA analog output) in the following circumstances:

The analog loop is turned on, but nothing is connected to the

analog output connector. In this case, press the [MENU] key

to enter the programming mode. Use the [UP/DOWN

ARROW] keys to set this option to OFF. Press the [STORE]

key to temporarily save the change. Press the [RUN] key,

followed by the [SELECT] key to save the change

permanently and return on-line.

The analog loop is turned on and connected, but the

connection has been broken. In this case, repair the broken

connection, or turn the loop off using the method described

in the previous paragraph.

Load resistance exceeds 600 ohms. In this case, reduce the

resistance.

Display is blank

Press the [S1 INCR] key. If the display illuminates and displays

the increasing set point for Switch 1, then the Disp display update

option has been set to OFF.

If the display does not react, there has been an internal component

failure. Contact Neo-Dyn Customer Service for assistance.

Display shows E-95

This code indicates that the internal manufacturing data, which is

saved in the nonvolatile RAM, has become corrupt.

Power down the unit and then turn the power back on. If the unit

continues to show E-95, contact Neo-Dyn Customer Service for

assistance.

Page 32 Installation and Operation Manual

Page 37

Display shows E-96

This code indicates an internal A/D reading that is out of its

allowable tolerance. Although this can indicate an internal

component failure, the most common cause of this error is

vacuum applied to the pressure port of the unit. If the cause is

vacuum, once the pressure returns to near zero, the unit will return

to monitoring and controlling. If the cause is internal component

failure, contact Neo-Dyn Customer Service for assistance.

Display shows E-97

This error indicates that the internal user data, saved in the

nonvolatile RAM, has become corrupt. Press the [SELECT] key to

cause the unit to reboot. If the unit continues to show E-97,

contact Neo-Dyn Customer Service for assistance.

Page 33 801P5 Smart SwitchTM

Page 38

Page 34 Installation and Operation Manual

Page 39

CHAPTER

DB9 Connection

6

SERIAL COMMUNICATIONS

(Z Option)

GENERAL

The Smart SwitchTM with the Z Option installed is capable of

RS232 communications with an IBM compatible computer. This

option includes Windows 3.x / 95 / 98 / Me / 2000 compatible

software, which allows remote monitoring and programming of

the Smart Switch, as well as data tracking functions.

To install the software, follow the Setup instructions on the

diskette label. Once it is installed, the Help menu provides

detailed operating instructions.

The default BAUD rate is 9600, but it may be set to 2400 BAUD

for noisy environments.

WIRING

Smart Switch

Connector (Pin)

A Transmit 2 3

B Receive 3 2

Function

(Pin)

DB25

Connection

(Pin)

Page 35 801P5 Smart SwitchTM

Page 40

Page 36 Installation and Operation Manual

Page 41

CHAPTER

7

SPECIFICATIONS

This section shows the standard specifications and available

options for the Neo-Dyn® 801P5 Smart-SwitchTM .

STANDARD

Interface

The Smart-SwitchTM weighs approximately 6 pounds (2.7 kg).

½” - 14 NPT Conduit Connection with 22 AWG Free Leads

¼” - 18 NPT Female Pressure Port

Two independent Solid State or Relay Switches

Temperature Range

Operating: -15°F (-26°C) to +140°F (+60°C)

Storage: -30°F (-34°C) to +170°F (+72°C)

Input power

115 VAC, 50/60 Hz

230 VAC, 50/60 Hz

18-30 VDC

Page 37 801P5 Smart SwitchTM

Page 42

Part Number

Operating

Percent of

Operating

The part number contains information about which configurations

and options are included in your Smart-SwitchTM. To determine

the pressure range, electrical rating, and options, compare the part

number of your unit with the information below.

801P 5 ## X X X

Model Series

Wetted Material

Range Number

Input Power

Switch Type

Options

Figure 10 Part Number Breakdown

Pressure Rating Information

Range

No.

Range

psig

Increasing

Range

psig

Deadband

Full Scale

Minimum

Decreasing

Setpoint

psig

Max

Pressure

Pressure

psig

02 0 - 5 .10 - 5 1-99 .05 12.5 25

04 0 - 15 .30 - 15 1-99 .15 37.5 75

05 0 - 30 .60 - 30 1-99 .30 75 150

07 0 - 100 2 - 100 1-99 1 250 500

09 0 - 250 5 - 250 1-99 2.5 625 750

11 0 - 500 10 - 500 1-99 5 1250 1500

12 0 - 1000 20 - 1000 1-99 10 2500 3000

14 0 - 3000 60 - 3000 1-99 30 3000 7500

Page 38 Installation and Operation Manual

Proof

psig

Page 43

Operating

Percent of

Decreasing

Operating

Range

creasing

Percent of

Range

No.

