Page 1

innovation in utility networking

Gas IMU Installation

and Configuration

February 14, 2011

Page 2

2

© 2010 Silver Spring Networks | Company Confidential

Overview

• Remove existing index and prepare the meter

• Attach the tamper magnet holder

• Attach the index to the IMU

• Attach the IMU assembly to the meter

• Inspect

• Prepare IMU for programming

Page 3

3

© 2010 Silver Spring Networks | Company Confidential

Safety First!

• Always follow applicable standards for safety!

• Refer to the meter documentation for further safety information.

• Follow your employer’s best practices.

• If you smell gas, report it to the utility.

• Do not use power tools!

Page 4

4

© 2010 Silver Spring Networks | Company Confidential

RF Exposure Notice (509)

• The antenna of this transmitter must not be co-located or operating in conjunction with any other antenna

or transmitter.

• The device should be installed so that people will not come within 20 cm (8 in.) of the antenna.

• This equipment has been tested and found to comply with Part 15 of the FCC Rules. This equipment

generates, uses and can radiate radio frequency energy, and if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver disconnected.

• Consult the dealer or an experienced Radio/TV technician for help.

Modifications to the IMU not

expressly approved by Silver Spring Networks

may void your authority to operate the IMU.

Page 5

5

© 2010 Silver Spring Networks | Company Confidential

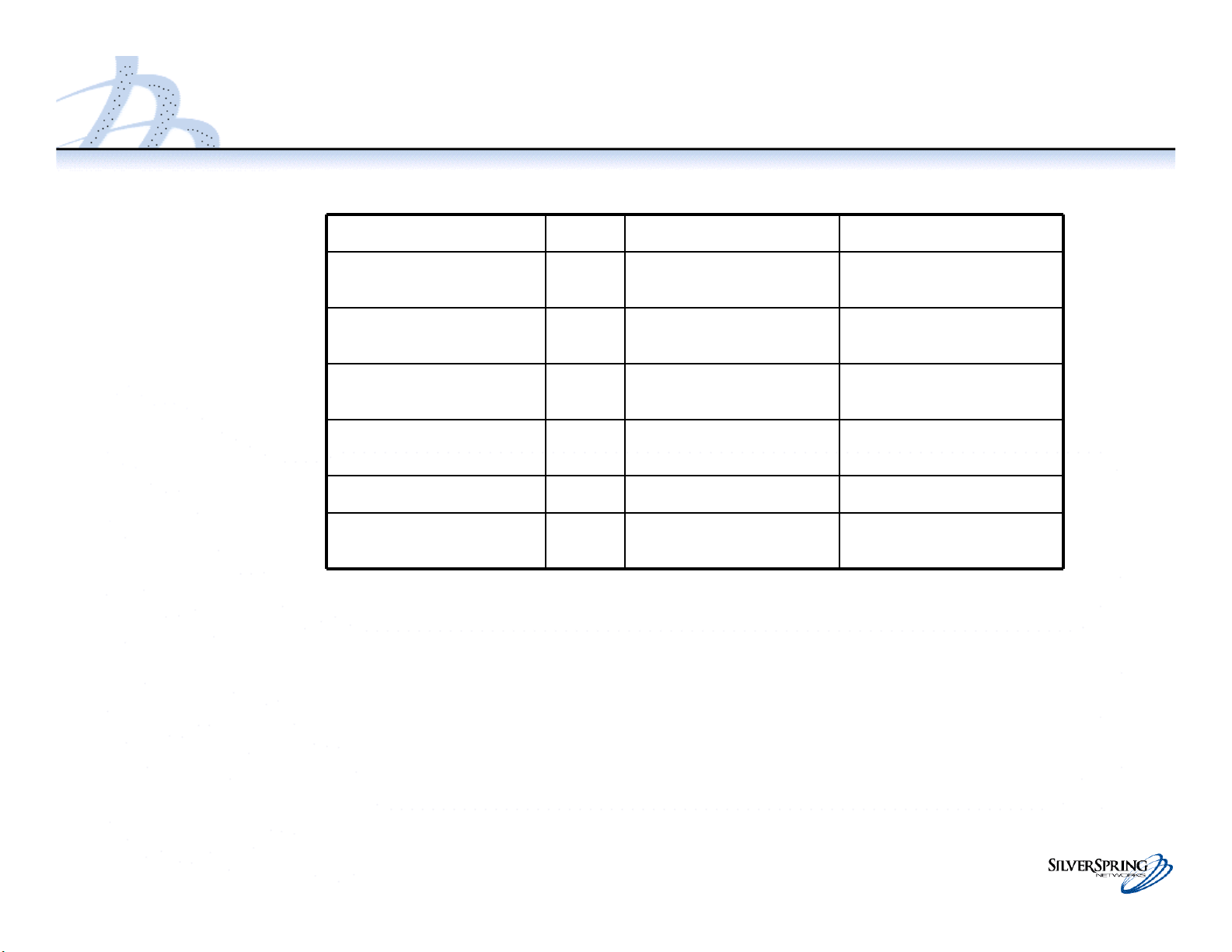

Components and Tools

• Components:

• Tools:

– Flathead screw driver (capable of torque setting)

– Phillips screw driver (capable of torque setting)

– Nut driver

– Awl, scraper, wire brush

– Service magnet

– Guide pins

Service magnet

Component Qty. Size Part Numbers

SSN IMU (top level,

includes hardware)

1 n/a 221-010001 (Am)

222-010001 (RW)

Index cover 1 n/a 976-000195 (Am)

976-000196 (RW)

Index cover screws 4 ¼-20” x 21/8”

