Page 1

SL7000

RT

Installation

Guide

Page 2

Page 3

Copyright © 2012

Itron France

. All rights reserved.

Itron France

No part of this publication may be reproduced, transmitted, stored in a retrieval system, or translated

into any language in any form by any means without the written permission of Itron FRANCE.

All trade marks are acknowledged.

While Itron strives to make the content of its marketing materials as timely and accurate as possible,

Itron makes no claims, promises, or guarantees about the accuracy, completeness, or adequacy of,

and expressly disclaims liability for errors and omissions in, such materials. No warranty of any kind,

implied, expressed, or statutory, including but not limited to the warranties of non-infringement of third

party rights, title, merchantability, and fitness for a particular purpose, is given with respect to the

content of these marketing materials.

ZI Chasseneuil - Avenue des Temps Modernes

86361 Chasseneuil du Poitou cedex

France

Tel: +33 5 49 62 70 00

Fax: +33 5 49 62 70 89

Page 4

Page 5

Installation Guide SL7000 RT

D2021471

-AA

Contents

1. About this guide .......................................................................................................... 3

1.1.

1.2.

Audience ............................................................................................................................. 3

Scope ................................................................................................................................. 3

2. Certification ................................................................................................................. 6

2.1.

2.2.

2.3.

Applicable standards .......................................................................................................... 6

CE Certificate of conformity ................................................................................................ 7

End-of-life disposal ............................................................................................................. 7

3. Safety information ..................................................................................................... 10

4. General information .................................................................................................. 12

4.1.

4.2.

4.3.

4.4.

4.4.1.

4.4.2.

4.5.

4.5.1.

Meter overview ................................................................................................................. 12

General specifications ...................................................................................................... 13

Meter support tools ........................................................................................................... 14

Configuration options ........................................................................................................ 14

Meter identification ........................................................................................................... 14

Meter product coding ........................................................................................................ 15

Meter markings ................................................................................................................. 16

Terminal numbering .......................................................................................................... 17

5. Technical specification ............................................................................................. 18

6. Technical description ................................................................................................ 22

6.1.

Metrology .......................................................................................................................... 23

7. Communications ....................................................................................................... 24

8. Meter displays ........................................................................................................... 25

9. Installation ................................................................................................................. 26

9.1.

9.2.

9.3.

9.4.

9.5.

9.6.

9.7.

9.8.

9.9.

9.10.

9.11.

9.12.

Warnings .......................................................................................................................... 26

Environmental ................................................................................................................... 26

Dimensions ....................................................................................................................... 26

Fixings .............................................................................................................................. 27

Auxiliary and communication wiring.................................................................................. 29

Cabling ............................................................................................................................. 30

Battery .............................................................................................................................. 32

Installation checks ............................................................................................................ 32

Start-up and functional checks ......................................................................................... 33

Metrology parameters settings ......................................................................................... 33

Sealing the meter ............................................................................................................. 34

Current conductors environment recommendations ......................................................... 34

10. Technical appendix ................................................................................................... 36

i

Page 6

Page 7

D2021471

-AA

1. About this guide

1.1. Audience

This guide is intended for use primarily by meter installers, utility testers and specifying engineers.

1.2. Scope

This installation guide provides all information required to:

• understand the principles of operation of the meter

• assess the suitability of the meter for any particular application

• install the meter safely and correctly

Additional information will be provided in the SL7000 User Guide, when referred to.

Installation Guide SL7000 RT

3

Page 8

Installation Guide SL7000 RT

D2021471

-AA

Abbreviations

AC Alternating current MDI Maximum demand indicator

ANSI American national standards

Min Minimum

institute

CE European conformity (logo) mm Millimetres

Cosem Companion specification for energy

MV Medium voltage

metering

DLMS Device language message

Nom Nominal

specification

EMC Electro-magnetic compatibility NVM Non-volatile memory

G Giga (109) OBIS Object identification system

GSM Global system for mobile

PSU Power supply unit

communications

HF High frequency RF Radio frequency

Hz Hertz RH Relative humidity

I Current RMS Root mean square

i.a.w In accordance with Rogowski Ironless derivative current sensing technique

based on Ampère’s law

Ib Base current RTC Real-time clock

I/O Inputs and outputs SCADA Supervisory control and data acquisition

IR Infrared secs Seconds

IEC International electrotechnical

T Tera (1012)

commission

k Kilo (103) TER Total energy register

LAN Local area network THD Total harmonic distortion

LCD Liquid crystal display TOU Time of use

LED Light emitting diode V Volt

LV Low voltage WEEE Waste electrical and electronic equipment

directive (European Union)

M Mega (106) W Watt

Max Maximum

4

Page 9

Installation Guide SL7000 RT

D2021471

-AA

Page intentionally left blank

5

Page 10

D2021471

-AA

2. Certification

2.1. Applicable standards

The SL7000 RT meters comply, where applicable, with the following standards and regulations.

