INSTRUCTION MANUAL

MODEL: BT-100

SINGLE BUCK BODY AND SLEEVER

SERIAL NUMBER :

PURCHASED DATE:

ITSUMI SEISAKUSHO CO., LTD. SAITAMA JAPAN

TITLE: INSTRUCTION MANUAL

DWG.NO. TOR-060404

REV. 04/20//2006

CONTENTS

● SAFETY INSTUCTIONS A-1~ A-4

●INSTALLATION OF THE MACHINE B-1~ B-4

●PERIODIC CHECK C-1~C-2

●FUNCTIONS OF SECTIONS D-1~D-5

●HOW TO OPERATE E-1~E-6

●MAINTENANCE AND SERVICE F-1~F-12

●SPECIFICATIONS OF THE MACHINE G-1~ G-6

●TROUBLE SHOOTING AND COUNTERMEASURES H-1~ H-4

SAFETY INSTRUCTIONS

PREFACE

This Instruction Manual states the way how to use the Machine correctly, the cares to be taken in using the

Machine, and so on. In order for you to fully make use of the performance of the Machine and use it safely,

please read through this Instruction Manual to its end before using the Machine. After having read it, please

do not forget to keep this Instruction Manual so that you can utilize it right away in case you need it.

INDICATIONS OF RISKS

In order for you to use the Machine safely and in the right way and to prevent any injury from occurring to the

Machine attendants and any other persons as well as any property, this Instruction Manual has the indications of

risks. Kinds of such indications and their meanings are as follows:

WARNING

CAUTION

A WARNING is used to indicate instructions necessary to

cause any injury to human body and life if ignore this

indication and/or incorrect operation.

A CAUTION is used to indicate instructions necessary

to cause any injury to human body and life if ignore this

indication and/or incorrect operation.

A NOTE is used to indicate proper operating methods

and inspection points if ignore this indication to cause

any injury to human body and/or physical damage.

NOTE

A-1

SAFETY INSTRUCTIONS

WARNING

WARNING

DON’T BE TRAPPED

When the machine begins to operate, do not move your hand,

face, or other parts of the body within the moving space of the

iron and/or the machine.

●You may get suppressed, bruised, or burned.

BE CAREFUL WITH HIGH-TEMPERATURE PARTS

Steam pipes, steam hoses, and iron get extremely hot. Never

touch these parts with your hand.

●This could cause burns.

Nobody is allowed to operate or service this machine other than

those who first read and understand this instruction manual.

WARNING

WARNING

WARNING

TURN THE POWER OFF BEFORE INSPECTION

When replacing covers, doing inspection/maintenance work, or

cleaning the unit, be sure to turn the power switch off so the

machine would not operate while you work.

●This could cause an accident and/or an electric shock.

SECURE A GROUND CONTACT

After setting up the machine or moving it, be sure to secure a

ground connection.

●Electric leakage and charges of static electricity could cause an

electric shock or natural fire.

A-2

WARNING

WARNING

STOP IMMEDIATELY IF THE MACHINE

DAMAGES A SHIRT

While using the unit properly and correctly, if any damage is

found on the shirt being pressed, stop the operation immediately

and find the cause.

●This minimizes the damage.

DO NOT REORGANIZE OF THE MACHINE

We are surely recommended to prohibit reorganize of the

machines specification changes and removal of the warning

label etc.

●May cause of unexpected accident.

WARNING

WARNING

CAUTION

PAY ATTENTION TO THE INSTALLATION

LOCATION OF THE MACHINE

Make sure to install the machine in a room where there is no

influence from weather and to keep it free from water and steam.

●Improper installation may cause damage to the machine and an

electric shock due to a short circuit.

INSPECT STEAM LEAKS

Please inspect loose steam piping and steam leaks carefully.

●If steam leaks remain untouched, steam may be discharged and

cause burns.

CLEAN AIR-FILTER AND LINTO COVER

Prior to start work please clean and get rid of the drain filter for

the air and be accumulated in the oil mist separator as drain and

the oil are daily. Lint covers for the hot air blowing fan motor is

also.

● It is cause to be inferior the quality of the air parts and drying

condition if accumulated drain and the dust.

A-3

CAUTION

CAUTION

EXECUTE THE REGULAR CHECK

We are surely recommended execute the regular inspection more

than once per year for confirm the performance and activates

safely of the machine. Also please execute to replace the

consumption articles when limit the life time has come.

CONSUMPTION ARTICLES ARE MUST BE USE GENUINE

PARTS

We surely recommends to use our genuine parts when replace

each kind of pad or cover.

●In case to use except our genuine replace parts, it could not

well enough perform to activation than original piece.

A-4

INSTALLATION OF THE MACHINE

INSTALLATION OF THE MACHINE

Place the Machine on a proper level surface. It is a great impact on the action and life time of

the Machine whether it is ensured to be leveled.

For a place where the Machine is positioned, choose a secure floor that can withstand it’s

weight.

Secure space around the Machine so that the maintenance work will be done without

difficulty (More than 80cm is necessary).

For set up, more than 2 anchor bolts are needed to prevent fall.

Secure the space to see the name plate for confirm the type and serial numbers for repair the

machine etc.

