Page 1

Intelis Gas Meter Installation Guide

Technical

Communications

knowledge to shape your future

Page 2

Identification

Intelis Gas Meter Installation Guide

8 March 2019

TDC-1782-002

Copyright

© 2018-2019 Itron, Inc. All rights reserved.

Confidentiality Notice

The information contained herein is proprietary and confidential and is being provided

subject to the condition that (i) it be held in confidence except to the extent required

otherwise by law and (ii) it will be used only for the purposes described herein. Any third

party that is given access to this information shall be similarly bound in writing.

Trademark Notice

Itron is a registered trademark of Itron, Inc.

All other product names and logos in this documentation are used for identification purposes

only and may be trademarks or registered trademarks of their respective companies.

Suggestions

For more information about Itron or Itron products, see www.itron.com.

If you have questions or comments about the software or hardware product, contact Itron

Technical Support Services.

Contact

• Email: support@itron.com

• Itron Access: https://support.itron.com

• Telephone Itron Technical Support North America: 1-877-487-6602

For technical support contact information by region, go to www.itron.com and select your

country and language.

Page 3

Contents

Chapter 1 Important Safety and Compliance Information.............................. 1

USA, FCC Part 15 spectrum compliance............................................................................................................. 1

Canada, ISED spectrum compliance....................................................................................................................2

RF Exposure (FCC/ISED)...................................................................................................................................... 2

Australia, ACMA spectrum compliance................................................................................................................ 2

Electromagnetic compatibility...............................................................................................................................3

Intrinsic safety.......................................................................................................................................................3

Lithium battery...................................................................................................................................................... 3

Transportation classication................................................................................................................................. 3

Electrostatic discharge..........................................................................................................................................3

Electrostatic ignition hazard..................................................................................................................................4

Device cleaning.....................................................................................................................................................4

Do not drop...........................................................................................................................................................4

Product notication...............................................................................................................................................5

Chapter 2 Intelis Gas Meter................................................................................6

Related documents...............................................................................................................................................6

Intelis Gas Meter models...................................................................................................................................... 7

Intelis Gas Meter components..............................................................................................................................7

Internal safety shutoff valve....................................................................................................................... 7

Automatic shutoff conguration..........................................................................................................7

Integrated 500G communications module.................................................................................................8

Intelis Gas Meter specications............................................................................................................................8

Intelis Gas Meter dimensions .............................................................................................................................10

Chapter 3 Installing the Intelis Gas Meter.......................................................11

Prior to start-up...................................................................................................................................................12

Start-up...............................................................................................................................................................12

Removing or installing the pipe plug.................................................................................................................. 13

Removing the pipe plug........................................................................................................................... 13

Installing the pipe plug............................................................................................................................. 14

Chapter 4 Intelis Gas Meter LCD Operation................................................... 15

The Intelis Gas Meter LCD..................................................................................................................................15

Intelis Gas Meter LCD display alarms......................................................................................................17

Additional LCD screen displays............................................................................................................... 19

Intelis Gas Meter LCD display icons........................................................................................................ 19

Performing an LCD test............................................................................................................................20

Chapter 5 Proving the Intelis Gas Meter......................................................... 21

Intelis Gas Meter Test Mode............................................................................................................................... 22

Entering Test Mode.................................................................................................................................. 22

Recording Test Mode consumption......................................................................................................... 22

Exiting Test Mode.....................................................................................................................................23

Prover types........................................................................................................................................................23

Intelis Gas Meter Installation Guide TDC-1782-002 iii

Proprietary and Confidential

Page 4

Proving the Intelis Gas Meter using the Honeywell SNAP proving system............................................. 23

Tempering the meter by exercising...................................................................................................24

Setting up the prover........................................................................................................................ 25

Proving the Intelis Gas Meter............................................................................................................29

Proving the Intelis Gas Meter using the Measurement Systems proving system....................................32

Temper the meter by exercising the meter....................................................................................... 33

Setting up the Measurement Systems prover.................................................................................. 34

Proving the Intelis Gas Meter............................................................................................................42

Proving the Intelis Gas Meter using the Energy Economics (EEI) proving system...................................44

Temper the meter by exercising the meter....................................................................................... 44

Setting up the EEI prover..................................................................................................................46

Proving the Intelis Gas Meter............................................................................................................50

Chapter 6 Adjusting the Intelis Gas Meter Calibration.................................. 52

To adjust the calibration of an Intelis Gas Meter.................................................................................................52

To seal an Intelis gas meter.................................................................................................................................58

To unseal an Intelis gas meter's UMU................................................................................................................ 60

Chapter 7 Intelis Gas Meter Index Replacement............................................62

Replacing the Intelis Gas Meter index assembly................................................................................................62

Intelis Gas Meter Installation Guide TDC-1782-002 iv

Proprietary and Confidential

Page 5

Chapter 1 Important Safety and Compliance

Information

This section provides important information for your safety and product compliance.

USA, FCC Part 15 spectrum compliance

This device complies with Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation.

Operation is subject to the following two conditions:

• This device may not cause harmful interference.

• This device must accept any interference that may cause undesirable operation.

This device must be installed to provide a separation distance of at least 20 centimeters (7.9

inches) from all persons to be compliant with regulatory RF exposure.

USA, FCC Class B-Part 15

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio or TV technician for help.

Modifications and Repairs

To ensure system performance, this device and antenna shall not be changed or modified

without the express approval of Itron. Per FCC rules, unapproved modifications or operation

beyond or in conflict with these instructions for use could void the user's authority to operate

the equipment.

Intelis Gas Meter Installation Guide TDC-1782-002 1

Proprietary and Confidential

Page 6

Important Safety and Compliance Information

Canada, ISED spectrum compliance

Compliance Statement Canada Déclaration de Conformité

This device complies with Innovation, Science

and Economic Development Canada (ISED)

license-exempt RSS standard(s). Operation is

subject to the following two conditions: (1) this

device may not cause interference, (2) this

device must accept any interference, including

interference that may cause undesired operation

of the device.

Under Innovation, Science and Economic

Development Canada (ISED) regulations, this

radio transmitter may only operate using an

antenna of a type and maximum (or lesser) gain

approved for the transmitter by Industry Canada.

To reduce potential radio interference to other

users, the antenna type and its gain should be so

chosen that the equivalent isotropically radiated

power (e.i.r.p.) is not more than that necessary

for successful communication.

Le présent appareil est conforme aux CNR

d'Industrie Canada applicables aux appareils

radio exempts de licence. L'exploitation est

autorisée aux deux conditions suivantes: (1)

l'appareil ne doit pas produire de brouillage, (2)

l'utilisateur de l'appareil doit accepter tout

brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le

fonctionnement.

Conformément à la réglementation d'Industrie

Canada, le présent émetteur radio peut

fonctionner avec une antenne d'un type et d'un

gain maximal (ou inférieur) approuvé pour

l'émetteur par Industrie Canada. Dans le but de

réduire les risques de brouillage radioélectrique à

l'intention des autres utilisateurs, il faut choisir le

type d'antenne et son gain de sorte que la

puissance isotrope rayonnée équivalente (p.i.r.e.)

ne dépasse pas l'intensité nécessaire à

l'établissement d'une communication

satisfaisante.

RF Exposure (FCC/ISED)

This equipment complies with radiation exposure

limits set forth for an uncontrolled environment.

This equipment should be installed and operated

with minimum distance 20 cm between the

radiator and your body

be co-located or operating in conjunction with

any other antenna or transmitter.

. This transmitter must not

Cet équipement est conforme aux limites

d'exposition aux radiations dans un

environnement non contrôlé. Cet équipement do

it être installé et utilisé à distance minimum de 20

cm entre le radiateur et votre corps. Cet émetteur

ne doit pas être co-localisées ou opérant en

conjonction avec tout autre antenne ou

transmetteur.

Australia, ACMA spectrum compliance

When this device is sold and shipped to Australia, it is configured and labeled accordingly to

be compliant with ACMA Standards for the Radio, EMC and RF Exposure. This includes

standard AS/NZS 4268 RF spectrum standard for frequency and power out.

Intelis Gas Meter Installation Guide TDC-1782-002 2

Proprietary and Confidential

Page 7

Electromagnetic compatibility

Caution: Use only approved accessories with this equipment. All cables must be

high quality, shielded, and correctly terminated. Unapproved modifications or

operation beyond or in conflict with these use instructions may void the authority's

authorization to operate the equipment.