• IEC 62052-11 Electricity metering equipment (AC) - General requirements, tests and test conditions, part 11:

Metering equipment (equivalent to EN 6205-11)

• IEC 62053-21 Electricity metering equipment (AC) - Particular requirements, part 21: Static meters for active

energy (classes 1 and 2), (equivalent to EN 62053-21)

• IEC 62053-23 Electricity metering equipment (AC) - Particular requirements, part 23: Static meters for

reactive energy (classes 2 and 3)

• IEC 62053-24 (Project) Electricity metering equipment (AC) - Particular requirements, part 24: Static meters

for reactive energy (classes 0,5 S, 0,5, 1S and 1)

• IEC 62053-31 Electricity metering equipment (AC) - Particular requirements, part 31: Pulse output devices

for electro-mechanical and electronic meters (equivalent to EN 62053-31)

• IEC 62053-52 Electricity metering equipment (AC) - Particular requirements, part 52: Symbols

• IEC 62053-61 Electricity metering equipment (AC) - Particular requirements, part 61: Power Consumption

and Voltage Requirements

• IEC 62054-21 Electricity metering equipment (AC) - Tariff Load control, part 21: Particular requirements for

time switches (equivalent to EN62054-21)

• IEC 62056-21 Electricity Metering – Data exchange for meter reading, tariff and load control - Direct local

data exchange (supersedes IEC61107)

• IEC 62056-42 Electricity Metering – Data exchange for meter reading, tariff and load control, part 42:

Physical layer services and procedures for connection-oriented asynchronous data exchange

• IEC 62056-46 Electricity Metering – Data exchange for meter reading, tariff and load control, part 46: Data

link layer using HDLC protocol

• IEC 62056-47 Electricity Metering – Data exchange for meter reading, tariff and load control, part 47:

COSEM transport layers for IPv4 networks

• IEC 62056-53 Electricity Metering – Data exchange for meter reading, tariff and load control, part 53:

COSEM Application layer

• IEC 62056-61 Electricity Metering – Data exchange for meter reading, tariff and load control, part 61: Object

identification system (OBIS)

• IEC 62056-62 Electricity Metering – Data exchange for meter reading, tariff and load control, part 62:

Interface classes

• EMC Directive 2004/109/EC as amended by 92/31/EEC and 93/68/EEC. Compliance has been

demonstrated by compliance with EN62052-11 and EN62053-21.

Installation Guide SL7000 RT

6

Page 11

Installation Guide SL7000 RT

D2021471

-AA

2.2. CE Certificate of conformity

TO BE UPDATED

2.3. End-of-life disposal

SL7000 RT meters comply with the requirements of WEEE regulations for recycling or reuse of materials.

At the end of their service life, meters should be uninstalled and then passed to a licenced/certified contractor for

7

Page 12

Installation Guide SL7000 RT

D2021471

-AA

disposal in accordance with these regulations and with all applicable local regulations.

Before passing the meters to the contractor the legal certification stamps or marks must be removed or defaced.

8

Page 13

Installation Guide SL7000 RT

D2021471

-AA

Page intentionally left blank

9

Page 14

D2021471

-AA

3. Safety information

Meters must be installed and maintained only by suitably-qualified personnel. Observe the following safety advice

when performing installation or service work on meters.

Meter handling

Before installing or removing a meter, or removing the terminal cover for any reason, isolate the

meter from the mains supply by removing the supply-side fuses or using alternative local

arrangements. Take appropriate measures to ensure that the isolation cannot be overridden by

another person. For example, keep physical possession of the supply fuses.

• Adhere strictly to all relevant national regulations for the avoidance of electrical accidents.

• Always disconnect all measurement and auxiliary circuit connections from the meter before

attempting to open the meter housing.

• Use only tools that have been approved for electrical installations.

• Clean meters only with a damp cloth or sponge. Do not use excessive or running water.

Installation

Install meters in accordance with the voltage and current specifications printed on the front panel and

the wire and environmental specifications given in the installation information.

• The meter measuring and auxiliary circuits must be galvanically isolated.

Installation Guide SL7000 RT

• All voltage paths (measurement and auxiliary) must be fused.