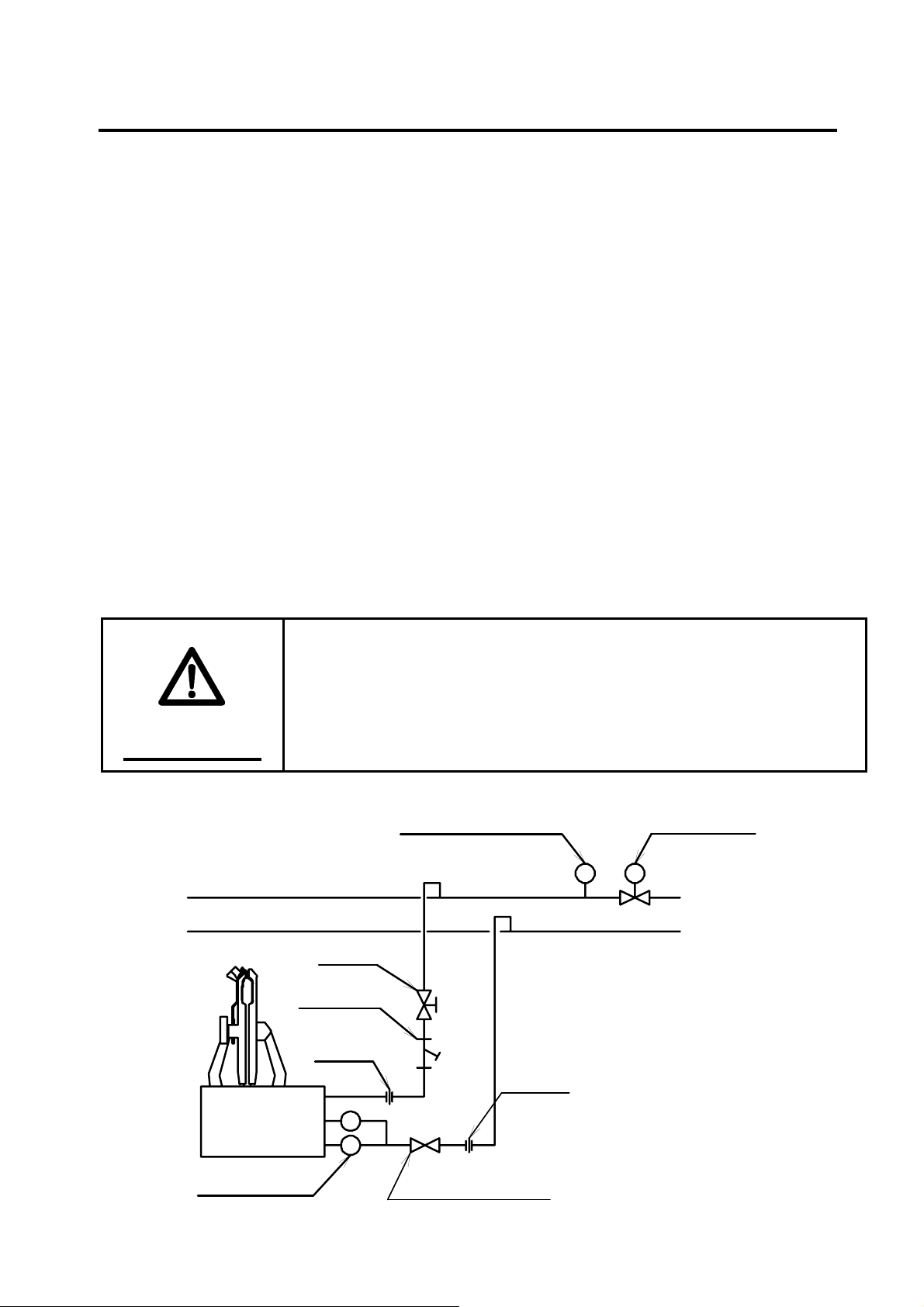

STEAM PIPING WORK

For use in steam piping, use steel pipes for pressure of 1/2in. or greater.

Make the whole piping slightly down to the ground so it’s not to cause of any stagnant drain

water.

Regulate the pressure of steam entering to the Machine between 0.5 and 0.65MPa.

Install valve and strainer to the steam inlet side of the Machine.

Install the trap where steam outlet side of the machine.

WARNING

Reduce pressure up to 0.65MPa or lower which steam is

supplied to the machine.

●Suspect to damage steam iron and presser vessel.

STEAM INLET

STEAM OUTLET

VALVE

STRINER

UNION

PRESSURE GA UGE

UNION

REGULATOR

STEAM TRAP

CHECK VALVE

B-1

ELECTRIC WORK

Power source is 3-phase, 200V, 30amps, 50/ 60Hz. It has 4 lines, one of which is ground wire

(green co lour).

When fitting a suitable plug to the AC line cord, it is essential that it contains an

earth/ground contact and that must be connected. Earth wire into the ground without fail.

Keep electric wiring part at least 15cm from steam pipe due to escape the heat.

Make sure that the turning direction of blower motor is same direction of below drawing that

the turning direction is anti counter clockwise from the front view.

Install the short circuit breaker where the side of power source

of the machine due to prevent the trouble and electric shock.

●Recommend short circuit breaker: 30A

●Regular electric current: 30mA

●Power source: 3-phase, 200-220V, 60Hz

WARNING

ENFORCE THE CONTACT EARTH WIRE INTO THE

GROUND

In case of the earth wire has not been adopt, can not have the

place to escape the abnormal electricity and/or static electricity

and it may cause of the risk of electric shock. Also, the high risk

WARNING

for the incorrect activation of the machine if affect by the

thunderbolt struck. And it may cause if the serious fire explosion

accident.

Direction of Rotation

B-2

AIR PLUMBING

This machine will be needed to work that the power is more than 1 horse power (0.75 Kw)

compressor. Please use it well enough power even if the power is more than 1 horse power if

it’s to operate complex of the machine at the same time.

Please use the inner size of the pipe is bigger than 8mm for the air plumbing in case if it’s use

under 8mm it may result of reduce the pressure momentary and influence the function of the

machine incorrectly and finish condition as well.

Standard pressure of the main air regulator will be 0.5MPa if reducing the pressure during

the service it may cause of the shortage of the air supply so check the following cause.

・Capacity shortage of the compressor

・Shortage of the hose.

・Operating the complex of the machine at the same time.

・Leak the air and shut the air valve.

Set the valve as for the inlet side to able to shut the air when periodic maintenance.

We are surely recommended to have space approximately plumbing distance 10m between

compressor and the machine. Pressed air has been cool and easy to remove the moisture by

the filter.

CAUTION

CONTROL THE COMPRESSOR

Moisture and oil and impurities are makes the air filter being

short life and affects bad influence of the air parts so keep the

compressor in good condition for use long.

B-3

TRIAL OPERATION OF THE MACHINE

After install the machine, upon confirm connect for the steam, electricity and the air activate trial

operation.

1. Open the machine

・ Get rid of the vinyl cover and lapping paper.

・ Get rid of the rectangular timber where fixed the back iron for the body press and left arm.

・ Remove the foot switch to the easy operation at the front part of the machine.

2. SET THE COVER FOR LEFT EDGE OF THE MACHINE.

3. RELEASE THE LOCK CONCERNING THE AIR.

・ Supply the air for the machine and make sure

Status of the body press iron is closed by

・

manual o

valve for body press. For release the body

press iron, remove the manual switch of the

electro-magnetic valve for press from

condition of 「ON」to 「OFF」. Normally it

is available to work 「OFF」 status.

4. R

ETURN TO THE ORIGIN POINT.

・ eep press stop button more than 2 seconds,

K

each device will move to the origin po

pen the dummy

5. O

Re

・ move the lapping paper covered on the dummy.

・ Remove rectangu

6. Connect the power supply

C

・ onnect the breaker for the factory.

・ Check the indication on th

7. Steam Supply

・

Open the steam valve for supply the steam for the machine.

・ Check the stea

8. TRIAL OPERATION OF THE MACHINE.

・

According to the operating process later on, activate the machines function.