Intrinsic safety

Warning: Substitution of components may impair intrinsic safety.

Lithium battery

Warning: Follow these procedures to avoid injury to yourself or others.

• The lithium battery may cause a fire or chemical burn if it is not disposed of

properly.

• Do not recharge, disassemble, heat above 212°Fahrenheit (100°C Celsius),

crush, expose to water, or incinerate the lithium battery. Fire, explosion, and

severe burn hazard.

• The battery used in this device may present a risk of fire or chemical burn if

mistreated.

• Keep the lithium battery away from children.

Important Safety and Compliance Information

Transportation classification

The Federal Aviation Administration prohibits operating transmitters and receivers on all

commercial aircraft. When powered and not in Factory ship mode, the Itron device is

considered an operating transmitter and receiver and cannot be shipped by air. All product

returns must be shipped by ground transportation.

Electrostatic discharge

Warning: Internal circuit components can be sensitive to electrostatic discharge.

Before installation, discharge electrostatic buildup by touching a metal pipe or other

earth-grounded metal object prior to touching the meter body

Itron device.

Intelis Gas Meter Installation Guide TDC-1782-002 3

Proprietary and Confidential

, register housing, or

Page 8

Important Safety and Compliance Information

Electrostatic ignition hazard

Warning: Verify the area is not hazardous when installing, servicing, cleaning, or

touching the Itron device.

Device cleaning

Warning: Clean only with a damp cloth.

Do not drop

Warning: While Itron meters are designed to withstand a drop, dropping the meter

may damage the device, impact the meter accuracy, and void the warranty.

Intelis Gas Meter Installation Guide TDC-1782-002 4

Proprietary and Confidential

Page 9

Product notification

Warning: These instructions are not intended to replace any utility or companyestablished meter installation procedures. These instructions are provided for

additional information when the Intelis Gas Meter is installed. The meter installation

must comply with all country, state, and local building and safety regulations as well

as federal regulations including Section 192.353 of Title 49 of the Code of Federal

Regulations. Two pertinent paragraphs of the code are:

• Each meter and service regulator, whether inside or outside of a building must be

in a readily accessible location and be protected from corrosion and other

damage.

• Each meter installed within a building must be located in a ventilated place and

not less than 3 feet from any source of ignition or any source of heat which might

damage the meter.

The Intelis Gas Meter is rated for the following operating and storage temperature

ranges. Use of the meter outside of the listed temperature ranges is not

recommended.

• Operating ranges:

◦ Measurement -30° F (-34° C) to +131° F (55° C)

◦ Valve -13° F (-25° C) to +131° F (55° C)

◦ 500G -40° F (-40° C) to +158° F (70° C)

• Storage range:

◦ -40° F (-40° C) to +158° F (70° C)

Important Safety and Compliance Information

Direct customer inquiries as to the selection and application of gas meters to your

local Itron sales representative or Itron Support.

• Itron does not endorse or warrant the completeness or accuracy of any third-party

meter installation procedures or practices, unless otherwise provided in writing by

Itron.

• Follow your company's standard operating procedures regarding the use of

personal protection equipment (PPE).

• Adhere to guidelines issued by your company in addition to those given in this

document when installing or repairing meters.

• This product, as of the date of manufacture, is designed and tested to conform to

all governmental and industry safety standards as they may apply to the

manufacturer.

• The purchaser and user of this product must comply with all fire control, building

codes, and other safety regulations governing the application, installation,

operation, and general use of this meter to avoid leaking gas hazards resulting

from improper installation, start-up, or use of this product.

• To ensure safe and efficient operation of this product, Itron strongly recommends

installation by a qualified professional.

Intelis Gas Meter Installation Guide TDC-1782-002 5

Proprietary and Confidential

Page 10

Chapter 2 Intelis Gas Meter

The Intelis Gas Meter is a solid state ultrasonic meter featuring an internal safety shut-off

valve, built-in temperature conversion, and an integrated 500G communications module.

The meter supports the listed functionality.

• High flow alarm with optional automatic valve shutoff.

• High temperature alarm and optional automatic valve shutoff.

• Air detection.

• Reverse flow detection.

The Intelis Gas Meter can be configured for Mobile Mode or OpenWay Riva Network Mode.

This compact meter weighs only 4-1/2 pounds and mounts well within existing meter

footprints for easy meter installation and replacement of existing gas meters.

Note: OpenWay Riva Network Mode functionality will be available in a future Riva release.

Related documents

For more information about the Intelis Gas Meter and compatible system architecture

documentation, see your product's documentation.

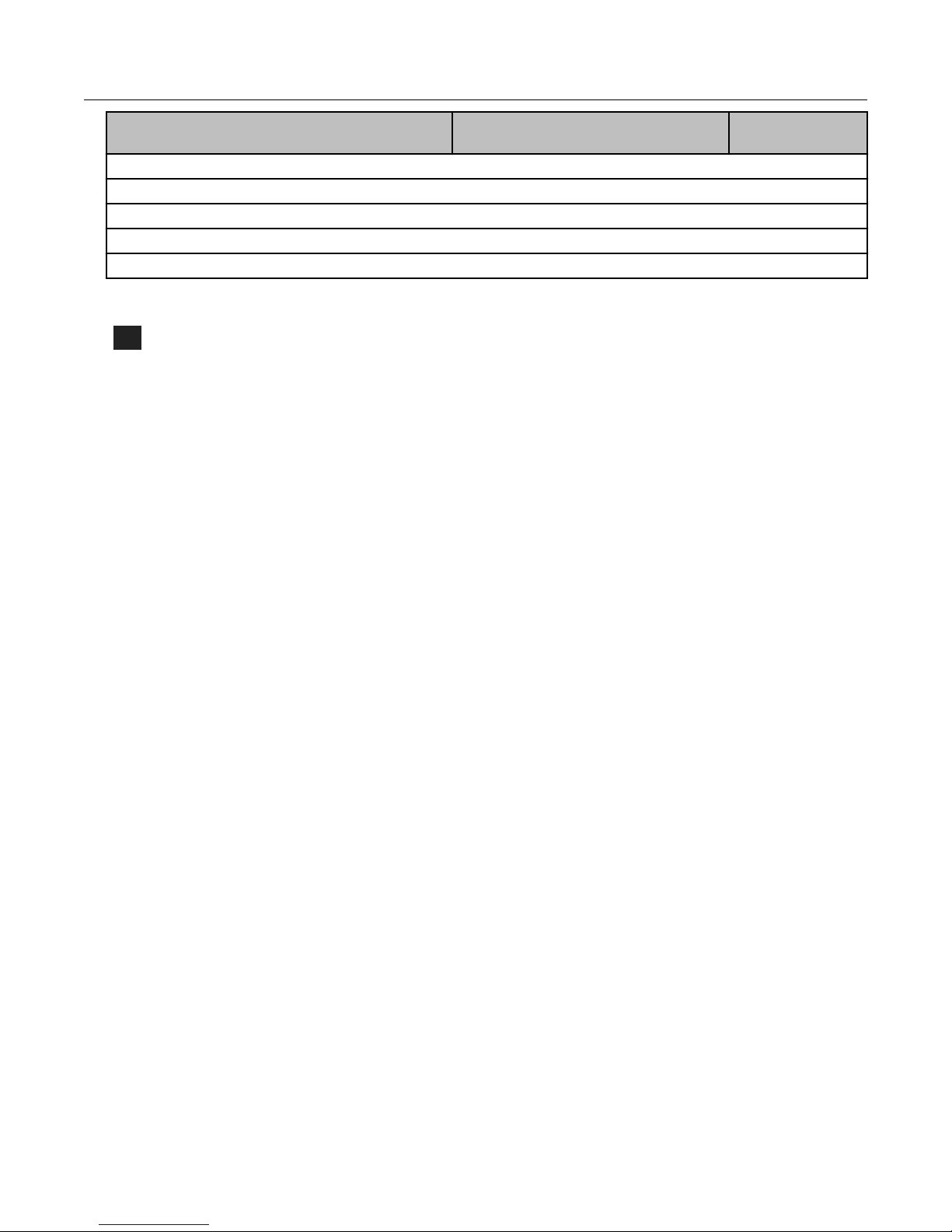

Document Itron part number

Intelis Gas Meter Technical Reference Guide TDC-1805-XXX

Intelis Gas Meter Ordering Guide PUB-1309-000

Intelis Gas Meter Specification Sheet 101584-SP-XX

Intrinsic Safety Control Drawing Index Module Replacement

Intelis Gas Meter

OpenWay® Operations Center Collection Manager Device

Interface Guide

Itron Security Manager User Guide TDC-1380-009

Field Deployment Manager Tools Configuration Guide TDC-1711-XXX

Intelis Gas Meter Installation Guide TDC-1782-002 6

TDC-0908-009

TDC-7083-XXX

Proprietary and Confidential

Page 11

Document Itron part number

Field Deployment Manager Tools Application Guide TDC-1713-XXX

Field Deployment Manager Field Representative's Guide TDC-1714-XXX

Intelis Gas Meter models

The Intelis Gas Meter is available in the listed types.

