Page 1

Single Channel Rotary and

Turbine Meter IMU Installation

April 6, 2011

innovation in utility networking

Page 2

Overview

• Connect the pulser and IMU cables

• Connect the IMU battery cable

• Configure the IMU for field use

• Attach the mounting plate and the cover to the IMU enclosure

• Attach the IMU and mounting plate to the pipe or wall

© 2010 Silver Spring Networks | Company Confidential

2

Page 3

Safety First!

• Always follow applicable standards for safety!

• Refer to the meter documentation for further safety information.

• Follow your employer’s best practices.

• If you smell gas, report it to the utility.

• Do not use power tools!

© 2010 Silver Spring Networks | Company Confidential

3

Page 4

RF Exposure Notice (509)

• The antenna of this transmitter must not be co-located or operating in conjunction with any other antenna

or transmitter.

• The device should be installed so that people will not come within 20 cm (8 in.) of the antenna.

• This equipment has been tested and found to comply with Part 15 of the FCC Rules, and

Canada licence-exempt RSS standard(s). This equipment generates, uses and can radiate radio frequency

energy, and if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver disconnected.

• Consult the dealer or an experienced Radio/TV technician for help.

with Industry

Modifications to the IMU not

expressly approved by Silver Spring Networks

may void your authority to operate the IMU.

© 2010 Silver Spring Networks | Company Confidential

4

Page 5

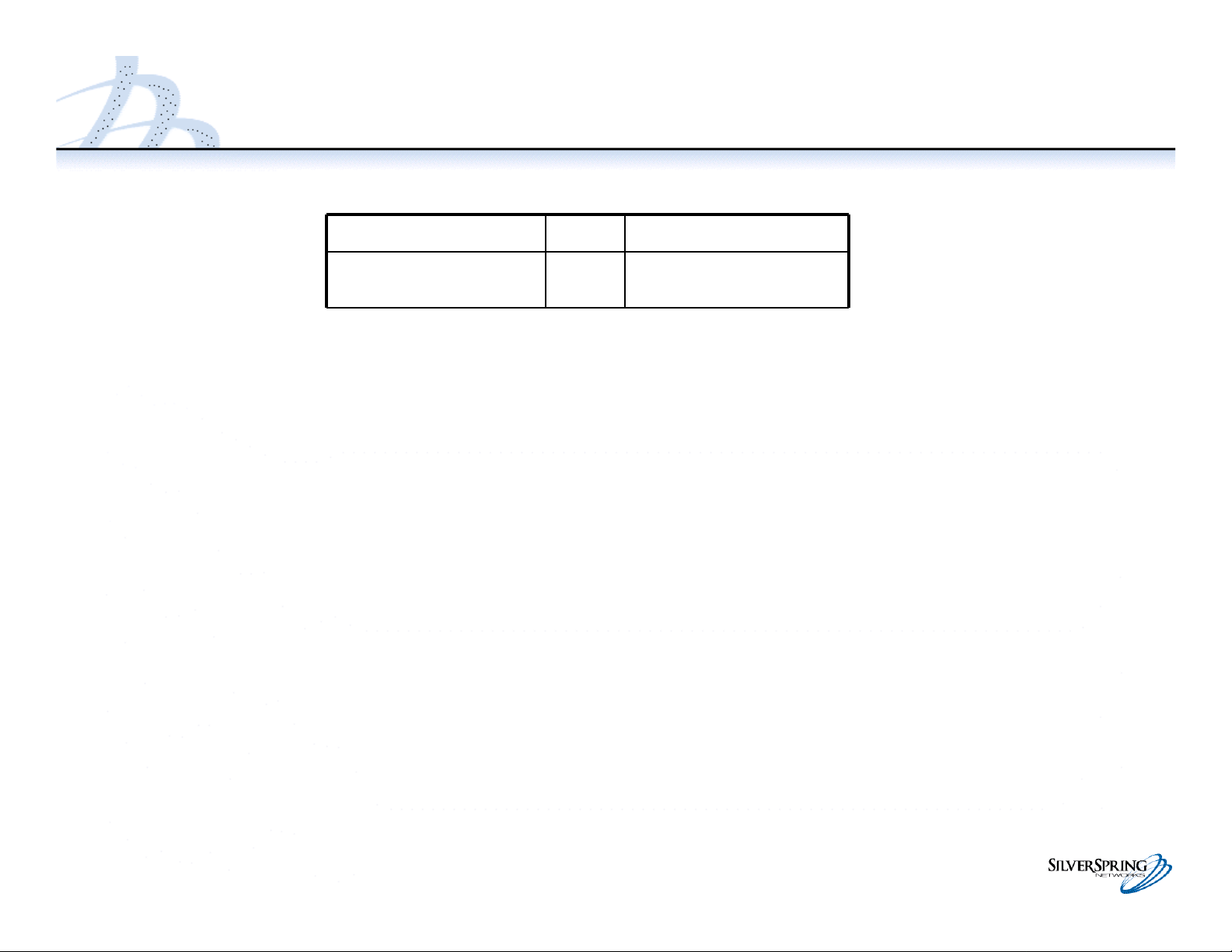

• Components:

Components and Tools

Component Qty. Part Number

SSN IMU (top level,

includes hardware)

– See next page for hardware component detail

• Tools:

– Flathead screw driver (capable of torque setting)

– Phillips screw driver (capable of torque setting)

– Pliers

– Nut driver

– Service magnet

1 224-040001

© 2010 Silver Spring Networks | Company Confidential

Service magnet

5

Page 6

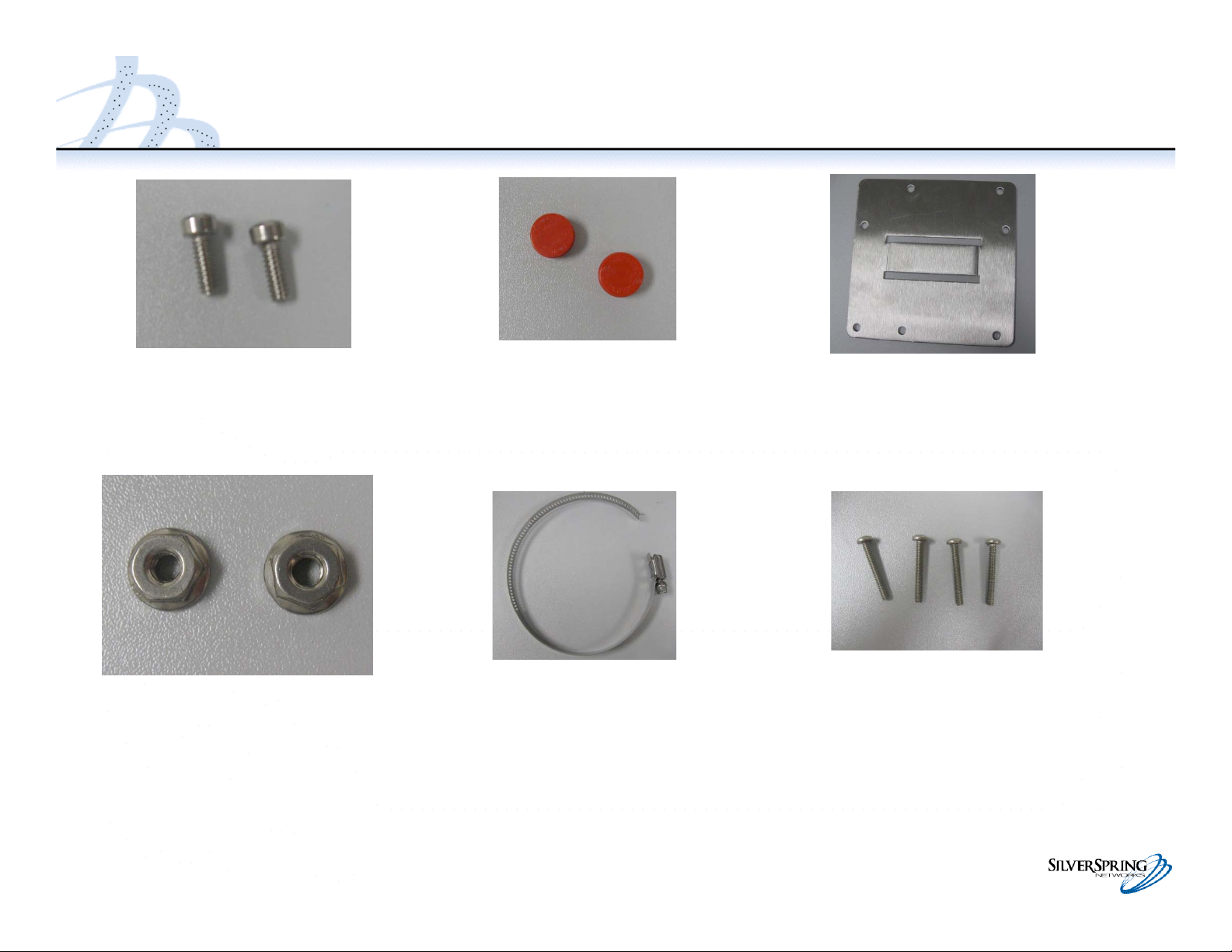

Components

Screws 10-24 x 1/2 Tamper Seals

Flanged nut 10-24

Pipe clamp

Mounting Plate

Cover screws, 6-32 x 1”