・ It is necessary to activate 4 or 5 times trial pre

peration of the electro-magnetic

int as regulated turn.

lar timber for fix the collar cramp.

e machine when you turn on the power switch of the machine.

m leakage from the steam circuit.

that the pressure level should be 0.5MPa.

4KB310

ss w/o shirt when you finish actual shirt.

B-4

PERIODIC CHECK

DAILY PRE-USE CHECK

Do not use the machine if all the safety devices and stop

buttons are does not work normally. Check this matters

everyday before use this machine.

WARNING

Air filter for moisture and oil contents can automatically discharge such impurities with drain

when drains are accumulates. Check if impurities are discharged normally, and in case drains

are stagnant, and then please dispose of it by hand.

Check if all the pressure decompression valves are at specified pressures.

Main Regulator 0.50MPa

Tuck Slide Start 0.09Mpa

Tuck Slide Back 0.12Mpa

Dummy Slide Regulator 0.30Mpa

Remove the dust gathered on the inlet filter of the hot air blower for an arm.

Check if the cover of the dummy has not torn around the body and the tuck and if the pad has

not worn out if can not use please replace it as our genuine replace parts.

Check if air does not leak at the interconnected of the air hoses.

Check if steam does not leak at the interconnected of the steam as steam hose and/or each

plumbing parts.

Check if the air pressure is stable during operating the machine. If air pressure does not stay

appropriate level during the work check air filter and decompression valve.

PERIODIC CHECK A YEAR

Please execute periodically replace the filter elements as for following method.

NAME ELEMENTS REPLACEMENT TERM

Drain filter E-60D 2 years passes or pressure under 0.1MPa

Filter F4000-KIT 2 years passes or pressure under 0.1MPa

Oil mist separator MANTLE-ASSY 1 year passes or pressure under 0.1MPa

Please apply the grease for the dummy slide rail as well as apply the slide rail for tuck press

device for smooth movement.

Check if leakage from the packing of interconnected circuit of hot air blowing as for the

sleeves and air bag if you found any leakage, replace the packing for use long time.

C-1

Efficiency of the filter for the air will be decrease by time passed

by so that the volume of the passes the air will be decreased

naturally. We are surely recommended to replace it as regulated

condition.

NOTE

C-2

FUNCTIONS OF THE SECTIONS

13 7 71 9 10 11 12 5 8

P RE SS TI ME R

TUCK OFF

ST OP

CO U NT ER

O N

START ST A RT

OFF

PRO

TIMING TIMER

AIR HEAT TUCK

2 3 4 6

OPERATION PANEL

①POWER SWITCH

When you turn the switch lever to “ON", that the Machine becomes ready to be operated. Times

you select are indicated in the timer display window.

②AIR (Timer for airbag start activate)

You can set the timing for air coming in the airbag (placed at the sides of the Dummy). This

timer counts at the time when trunk pressing starts, and when the set time passes by, hot air

comes in the sides of the Dummy.

REMARK:

-The longer set the time, the later timing for the hot air blowing comes.

→If the front placket curves, then set the time longer.

-The shorter set the time, the earlier timing for the hot air blowing comes.

→If wrinkles come out at the sides, then set the time shorter.

D-1

③HEAT (Timer for hot-air come)

You can set the timing for hot air comes into the sleeves. When you press cuffs setting button

that the timer starts counts and passes the previously sat the time hot-air blowing comes into

the sleeves.

REMARK:

-The longer set the time, the later timing for the hot air blowing comes.

→If the tuck spread becomes shorter, then set the time longer.

-The shorter set the time, the earlier timing for the hot air blowing comes.

→If you can see the wrinkles on the sleeve, then set the time shorter.

④TUCK (Timer for press the tuck)

You can set the timing for pressing the tucks. This timer starts concurrently with the HEAT

Timer.

REMARK:

-SET THE TIME LONGER, TIMING FOR PRESSING THE TUCKS BECOMES LATER.

→IF YOU CAN SEE THE WRINKLES ON THE SLEEVE, THEN SET THE TIME LONGER.

- SET THE TIME SHORTER, TIMING FOR PRESSING THE TUCKS EARLIER.

→ IF THE TUCKS OPEN AND BECAME SHORT, THEN SET THE TIME SHORTER.

⑤PRESS TIMER (Timer for press )

You can set 3 different pressing times from the Course 1 to 3. Choose any of them depending on

the material and moisture condition of a shirt.

⑥TUCK OFF (The Key)

When you press this button that the lamp turns on and the tuck pressing stops if you push it

once again, the lamp light turns off and the tuck press will start finishing works.

⑦START (Button)

After you have finished to setting the collar and vacuum, press these 2 buttons that the Dummy

moves to the right, making it ready for the trunk to be pressed and for the cuffs to be set. Keep

on pushing the buttons until the iron touches the Dummy.

⑧STOP (Button)

When you press this button return to the status of the press released condition and stops other

activations. If you would like to start again, keep on push this button more than 3 seconds.

Each of the devices will be returned to the origin point.

In case if you could touch the safety device where located

tuck and truck trunk iron, activate the same function as press

the stop button.

NOTE

D-2

➉ to ⑪ TIME ALTERATION BUTTON

Please refer “SET THE TIMER” paragraph.

⑫ TIME INDICATION WINDOW

Indicate remaining time if you are in the finishing process, without this process will indicate

the setting time. If the timer became out of order it will be shown “ERROR MARK” in the

window.

⑬ COUNTER WINDOW

Count the finished pieces.

HOW TO SET THE TIMER

1. SELECT THE COURSE

Push the timer button which you would like to change the

course and the lamp turns on that you have selected. Indicate

current setting time in the time indication window number 12

twelve.

2. PROGRAMMING MODE BUTTON

Push this programming button number 9 nine approximately

1.5 seconds and time indication numbers turns into blinking

signal so that you can rewriting your favorable time.

3. SET THE TIME.

For an adjust your favor time push these marked ▲(Plus)

number ➉ ten ▼(Minus) number ⑪ eleven buttons. If you

would like to change the time widely keep press these button to

adjust your favorable time quickly.

4. ENTRY THE MEMORIZE

Push programming button number ⑨ nine about 1.5

seconds again memorize the renewal time together with stop

blinking signal and the high tone P sound.

PRO

PRO

PRO

1

2

3

設定時間

D-3

EXTERNAL FEATURES OF THE MACHINE

6 65 5

8

9

10

2

3

7

4

1

①CONTROL BOX

This contains electric control-related parts, such as sequencer and relay (thermal breaker).

②FOOT SWITCH

Pedaling this switch activates the collar fixer, where in turn operates vacuum.