10-24 x 21/4”

901-000067 (Am)

901-000053 (RW)

Index screws 2 8-32 x 3/16”

6-32 x 3/4”

901-000054 (Am)

901-000057 (RW)

Red tamper seals 2 n/a 976-000204

Tamper magnet holder

& magnet

1 n/a 976-000212 (Am)

976-000213 (RW)

Page 6

6

© 2010 Silver Spring Networks | Company Confidential

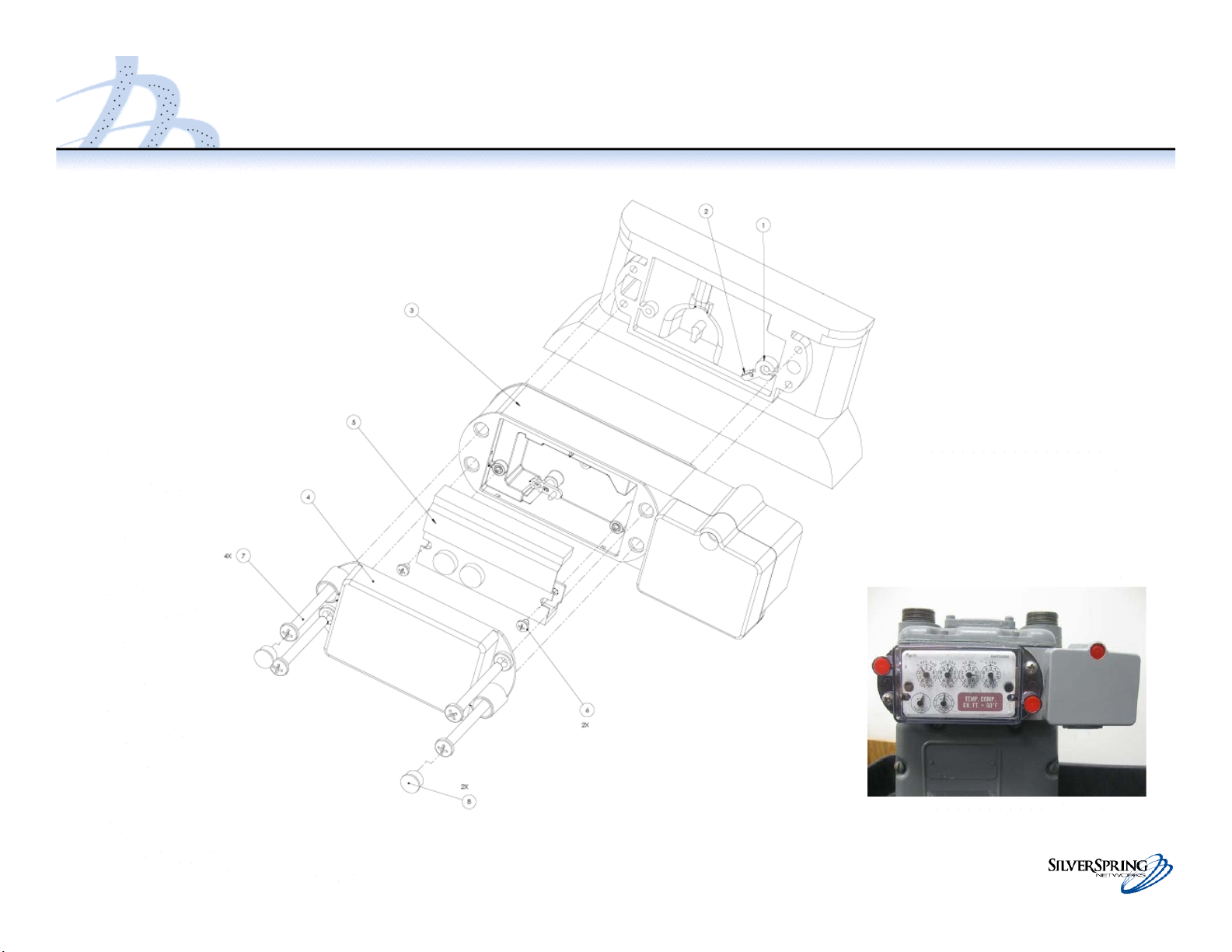

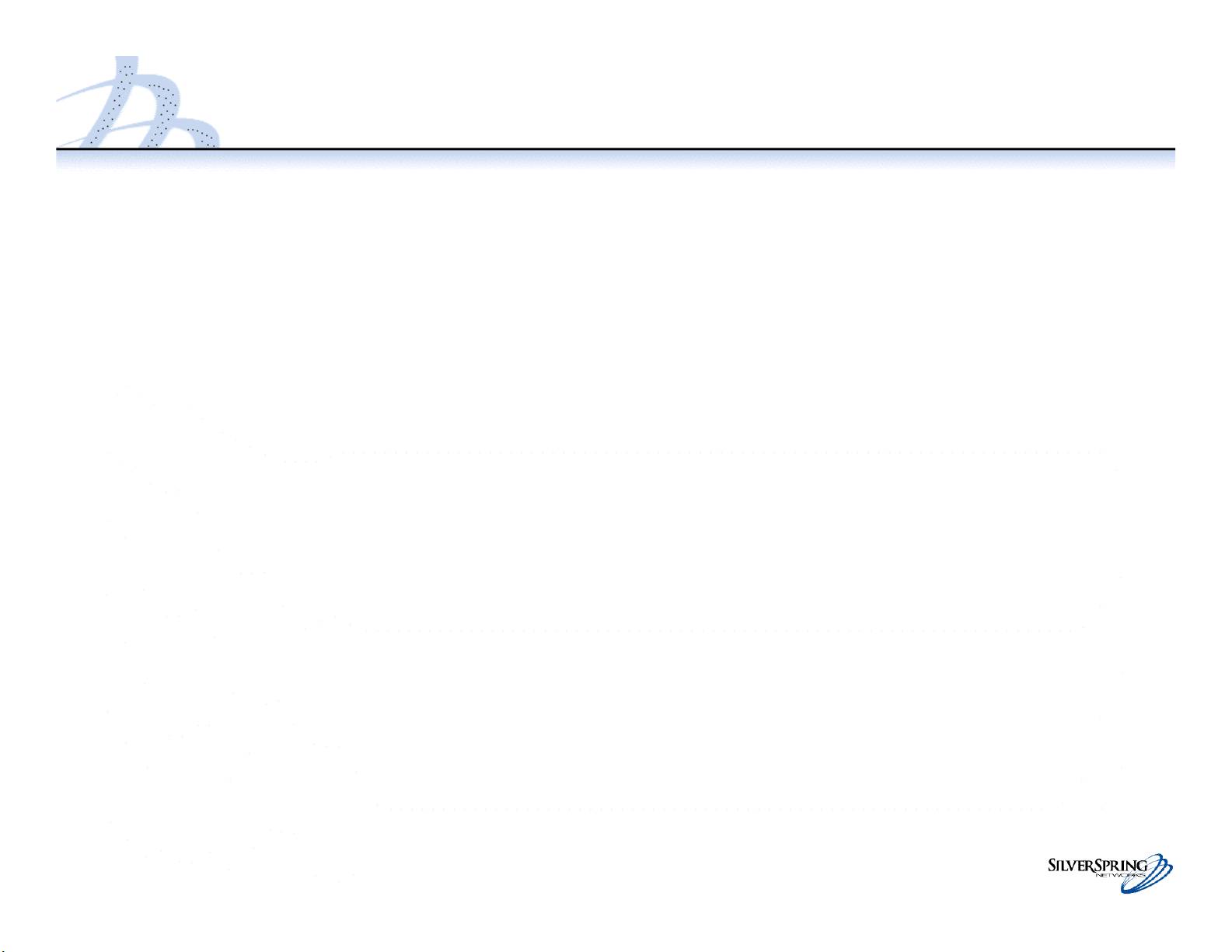

Components

Tamper magnet holder

and magnet for Rockwell

Index

cover

(American)

Index

screws

Index cover

screws

Tamper

seals

Tamper magnet holder

with magnet for American

Page 7

7

© 2010 Silver Spring Networks | Company Confidential

Assembly Drawing (American)

Index

cover

Index

screws

Index cover

screws

Tamper seals

Tamper magnet holder

(for American)

Tamper magnet

IMU

Index

Battery

compartment

¼-20” x 2.125”

Torque 10-11 in

lb

8-32 x 3/16”

Torque 8-10 in lb

Page 8

8

© 2010 Silver Spring Networks | Company Confidential

Assembly Drawing (Rockwell)

Index

cover

Index screws

Index cover screws

Tamper seals

Tamper magnet holder

and magnet (for Rockwell)

IMU

Index

Battery

compartment

10-24 x 2.25”

Torque 6-8 in lb

6-32 x 3/4”