• The meter voltage connections must be physically separated from the communication lines

in accordance with local laws and regulations.

• Do not install meters that are obviously damaged.

• Do not install meters that have been dropped or otherwise subjected to significant impact

even if no damage can be seen.

• Do not HIPOT/Dielectric test the auxiliary or communication circuit connections.

• Do not use any meter functions or features for primary protection purposes.

• Do not install meters where failure of the device could cause death, injury or release

sufficient energy to start a fire.

• Following installation, ensure that the meter terminal covers are correctly fitted and sealed

to prevent user access.

10

Page 15

Installation Guide SL7000 RT

D2021471

-AA

Page intentionally left blank

11

Page 16

D2021471

-AA

4. General information

4.1. Meter overview

Depending on the factory configuration, the meter provides the following minimum features and functions:

Installation Guide SL7000 RT

The SL7000 RT is a static, polyphase, four-quadrant, multi-rate

meter. It is intended for monitoring of MV/LV substations on their

LV side.

Multi-energy registering Active, Reactive and Apparent energy (import and export)

Units - Watt (W), Kilowatt (kW) and Megawatt (MW)

Maximum 32 individual energy rate registers for 10 energy channels

(incremental or cumulative)

Up to 8 energy rates per channel

Multi-rate billing and switching Billing for both energy and demand

Energy rate switching performed by internal clock/calendar

• Up to 12 seasons

• Up to 24 day profiles

• Up to 16 switching times per day profile

• Up to 100 special days (repetitive or non-repetitive)

Demand registering Maximum 24 individual demand rate registers for 10 demand channels

Up to 8 energy rates per channel

Load profiling 2 independent sets of 8 recording channels giving up to 16 load profile channels

Incremental data

Communication RS232 + RS232 or RS485

DLMS-Cosem compliant

PSTN, LAN (TCP/IP), GSM and GPRS media supported

Network quality monitoring Voltage cuts, sags and swells

Total Harmonic Distortion (THD)

12

Page 17

Installation Guide SL7000 RT

D2021471

-AA

The diagram below shows the main functional elements of the meter:

1 Liquid crystal display (LCD)

2 Infrared communication port

3 Auxiliary I/O terminal blocks

4 Main wiring terminal block

5 Reactive power metrology LED (Rlq)

6 Active power metrology LED (Rlp)

7 Display pushbutton

8 Reset pushbutton

9 Battery holder

10 Serial communication ports

4.2. General specifications

Frequency 50/60 Hz

Connection wiring 4 wires

Connection configuration Rogowski sensors

Terminal wiring Current sensors presassembled – Voltages 3Ph+N

Real Time Clock backup Field-replaceable battery and Internal super-capacitor

Enclosure type Panel mounting DIN compliant

Environmental protection IP 51

Operating temperature Storage : -40°C to +70°C

Relative Humidity < 75% (maximum 95%)

Net weight 1.9kg

Maximum meter dimensions (W x H x D)

Meter body 179 x 261 x 83mm

With short terminal cover 179 x 270 x 83mm

With long terminal cover 179 x 359 x 83mm

Standard terminal cover 179 x 324 x 83mm

13

Page 18

Installation Guide SL7000 RT

D2021471

-AA

Connection specifications

Voltage 3 x 127/220V up to 3 x 277/480V auto ranging

Current Nominal (Ib) Ib: 300A

Maximum (Imax) Imax : 3000A at 50Hz

2500A at 60Hz

Global accuracy

(current sensors included)

Active energy Class 1

Reactive energy Class 1 or 2

Auxiliary power supply specifications (optional)

Auxiliary Power Supply 48V DC to 145V DC

48V AC to 288V AC

4.3. Meter support tools

The SL7000 RT meters have an extensive range of optional facilities and settings, enabling them to be

configured to suit individual requirements. In general, a meter is fully configured and programmed for its intended

application prior to despatch from the factory.

However, some aspects of the configuration may be changed at any time using dedicated Windows™-based

support tools that typically communicate via the optical port on the front of the meter.

Support tool applications provide the following main features:

• metering point management

• configuration creation and editing

• configuration programming and reading

• meter data reading

• meter firmware upgrading

The following support tool is currently available:

ACE Pilot

ACE Pilot is compliant with the following Microsoft Windows™ operating systems:

• XP (SP3)

• 2003 and 2008

• Vista and Seven

4.4. Configuration options

4.4.1. Meter identification

Meter options are specified by a multi-character product code, in which each option is designated by one or more

characters. The meter cover is laser-marked with this legally required identification code.