③AIR FILTER

This serves as the inlet of hot air coming in the sleeves and forms a filter (net) collecting dust.

④AIR PRESSURE-REGULATING VALVE OF THE TUCK SLIDE

This regulates the expansion force of the sleeves.

⑤CUFFS CRAMP SWITCH

Push this button close the cuffs cramp and push it again it will be opened.

⑥START BUTTON (GREEN)

After sat both right and left cuffs press these two buttons enter the process of trunk finish work.

Keep the buttons on till the tuck press touches the shirt.

D-4

⑦STOP BUTTON (RED)

Push this button effects to return the status of released the press and stop the other function.

When you re-start to work the machine press this button more than three seconds each device

will be returned to the origin point.

⑧SAFETY GUARD

Safety guard device is installed where at in front of the tuck press iron and side of trunk iron if

this device start to work it is the same function of press the stop button. When you re-start to

work the machine keep stop button on more than three seconds then each device will be

returned to the origin point.

⑨OPERATEING PANEL

This panel has installed each setting and dummy movement button.

➉REGULATION BOX (ELECTRIC MOTOR CIRCUIT)

Installed magnet relay for the motor.

D-5

HOW TO OPERATE

FINISH PROCESS (Long Sleeves)

1. FASTEN THE SHIRT

Put the shirt to the dummy from left side back

around the dummy.

2. SET THE SHOULDER

Set the shirt to the dummy to make equal to the

seam line of the shirt.

3. SET THE COLLAR

Fix the collar by using the foot switch to make

equal space between collar and the collar block

then activates the vacuum when you press the

collar. When you release the collar press, step

on the foot press switch once again

E-1

4. SET THE BACK OF THE SHIRT

Pull down the bottom of the shirt lightly to not

appear any of slack wrinkles.

5. SET THE FRONT BOTTOM PART

Spread the bottom of a shirt for appropriate

condition to the dummy.

6. SET THE FRONT BOTTOM PART

Spread the bottom of a shirt for appropriate

condition to the dummy.

7. FRONT STAND

Set the front stand become straight from your

view. If you can find the curve on the shirt,

make it straight for fine finish. The angle for

the front stand both right or left makes narrow

as for the bigger shirt.

E-2

8. SMOOTH OUT OF SMALL WRINKLE

It may appear little wrinkle where the part of

pocket. shoulder, and the side so prior to finish

apply appropriate stroke or pull the shirt.

9. MOVE THE DUMMY

When you finished process number 8, press

START buttons at the same time by both hand

that the dummy will move to the right side.

* Keep the buttons on till the iron is completely

pressed.

10. TRUNK PRESS

The dummy was stopped at the extremely right

end and activates trunk press at the same time

and left arm comes to the front.

11. SET THE CUFF

Through the cuff on the pedestal for finish an

arm and the cuff place on the right position

without appear any wrinkles for the cuff and

tuck. Fixed the cuff by press the cuff cramp

switch. You can set the cuff either right or left

first.

E-3

12. SET THE CUFF

Insert the cuff tip part approximately 2 to 3 cm

and pay attention to insert cuff deeply it may

cause to remain impressed part.

13. START FINISH WORK

Press the START buttons by the each hand at the

same time then start finish work. Time passes by

for previously set the timer that automatically

release and the dummy return to left.

ep the button on till the iron must be

* Ke

pressed completely.

4. END OF FINISH WORK

1

Remove the shirt from the

easy to remove if you handle as sample picture.

dummy (Trunk). It is

E-4

SHORT-SLEEVED SHIRTS FINISH WORK

1. to 10. FASTEN SHORT-SLEEVED SHIRT

Put the short-sleeve shirt onto the trunk as same

way from the numbers 1 to 9 of the long-sleeved

shirts.

11. T-SHIRT CRAMP DEVICE

Pull out the cramp in front of you.

12. SET THE T-SHIRT

Insert the sleeve to the cramp device for the

short-sleeve shirt and set it by press the button.

E-5

13. START FINISH WORK

Press the both of START button at the same

time and start finish work.

14. EXPAND THE SLEEVE

Pulling the sleeve with hot air blowing and

complete the arm part. As for the T-shirts finish

process does not activates the press device for

sleeve.

15. END OF THE FINISH WORK

Remove the T-shirt from the dummy (Trunk) as

the same way of long sleeves shirt.

E-6

MAINTENANCE AND SERVICE

When the maintain for this machine, evacuate steam and air,

disconnect electricity, and wait until all steam-heated

sections have been cooled.

●High risk for unexpected accident and electric shock may

WARNING

happen.

AIR FILTER REGULATOR

REGULATOR

DUMMY MOVING

OIL MIST SEPARATOR

FILTER

DRAIN FILTER

REGULATO R

MAIN

DRAIN FILTER (DF600-04-A)

Eliminate the moisture and filtration water will be discharged automatically. (Auto drain)

AIR-FILTER (F4000-15-F)

For the filter which percolation ratio 5μm affects remove the dust and foreign substance

mainly. Dust and foreign substance through the filter will be discharged automatically with

water. (Auto drain)

OIL MIST SEPARATOR (M400-15-F1)

For the filter which percolation ratio 0.01μm affects remove the oil mainly. Oiled substance

through the filter will be discharged automatically. (Auto drain)

F-1

DECOMPRESS VALVE (For main air pressure : R4000-15)

Adjust the air pressure entering the entire part of the machine.

Standard air pressure: 0.5MPa

Decompress valve (For the dummy movement: R3000-10)

Adjust the air pressure for the movement of the dummy.

Standard air pressure: 0.3MPa

REMOVAL OF THE DRAIN WATER

Percolation drain water will be accumulated into the definite volume cup or pressure in the bowl

became under the level 0.02MPa drain water will be discharged automatically. (Auto drain)

As for collect these drain water, connect the urethane tube (inner size 6mm) to the outlet

connector and put the receptacle plate. And also you can turn the drain knob to anti clockwise,

discharge the drain water by the manual.

REPLACE THE FILTER ELEMENTS

The filter elements apply to push the cup turns to approximately 30 degrees and set the marked

place then you can remove to turn the elements by hand directly. Replace time for the elements

are referring as below table.

FILTER ELEMENTS

NAME SERIAL NUMBERS ELEMENTS REPLACE TERM

Drain filter DF600-04-A E-60D 2 years or pressure under 0.1MPa

Filter F4000-15-F F4000-KIT 2 years or pressure under 0.1MPa

Oil mist separator M4000-15-F1 M type 1 year or pressure under 0.1MPa

F-2

ADJUST THE AIR PRESSURE

This machine has 4 decompression valves for the main,

dummy movement, enter and return of the tuck slide part.