Torque 6-7 in lb

Page 9

9

© 2010 Silver Spring Networks | Company Confidential

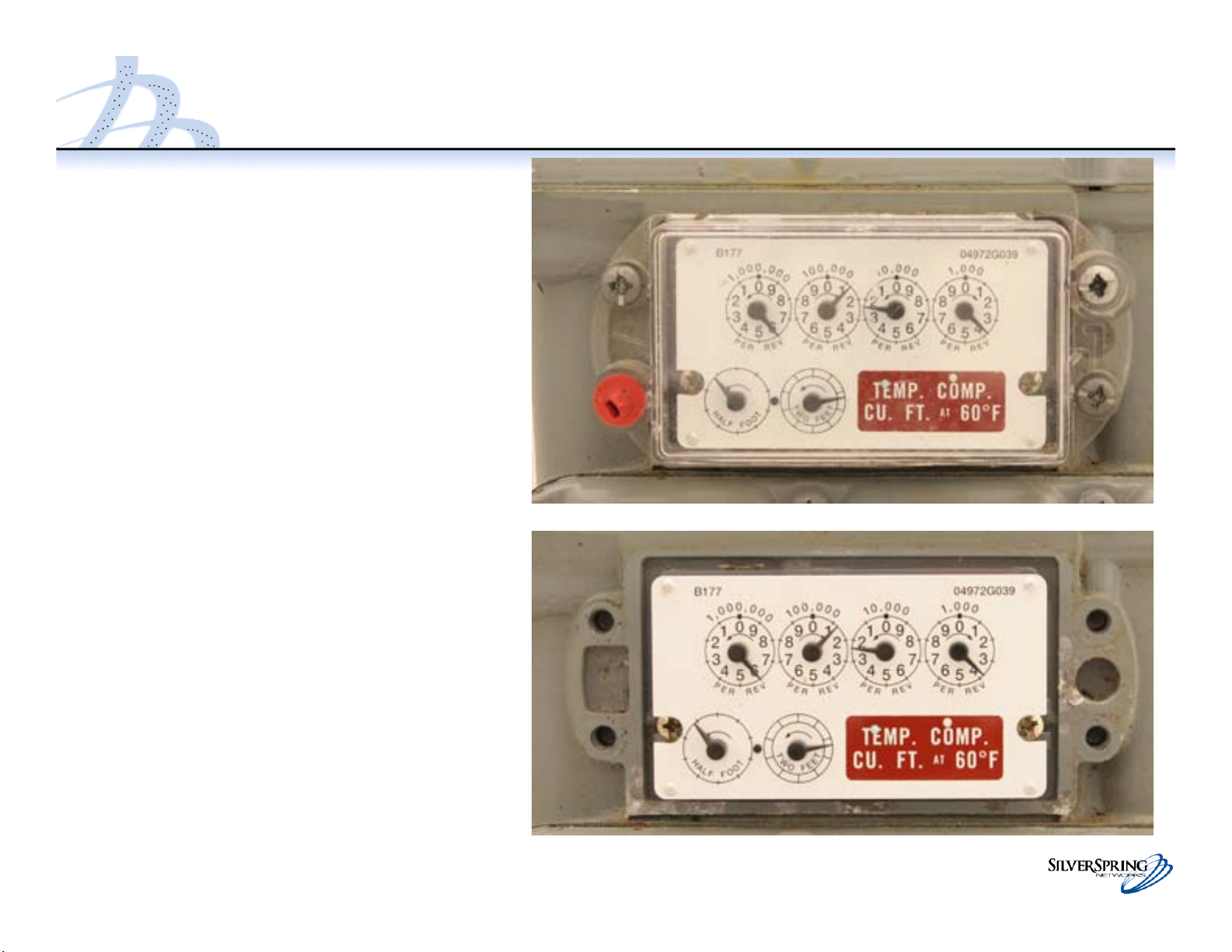

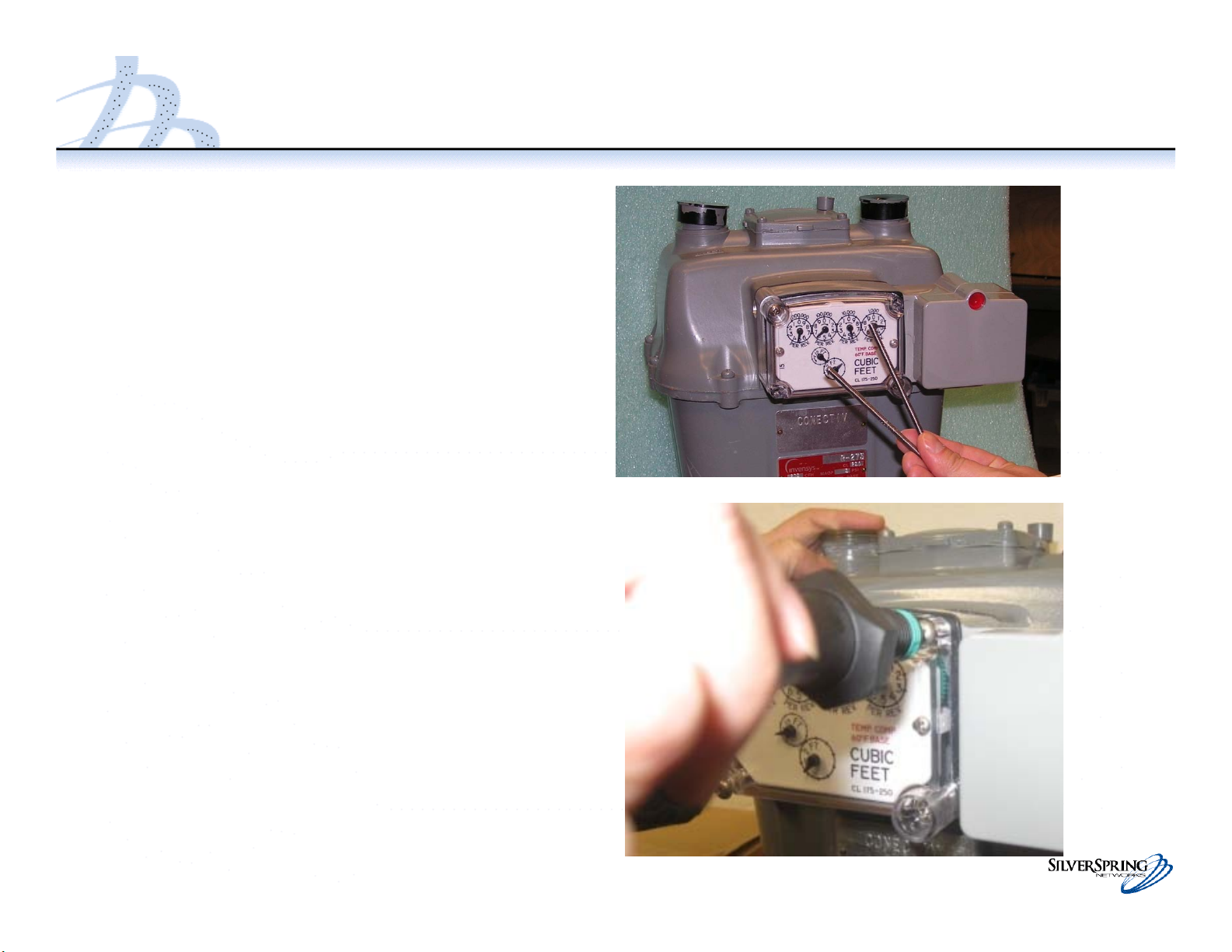

Remove Existing Cover & Prep Meter

• Remove the existing index cover

and index from the meter.

• Clean the meter index area

and make sure to remove

any remaining parts

of the old gasket.

Page 10

10

© 2010 Silver Spring Networks | Company Confidential

Attach the Tamper Magnet Holder

• On an American meter,

attach the magnet so that

the protrusion holding the

magnet points down and to

the left and the gap in the

circle fits around the

notch on the meter.