• Temperature compensated

• Non-temperature compensated

Intelis Gas Meter components

The Intelis Gas Meter features these components in a compact solid state meter.

• Intelis Gas Meter index

◦ The index contains the integrated 500G communications module, battery pack, and

the liquid crystal display (LCD). The LCD provides a visual display of consumption,

alarm messages, and status information. For information about LCD operation, see

The Intelis Gas Meter LCD on page 15.

• An internal shutoff valve

• Ultrasonic measuring unit (UMU)

• Inlet and outlet tube

• Dust trap and filter

• Die cast aluminum case

• Steel hubs

Intelis Gas Meter

Internal safety shutoff valve

Caution:

valve and ensure safe conditions before the flow of gas is resumed after a valve has

been closed.

The Intelis Gas Meter shutoff valve is located in the outlet of the meter. The automatic

shutof

automatic shut off for high flow or high temperature events. The valve can also be shut off

through an RF command over the Mobile or OpenWay Riva Network.

f valve is a safety feature automatically triggered if the meter is configured for

Automatic shutoff configuration

The Intelis Gas Meter can be configured for an automatic shut off for the following event

types.

• High flow. Configuration for a high flow event enables an automatic shut off if the high

flow threshold is reached or exceeded in a configurable window of time.

Intelis Gas Meter Installation Guide TDC-1782-002 7

It is mandatory that a technician be on site at the meter to re-open the

Proprietary and Confidential

Page 12

Intelis Gas Meter

• High temperature. Configuration for a high temperature event enables an automatic shut

off if the high temperature threshold is reached or exceeded.

Note: For more information about high flow and high temperature event configuration, see

the FDM documentation. For document information, see Related documents on page 6.

Integrated 500G communications module

The integrated 500G RF communications module is designed to operate in either Mobile or

OpenWay Riva Network Mode. When the Intelis Gas Meter is operating in Mobile Mode, it

may be read by ChoiceConnect handheld readers, mobile collection, or the Itron Mobile

Radio connected to a user-supplied computer or Bluetooth device. When the meter is

operating in OpenWay Riva Network Mode, it is read by the OpenWay Riva Network. For

compatible Itron reading and programming devices, see the Intelis Gas Meter Technical

Reference Guide (TDC-1805-XXX).

Note: The communication functionality is dependent on the module's firmware version.

Intelis Gas Meter specifications

This section lists the Intelis Gas Meter product specifications.

Specification Specification value

Meter capacity

Measurement principle Ultrasonic time of flight

Accuracy Class 1 and ±0.5% at room temperature

Meter type Temperature compensated (TC) or non-temperature

Hub center-to-center 6 inches (152.4 mm)

Hub size options

Meter MAOP 5 PSIG (35 kPa)

Valve Actuated swing valve, maximum 0.035 CFH (1 L/H)

LCD displayed units CCF (100 x cubic foot) or cubic meter

LCD resolution

Case Aluminum case with ASA 49 gray powder coat finish

Weight 4.5 lbs (2.0 kg)

Gas type Natural gas Type H, E, L (per EN 437)

250 CFH at ½ w.c. / 7.1 m3/h @0.125 kPa

compensated (NTC)

• 10LT

•

20LT

• 30LT

• 1A/Sprague standard

• 1-1/4", 1" Pittsburgh

• ISO G 1-1/4"

leakage rate

00000.001 CCF (0.1 CF) or 00000.001 m

Reference gases G20, G21, G23, G25, G26, G27

3

Intelis Gas Meter Installation Guide TDC-1782-002 8

Proprietary and Confidential

Page 13

Specification Specification value

Component materials

• UMU (ultrasonic measuring unit): polybutylene

terephthalate (PBT) and polycarbonate (PC)

• Valve plastics: PBT

• Inlet and outlet tubes: polyoxymenthylene (POM)

Intelis Gas Meter

Intrinsically safe

Regulatory

Operational

Australia

For use in Class I, Division 1, Group D hazardous

locations. Temp Code T1 -40°C ≤ Ta ≤ +70°C

IECEx UL 18.0144X Ex ia IIA T1 Ga

FCC: Part 15.247, Part 15.249 (programming)

FCC ID: EWQINTELISG

Innovation, Science, and Economic Development Canada

(ISED): RSS-247 and RSS-210 (programming)

IC: 864D-INTELISG

Measurement Canada: Pending

All Intelis Gas Meters operate without the need for an FCC

or ISED license

Frequency: 902-928 MHz ISM band

Program frequency: 908-923.8 MHz

ACMA AS/NZS 4268

Frequency: 915-928 MHz ISM band

Program frequency: 916-926.8 MHz

Measurement -30° F (-34° C) to +131° F (55° C)

Operating temperature ratings

Valve -13° F (-25° C) to +131° F (55° C)

500G -40° F (-40° C) to +158° F (70° C)

Storage temperature ratings -40° F (-40° C) to +158° F (70° C)

Battery information 4 Lithium manganese dioxide (LiMnO2) 'A' cell batteries,

replaceable

Battery life 20 years for meter, 500G, and valve using recommended

operating parameters

Pressure tap 1/8" NPT pipe plug pressure tap standard on meter outlet

Badging Standard aluminum manufacturing and optional customer

badge

Test pulse weight (volume per pulse)

0.10CF, 0.25CF, 0.50CF, 1.0CF, 10dm3, 50dm

3

Test pulse width 10 ms - 1000 ms (1 second)

Minimum compatible collection

FCS v4.1

software

FDM Tools v4.1.1

Intelis Gas Meter Installation Guide TDC-1782-002 9

Proprietary and Confidential

Page 14

Intelis Gas Meter

Specification Specification value

ISM v3.6 (if using enhanced security)

Itron Mobile v1.5

Mobile Collection v3.8.2

Standards Designed in compliance with ANSI B109.1, ANSIB109.0

(draft), and Measurement Canada PS-G-06

Intelis Gas Meter dimensions

This section lists the Intelis Gas Meter dimensions. Dimensions are listed in Imperial and

Metric units.

A B C D E F G

8.4 inches 6.4 inches 6.0 inches 5.4 inches 3.1 inches 9.1 inches 1.9 inches

214.4 mm 161.9 mm 152.4 mm 138.3 mm 78.6 mm 230.6 mm 48.8 mm

Note: B dimension can vary with dif

ferent hubs options. (20LT is shown).

Intelis Gas Meter Installation Guide TDC-1782-002 10

Proprietary and Confidential

Page 15

Chapter 3 Installing the Intelis Gas Meter

This section provides the Intelis Gas Meter installation information.

Warning: This product, as of the date of its manufacture, is designed and tested to

conform to all governmental or industry safety standards then existing as they may

apply to the manufacturer. The purchaser and user of this product are warned that

compliance with all country, state, and local codes required in order to avoid the

hazards of leaking gas resulting from improper installation, start-up, or use of this

product, and further, that all fire control, building codes, or other safety regulations

established under public laws which regulate or govern the application, installation,

operation, or general use of this product, should be complied with. In order to ensure

the safe and proper operation of this product, the manufacturer recommends that a

qualified technician install this product.

The Intelis Gas Meter must be installed with the inlet to the left, the outlet to

the right, the meter in a horizontal position and with the LCD facing out. INLET

and a flow arrow are marked on the Intelis Gas Meter casing.