Decompression valve for the air role keep the supplying

pressure to definite level and the way of the pressure

adjustment is pull up the knob lightly and turn it properly

and check the pressure level by the pressure gauge.

Turn the knob to clock wise effects high pressure and turn

anti clock wise effects lower pressure from the view of the

knob side. After set the appropriate level that the knob

return to the origin point and lock it accordingly by hand

press.

*Confirm the pressure level by activate the machine after

sat the pressure if the pressure has changed re-adjust it.

STANDARD PRESSURE OF THE AIR DECOMPRESSION VALVE

NAME STANDARD PRESSURE EXPLAIN THE ACTIVATION

Main 0.5MPa Adjust pressure where supply to the machine

Move the dummy 0.3MPa Adjust pressure for dummy move cylinder

Tuck slide ENTER 0.05MPa Adjust pressure for pull the sleeve

Tuck slide RETURN 0.1MPa Adjust pressure for return the device for pull

the sleeve.

PRESSUER GAUGE

KNOB

F-3

REPLACE THE TRUNK PAD AND COVER

Due to have activates the machine many times that the part of the trunk and air bag, pad and the

cover for the tuck press part will be exhausted. We are surely recommends to replace that the

parts periodically.

When you replace the pad and cover we are surely recommends

to use our genuine parts.

●If you set different parts it may happen to raise cause of worse

finish condition and the life time of the machine shorter.

NOTE

STRUCTURE OF THE TRUNK PAD, COVER AND AIR BAG

① Cover

② Uniron pad

③ Silicone pad

④ Air bag

⑤ Spring for hang air bag

⑥ Bottom fix spring

⑦ Stop plate of the back

⑧ Nut

⑨ Dummy

⑩ Collar fixer

10

6

5

1

4

2

3

8

5

9

7

F-4

REMOVE THE PAD AND COVER

1. Loose two anchor bolts where fixed collar fixer and remove it from the dummy.

2. Loose the fixed hose nut where connecting the cylinder of collar fixer and remove air hose.

3. Remove the strings where in the arm cover.

4. Remove the spring for bottom fixed.

5. Remove the rope where at the blowing inlet of shoulder air bag.

6. Remove the cover from the dummy.

7. Pull out the bottom bar which previously removed the cover.

8. Remove the union pad from the dummy.

FITTING THE PAD AND COVER

1. Fit new union pad on the dummy and to be dressed equal space for both right and left and does

not appear the slacks.

2. Insert the bottom bar for the new cover.

3. The cover will fit and dressed on the dummy.

4. Tight the strings at blowing inlet for the shoulder air bag.

5. Suspend the bottom fix spring to the cover.

6. Remove the strings of an arm cover.

7. Connect the air hose to the collar fix cylinder.

8. Set the collar fixer to the dummy.

REMOVE THE AIR BAG

1. Remove the suspend spring where located both upside and lower part of the air bag.

2. Remove the setting nut where located at both upside and lower part of the air bag.

3. Remove the air bag together with fix plate of the bag from the dummy.

4. Pull out the bag fix plate from the air bag.

FITTING THE AIR BAG

1. Insert the bag fix plate for the new air bag.

2. Fitting the air bag and fix plate of the bag on the dummy

3. Fixed the air bag for using the nut.

4. Set the suspend spring where upside and lower part of the air bag.

F-5

STRUCTURE OF THE TUCK

AND PAD COVER

① Tuck cover

② Tuck uniron pad

③ Tuck silicone pad (Upper)

④ Tuck silicone pad (Lower)

⑤ Tuck frame

4

1 23

5

REPLACEMENT OF THE TUCK AND PAD COVER

1. Release string of the tuck cover to remove the cover.

2. Remove the tuck uniron pad.

3. Peel away silicone pad by striper.

4. Apply silicone adhesive to the tuck frame.

5. Set tuck uniron pad.

6. Set tucks cover.

Set the silicone pad to the tuck frame. Drying time for

silicone adhesive will be necessary approximately 24 hours.

CAUTION

F-6

CIRCUIT PROTECTOR (CP31F-M/2)

Due to happen to had over load capacitance caused by the damage of the parts or short circuit for

the interconnected electrical wiring part shut down the interconnected circuit and protect the

regulation circuit of the electric regulation box if does not showing consequences the operation

even turn on the power supply switch check the circuit protector and in case the switch turn off

inspect the cause of it and when you cleared the reason then turn the lever on in due course.

Installation place: Control box

POWER SUPPLY (S8PS-0524D)

This is a parts for transforming the electrical regulation from outer AC200V to DC24 which

supplying the electricity to the machine. When the machine activating normally where the green

LED lamp will be turned on.

Installation place: Control box.

SEQUENCER (CPM1A-40CDT-D-V1)

This is a parts activates each mechanical function as for electro magnetic valve and relay

according to previously programmed when enter the signal of the press button and sensor.

Confirming the machine to enter the signal of the inlet and outlet that this parts will be shown by

the LED signal and to this sign it is available to know the status of the machine and cause of

abnormal activation.

Installation place: Control box.

POWER SUPPLY

CIRCIT

PROTECTOR

SEQUENCER

CONTROL BOX

F-7

THERMAL RELAY

Thermal relay is located at regulate box for electric motor

where the back part of the machine.

When applying over load capacitance to the electric motor

raise the thermal and shut down the circuit when you recover

circuit be cleared the cause of it and push that resetting

button.

Installation place: Control box for electric motor.

RESET BUTTON

SPEED CONTROL

This is a parts for regulate the movement speed of the cylinder as for adjust air volume where

discharge from the cylinder and you can select from both two types which set the connector of the

cylinder hose and set discharging platform for the electro magnetic valve.

HOW TO ADJUST THE SPEED

① Loose the lock nut.

② Turn the adjustment knob and the volume will

about a quarter a time, this adjustment knob

effects to became slowly if apply tightly and became

faster when you open it vice varsa.

③ Confirm the speed to activate the machine.

④ Repeat that work and if you can not see any of the

trouble then fix the lock nut.

REGULA TING THUMB SCREW

LOCKNUT

REGULATING THUMB SCREW

LOCKNUT

F-8

ELECTRO MAGNETIC VALVE

The electro magnetic valve turn the air direction by electric signal and affects the cylinder works

expand and shrink. For this machine built in nine ranges manifold type and also single setting

type electro magnetic valve.

9 (NINE) RANGES MANIFOLD TYPE

①Signal code

Wiring to the regulate box.

②Plug connector

Able to alternate electrical wiring easily as touch

at once whether replace the electro magnetic

valve and in case of unfastening pick it out with

the fingers.