© 2010 Silver Spring Networks | Company Confidential

6

Page 7

Assembly Drawing (Single Channel Rotary and Turbine Meter IMU)

© 2010 Silver Spring Networks | Company Confidential

7

Page 8

Assembly Drawing (Single Channel Rotary and Turbine Meter IMU)

© 2010 Silver Spring Networks | Company Confidential

8

Page 9

Inspect the Pulser Cable

• Inspect the end of the pulser

cable that will connect to the

IMU.

– There should be three wires

exiting the outside insulation.

– The red and black wires are

insulated.

– The 3

rd

wire is bare coming out

of outside insulation, with a

white sleeve on the end.

• If needed, trim the pulser wires

so the conductor is flush with

the insulation and sleeve.

Insert photo

Pulser installation onto the gas meter is not

covered here. Refer to the pulser

manufacturer’s installation instructions.

© 2010 Silver Spring Networks | Company Confidential

9

Page 10

• Verify that the IMU has 3 wires

Inspect the IMU

• Verify that the enclosure is not

cracked and that the MAC Address

label is present

• Verify that the

battery

connectors are

undamaged.

• Verify

If the IMU is damaged, return it to your supervisor and get a replacement.

© 2010 Silver Spring Networks | Company Confidential

10

Page 11

Connect the Pulser to the IMU

•Thread the pulser cable through

the cable seal connector.

•Thread the pulser cable through

the tie wrap.

•Connect the 3 cables with the gel

splices.

– Do not strip the insulation from

the wires.

– Insert the wire pair (red and red,

black and black, white and

white) to be connected into a gel

splice; push all the way forward.

– Close the gel splice by squeezing

the gel splice with pliers.

– Repeat for the 3 pairs of wires

© 2010 Silver Spring Networks | Company Confidential

11

Page 12

Connect the Pulser to the IMU

• Make sure the 3 gel splices are to

the right of the cable tie.

• Tighten the cable tie. This

provides extra strain relief for the

cable.

• Trim the cable tie.

• Leave 1” of cable slack inside the

IMU, and pull the rest of the

cable out of the cable seal

connector.

• Tighten the cable seal connector.

© 2010 Silver Spring Networks | Company Confidential

12

Page 13

Connect the Battery Cable Connector

•Connect the battery cable to the

IMU cable. The connectors are

keyed; you will not need to force

them together.

•Put the battery inside the battery

compartment as shown.

– The connector fits underneath

the battery.

– The flat part of the battery

should be next to the inside wall.

© 2010 Silver Spring Networks | Company Confidential

13

Page 14

Program the IMU for Field Use

• Slowly pass the service magnet

once (for 2 to 5 seconds) over the

top of the IMU.

• Watch for the light-emitting diode

(LED) to flash on the lower left

corner of the IMU circuit board

– If you don’t see the LED flash,

make sure the battery cable

connections are made.

– If you still don’t see the LED flash

after checking that all the battery

connections are made and reswiping the magnet, return the IMU

to your supervisor. Insert photo

• Configure the IMU with the

programming tool.

Configuration is a separate document).

© 2010 Silver Spring Networks | Company Confidential

(Field

14

Page 15

Inspect the Gasket and Fasten the Cover

• Re-inspect the gasket to

ensure it seals the area

between the enclosure and

cover. Insert photo

• Fasten the cover to the

enclosure with the 4 cover

screws.

– The Silver Spring logo faces

up

– Torque the cover screws to

xxx

• Use a nut driver to push two

tamper seals into the

openings on the IMU cover.

© 2010 Silver Spring Networks | Company Confidential

15

Page 16

Attach the IMU Enclosure to the Mounting Plate

• Determine where you want to

install the IMU. This will

determine if the plate should

attach to the pipe horizontally or

vertically.

The photos here show a vertical attachment.

• Attach the IMU enclosure to the

mounting plate with the 2 screws

and 2 flanged nuts.

• Torque the screws to…

© 2010 Silver Spring Networks | Company Confidential

16

Page 17

Attach the IMU and Mounting Plate to the Pipe

• Guide the metal clamp through

the slot in the mounting plate.

• Wrap the metal clamp around

the pipe.

• Tighten the metal clamp around

the pipe by torquing the screw to

12-20 in lb.

© 2010 Silver Spring Networks | Company Confidential

17

Loading...

Loading...