• On a Rockwell meter, attach the

magnet holder so that the

protrusion holding the magnet

points down and to the left and

the inner pin is inserted into

the index screw hole.

American

American

American

Rockwell

Page 11

11

© 2010 Silver Spring Networks | Company Confidential

Inspect IMU

• Inspect the IMU, ensuring that

there is no visible damage.

• Check the front and rear gaskets.

Make minor placement

corrections as needed.

– The front gasket should adhere

to the enclosure and keep the

screw holes clear.

– The rear gasket should be

attached to the enclosure on the

left and right, and remain

straight in the middle such that

the gasket will seal between the

enclosure and meter. The

gasket must keep the screw

holes clear.

Page 12

12

© 2010 Silver Spring Networks | Company Confidential

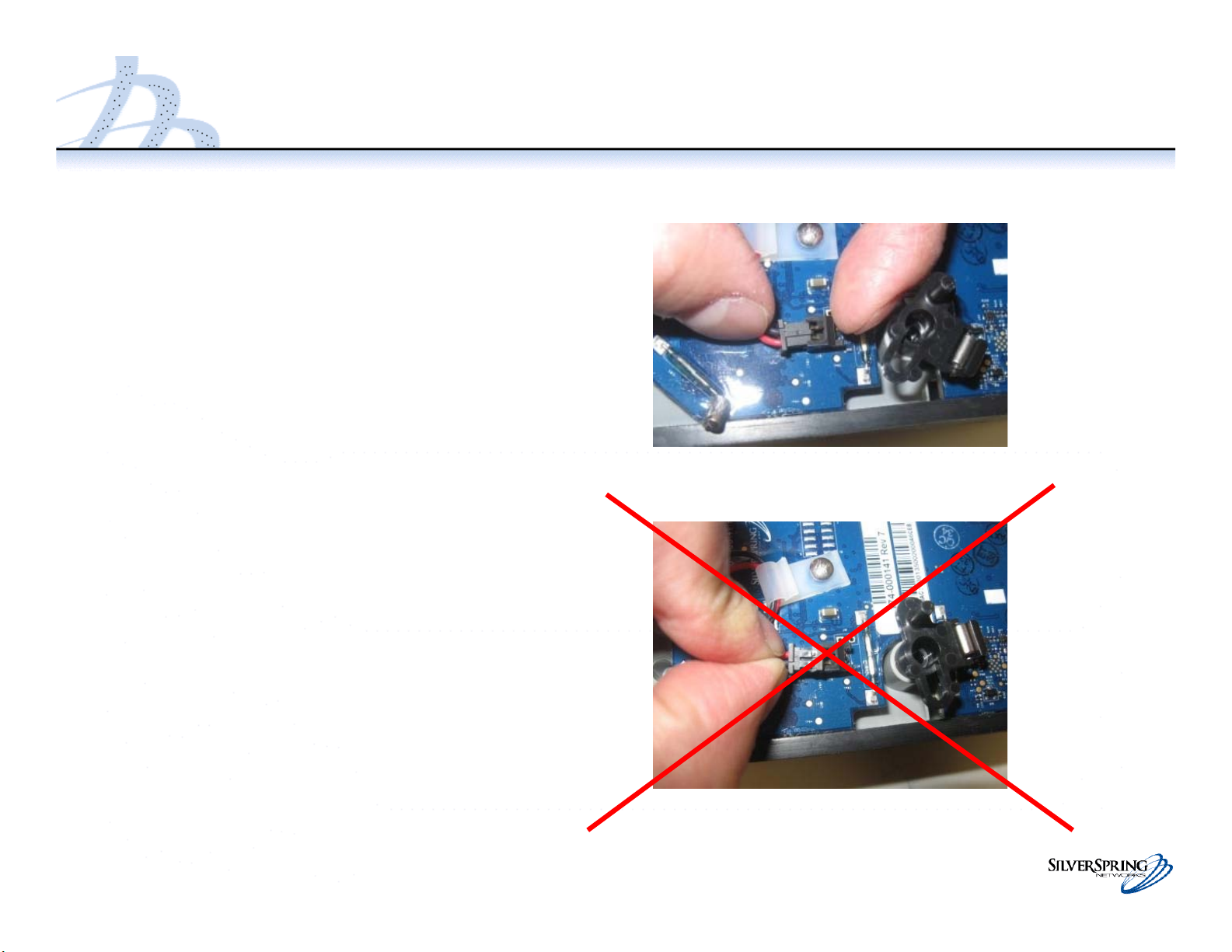

Connect Battery Cable Connector

• Gently plug in the battery cable

connector to the PCB, if it is not

already connected.

– The connectors are keyed. The

top side of the male connector

has a feature that fits into a slot

on the top side of the female

connector on the PCB.

– Orient the connectors before

attempting to connect.

– Carefully insert the male

connector while holding the

opposite end of the female

connector. Do not push the

male connector without holding

the opposite end of the female

connector.