③Indicator lamp

Turn the lamp on when through the electricity.

④Manual control button (Orange co lour)

Press the button affects same movements as turn

on the electricity to the electro magnetic valve.

When press this button use the tip part must be

thin object like ball point pen.

⑤Setting screw

This is the screw for fix the electro magnetic

valve. Remove this screw when replace it.

⑥Quick release joint

When you remove the hose, pull out the hose

with pushing the ring.

⑦Silencer

Installed at the air discharging outlet and reduce

the exhaust sound.

6 3

1

4 57

12 23

PLACE THE ELECTRO MAGNETIC VALVE

OUT LET NUMBERS ROLE OF THE ELECTRO MAGNETIC VALVE

1102 Air bag cut valve

1005 Tuck slide

1004 Tuck apply pressure

1006-1007 Arm circling front and back

1100 Cuffs cramp right

1101 Cuffs cramp left

1106 Fix the dummy

1107 Collar fixer

1104 Sleeve expand

F-9

FOR TRUNK PRESSURIZATION

①Signal code

To be wired to the regulation box.

②Plug connector plus indicator lamp.

When turn on electricity the lamp will be on

and when you remove pull out the center

screw.

③Manual control knob

Regular: Turn to the 0 (zero)

Manual: Turn to the 1 (one)

④Silencer with speed control

Control air exhaust sounds as well as regulate

the volume of the discharging air and then

adjust the iron speed of the open and shut.

E1: Close the iron

E2: Open the iron

⑤Setting screw

Pull out this screw when the time for replace

the electro magnetic valve and it is available

to replace valve part w/o manifold to remain.

4 5

1

2

3

FOR REMOVE THE DUMMY

①Signal code

It is wiring to

magnetic v

solenoid so existing signal code for two places.

②

Manual control button (green)

When y

sam

e movements as turn on the electricity.

Setting screw

③

Remove this screw when the time to replac

electro magnetic valve and it is available to

replace part o

remain.

Silencer

③

Installed

the regulation box. This electro

alve has been work double

ou push this button you can see the

e

f the valve w/o manifold to

at the air discharging place to reduce exhaust sounds.

1

2

2

4

3

1

F-10

AIR CYLINDER

The actions of each section of the

machine are brought by the air cylinder.

Understand the outline of the air

cylinder and make use of it for

countermeasures in case any trouble

occurs.

Names of each part

① Cylinder tube

② Piston rod

③ Air cushion valve

④ Contact less switch

⑤ Speed control

⑥ Knuckle joint

Air cushion

Outline

This absorbs the shock arising when the

cylinder stops by reducing air flow.

Regulation

Loosen the locknut and turn the

regulating valve.

Turn to the right: Effect becomes stronger.

Turn to the left: Effect becomes weaker.

6 5 512

3 34 4

LOCKNUT

REGULATING THUMB SCREW

CAUTION

If effect is made too strong or moisture accumulates in the air

cushion hole, the piston will not go up to the ending points, thus

causes the machine to stop.

F-11

Contact less switches

Outline

When the piston comes under the contact less switch, it switches on and the lamp lights on. The

machine confirms the position of the cylinder in this way.

“The contact less switch does not work."

This happens in almost all cases when the position where the piston stops has changed. Check the

cause of it and correct it.

FIXING SCR EW

INDICATOR LAMP

CONTACTLES S SWITCH

RED(+)

BLACK(-)

Do not change the position of the contact less switch

thoughtlessly.

NOTE

F-12

SPECIFICATIONS OF THE MACHINE

MAIN ITEMS

Name: Single Buck Body and Sleever

Model: BT-100

Air supply pressure: 0.5 - 0. 7 MPa

Max Steam consumption pressure: 0.7MPa

Power source: 3 phase 200 V

Electricity consumption: 2.5 Kw (50Hz) / 2.7Kw (60Hz)

Net weight: 650 Kg

AIR ADJUSTMENT

Main regulator: 0.5 MPa

Tuck slide enter: 0.04 MPa

Tuck slide return: 0.1 MPa

Moving the Dummy: 0.3 MPa

Recommend Compressor capacity: 2 Horse power

PLUMBING DIMENSION

Steam inlet: 3/4 inches

Steam outlet: 1/2 inches

Air inlet: 1/2 inches

TIMER SETTING

Air blowing: 1.0 second

Hot air blowing: 2.0 seconds

Tuck pressing: 2.5 seconds

Course 1: 13 seconds

Course 2: 15 seconds

Course 3: 20 seconds

REMARK

1 MPa ≒10.2kg f/cm2

1 kg f/cm2 ≒0.98 MPa

G-1

TOP ASSEMBLY DRAWING

650

540

STEAM INLET 1/2"

1670

ANCHOR

4

1

φ

455

1082

897

1613

248

AIR INLET 1/2"

2127

50

1211

750

938

STEAM OUTLET 1/2"