14

Page 19

D2021471

-AA

4.4.2. Meter product coding

The meter is equipped with input and output (I/O) ports, as shown:

I/O Number

Control inputs 2

Pulse inputs 4

Control outputs 4

Pulse inputs 6

1st COM port RS232 or RS485

2nd COM port RS232

Product code

The example below illustrates the options and the positions of the associated characters in the product code.

Installation Guide SL7000 RT

The following tables provide full details of the individual options:

Product version

Code Option

1 International

Connection and Class

Code Option

R Rogowski - Global Class 1

I/O and COM configuration

Code Option I/O Level

06 2 x RS232 Full

07 1 x RS232 + 1 x RS485 Full

08 2 x RS485 Full

Auxiliary Power Supply (APS)

Code Option

0 No APS

1 APS fitted

Note: Legal product code is composed of “SL76” + “product version” + “Connection and class”. Following

numbers composing the product code are not legal part (for internal and market use only).

15

Page 20

Installation Guide SL7000 RT

D2021471

-AA

4.5. Meter markings

The meter cover is laser-marked with at least the information illustrated below, in accordance with IEC 62053-52.

Additional markings may be present, and the layout of the markings will vary, according to the meter

configuration and specific customer requirements.

1 Manufacturer name

2 Commercial name

3 Nominal voltage

4 Nominal / maximum current and frequency

5 Metrology constant and accuracy class

6 Appropriate symbols (IEC 62053-52) identifying insulation class, measuring elements, and

other relevant characteristics

7 Manufacturers unique serial number

8 Meter legal product code and date of manufacture

9 Place of manufacture

10 Meter serial number - barcode and numerical format

This number may be the same as the manufacturers serial number (7) or be a customerspecified identification number

16

Page 21

D2021471

-AA

4.5.1. Terminal numbering

A connection diagram is displayed on the inside surface of the terminal cover showing typical main supply

connections for the meter configuration and type.

Terminal numbers corresponding to the connection diagram are moulded into the meter case, either above or

below the terminal block depending on the meter connection type.

Rogowski terminal block

Installation Guide SL7000 RT

17

Page 22

D2021471

-AA

5. Technical specification

General

Parameter Description Data

Meter Commercial Name SL7000 RT

Connection wiring 3 or 4 wires

Connection configuration Rogowski

Installation Guide SL7000 RT

Terminal wiring Voltage only

Rogowski current sensors are

irremovable (already attached to the

meter body)

Metrology Four quadrant Active and Reactive

(import and export)

Metrology sensors Rogowski derivative ironless sensors

(split type flexible loops)

Registering modes 4 selectable algorithms Ferraris

Static

Net result

Anti-fraud

Global Accuracy (Rogowski sensors

included)

i.a.w. EN/IEC62053-21 Class 1 for active energy

Voltage

Parameter Details

Reference voltage 3 x 127/220V up to 3 x 277/480V

auto ranging

Operating voltage -20% to + 15% Un

Voltage Interruptions 1 second

Current

Parameter Details

Nominal current (Ib) 300A

Maximum current (Imax) 3000A at 50Hz

2500A at 60Hz

Starting current 1.2 A (Ib/250) , per phase

Short-time over current Not limited by the SL7000 RT

Current Circuit Power Consumption Not applicable

Voltage Circuit Power Consumption

Parameter Details

Voltage per phase <2W

Apparent power per phase at Un <10VA

18

Page 23

Installation Guide SL7000 RT

D2021471

-AA

Display

Parameter Description Data

Type Liquid Crystal Display (LCD)

Digit height Main 12mm

Digit height OBIS code 8mm

Resolution Number of digits 9

Communications

Parameter Description Data

Optical communications i.a.w IEC62052-21 Mode C

Meter Constant Rogowski connection type 40 pulses per kWh

Serial Data Communications RS232, and RS232 or RS485 RJ45 connectors

Baud rate 9600 up to 19200

Supported protocols DLMS/Cosem Y

Communication media types TCP With external LAN modem

GPRS With external modem

GSM With external modem

Real-time operation “Real Time Port” i.a.w. IEC62056-21 Y

Modem power supply 10V -10/+20%, 100mA, 1W max on RJ45 connectors. 1W is the

maximum shared on the 2 ports

Input and output

Parameter Description Data

Control input Optically-isolated, high-level Up to 2 inputs + common

connection point

Minimum input voltage 64V (AC/DC)