Note: These instructions assume the gas is turned of

removed (when the Intelis Gas Meter is replacing an existing installation), piping

tests are completed, and all safety requirements are met.

Intelis Gas Meter Installation Guide TDC-1782-002 11

f, the previous gas meter is

Proprietary and Confidential

Page 16

Installing the Intelis Gas Meter

Prior to start-up

Note: The Intelis Gas Meter is shipped from the factory with the shutoff valve in the open

position. Verify the valve is open prior to installing the meter. Confirm the open valve icon

is displayed on the LCD display and that the valve closed icon is not displaying .

Perform a visual check of the inside of the meter outlet to also verify the shutoff valve is

open.

Before the Intelis Gas Meter start-up:

• Read the meter badge data regarding maximum allowable operating pressure (MAOP)

and capacity flow rate to be sure the meter meets the installation requirements.

• Sight across both swivel flanges or test with a suitable level to determine that the flanges

are nominally in the same plane and will not cause excessive strain on the meter or

piping when the connection nuts are tightened.

Start-up

1. Blowout the service lines before the meter is installed to ensure no dirt, debris, or liquids

of any kind will be carried into the meter when the gas is flowing in the line.

2. Place a new connection nut washer (gasket) on each connect nut or meter hub.

3. Support the meter so that both hubs are against the connection washers and run the

connection nuts down hand tight.

4. In an alternating fashion, tighten the nuts to the appropriate torque for the connection

size.

5. Check the meter's downstream system to ensure that all connections are leak free or that

the downstream valve, if one is present, is closed.

6. Open the upstream and downstream valves very slowly to prevent any pressure surges

into or out of the meter.

Intelis Gas Meter Installation Guide TDC-1782-002 12

Proprietary and Confidential

Page 17

Installing the Intelis Gas Meter

Caution: Avoid high differential pressure across the meter. Abnormal differential

pressures can damage internal meter components.

7. Alternate cracking open the upstream and downstream valves for a few seconds and

then slowly-over a period of 10 seconds (¼ PSIG systems)-turn the valve to the ¼ open

position and then to the full open position.

8. After the meter is pressurized, apply a soap solution or other good leak detecting liquid to

the connections to check for leaks.

9. Test the meter to verify the meter is registering the gas flow.

1. Press the button to activate the LCD.

2. Observe the LCD display and look for usage to increase.

Note: If the LCD does not display any expected consumption, investigate the

installation. If necessary, change out the meter.

10. Perform a shadow or lock-in test following company or utility procedures.

11. After the Intelis Gas Meter installation testing is complete, purge all air from the gas line

including the piping section.

Warning: Never allow gas to discharge into a confined space or area where there

are ignition sources unless precautions are in place to eliminate potential

hazardous conditions.

It is possible to get air detection alarms during Intelis Gas Meter installation due to

installation setups, gas pressure, flow rates, pipe length, and general installation

practices. Air detection alarms during installation should be ignored.

A rapid flow rate change can cause a temporary flow measurement hard failure alarm.

For example, a flow measurement hard fail alarm could occur during installation, T

Mode (proving the meter), external leak test (water tank test), or other rapid flow rate

change situations. The alarm will display on the LCD and as long as it is temporary (and

not continuously in the flow measurement hard fail alarm state), is acceptable behavior. If

the flow measurement hard fail alarm remains active and does not clear, remove the

meter and return it to Itron for evaluation.

Removing or installing the pipe plug

This section provides the steps to remove or re-install the pipe plug.

Removing the pipe plug

• Using a 3/16" hand-driven Allen wrench, remove the pipe plug.

est

Intelis Gas Meter Installation Guide TDC-1782-002 13

Proprietary and Confidential

Page 18

Installing the Intelis Gas Meter

Installing the pipe plug

1. Clean any debris from the pipe plug and inspect it for any damage or deformation.

Replace the pipe plug if any defects or wear are found.

2. Apply new sealant to the leading 3 to 4 threads of the pipe plug.

Note: Itron recommends RectorSeal #5 sealant.

3. Using a 3/16" hand-driven Allen wrench, begin tightening the pipe plug into the threads,

using care not to cross-thread or remove the sealant during the process.

4. Tighten the pipe plug. Do not exceed 50 inch-pounds torque (5.6 Newton Meters).

5. Leak test following your utility's leak test procedure.

Intelis Gas Meter Installation Guide TDC-1782-002 14

Proprietary and Confidential

Page 19

Chapter 4 Intelis Gas Meter LCD Operation

This section provides information about the Intelis Gas Meter LCD.

The Intelis Gas Meter LCD

This section describes the Intelis Gas Meter LCD menus that are displayed in a pre-defined

order (1-8).

Note: The Intelis Gas Meter ships in a sealed (locked) state.

Additionally, there are two screens that display in response to an overflow or test condition.

Note: The two additional menu pages provide overflow condition information and an

interface to perform an LCD test.

The LCD test is initiated by a long press. These additional menu pages are not a part of the

normal sequence. The LCD normal mode is of

menu page is active for 6 seconds before the LCD advances to the next menu page. When

the last menu page is reached, the process loops to the first menu page until the configured

timeout is reached.

f. A button press will activate the LCD. Each

Note: A button press will also advance the LCD to the next menu page.

LCD

menu

1.

LCD display Description

• TC meter display in Imperial units.

• NTC meter display in Imperial units.

• TC meter display in Metric units.

Note: All menu displays can be

configured for Imperial or Metric units.

The remaining displays are shown in

Imperial units.

The LCD displays with 5 digits to the left of

the decimal and 3 to the right of the decimal

(in cubic feet x 100 [Imperial] or m3 [Metric]

dependent on customer configuration). The

primary index (Menu 1) will be either TC or

NTC measurement based on the meter

configuration.

Intelis Gas Meter Installation Guide TDC-1782-002 15

Proprietary and Confidential

Page 20

Intelis Gas Meter LCD Operation

LCD

LCD display Description

menu

2. Displays current index volume measured

under an alarm condition.

3. Displays active alarms.

Note: In the illustration, 001 indicates the

number of the current displayed alarm while

003 indicates the total number of alarms.

Before the display moves to the next menu

page, all active alarms are displayed. If

there are no alarms, NO ALARM

displays.

For more information about the Intelis Gas

Meter display events and alarms, see Intelis

Gas Meter LCD display alarms on page 17.

4. Local date and time. The local date is

formatted as configured. The date and time

are adjusted by the local time zone and DST

configuration.

5. Current gas temperature and conversion

factor

. This is the gas temperature from the

temperature sensor in the UMU.

6.

Test mode. Flow rate and volume.

7. Pressure compensation.

8.

• R LNF: Register Legal Non-Fixed

Firmware; R LF: Register Legal Fixed

Firmware

Firmware versions. The display cycles

through three screens to display the six

Intelis Gas Meter firmware versions. The

firmware version types are displayed on the

three LCD display menus.

• E LNF: Encoder Legal Non-Fixed

Firmware; E NL: Encoder Non-Legal

Firmware

Intelis Gas Meter Installation Guide TDC-1782-002 16

Proprietary and Confidential

Page 21

Intelis Gas Meter LCD Operation

LCD

menu

LCD display Description

• E LF: Encoder Legal Fixed Firmware;

UMU: Ultrasonic Measurement Unit CRC

Intelis Gas Meter LCD display alarms

The Intelis Gas Meter reports the following alarms on the LCD. Active alarms are logged.

Events that create alarms are logged with a start and an end time. Users may cross check

alarms over the network or with a device loaded with FDM T

Cross checking Events with FDM.

LCD event or alarm Description

Reverse flow detect. The meter is currently detecting

reverse flow; gas flowing from out to in.

The reverse flow event is an alarm for utilities that alert

them about possible tampering. If a reverse flow is

detected, the meter may be installed backwards.

ools. For more information, see

Ext. high flow detect. The meter detected flow that

exceeded the customer configured or Itron configured

high flow threshold of 500 CFH over 5 counts (about 10

seconds).

High temp detect. The meter detected that the

temperature exceeded the customer configurable high

temperature threshold.

Air in pipe detect. The meter detected air in the meter.