Page 13

13

© 2010 Silver Spring Networks | Company Confidential

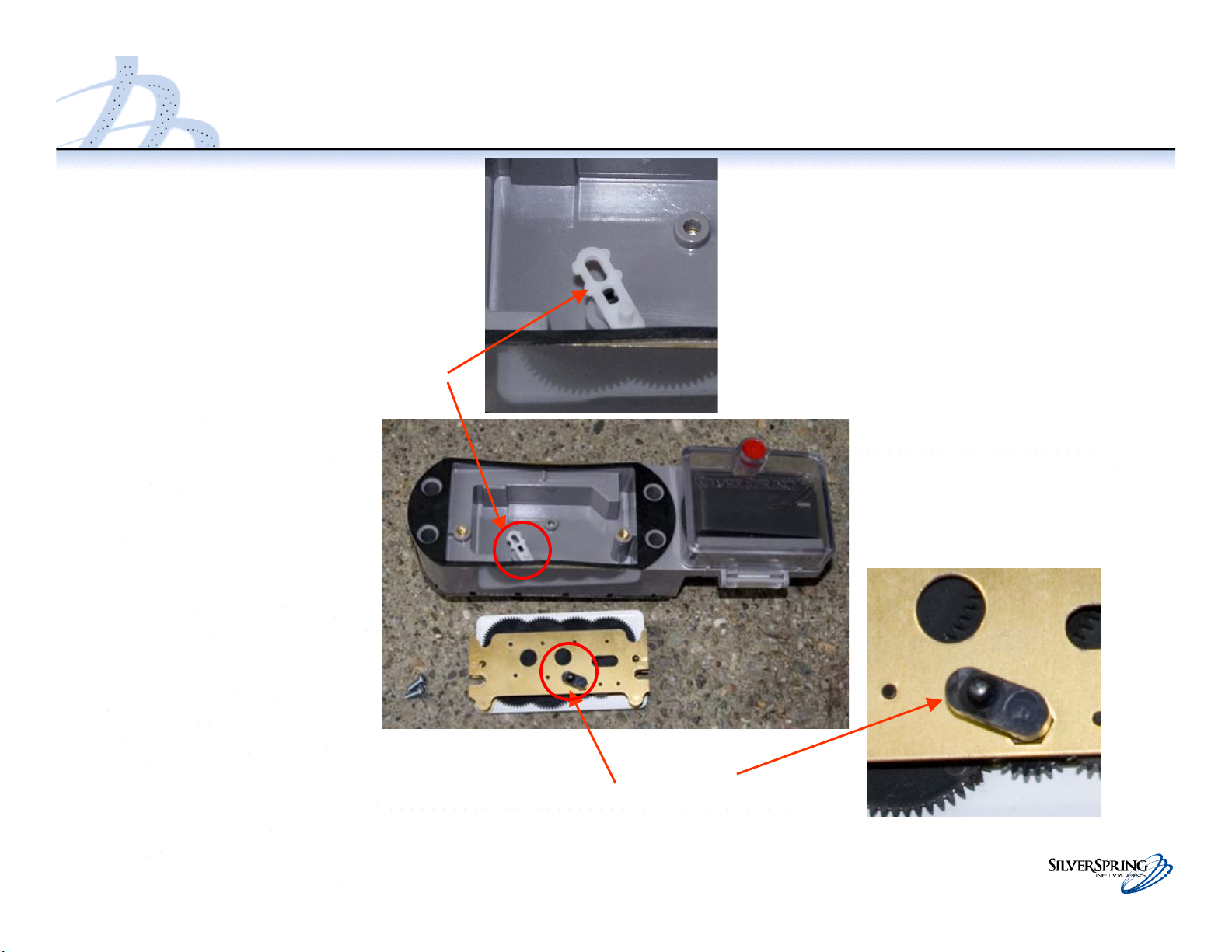

Attach the Meter Index to the IMU

• Align the IMU drive train

with the index wriggler.

IMU Drive Train

Index Wriggler

Page 14

14

© 2010 Silver Spring Networks | Company Confidential

Attach Meter Index to IMU

• Use the two index screws

to firmly attach the index

to the IMU.

• Index screw torque:

– Rockwell: 6-7 inch pounds

– American: 8-10 inch pounds

• Rotate the drive shaft two turns from

the rear, clockwise or counterclockwise, and observe that the 2 foot

test hand also moves 2 turns. The test

hand should spin freely. If not, correct

by fixing or replacing the index or IMU.

Two rotations of the IMU drive shaft will

rotate the 2 ft drive hand two

rotations.

Page 15

15

© 2010 Silver Spring Networks | Company Confidential

Attach IMU Assembly to Meter

• Temporarily fasten the guide pins

to the meter (3-4 threads into

the meter). You will remove

these in a later step.

• Using the guide pins, align the

IMU to the meter and match the

meter wriggler to the IMU drive

by adjusting the index test hand.

– On the Rockwell meter, rotate

the magnet to 12 o’clock to

avoid the screw in the index

well.

– Watch (from the side or top) the

IMU drive link to the meter

wriggler.

• On the American meter, the

pin goes into the slot.

• On the Rockwell meter, the

cup fits over the wriggler

(meter gear).

Page 16

16

© 2010 Silver Spring Networks | Company Confidential

Attach IMU Assembly to Meter

• Hold the enclosure against the meter to

maintain proper alignment to perform

the following checks:

– If no gas is flowing through the meter,

verify that the half cubic ft test hand

rotates approximately 180 degrees when

turned gently by hand

– If gas is flowing through the meter, you

should see the test hands rotating. You

do not need to manually rotate the test

hand.

• Verify that:

– There are no clicking or snapping

sounds

– There is no gap between the meter and

IMU

– The rear gasket seals the meter to the

IMU

Half foot test hand

Two foot test hand

Page 17

17

© 2010 Silver Spring Networks | Company Confidential

Attach IMU Assembly to Meter

• If you hear clicking or snapping, or if

there is a gap or a poor gasket seal,

remove the IMU and reinstall.

Repeat the verification checks.

• Attach the index cover and 2

screws to the meter and IMU as

shown. On a Rockwell meter, the

curved side of the index cover goes

on top. The red tamper plugs will fit

to the upper left and lower right

corners.