Maximum input voltage 288V DC - 300V AC

Maximum input current 3mA

Control output Optically-isolated, high-level Up to 4 outputs + common

connection point

Maximum switching voltage 288V DC - 300V AC

Maximum switching current 100mA

Pulse input (DIN S0) Optically-isolated Up to 6 inputs + common

connection point

Maximum switching voltage 27V DC

(provided by the meter)

Maximum switching current 30mA

Impedance

1.1kΩ

Pulse output (DIN S0) Optically-isolated Up to 4 outputs + common

connection point

Impedance

19

< 300Ω

Page 24

Installation Guide SL7000 RT

D2021471

-AA

-

40°C

to +70°

C

Environmental

Parameter Description Data

Temperature Range Operating range

Humidity range Maximum operating value 95%

Protection class According to IEC 60529 IP 51

Isolation Protection AC voltage at 50Hz for 1 minute 4kV Class 2

Immunity to impulse voltage According to IEC 62052-11

8kV

Waveform of pulse voltage

1.2/50µsecs

Source impedance 500ohms, energy

0.5 joules

Immunity to magnetic fields Magnetic AC (50Hz) field 0.5mT

Fully immune

according to IEC62053 - 21 (400AT

coil)

Magnetic DC field according to IEC

Fully immune

62053-21 (electromagnet with

1000AT)

Magnetic DC field according to

Fully immune

VDEW (perm magnet) field strength

200mT

1.2 Tesla DC Magnets Fully immune

Surge immunity

main circuits

Surge immunity

auxiliary circuits

Electrostatic discharge Electrostatic discharge according to

According to IEC61000-4-5

Source impedance 2 ohms

According to IEC61000-4-5

Source impedance 42 ohms

4kV

1kV

IEC61000-4-2

Contact discharge 8kV, 10 cycles

Air discharge 15kV, 10 cycles

Immunity to RF fields RF fields i.a.w. IEC61000-4-3

With current

10V/m

80MHz to 2GHz

Without current,

30V/m

80MHz to 2GHz

Fast transient burst

Main circuits : Fast transient burst

i.a.w. IEC 61000-4-4

4kV

common-mode and pseudo

differential

Auxiliary circuits : Fast transient

burst i.a.w. IEC 61000-4-4

2kV

common-mode

Radio Interference RF suppression CISPR22 Class B

20

Page 25

Installation Guide SL7000 RT

D2021471

-AA

Weight and Dimensions

Parameter Description Data

Weight 1.9kg nominal

Dimensions

Without terminal cover 179 x 261 x 83mm

(width x height x depth)

With short terminal cover 179 x 270 x 83mm

With long terminal cover 179 x 359 x 83mm

With standard terminal cover 179 x 324 x 83mm

Rogowski sensors Aperture for the primary conductor 120 mm diameter

Thickness of the loop 5 mm diameter

Weight (loop only) 40 g

Cable length 3 m between the loop itself and

the meter body

21

Page 26

D2021471

-AA

6. Technical description

Rogowski

The main components of the SL7000 meter are assembled onto four printed circuit boards (PCBs):

• metrology voltage divider circuitry and the switched-mode power supply

• microcontroller and memory devices

• I/O circuitry

• LCD display

As a manufacturing option, the meter may be equipped with an additional PCB providing further serial

communication ports.

The block diagram below shows the main functional elements of the meter.

Installation Guide SL7000 RT

22

Page 27

Installation Guide SL7000 RT

D2021471

-AA

6.1. Metrology

The SL7000 RT uses Rogowski loops as current sensors, instead of MCT that are used in the conventional

SL7000 CT or DC.

Rogowski loops are based on Ampère’s law stating that the integral value of the magnetic field over any closed

path surrounding a current conductor is related to the amount of current flowing through this path.

A Rogowski sensor delivers a voltage strictly proportional to the derivative value of the current(s) embraced. So

their output is equivalent to the MCT sensors.

The SL7000 RT meters are calibrated in the factory with their Rogowski loops attached, as shipped, so no

additional calibration is required in the field.

The Rogowski sensors used by the SL7000 RT can be installed over current cables easily thanks to its quick clipon system. Their dynamic range allows using a unique model addressing installations rated from 200kVA to

2MVA.

The three current sensors generate a signal per phase that is proportional to the instantaneous current, while

voltage signals are derived by dividing the distribution-network line voltages through a resistive divider.

The current and voltage input signals are sampled and digitised 40 times per cycle (50Hz) by an analogue to

digital (A-to-D) converter, then processed by a microcontroller to derive various energy values. The

microcontroller records these values in a suite of registers that are independent of any meter configuration and

are always available.