The air in pipe alarm will be set to ‘ready to detect’ state

after measuring more than 1.4 CFH (40 L/H). The speed

of sound of the gas being measured is periodically

compared to the speed of sound of air to determine if an

air in pipe alarm/event is triggered. The minimum flow

rate was chosen to reduce nuisance air in pipe alarms

upon initial installation.

Intelis is rated as Class 1 (+/-1% accuracy) for Natural

Gas T

ype H, E, L for reference gases G20, G21,G23,

G25, G26 and G27 which includes gas compositions

with up to 13% propane. It should be noted that during

Intelis Gas Meter Installation Guide TDC-1782-002 17

Proprietary and Confidential

Page 22

Intelis Gas Meter LCD Operation

LCD event or alarm Description

propane peak shaving, for example, higher

concentrations in propane or nitrogen can occur which

are outside these reference gases. This can result in the

speed of sound for the gas composition being closer to

that of the speed of sound of air, which could result in a

false indication of air detection. For this reason, air

detect alarms/events should be compared to incidences

of propane peak shaving along with typical homeowner

gas usage and reverse flow detection before

considering further action for suspect tampering.

Time sync. The meter detected that its time significantly

fers (5 minutes or greater difference) from the network

dif

time.

Flow meas. hard fail. The meter detected that the flow

measurement sensor failed. The preconfigured meter

Qlmax of 500 CFH (14.2 m3/h) was exceeded. This

condition is a recoverable error with a start and end

event recorded.

Important:

temporary flow measurement hard failure alarm. For

example, a Flow measurement hard fail alarm could

occur during installation, Test Mode (proving the meter),

external leak test (water tank test), or other rapid flow

rate change situations. The alarm will display on the

LCD and as long as it is temporary (and not

continuously in the Flow measurement hard fail alarm

state), is acceptable behavior. If the Flow measurement

hard fail alarm remains active and does not clear,

remove the meter and return it to Itron for evaluation.

A rapid flow rate change can cause a

Intelis Gas Meter Installation Guide TDC-1782-002 18

Flow meas. OOR detect. The meter detected flow that is

outside the physical range of the measurement sensor

Gas temp OOR detect. The meter detected that the

maximum (133° F/56° C) or minimum (-31° F/-35° C)

temperature range was exceeded. This condition is a

recoverable error with a start and end recorded.

Flow sens. meas. error. The meter detected that a flow

sensor measurement error occurred. This is an

unrecoverable error

Important: If the Flow Sens. Meas. Error remains active

and does not clear, remove the meter and return it to

Itron for evaluation.

Proprietary and Confidential

.

.

Page 23

Intelis Gas Meter LCD Operation

LCD event or alarm Description

Transducer error. The meter detected that its ultrasonic

transducers experienced an error. This is an

unrecoverable error.

Important: If the Transducer Error remains active and

does not clear, remove the meter and return it to Itron

for evaluation.

Additional LCD screen displays

The LCD displays two additional screens in an overflow or test event.

• Overflow. This screen displays if the meter reaches an overflow condition.

• Display test. This screen displays after a long button press of 4.8 seconds. The test

provides a visual confirmation that the LCD is functioning correctly

.

Intelis Gas Meter LCD display icons

The Intelis Gas Meter LCD display provides the following menu icons as a visual indications

of status information.

Display icon Icon definition

Meter status icons

Battery level

• Battery is greater than or equal to 80%

• Battery is greater than 40% and less than 80%

• Battery is greater 10% and less than 40%

•

Battery is less than 10%

Note: Battery life is checked every 12 hours and the icon is

updated accordingly

reaches 5% remaining power.

The meter has an active alarm.

. The battery icon flashes when the battery

Intelis Gas Meter Installation Guide TDC-1782-002 19

Proprietary and Confidential

Page 24

Intelis Gas Meter LCD Operation

Display icon Icon definition

The meter is in Factory Ship Mode.

Note: The truck icon clears when the Intelis Gas Meter is moved

to an operational mode.

Closed padlock icon. The meter is sealed. The lock icon clears

when the meter is unsealed.

Shutoff valve status icons

The shutoff valve is open.

The shutoff valve is closed.

Shutoff valve is in armed state. The shutoff valve opening is

actuated by pressing the button for 2 seconds and releasing it.

Important:

long, the LCD Test screen appears.

A technician should ensure the installation premise is safe by

ensuring there is no flow downstream of the meter prior to

opening the valve. Prior to pressing the button to open the valve,

the technician must check the LCD to verify there are no alarms.

If any alarms are present, investigate and remediate them prior to

opening the valve.

If the Intelis Gas Meter LCD button is pressed too

Performing an LCD test

The Intelis Gas Meter LCD T

and that there are no non-displaying pixels that could lead to misinterpretation of a value.

• Hold down the meter button longer than 4.8 seconds (long press).

The long press initiates the LCD test. After the long press, the display turns black for

600ms. After 600ms, the screen displays LCD TEST again.

Intelis Gas Meter Installation Guide TDC-1782-002 20

est is used to confirm the LCD display is functioning properly

Proprietary and Confidential

Page 25

Chapter 5 Proving the Intelis Gas Meter

This section provides information about proving the Intelis Gas Meter. Meteorological

proving allows users to test the Intelis Gas Meter accuracy. Temper meters unpackaged in

the proving area for 24 hours prior to the testing.

Warning: Follow your company's standard operating procedures regarding the use

of personal protection equipment (PPE). Adhere to guidelines issued by your

company in addition to those contained in this document when proving meters.

The Intelis Gas Meter Test Mode and a prover station are used to confirm the accuracy of

the meter.

Note: The Intelis Gas ultrasonic meter is highly accurate and sensitive to air flow. The meter

displays registration to 0.001 CCF. The meter sensitivity makes it possible to see the index

incrementing even with the hub caps in place.

The prover station captures and counts pulses. Each pulse reflects a specific volume (pulse

weight) of gas. Pulse width is a length of time for the pulse. Both pulse width and pulse

weight are configurable parameters using FDM. The Intelis Gas Meter pulse weight must

match the prover setup as described in this section's proving instructions.

Note: The Intelis Gas Meter cannot be programmed (configured) or calibrated while the

meter is in Test Mode. You must exit Test Mode to program or configure the meter.

Attempting to program or configure parameters while the meter is in Test Mode will result in

a temporary error. If the valve icon is blinking, the meter is unable to go into Test Mode. Wait

a few minutes and try again.

Test Mode is used in a meter shop or by a regulatory body. Some meter configuration and

prover setup are required for the prover to properly interpret the meter pulses. Meter

configuration is completed using FDM. Proving the Intelis Gas Meter requires attaching the

pulse output prover cable between the meter and the proving station. After the test is

complete, the proving cable is removed and the meter returns to normal operation.

Important: A rapid flow rate change can cause a temporary Flow measurement hard failure

alarm. For example, a Flow measurement hard fail alarm could occur during installation,

Test Mode (proving the meter), external leak test (water tank test), or other rapid flow rate

change situations. The alarm will display on the LCD and as long as it is temporary (and not

continuously in the Flow measurement hard fail alarm state), is acceptable behavior. If the

Flow measurement hard fail alarm remains active and does not clear, remove the meter and

return it to Itron for evaluation.

Proving accessory Itron part number

Honeywell SNAP pulse output prover cable CFG-7100-100

Measurement Systems pulse prover cable CFG-7100-500

Energy Economics (EEI) pulse prover cable CFG-7100-400

Can-Tronics pulse prover cable CFG-7100-200

Intelis Gas Meter Installation Guide TDC-1782-002 21

Proprietary and Confidential

Page 26

Proving the Intelis Gas Meter

Proving accessory Itron part number

Itron BPG SONICAL SN G6 pulse prover cable CFG-7100-700

Intelis Gas Meter proving stand FIX-7100-001

Intelis Gas Meter Test Mode

You must exit Test Mode to program Test Mode parameters. Attempting to program Test

Mode parameters while the meter is in Test Mode will result in a temporary error. Test Mode

configurable parameters include:

• Pulse width. Default pulse width is 150 ms.

• Pulse weight. Default pulse weight is 0.25 cf/pulse.

• Maximum Test Mode time. Default is 1 hour.

Important: The default Test Mode time is 1 hour. The Intelis Gas Meter will automatically

time out after 1 hour in Test Mode whether there is activity or not.