115 1710 302

G‑2

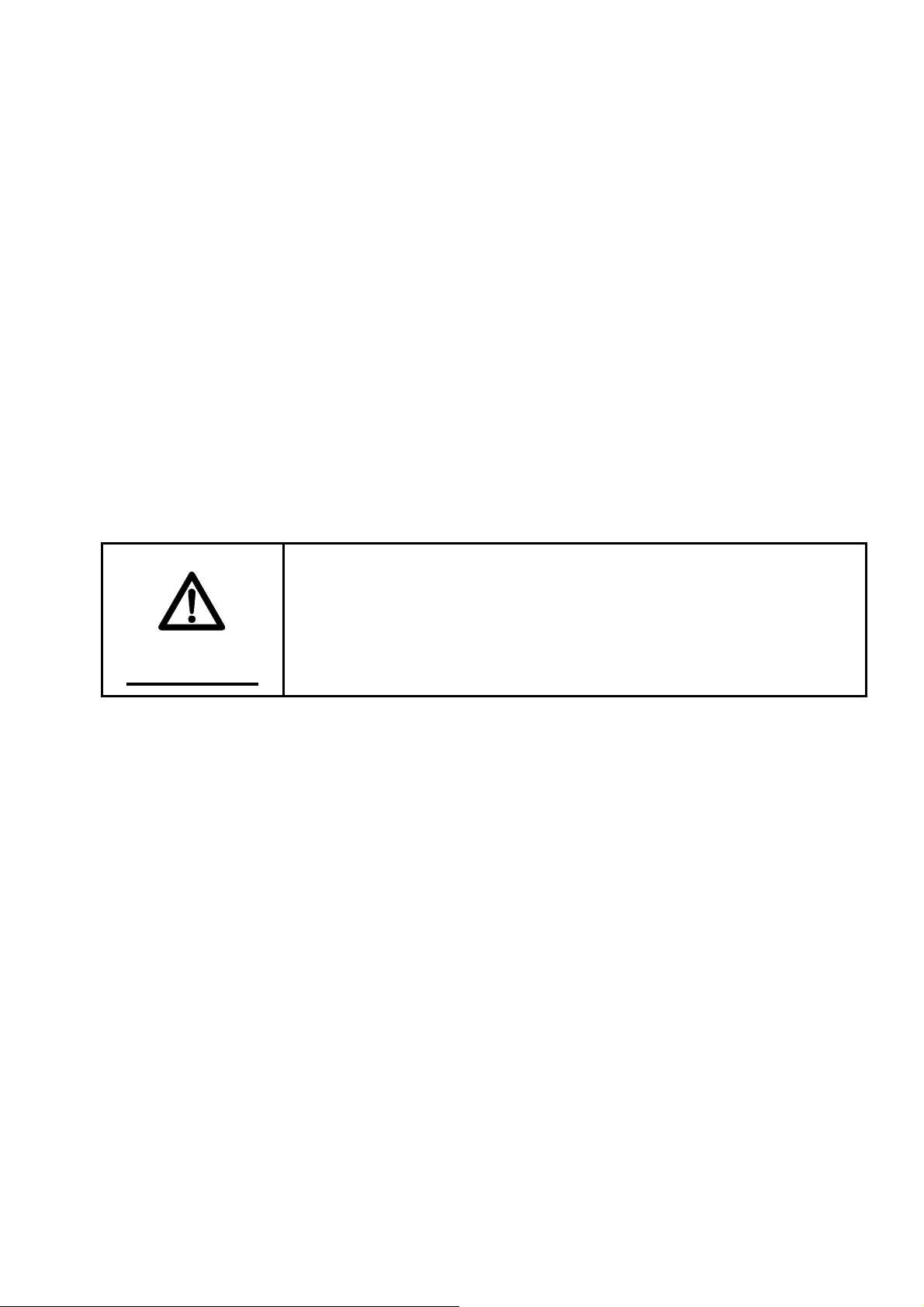

WIRING DIAGRAM

0V

TRUNK OPEN

TRUNK CLOSE

DUMMY RIGHT

DUMMY LEFT

00

01

02

+24

P C 0V

COM

00

COM

01

COM

03

10CH

02

03

COM

START BUTTON

CUFF RIGHT BUTTON

CUFF LEFT BUTTON

PRESS BUTTON

STOP BUTTON

ARM BACKWARD

ARM FORWARD

04

05

06

07

08

0CH1CH

04

05

COM

09

06

07

COM

AIR BUG TIMER

10

11

00

01

00

TIME

SS‑2

COLOR CLAMP SWICH

HOT AIR TIMER

01

02

MS1

TH1

TUCK OFF

TUCK PRESS TIMER

FINISH TIMER

02

03

11CH

03

COM

MS2

COUNTER

TH2

DUMMY LOCK UP

DUMMY LOCK DOWN

04

05

06

07

04

05

06

07

HOT AIR (SLEEVE)