These registers accumulate their respective energy values in an incremental fashion, until they reach the register

limit. At that point they are automatically reset to zero in the same way as roll-over electromechanical meter

types.

The contents of these registers can be displayed at any time as instantaneous values on the meter LCD.

The microcontroller also controls the data transfer to the various inputs and outputs, visible metrological LEDs

and infrared port.

Refer to the SL7000 User Guide for more technical description.

23

Page 28

D2021471

-AA

7. Communications

Refer to the SL7000 User Guide

Installation Guide SL7000 RT

24

Page 29

D2021471

-AA

8. Meter displays

Refer to the SL7000 User Guide.

Installation Guide SL7000 RT

25

Page 30

D2021471

-AA

9. Installation

9.1. Warnings

DANGER OF ELECTRIC SHOCK

Before and during installation of a meter, observe all requirements given in the Safety information.

In particular:

Installation Guide SL7000 RT

• Meters must be installed only by suitably-qualified personnel.

• Ensure that the meter supply cabling is isolated from the mains supply, and that the

isolation cannot be overridden by another person.

• Following installation, ensure that the meter covers are correctly fitted and sealed to

prevent user access.

DANGER OF ELECTRIC SHOCK

The SL7000 RT meter is designed for live installation on isolated primary conductors or cables in

low voltage (not exceeding 500V).

In case of installation on bare conductors or bars systems, an additional isolation of the conductors

or bars must be recovered at the location intended for the Rogowski loops prior of their installation.

9.2. Environmental

SL7000 RT meters are certified for indoor use only. Do not install meters outdoors unless they are housed in an

enclosure which can maintain the specified environmental requirements.

Parameter Range

Temperature -40° to +70°

Humidity Up to 95% RH

Environmental protection IP 51

9.3. Dimensions

The meter can be factory-fitted with either a short, standard or long terminal cover.

26

Page 31

Installation Guide SL7000 RT

D2021471

-AA

Item Dimension Description

A 179 Meter body width

B 270 Meter length - with short terminal cover

324 Meter length - with standard terminal cover

359 Meter length - with long terminal cover

C 83 Meter body depth

All dimensions are in millimetres.

9.4. Fixings

The meter is provided with two upper fixing points (1) and (2), select the appropriate one to use, as required. A

hanging bracket is also provided with the meter.

Two further lower fixing points are located within the terminal area; these can be accessed only by removing the

terminal cover.