Test Mode configuration can be completed at the factory at the time the meter is

manufactured. Parameters are configured in one of three ways:

• Through a custom programming file.

• Through programmed default configuration.

• In the field using FDM Tools.

Note: Refer to the instructions for your prover type in the following sections for the

recommended Test Mode pulse width and pulse weight parameters.

Entering Test Mode

Entering Test Mode is accomplished using either the FDM mobile client or through the

magnet in the prover connection end of the prover cable. After the Intelis enters Test Mode,

the following steps occur.

1. The Intelis Gas Meter logs an Entering Test Mode event.

2. The Intelis Gas Meter enters Test Mode.

3. The Intelis Gas Meter Test Mode index is reset to a zero reading.

4. The Intelis Gas Meter starts an optical pulse output.

Caution:

constantly pulsing (such as a small pulse weight and a long pulse width with a

high flow rate.) Adjust the pulse width, the pulse weight, or flow rate as needed.

5. The Intelis Gas Meter LCD moves to Test Display Mode.

There are some parameters that could result in the Intelis Gas Meter

Recording Test Mode consumption

While the Intelis Gas Meter is in Test Mode, the listed operations occur.

Intelis Gas Meter Installation Guide TDC-1782-002 22

Proprietary and Confidential

Page 27

Proving the Intelis Gas Meter

1. The Intelis Gas Meter records the Test Mode consumption in the Test Mode index

register.

2. The Intelis Gas Meter continues to output an optical pulse.

Note: While the Intelis Gas Meter is in Test Mode, the LCD refresh rate is more frequent

than when the meter is operating in Normal Mode.

3. The Intelis Gas Meter continues to update the normal volume registers.

Exiting Test Mode

The Intelis Gas Meter exits Test Mode after it receives a command from the FDM mobile

client, after the proving cable is removed from the meter, or when the Test Mode timeout is

reached. The following operations occur when the Intelis Gas Meter exits Test Mode.

1. The Intelis Gas Meter logs an Exiting Test Mode event.

2. The Intelis Gas Meter ends the optical pulse output.

3. The Intelis Gas Meter LCD returns to normal display mode.

Note: Check the LCD display to verify the Intelis Gas Meter is no longer displaying Menu

6: Test Mode.

Prover types

The Intelis Gas Meter compatible prover types are listed. See the procedure for your prover

type. For questions about your specific prover type, see the manufacturer's prover

documentation.

Prover type

Honeywell SNAP

Measurement Systems

Energy Economics (EEI)

Can-Tronics

Itron BPG SONICAL SNG6

Proving the Intelis Gas Meter using the Honeywell SNAP

pr

oving system

This section provides the information to set up an Intelis Gas Meter using a Honeywell

SNAP proving system.

Note: Proving the Intelis Gas Meter requires Honeywell SNAP prover software .NET X.Y.

Temper meters unpackaged in the proving area for 24 hours prior to testing. If tempering is

not possible, complete steps 1-9 of Tempering the meter by exercising on page 24. If the

meters are tempered, continue to Setting up the prover on page 25.

Intelis Gas Meter Installation Guide TDC-1782-002 23

Proprietary and Confidential

Page 28

Proving the Intelis Gas Meter

Warning: Follow your company’s standard operating procedures regarding the use

of personal protection equipment (PPE). Adhere to guidelines issued by your

company in addition to those contained in this document when proving meters.

Adjust the proving table to accommodate the height of the Intelis Gas Meter. If necessary,

use the Intelis Gas Meter prover stand (Itron part number FIX-7100-001). Place the prover

stand on the prover table and set the meter on the stand.

Itron recommends these Intelis Gas Meter Test Mode parameter settings for the Honeywell

SNAP proving system:

• Test Mode pulse weight: 0.25 CF

• Test Mode pulse width: 150 ms

Tempering the meter by exercising

1. Log on to the prover as a Supervisor.

2. Select Special Functions.

3. Select Diagnostics (local).

4. After the Diagnostics screen opens, clamp the meter in place by pressing Clamp in the

lower right screen corner.

5. Press the clamp buttons on both sides of the SNAP prover.

6. After the Intelis Gas Meter is clamped to the prover, turn on the appropriate nozzles in the

center of the screen to exercise the meter.

Note: Typically, Nozzle Number 2-245 CFH is used to exercise the Intelis Meter.

Exercise the meter for 10 to 15 minutes prior to proving the meter.

Select Close Nozzles.

7.

8. Unclamp the meter.

9. Exit Special Functions.

Intelis Gas Meter Installation Guide TDC-1782-002 24

Proprietary and Confidential

Page 29

Proving the Intelis Gas Meter

Setting up the prover

1. If you have not previously done so, log on to the prover.

Note: If you are proving an Intelis Gas Meter for the first time on the prover or if you are

changing proving parameters for the Intelis Gas Meter, you must log on as a Supervisor.

To set up Itron Intelis Gas Meter and ITRON-RTY for the first time, follow steps 2 through

10.

2. Select Special Functions.

3. Select Edit Config T

4. Select Edit Setup V

ables.

alues.

Intelis Gas Meter Installation Guide TDC-1782-002 25

Proprietary and Confidential

Page 30

Proving the Intelis Gas Meter

5. Select the MeterMfg_T

able checkbox.

6. Click in the next available (open) row in the top left table and enter ITRON-RTY for the

meter manufacturer. Click off of the table and select Update Table.

Intelis Gas Meter Installation Guide TDC-1782-002 26

Proprietary and Confidential

Page 31

Proving the Intelis Gas Meter

Important: If Itron, Actaris, Sprague, or other is listed, it is still necessary to add a new

manufacturer name specifically for the Intelis Gas Meter. Itron suggests using ITRONRTY following the steps listed below. The MFR Type must have the RTY suffix to allow

setting and saving the revs desired for any given test and flow rate. Without the RTY

suffix, the settings will not be saved.

7. Select Meter_Table checkbox.

This step allows you to copy an existing meter setup and modify it to create the new

Intelis Gas Meter (for example, choose I-250, Itron). Select a similar meter's row

. Follow

the Meter-Table instructions: Click on the next open/empty row. To complete the addition,

click off of the table and select Add Chosen Meter. The following illustration shows the

successful copy of the I-250 meter to create the Intelis 250 MeterName, ITRON-RTY

MeterMfr.

8. Update the parameters in the table.

MeterName: Intelis 250

•

• MeterMfg: ITRON-RTY

• Open proof: 100

• Check proof: 100

• Other proof: 100

• Open flow: 250 (or the setting required by your utility)

• Check flow: 50 (or the setting required by your utility)

• Other flow: 100

• Open revs: 6

• Check revs: 2

Intelis Gas Meter Installation Guide TDC-1782-002 27

Proprietary and Confidential

Page 32

Proving the Intelis Gas Meter

• Other revs: 1

• Exercise revs: 1

• Revs unit volume: 4

• Jog rate: 50

• Max press diff: 0.5

• Miscellaneous customer-specific parameters as required (covered in Step 9)

9. Verify or enter the T

OLERANCE values for POS, NEG, Slope, Repair, and Meter Size.

These settings (values) are customer-specific.

10. Click off the table and select Update T

11. Select Exit, select Exit.

able.

Intelis Gas Meter Installation Guide TDC-1782-002 28

Proprietary and Confidential

Page 33

Proving the Intelis Gas Meter

1. Select Prove Meter.

2. Select the meter manufacturer (ITRON-RTY).

3. Select Intelis 250.

Proving the Intelis Gas Meter

4.

Select the correct mode for your meter (TC or NTC).

Note: REG is equivalent to NTC.

5. Select the meter results mode (% error, % accuracy, % proof).

Intelis Gas Meter Installation Guide TDC-1782-002 29

Proprietary and Confidential

Page 34

Proving the Intelis Gas Meter

6. Select the test mode (intest, outtest).

7. Select the optic test method (optic, mag).

8. Select the correct Index (volume per pulse) setting (Imperial, ¼ CF; Metric, 10 dm3).

Intelis Gas Meter Installation Guide TDC-1782-002 30

Proprietary and Confidential

Page 35

Proving the Intelis Gas Meter

Note: T

o reduce cycle time, contact the prover manufacturer to request a 0.10 CF per

pulse option added. Testing has shown acceptable results with settings as low as 4

pulses on open and 1 on check but Itron recommends more pulses to obtain better

results.