• Tighten the 2 screws.

Torque:

– Rockwell: 6-8 inch pounds

– American: 10-11 inch pounds

Page 18

18

© 2010 Silver Spring Networks | Company Confidential

Inspect Gaskets

• Verify that the front and rear

gaskets seal the mating surfaces

all the way around the IMU and

index cover.

• If the gaskets have not seated

correctly, remove all the cover

screws, adjust the gasket

position, and reinstall the IMU.

Page 19

19

© 2010 Silver Spring Networks | Company Confidential

Attach IMU Assembly to Meter

• Remove the guide pins

• Install the remaining 2 screws

Install the remaining 2 screws

and tighten

Torque:

– Rockwell: 6-8 inch pounds

– American: 10-11 inch pounds

Page 20

20

© 2010 Silver Spring Networks | Company Confidential

Inspect the gaskets and install the tamper seals

• Re-inspect the front and rear

gaskets to ensure that they

form a seal between the

index cover, enclosure, and

meter.

• Use a nut driver to push the

three tamper seals into the

openings on the IMU (2 in the

index cover and 1 in the

battery door).

Page 21

21

© 2010 Silver Spring Networks | Company Confidential

Prepare the IMU for Programming

• Slowly pass the service magnet once (for 2 to 5 seconds) over the top of the IMU.

• Doing so wakes up the IMU, enabling you to program it.

Page 22

innovation in utility networking

Rockwell 415

Gas IMU Installation

and Configuration

January 28, 2011

Page 23

23

© 2010 Silver Spring Networks | Company Confidential

Rockwell 415 IMU Retrofit

Overview

• Check the components and tools list.

• Remove the index cover and index.

• Fasten the adapter plate to the meter.

• Fasten the meter index to the IMU.

• Fasten the IMU to the meter.

• Fasten the index lens cover and the tamper seals.

• Inspect

• Prepare the IMU for programming.

Page 24

24

© 2010 Silver Spring Networks | Company Confidential

Check the Components and Tools List

• Components:

• Tools:

– Flathead screw driver (capable of torque setting)

– Phillips screw driver (capable of torque setting)

– Nut driver

– Awl, scraper, wire brush

– Service magnet

– Guide pins

Service magnet

Component Qty. Size Part Numbers

Silver Spring Networks

IMU

1 n/a 178-000101 rev 06

Adapter system 1 n/a 178-000098 rev 02

Index cover 1 n/a 976-000196 rev 1

Index cover screws 4 10-24 X 2.75” L 901-000061 rev 01

Index screws 3 6-32 X ¾” L 901-000063 rev 01

Red tamper seals 3 n/a 976-000203 rev 1

Page 25

25

© 2010 Silver Spring Networks | Company Confidential

Components

Index screws Index cover screws

Tamper seals

Adapter plate

IMU Index cover

Page 26

26

© 2010 Silver Spring Networks | Company Confidential

Assembly Drawing (Rockwell 415)

Rockwell 415

assembly

Index cover screws

Index screws and

adapter plate screw

6-32 x 3/4”

Torque 6-7 in lb

10-24 x 2.75”