27

Page 32

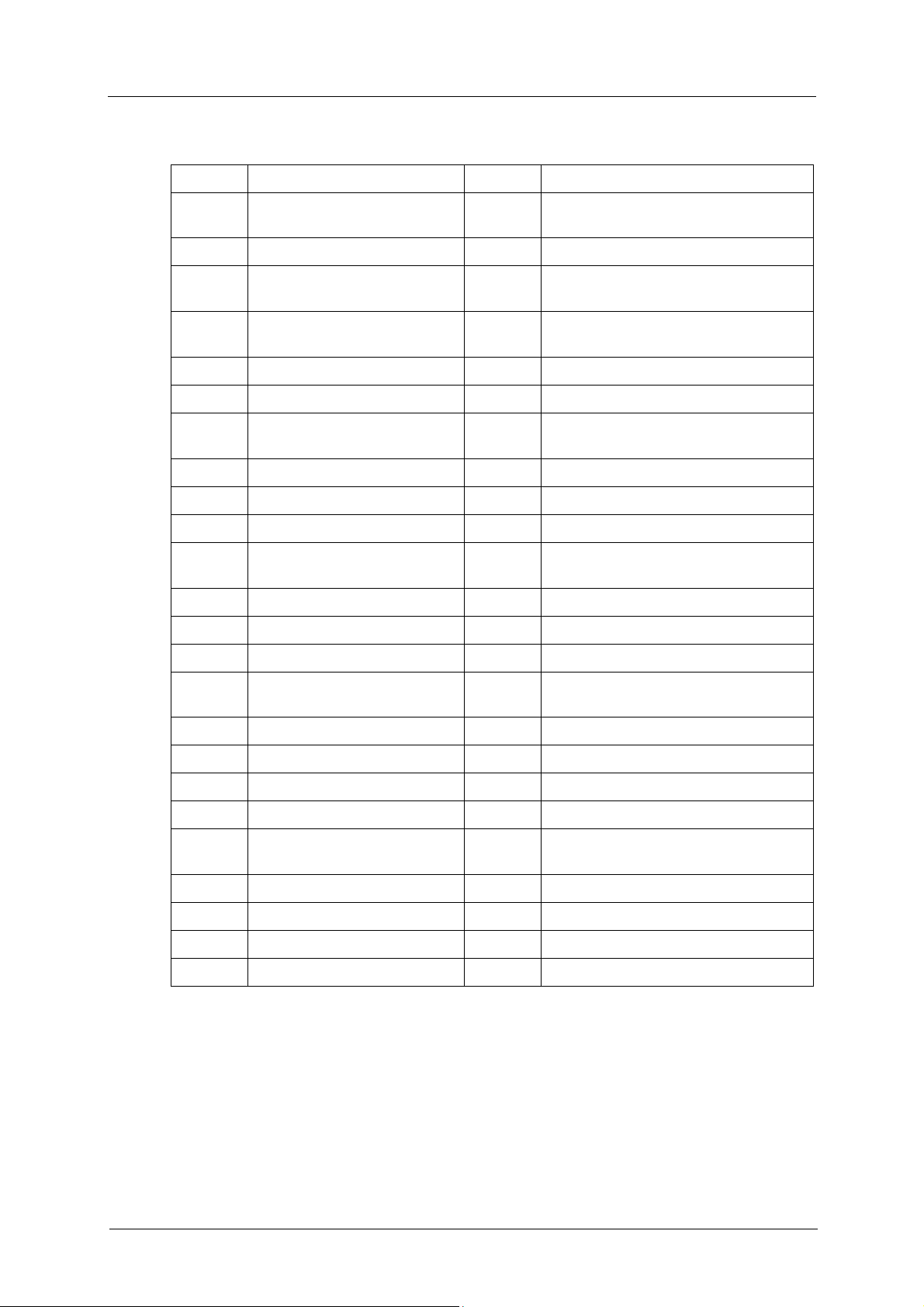

Descriptio

Upper fixing point (1) to lower fixing points (centre to centre)

Upper fixing point (2) to lower fixing points (centre to centre)

Left to right lower fixing points (centre to centre)

Upper fixing point (1) centre to lower edge

Lower edge of meter body to lower edge of short terminal cover

Lower edge of meter body to lower edge of standard terminal cover

Lower edge of meter body to lower edge of long terminal cover

All dimensions are in millimetre

Installation Guide SL7000 RT

D2021471

-AA

Item Dimension

A 230

B 201

C 150

D 252

E 4

E 58

E 93

n

of meter body

s.

28

Page 33

Installation Guide SL7000 RT

D2021471

-AA

9.5. Auxiliary and communication wiring

Auxiliary wiring

Terminal Function Terminal Function Terminal Function

20 Control output 1 29 Pulse output 1 36 Pulse input 1

21 Control output 2 30 Pulse output 2 37 Pulse input 2

22 Control output 3 31 Pulse output 3 38 Pulse input 3

23 Control output 4 32 Pulse output 4 39 Pulse input 4

24 No connection 33 Pulse output 5 40 PI Common

25 CO Common 34 Pulse output 6

26 Control input 1 35 PO Common

27 Control input 2

28 CI Common

The control output and input terminal blocks accept cables up to 2.5mm².

The pulse output and input terminal blocks accept cables up to 1.5mm².

Note: Depending on meter factory configuration, some of the inputs and outputs shown above may not be

available.

Communication wiring

Both RS232 and RS485 type communication ports use RJ45 connectors:

It is recommended that twisted and shielded cables are used for communication line wiring and that one end of

the cable shield should be connected to ground.

Pin RS232 Function RS485 Function

1 VMDM Approx +10V DC at 100mA (0.9W max) VMDM Approx +10V DC at 100mA (0.9W max)

2 No connection RX -

3 No connection No connection

4 RX RX +

5 TX TX +

6 0V - Ground 0V - Ground

7 DTR TX -

8 No connection No connection

29

Page 34

Installation Guide SL7000 RT

D2021471

-AA

9.6. Cabling

Main terminal wiring - voltage connection

Terminal Function Terminal Function Terminal Function Terminal Function

1 Not used 4 I3 sensor 7 U1 11 Neutral

2 I1 sensor 5 Not used 8 U2 14 APS

3 I2 sensor 6 Not used 9 U3 15 APS

Main terminal specification

Terminal type Clamp screws Cable diameter

Voltage 2 x M4 5mm (max)

Current sensors Factory set – No need to manipulate

30

Page 35

Installation Guide SL7000 RT

D2021471

-AA

Installation of the Rogowski loops over the main power cable(s)

1.

1. The 3 Rogowski loops are marked by a colored

sleeve close to their junction block.