9. Click Select Meter to advance to the next screen.

10. Connect the SNAP pulse prover cable end (Itron part number CFG-7100-100) to the J4

(1) optical sensor port typically on the top of the SNAP prover electronic enclosure, next

to the meter temperature probe port.

Intelis Gas Meter Installation Guide TDC-1782-002 31

Proprietary and Confidential

Page 36

Proving the Intelis Gas Meter

11. Connect the Intelis Gas Meter end of the SNAP pulse prover cable to the Intelis Gas

Meter optical port by firmly pressing the aluminum round threads of the cable into the

port. Begin by positioning the cable at the 4:30 o'clock position. T

6:30 o'clock position.

Note: The Intelis Gas Meter will automatically go into T

prover output cable is connected.

12. Start the proving test by clicking RUN on the SNAP prover.

13. Verify the LED blinks (pulses) when the air begins to flow through the meter.

est Mode (Menu 6) when the pulse

ighten the cable to the

Proving the Intelis Gas Meter using the Measurement

Systems proving system

This section provides the information to set up an Intelis Gas Meter using a Measurement

Systems proving system.

Intelis Gas Meter Installation Guide TDC-1782-002 32

Proprietary and Confidential

Page 37

Proving the Intelis Gas Meter

Note: Proving the Intelis Gas Meter requires Measurement Systems prover software. See

the Measurement Systems prover documentation for version requirements.

Temper meters unpackaged and uncapped in the proving area for 24 hours prior to testing.

If tempering is not possible, complete steps 1-8 of Temper the meter by exercising the meter

on page 33. If the meters are tempered, continue to Setting up the Measurement Systems

prover on page 34.

Warning: Follow your company's standard operating procedures regarding the use

of personal protection equipment (PPE). Adhere to guidelines issued by your

company in addition to those contained in this document when proving meters.

Adjust the proving table to accommodate the height of the Intelis Gas Meter. If necessary,

use the Intelis Gas Meter prover stand (Itron part number FIX-7100-001). Place the prover

stand on the prover table and set the meter on the stand.

Note: The Measurement Systems application software on the Measurement Systems

proving system provides touch screen functionality. You may prove the Intelis Gas Meter

using the Measurement Systems Prover screen or a traditional mouse-click to complete the

steps.

Itron recommends these Intelis Gas Meter Test Mode parameter settings for the

Measurement Systems proving system:

• Test Mode pulse weight: 0.10 CF

• Test Mode pulse width: 150 ms

Temper the meter by exercising the meter

1. Open the Measurement Systems Proving System application software.

2. Select Meter Setup to exercise the meter.

3. Select the Global

Intelis Gas Meter Installation Guide TDC-1782-002 33

tab > Operate Valves and View Sensor Readings.

Proprietary and Confidential

Page 38

Proving the Intelis Gas Meter

4. From the Operate Valves and Observe Sensor Readings screen, press the 1 key or

Chuck V

alve to clamp the meter in place.

5. After the Intelis Gas Meter is clamped to the prover, turn on the appropriate nozzle in the

center of the screen to exercise the meter

.

Note: Nozzle 6-250 is typically used for the Intelis Gas Meter.

Exercise the meter for 10 to 15 minutes before proving the meter.

Close the nozzle.

6.

7. Unclamp the meter by pressing the Chuck Valve button.

8. Exit Operate Valves and Observe Sensor Readings.

Setting up the Measurement Systems prover

1. Open the MMS prover application.

2. Select Meter Setup Menu.

Intelis Gas Meter Installation Guide TDC-1782-002 34

Proprietary and Confidential

Page 39

3. Select the Meter Model-1 tab.

Proving the Intelis Gas Meter

4. Select the meter model. If the Intelis 250 or Intelis 250 TC are set up in the MMS prover,

go to step 10. If the Intelis 250 or Intelis 250 TC is not listed, continue to step 5.

5.

Select the Prover tab.

Note: To access the Prover tab, you will be asked for a password. Contact Measurement

Systems if you do not have a password.

6. Select Enter New Meter Model.

Intelis Gas Meter Installation Guide TDC-1782-002 35

Proprietary and Confidential

Page 40

Proving the Intelis Gas Meter

7. Select an existing meter model similar to the new meter as a template. Itron recommends

using the S-250 for an Intelis 250 gas meter and an S-250 TC for the Intelis 250 TC gas

meter

. Select the green bar on the bottom of the screen to use the selected meter as the

starting point.

Note: Measurement Systems uses the lack of TC at the end of the meter name to

designate a non-TC meter, for example; an S-250 is an Itron I-250 CFH non-TC meter

and an Intelis 250 would designate an Intelis 250 CFH non-TC meter.

8. Enter the new meter name in the New Meter Model Name text box (1) and click OK (2).

Intelis Gas Meter Installation Guide TDC-1782-002 36

Proprietary and Confidential

Page 41

Proving the Intelis Gas Meter

9. Press Enter or click the blue bar at the bottom of the screen to go back to the meter

setup menu.

10. Select the Exercise Cycle Duration. The Intelis Gas Meter Exercise Cycle Duration is

typically 15 seconds.

11. Set Leak T

Intelis Gas Meter Installation Guide TDC-1782-002 37

est to Yes.

Proprietary and Confidential

Page 42

Proving the Intelis Gas Meter

12. Verify or enter Test Revs: Index Open, Check, Other settings. Itron recommended

settings are listed.

• Open: 6

• Check: 2

• Other: 0

Note: T

esting has shown acceptable results with settings as low as 4 pulses on open and

1 on check but Itron recommends more pulses to obtain better results.

13. Select the Volume: Index setting. The Volume: Index setting is the recommended

volume per pulse. Itron recommended settings are listed.

• Imperial setting: 0.10 cu ft/rev

• Metric setting: 0.01 m3/rev

Note: Intelis Gas Meter volume per pulse is in dm3; 10dm3 = 0.01 m3.

14. Verify or enter Flow rates (Air Rate): Open, Check, Other settings. Itron recommended

typical settings are listed. For metric flow rates: choose from the flow rate dropdown list

options. These convert the Imperial (CFH) flow rates to Metric (CMH). The Other flow

rate is not required if the Test Revs: Index-Other is set to 0.

• Open: 250

Intelis Gas Meter Installation Guide TDC-1782-002 38

Proprietary and Confidential

Page 43

• Check: 50

• Other: 125

Proving the Intelis Gas Meter

Important: Required Open and Check flow rates may be dif

ferent than those shown

here.

15. Select the Proving Method: Index. The options are Index or Magnetic.

16. Select the mode for your meter. Available options are TC or NON-TC.

17. Select the Meter Model-2 tab.

Intelis Gas Meter Installation Guide TDC-1782-002 39

Proprietary and Confidential

Page 44

Proving the Intelis Gas Meter

18. Verify or enter the InTest and OutTest limit values for Open Limits, Check Limits, Other

Limits, and Delta Limit. The Open, Check, Other

, and Delta Limit settings (values) are

customer-specific.

19. Verify or enter the limit values for Check Dif Limits, Monitor Peaks?, and Max Peak.

The Check Dif Limits, Monitor Peaks? and Max Peak settings (values) are customerspecific.

Intelis Gas Meter Installation Guide TDC-1782-002 40

Proprietary and Confidential

Page 45

Proving the Intelis Gas Meter

20. Verify or enter Tangent Adjustment: Tangent Type.

Note: The Tangent Adjustment: Tangent Type setting can be any non-blank value. The

Tangent Adjustment: Tangent Type value is not used to prove the Intelis Gas Meter.

21. Select the Global

options are listed.

• Error

• Accuracy

• Proof

22. Select InT

est/OutTest. The options are InTest or OutTest.

tab and Display Method for your meter results. Display Method

Intelis Gas Meter Installation Guide TDC-1782-002 41

Proprietary and Confidential

Page 46

Proving the Intelis Gas Meter

23. Press or click the green bar at the bottom of the screen to exit the Meter Setup Menu.

Proving the Intelis Gas Meter

1.

Connect the Measurement Systems pulse prover cable (Itron part number

CFG-7100-500) to the port on the left side of the Measurement Systems prover.