Range

22 0 - 350

24 0 - 1000

bar

mB

mB

Increasing

Range

bar

7 - 350

mB

20 - 1000

mB

Deadband

Minimum

Max

Full Scale

Setpoint

bar

Pressure

bar

1-99 3.5 mB 0.86 1.7

1-99 10 mB 2.6 5.1

Pressure

25 0 - 2 0.04 - 2 1-99 0.02 5.2 10.3

27 0 - 6.5 0.013 - 6.5 1-99 0.065 17.2 34.4

29 0 - 17 0.34 - 17 1-99 0.17 43.1 51.7

31 0 - 35 0.7 - 35 1-99 0.35 103 103

32 0 - 65 1.3 - 65 1-99 0.65 172 206

34 0 - 200 4 - 200 1-99 2 206 344

No.

Operating

Range

in H2O

In

Range

in H2O

Deadband

Full Scale

Minimum

Decreasing

Setpoint

in H2O

Max

Operating

Pressure

psig

Pressure

Proof

bar

Proof

psig

72 0 - 100 2 - 100 1-99 1 12.5 25

74 0 - 415 8.3 - 415 1-99 4.15 37.5 75

Total Accuracy

± 0.2% F.S.O., including linearity, hysteresis, repeatability, and

temperature

Page 39 801P5 Smart SwitchTM

Page 44

Standard Electrical Ratings are:

Electrical Rating Code

Input Power

A 90 - 130 VAC 50/60 Hz

E 180 - 260 VAC 50/60 Hz

D 18 - 30 VDC

The Switch Types are:

Switch Code Switch Type Switch Rating Leakage Current

A Solid State

SPDT

D Solid State

SPDT

R Relay SPDT 115 VAC

12-140 VAC

3 Amp Resistive

5-60 VDC

3 Amp Resistive

5 mA max

1 mA max

N/A

24 VDC

3 Amp Resistive

OPTIONS

The 801P5 options are listed below. You can combine these

options, but every option ordered should be indicated in the part

number of the unit.

Option Description

E 7/16"-20 SAE Pressure Port

Q Scalable Readout

V Analog Output, 4 - 20 mA

Z RS232 Communications

Page 40 Installation and Operation Manual

Page 45

WARRANTY INFORMATION

A. Warranty:

ITT Industries (ITT) warrants that at the time of shipment, the

products manufactured by ITT Neo-Dyn and sold hereunder, will

be free from defects in material and workmanship and will

conform to the specifications furnished or approved by ITT.

B. Warranty Adjustment:

If any defect within this warranty appears, the Buyer shall notify

ITT immediately.

ITT agrees to repair or furnish a replacement for, but not install,

any product which, within one (1) year from the date of shipment

by ITT shall, upon test and examination by ITT, prove defective

within the above warranty.

No product will be accepted for return or replacement without the

written authorization of ITT. Upon such authorization, and in

accordance with instructions by ITT, the product will be returned

with shipping charges prepaid by the Buyer. Replacements made

under this warranty will be shipped prepaid.

C. Exclusion from Warranty:

THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES

ALL OTHER EXPRESSED OR IMPLIED WARRANTIES OF

MERCHANTABILITY, OR FITNESS, OR OTHERWISE.

Components manufactured by any supplier other than ITT shall

bear only the warranty made by the manufacturer of that product,

and ITT assumes no responsibility for the performance or

reliability of the unit as a whole.

“In no event shall ITT be liable for indirect, incidental or

consequential damages nor shall the liability of ITT arising in

connection with any products sold hereunder (whether such

liability arises from a claim based on contract, warranty, tort or

otherwise) exceed the actual amount paid by Buyer to ITT for the

products delivered hereunder.”

The warranty does not extend to any product manufactured by

ITT which has been subject to misuse, neglect, accident, improper

installation, or to use in violation of instructions furnished by ITT.

The warranty does not extend to or apply to any unit which has

been repaired or altered at any place other than at ITT’s factory or

service locations, by persons not expressly approved by ITT.

801P5 Smart Switch Page 41

Loading...

Loading...