• Grey for phase 1 sensor

• Brown for phase 2 sensor

• Black for phase 3 sensor

It is key that the Rogowski sensors are installed

accordingly their corresponding phase otherwise the

measurement will be mixed up.

2. The junction block of the Rogowski loop bears a

direction arrow.

Make sure that the loop is installed in such a way

that :

Network

• The arrow is located at the inner side of the

loop (do not force thenatural curvature of

the lop in the opposite way)

Colored

sleeve

Load

• The arrow points towards the LOAD side

It is key that the direction of the Rogowski sensors is

correct, otherwise the measurement will be reversed

(import for export and vice-versa).

3. General recommendations

• When securing the loop part against the main conductor or cable, a moderate pressure is sufficient

thanks to the light weight of the sensor, do not flatten the loop part

• As far as possible, keep the loop part away from adjacent conductors (the other phases for instance)

31

Page 36

Installation Guide SL7000 RT

D2021471

-AA

9.7. Battery

The meter is designed so the lithium battery can be safely installed or replaced while the meter is operating, as

follows:

1. If fitted, remove the seal from the battery holder securing screw.

2. Undo the securing screw and carefully extract the battery holder from the meter housing.

3. The meter may be initially shipped with the battery cable in the disconnected position (1). If this is the case,

move and fit the cable connector into the moulded pillar, as shown (2).

The illustrations show a rear view of the battery holder.

4. If the battery is being replaced, slide the old one out from under the securing tab and exchange.

5. Ensure the battery connector is the correct way round, as shown above.

6. Replace the battery holder into the meter, ensuring the moulded plastic connector pillar is inserted into the

lower aperture.

7. Tighten front securing screw.

8. Using the meter support tool, clear any battery error indications/alarms and reset the battery expected life

time value.

9. Seal the meter, as necessary.

9.8. Installation checks

Before connecting the mains supply to the installed meter, carefully check that:

• the correct meter type with the right identification number has been installed for this client at this metering

point.

• all mains supply and auxiliary cables are connected to the correct terminals.

• all cable clamp screws are securely tightened.

• the battery has been correctly installed.

32

Page 37

Installation Guide SL7000 RT

D2021471

-AA

9.9. Start-up and functional checks

Take the following steps to check that the meter is functioning.

1. Connect the mains supply to the meter.

2. Check that the LCD display turns on and shows coherent displays.

Depending on the meter configuration, the LCD may move automatically through a sequence of displays, or

it may be necessary to use the meter display pushbutton to move through the sequence.

3. Check that the meter is in the start mode (STOP is not displayed).

4. Check the phase sequence is correct; the quadrant indicator icons in the LCD should not be flashing.

5. Apply a load to the meter and check that the metrology LED (active - kWh) starts to flash.

The flash rate is proportional to the load.

6. Using the IR port, connect a support tool enabled PC to the meter and:

• read the Total Energy Registers (TER) values

• read all instantaneous values

• read the meter status values and its configuration

• erase any non-fatal alarms

7. Carry out the LCD test and confirm all the display segments and annunciator icons are lit.

8. Wait for approx 15 minutes while the meter operates.

9. Check the TER values have incremented from their initial values.

10. Check the maximum demand value is consistent with the applied load.

11. Re-check meter status.

9.10. Metrology parameters settings

With the ACE Pilot support tool, open the meter configuration

1. Make surre that the General Ressources are set for a SL7000 with: Meter Type SL761, FW Version 9.xx and

Meter connection Transformer

2. Make sure that the Metrology Connection parameters are set to a CT ratio 250/1 and a VT ratio 1/1

3. Make sure that the Metrology/Network parameters are set to 12 A Max Current

The Maximum Usual current may be set to a lower value depending on the application.

4. Use the Toolbox functions to verify all aspects of meter operation.

5. Save and print the results as evidence of correct operation.

33

Page 38

Installation Guide SL7000 RT

D2021471

-AA

9.11. Sealing the meter

Before leaving the installation site, fit the terminal cover, and seal the meter against unauthorised access or

tampering by fitting wire or plastic seals, as required, in the following locations:

1 IR Port

2 Reset pushbutton

3 Battery holder

4 Main cover

5 Terminal cover

9.12. Current conductors environment recommendations

TO BE DEVELOPPED

34

Page 39

Installation Guide SL7000 RT

D2021471

-AA

Page intentionally left blank

35

Page 40

D2021471

-AA

10. Technical appendix

Refer to SL7000 User Guide

Installation Guide SL7000 RT

36

Loading...

Loading...