Note: If your Measurement Systems prover does not look like the illustration, contact

Measurement Systems for an adapter cable to connect the Measurement Systems pulse

prover cable to your prover.

Intelis Gas Meter Installation Guide TDC-1782-002 42

Proprietary and Confidential

Page 47

Proving the Intelis Gas Meter

2. Connect the Intelis Gas Meter end of the Measurement Systems pulse prover cable to

the Intelis Gas Meter by firmly pressing the aluminum round threads of the cable into the

port. Begin by positioning the cable at the 4:30 o'clock position. T

ighten the cable to the

6:30 o'clock position.

Note: The Intelis Gas Meter automatically goes into Test Mode (Menu 6) after the cable is

properly connected to the optical port.

3. Enter the Intelis Gas Meter serial number.

Intelis Gas Meter Installation Guide TDC-1782-002 43

Proprietary and Confidential

Page 48

Proving the Intelis Gas Meter

4. Press or click the green bar on the bottom of the screen to begin the Measurement

Systems proving test.

5. Verify the LED blinks (pulses) when the air begins to flow through the meter.

Pr

oving the Intelis Gas Meter using the Energy Economics

(EEI) proving system

This section provides the information to set up an Intelis Gas Meter using an EEI proving

system.

Note: Proving the Intelis Gas Meter requires Energy Economics prover software.

Temper meters unpackaged in the proving area for 24 hours prior to testing. If tempering is

not possible, complete steps 1-5 of Temper the meter by exercising the meter on page 44.

If the meters are tempered, continue to Setting up the EEI prover on page 46.

Warning: Follow your company’

of personal protection equipment (PPE). Adhere to guidelines issued by your

company in addition to those contained in this document when proving meters.

Adjust the proving table to accommodate the height of the Intelis Gas Meter. If necessary,

use the Intelis Gas Meter prover stand (Itron part number FIX-7100-001). Place the prover

stand on the prover table and set the meter on the stand.

Itron recommends these Intelis Gas Meter Test Mode parameter settings for the EEI proving

system:

• Test Mode pulse weight: 0.10 CF

• Test Mode pulse width: 150 ms

s standard operating procedures regarding the use

Temper the meter by exercising the meter

1. Log on to the EEI prover application.

Intelis Gas Meter Installation Guide TDC-1782-002 44

Proprietary and Confidential

Page 49

Proving the Intelis Gas Meter

Note: Logging on to the EEI prover application requires maintenance level security

.

2. Select Maintain > Sensor Maintenance.

3. Clamp the Intelis Gas Meter to the prover and turn on appropriate nozzles in the center

column of the Sensor Maintenance window to exercise the meter

.

Note: Nozzle 192 CFH is typically used to exercise the Intelis Gas Meter.

4. Exercise the meter for 10 to 60 minutes until the Out T

than 0.2° F within a minute.

5. Close the nozzle.

Intelis Gas Meter Installation Guide TDC-1782-002 45

emp value does not vary by more

Proprietary and Confidential

Page 50

Proving the Intelis Gas Meter

6. Unclamp the meter.

7. Exit the Sensor Maintenance window by clicking Done in the lower right corner of the

window.

Setting up the EEI prover

1. Log on to the EEI prover application.

2. Clamp the Intelis Gas Meter to the EEI prover.

3.

Select the Meter tab and choose ITRON from the Manuf drop-down list.

Important: If ITRON is not in the Manuf. drop-down list, contact EEI Prover Systems for

help in adding ITRON to your EEI Systems Prover.

4. Select Intelis 250, Intelis 250 TC, or the name for the Intelis Gas Meter designated by

your company from the T

ype drop-down list.

Important: If the correct Intelis Gas Meter type is not in the Type drop-down list, contact

EEI Prover Systems for help adding the correct meter type to your EEI Systems Prover.

Intelis Gas Meter Installation Guide TDC-1782-002 46

Proprietary and Confidential

Page 51

5. Click the Options tab.

Proving the Intelis Gas Meter

The Meter Information > T

6. Select Eye

for the Test Options Sensor.

est Options window opens.

Intelis Gas Meter Installation Guide TDC-1782-002 47

Proprietary and Confidential

Page 52

Proving the Intelis Gas Meter

7. Select Open & Check for the Run T

8. Enter 100 for Flow

> Open %.

ype Test Options.

Intelis Gas Meter Installation Guide TDC-1782-002 48

Proprietary and Confidential

Page 53

Proving the Intelis Gas Meter

Important: Required Open flow rates may be dif

9. Enter 20 for Flow > Check %.

Important: Required Check flow rates may be dif

10. Select 1/10 cuft for Hand Size.

ferent than those shown here.

ferent than those shown here.

Intelis Gas Meter Installation Guide TDC-1782-002 49

Proprietary and Confidential

Page 54

Proving the Intelis Gas Meter

11. Click Done to complete the Meter Information > T

Note: All other settings (T

angents, Ultra Intest Lock, Ultra Adjust Lock and Station) on the

Test Options window are not relevant for the Intelis meter

Proving the Intelis Gas Meter

est Options and close the window.

1. Connect the EEI pulse prover cable (Itron part number CFG-7100-400) to the EEI prover

index eye connector.

Intelis Gas Meter Installation Guide TDC-1782-002 50

Proprietary and Confidential

Page 55

Proving the Intelis Gas Meter

2. Connect the Intelis Gas Meter end of the EEI pulse prover cable to the Intelis Gas Meter

by firmly pressing the aluminum round threads of the cable into the port. Begin by

positioning the cable at the 4:30 o'clock position. T

ighten the cable to the 6:30 o'clock

position.

Note: The Intelis Gas Meter automatically enters Test Mode when the pulse output cable

is connected to the meter.

3. Press the EEI prover's green button to begin the proving test.

4. Verify the LED blinks (pulses) when the air begins to flow through the meter.

Intelis Gas Meter Installation Guide TDC-1782-002 51

Proprietary and Confidential

Page 56

Chapter 6 Adjusting the Intelis Gas Meter

Calibration

Intelis Gas Meters are calibrated at the factory prior to shipment. FDM is used if it is

necessary to recalibrate the meter. For more information about calibrating the Intelis Gas

Meter using FDM, see the FDM Field Service Representatives Guide. For documentation

information, see Related documents on page 6. Sending new calibration values using FDM

initiates the following calibration operations.

1. Run the meter on a prover.

2. Exit Test Mode.

3. Enter the prover station results values into FDM.

Note: The Intelis Gas Meter must be unsealed to adjust the meter calibration.

4. Wait for the meter to complete calibration.

5. Enter Test Mode.

6. Re-prove the meter to verify the calibration.

7. Exit Test Mode.

To adjust the calibration of an Intelis Gas Meter

Before you perform the Adjust Calibration command, you are required to run the meter on a

prover station. This determines the meter's accuracy, and the results are used during the

Adjust Calibration workflow. Before you start the Adjust Calibration command, review all

information in the sections that follow.

Note: The meter must be out of test mode to perform the Adjust Calibration command. If the

meter is in test mode, perform the Exit Test Mode command before you start this procedure.

Part of this Adjust Calibration workflow includes unsealing the meter. After you complete this

workflow, you must use the separate Seal Meter command to re-seal the meter.

If the meter is operating in mobile mode, you must know the meter's Unlock ID to complete

the Adjust Calibration command.

1. From the Tools menu, select OWR Intelis Gas.

2. Select Test Mode Operations.

3. Select Adjust Calibration.

A warning message appears indicating that Adjusting Calibration will unseal the meter.

Intelis Gas Meter Installation Guide TDC-1782-002 52

Proprietary and Confidential

Page 57

Adjusting the Intelis Gas Meter Calibration

4. Select Y

es.

5. (Mobile endpoint mode only) If you are prompted to enter the Unlock ID, enter the Unlock

ID.

Intelis Gas Meter Installation Guide TDC-1782-002 53

Proprietary and Confidential

Page 58

Adjusting the Intelis Gas Meter Calibration

6. Select Next.

The Parameters screen appears.

Intelis Gas Meter Installation Guide TDC-1782-002 54

Proprietary and Confidential

Page 59

Adjusting the Intelis Gas Meter Calibration

To demonstrate an example of adjusting the calibration, a sample prover station test

results is displayed below and is provided as a reference.