Torque 6-8 in lb

Page 27

27

© 2010 Silver Spring Networks | Company Confidential

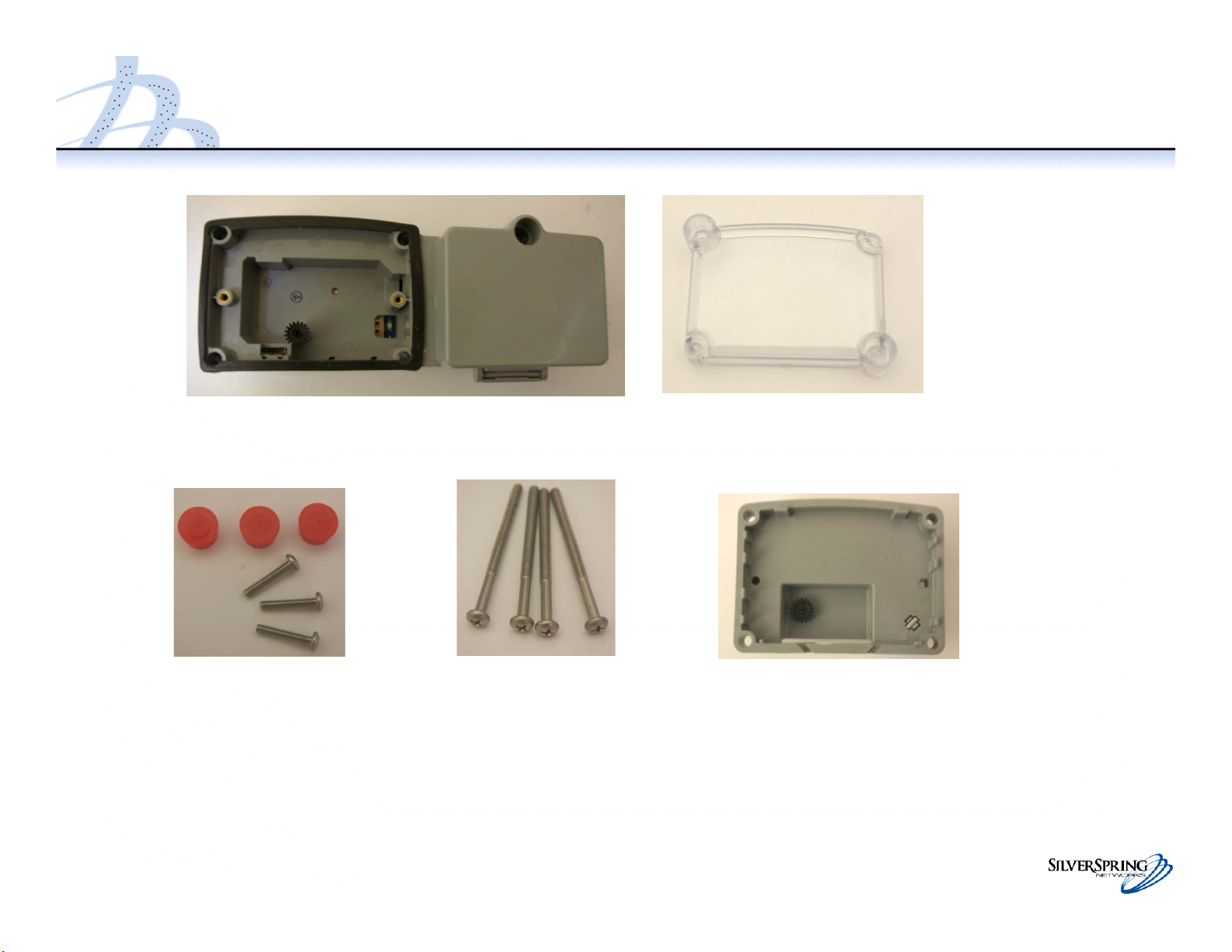

Remove the Index Cover and Index

• Remove the existing index

cover and index from the meter.

• Clean the meter index area

and make sure to remove

any remaining parts of the

old gasket.

Page 28

28

© 2010 Silver Spring Networks | Company Confidential

Install the Guide Pins

• Temporarily fasten the guide

pins to the meter (3-4 threads

into the meter). You will

remove these in a later step.

Page 29

29

© 2010 Silver Spring Networks | Company Confidential

Fasten the Adapter Plate to the Meter

• Position the adapter plate pin

into the center left hole on the

meter and seat the adapter

plate onto the meter.

• Verify proper engagement of

the gears. The gear should

rotate at least 120 degrees.

• Position an index screw in the

center right hole and fasten

the adapter using 6-7 in-lbs of

torque.

Page 30

30

© 2010 Silver Spring Networks | Company Confidential

Fasten the Adapter Plate to the Meter (continued)

• If gas is not passing through

the meter, rotate the gear on

the plate clockwise until you

feel it engage with the meter

wriggler. The gear should

rotate at least 120 degrees.

• If gas is passing through the

meter, the gear should rotate

in conjunction with the meter.

• You should not hear any

clicking or snapping sounds.

Page 31

31

© 2010 Silver Spring Networks | Company Confidential

Inspect IMU

• Inspect the IMU, ensuring that

there is no visible damage.

• Check the front and rear gaskets.

Make minor placement

corrections as needed.

– The front gasket should adhere

to the enclosure and keep the

screw holes clear.

– The rear gasket should be

attached to the enclosure on the

left and right, and remain

straight in the middle such that

the gasket will seal between the

enclosure and meter. The

gasket must keep the screw

holes clear.

Page 32

32

© 2010 Silver Spring Networks | Company Confidential

Connect Battery Cable Connector

• Gently plug in the battery cable

connector to the PCB, if it is not

already connected.

– The connectors are keyed. The

top side of the male connector

has a feature that fits into a slot

on the top side of the female

connector on the PCB.

– Orient the connectors before

attempting to connect.

– Carefully insert the male

connector while holding the

opposite end of the female

connector. Do not push the

male connector without holding

the opposite end of the female

connector.

Page 33

33

© 2010 Silver Spring Networks | Company Confidential

Fasten the Meter Index to the IMU

• Attach the meter index to the

IMU with two index screws

using 6-7 in-lbs of torque.

• Make sure that the gears are

engaged and not bound up.

The test hands should move

freely, and in conjunction with

the IMU drive.

Page 34

34

© 2010 Silver Spring Networks | Company Confidential

Fasten the IMU to the meter

• Make sure the gears are

engaged and not bound by

rotating the test hand.

• Attach the index cover and 2

screws to the meter and IMU

as shown.

• Tighten the 2 screws.

Torque: 6-8 inch pounds

Page 35

35

© 2010 Silver Spring Networks | Company Confidential

Attach IMU Assembly to Meter

• Hold the enclosure against the meter to

maintain proper alignment to perform

the following checks:

– If no gas is flowing through the meter,

verify that the half cubic ft test hand

rotates approximately 120 degrees when

turned gently by hand

– If gas is flowing through the meter, you

should see the test hands rotating. You

do not need to manually rotate the test

hand.

• Verify that:

– There are no clicking or snapping

sounds

– The gaskets are sealed and there is no

gap between the meter, IMU, adapter

plate, and cover.

Page 36

36

© 2010 Silver Spring Networks | Company Confidential

Fasten the IMU to the meter

• Remove the guide pins

• Install the remaining 2

screws

Torque: 6-8 inch pounds

Page 37

37

© 2010 Silver Spring Networks | Company Confidential

Inspect the Gaskets

• Verify that the front and rear

gaskets are properly seated all

the way around the IMU. If not,

remove and reinstall the IMU.

Page 38

38

© 2010 Silver Spring Networks | Company Confidential

Install the tamper seals

• Use a nut driver to push the three

tamper seals into the openings on

the IMU.

Page 39

39

© 2010 Silver Spring Networks | Company Confidential

Prepare the IMU for Programming

Slowly pass the service magnet once (for 2 to 5 seconds) over the top of the IMU.

This activates the IMU so you can program it. (tamper seals not shown)

Loading...

Loading...