TIMER START

DUMMY RIGHT

DUMMY LEFT

TUCK PRESS

ARM FORWARD

TUCK SLIDE

24V

HOT AIR

BLOWER

MOR1

W1

V1

U1

INVERTER

FWD CM

BLOWER

AIR BUG

MOR2

W2

V2

U2

TH1

MS1

BLOWER

VACUUM

MOR3

U3

V3

W3

TH2

MS2

CUFF RIGHT

ARM BACKWARD

CUFF LEFT

P

L

VACUUM

AIR BUG

AIR BUG VALVE

COM

N

N

TRUNK PRESS

SHOULDER EXPANSION

BUMMY LOCK

START

AIR BUG

TUCK PRESS

HEAT

FINISH

102

101

100

1001

1234578

103

11

12

+24V

‑24V

COLLAR CLAMP

COM

TUCK OFF

104

TIMER

T1

AC200V

R S T

E

CP

U

G‑3

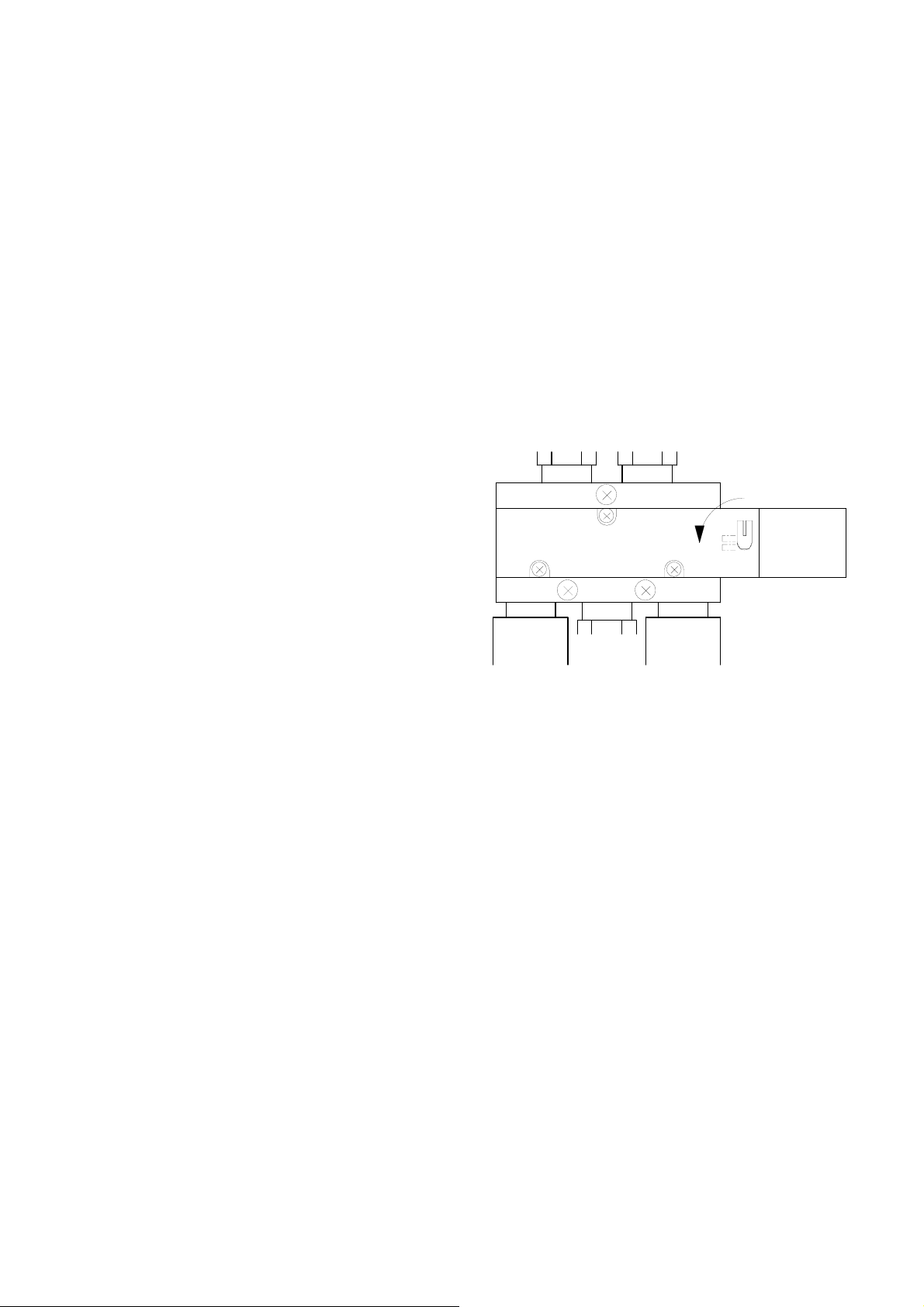

WIRING DIAGRAM

SHOULDER EX R

TUCK SLIDE R

TUCK SLIDE L

TUCK PRESS R

46

45 5

9

TUCK PRESS L

10

ARM TURNS

CUFF CLAMP R

CUFF CLAMP L

COLLAR CLAMP

27

49

50

SHOULDER EX L

DUMMY LOCK

28

29

33

33

545 49

16 1146 44 48

46

14

41

10

42

42 42

TRUNK PRESS

3030

4342

DUMMY MOVES

434215

8 22

2 3 4

1

G‑4

TROUBLE SHOOTING

A

Symptom Cause Treatment

Power does not come to

switch and does not

indicate operation panel.

Collar cannot be set. Some section is not return to

Fixing of the collar is not

strong enough.

Electricity is not supplying

Activating circuit breaker

its starting point or not

apply the command.

Foot switch is damaged.

Some abnormal input is in.

Electro magnetic valve is

damaged.

Fixing rubber has worn.

ir is leaking from the

cylinder.

Air hose is broken or leaking

Check the power source cord and your

factory's breaker.

Check the cause of short circuit, etc and

reset the circuit protector.

Check the sensor for releasing the iron,

left side of dummy, or left arm in the back.

Check if the signal of the foot switch

comes in the sequencer.

Buttons for the emergency stop, cuffs,

press, etc. usually receives no input.

Check the voltage and actions of the

electro magnetic valve for collar fixer.

Regulate it by tightening the regulating

bolt at the cylinder head.

If there is no room for regulation, replace

the fixing rubber.

Replace packing of the cylinder.

After checked around hose and amend it.

Vacuum does not work.

Weak vacuum work. Lost vacuum hose quality

Foot switch is broken.

The thermal relay is

working due to over load

capacitance.

and/or gap the hole.

H-1

Replace foot switch. Vacuum starts at

the same time with the collar fixing. In

case the foot switch is broken, the collar

is not fixed either.

This is caused by over load capacitance

in the vacuum motor and activating

thermal relay.. Remove the cause of over

load capacitance on the motor and reset

the thermal relay.

Replace the vacuum hose.

TROUBLE SHOOTING

Symptom Cause Treatment

Dummy does not move to the

right.

Does not come left arm in

front.

Do not press the trunk.

To see the devices are not

returned to regulate position or do

not enter command even

returned at regulate position.

Damaged electro magnetic valve.

Damaged start button.

Dummy does not move right end.

Damaged electro magnetic valve.

Dummy does not move right end.

Damaged electro magnetic valve.

Check the sensor for release iron,

left side of dummy and back of left

arm.

Check electro magnetic valve for

dummy move or replace in case.

Check start button or replace in case

Check the sensor for dummy move

device and right side of dummy.

Check electro magnetic valve for

arm revolving or replace it in case.

Check the sensor for dummy move

device and right side of dummy.

Check electro magnetic valve for

trunk press or replace it in case.

Do not set cuffs

Do not start finish timer. Damaged button for start sleeve

Do not pull sleeve. Appropriate air pressure level

Damaged button for cuffs press.

Damaged electro magnetic valve.

Do not enter the command for

shut the trunk iron.

Damaged electro magnetic valve

Replace cuffs press button.

Check electro magnetic valve for

cuff or replace it in case.

Check sleeve button and replace it

in case.

Check the sensor for shut the

trunk iron.

Adjust the pressure level of electro

decompression valve for tuck slide

in tuck slide return.

Check electro magnetic valve for

tuck slide or replace it in case.

H-2

TROUBLE SHOOTING

Symptom Cause Treatment

Do not come hot air. Proper setting of the timer for

hot air blowing.

Activating thermal relay due to

over load capacitance of hot air

motor.

Do not press tuck Place the switch to TUCK OFF.

Timer for press tuck to be later

activation is too late.

Damaged electro magnetic valve.

Do not end finish work.

Finishing timing is too long.

Damaged the timer.

Reset the timer to a suitable time.

Remove cause of over load

capacitance of motor and reset

thermal relay.

Push TUCK PRESS button again to

make the status of turn off the lamp.

Set appropriate the timer.

Check electro magnetic valve for

tuck press or replace it in case.

Adjust and set the timer appropriate

time for finish.

Check signal of end of finish sign

must be entered to sequencer when

timer has over.

Worse finish condition of

side.

Affect to see the curve at

front stand.

Swelling air bag is weak.

Swelling time of air bag is late.

Swelling the air bag is too fast. Adjust appropriate timing of the

Check if air leakage between blower

motor for air bag and air bag.

Adjust the timer to swell air bug

properly.

timer set longer in this case.

H-3

TROUBLE SHOOTING

Symptom Cause Treatment

Raising the wrinkles in

front and back of the

trunk.

Raising small wrinkles

where at the sleeve.

Tuck for the sleeve will

open.

Raising stain. Stained the pad cover.

Worn out the part of the cover and

cover.

Poor drying condition due to hot

air blowing is not well enough.

Timing of hot air come into the

sleeve is earlier.

Drying condition is not well

enough.

Replace the pad and cover.

Check root valve of steam and trap

and/or check filter for finish timer or

clean it in case.

Adjust the timer to appropriate time

for hot air blowing in this case set

the timer to long.

Replace the pad cover.

Make the timer to long for finishing

or dehydrate to strong.

H-4

Loading...

Loading...